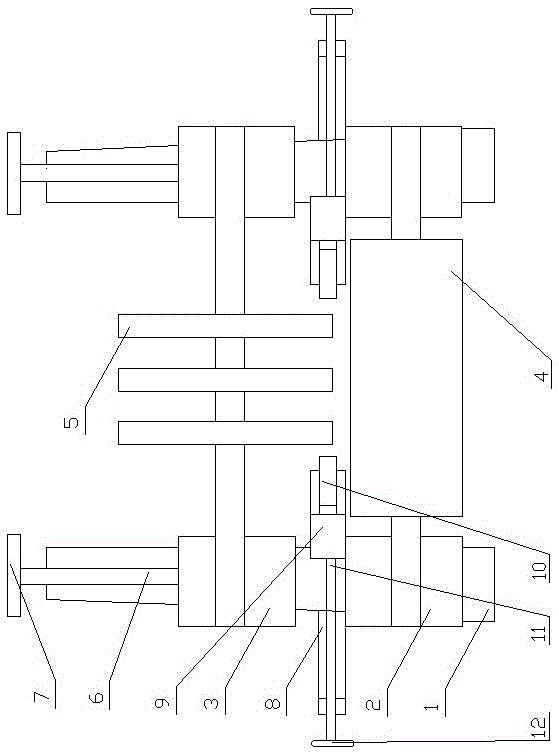

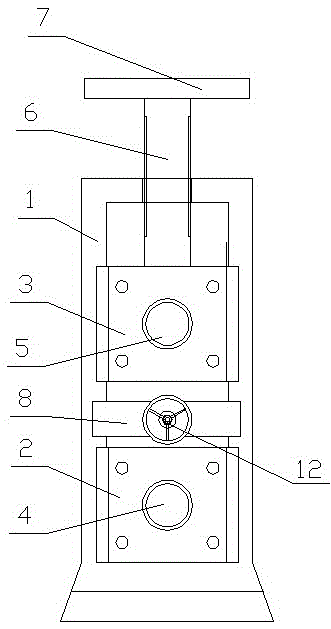

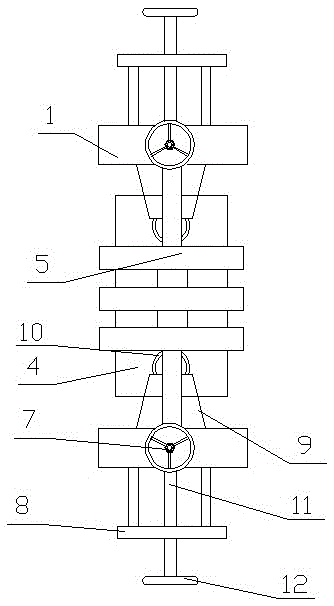

Four-roller Synchronous Deformation Mechanism of Section Steel Cold Bending Machine

A technology of deformation mechanism and cold bending machine, which is applied in the field of metal profile cold bending machine, which can solve the problems of large friction force on both sides, uncontrollable wire drawing, and displacement of roller printing line, etc., and achieves enlarged adjustment range, flat bottom plate, and straight line The effect of face length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] like figure 1 , 2 , 3, the present invention comprises a frame-shaped support 1 symmetrically arranged left and right, a lower roller support 2 and an upper roller support 3 are respectively symmetrically arranged in the frame-shaped support 1 on both sides, and the lower roller support 3 is fixed on the frame-shaped The lower part of the bracket 1, the upper roller support 2 is installed above the lower roller support 2, the powered lower roller 4 and the unpowered upper roller 5 are installed between the frame-shaped supports 1 on both sides, and the two ends of the powered lower roller 4 are respectively supported On the lower roller support 2 of the frame-shaped support 1 on both sides, the two ends of the unpowered upper roller 5 are respectively supported on the upper roller support 3 of the frame-shaped support 1 on both sides.

[0012] The middle part of the upper end of the upper roller support 3 of the frame-shaped support 1 on both sides is fixedly connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com