Screen frame positioning equipment and screen frame positioning method

A technology for positioning equipment and screen frames, applied to screen printing machines, rotary printing machines, printing, etc., can solve problems such as inaccurate positioning, screen frame installation deviation, and low accuracy, and achieve convenient installation and disassembly, accurate overprinting, The effect of precise positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

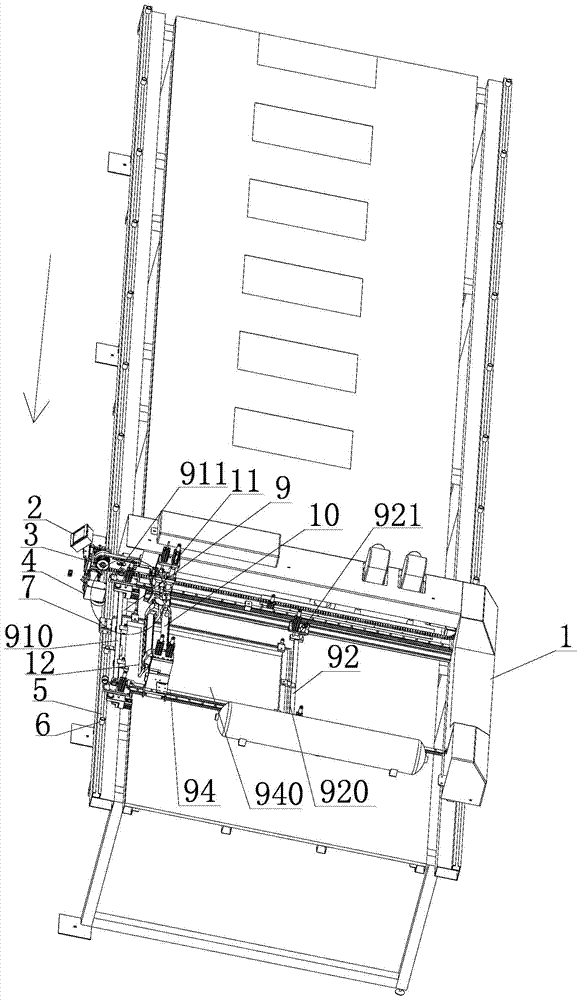

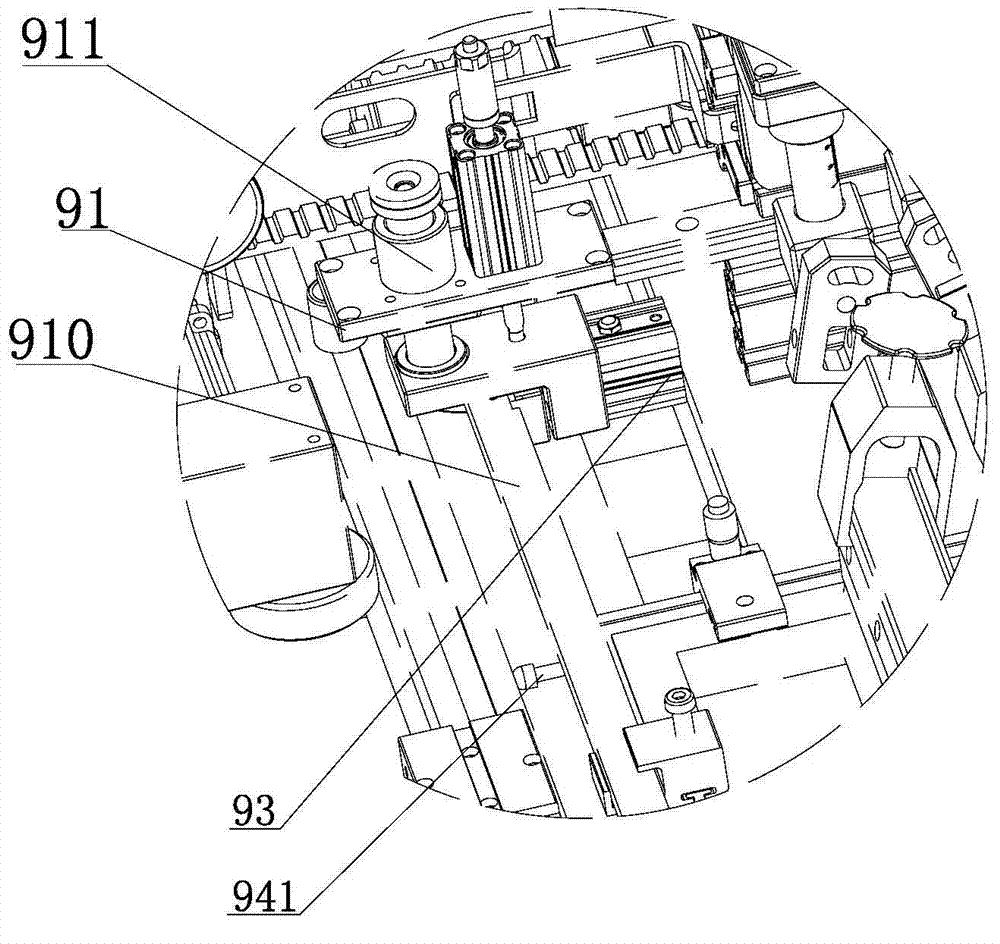

[0033] Example 1: See Figure 1 to Figure 3 , a method for positioning a screen frame, comprising the steps of:

[0034] (1) The front frame crossbeam 910 descends under the action of the front crossbeam lifting cylinder 911, and the crossbeam 10 descends with the screen frame 94;

[0035] (2) The front beam 910 of the screen frame is pushed under the action of the front and rear movement cylinder 911 of the front beam until the frame positioning pin 941 on the screen frame 94 is tightly attached to the guide rail 5. This step is referred to as "forward operation", here Forward movement refers to the direction of the front end of the screen frame;

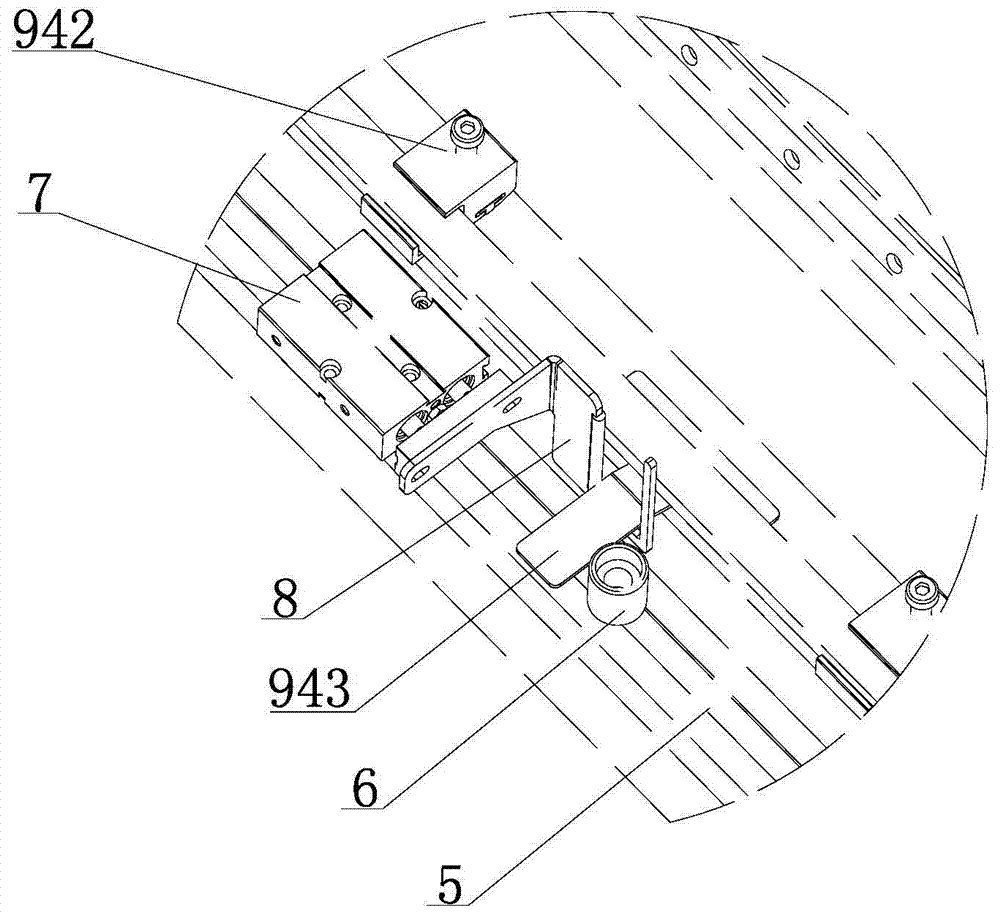

[0036] (3) The double-rod left and right positioning cylinder 7 pushes the positioning push block 8, and the positioning push block 8 pushes the T-shaped iron 943 on the screen frame to move to the right until the T-shaped iron 943 is close to the positioning column 6. This step is referred to as "moving to the right". Operation"...

Embodiment 2

[0039] Example 2: see Figure 1 to Figure 3 , a method for frame positioning, comprising the steps of:

[0040] (1) The front frame crossbeam 910 descends under the action of the front crossbeam lifting cylinder 911, and the crossbeam 10 descends with the screen frame 94;

[0041] (2) The double-rod left and right positioning cylinder 7 pushes the positioning push block 8, and the positioning push block pushes the T-shaped iron 943 on the screen frame to move to the right until the T-shaped iron 943 is close to the positioning column 6, which is "right shift operation";

[0042] (3) The front frame crossbeam 910 is pushed under the action of the front and rear movement cylinder 911 until the screen frame positioning pin 941 on the screen frame 94 is tightly attached to the guide rail 5, which is "forward operation";

[0043] (4) The rear screen frame crossbeam 920 descends under the effect of the rear crossbeam lifting cylinder 921, and the crossbeam 10 descends together with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com