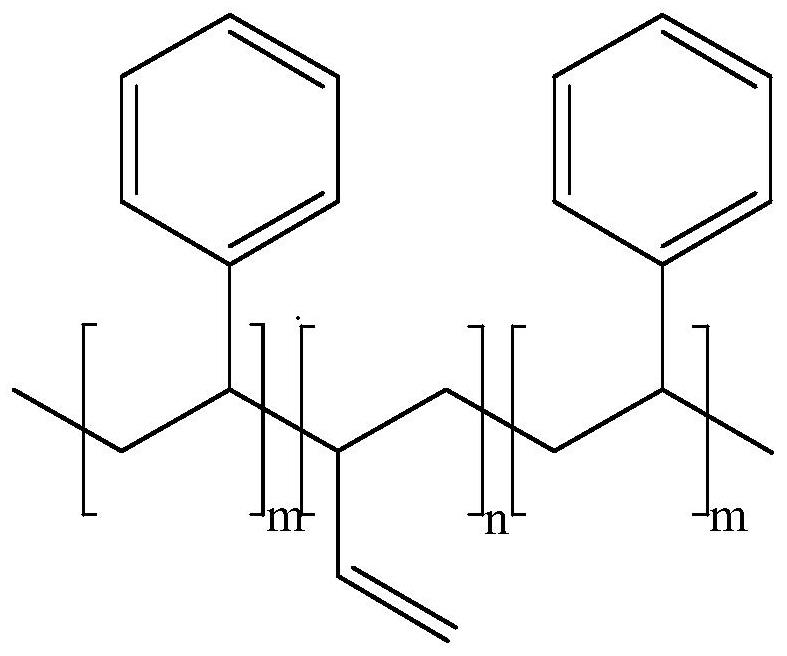

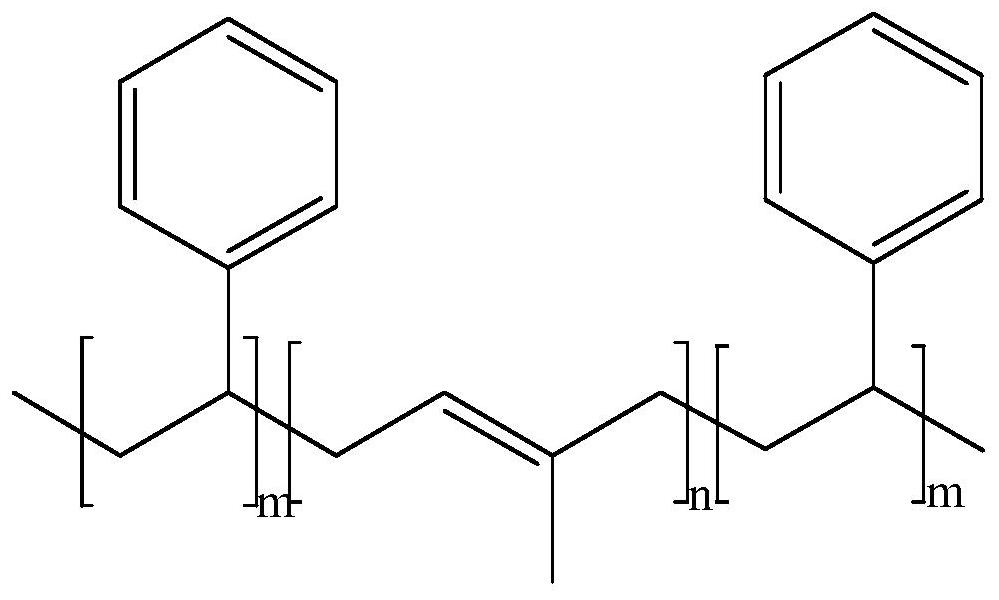

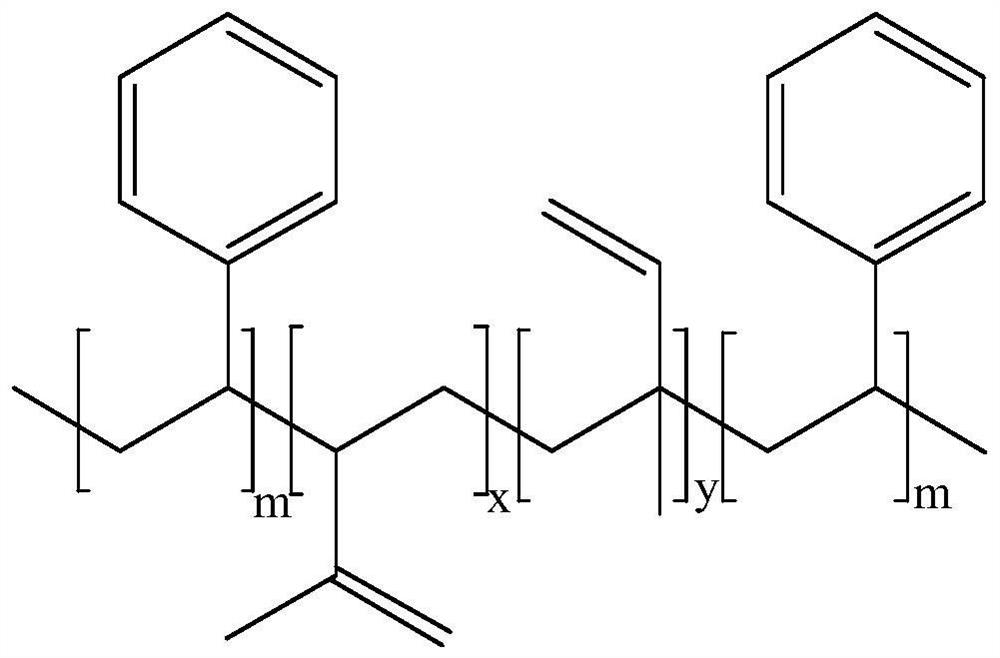

Ultrahigh melt index type styrene thermoplastic elastomer and preparation method thereof

A thermoplastic elastomer, thermoplastic elasticity technology, applied in the field of styrene thermoplastic elastomer, can solve the problems of poor adhesion strength and low temperature resistance, lack of viscosity, high cost, and achieve high compatibility, simplified process, low melt viscosity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0055] The preparation method of linear triblock copolymer is as follows:

[0056] Step 1: After the polymerization solvent, initiator, and monovinyl aromatic hydrocarbon are added in sequence to initiate the first stage of polymerization, a microstructure regulator is immediately added to speed up the polymerization reaction rate and prepare to regulate the microstructure of step 2. The monomer concentration of the polymerization reaction is preferably 8-30%, further preferably 13-25%, most preferably 17-20%; the polymerization temperature is preferably 0-100°C, further preferably 10-70°C, most preferably 20-40°C; atmosphere The condition is a slight positive pressure of nitrogen; the reaction time of the first stage of polymerization is preferably 15-60min, more preferably 20-50min, most preferably 30-40min; the addition amount of the microstructure regulator in the polymer is preferably 1000-5000ppm, more preferably 2000-4000ppm, Most preferably 2500-3000ppm;

[0057] Step...

Embodiment 1

[0072] Preparation of base glue SBS

[0073] The polymerization reaction is carried out in a polymerization kettle with an internal volume of 5 liters. The polymerization kettle is equipped with stirring, electric heating, and temperature control of 10°C circulating water. Before the polymerization reaction, add 4 liters of cyclohexane (water value Figure 10 . In addition, the BRUKER company's AV-600 model, 600MHz hydrogen nuclear magnetic resonance instrument was used to analyze the microstructure of the polymer with deuterated chloroform as the test solvent. For the structural analysis method, see the master's degree thesis of Wang Dongfang and Zhang Chuanqi, Beijing University of Chemical Technology, For polymer microstructural data see Figure 10 with Figure 7 .

[0074] Preparation of hydrogenated gum HSBS

[0075]After the hydrogen gas was terminated, the temperature of the hydrogenation tank was maintained at 70°C, and then 22 ml of the above-mentioned hydrogenati...

Embodiment 2

[0078] Preparation of base glue SIS-1

[0079] The polymerization process can refer to Example 1, but tetrahydrofurfurylamine is not added, and 545 grams of isoprene monomer is added in the second stage of polymerization instead. For molecular weight information and microstructural data see Figure 10 .

[0080] Preparation of Hydrogenated Glue HSIS-1

[0081] The hydrogenation process can refer to embodiment 1. For iodine value, degree of hydrogenation, molecular weight information, mechanical properties and melt index data, see Figure 11 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com