Positioning device for manual silk-screen wheel transfer printing machine

A positioning device and printing machine technology, applied to rotary printing machines, screen printing machines, printing machines, etc., can solve the problems of easy shifting of screen plates, reduced work efficiency, and poor product quality, so as to reduce manufacturing costs and improve Good work efficiency and product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

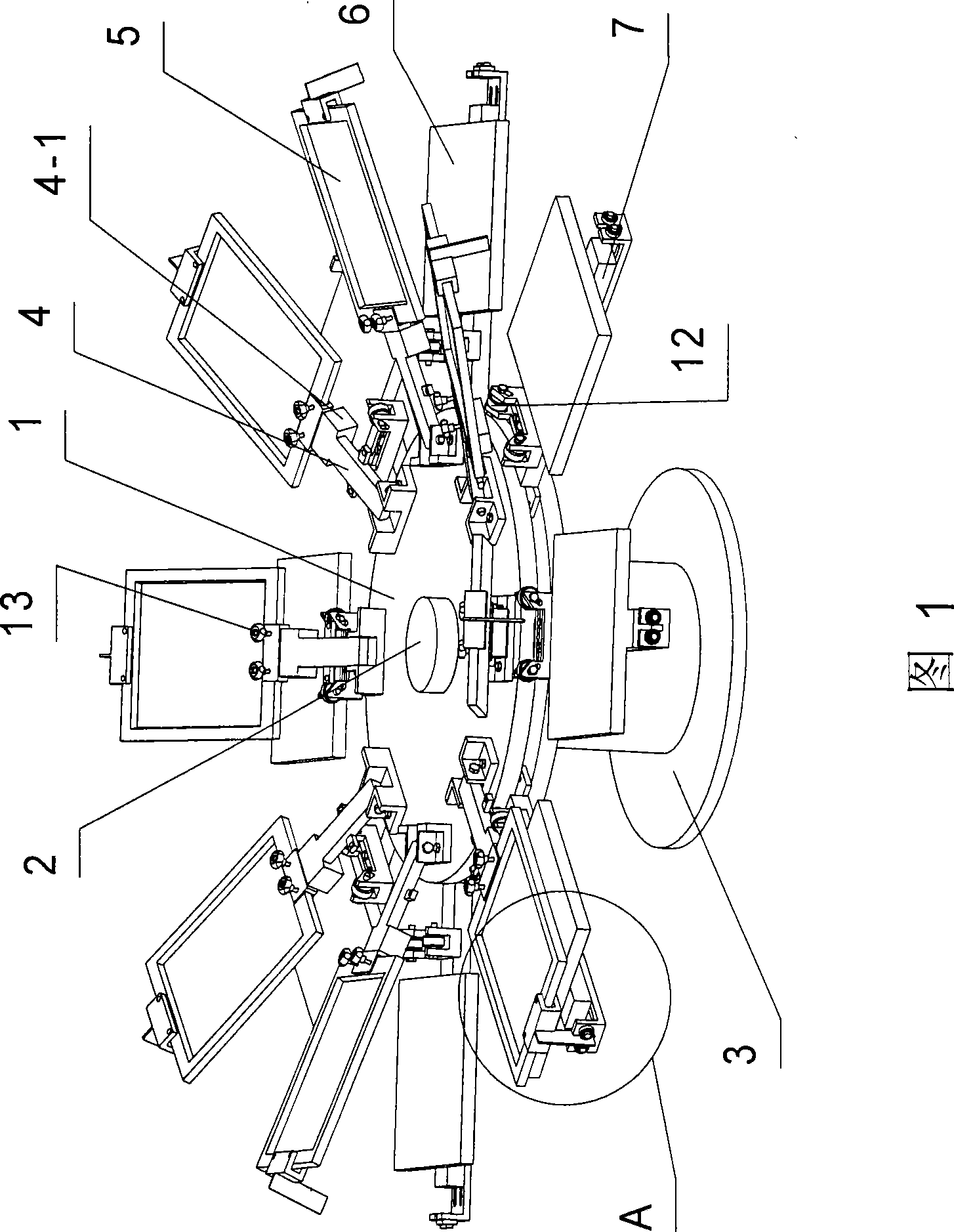

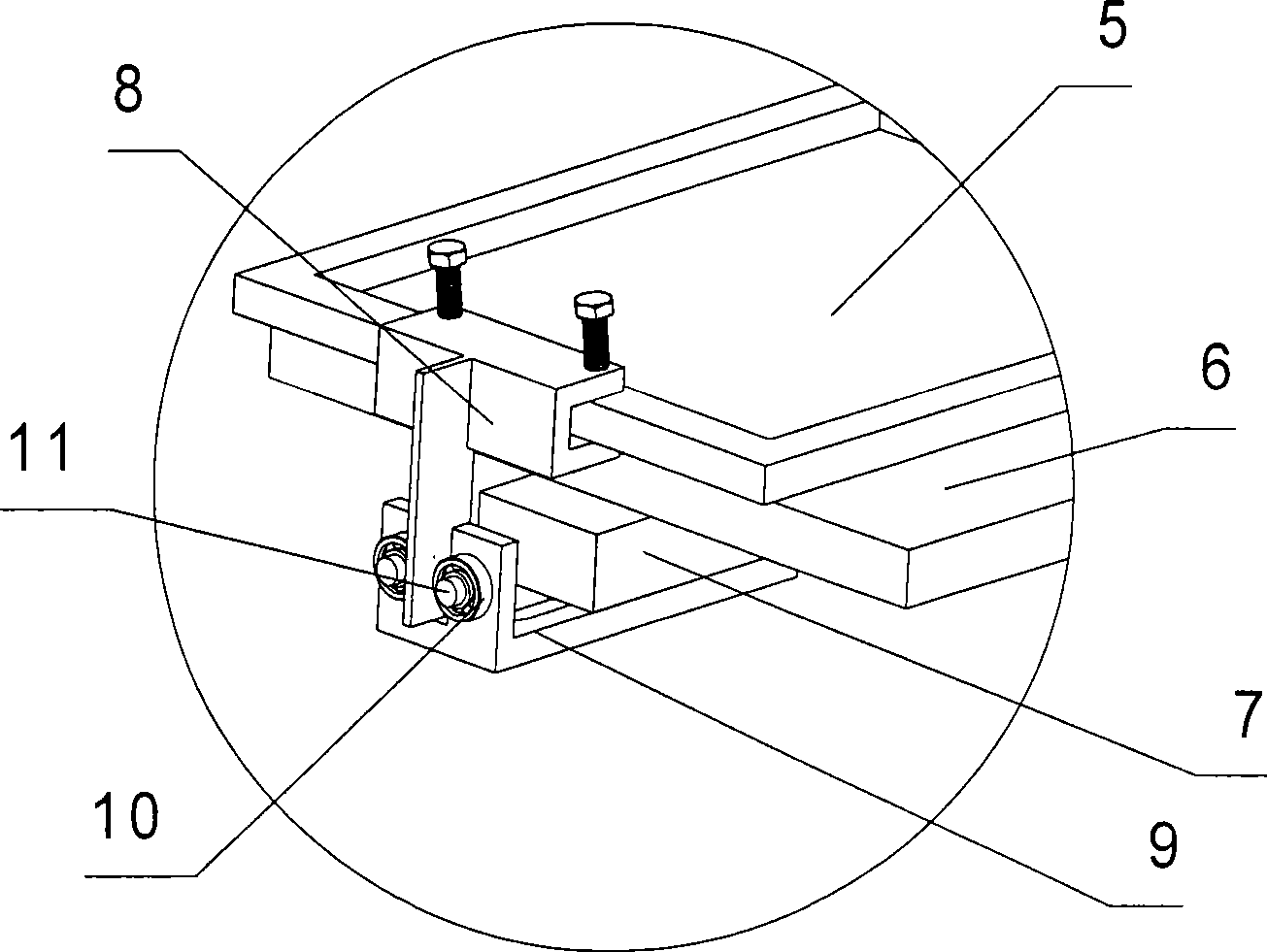

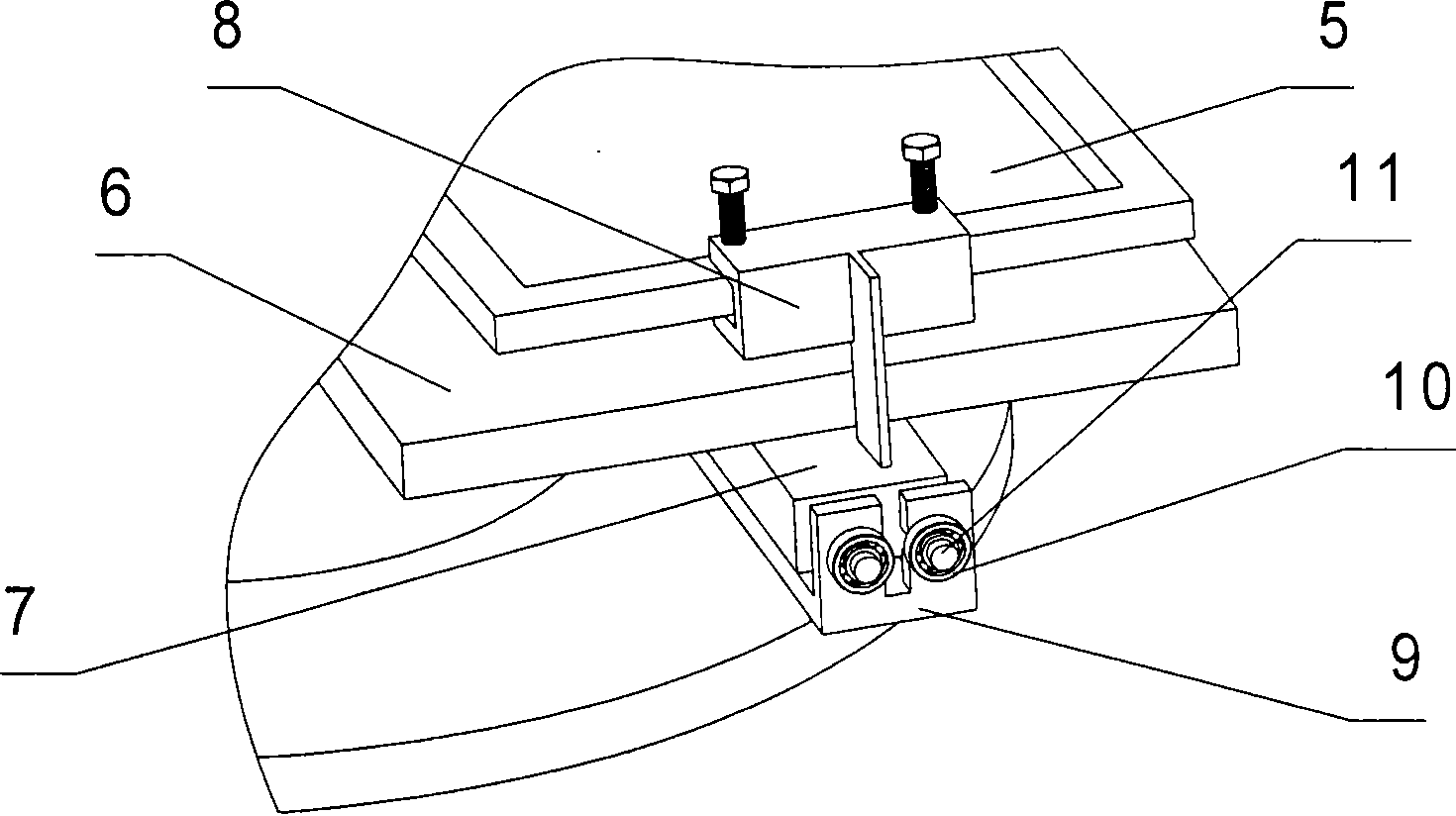

[0017] 1 turntable 2 rotating shaft 3 base 4 cantilever 4—1 positioning block 5 screen plate 6 printing pad 7 supporting legs 8 positioning plate 9 positioning seat 9—1 positioning slot 10 a pair of bearings 11 a pair of core shafts 12 a pair of runners 13 adjusting screws

[0018] From Figure 1— Figure 4 It can be seen that the manual screen rotary printing machine includes a base 3 with a platen, a rotating shaft 2 installed on the base, a turntable 1 mounted on the rotating shaft 2 through a bearing, and a plurality of screen plates 5 evenly distributed around the turntable through a cantilever 4 1. A plurality of printing pads 6 evenly distributed on the periphery of the platen through the supporting legs 7; the number of the screen plate is the same as that of the platen, which can be 4-20, and the screen plate 5 is located abov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com