Tipping paper gravure online fine gold stamping device and gold stamping process

A tipping paper, fine technology, applied in the field of printing, can solve the problems of the difference between the bronzing pattern and the printing pattern, and the hot stamping process cannot be produced by a gravure machine on-line.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

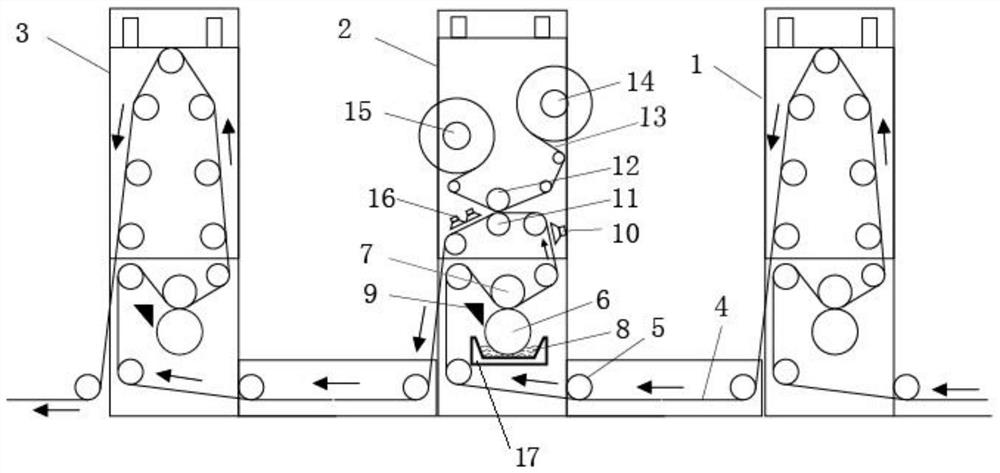

[0024] refer to figure 1 , a tipping paper gravure on-line fine bronzing device of the present embodiment is installed between the non-level printing color group 1 and the glazing unit 3 of the gravure printing machine, including a gravure cold stamping frame 2, the gravure printing Paper guide rollers 5 are installed on both sides of the lower part of the cold stamping frame 2, and the gravure cold stamping frame 2 is sequentially installed with a glue tank 17, a cold stamping roller group, a pre-curing UV lamp 10, and a cold stamping roller group from bottom to top. , curing UV lamp group 16, winder 15, unwinder 14, described winder 15, unwinder 14 cooperate to complete the retraction and unwinding of the cold stamping film, and the cold stamping roller group includes pressure rollers 7 arranged up and down and cold stamping roll 6, apply cold stamping glue to the tipping paper 4, the cold stamping roller set includes a cold stamping roller 12 and a backing roller 11 arrange...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com