Big stamping roller for planetary type flexible printer

A flexographic printing machine and large cylinder technology, which is applied to the general parts of printing machinery, printing machines, rotary printing machines, etc., can solve the problems of overall pattern deviation and inaccurate overprinting, achieve accurate overprinting, improve printing quality, The effect of improving smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

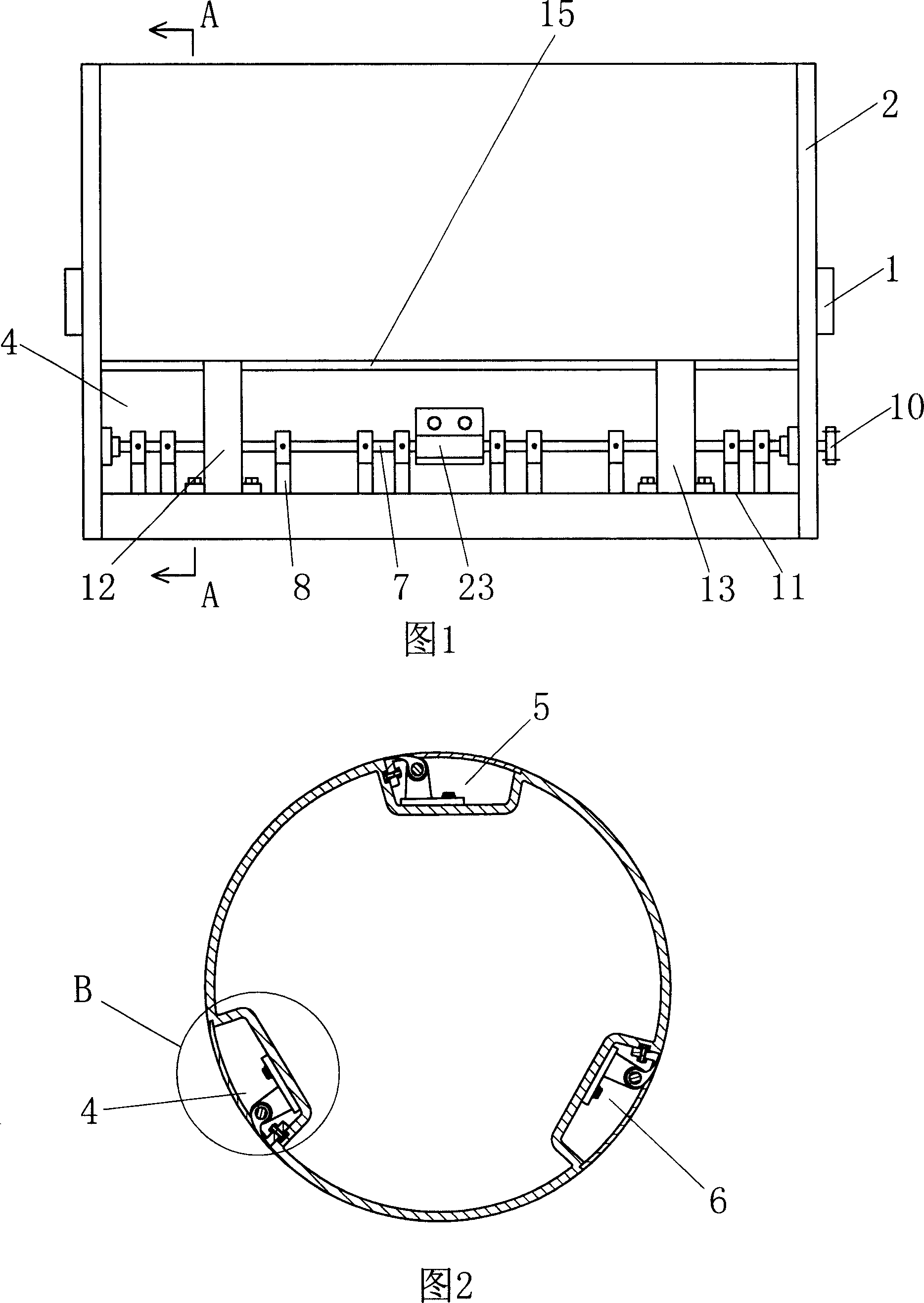

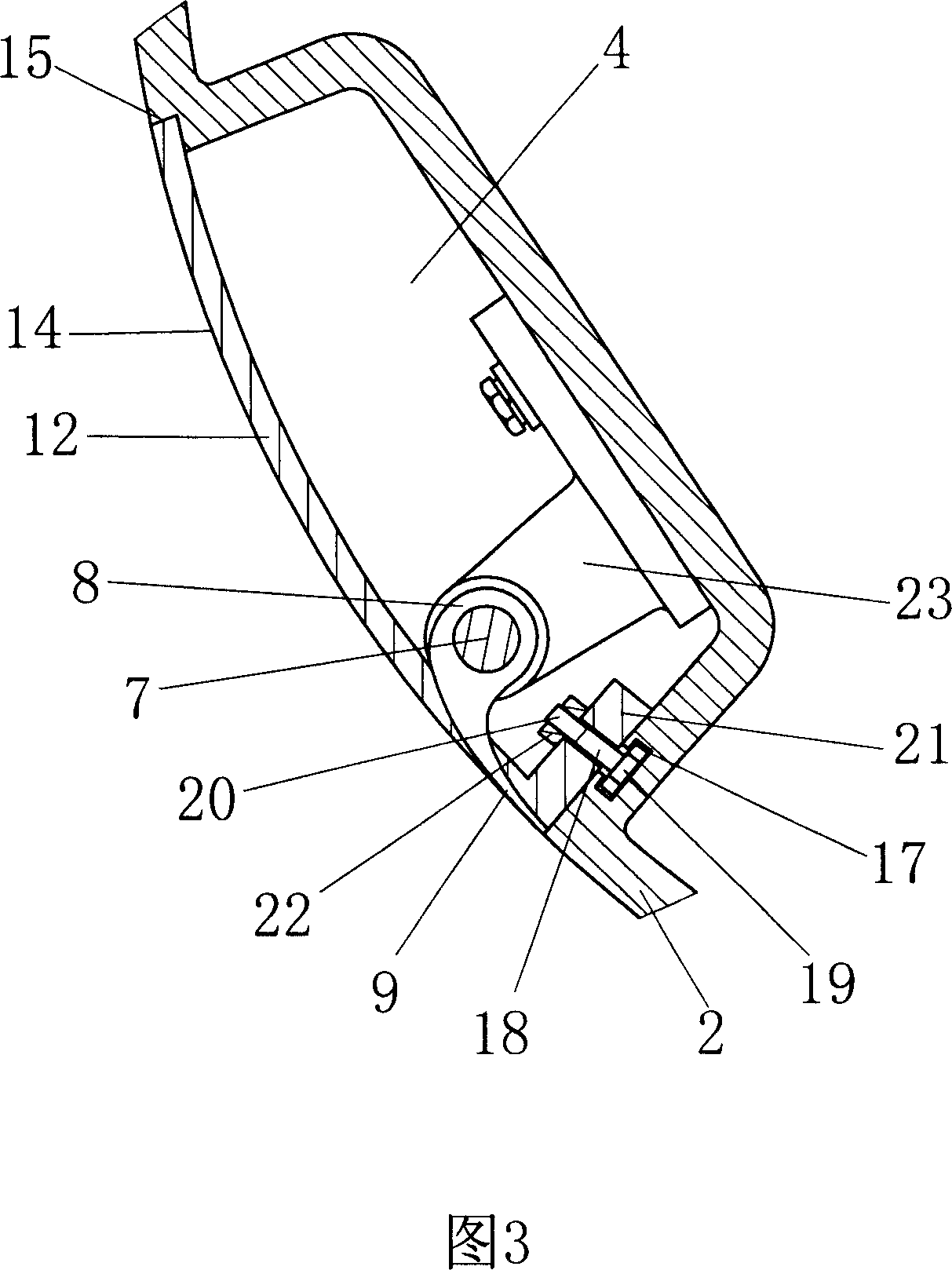

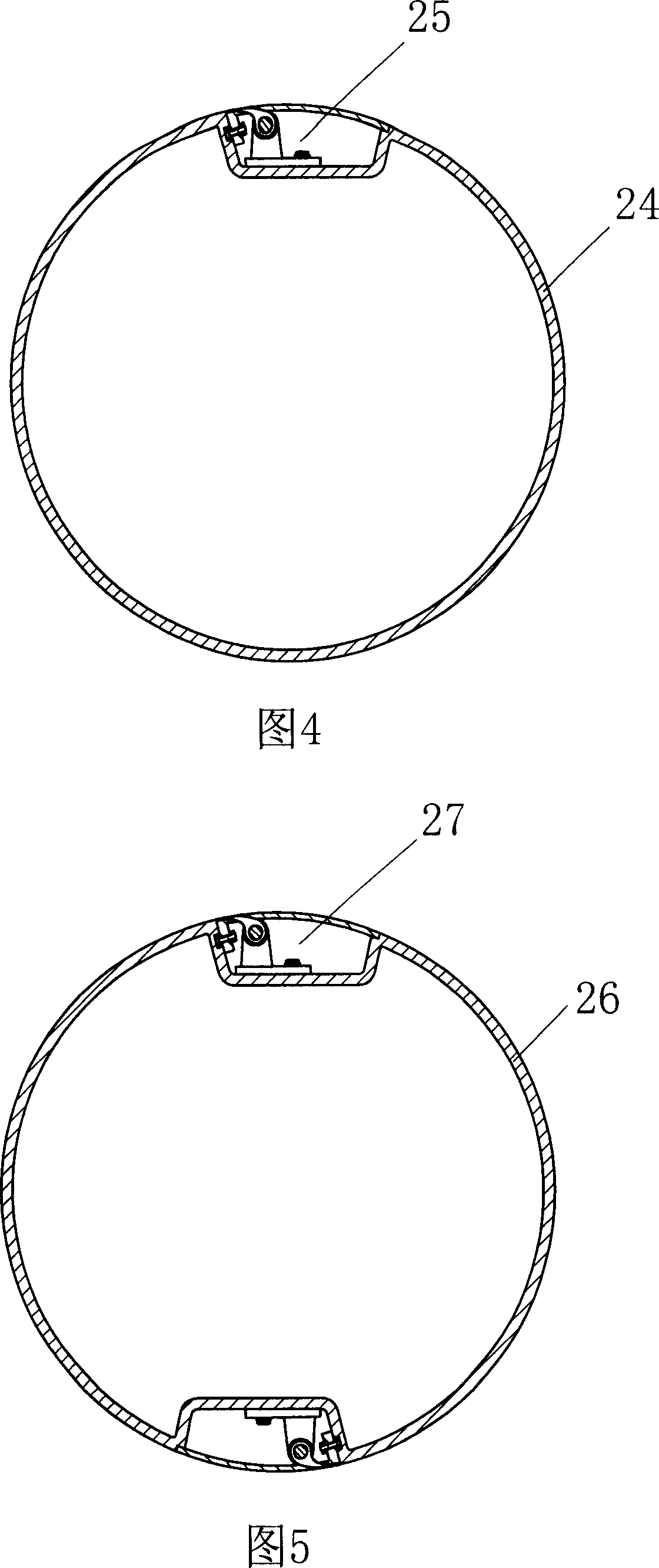

[0015] Referring to Figures 1 to 3, the large imprinting cylinder of the satellite flexographic printing machine is a cylinder 2 with a central axis 1, and its feature is that the arc surface 3 of the cylinder 2 has three axes along the axial direction. Evenly distributed grooves 4, 5, 6, each groove 4 is rotated and fitted with a jaw shaft 7 arranged along the axis direction, and ten jaws 8 are fixed on a jaw shaft 7, and the jaws The jaw end 9 of 8 etc. is matched with the mouth edge of the groove 4, the driving end 10 of the jaw shaft 7 is on the side of the cylinder 2, and the notch 11 of each groove 4 is provided with two grooves arranged along the circumferential direction. The entrainment bridge plates 12 and 13 for supporting the entrainment, the top surface 14 of the entrainment bridge plate 12 is an arc surface with the same radian as the cylinder arc surface 3 .

[0016] In addition, the entrained bridge plate 12 is erected on the concave step 15 of the notch 11 of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com