Wave spring

A technology of wave springs and wave crests, applied in the direction of springs, springs/shock absorbers, leaf springs, etc., can solve the problems of inconsistent pulling force of traction wire ropes, etc., so as to improve service life, reduce wear, and improve safety and reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

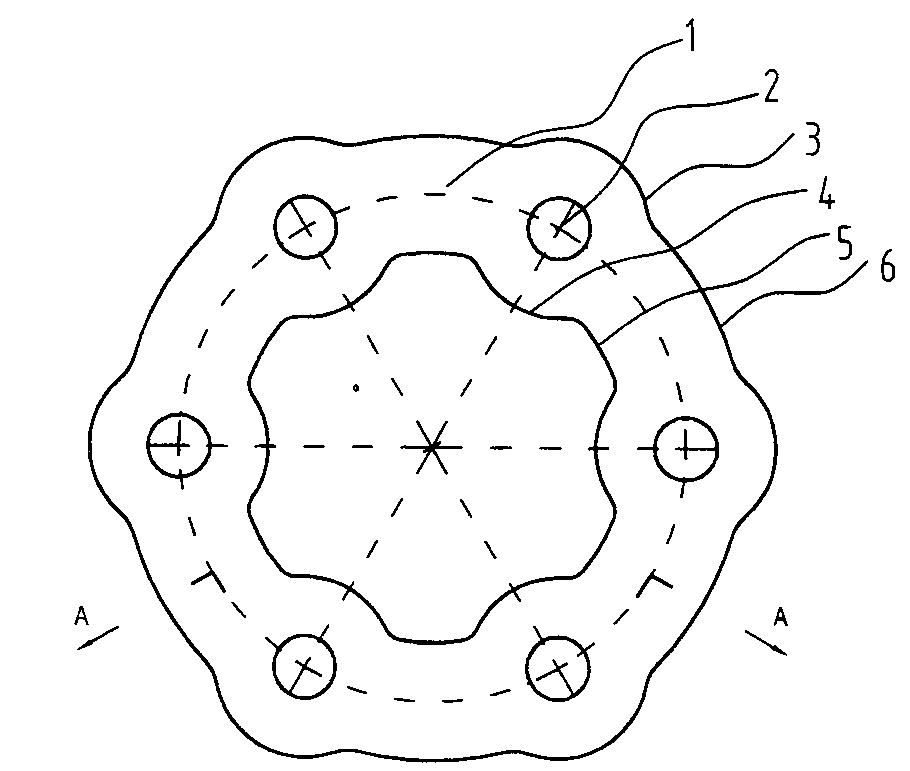

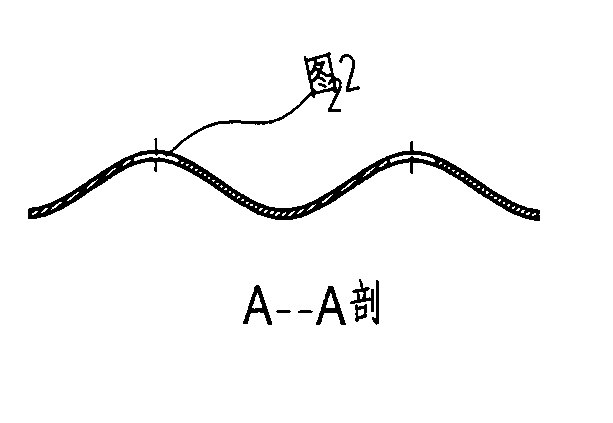

[0020] figure 1 is a part diagram of the present invention, figure 2 It is a cross-sectional view of the parts diagram of the present invention, and the wave spring (1) determines the quantity of the holes (2), that is, the quantity of the crests, according to the quantity of the steel wire ropes (11), and there are respectively outer ring convex arcs (3) on both sides of the hole (2). ) and the inner ring convex arc (4) correspond to it, the outer ring convex arc (3) is connected with the outer ring arc (6), the inner ring convex arc (4) is connected with the inner ring arc (5), and the wave spring ( 1) The shape is wavy along the circumference.

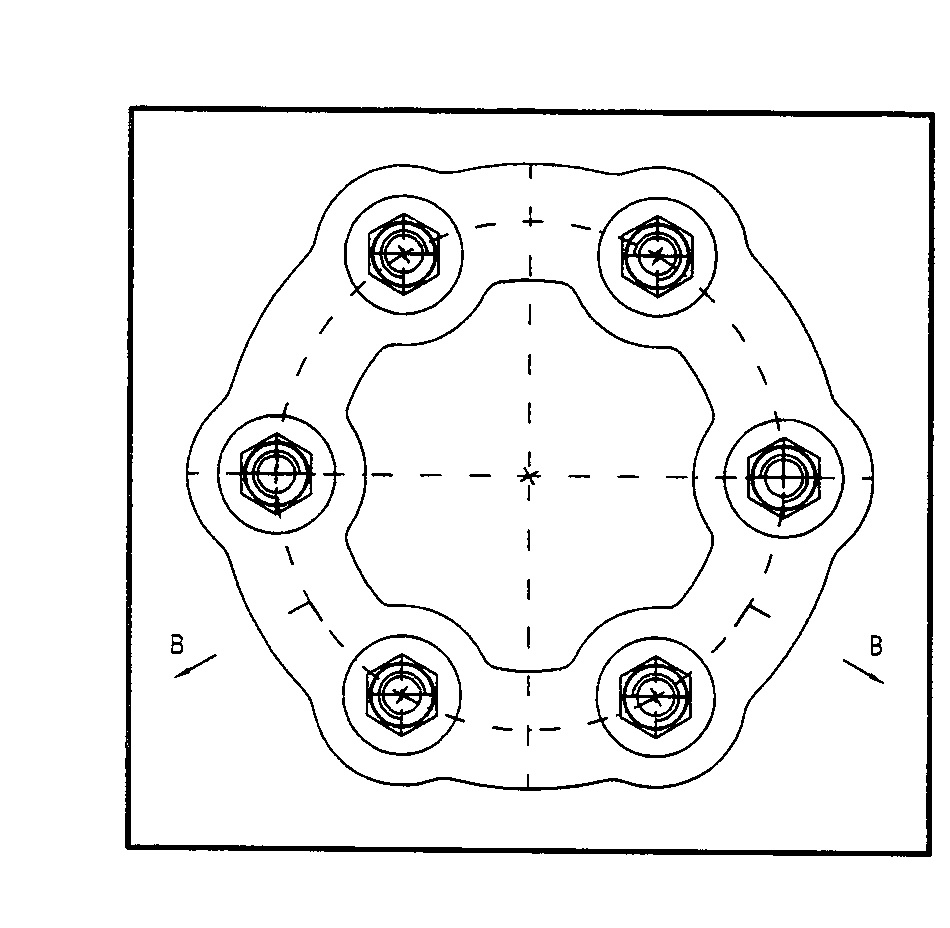

[0021] image 3 is the application assembly drawing of the present invention, Figure 4 It is an assembly sectional view of the application of the present invention. The device is a steel wire rope group composed of six steel wire ropes. The steel wire rope (11) is connected with the rope head combination (10), and the rope head...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com