Chassis dynamometer

A chassis dynamometer and an integrated technology, applied in power measurement, measuring devices, vehicle testing, etc., can solve problems such as tire adhesion, lower detection accuracy, and prone to slipping, so as to reduce the number of times, increase detection accuracy, and save manpower Material effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with the drawings.

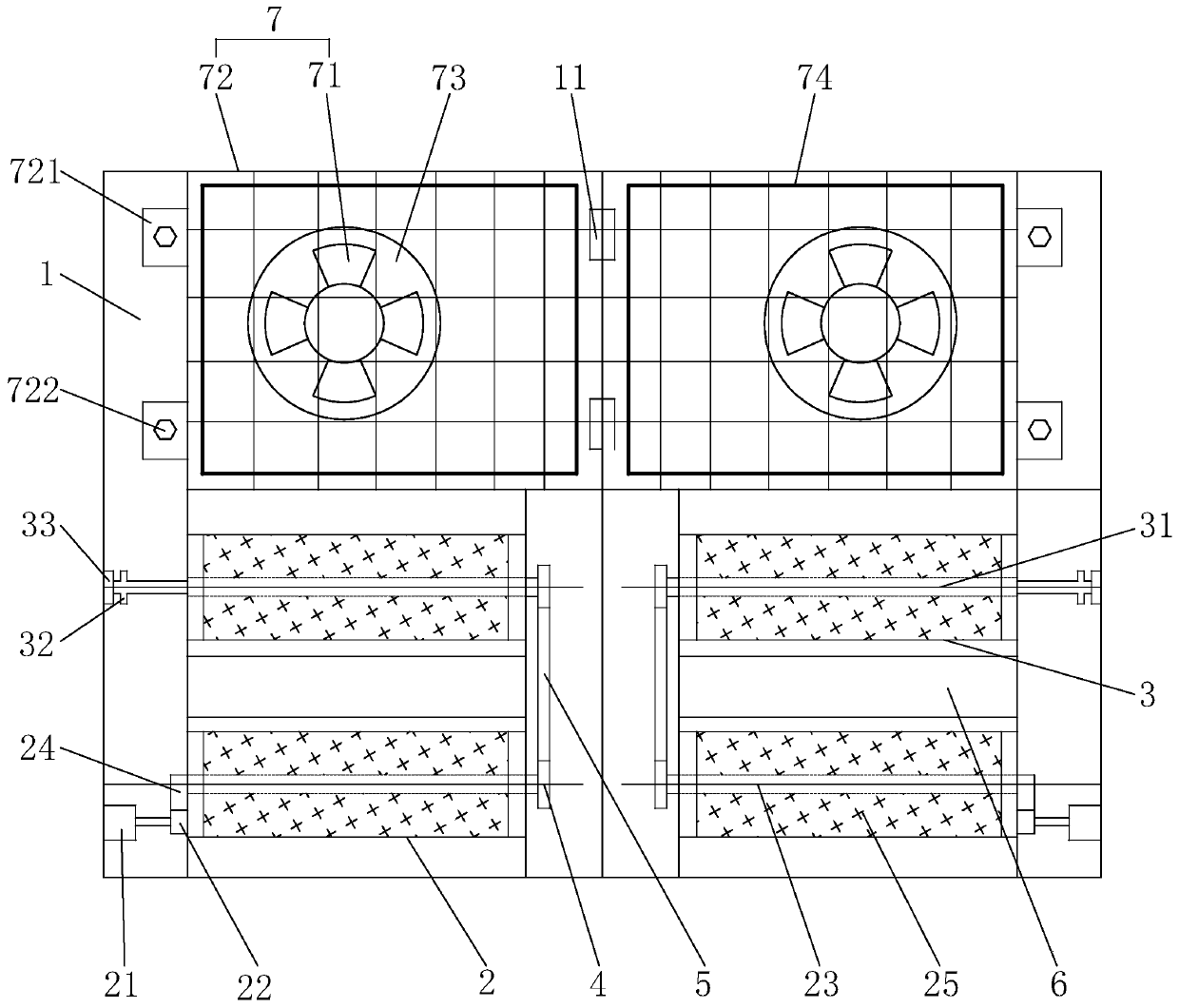

[0032] Reference figure 1 , Is a chassis dynamometer disclosed by the present invention, including a frame 1, a cylindrical driving roller 2 and a driven roller 3 installed in parallel in the frame 1, and the driving roller 2 is connected with power along one end of its length direction. Device. The power device includes a motor 21 and a first gear 22 fixed on the output shaft of the motor 21. The driving drum 2 is integrally formed with a main drum shaft 23 and fixedly connected to one end of the main drum shaft 23 along its length. The gear 24, the first gear 22 and the second gear 24 mesh with each other.

[0033] During detection, the drive motor 21 rotates, so that its output shaft drives the first gear 22 to rotate, and the first gear 22 and the second gear 24 mesh with each other. The rotation of the second gear 24 causes the main roller shaft 23 to drive the active ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com