Method for obtaining a part made of a composite material including a phase of tensioning filaments, and tools for implementing same

A composite material and tool technology, applied in the field of obtaining composite material components and their implementation tools including a monofilament tensioning step, can solve the problems of reduced productivity, no solution, laying of strips, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

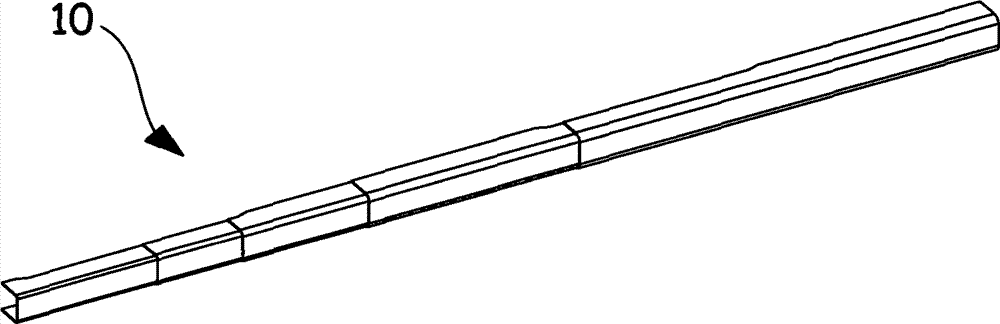

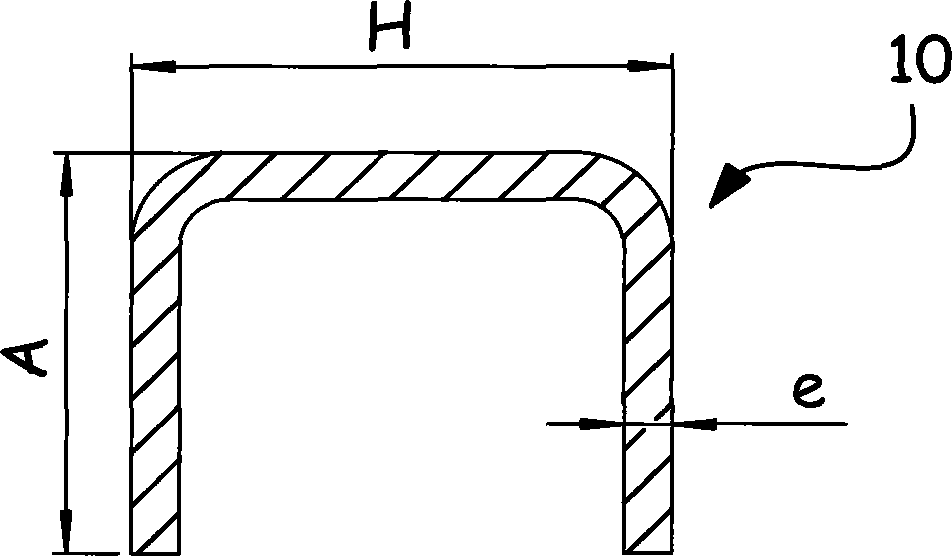

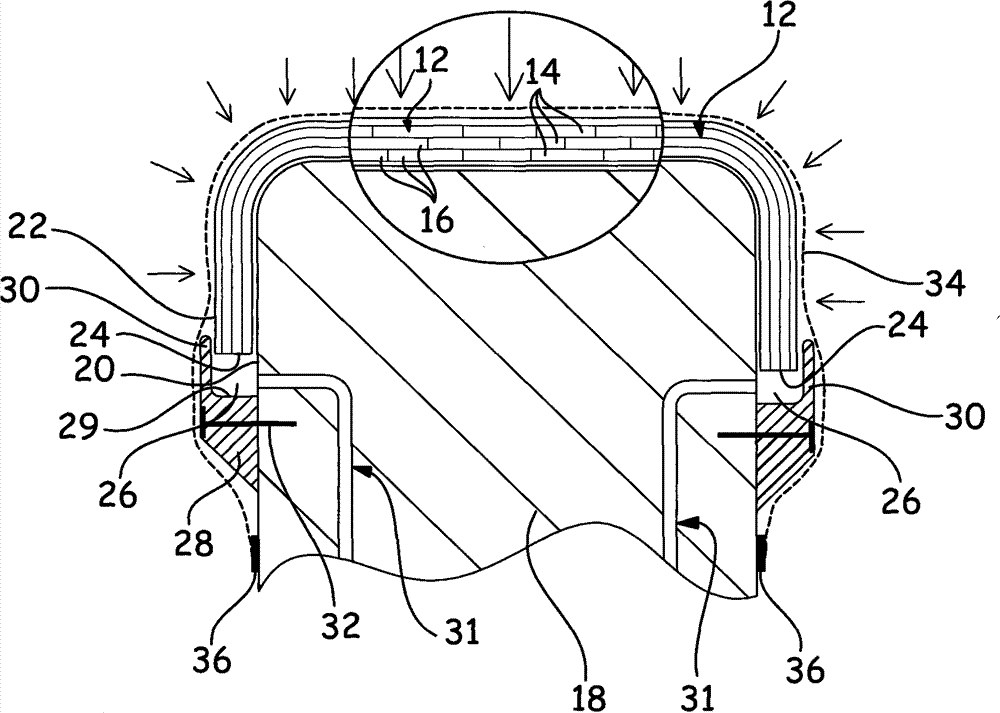

[0023] figure 1 and figure 2 A composite part 10 is shown having a U-shaped cross-section. For example, such a component could be used as a stringer for an aircraft wing. The thickness e of the stringer can vary from 7 to 25 mm, its height H can vary from 200 to 1500 mm, the width A of the stringer can vary from 200 to 400 mm, and its length can reach 10 m.

[0024] Of course, the invention is not limited to this application. It can be used to form different composite parts. Especially useful when parts have non-developable surfaces and / or very pronounced radii of curvature.

[0025] The component 10 is obtained from a preform 12 pre-impregnated with fibres, which has undergone a polymerization cycle. Once completed, part 10 includes reinforcing fibers embedded in a resin matrix.

[0026] In general, the fibers each consist of a plurality of monofilaments. The material of the monofilament and the resin can vary according to the application.

[0027] According to one e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com