High-stability drum brake

A drum brake and high stability technology, applied in the direction of mechanically driven drum brakes, etc., can solve the problems of inconsistent friction position, wear, and incomplete use of the braking area of the brake pad, so as to prevent inconsistent braking force and improve stability , the effect of preventing local wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

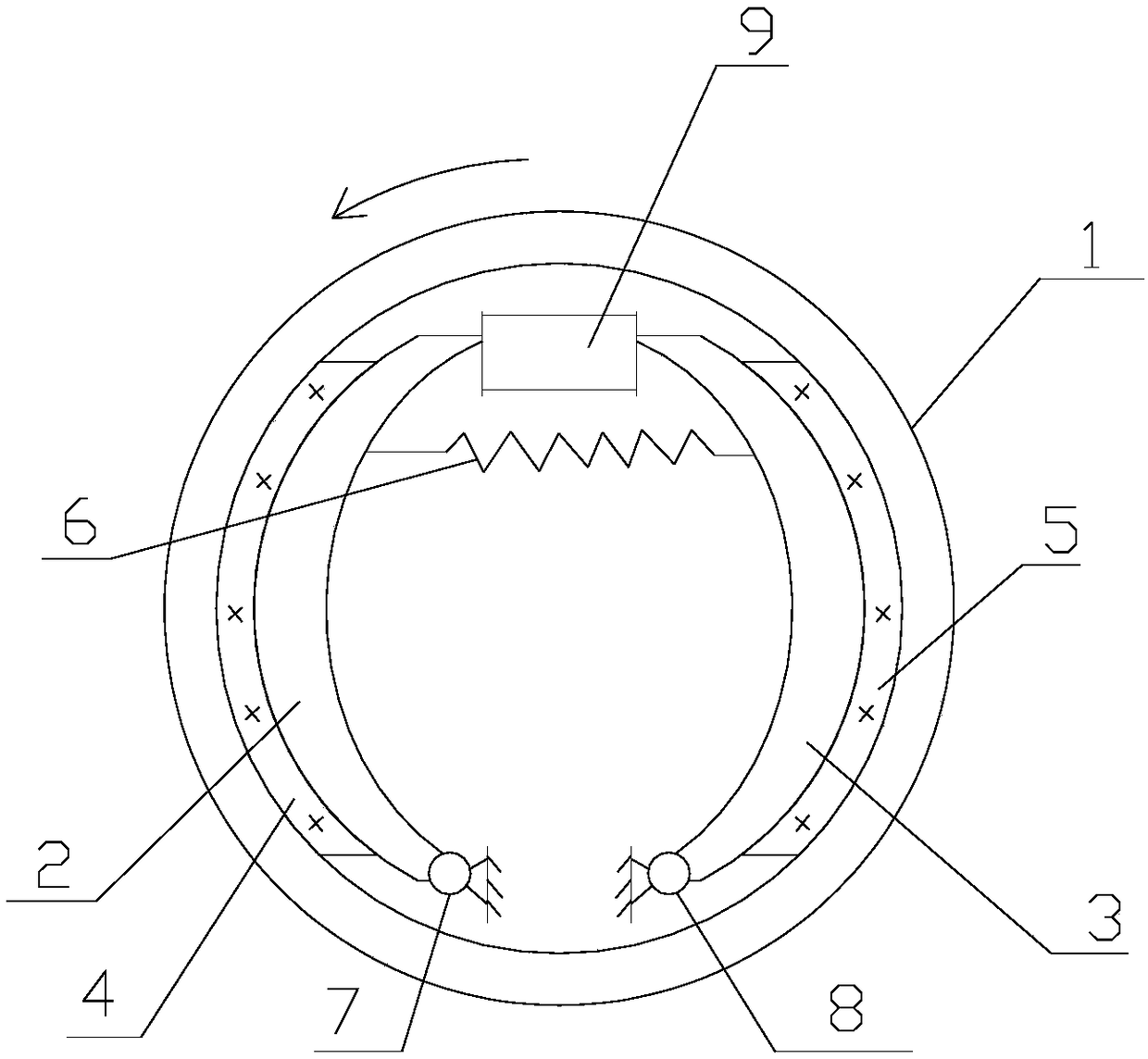

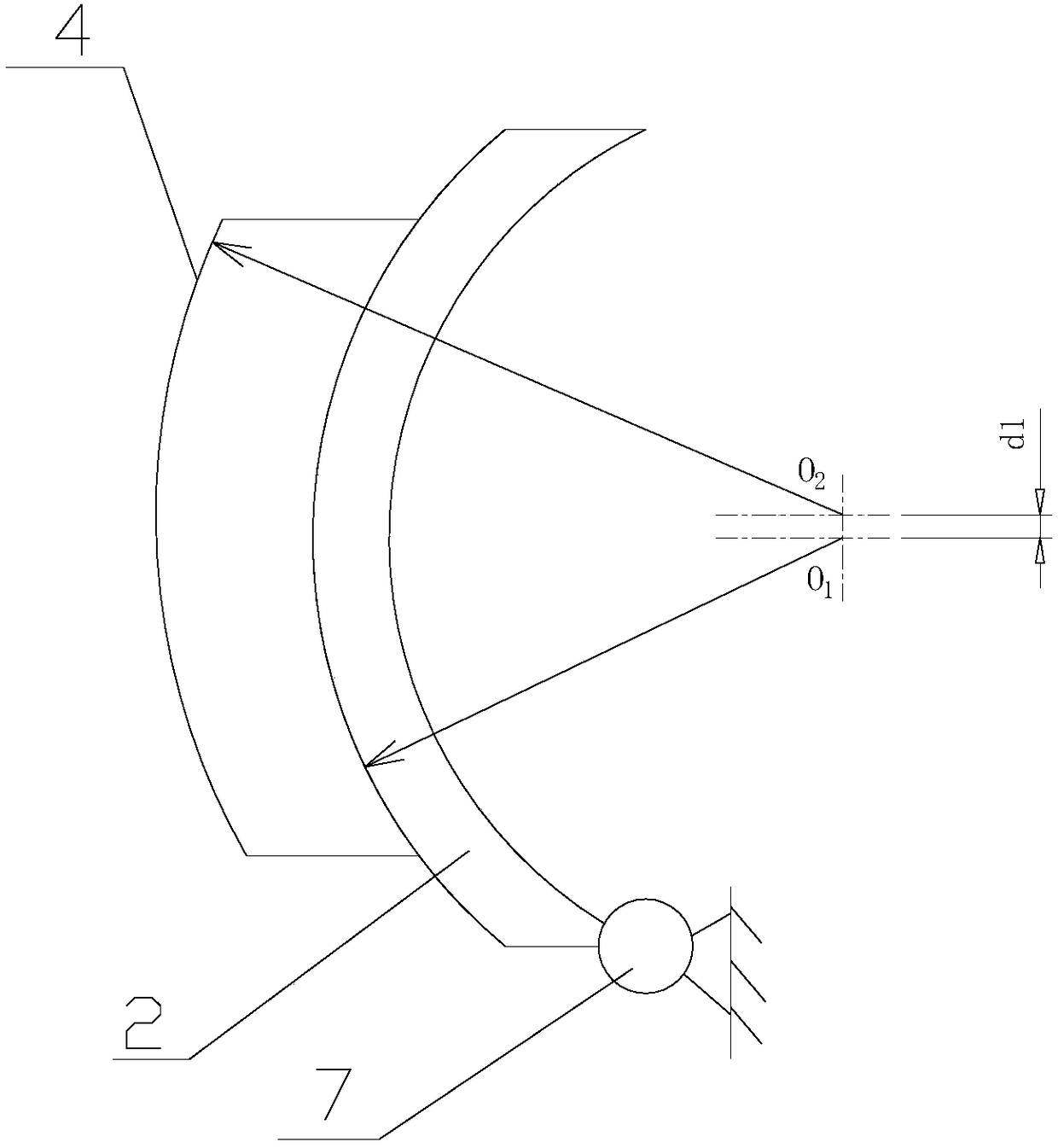

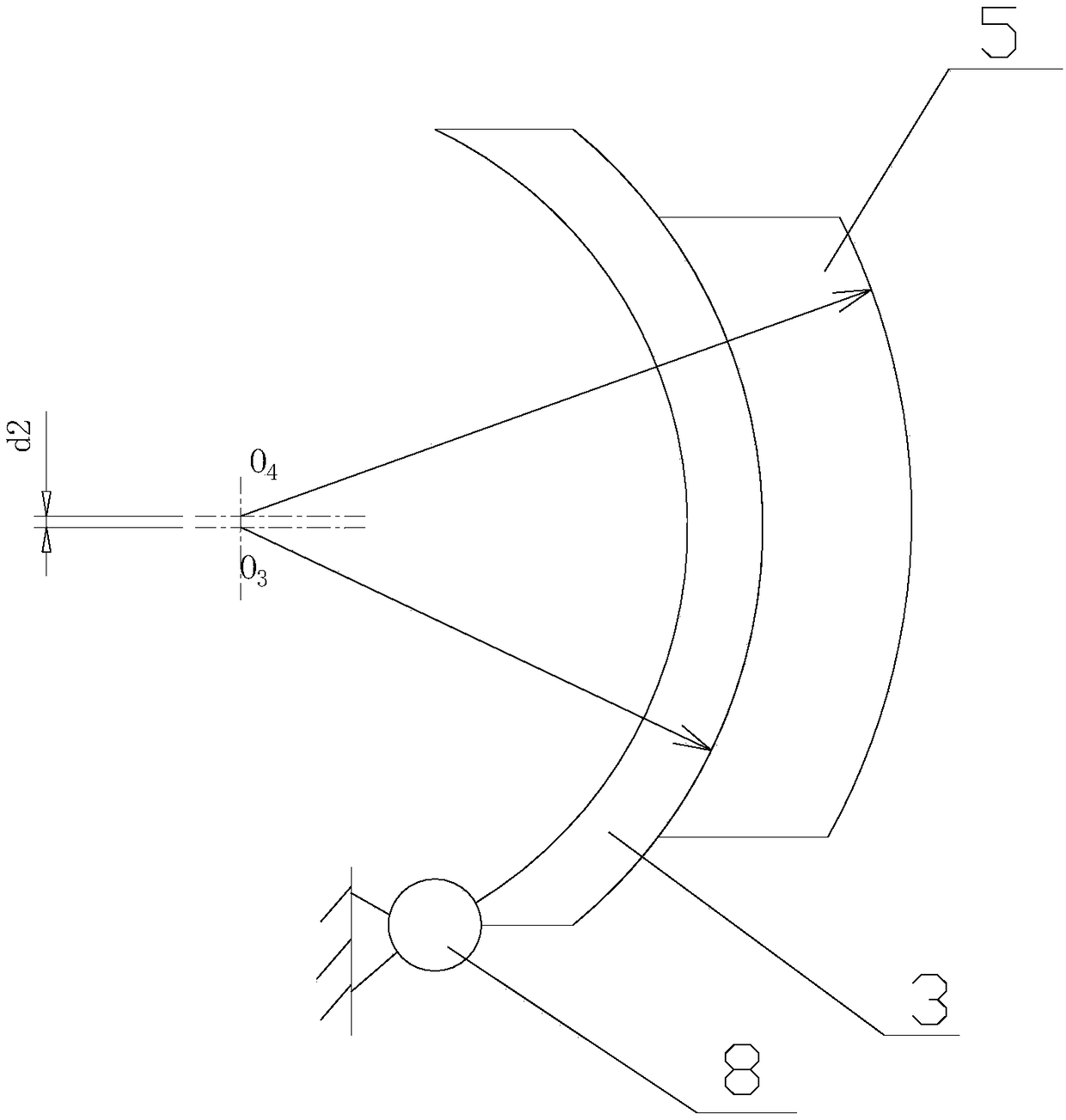

[0017] Such as Figure 1~3 Shown is a preferred embodiment, the drum brake includes brake drum 1, leading shoe 2, slave shoe 3, leading shoe brake pad 4, slave shoe brake pad 5, return spring 6, leading shoe fulcrum 7, slave shoe fulcrum 8, two-way brake wheel cylinder 9; the inner arc surface of the collar shoe brake pad 4 is fixedly connected with the outer arc surface of the collar shoe 2; the braking axis of the collar shoe 2 is connected to the collar shoe 2 The axes of the inner arc surfaces of the shoe brake pads 4 coincide; the inner arc surfaces of the slave shoe brake pads 5 are fixedly connected with the outer arc surfaces of the slave shoes 3; the brake axes of the slave shoes 3 It coincides with the axis of the inner arc surface of the slave shoe brake pad 5; one end of the leading shoe 2 is hinged to the leading shoe fulcrum 7, and the other end is fixed to the piston at one end of the two-way brake wheel cylinder 9 One end of the slave shoe 3 is hinged on the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com