Holographic positioning overprinting method between coils

A holographic and roll material technology, which is applied in the production of printing of special varieties of printed matter, general parts of printing machinery, printing, etc., can solve the problems of high registration difficulty, slow registration speed, and low production efficiency, and achieve improved registration Accuracy and overprinting efficiency, the effect of reducing the scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

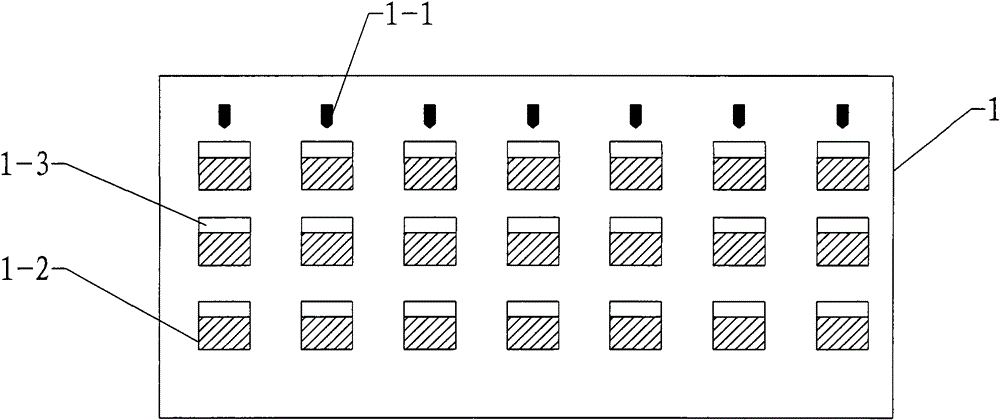

[0026] Such as figure 1 As shown, the roll substrate 1 of plastic products or paper products, each group of specific patterns 1-2 corresponds to a cursor I1-1, each specific pattern 1-2 is the same, and has an overprint area on the specific patterns 1-2 1-3;

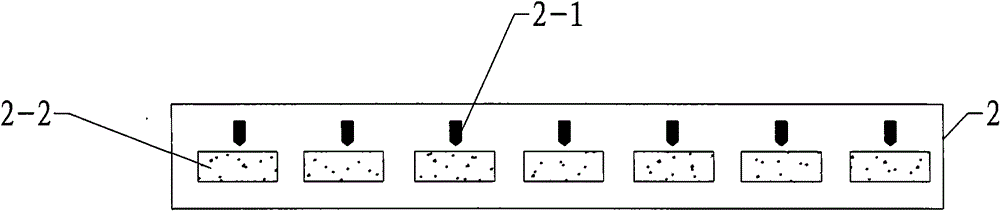

[0027] Such as figure 2 As shown, each holographic pattern 2-2 on the reel holographic anti-counterfeiting film 2 corresponds to a cursor II2-1, the holographic pattern 2-2 is similar in shape to the overprint area 1-3, and the holographic pattern 2-2 is slightly larger than the overprint area 1-3 3.

[0028] The cursor distances on the roll substrate 1 and the roll holographic anti-counterfeiting film 2 are equal. During overprinting, one roll of substrate 1 corresponds to three sets of same roll holographic anti-counterfeiting films 2 at the same time.

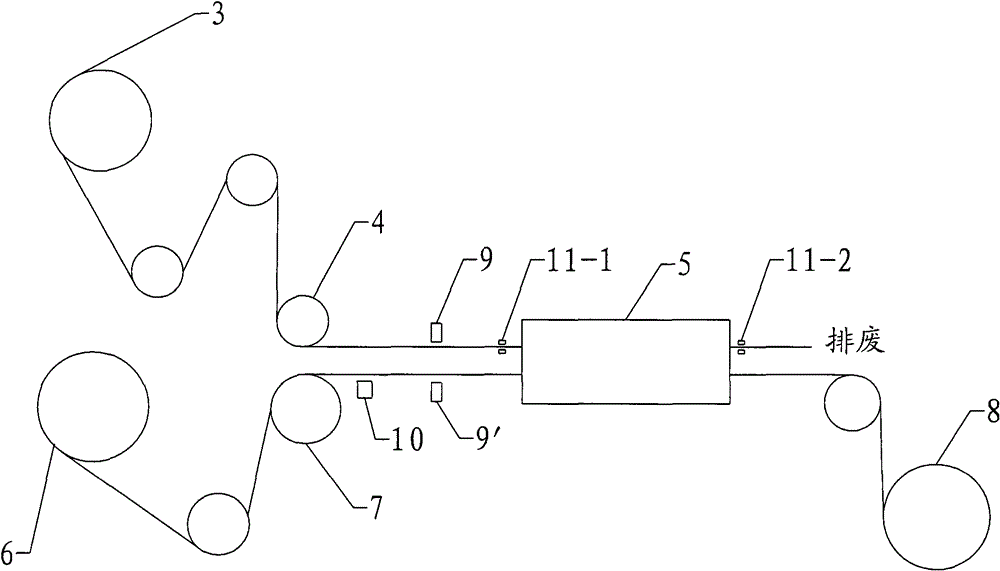

[0029] Such as image 3 As shown, the roll holographic anti-counterfeiting film 2 is placed on the unwinding shaft I3, and enters the overprinting device 5 throu...

Embodiment 2

[0031] Such as Figure 4 As shown, when the web 1 has different specific patterns 1-2 and 1-2', each group of specific patterns 1-2 has a cursor I1-1, and each specific pattern 1-2' has a cursor I1-1 Cursor I1-1', corresponding as Figure 5 As shown, at this time, the roll holographic anti-counterfeiting film 2 must also have different holographic patterns 2-2 and 2-2', each holographic pattern 2-2 has a cursor II2-1, and each holographic pattern 2-2' There is one cursor II2-1'. During overprinting, the specific patterns on the roll substrate 1 correspond to the holographic patterns on the roll holographic anti-counterfeiting film 2 respectively, that is, the specific pattern 1-2 corresponds to the holographic pattern 2-2, and the specific pattern 1-2' corresponds to the holographic pattern. 2-2' one-to-one correspondence. Wherein, the cursor distance of the cursor I1-1 on the roll substrate 1 is not equal to the cursor distance of the cursor II2-1 on the roll holographic a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com