Method for manufacturing wide-width color flexible preprinted corrugated carton

A technology of corrugated cardboard box and manufacturing method, which is applied in the direction of container manufacturing machinery, paper/cardboard containers, containers, etc., and can solve the problems of color vividness and glossiness of corrugated cardboard precision printed products, unsatisfactory gloss, incapable of coating treatment, and slow printing speed and other problems, to achieve the effect of bright colors, thick ink layer and accurate overprinting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

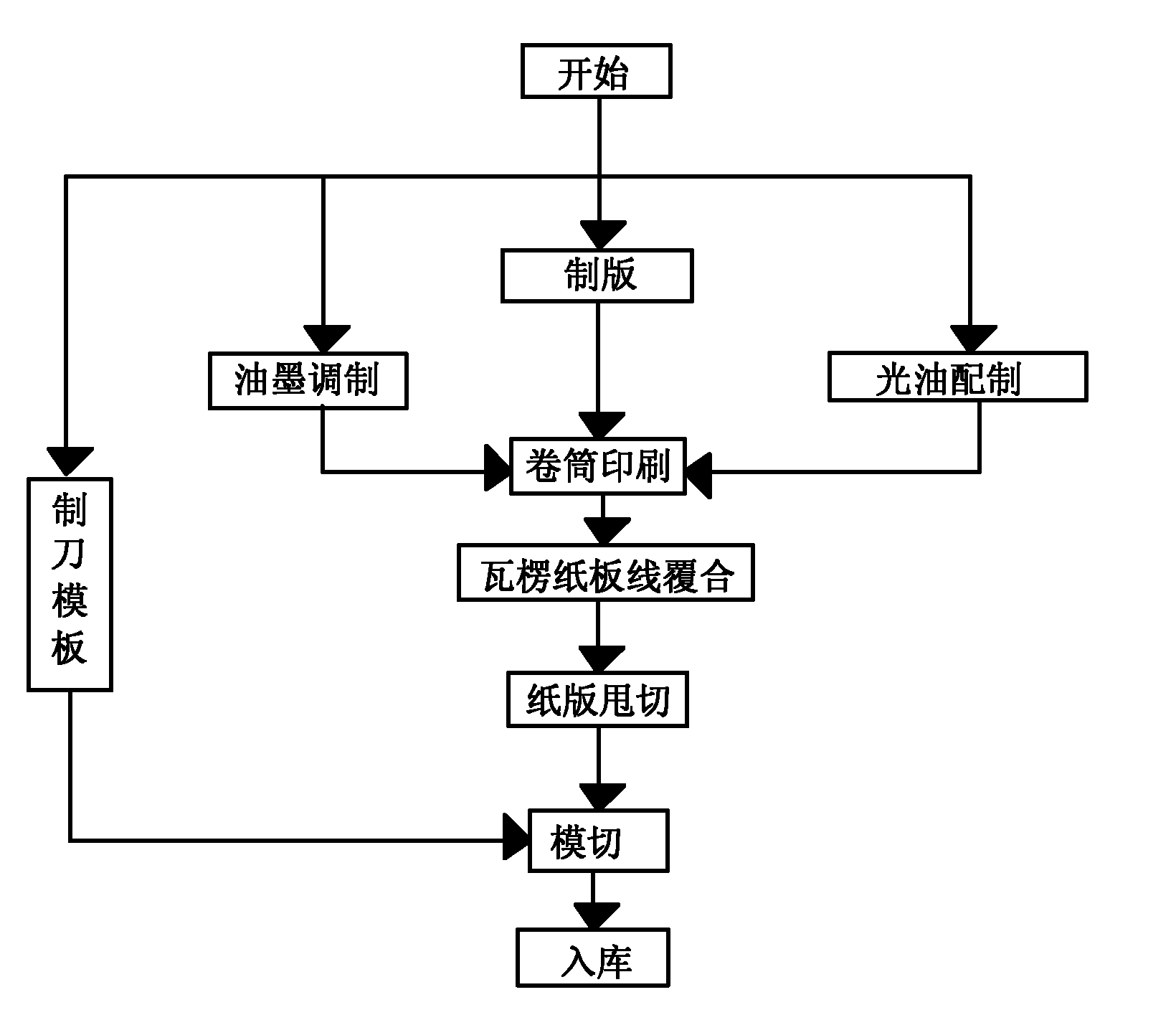

Method used

Image

Examples

Embodiment 1

[0028] (1) Plate making: According to the designed text pattern, use the high-end flexible resin plate DRC of DuPont Company in the United States to make a seamless sleeve flexible printing plate through laser engraving. The thickness of the printing plate is 1.7mm, and the hardness is 80 Shore hardness;

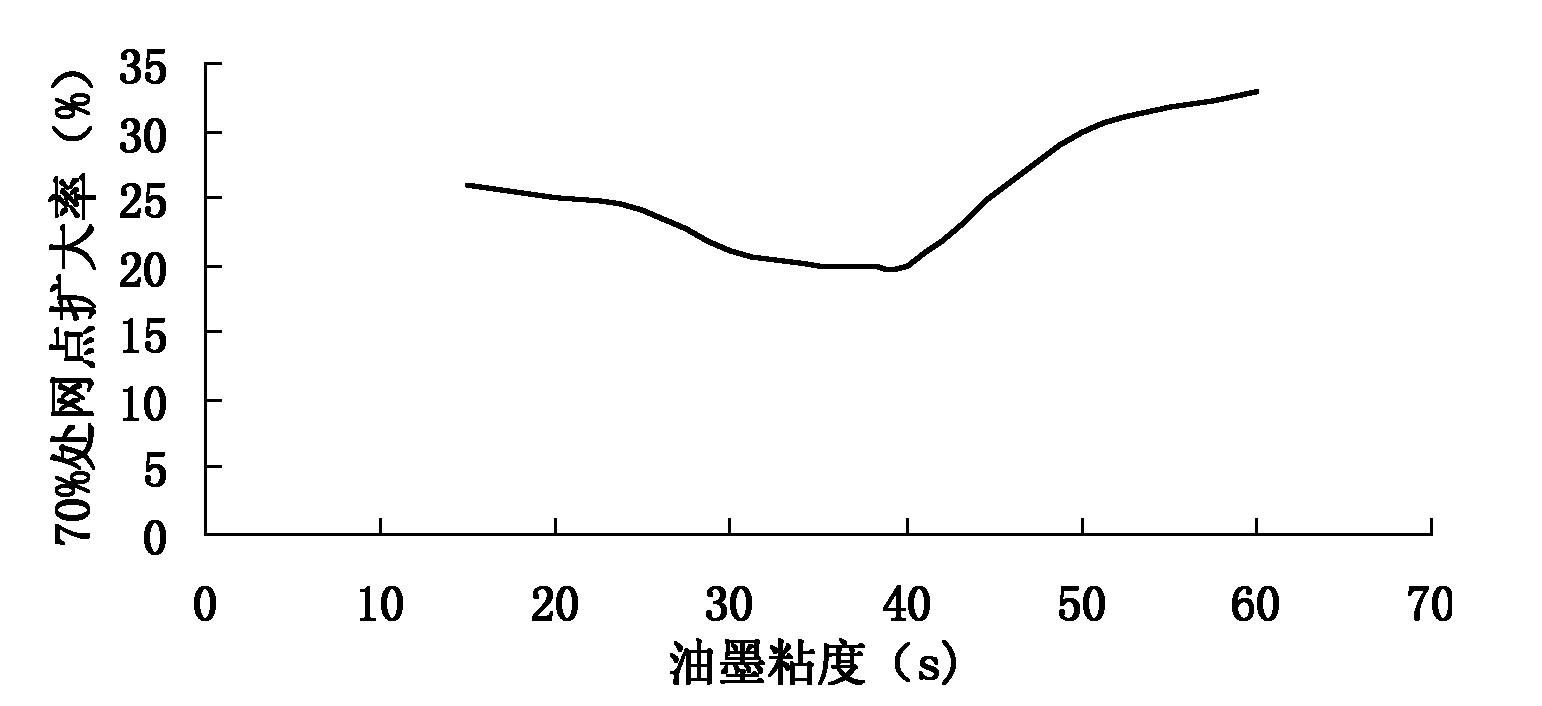

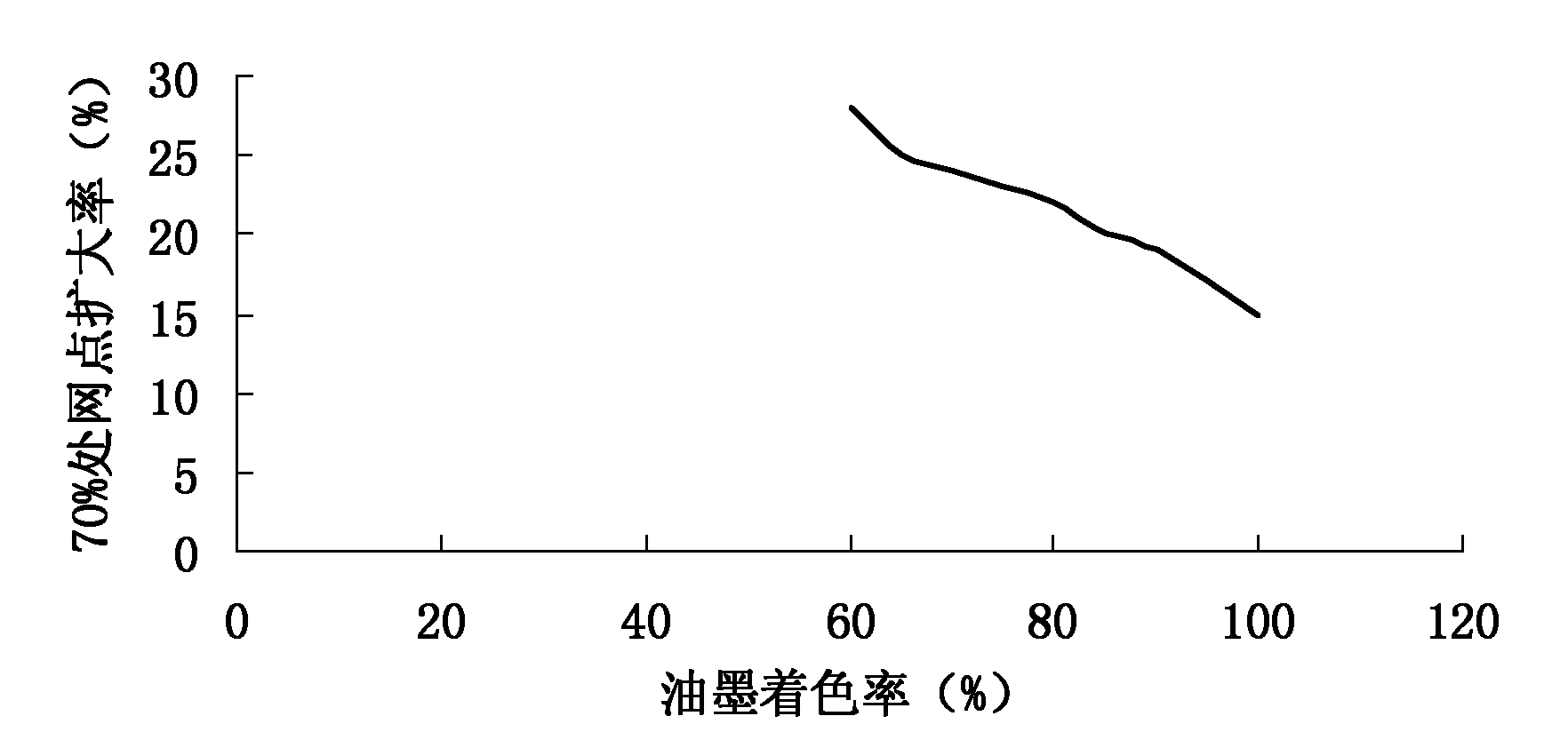

[0029] (2) Ink preparation: prepare water-based ink with a viscosity of 40 seconds, a coloring rate of 100%, a fineness of 26, and a pH value of 9;

[0030] (3) Varnish preparation: prepare a water-based varnish with a viscosity of 40 seconds and a solid content of 50% that can withstand high temperatures of 160-200°C;

[0031] (4) Roll printing: The ink in the ink tank is transferred to the honeycomb ceramic anilox roller through the ink roller, and then the anilox roller transfers the ink evenly to the flexographic plate. The graphics and text on the plate are transferred to 100g paper at a speed of 300-500 m / min; and the water-based varnish is covered on the printed matt...

Embodiment 2

[0038] (1) Plate making: According to the designed text pattern, use the high-end flexible resin plate DRC of DuPont Company in the United States to make a seamless sleeve flexible printing plate through laser engraving. The thickness of the printing plate is 3.94mm and the hardness is 60 Shore hardness;

[0039] (2) Ink preparation: prepare water-based ink with a viscosity of 30 seconds, a coloring rate of 100%, a fineness of 35, and a pH value of 8;

[0040] (3) Varnish preparation: prepare a water-based varnish with a viscosity of 30 seconds and a solid content of 50% that can withstand high temperatures of 160-200°C;

[0041] (4) Roll printing: The ink in the ink tank is transferred to the honeycomb ceramic anilox roller through the ink roller, and then the anilox roller transfers the ink evenly to the flexographic plate. The graphics and text on the plate are transferred to the 400g cardboard at a speed of 300-500 m / min; and the water-based varnish is covered on the prin...

Embodiment 3

[0049] (1) Plate making: According to the designed text pattern, use the high-end flexible resin plate DRC of DuPont Company in the United States to make a seamless sleeve flexible printing plate through laser engraving. The thickness of the printing plate is 2.9mm, and the hardness is 70 Shore hardness;

[0050] (2) Ink preparation: prepare water-based ink with a viscosity of 30 seconds, a coloring rate of 90%, a fineness of 30, and a pH value of 9;

[0051] (3) Varnish preparation: prepare a water-based varnish with a viscosity of 50 seconds and a solid content of 50% that can withstand high temperatures of 160-200°C;

[0052] (4) Roll printing: The ink in the ink tank is transferred to the honeycomb ceramic anilox roller through the ink roller, and then the anilox roller transfers the ink evenly to the flexographic plate. The graphics and text on the plate are transferred to the 200g cardboard at a speed of 300-500 m / min; and the water-based varnish is covered on the print...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com