Group-type logistics bidirectional holographic positioning overprinting machine

An overprinting machine and logistics technology, which is applied to printing machines, rotary printing machines, general parts of printing machinery, etc. Realize problems such as logistics hot stamping, achieve the effect of accurate overprinting, continuous two-way holographic positioning overprinting, and solve the problem of overprinting deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

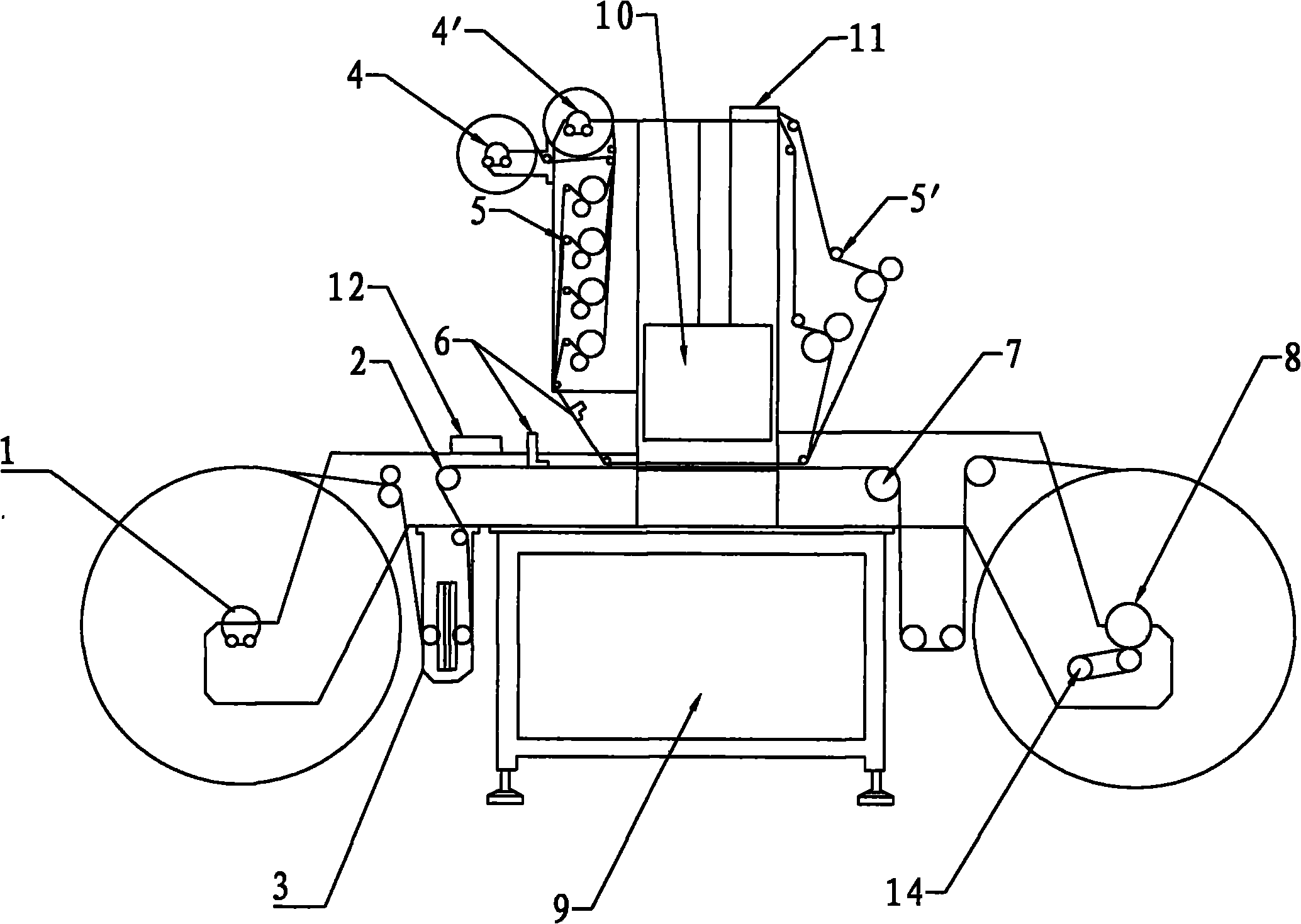

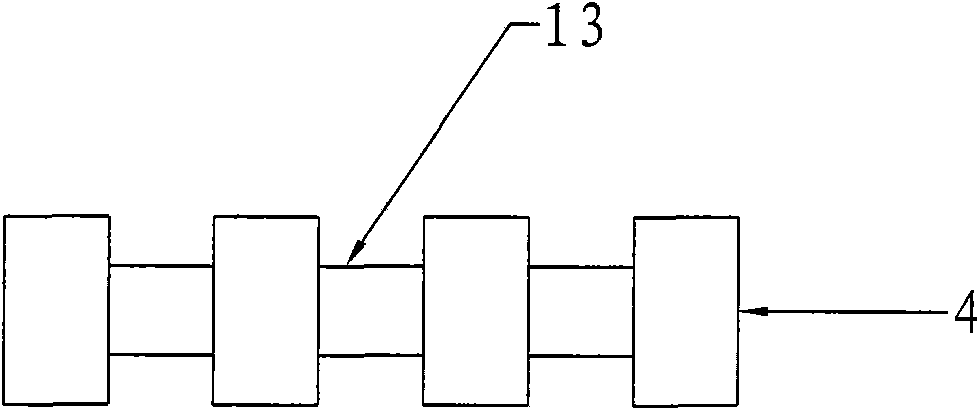

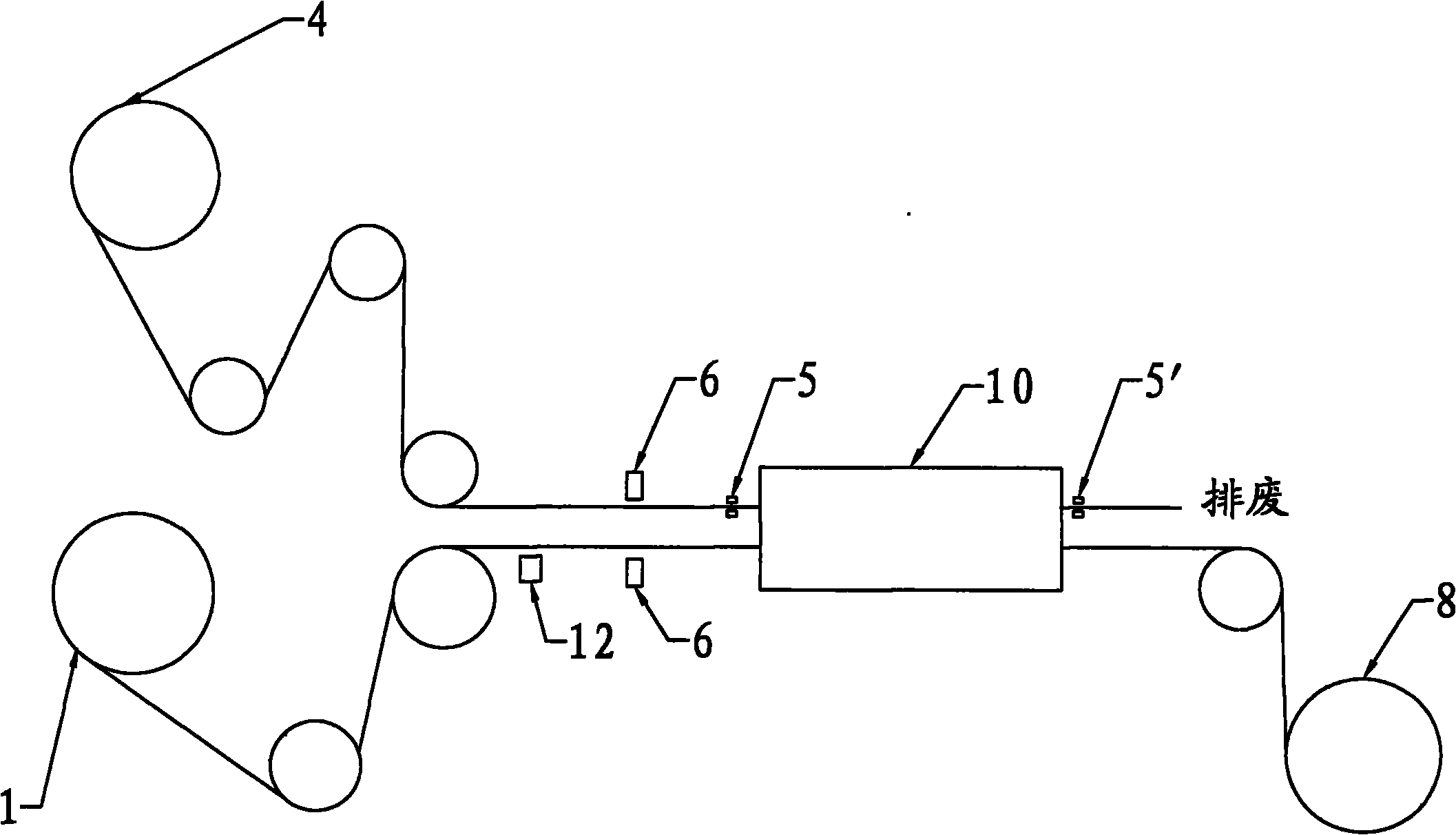

[0028] Such as figure 1 As shown, a group logistics two-way holographic positioning overprinting machine is composed of an unwinding device, a photoelectric identification control device 6, an electric control base 9, a traction device, an overprinting device 10, and a winding device, wherein the unwinding device is divided into rolls The drum substrate unwinding device and multiple sets of reel holographic anti-counterfeiting film unwinding devices, the unwinding and unwinding device and the electric control base 9 are in an integrated structure, the overprinting device 10 is located above the electric control base 9, and the unwinding and unwinding device is located on the overprinting On both sides of the device 10, each group of unwinding devices corresponds to a photoelectric identification control device 6. Among them, the roll substrate unwinding device is composed of an air expansion shaft 1 and an automatic deviation correction device 12, and the automatic deviation c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com