Volute iron printing side mark device

A side gauge and volute technology, applied in printing, printing machines, rotary printing machines, etc., can solve the problems of low raw material utilization rate and increased labor cost, and achieve the effect of improving raw material utilization rate, reducing labor cost, and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

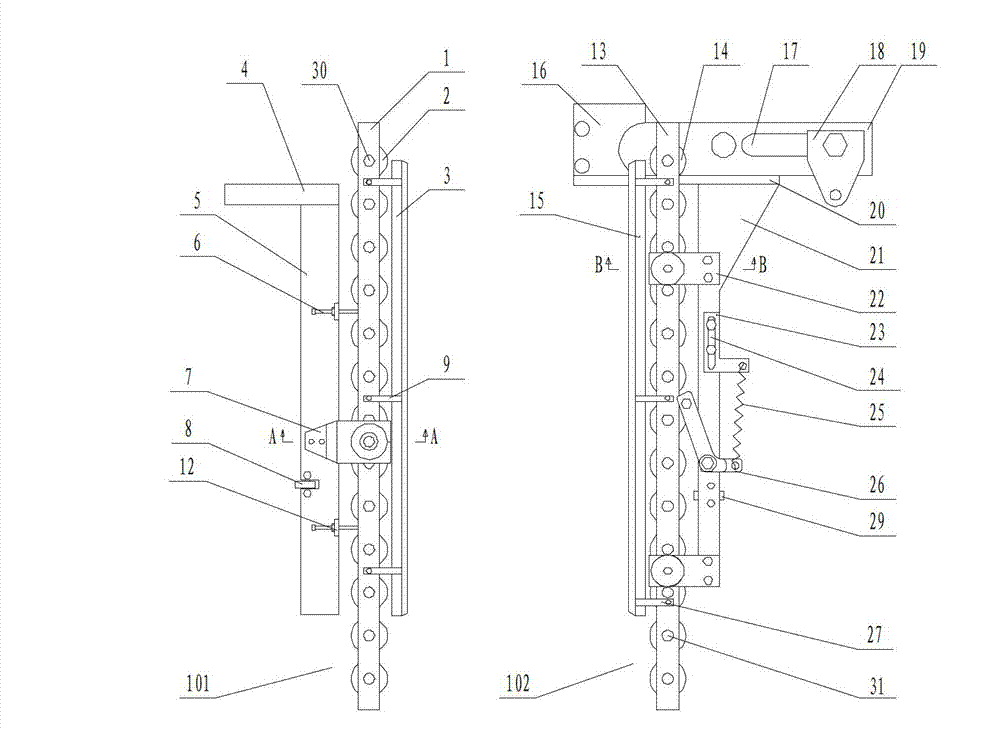

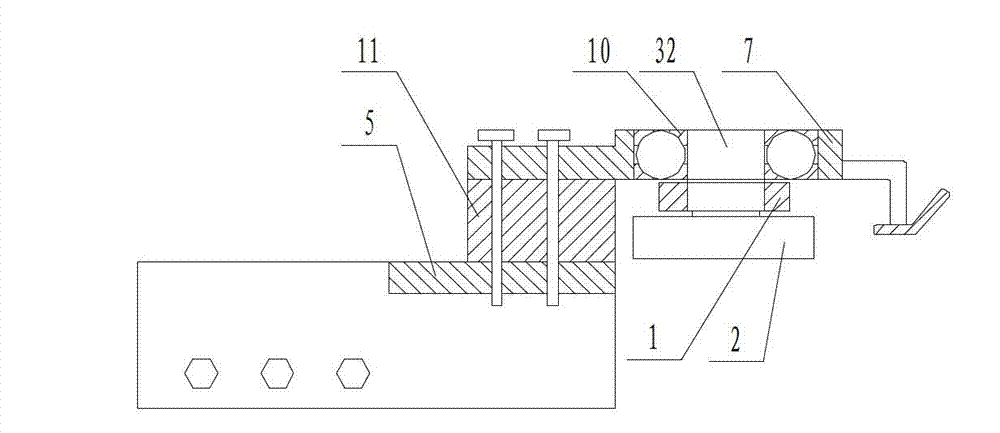

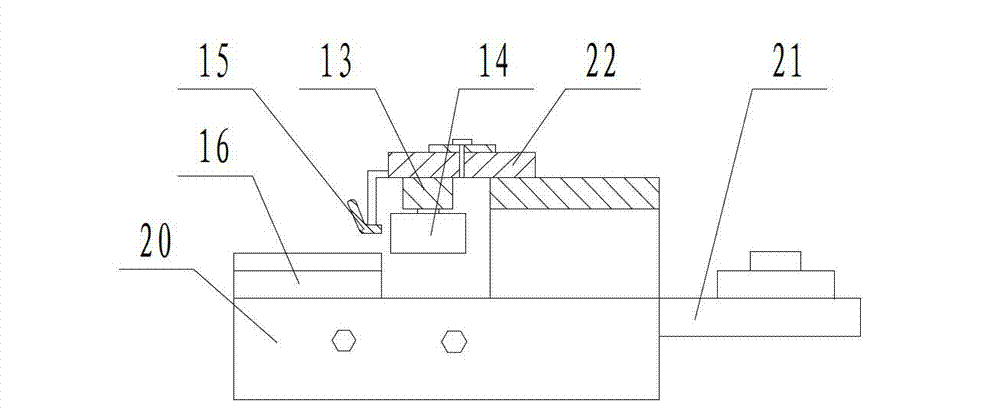

[0016] The present invention will be further described below in conjunction with accompanying drawing.

[0017] In the picture:

[0018] 1. Main support rod A; 2. Bearing group A; 3. Body pressure plate; 4. Horizontal support A; 5. Longitudinal support A; 6. Adjustable distance bolt; 7. Connecting part A; 1. Connecting rod A; 10. Positioning bearing; 11. Connecting pad; 12. Adjusting seat; 13. Main support rod B; 14. Bearing group B; 15. Side gauge pressure plate; 16. Bracket; 18, installation block; 19, horizontal support B; 20, horizontal support C; 21, longitudinal support B; 22, connecting part B; 23, fixed seat; 24, fixed seat groove; 25, spring; 26, moving rod; 27, connecting rod second; 28, spacing bearing; 29, support bearing second; 30, connecting shaft A; 31, connecting shaft second; 32, connecting shaft C.

[0019] 101, body; 102, side gauge; 103, scroll iron; 104, printing machine frame; 105, printing machine guide rail.

[0020] Such as Figure 1 to Figure 4 T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com