Method for forming vertical crack in brittle material substrate and method for dividing brittle material substrate

A technology for brittle material substrates and vertical cracks, applied in stone processing tools, stone processing equipment, electrical components, etc., can solve the problem of partial extension of vertical cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0077] In this example, it was confirmed that the load applied to the pressing body 100 affects the size of the indentation ID and the maximum length of the microcrack MC (hereinafter referred to as the maximum crack length).

[0078] Specifically, a glass substrate with a thickness of 0.2 mm was prepared as the brittle material substrate W, and as the pressing body 100, a diamond head with a conical tip 101 having an opening angle of 122° and a radius of curvature of 10 μm was used, and the applied The load to the pressing body 100 is divided into four levels of 1.3N, 2.5N, 3.8N, and 5.0N to form the indentation ID.

[0079] Figure 11 is a graph showing the relationship between the load and the diameter of the formed indentation ID, Figure 12 is a graph showing the relationship between load and the maximum crack length formed.

[0080] From Figure 11 and Figure 12 It was confirmed that the larger the load, the larger the size of the indentation ID and the larger the m...

Embodiment 2

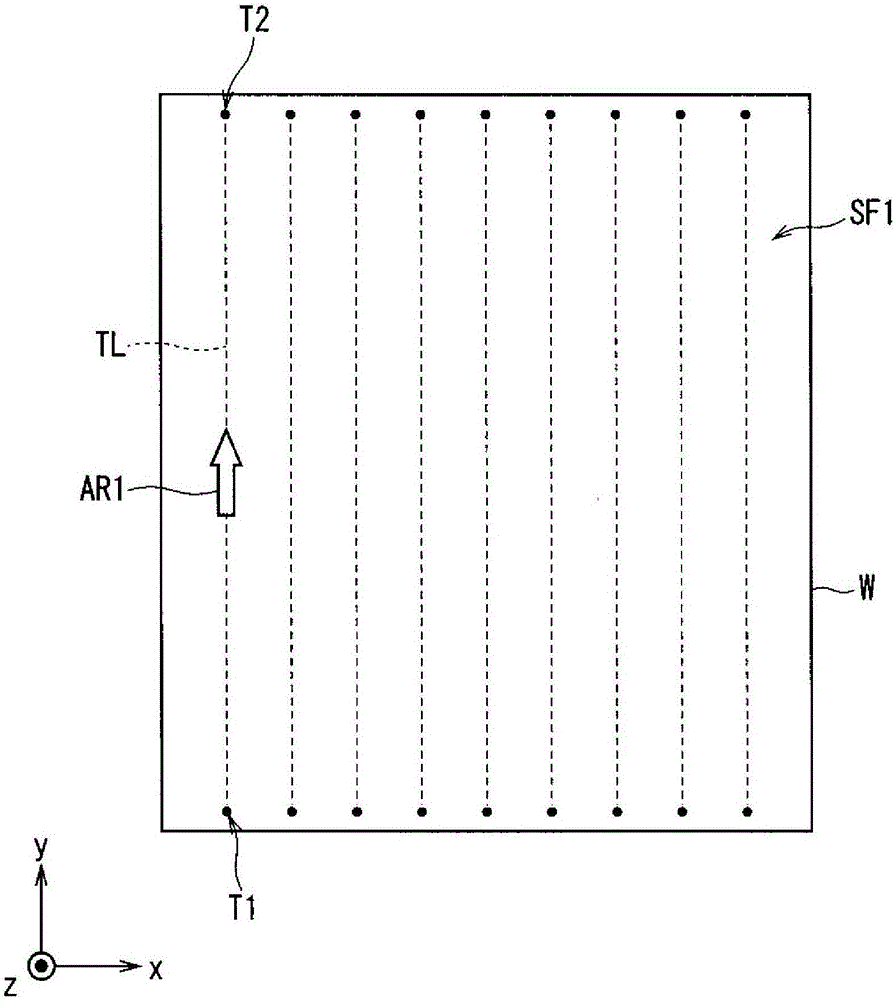

[0082] In this example, the influence of the load applied to the pressing body 100 and the distance of the indentation ID (more specifically, its center position) from the groove line on the extension of the vertical crack VC was investigated. The conditions of the pressing body 100 and the brittle material substrate W are the same as those of the first embodiment.

[0083] Specifically, by dividing the load applied to the pressing body 100 into four levels of 1.3N, 2.5N, 3.8N, and 5.0N, and dividing the distance between the center position of the indentation and the groove line into 0 μm, ±10 μm, and ±20 μm , ±30 μm, and ±40 μm in 9 levels, all 36 conditions in which the combination of the load applied to the pressing body 100 and the distance from the center position of the indentation to the groove line are different from each other were determined. In addition, the case where the distance between the center position of the indentation and the groove line is negative means ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com