Patents

Literature

48results about How to "Friction adjustment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

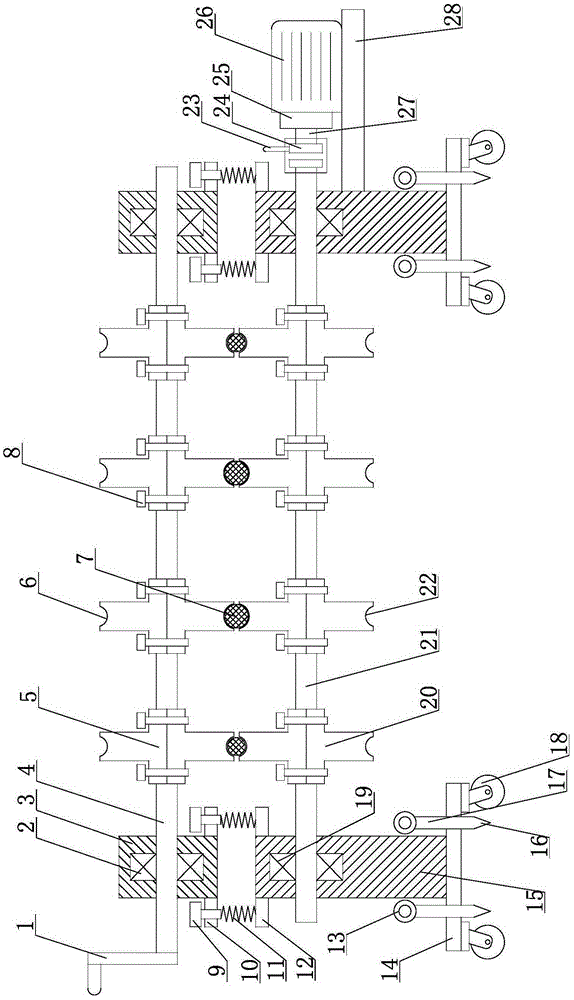

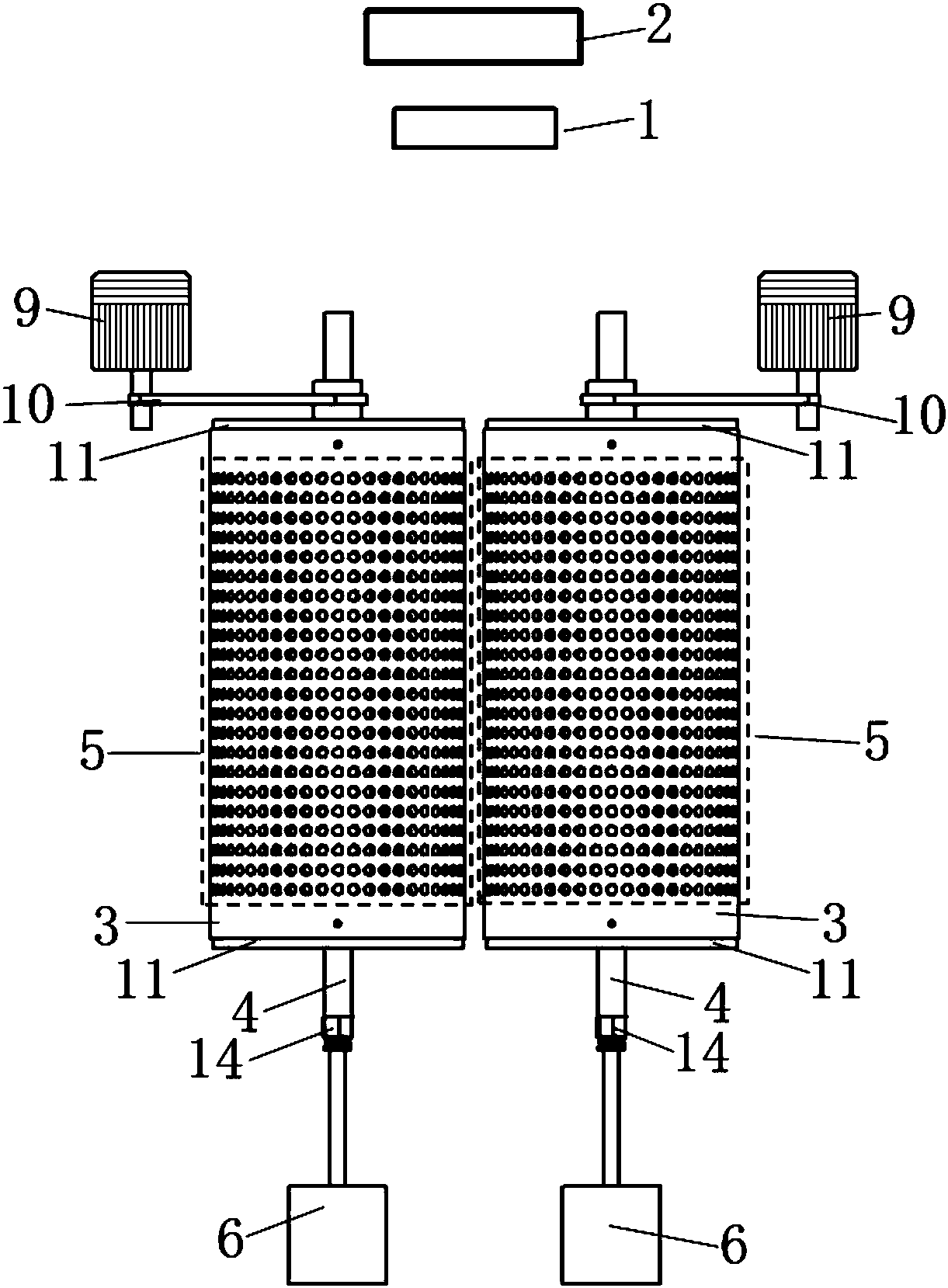

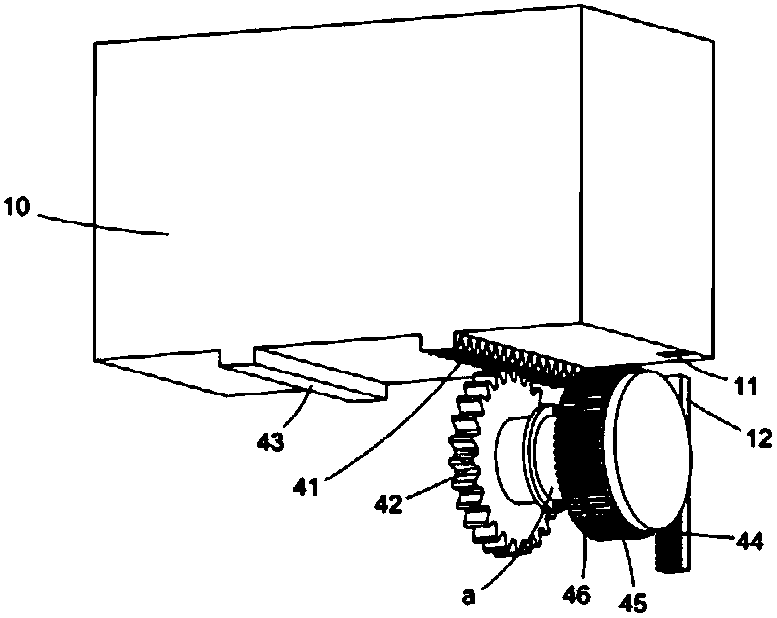

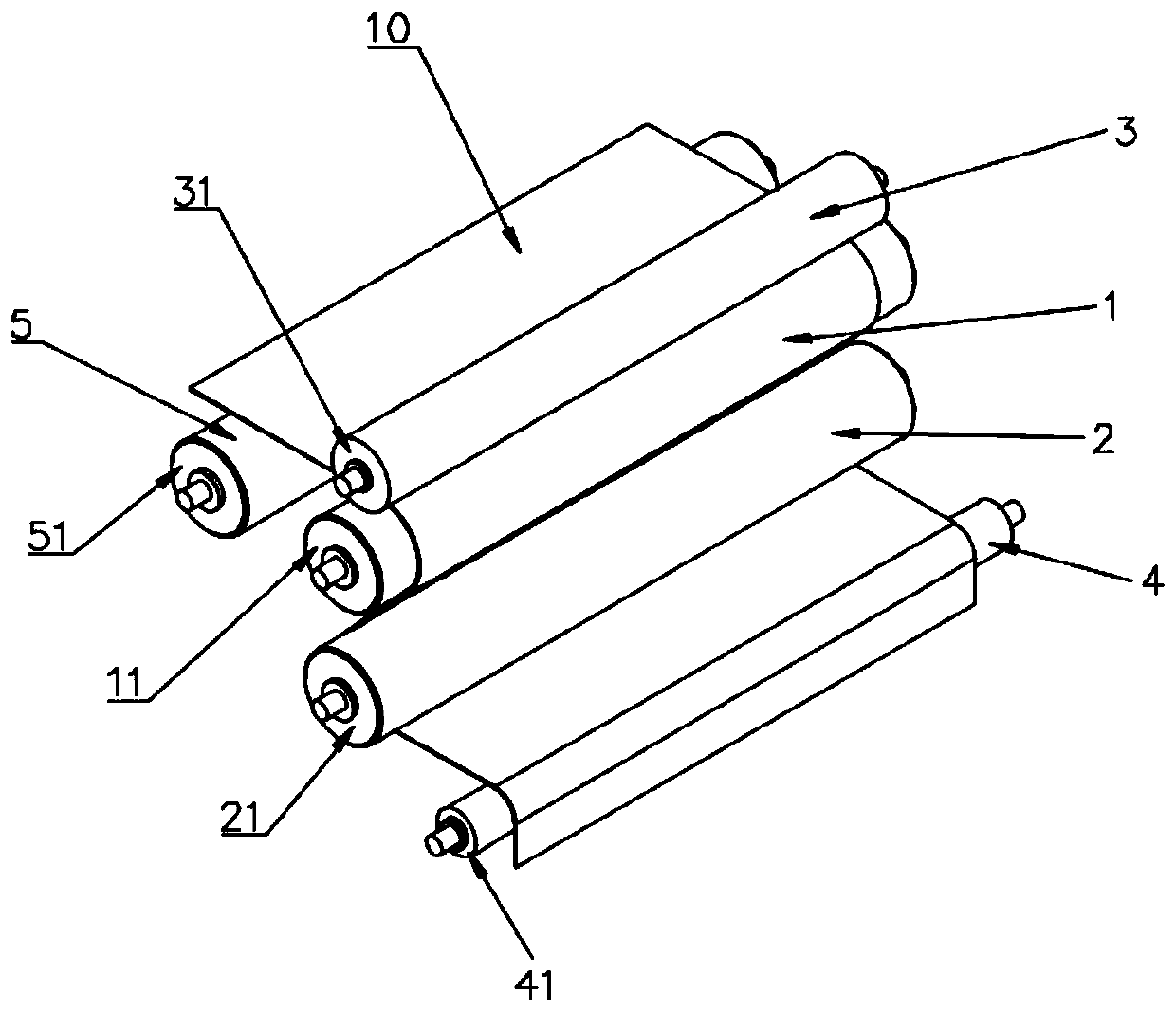

Power transmission line wiring device

InactiveCN105356381ASimple structureEasy to operateArrangements using take-up reel/drumApparatus for laying cablesReduction driveEngineering

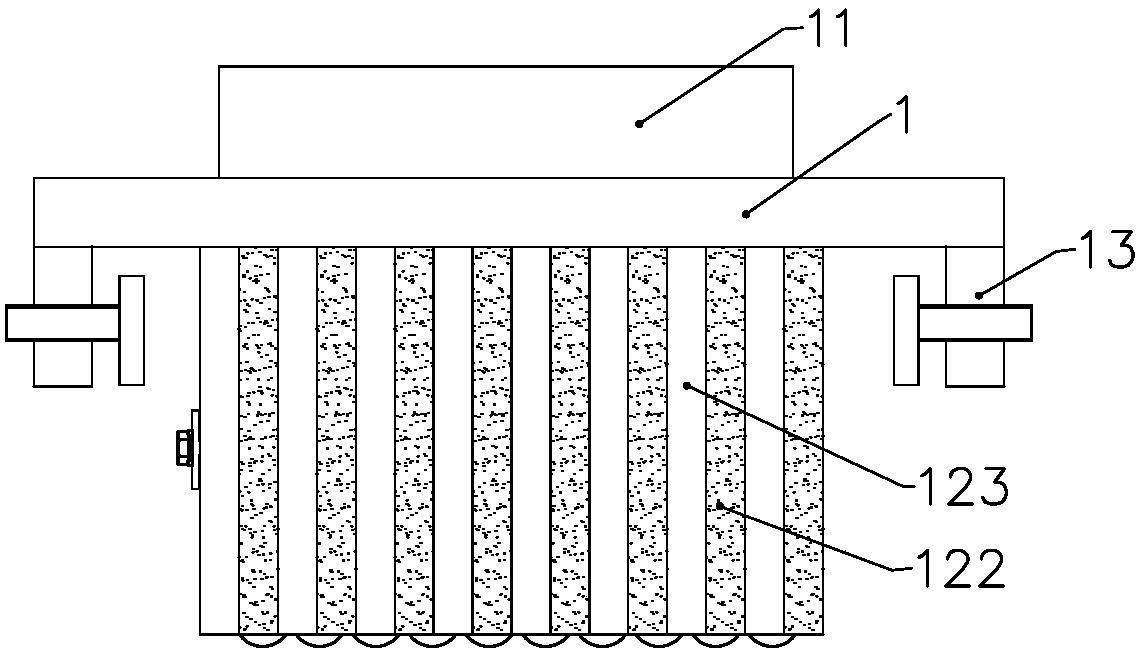

The invention discloses a power transmission line wiring device which comprises an upper rotation shaft and a lower rotation shaft. The lower rotation shaft is fixedly provided with a plurality of lower driving wheels. Upper driving wheels are in one-to-one correspondence with the lower driving wheels. The circumference direction of each upper driving wheel is provided with an upper driving groove. The circumference direction of each lower driving wheel is provided with a lower driving groove. The bottom surface of the upper driving groove and the bottom surface of the lower driving groove are arc surfaces. The upper driving groove and the lower driving groove of the corresponding upper driving wheel and the lower driving wheel are same in size. The wiring device also comprises a motor plate. The motor plate is fixedly provided with a motor. The motor is equipped with a speed reducer. The speed reducer is provided with a main shaft. A clutch is arranged between the main shaft and the lower rotation shaft. The clutch is provided with a clutch lever. The beneficial effects are that 1) the power transmission line wiring device is simple in structure; 2) the wiring device can carry out wiring on a plurality of same-diameter power transmission lines, and can also carry out wiring on a plurality of different-diameter power transmission lines; and 3) the wiring device not only has a manual wiring function, but also has an automatic wiring function.

Owner:国网山东东明县供电公司

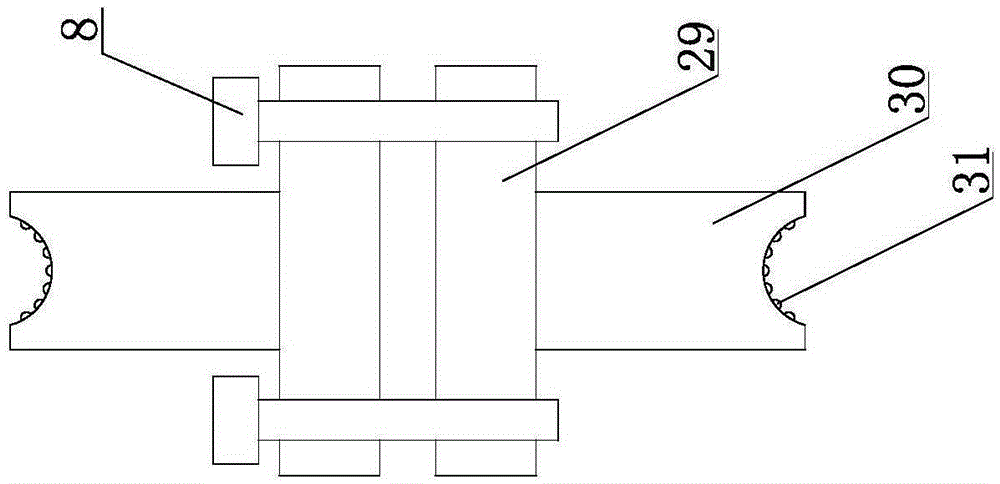

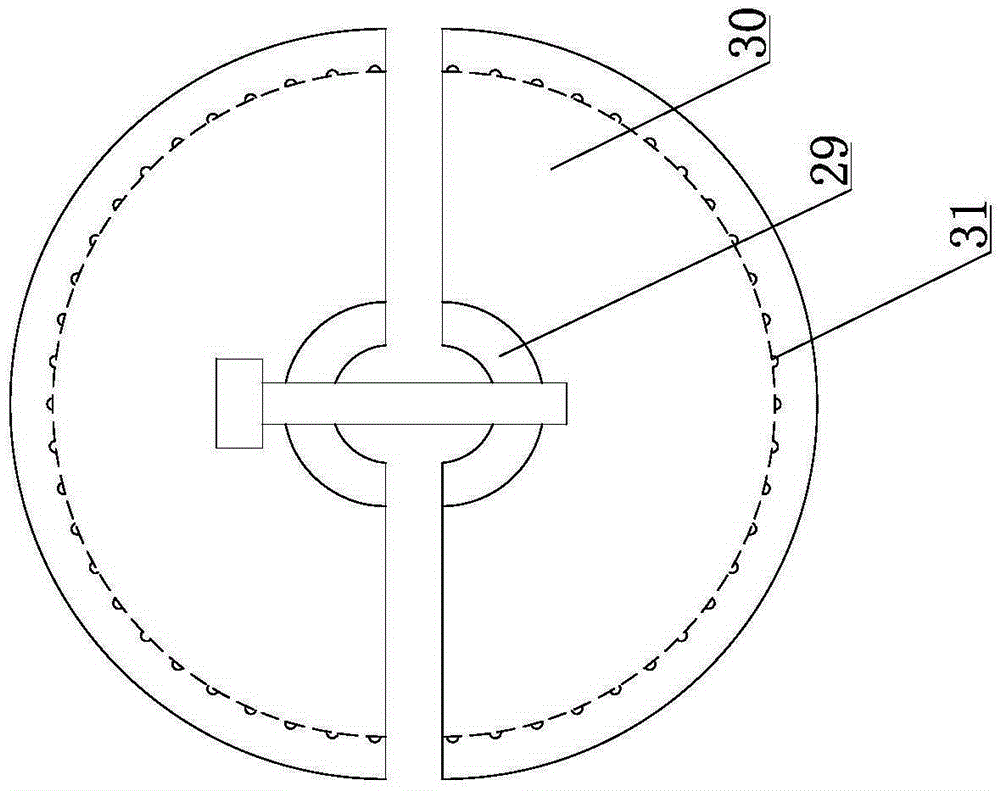

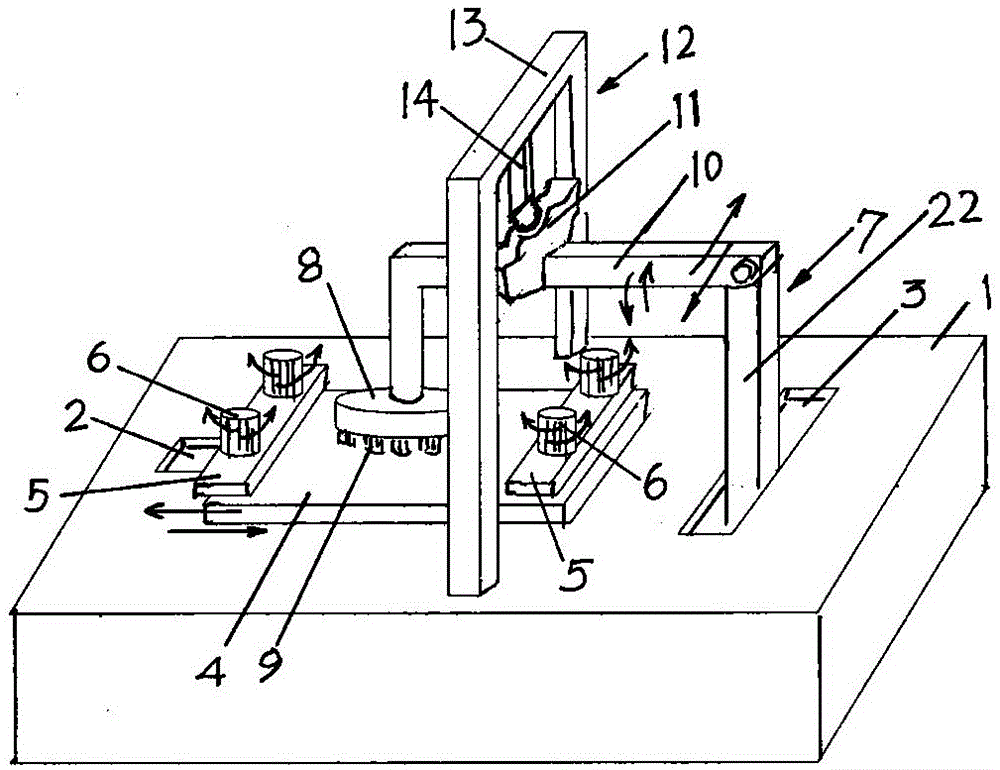

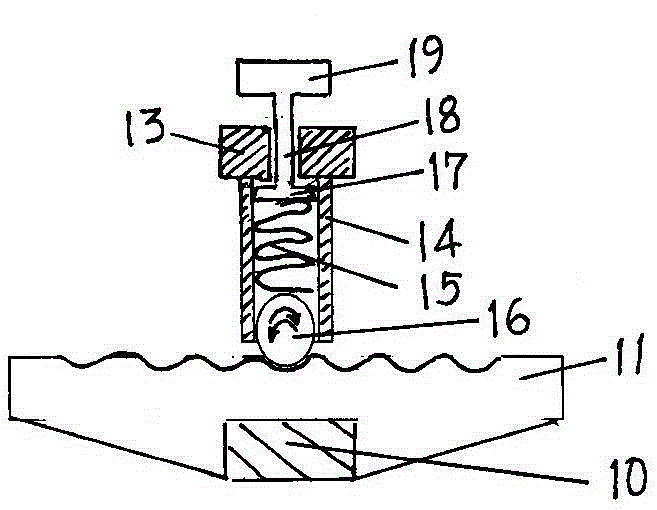

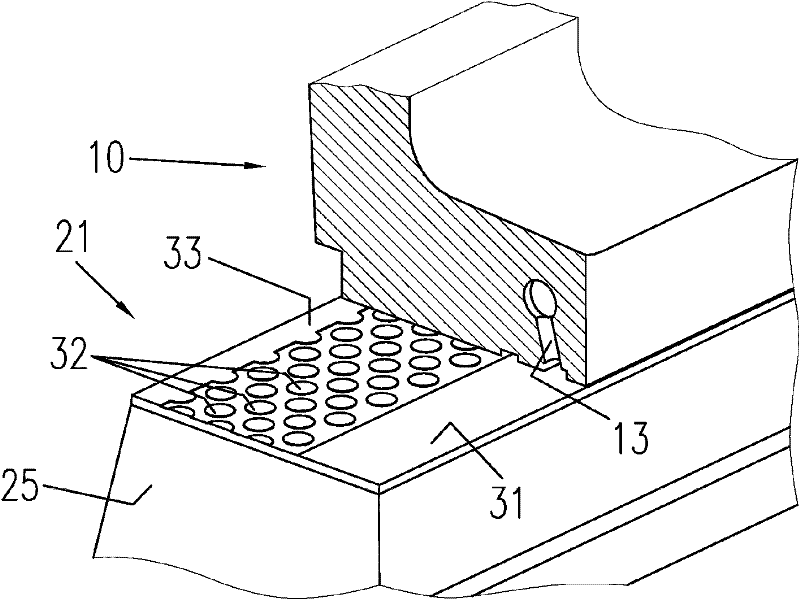

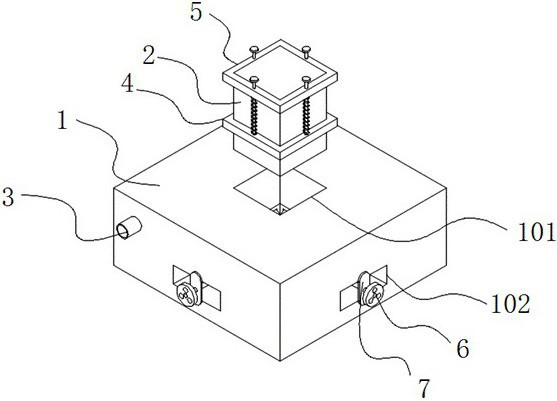

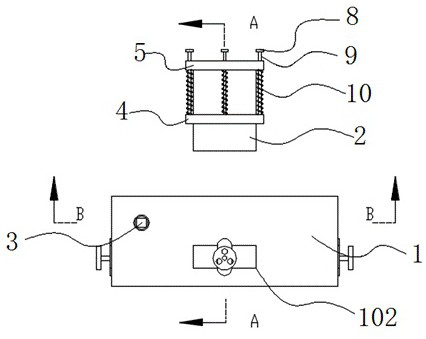

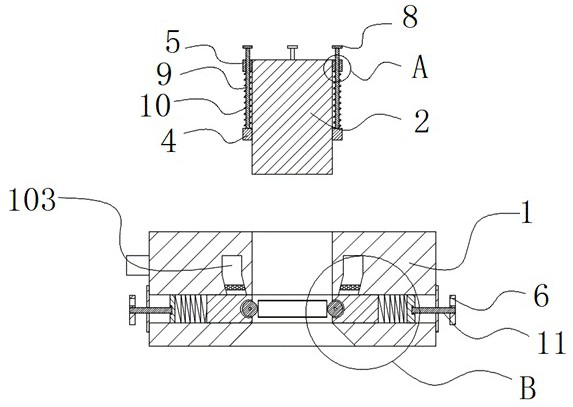

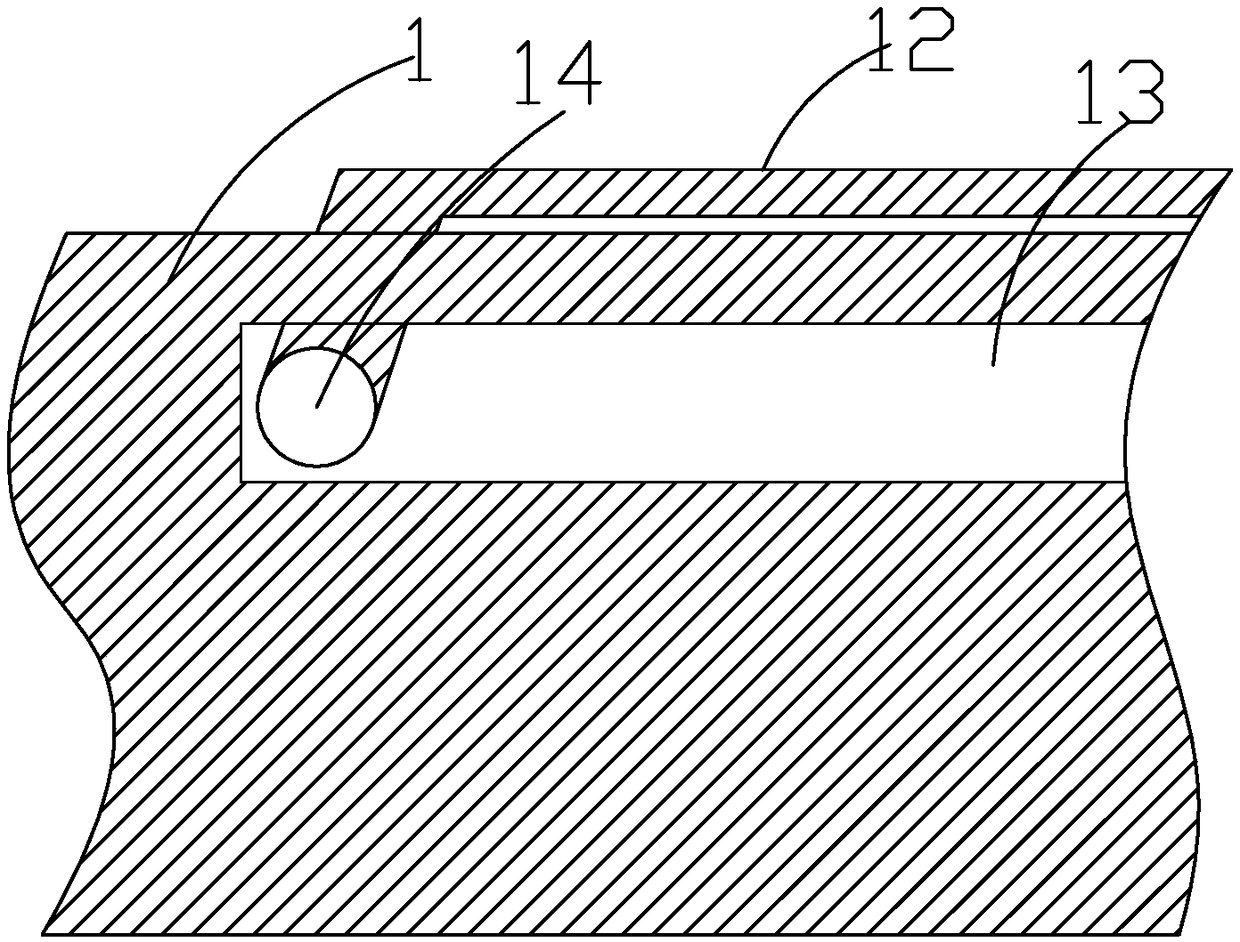

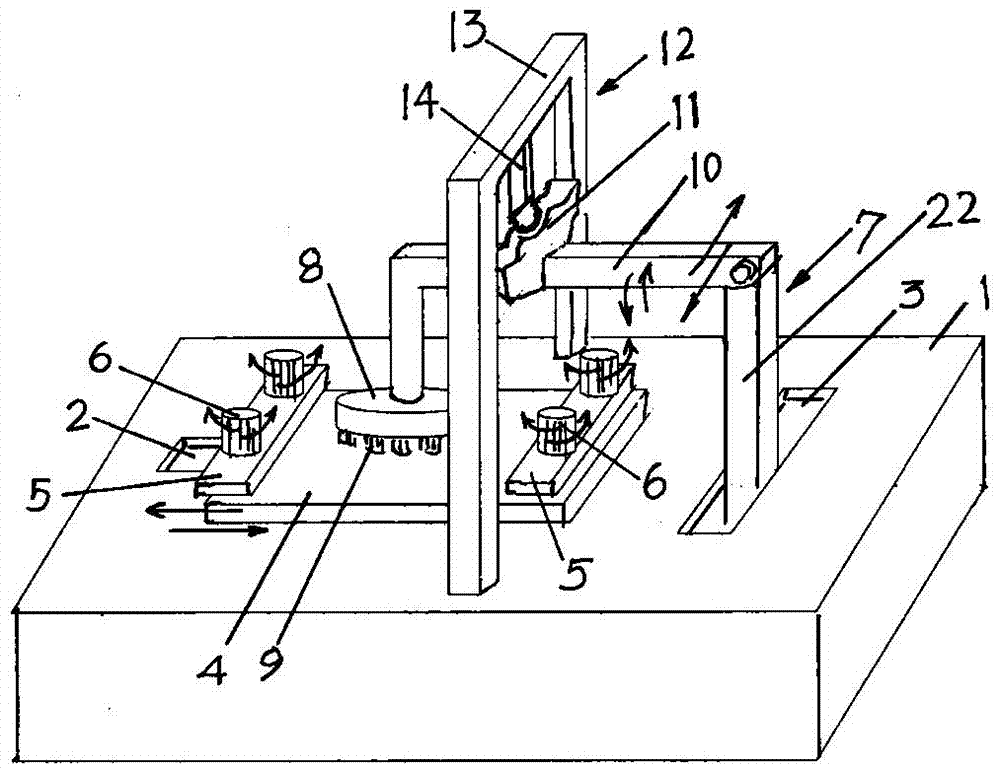

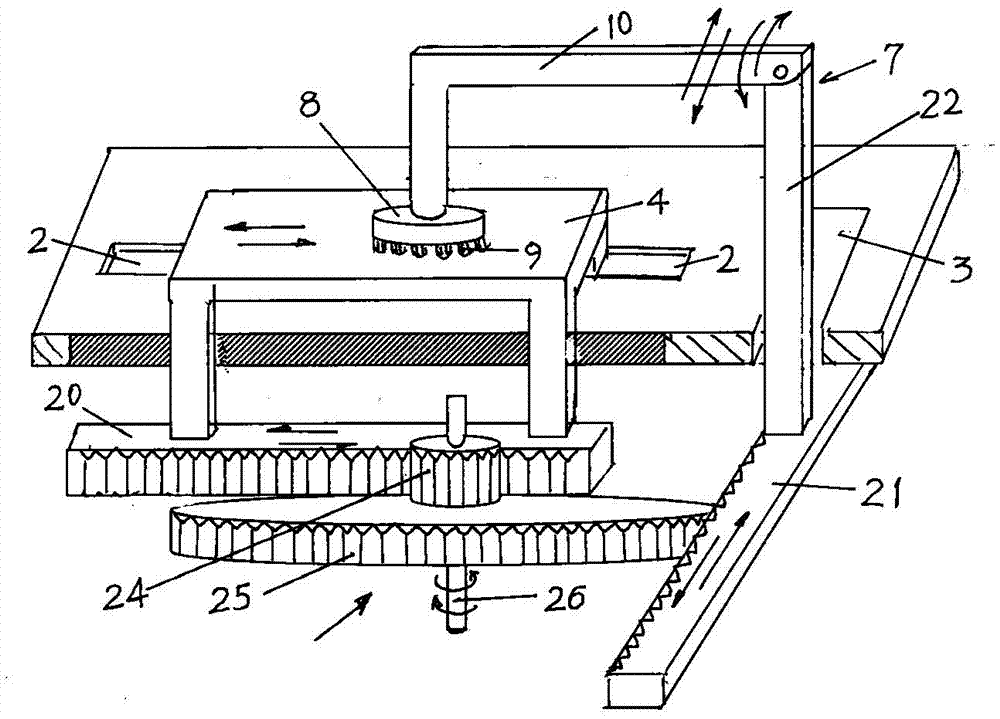

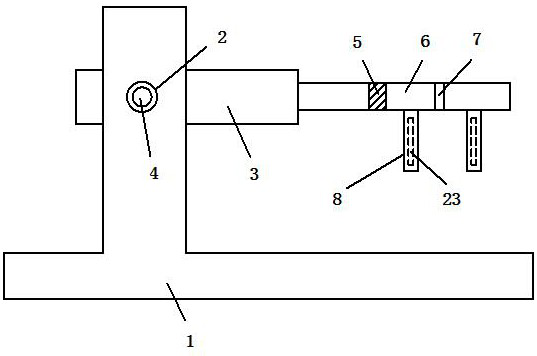

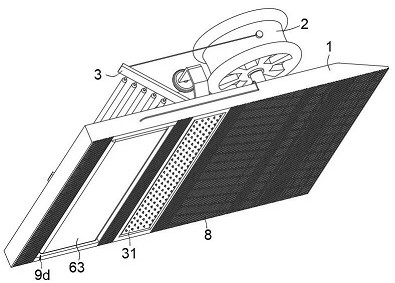

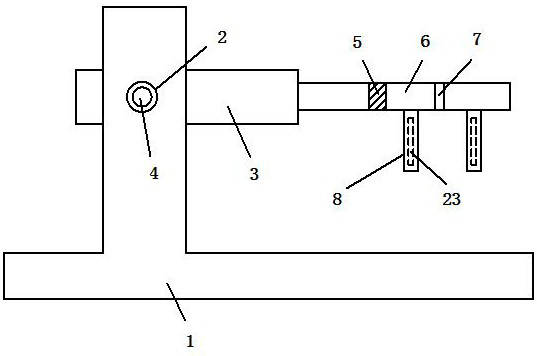

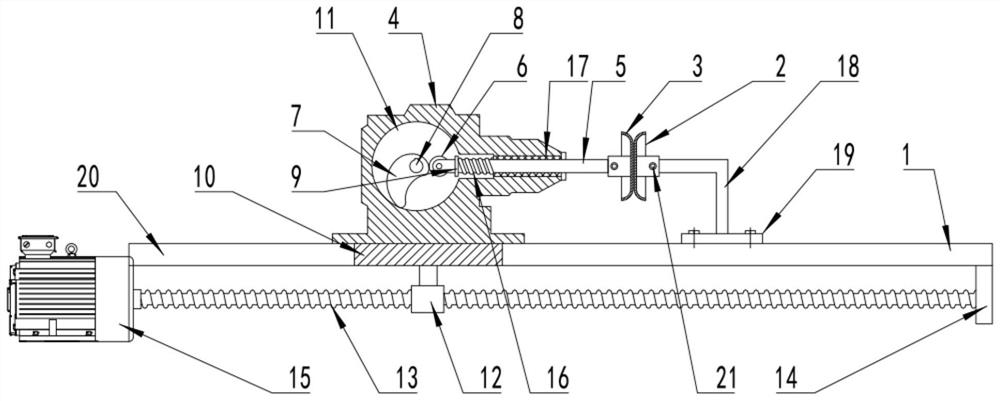

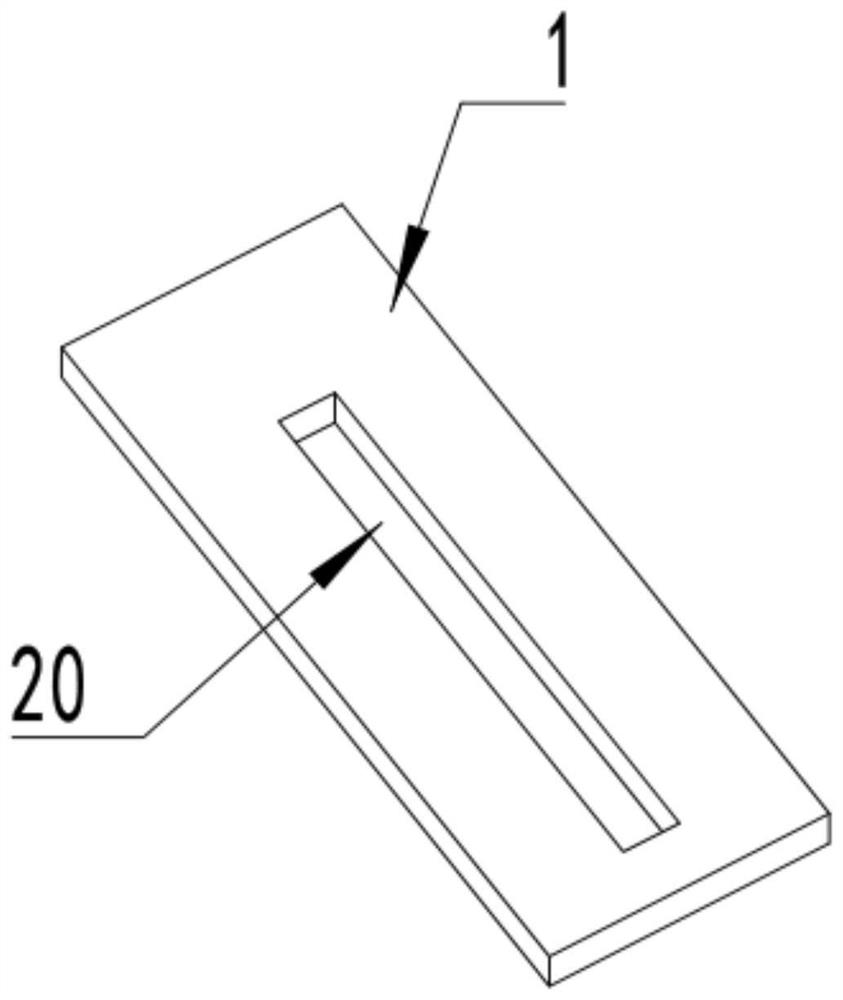

Simulation test device for surface friction resistance of braided fabric

InactiveCN105115843AHigh precisionFriction adjustmentInvestigating abrasion/wear resistanceFriction effectEngineering

The invention discloses a simulation test device for surface friction resistance of a braided fabric and belongs to friction test devices which simulate real using friction in the operation state. A horizontal long hole and a longitudinal long hole in the surface of a rack platform are mutually perpendicular; a bearing plate is arranged on the upper surface of the horizontal long hole, and a standard brush is arranged on the upper surface of the longitudinal long hole; the standard brush produces a motion curve on the bearing plate; a rolling ball of an n-shaped frame presses the standard brush to produce friction to the bearing plate. Friction effects of all positions of a tested object are consistent; during friction, the friction force changes and can be adjusted at any time.

Owner:SICHUAN ENTRY EXIT INSPECTION & QUARANTINE BUREAU INSPECTION & QUARANTINE TECHN CENT

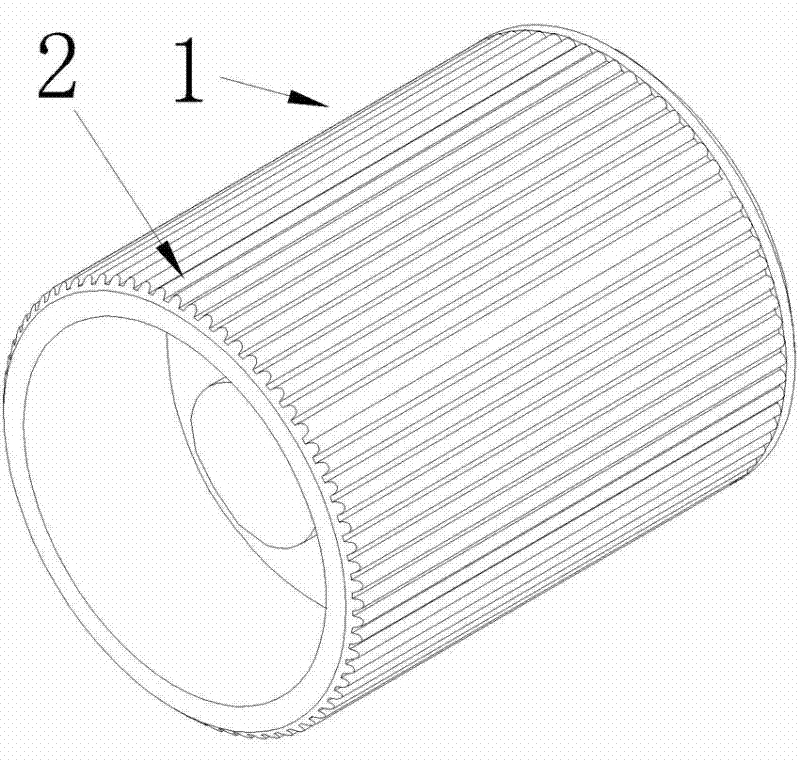

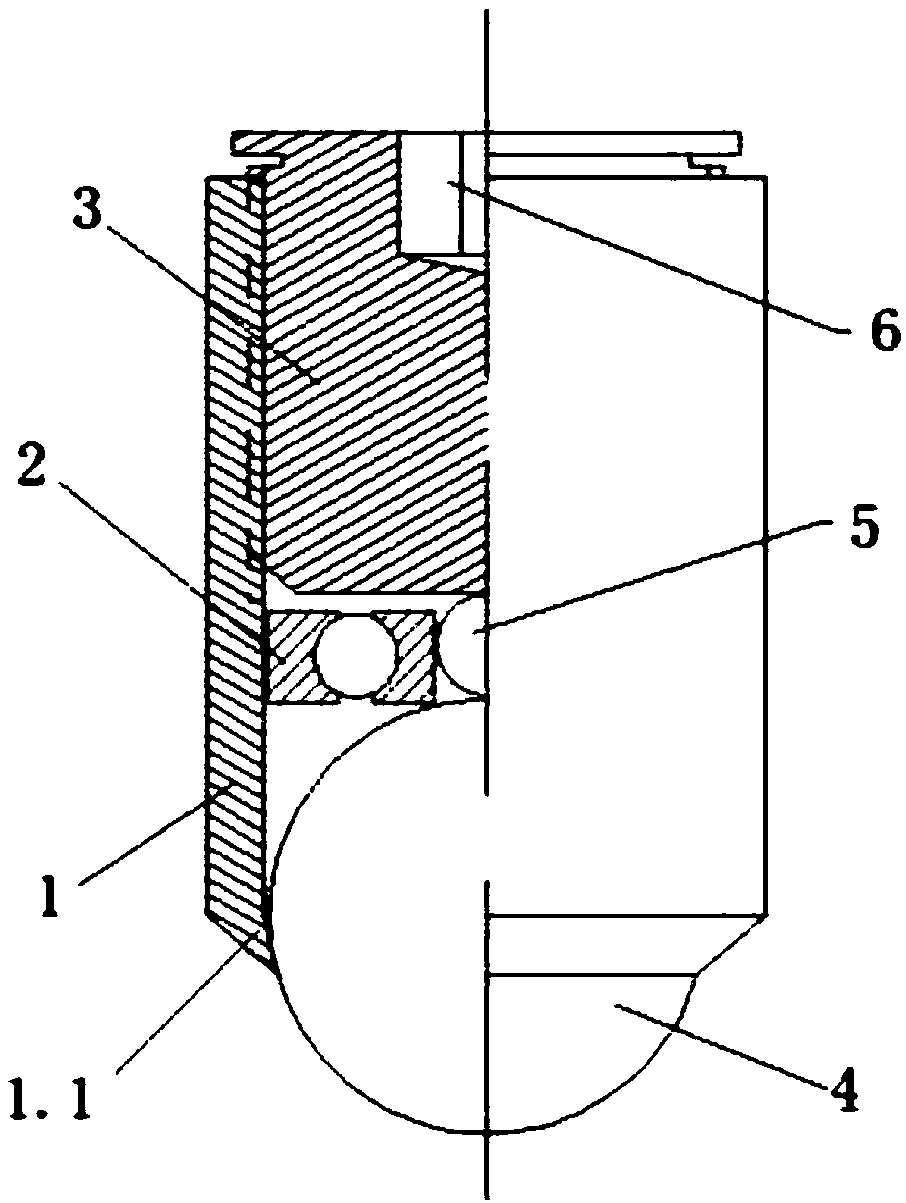

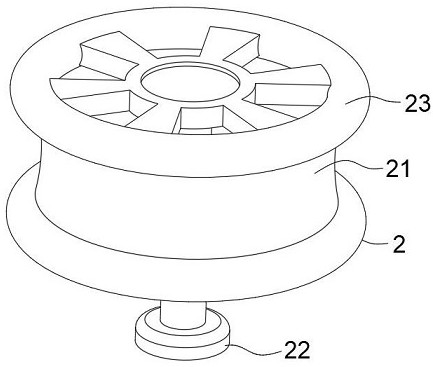

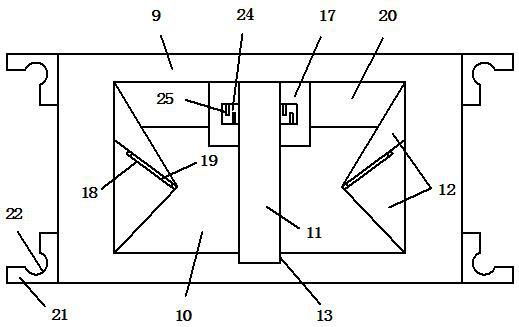

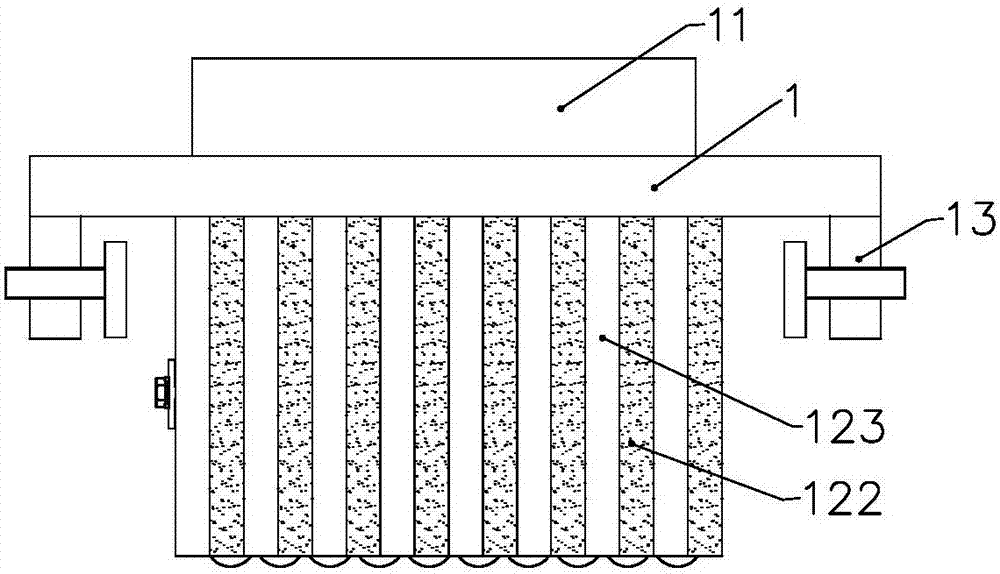

Computerized flat knitting machine press wheel assembly

The invention discloses a cloth pressing wheel assembly of a computerized flat knitting machine, which comprises a cloth pressing wheel and a cloth pressing wheel seat. The cloth pressing wheel is cylindrical and has a shaft hole inside; a cloth pressing wheel shaft seat is movably connected to the cloth pressing wheel seat , a cloth pressing wheel shaft is fixed on both sides of the cloth pressing wheel shaft seat, and the two cloth pressing wheels are respectively installed on the cloth pressing wheel shaft through the shaft holes; there is also a pressure adjusting screw seat and a pressure adjusting screw thread on the cloth pressing wheel seat It is connected to the pressure regulating screw rod seat, and the lower end of the pressure regulating screw rod is connected with the press wheel shaft seat. The press wheel assembly of the computerized flat knitting machine of the present invention can use different numbers of individuals to freely combine to form pulling devices of various lengths, and can provide greater friction under the same pressure, and can freely adjust the press wheel to the fabric The pressure can be adjusted to adjust the friction force, and it can also reduce the difficulty and cost of maintenance when the pulling device is damaged.

Owner:NINGBO CIXING

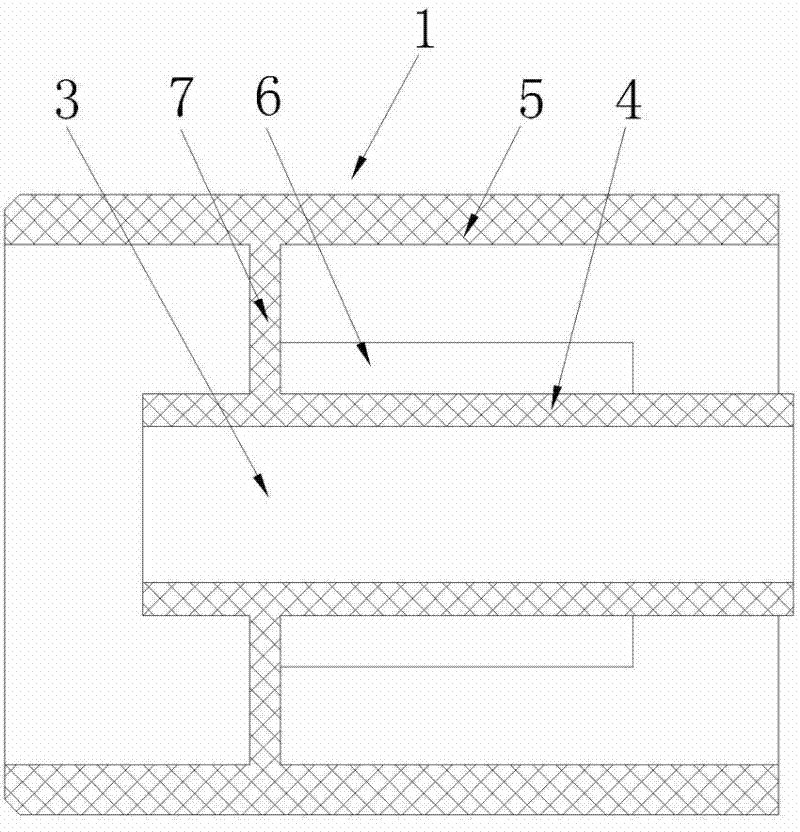

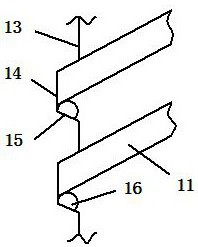

Anti-capsizing support of bridge

InactiveCN106087717AHigh sensitivityStrong blessingBridge structural detailsScrew threadFriction force

The invention discloses an anti-capsizing support of a bridge. The anti-capsizing support of the bridge comprises a first plate, a second plate and a third plate, wherein the first plate, the second plate and the third plate are arranged in parallel from top to bottom. Clamping grooves are formed in the two sides of a second insertion plate vertically. Each clamping groove communicates with a channel through a square hole between the clamping groove and the channel. A movable brake pad is placed in each clamping groove. A tie piece is arranged in the channel. Wedges are arranged on the two sides of the tie piece at intervals and face the same direction, and each wedge makes contact with the movable brake pad in the corresponding position. A threaded hole is formed in the end of the tie piece, and a tension bolt is installed in the threaded hole for tensioning connection. The anti-capsizing support of a bridge is of a pure mechanical structure, and long-term maintenance-free operation can be achieved; and in addition, main friction force happens to friction plates between the insertion plates, the automobile brake pads are used as the friction plates and are free of maintenance in the whole life, and the friction force of the brake pads can be adjusted conveniently through the tension bolt.

Owner:孙新迪 +11

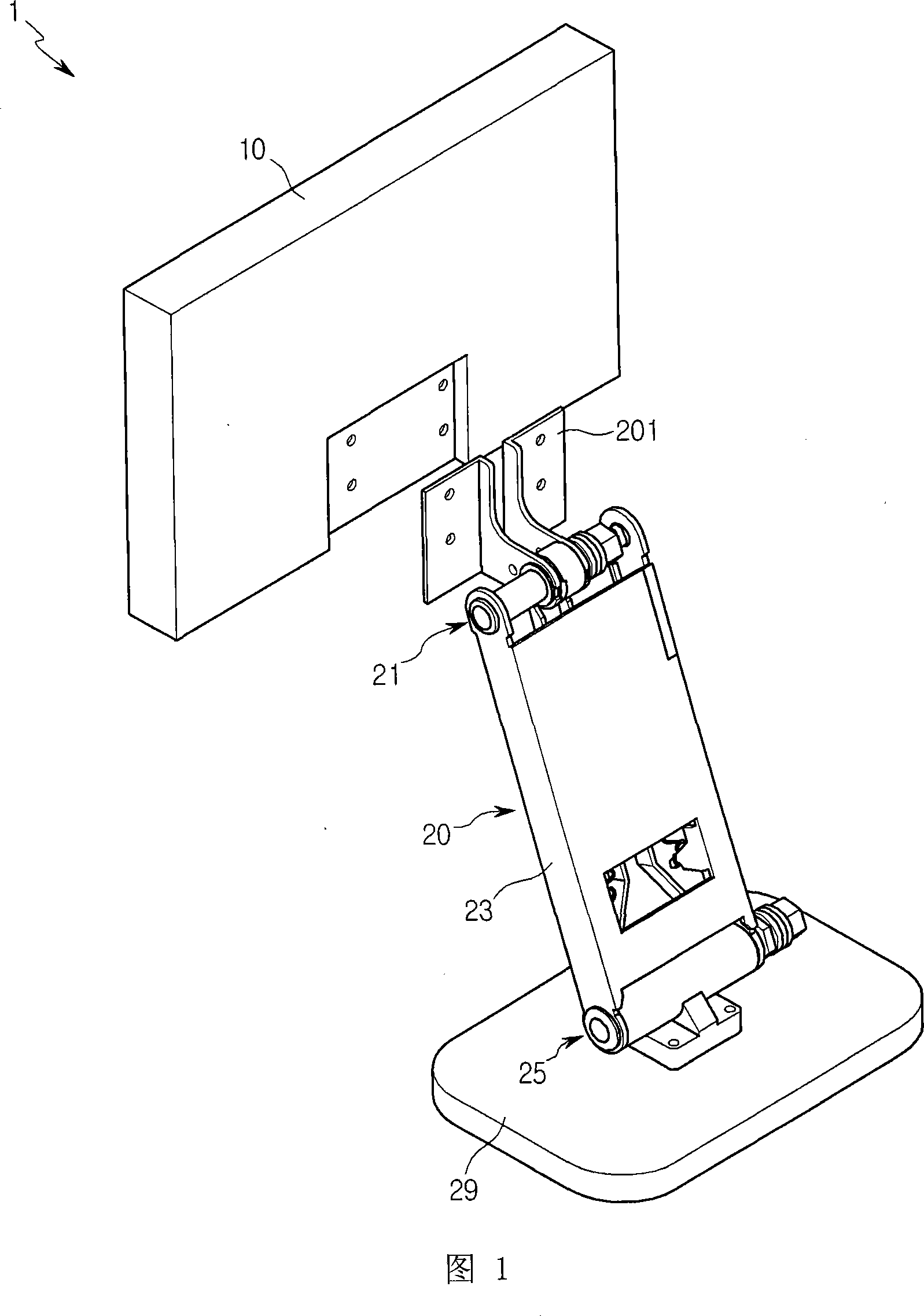

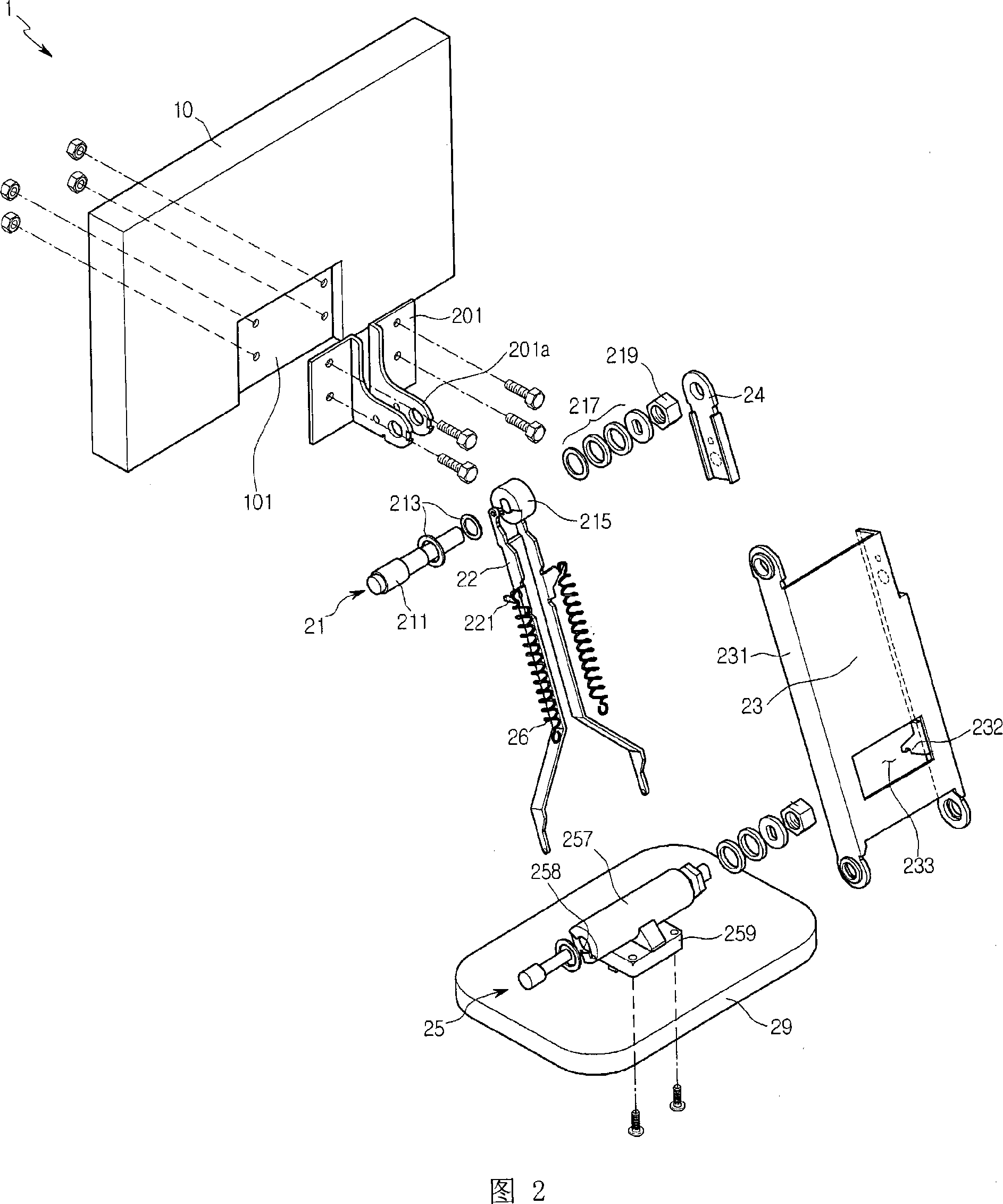

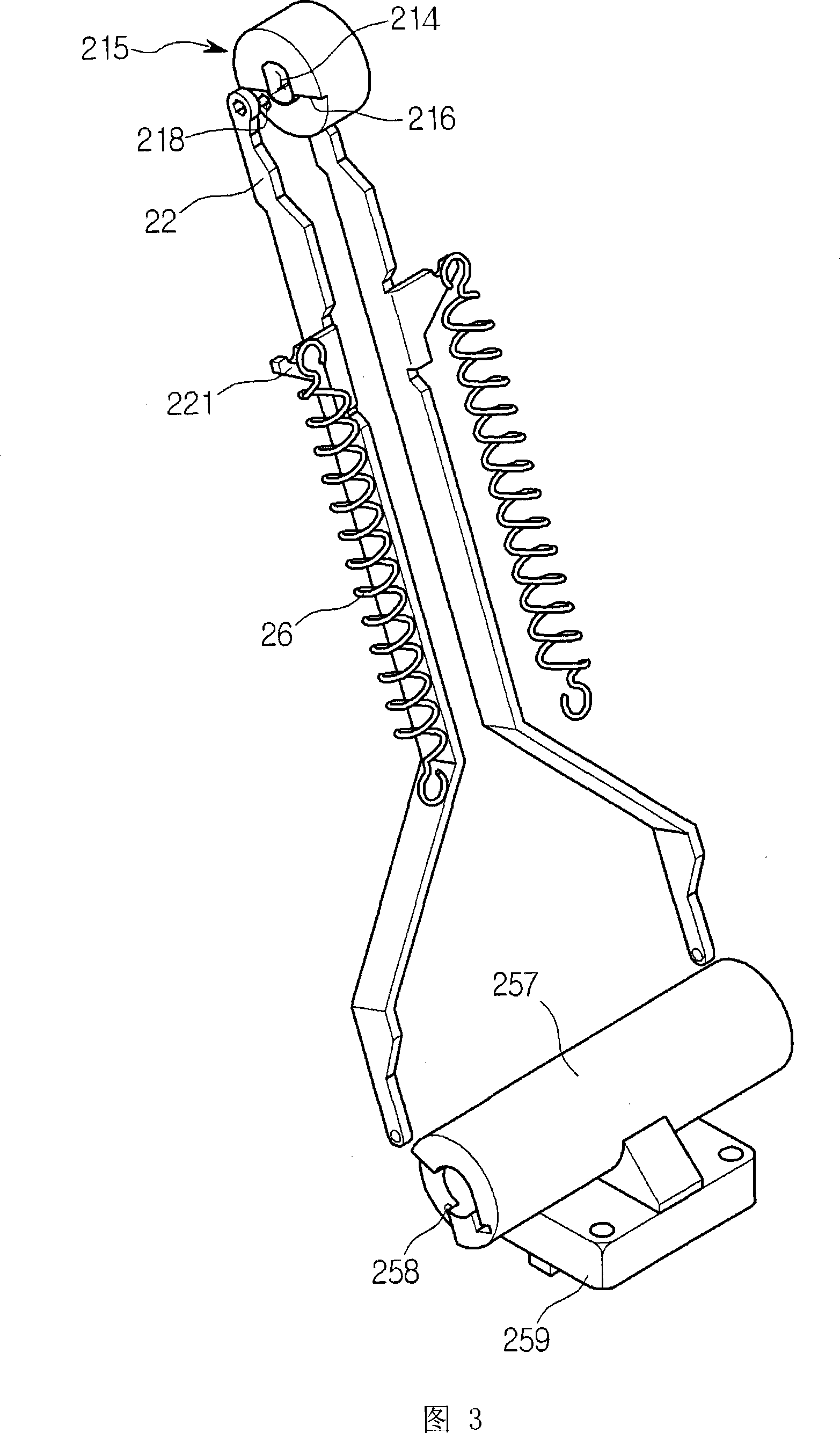

Display instrument

InactiveCN101149988AEasy to operateLow costTelevision system detailsInstrument housingComputer moduleDisplay device

Owner:NANJING LG TONGCHUANG COLOR DISPLAYS SYST CO LTD

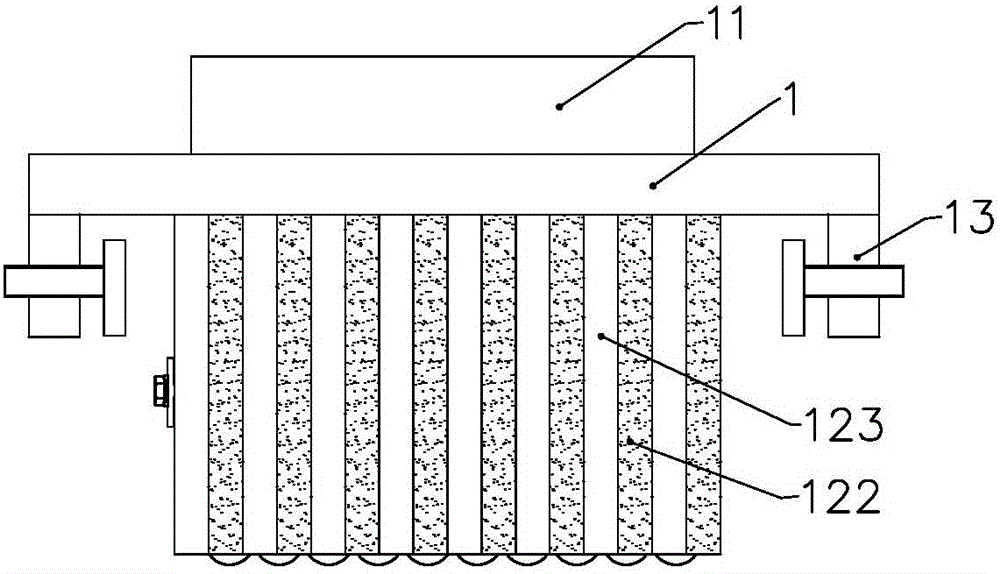

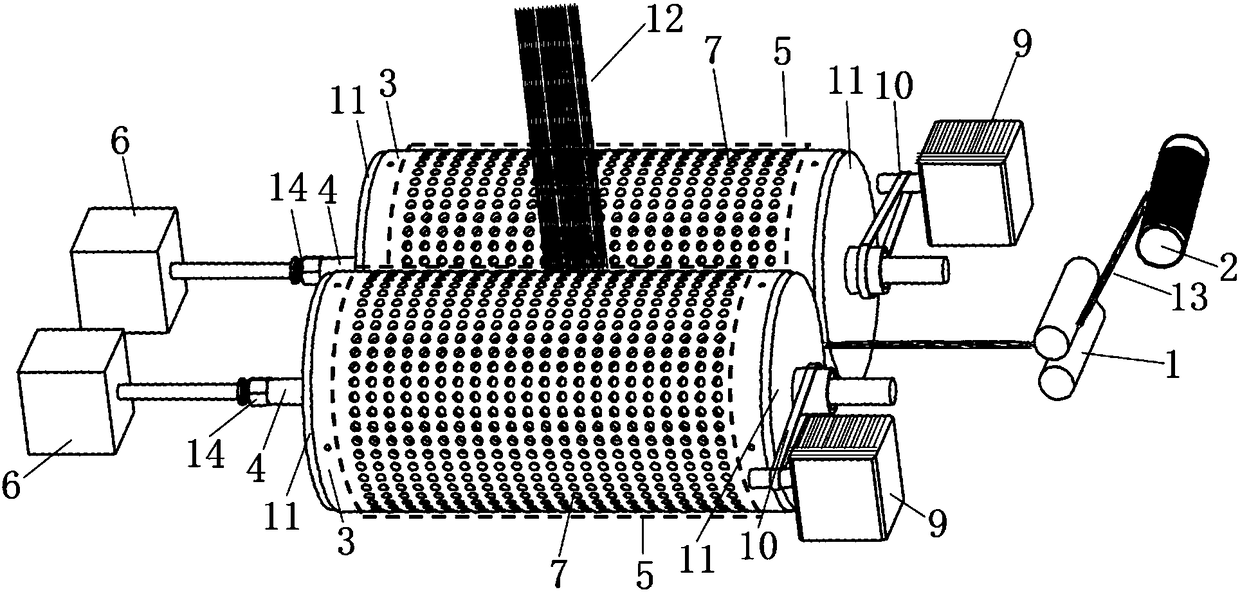

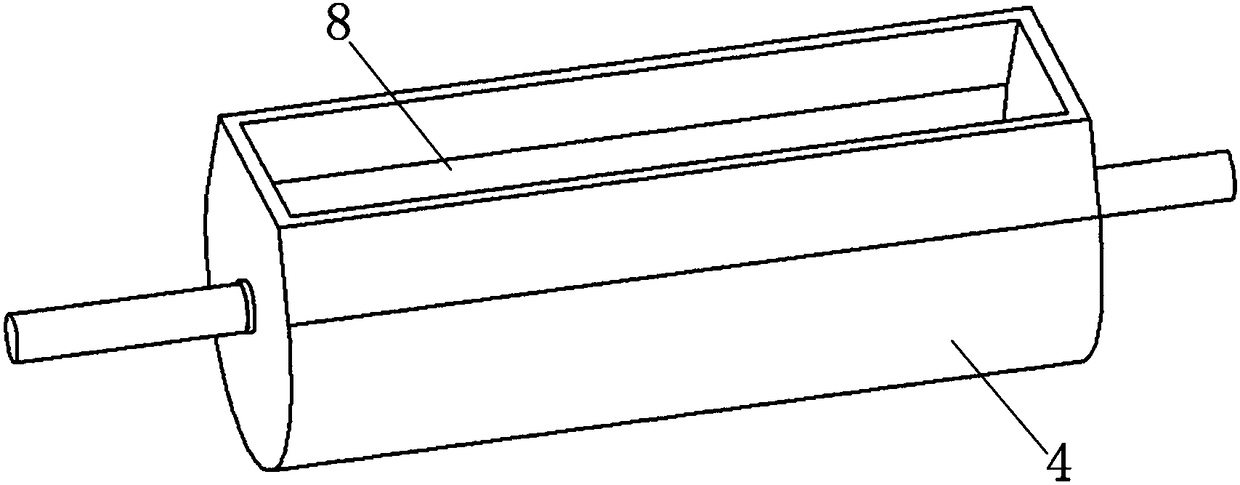

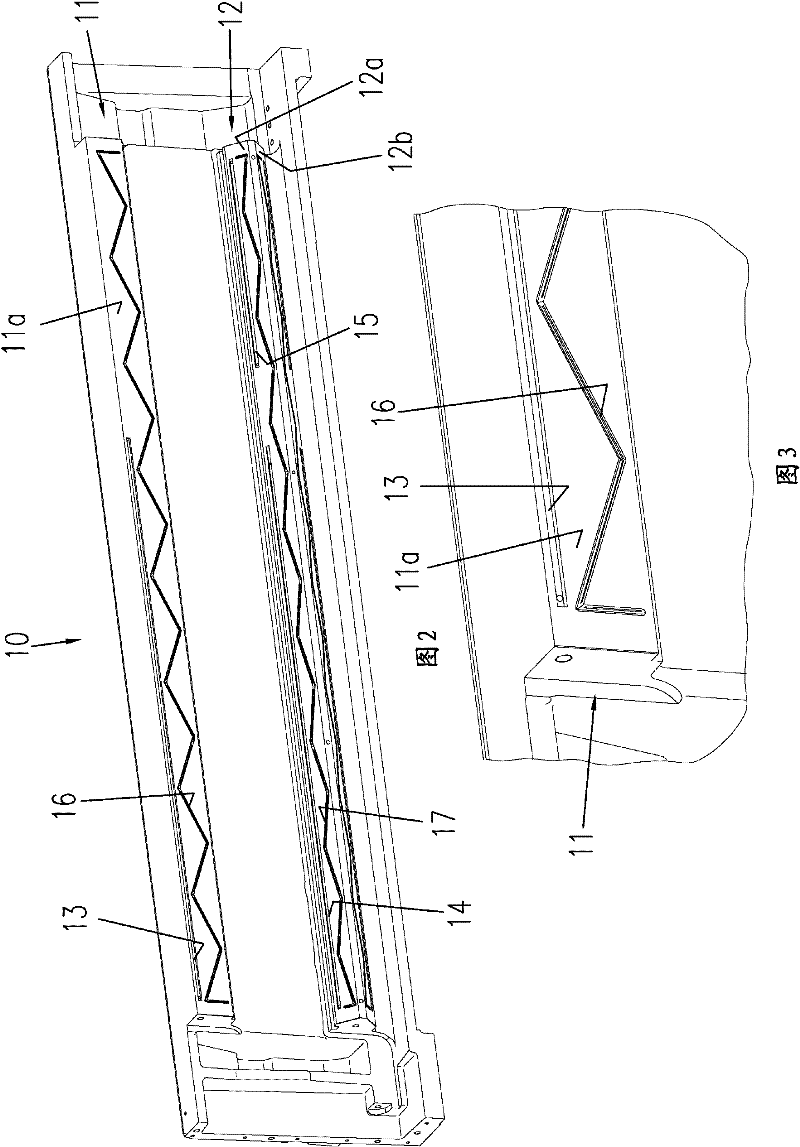

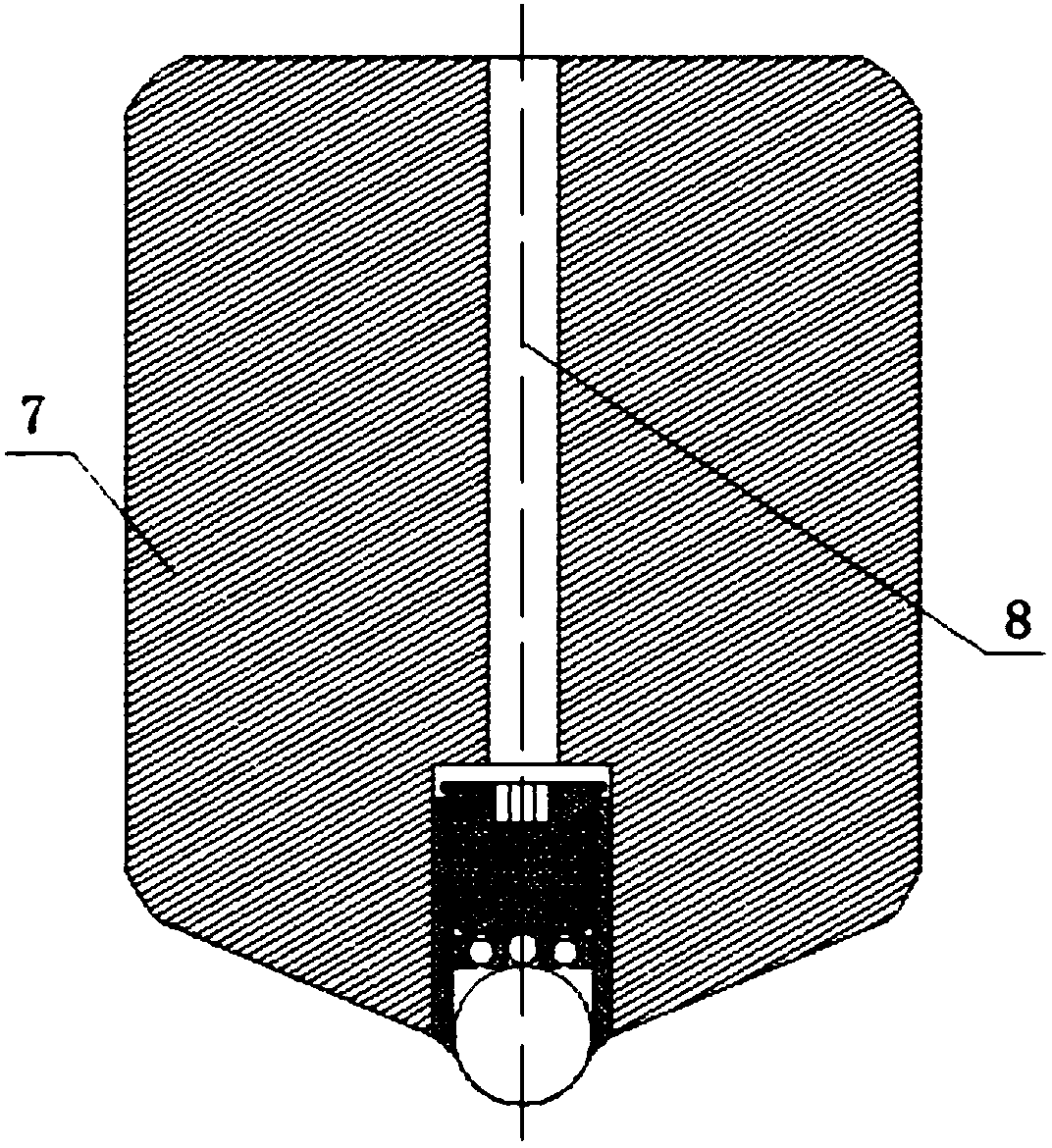

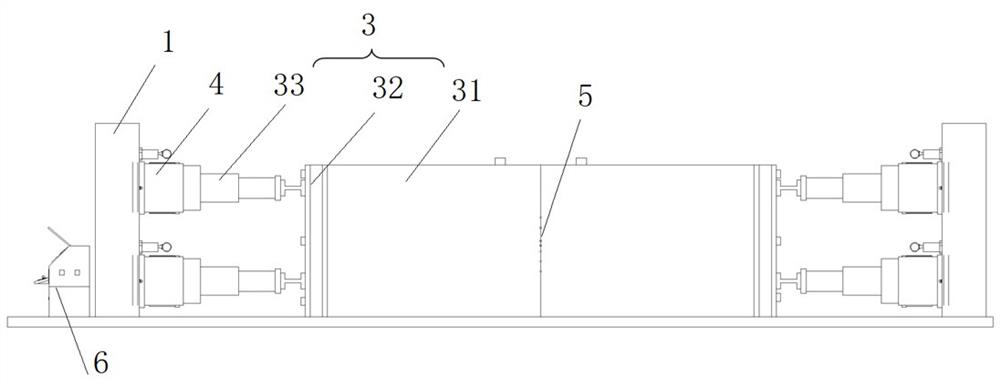

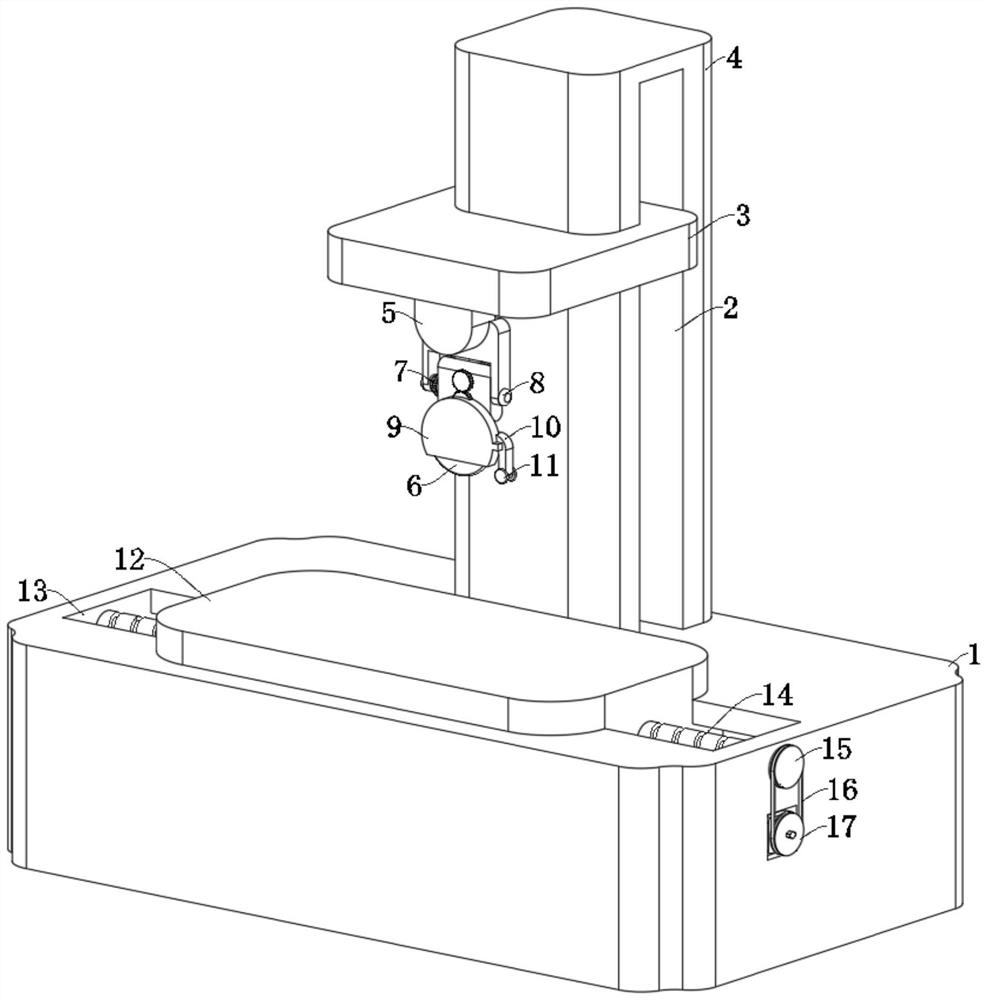

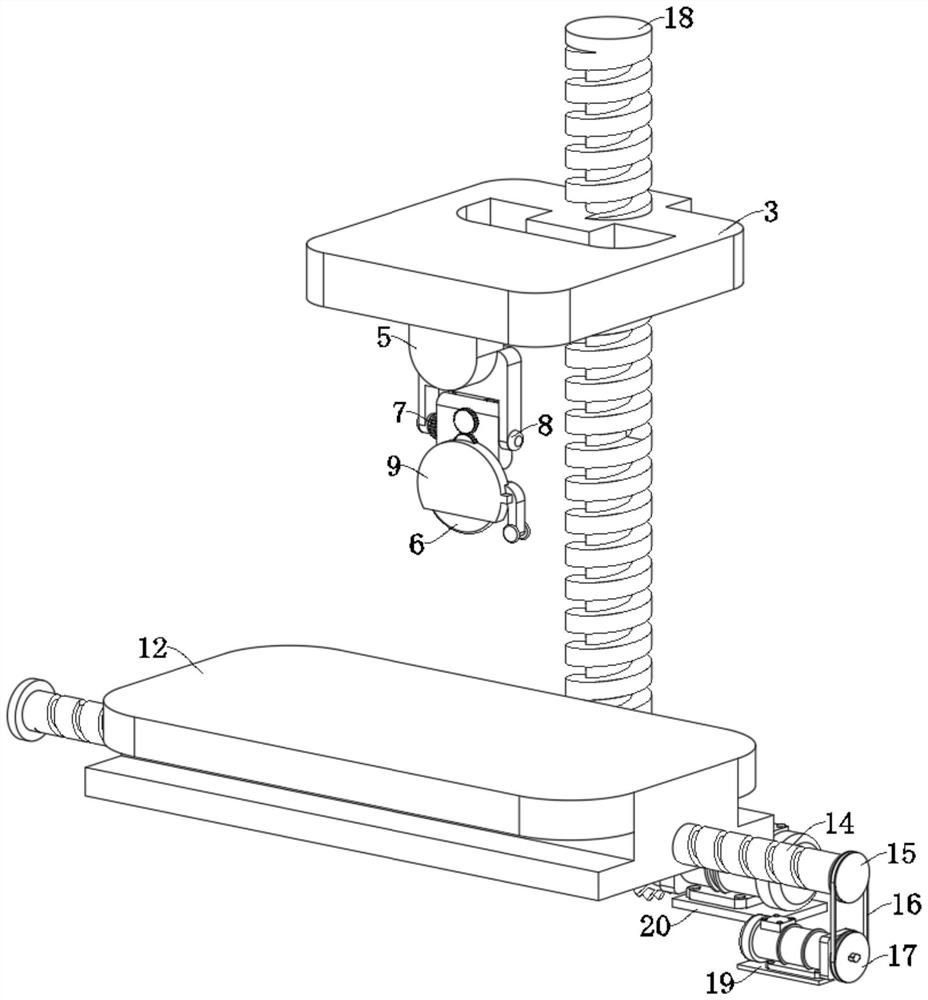

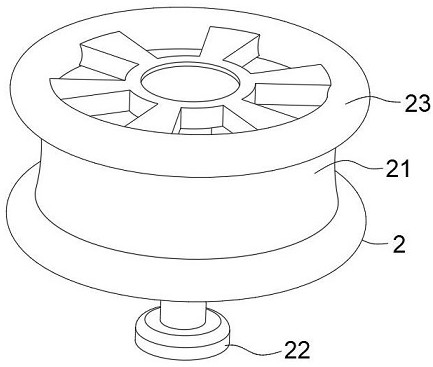

Nanofiber yarn twisting and winding device and use method thereof

InactiveCN108468116AFriction adjustmentImprove stabilityDrafting machinesContinuous wound-up machinesYarnFiber

The invention relates to a nanofiber yarn twisting and winding device and a use method thereof. Two hollow outer rollers of a cage twisting mechanism are horizontally symmetrically arranged, and a twisting gap is formed between the rollers. The hollow outer roller is provided with air holes distributed in a matrix manner. A separation net is covered on the surface of the hollow outer roller. The hollow outer roller rotates driven by a transmission mechanism. Airflow gathering inner sleeves are respectively fixed in the hollow outer rollers. The airflow gathering inner sleeve is internally provided with an air cavity and is provided with a gas gathering port along a side surface, and the gas gathering ports are arranged in an opposite manner. The airflow gathering inner sleeves are respectively connected with air extractors. A delivery roller is corresponding to the twisting gap and is arranged on the end of the hollow outer roller. The method comprises: starting the transmission mechanism to drive the two hollow outer rollers to rotate along the same direction; starting the air extractors to respectively extract air in the two airflow gathering inner sleeves; feeding a nanofiber cluster into the twisting gap to twist, to obtain a nanofiber yarn; and the nanofiber yarn pulling and winding. The device and the method realize to regulate nanofiber yarn twisting parameters, and improve stability of a twisting process.

Owner:DONGHUA UNIV

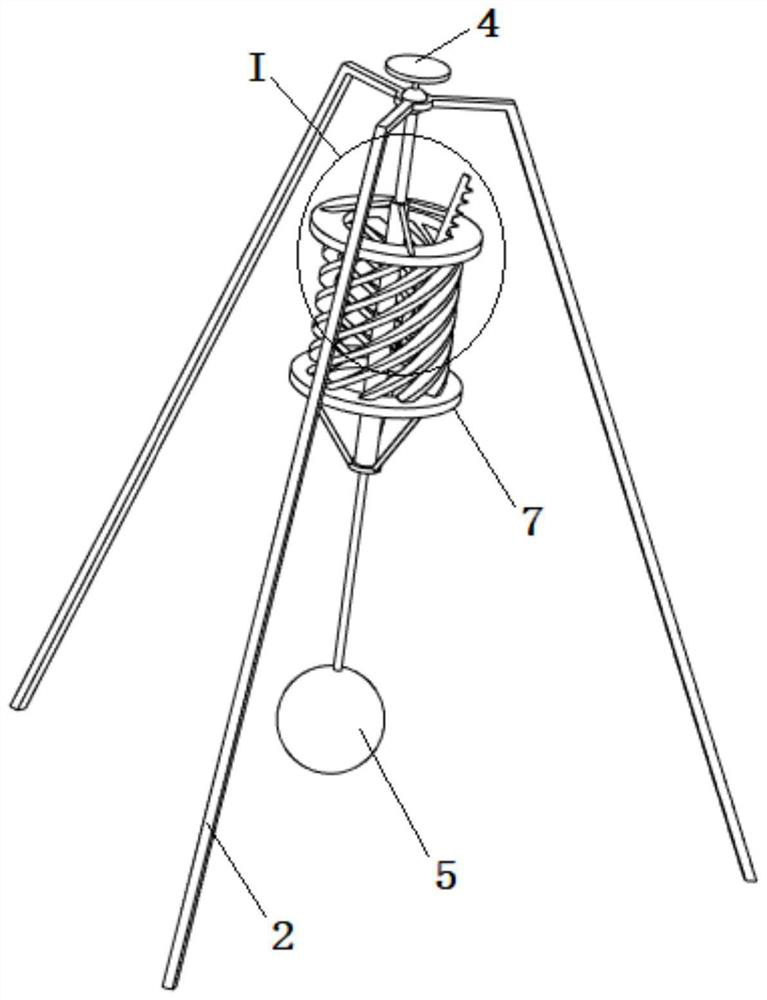

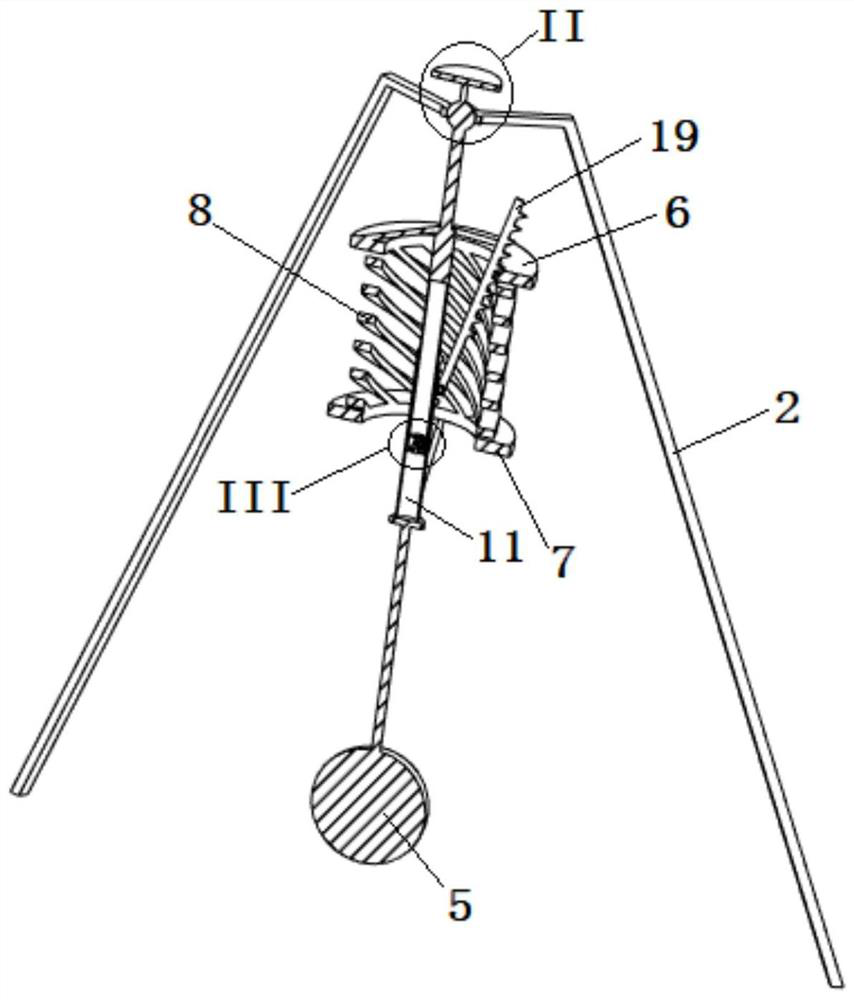

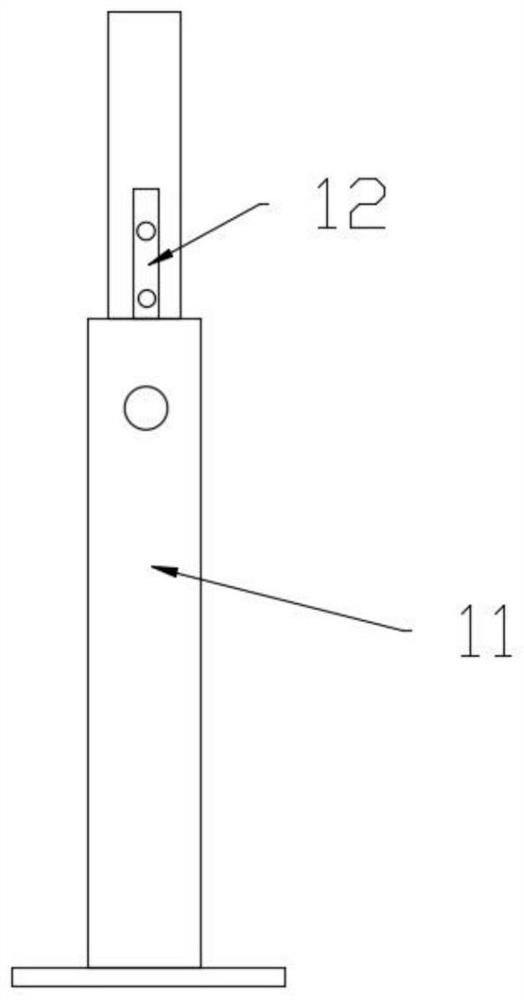

Engineering measurement equipment for urban and rural planning

InactiveCN113404986ATo ensure its own stabilityHigh leveling accuracyMachine framesSurveying instrumentsClassical mechanicsStructural engineering

The invention provides engineering surveying equipment for urban and rural planning, which comprises a bracket, the bracket comprises an annular seat body, the annular seat body is provided with supporting legs, the annular seat body is provided with a rotating ball in a ball socket matching manner, and the rotating ball is provided with a bearing plate for bearing a measurement equipment body above the annular seat body, the rotating ball is provided with a gravity block below the annular seat body, and a fine adjustment device is arranged between the gravity block and the rotating ball, so that the technical problem of improving the leveling precision is solved.

Owner:ZHENGZHOU UNIVERSITY OF AERONAUTICS

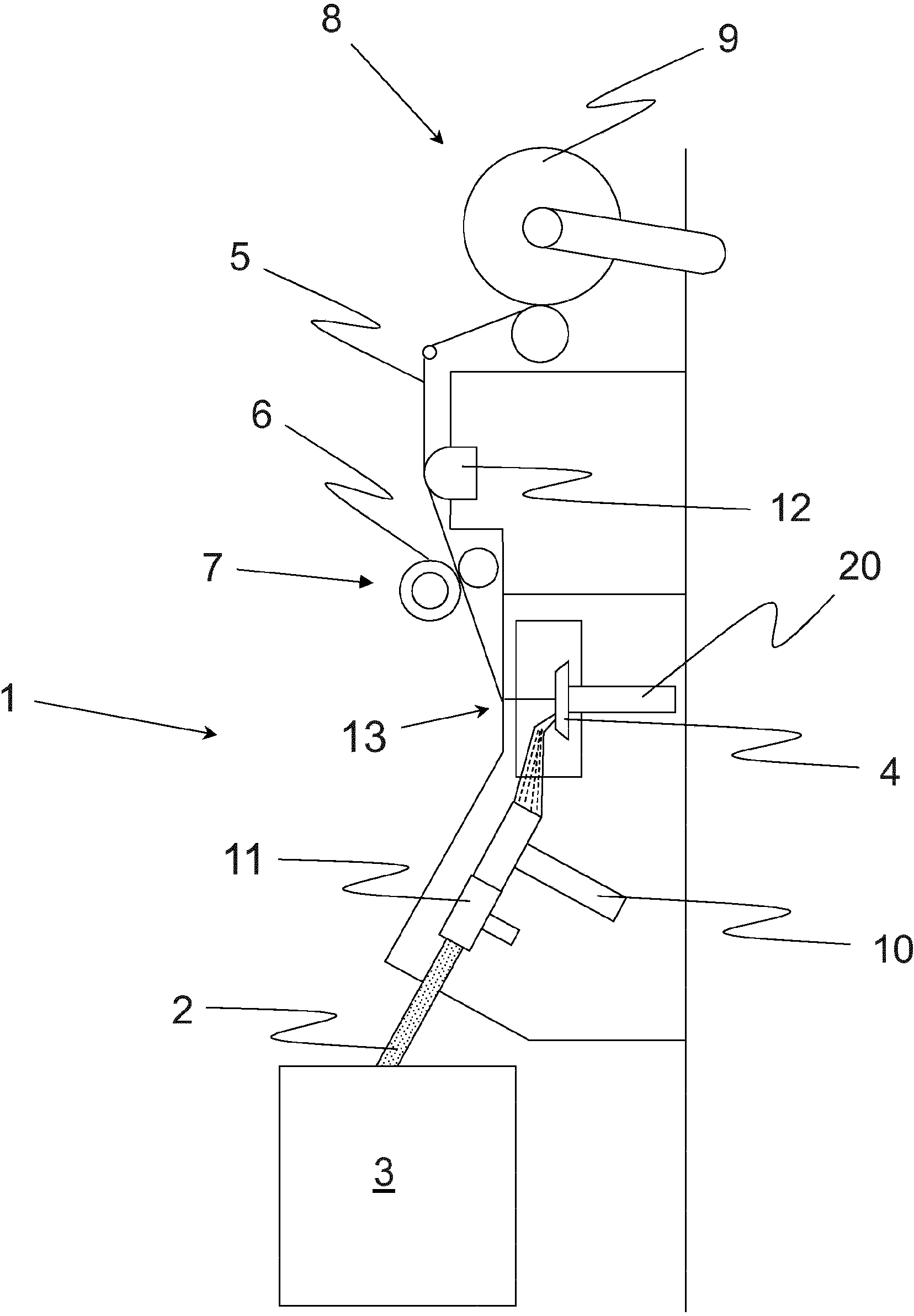

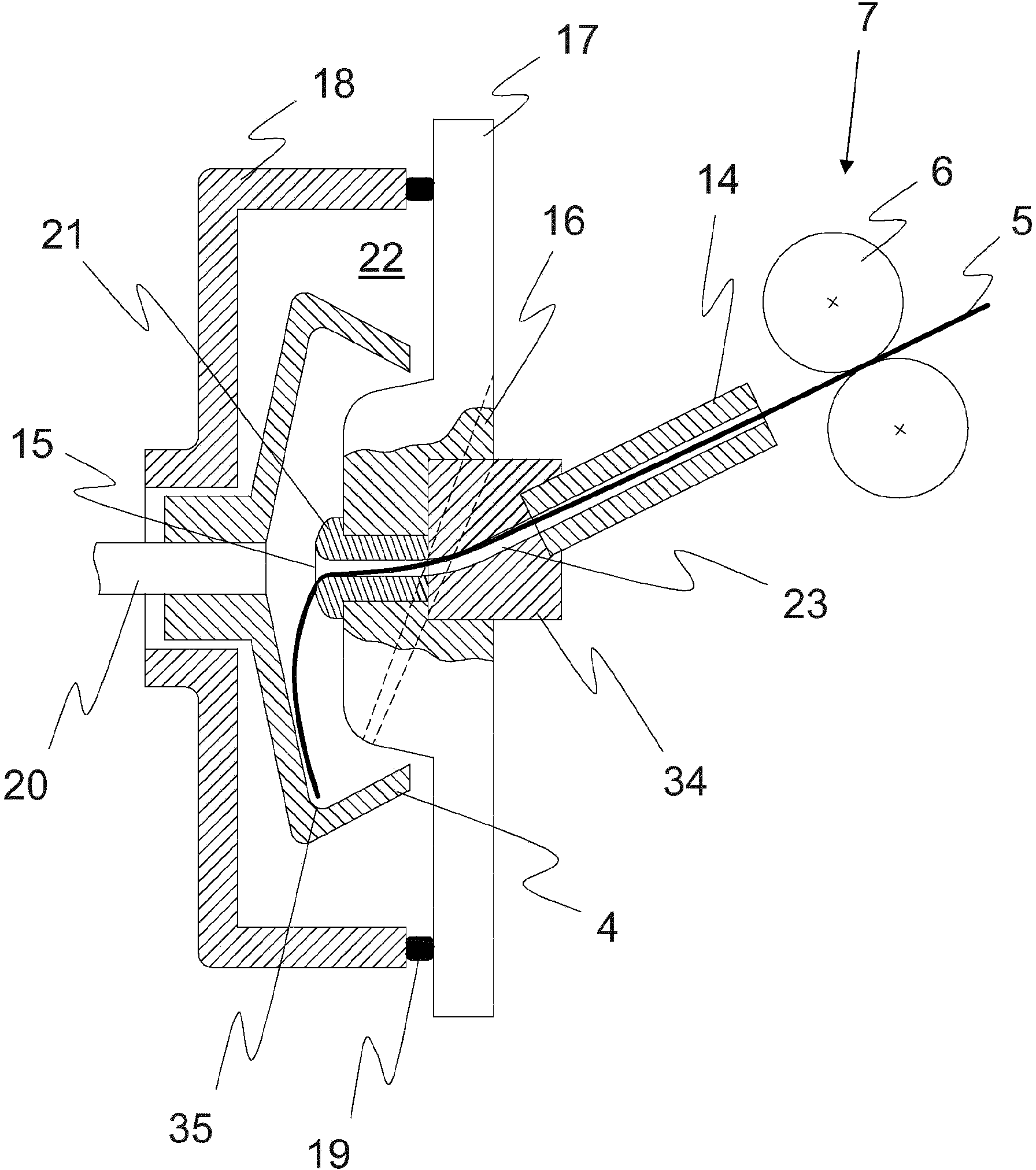

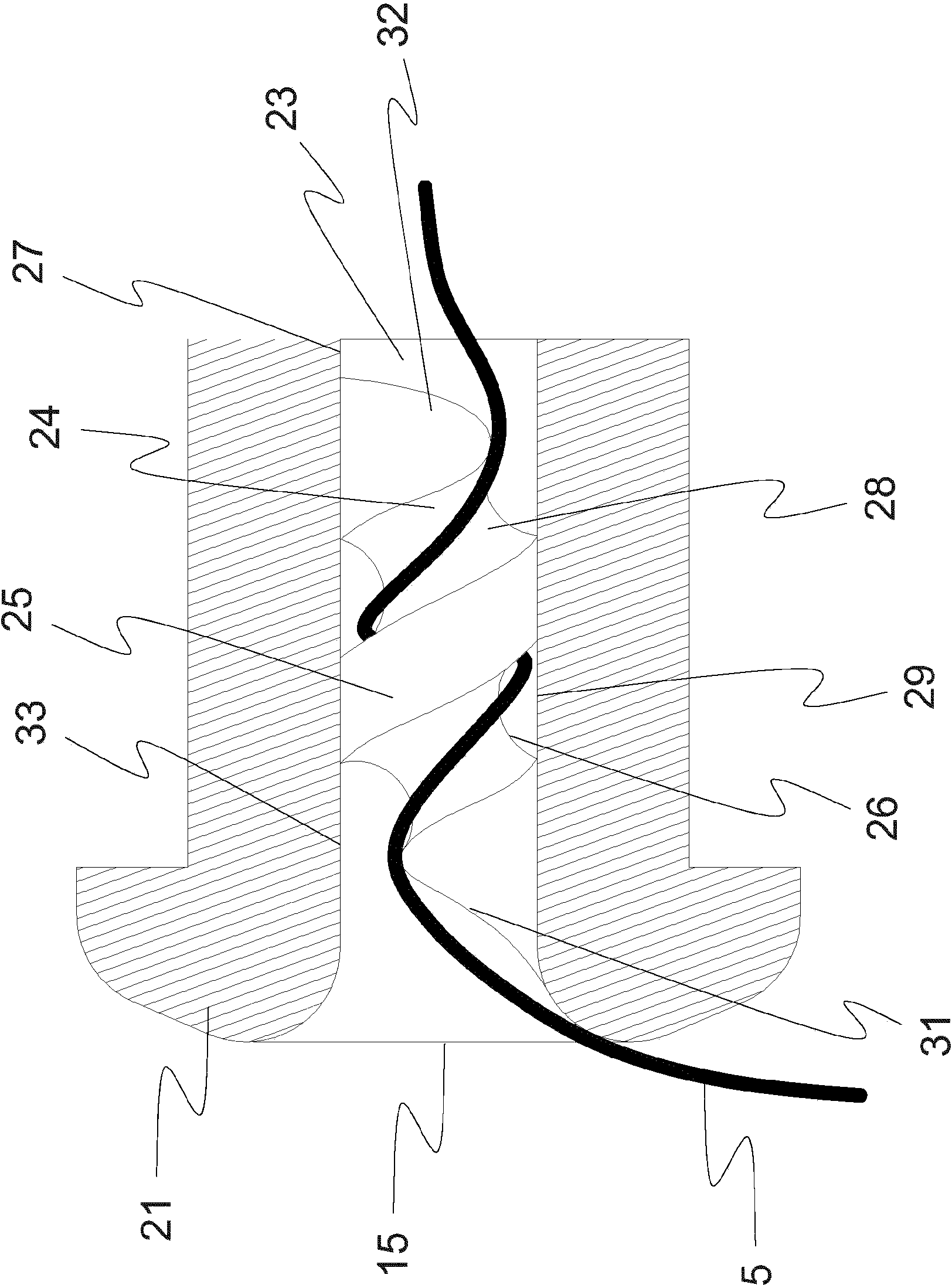

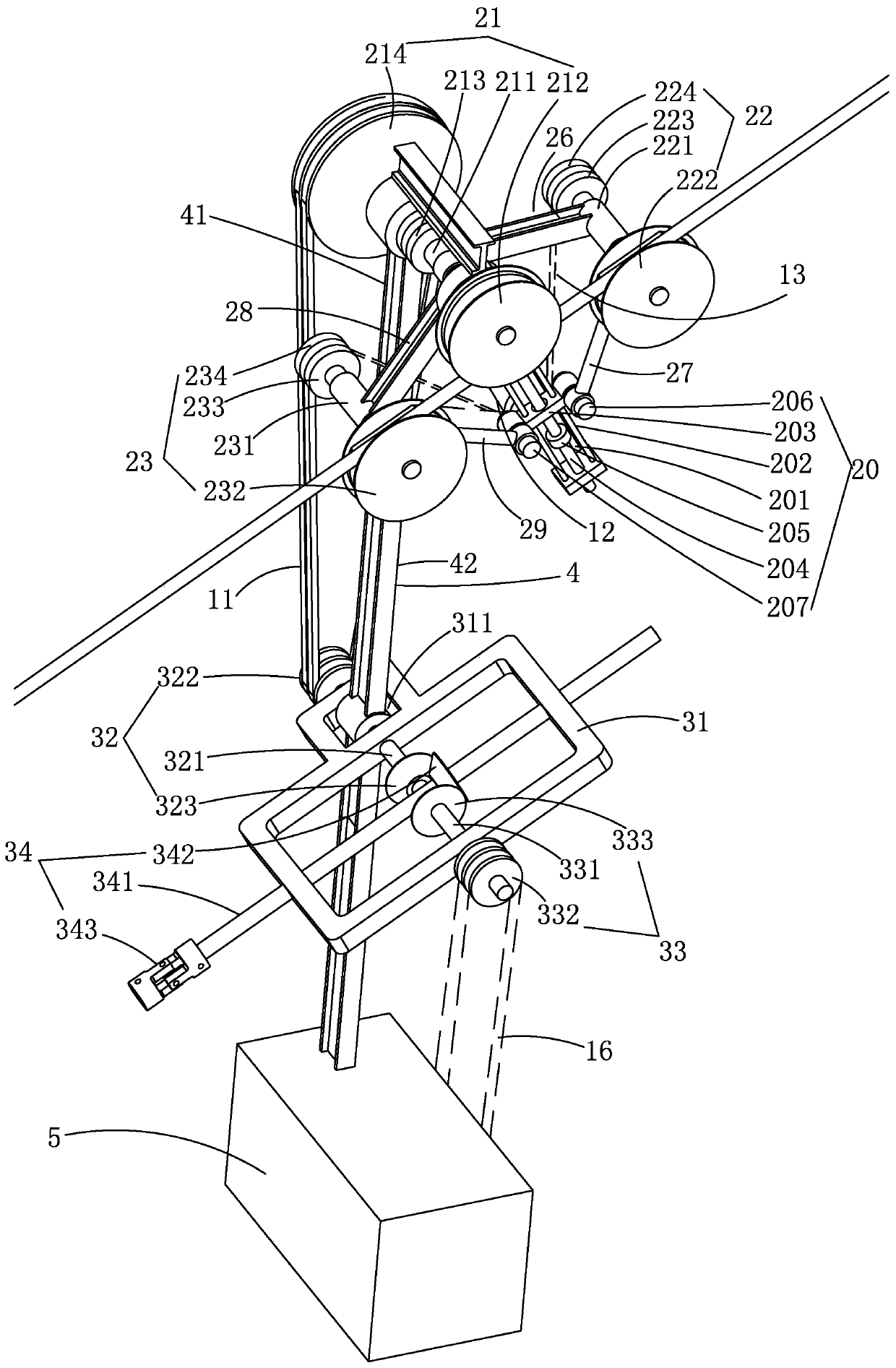

Yarn draw-off unit of a rotor spinning machine and method for producing a yarn with the aid of a rotor spinning machine

InactiveCN104114757AAccurate extensionSimple structureContinuous wound-up machinesOpen-end spinning machinesYarnNozzle

The invention relates to a yarn draw-off unit of a rotor spinning machine, having a draw-off nozzle (21) which projects into a spinning chamber (22) of the rotor spinning machine, and a draw-off conduit (23) for a yarn (5) produced within the spinning chamber (22), the draw-off conduit (23) being arranged downstream of the draw-off nozzle (21) in the draw-off direction of the yarn (5) that is drawn off from the spinning chamber (22). The draw-off conduit (23) comprises a helical section (24), with the aid of which a false twist can be imparted to the yarn (5) within the draw-off conduit (23). Furthermore, a draw-off nozzle for a rotor spinning machine is described, the draw-off conduit (23) of which comprises a helical section (24), with the aid of which a false twist can be imparted to the yarn (5) within the draw-off nozzle (21). Finally, the invention relates to a method for producing a yarn (5) with the aid of a rotor spinning machine. The method is characterised in that the yarn (5) is exposed to torque within a helical section (24) of the draw-off conduit (23), said torque causing the yarn (5) to rotate about its longitudinal axis, the direction of rotation of the rotation corresponding to the direction of rotation that is imparted to the yarn (5) by the spinning rotor (3).

Owner:MASCHINENFABRIK RIETER AG

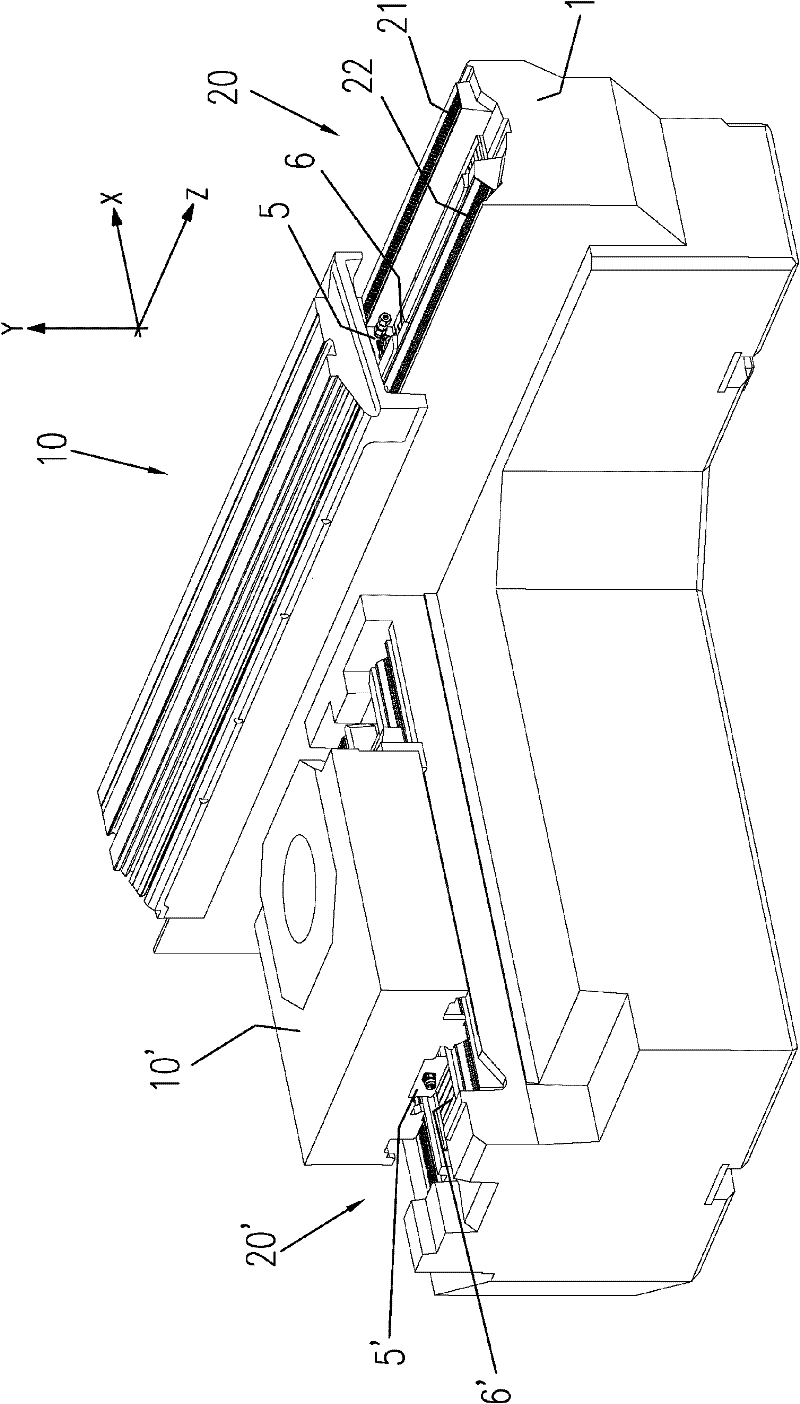

Device with a displaceable carriage and a linear guide

ActiveCN102601692AMove preciselyPrecise positioningLinear bearingsRevolution surface grinding machinesLubricant

Owner:FRITZ STUDER AG GLOCKENTHAL

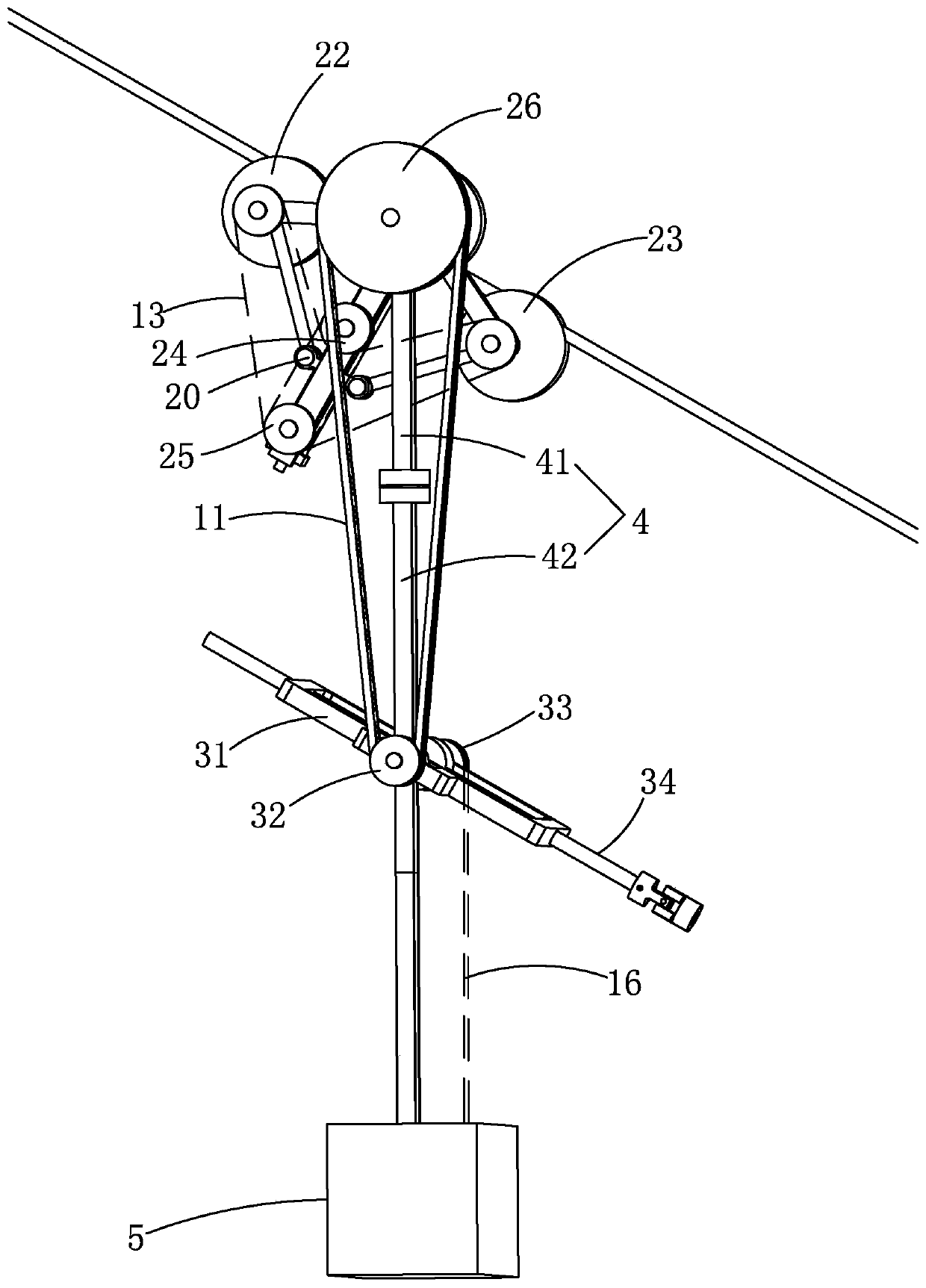

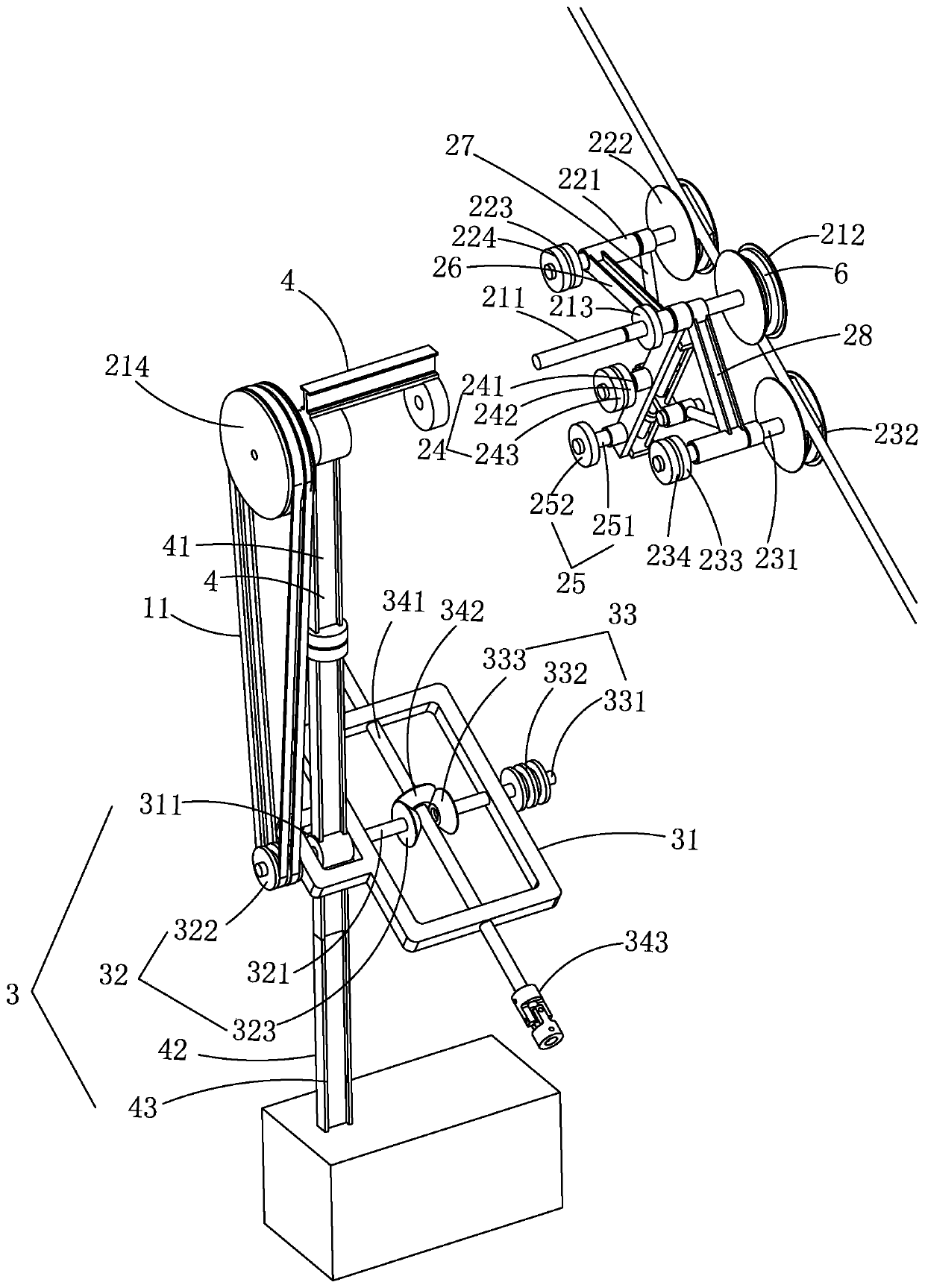

Cableway self-propelled transportation equipment

PendingCN111332319AImprove applicabilityEasy to operateRope railwaysStructural engineeringMechanical engineering

The invention relates to cableway self-propelled transportation equipment which comprises a transportation device running along a cableway rope. The transportation device comprises a sliding adjustingmechanism, a transmission mechanism and a pull arm, and the sliding adjusting mechanism and the transmission mechanism are movably connected with the pull arm. A sliding adjusting mechanism is arranged on a pull arm; a cableway rope clamping area is defined by a first transmission assembly, a second transmission assembly and a third transmission assembly of the sliding adjusting mechanism. When the cableway rope is positioned in the cableway rope clamping area; the cableway rope is clamped with the first transmission assembly, the second transmission assembly and the third transmission assembly; in addition, the sliding adjusting mechanism is provided with a first lifting assembly, the cableway rope clamping area can adapt to cableway ropes of different sizes and smoothly pass through thecableway rope connecting position or the cableway support turning position, and the applicability of the transportation device is improved.

Owner:郭延巍

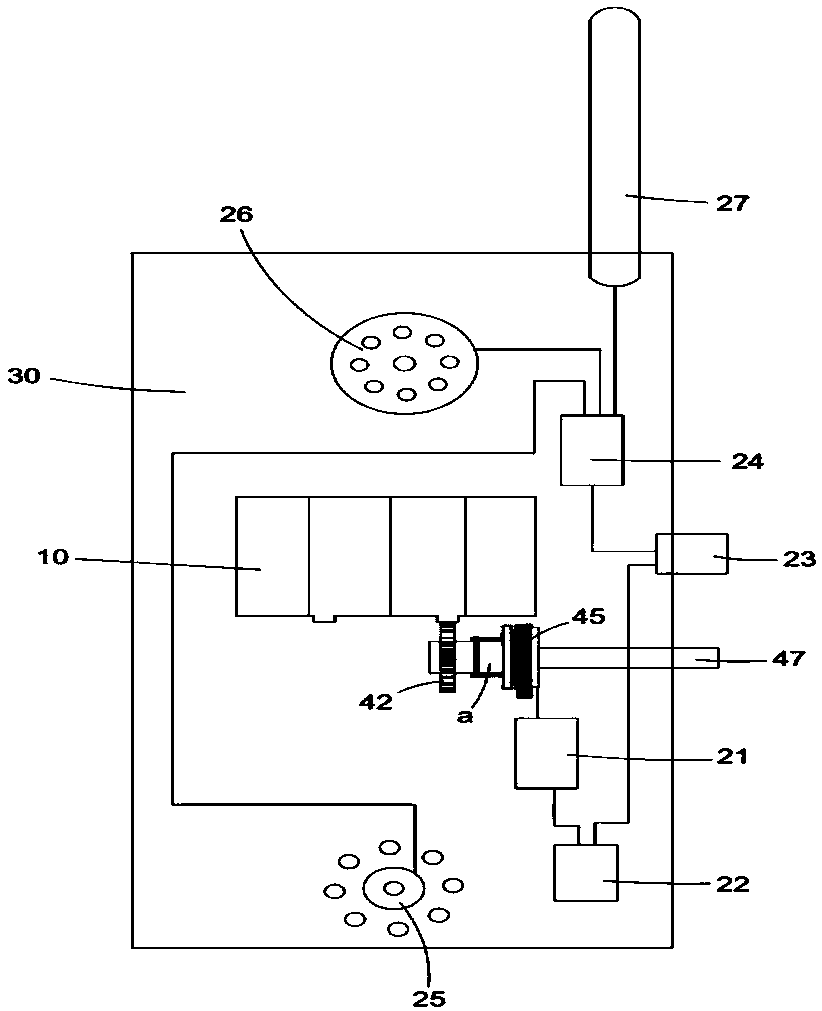

Child interphone using solar photovoltaic power generation as power source

InactiveCN107846235AFriction adjustmentAdjustable rotation angleBatteries circuit arrangementsElectric powerElectrical batteryTransmission delay

The invention discloses a child interphone using solar photovoltaic power generation as a power source. The child interphone comprises a housing, a solar battery, a photovoltaic controller, an energystorage battery, a switch, a control device, a microphone, a telephone receiver and an antenna; the solar battery is connected with the photovoltaic controller, the photovoltaic controller is connected with the energy storage battery, the energy storage battery is connected with the switch, the control device is connected with the switch, the control device is connected with the microphone, the control device is connected with the telephone receiver, and the control device is connected with the antenna; and a battery port is formed in the housing, and the solar battery is arranged in the battery port by sliding fit. Under the driving of a transmission device, the solar battery slides out from or slides into the battery port, when the solar battery slides into the battery port, the interphone is used normally, and when the solar battery slides out from the battery port, the contact surface of the solar battery with the sun light is increased to improve the charging efficiency.

Owner:DONGGUAN TIANHE ELECTROMECHANICAL DEV CO LTD

Convex-concave die device capable of preventing material clamping

InactiveCN112371829AAvoid material jamsFriction adjustmentCleaning using toolsStructural engineeringBrush

The invention discloses a convex-concave die device capable of preventing material clamping, and relates to the technical field of machining. The convex-concave die device comprises a concave die anda convex die, wherein a blanking hole is formed in the upper surface of the concave die, the convex die is in sliding fit with the blanking hole, sliding grooves are formed in the side faces of the periphery of the concave die, the sliding grooves communicate with the blanking hole, and sliding blocks are connected in the sliding grooves in a sliding mode. According to the convex-concave die device, a brush roller, the sliding blocks, a push block, a second spring and a screw rod are used, so that material clamping is avoided; and the screw rod can be driven to rotate by rotating a knob, the screw rod can drive the push block to move forwards or backwards, the closer the push block is to the blanking hole, the larger the pressure borne by the brush roller is, the larger the friction forceis, otherwise, the smaller the friction force is, so that the adjusting effect is achieved. According to the convex-concave die device, a fixed frame, a movable frame, a sliding rod and a first springare used, when the convex die is used for blanking a workpiece, a sliding frame can be extruded to slide upwards, when the convex die is reset, the sliding frame can be reset along with the convex die, in the process, the sliding frame can further remove waste on the surface of the convex die, and material clamping is further prevented.

Owner:烟台鑫洋电子有限公司

Money twisting mechanism of money counter

InactiveCN109034352AEasy to openConvenience of scoringCounting objects on conveyorsInterference fitDrive shaft

The invention discloses a money twisting mechanism of a money counting machine, and the mechanism comprises a shell. The front end of the shell of the cash counter is rotatably connected with a moneypassing shaft, a plurality of money passing wheels are interference-fitted on the money passing shaft, a money twisting shaft is rotatably connected between the inner walls of the money counter at a position on one side of the money passing shaft, the money twisting shaft is interference-fitted with a plurality of money twisting wheels, and a connecting mechanism is installed in the middle of themoney twisting shaft. By dragging the twisting shaft close to the drive shaft, the outer retainer ring is driven to slide on the guide rod and press the second spring, so that the distance between thetwo twisting shafts is reduced, so that the banknote twisting shaft adjacent to the drive shaft can be disengaged from the drive shaft, When the twisting ring on the twisting wheel is ground, the twisting shaft can be conveniently removed, so that the replacement of the twisting ring on the twisting wheel becomes convenient, the frictional force of the twisting ring can be maintained, the twisting wheel is not easy to slip with the banknotes, the counting stability is maintained, and the convenience of maintenance of the banknote counter is improved.

Owner:PINGYANG RANPENG ELECTRONICS MACHINERY

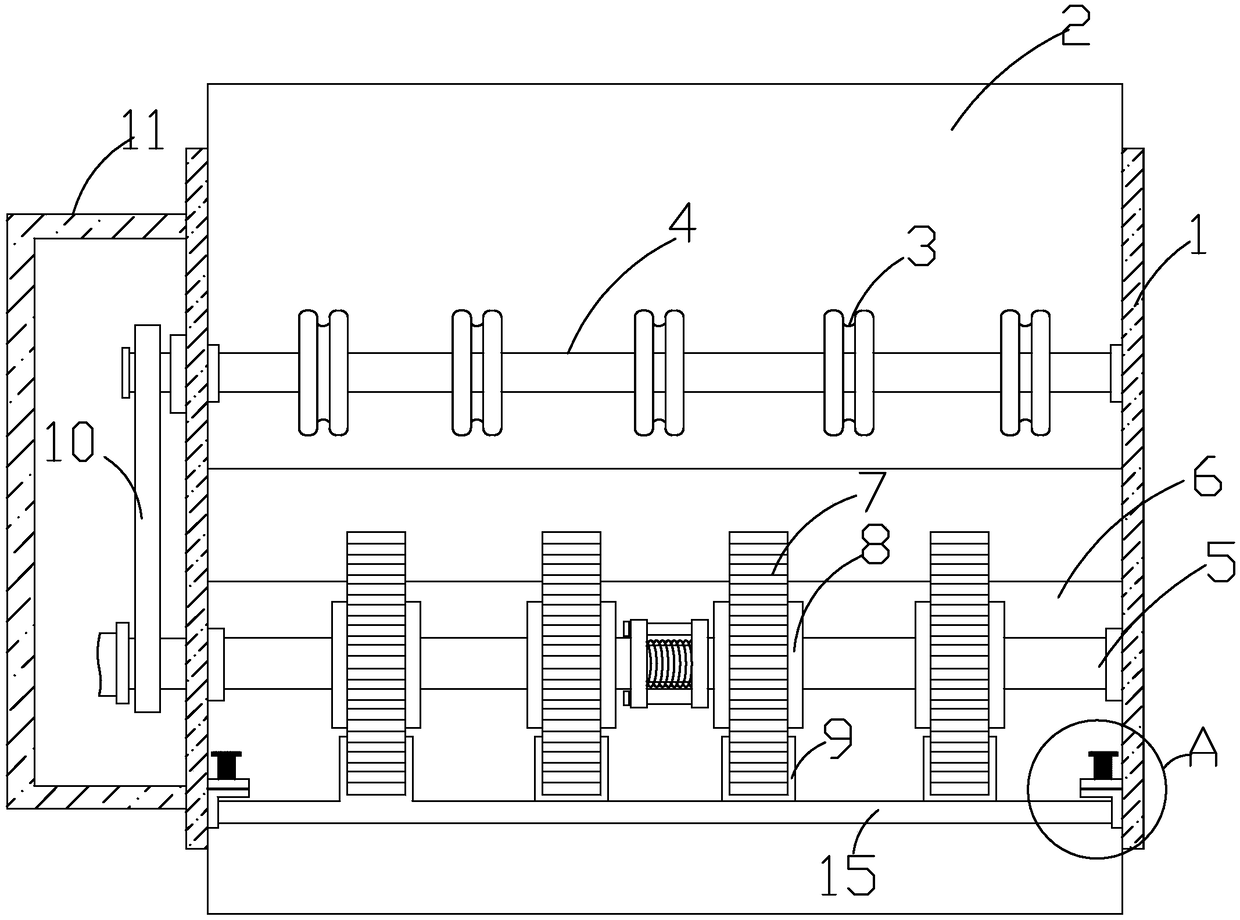

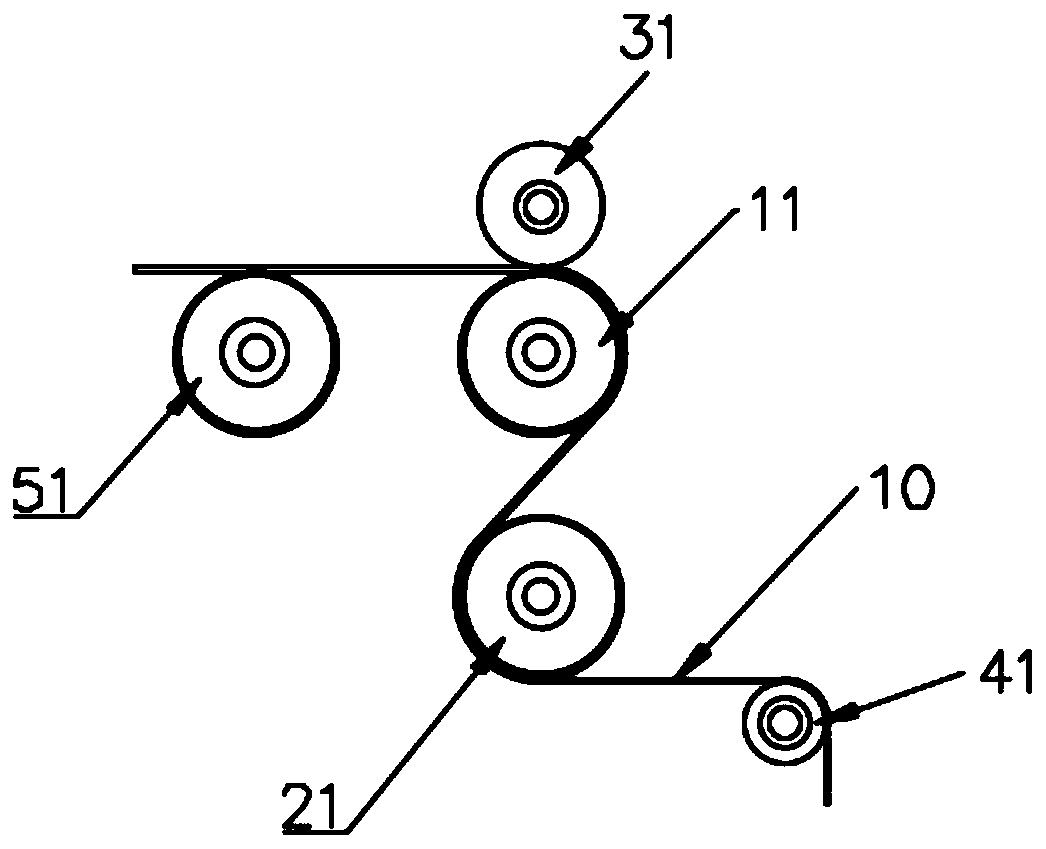

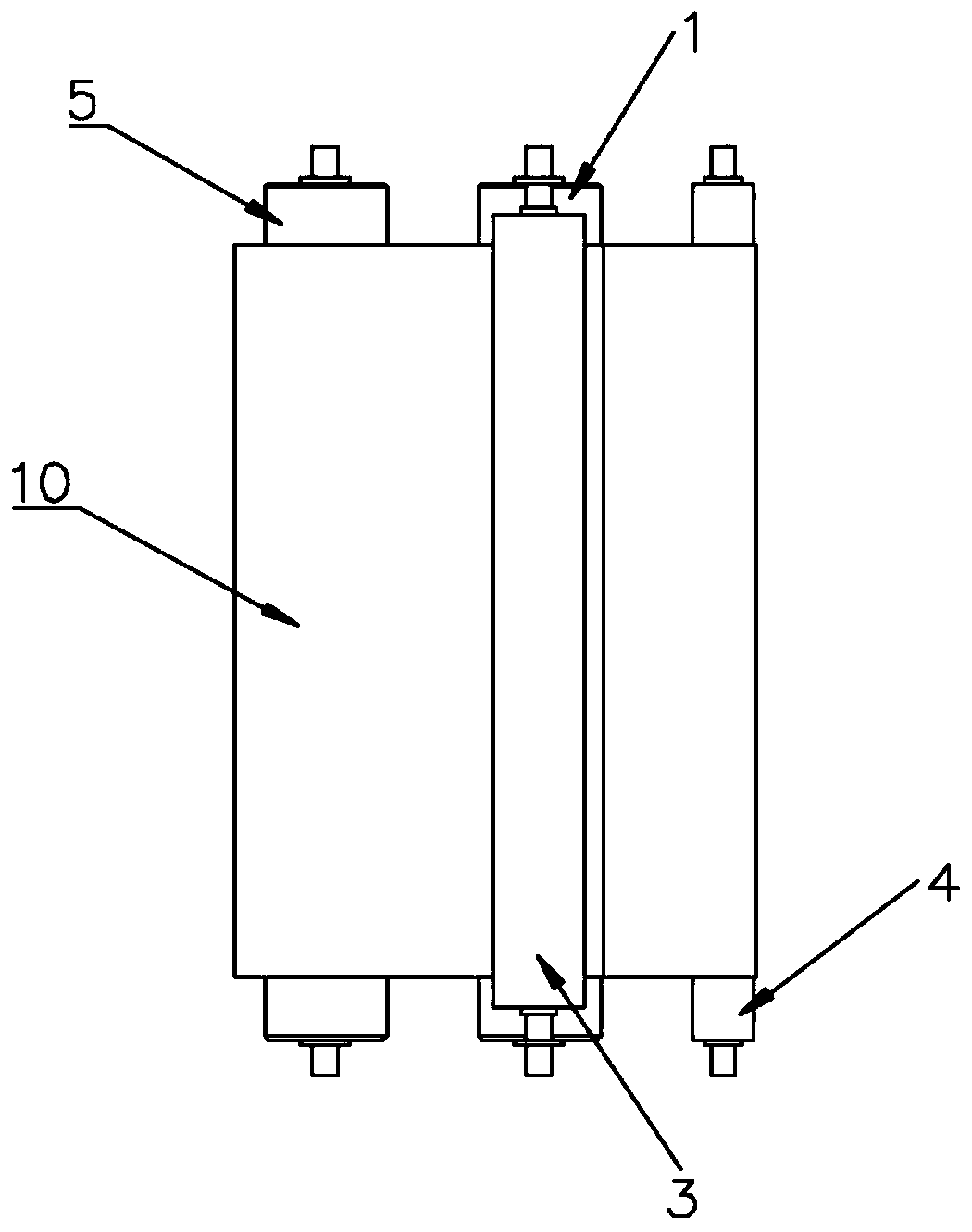

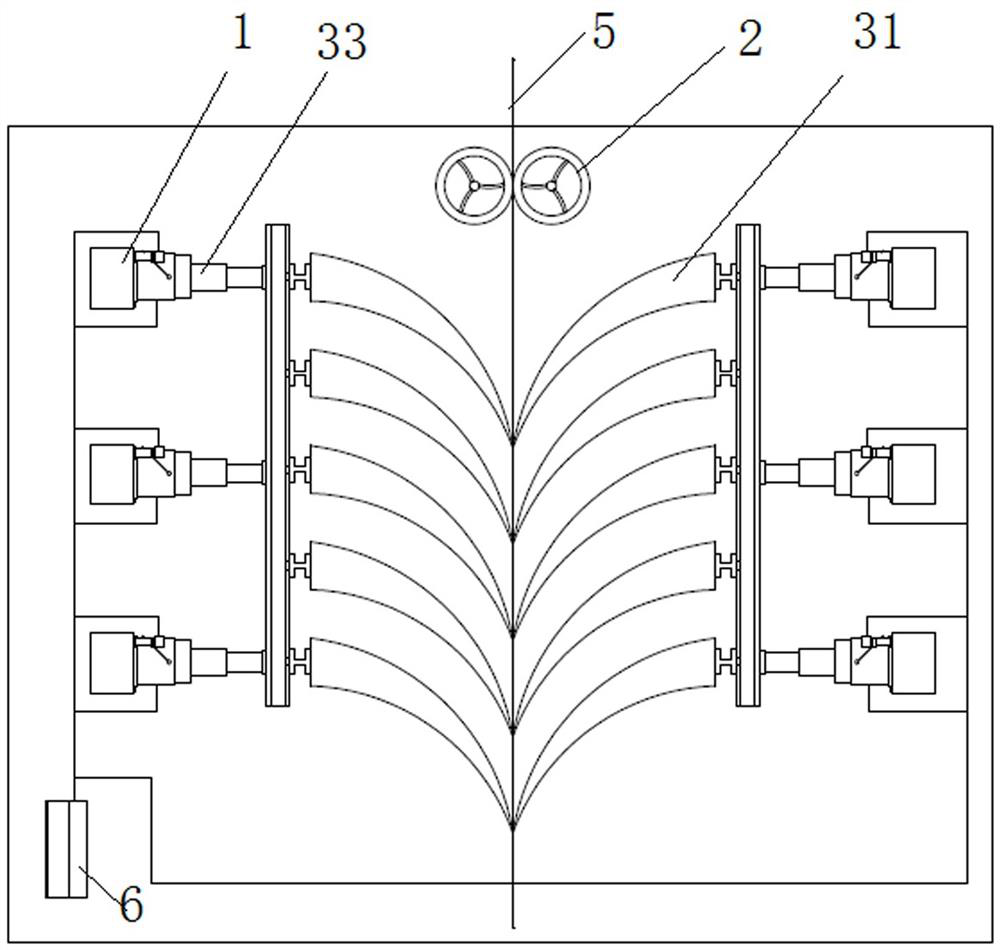

Roller conveying device for flexible belt materials

InactiveCN109761082AFriction adjustmentAdjust the wrap angle sizeWebs handlingEngineeringFriction force

The invention relates to the field of conveying devices, in particular to a roller conveying device for flexible belt materials. The roller conveying device for the flexible belt materials comprises amain driving roller, a driven driving roller, a pressure roller and a drive mechanism in drive connection with the main driving roller and / or the driven driving roller, wherein the main driving roller and the driven driving roller rotate; the rotating directions of the main driving roller and the driven driving roller are opposite; the flexible belt materials move along the rotating directions; and the pressure roller rotates and press the flexible belt materials. During the conveying process of the flexible belt materials, a big wrap angle can be formed, the main driving roller and the driven driving roller provide a larger friction force, and the pressure roller provides the pressure on the flexible belt materials, so that the flexible belt materials are at a strained state and are prevented from slipping or bouncing during the conveying process.

Owner:HANS LASER TECH IND GRP CO LTD

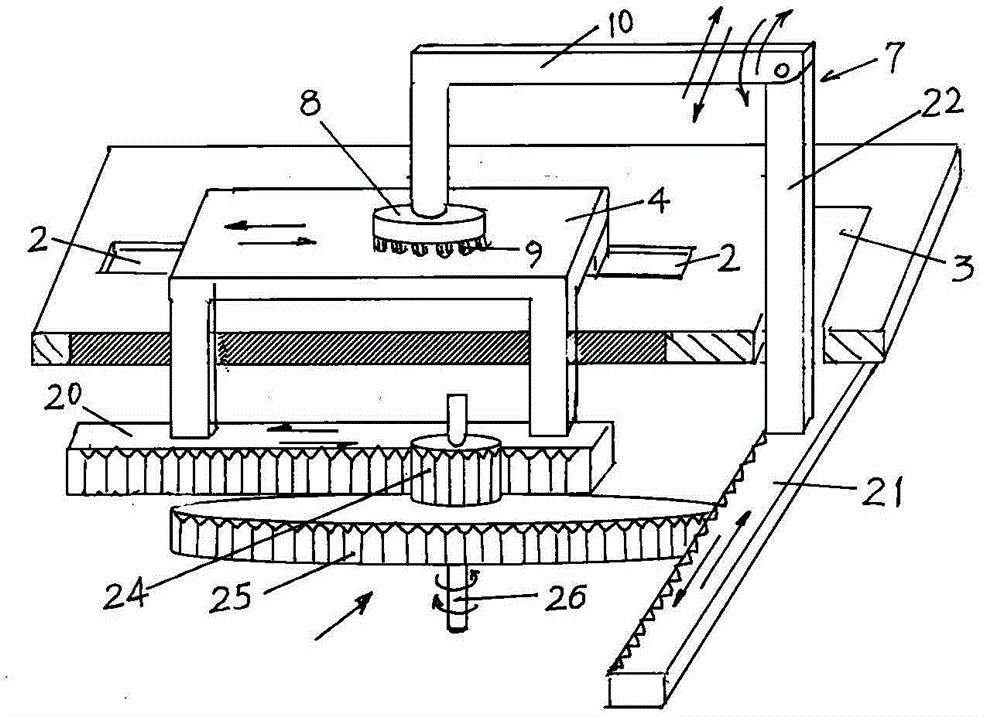

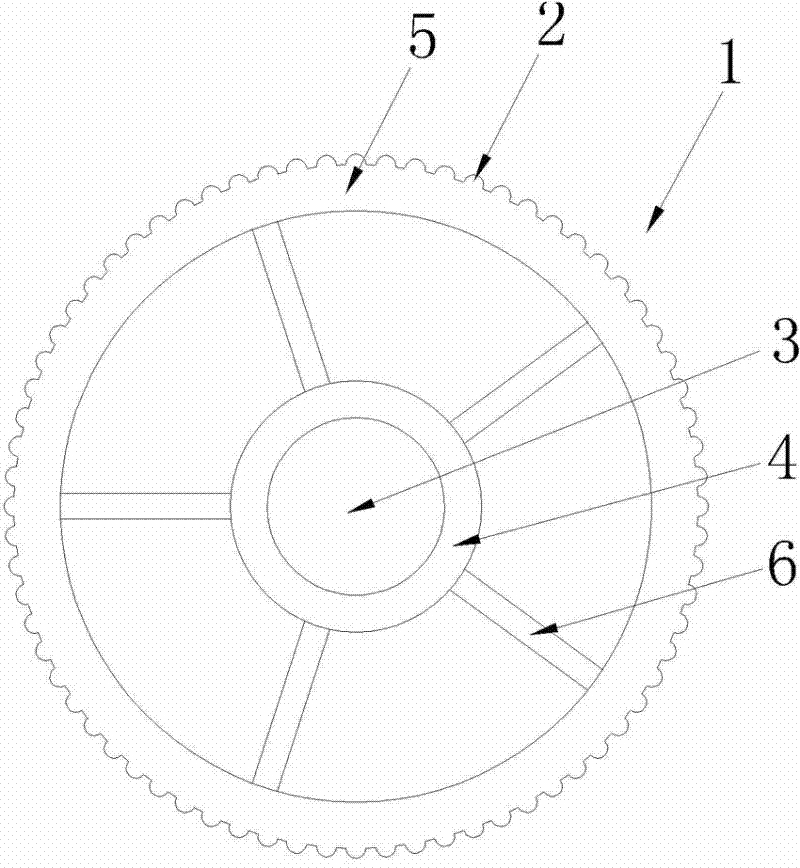

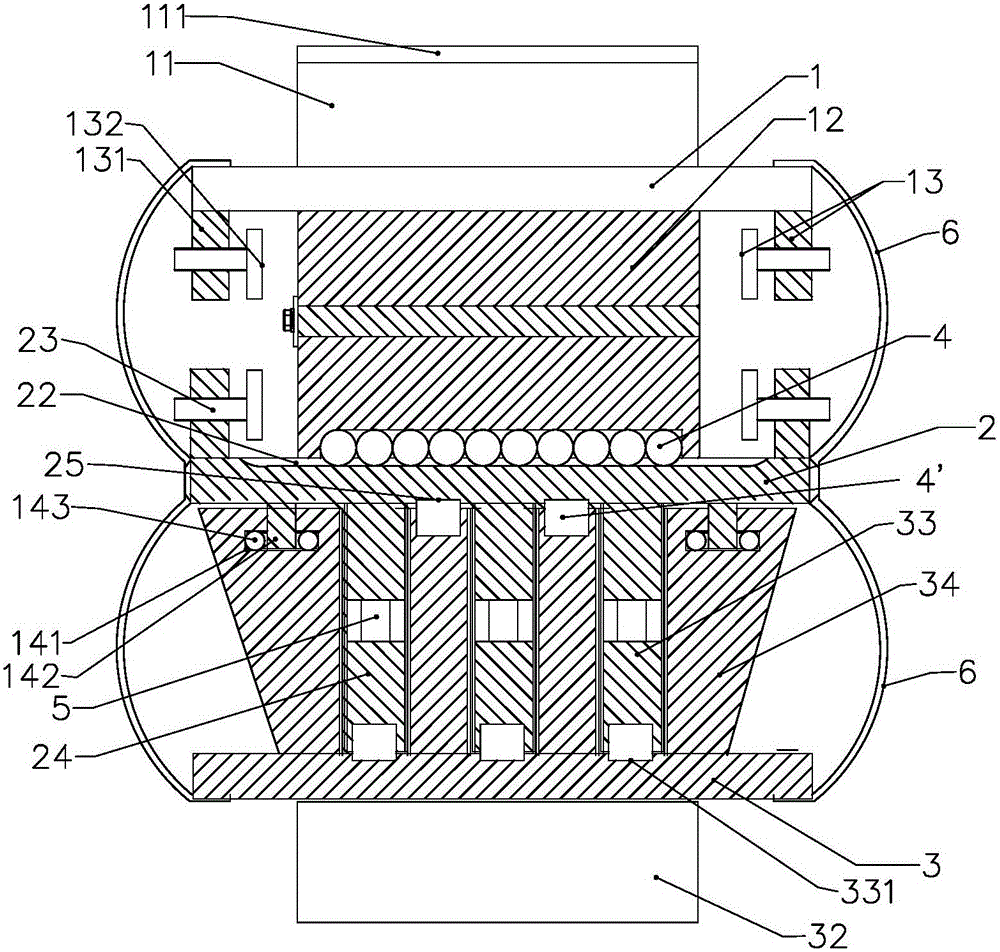

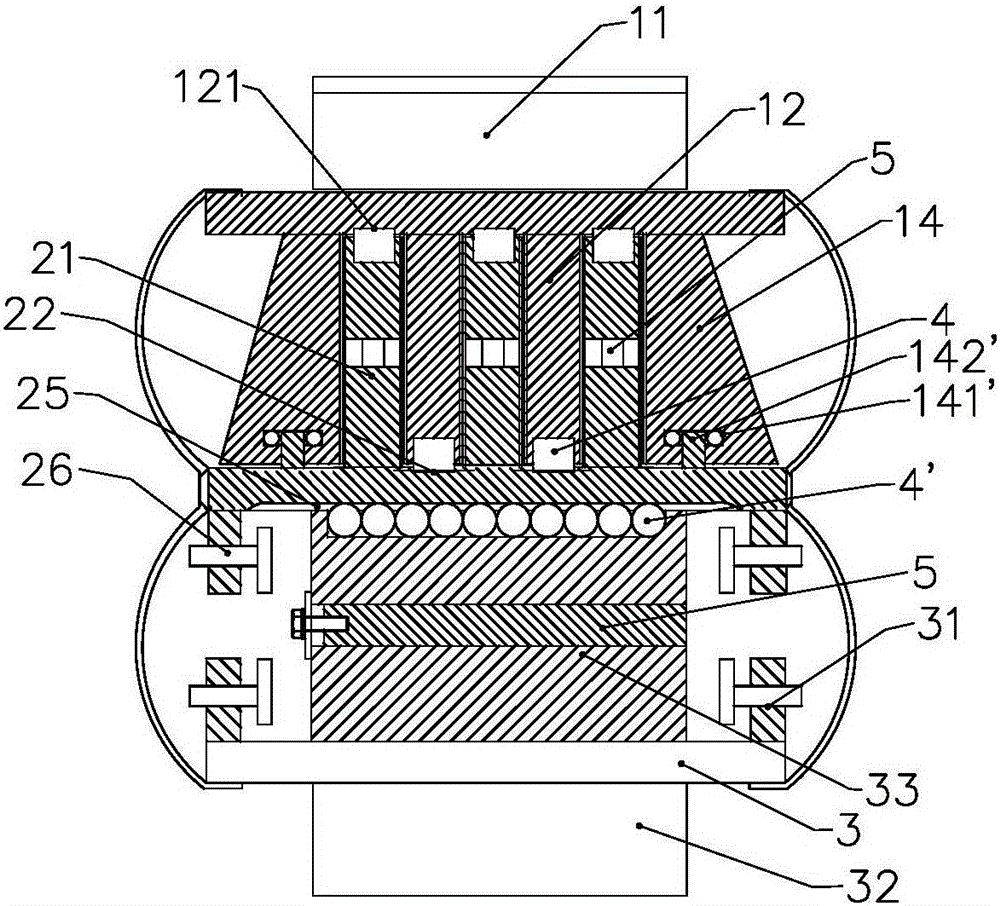

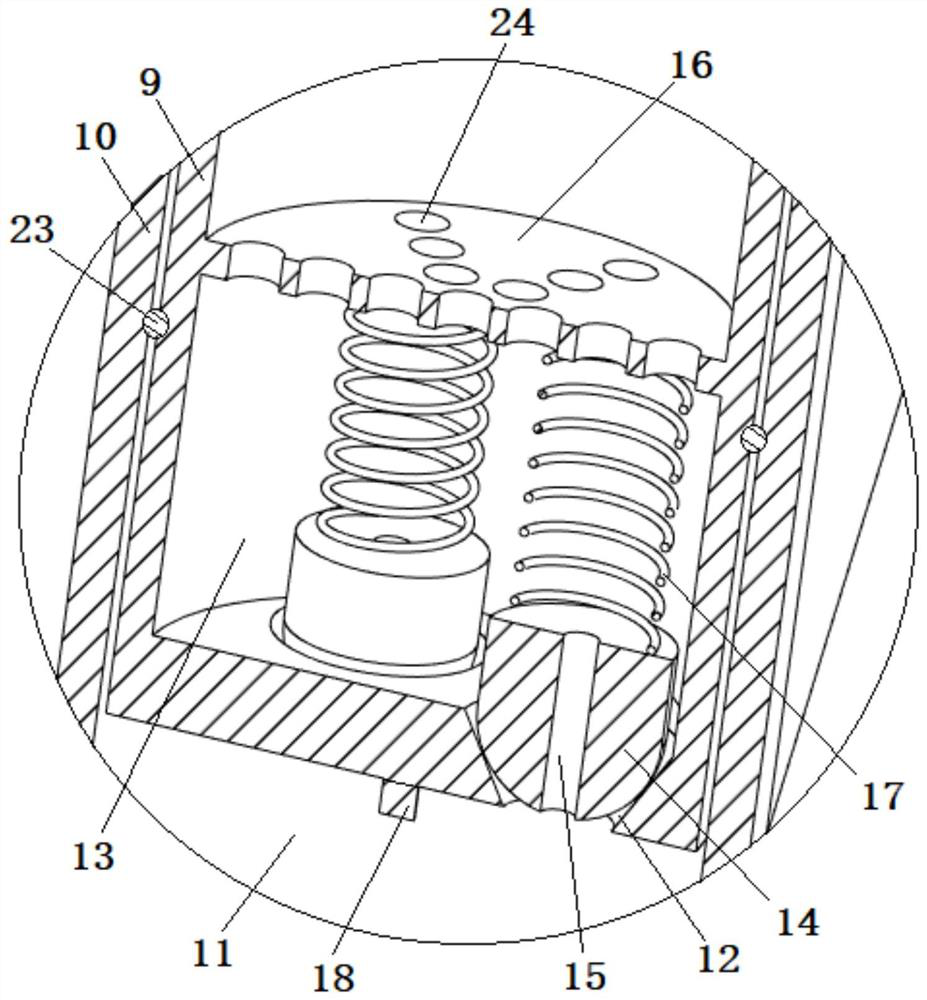

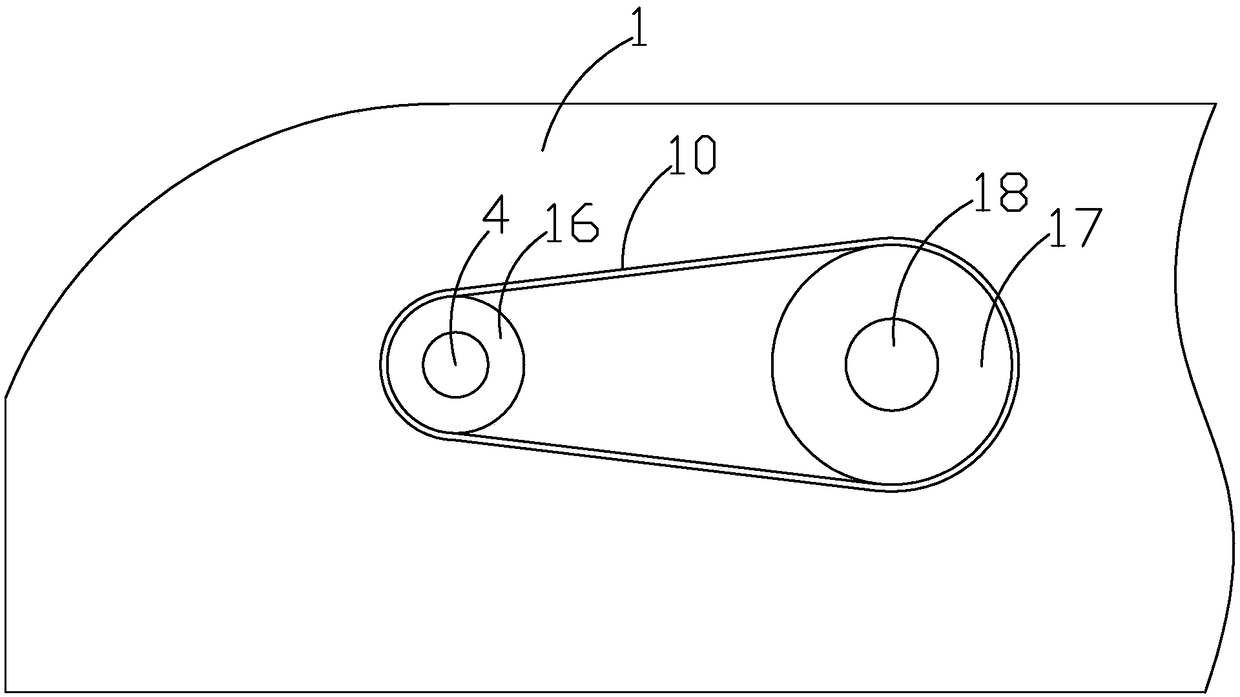

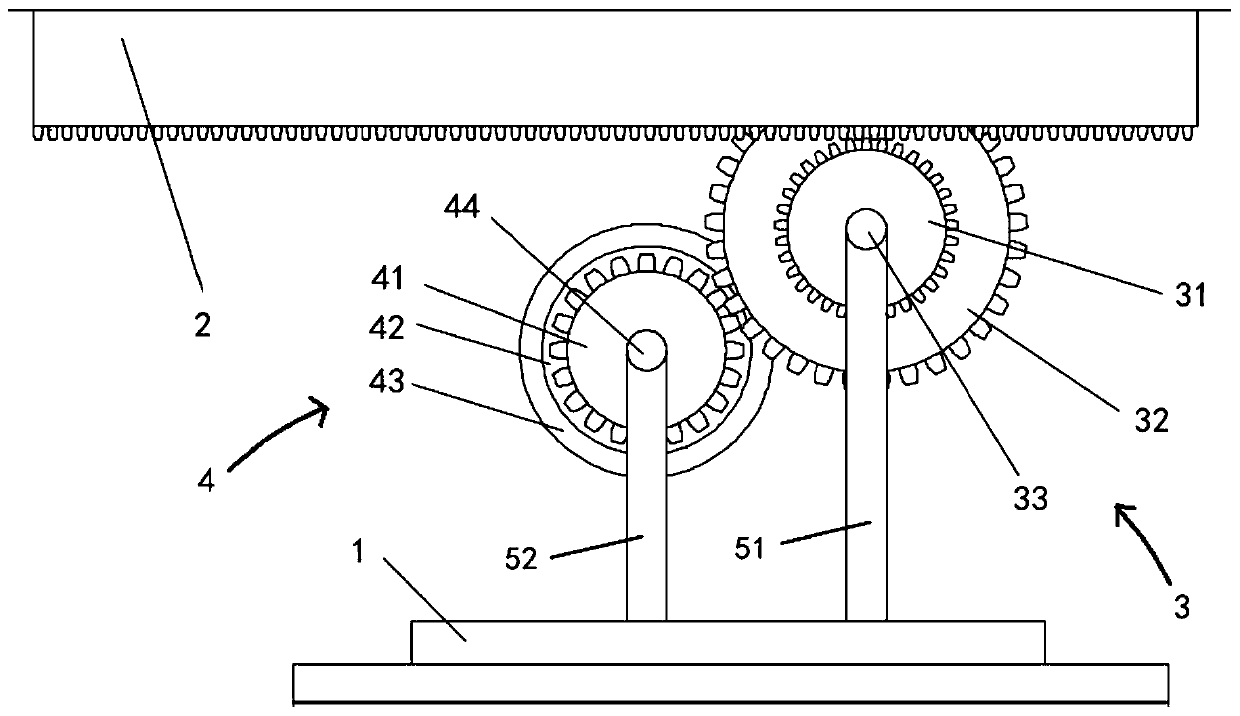

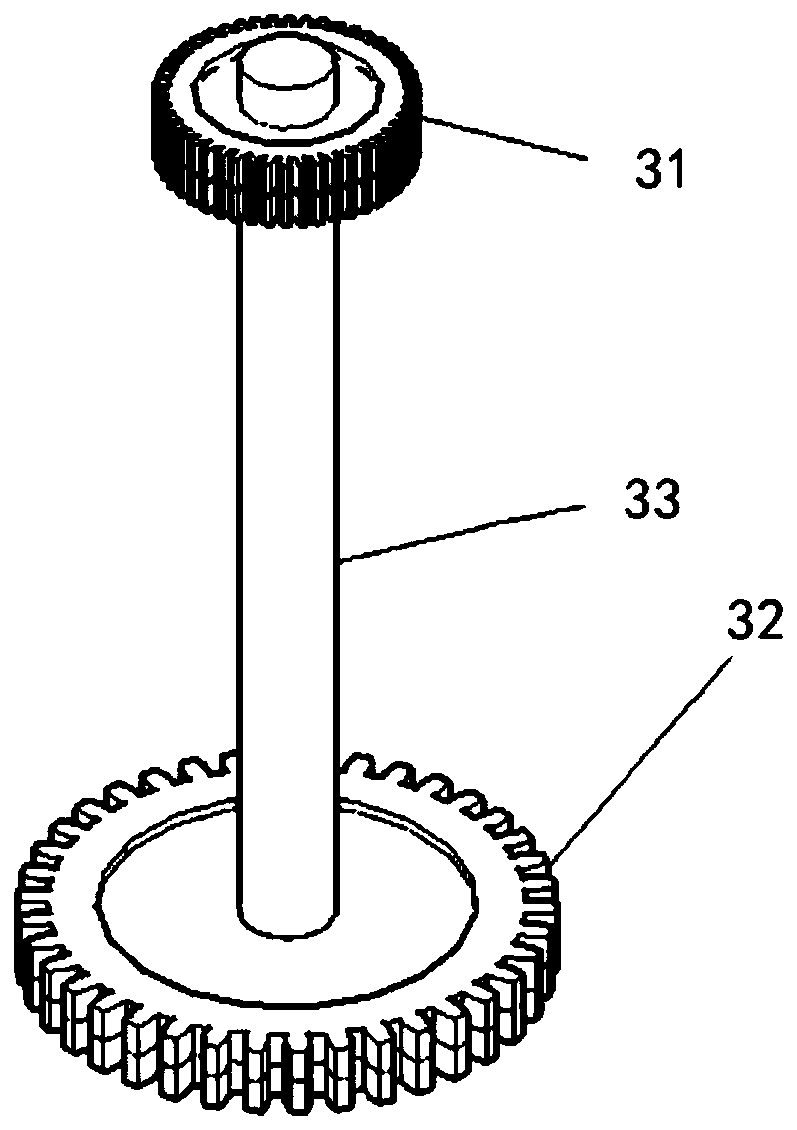

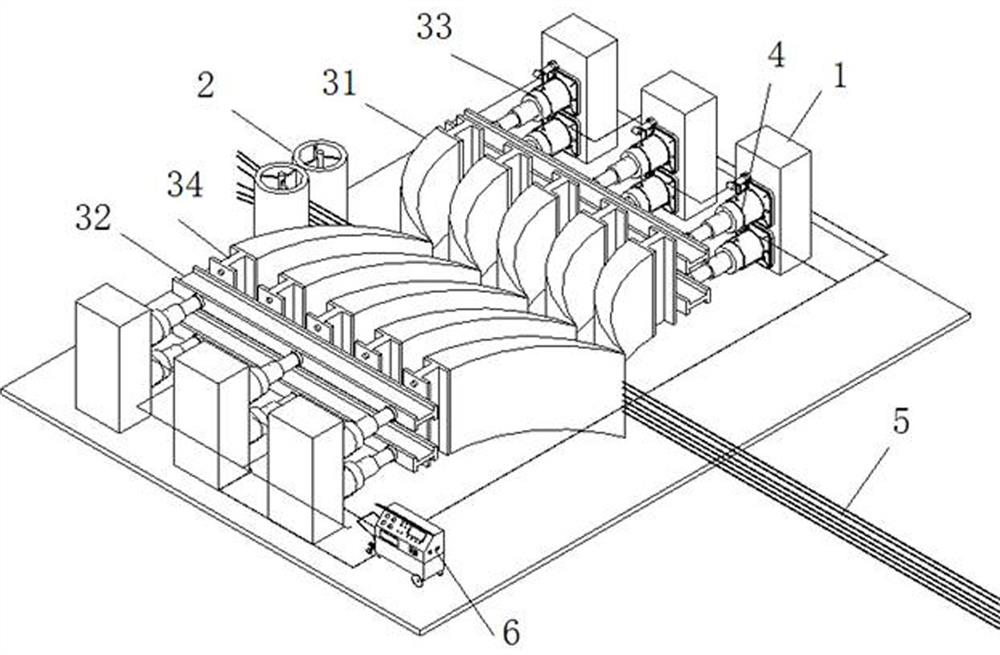

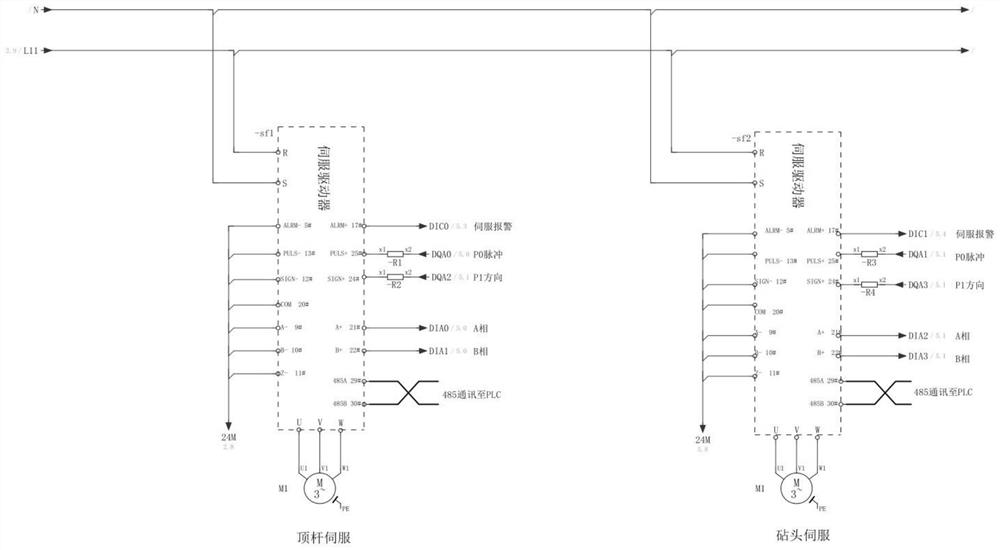

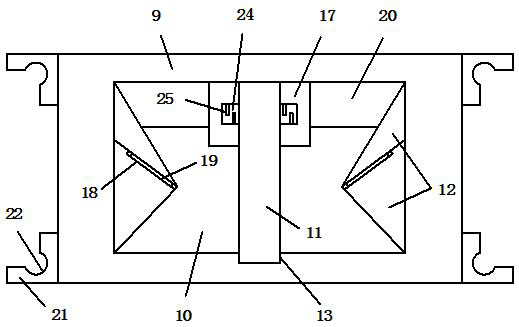

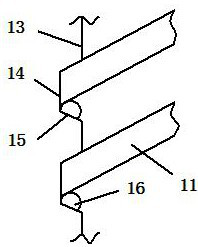

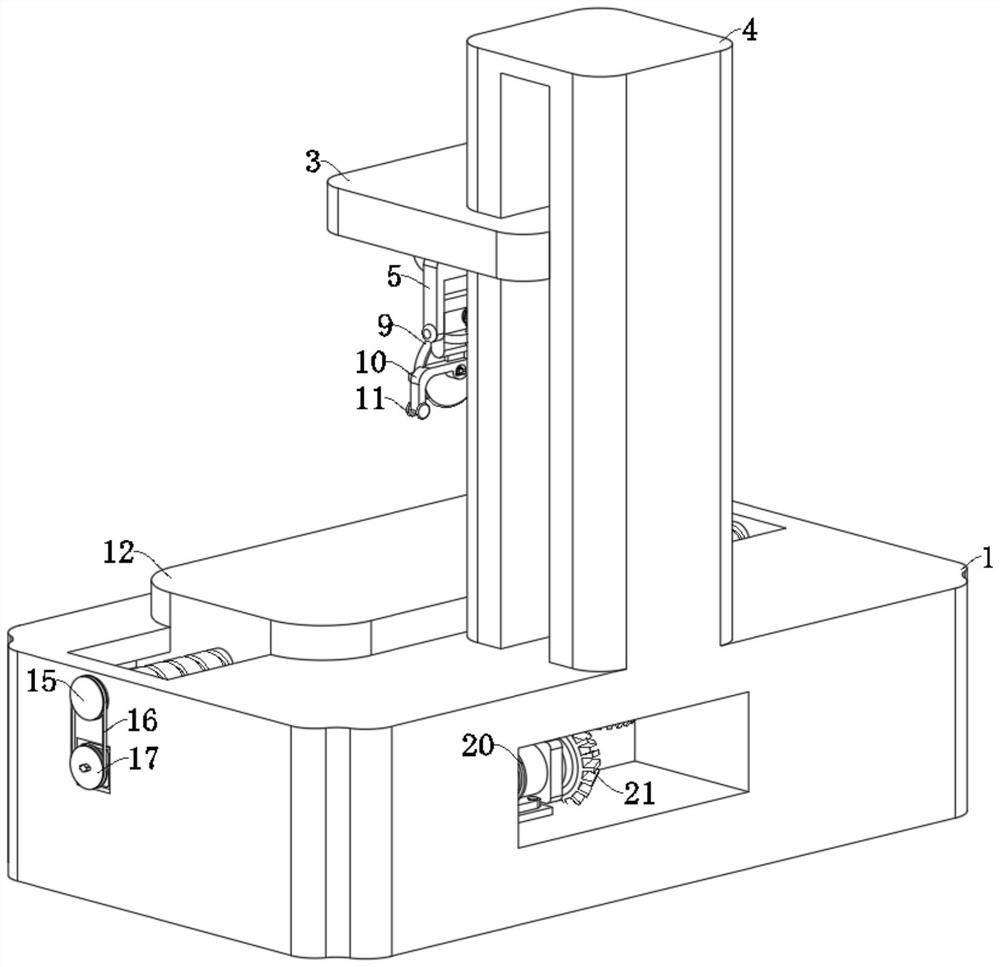

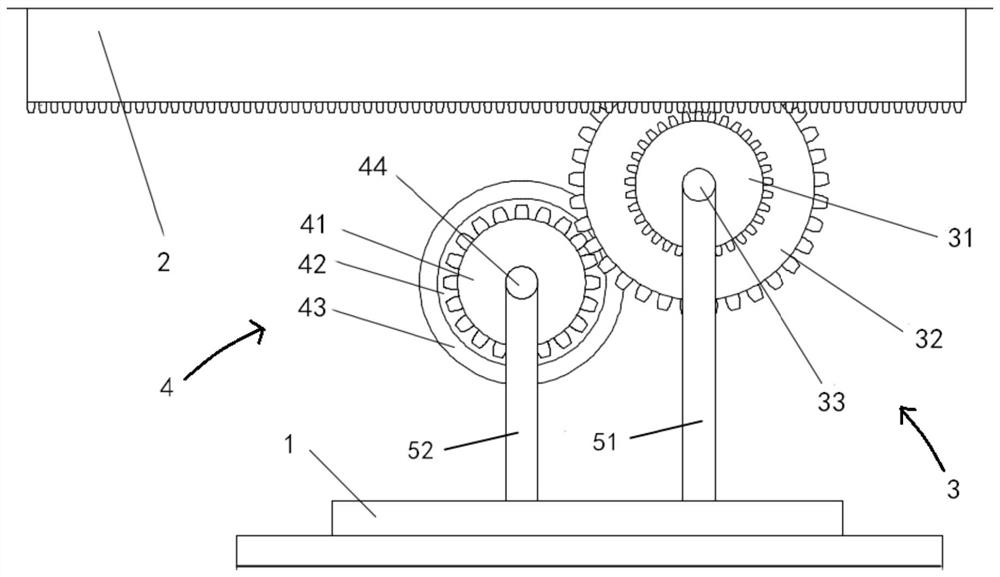

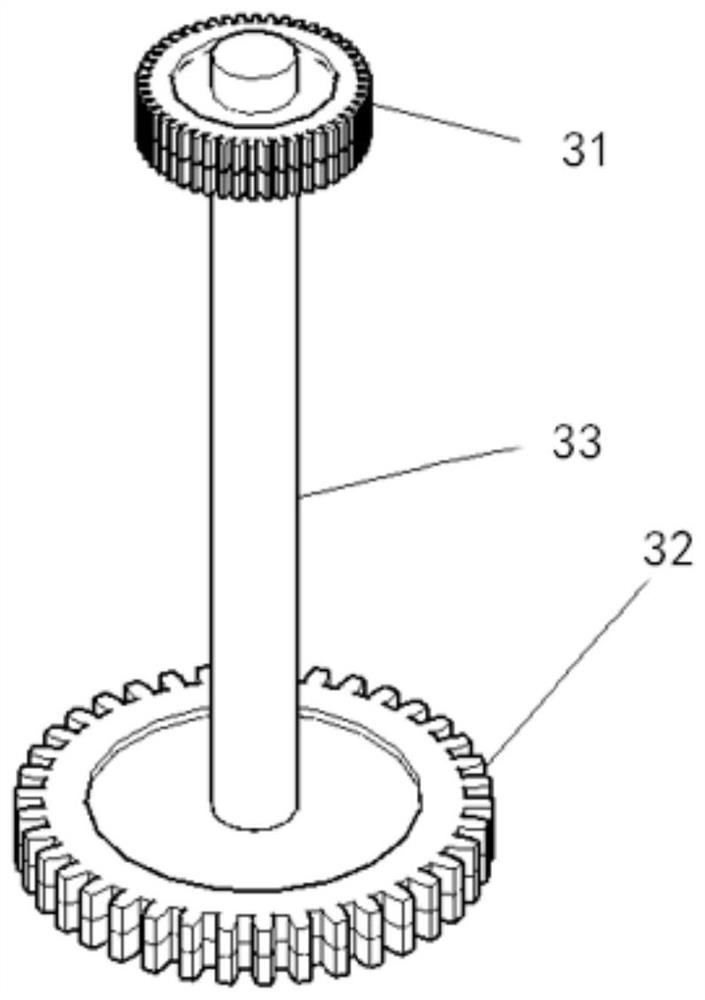

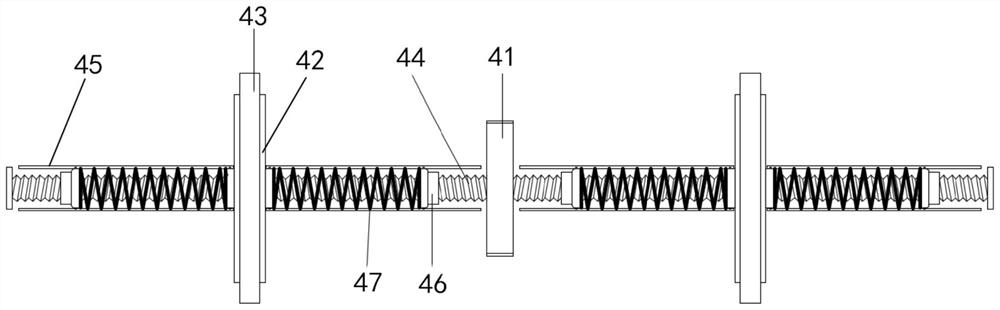

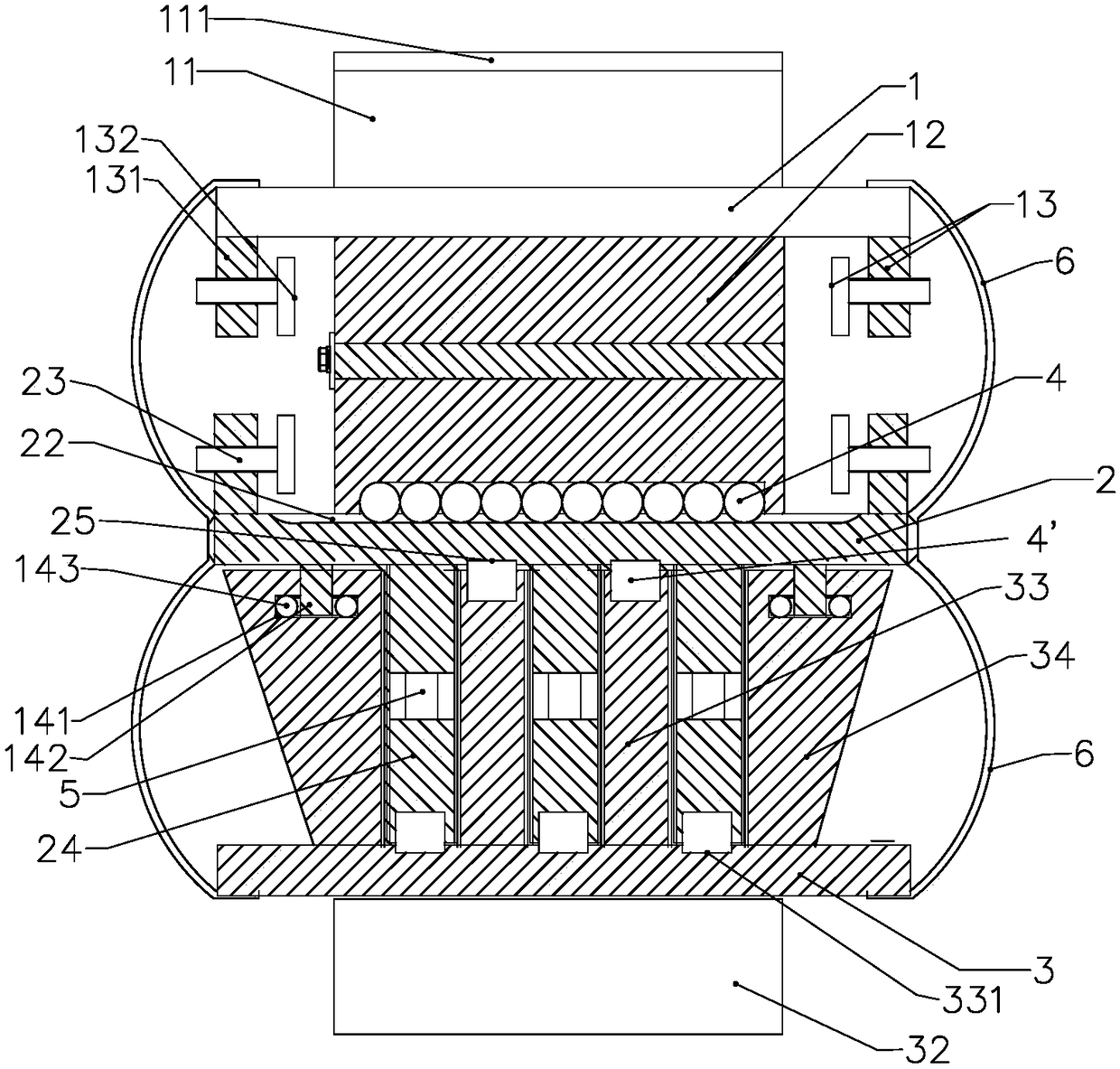

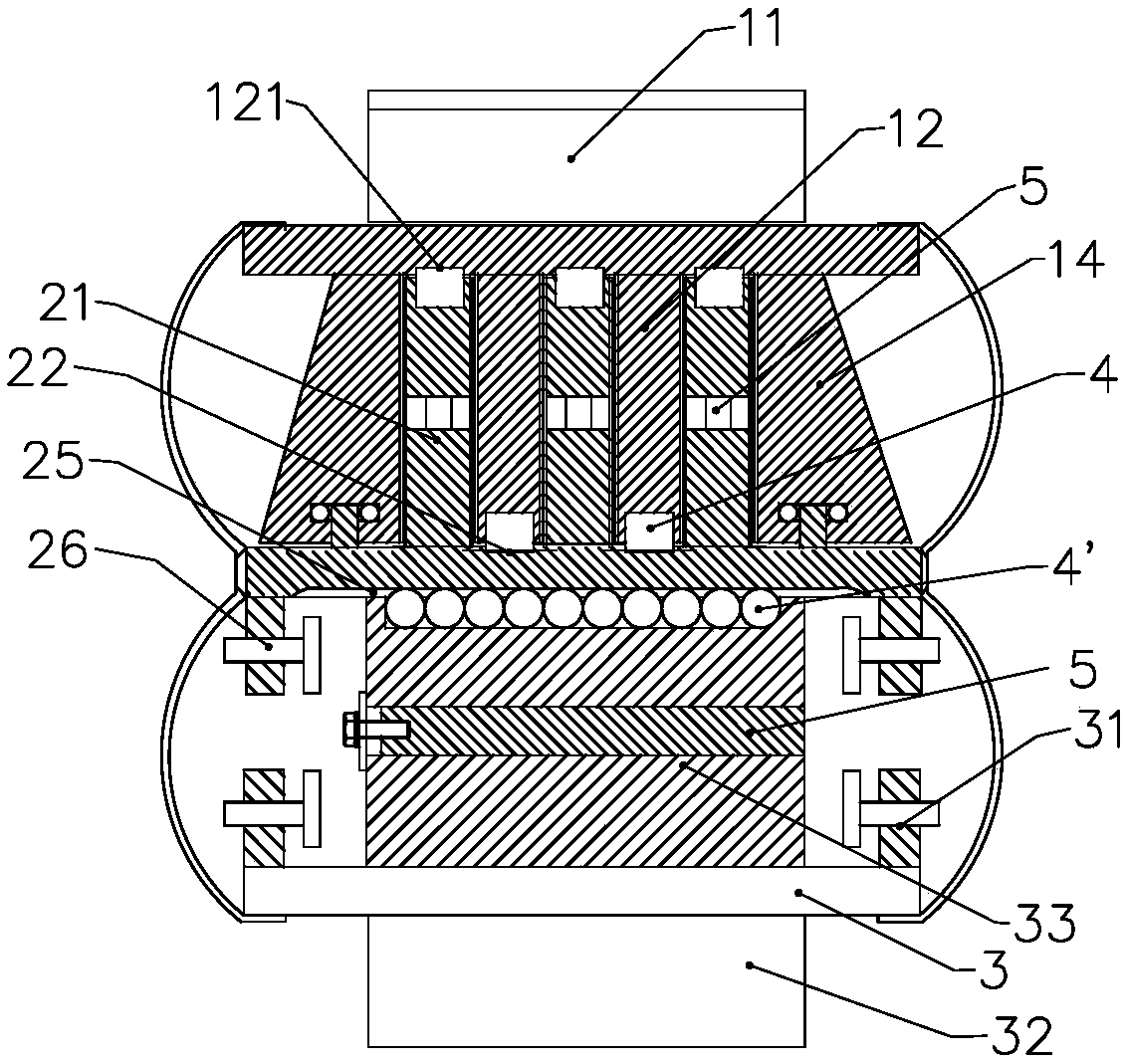

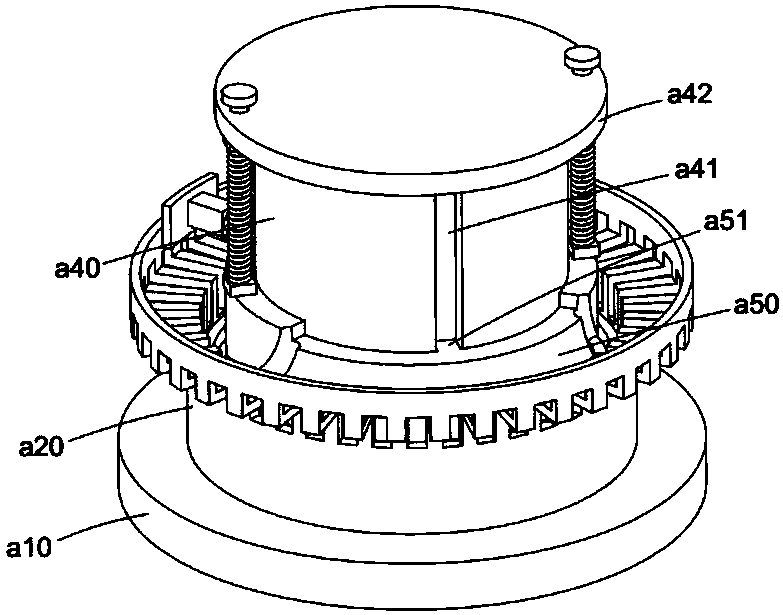

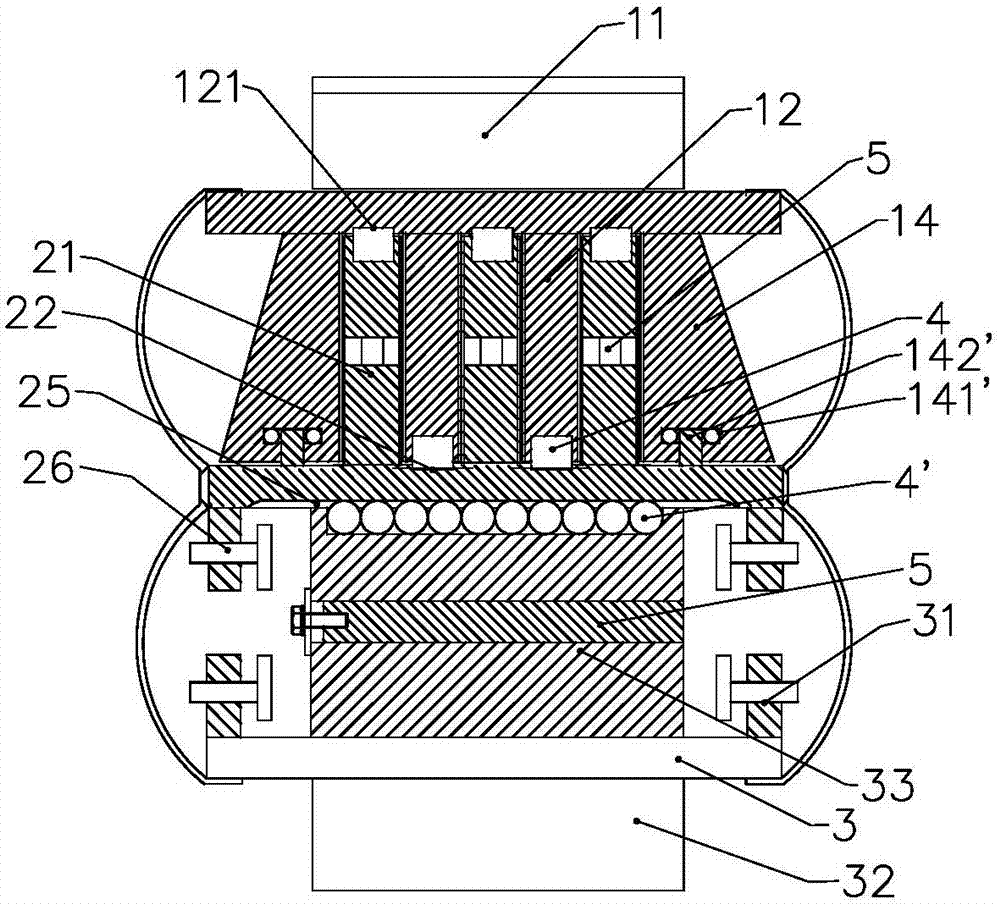

Self-adaptive friction energy consuming and vibration reducing device for bridge beam structure

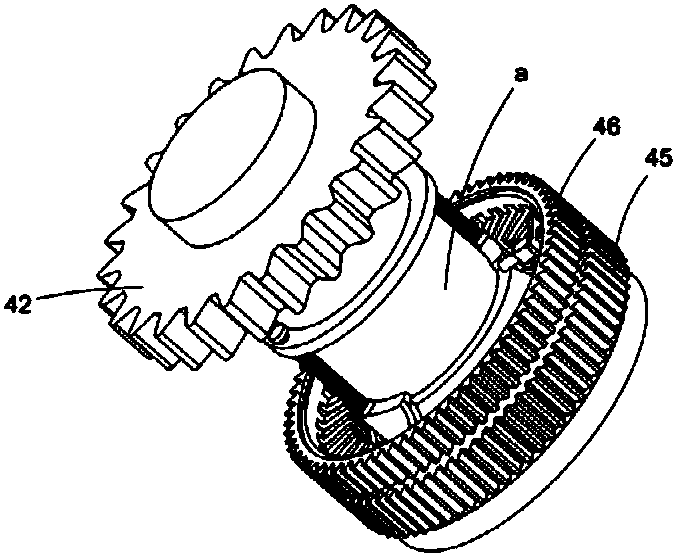

ActiveCN111306241AGood energy dissipation and vibration reductionPrevent mutual collision and falling beamsNon-rotating vibration suppressionGearingPhysicsEngineering

The invention discloses a self-adaptive friction energy consuming and vibration reducing device for a bridge beam structure. The self-adaptive friction energy consuming and vibration reducing device comprises a base, a displacement conversion rack, a displacement amplifying assembly and a friction energy consuming assembly. The displacement conversion rack is fixedly installed on the end portion of a bridge beam. The displacement conversion rack moves horizontally along with horizontal vibration of the bridge beam. The displacement amplifying assembly and the friction energy consuming assemblyare fixedly installed on the base. One end of the displacement amplifying assembly is in transmission connection with the displacement conversion rack, and thus the horizontal vibration of the bridgebeam is converted into rotating motion of the displacement amplifying assembly. The other end of the displacement amplifying assembly is in transmission connection with the friction energy consumingassembly, and thus while displacement of the horizontal vibration of the bridge beam is amplified indirectly, the rotating motion of the displacement amplifying assembly is conveyed to the friction energy consuming assembly. By means of friction energy consuming, braking of the rotating motion of the friction energy consuming assembly can be achieved, effective braking is obtained under heat energy consumption and dissipation generated by friction, and energy consuming and vibration reducing of the bridge beam are good.

Owner:武汉理工大设计研究院有限公司

Double-ball dynamic and static transition bridge and gyro with same

Owner:JIANGHAN UNIVERSITY

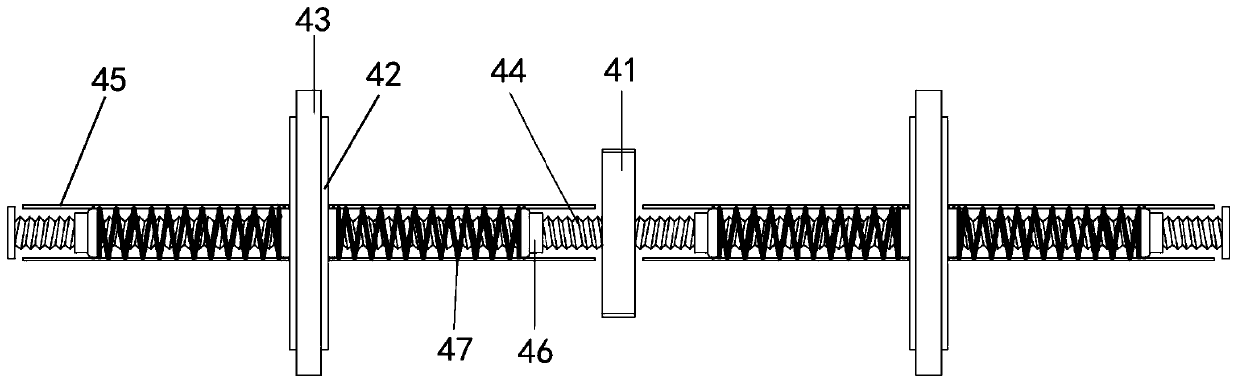

Steel strand braiding initial stress adjusting damping system

The invention discloses a steel strand braiding initial stress adjusting damping system which comprises an outer frame, a preliminary arrangement and positioning device, an initial stress adjusting device and a numerical control center, and the outer frame is used for providing a working face and a working foundation for the whole system; the preliminary arrangement and positioning device is arranged at the starting end of the traction movement direction of steel strands, the multiple steel strands enter the initial stress adjusting area from the preliminary arrangement and positioning device, and preliminary arrangement and positioning are conducted on the steel strands; the initial stress adjusting device is arranged in the initial stress adjusting area and comprises a rubber valve assembly, a fixed beam and a hydraulic jack, the two ends of the rubber valve assembly are fixedly connected with one side of the fixed beam, and the other side of the fixed beam is connected with the hydraulic jack so that pressure can be output through the hydraulic jack; a stress sensor is arranged at the end part of the hydraulic jack; and the numerical control center is respectively in signal connection with the hydraulic jack and the stress sensor.

Owner:中国建筑土木建设有限公司 +1

Simulation test device for friction resistance of braided surface

InactiveCN105115843BHigh precisionFriction adjustmentInvestigating abrasion/wear resistanceFriction effectEngineering

The friction testing device for the friction resistance of the braided fabric surface of the present invention belongs to the friction testing device with simulated actual use friction force in the working state. The horizontal long hole and the longitudinal long hole on the surface of the rack platform are perpendicular to each other; the horizontal long hole is provided with a loading plate, and the longitudinal long hole is provided with a standard brush; the standard brush generates a curved trajectory on the loading plate; The rolling ball of the "door" frame presses the standard brush to generate friction on the loading plate. Each position of the object to be tested is rubbed with the same effect; when rubbing, the friction force changes, and the friction force can be adjusted at any time.

Owner:SICHUAN ENTRY EXIT INSPECTION & QUARANTINE BUREAU INSPECTION & QUARANTINE TECHN CENT

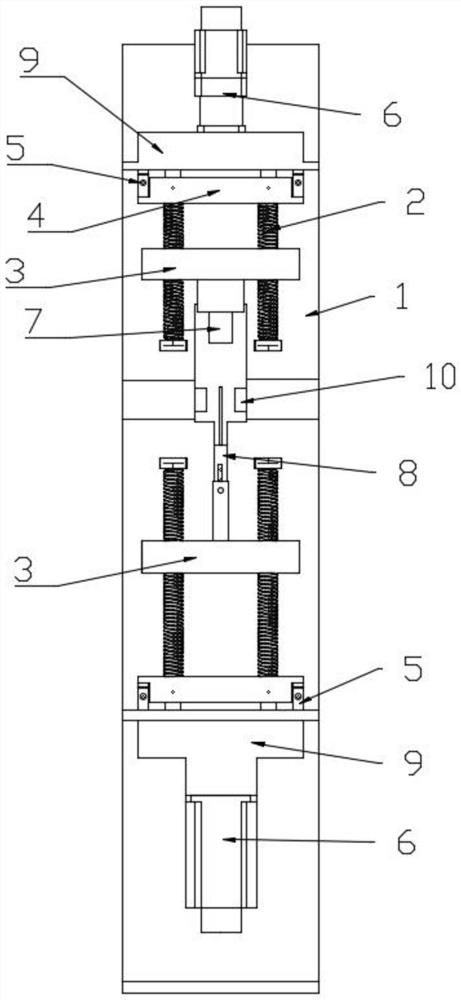

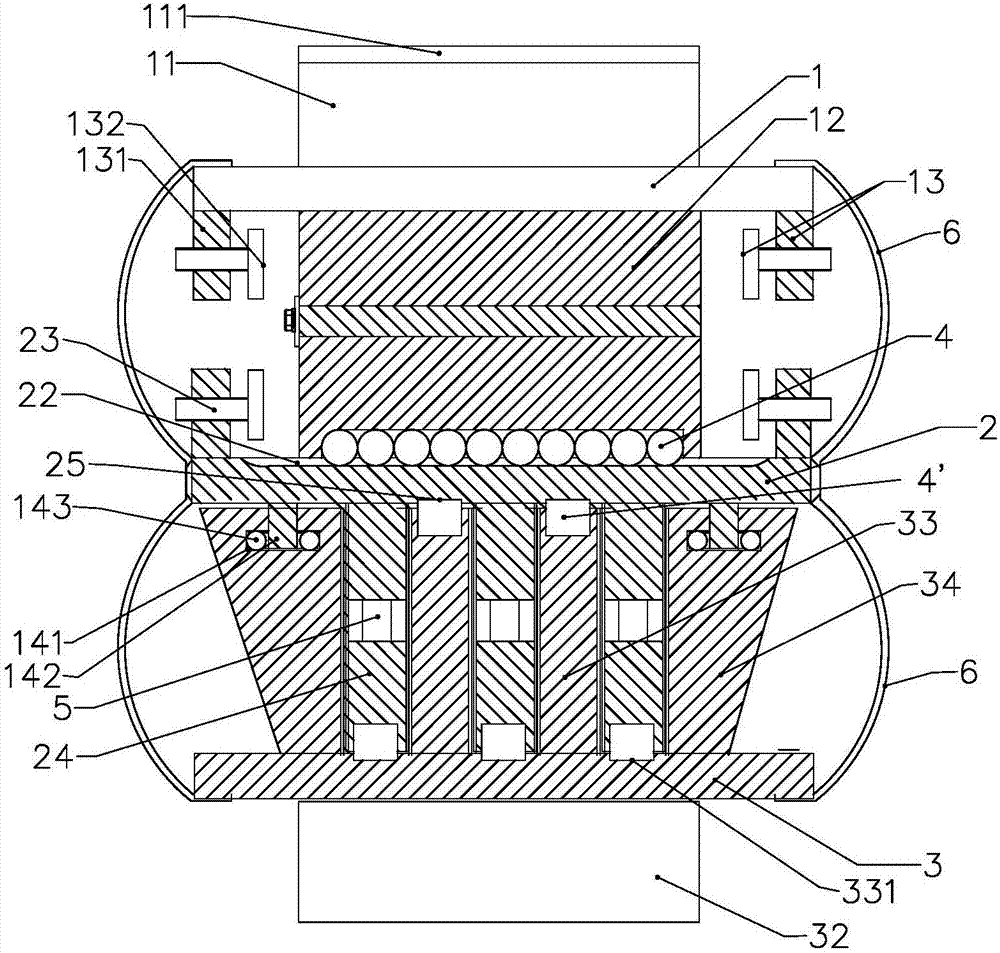

Full-servo electric upsetting machine and electric upsetting forming method

ActiveCN112024802BGuaranteed uptimeAvoid the problem of poor tilt stabilityForging press detailsForging press drivesEngineeringBar stock

The invention relates to a full-servo electric upsetting machine and an electric upsetting forming method, comprising a frame, an anvil drive mechanism is installed on the frame above the bar clamping module, and a frame below the bar clamping module is installed on the frame. Install the upsetting drive mechanism. The upsetting drive mechanism includes a slider, a pressure plate, and a transmission assembly. The transmission assembly is installed on the frame. The pressure plate is located between the slider and the transmission assembly and is rotatably connected with the lead screw. Two pressure sensors are fixed between the pressing plate and the transmission assembly, and the two pressure sensors are respectively located at two ends of the bottom of the pressing plate. In the present invention, pressure sensors are respectively installed at both ends of the pressure plate corresponding to the anvil head, so that the pressure of the forming position formed by the anvil head and the bar can be detected in real time, so that the upward movement speed of the ejector rod can be adjusted to change the pressure value of the forming position, so as to ensure The temperature and pressure required for upsetting are within the preset temperature and pressure to ensure the upsetting effect.

Owner:TIANJIN PENGHU TECH

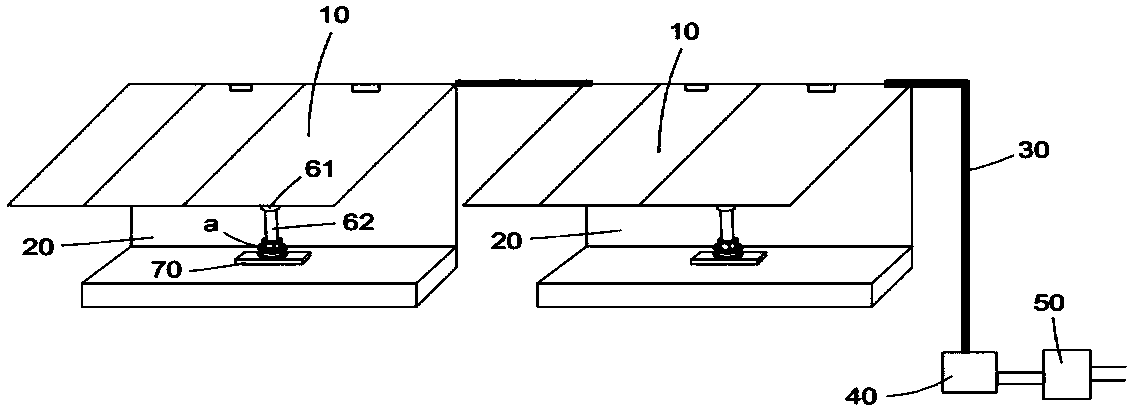

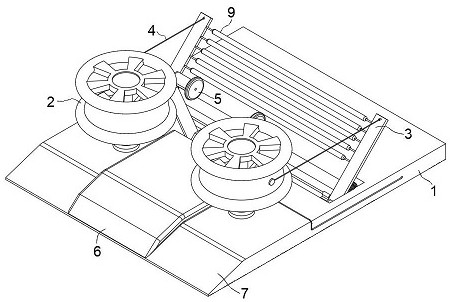

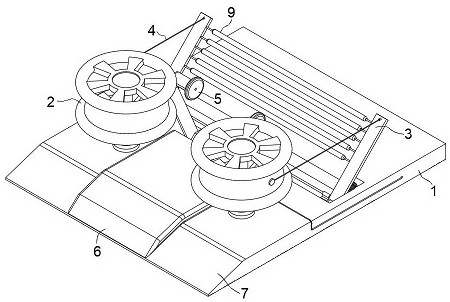

Single dimension tracking based snow-proof solar photovoltaic power generation device

InactiveCN107565896AFriction adjustmentAdjustable rotation anglePhotovoltaic supportsSolar heating energyEngineeringElectric power

The invention discloses a single dimension tracking based snow-proof solar photovoltaic power generation device. The device includes a solar photovoltaic assembly, a fixed support, a stroke adjustingdevice, a power output line, a combiner box and an inversion device. One side edge of the solar photovoltaic assembly is hinged to the fixed support while the other side edge is connected with the stroke adjusting device. The stroke adjusting device includes a thread sleeve, a thread rod and a transmission device. The top end of the thread sleeve is hinged to the solar photovoltaic assembly. The bottom end of the thread sleeve is threaded with the top end of the thread rod. The bottom end of the thread rod is mounted on a rotary shaft. A plate-shaped base is hinged to the fixed support. By adopting the above scheme, the stroke adjusting device adjusts the included angle between the solar photovoltaic assembly and the horizontal plane, so that the solar photovoltaic power generation efficiency is improved. When snowing, a board of the photovoltaic assembly can be adjusted to be perpendicular to the horizontal plane, so that snow accumulation on the board of the photovoltaic assembly isavoided.

Owner:DONGGUAN TIANHE ELECTROMECHANICAL DEV CO LTD

Limb training recovery device for fracture patient

ActiveCN111700771AFast recoveryImprove lateral support strengthChiropractic devicesRotational axisEngineering

The invention discloses a limb training recovery device for a fracture patient. The limb training recovery device comprises a frame body, an air cylinder is installed on the frame body through a rotating shaft, a locking buckle is arranged at one end of the rotating shaft, a limb fixing plate is connected to the top end of a piston of the air cylinder through a buffering cushion, and a hinge is arranged in the middle of the limb fixing plate; a plurality of binding belts are arranged on the edge of the limb fixing plate; the buffering cushion comprises a rubber body, a cavity is formed in therubber body, a spring is longitudinally installed in the center of the cavity, and a plurality of rubber sheets making contact with one another are arranged on the edge of the cavity. Defects in the prior art can be overcome, and vibration is well absorbed and buffered while the cost is controlled.

Owner:南京捷科生物科技有限公司

High-flexibility numerical control cylindrical grinding machine

PendingCN114770244ASurfaceImprove machining accuracyGrinding wheel securing apparatusRevolution surface grinding machinesNumerical controlEngineering

The invention discloses a high-flexibility numerical control cylindrical grinding machine, and relates to the technical field of article processing and grinding equipment, the high-flexibility numerical control cylindrical grinding machine comprises a machine tool with a support column at the top, a lifting mechanism arranged on the support column, and a direction adjusting mechanism arranged on the lifting mechanism, the direction adjusting mechanism comprises a driving part, a fixed base plate, a rotating shaft, a rotating plate and a driven toothed bar, the fixed base plate is arranged on the lifting mechanism, and the rotating shaft is rotationally connected to the fixed base plate. According to the high-flexibility numerical control cylindrical grinding machine, the direction of the grinding wheel can be adjusted through the use of the direction adjusting mechanism, and the grinding wheel can be adjusted when positions such as an arc surface and a corner of a ground object appear, so that the grinding wheel is more attached to the surface of the object, and the machining precision is greatly improved; the position of the grinding wheel can be sensed in the advancing direction, so that the overall use is more flexible, the structure is stable and reliable, meanwhile, the structure is simple, manufacturing is easy, the grinding advantage is highlighted, and the grinding efficiency is improved.

Owner:厦门创云精智机械设备股份有限公司

Adaptive Friction Energy Dissipation and Vibration Reduction Device for Bridge Structures

ActiveCN111306241BGood energy dissipation and vibration reductionFriction adjustmentNon-rotating vibration suppressionGearingBridge deckEngineering

Owner:武汉理工大设计研究院有限公司

Anti-landslide device for new energy vehicle

InactiveCN113968200AOffset rolling degrees of freedomFriction adjustmentPortable braking systemNew energyStructural engineering

The invention relates to the technical field of new energy automobiles, in particular to an anti-landslide device for a new energy vehicle. The anti-landslide device for the new energy vehicle comprises a slope plate, the front end face of the slope plate is provided with a transition arc face, and a plurality of integrally-formed trapezoidal anti-slip edges are embedded in the bottom of the slope plate; and a slope plate which is provided with a through cavity, the two tire screwing parts are symmetrically located on the slope plate, the slope face abutting parts are located in the through cavity formed in the slope plate, each slope face abutting part comprises a pressing plate, the pressing plates are located in the through cavity, and a plurality of ground thorns arranged in a square matrix mode are fixedly embedded in the lower surfaces of the pressing plates. According to the anti-landslide device for the new energy automobile, the self-locking effect on automobile tires can be achieved, and the friction force between the slope plate and the ramp can be enhanced.

Owner:浙江浦数科技有限公司

Anti-overturning high-voltage transmission line tower

ActiveCN106168078BChange vibration frequencyChange the vibration amplitudeTowersDamping functionEngineering

The invention discloses an anti-overturning high-tension transmission line iron tower used for solving the problem that an iron tower is prone to overturning. The iron tower comprises an iron tower body and a transition part, and the middle portions of the iron tower body are disconnected and movably connected through the transition part, with buffering and damping functions, on the corner. The transition part comprises a first plate, a second plate and a third plate which are arranged in parallel from top to bottom, wherein the portion between the first plate and the second plate and the portion between the second plate and the third plate are each designed to be a buffering structure with a brake structure. As the lower middle portions of the iron tower are disconnected and provided with the transition part, the portion prone to bending in the iron tower shifts in the horizontal direction in the presence of the transition part, in the shifting process, vibrating energy is consumed through effective friction, vibrating frequency and amplitude are changed, bending is avoided, the method of increasing the use amount of profile steel to improve strength traditionally is changed, and the seismic resistance is improved by 40% without changing the steel amount.

Owner:连云港强连铁塔制造有限公司

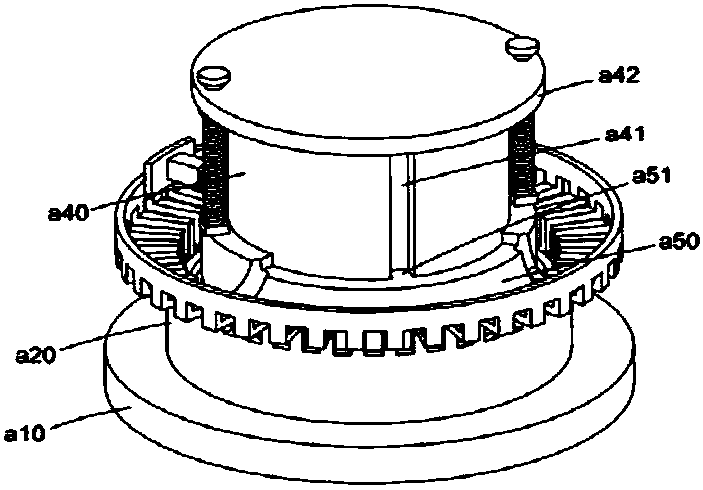

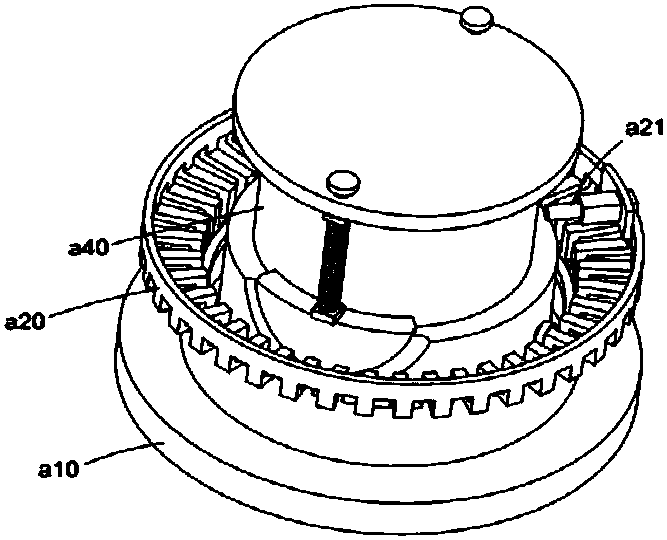

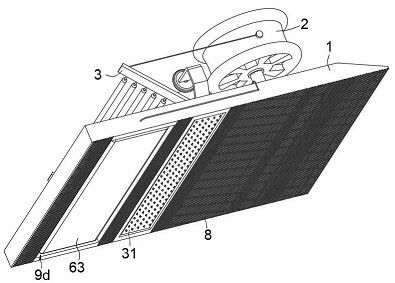

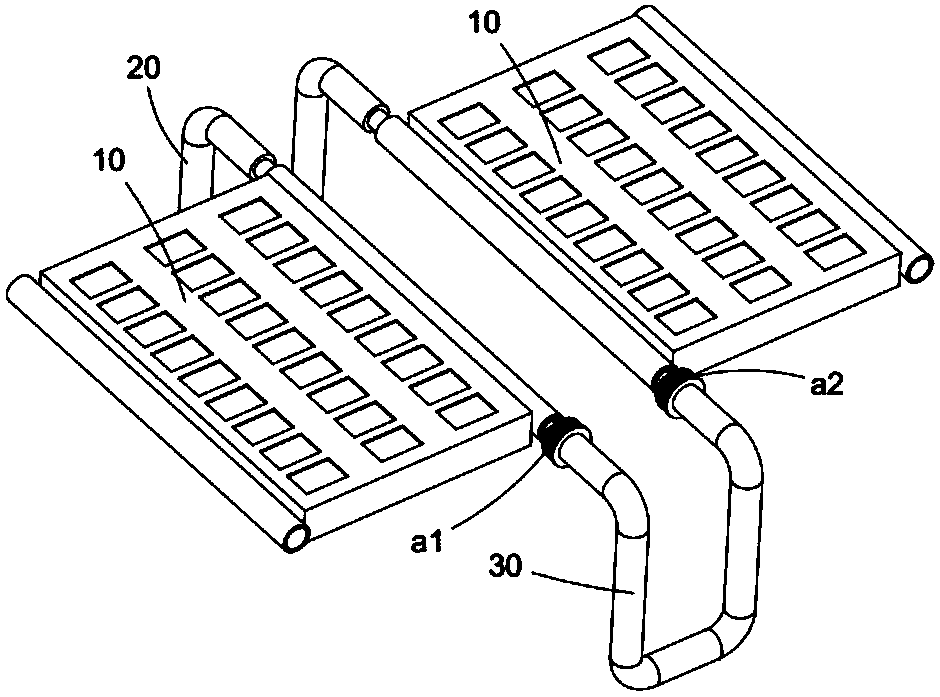

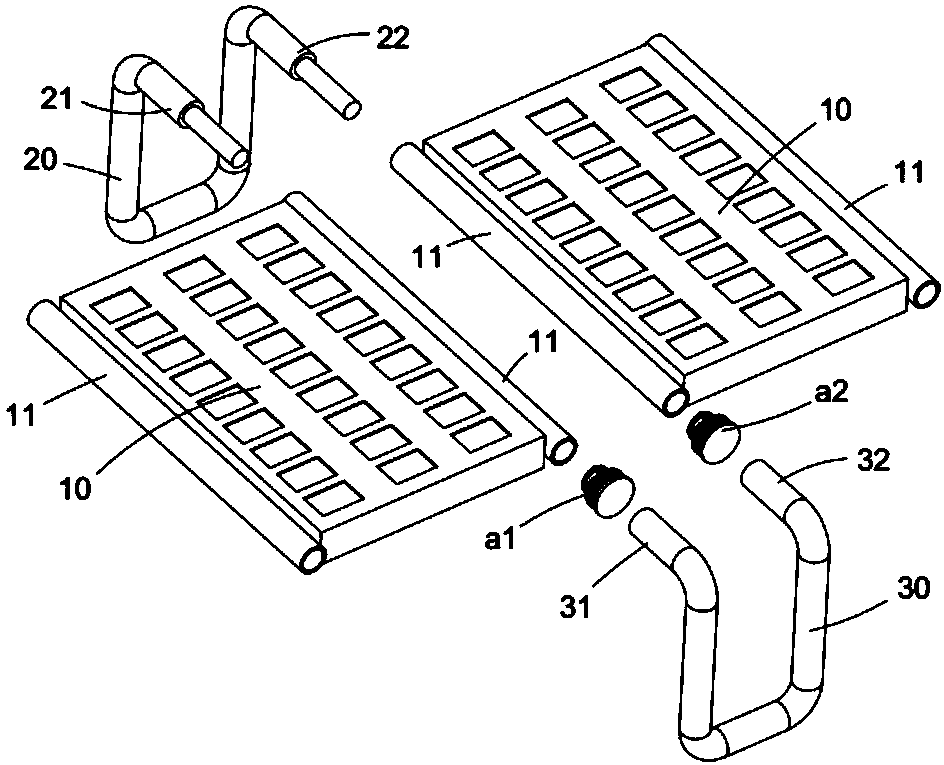

Solar photovoltaic module array structure

InactiveCN107800362AFriction adjustmentAdjustable rotation anglePhotovoltaic supportsPhotovoltaic energy generationEngineeringSunlight

The invention discloses a solar photovoltaic module array structure. The solar photovoltaic module array structure comprises a solar photovoltaic module and a support, wherein the support comprises afront leg and a rear leg, a frame of the solar photovoltaic module is provided with a side rod, the front leg is pivoted with the side rod, the rear leg is connected with the side rod via a transmission combination body, the transmission combination body comprises a rotation cylinder and a rotation shaft which are in linkage, the rotation cylinder is driven, the rotation shaft rotates by an accurate angle, the side rod and the solar photovoltaic module where the side rod is located are driven to rotate by an accurate angle by the rotation shaft, so that the solar photovoltaic module efficiently receives solar energy.

Owner:DONGGUAN TIANHE ELECTROMECHANICAL DEV CO LTD

Anti-landslide device for new energy automobile

InactiveCN114212060AOffset rolling degrees of freedomFriction adjustmentPortable braking systemNew energyStructural engineering

The invention relates to the technical field of new energy automobiles, in particular to an anti-landslide device for a new energy automobile. The anti-landslide device for the new energy automobile comprises a slope plate, the front end face of the slope plate is provided with a transition arc face, and a plurality of integrally-formed trapezoidal anti-slip edges are embedded in the bottom of the slope plate; the slope plate is provided with a through cavity, the two tire screwing parts are symmetrically located on the slope plate, the slope face abutting parts are located in the through cavity formed in the slope plate, each slope face abutting part comprises a pressing plate, the pressing plates are located in the through cavity, and a plurality of ground thorns arranged in a square matrix mode are fixedly embedded in the lower surfaces of the pressing plates. According to the anti-landslide device for the new energy automobile, the self-locking effect on automobile tires can be achieved, and the friction force between the slope plate and the ramp can be enhanced.

Owner:浙江浦数科技有限公司

A limb training recovery device for patients with fractures

ActiveCN111700771BFast recoveryImprove lateral support strengthChiropractic devicesRotational axisPhysical medicine and rehabilitation

The invention discloses a limb training and recovery device for patients with fractures, which comprises a frame body. A cylinder is installed on the frame body through a rotating shaft. One end of the rotating shaft is provided with a locking buckle. The middle part of the limb fixing plate is provided with a hinge, and the edge of the limb fixing plate is provided with several restraint straps; the buffer pad includes a rubber body, and a cavity is arranged in the rubber body, and a spring is installed longitudinally in the center of the cavity, and the edge of the cavity There are several rubber sheets in contact with each other. The invention can improve the deficiencies of the prior art, and realize good absorption and buffering of vibration while controlling the cost.

Owner:宜兴捷瑞医疗生物科技有限公司

Bridge anti-overturn bearing

The invention discloses an anti-capsizing support of a bridge. The anti-capsizing support of the bridge comprises a first plate, a second plate and a third plate, wherein the first plate, the second plate and the third plate are arranged in parallel from top to bottom. Clamping grooves are formed in the two sides of a second insertion plate vertically. Each clamping groove communicates with a channel through a square hole between the clamping groove and the channel. A movable brake pad is placed in each clamping groove. A tie piece is arranged in the channel. Wedges are arranged on the two sides of the tie piece at intervals and face the same direction, and each wedge makes contact with the movable brake pad in the corresponding position. A threaded hole is formed in the end of the tie piece, and a tension bolt is installed in the threaded hole for tensioning connection. The anti-capsizing support of a bridge is of a pure mechanical structure, and long-term maintenance-free operation can be achieved; and in addition, main friction force happens to friction plates between the insertion plates, the automobile brake pads are used as the friction plates and are free of maintenance in the whole life, and the friction force of the brake pads can be adjusted conveniently through the tension bolt.

Owner:孙新迪 +11

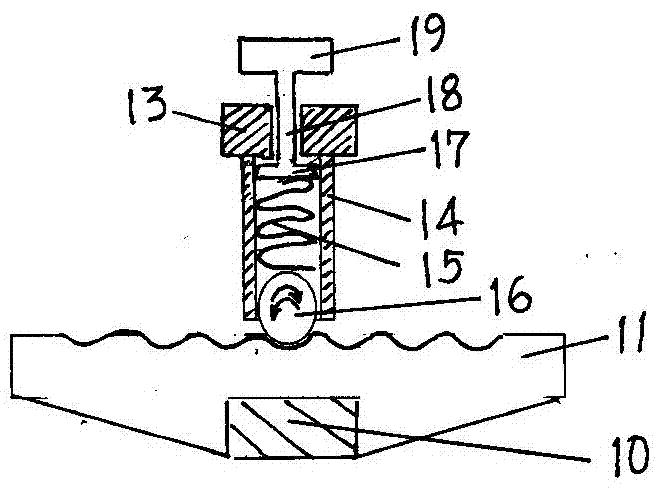

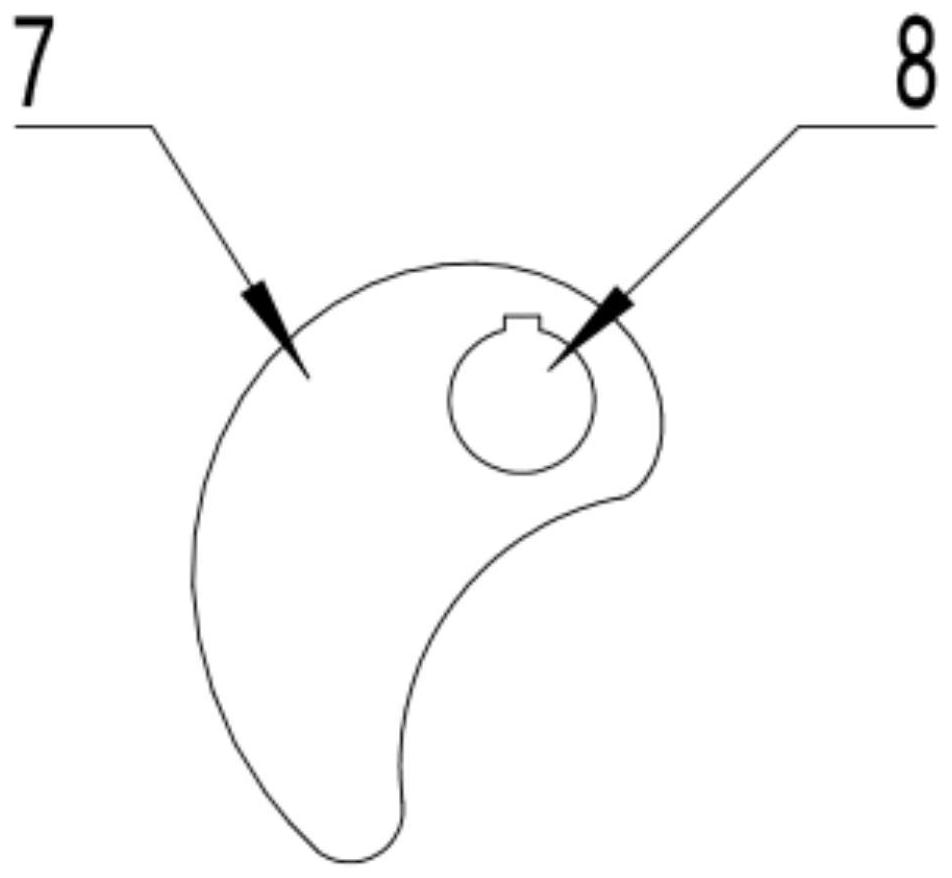

Basalt fiber disc type tension adjusting device

PendingCN112209613AFriction adjustmentEasy to go onlineGlass making apparatusCircular discProduction line

The invention discloses a basalt fiber disc type tension adjusting device, and relates to the technical field of basalt fiber processing, the basalt fiber disc type tension adjusting device comprisesa table top, a fixed disc, a movable disc, an adjuster and a driving mechanism for driving the adjuster to move along a straight line, the center of the fixed disc is connected to a fixed rod by a locking screw, the fixed rod is fixed to the table top through a fixed base and a bolt, the fixed disc and the movable disc are opposite in position, the movable disc is fixed to the end of a movable rodthrough a locking screw, the movable rod extends into a circular mounting cavity in the adjuster, and the wheel face of a rolling wheel makes contact with an irregular rotating block. And the distance between any point on the irregular rotating block and the rotating center of the irregular rotating block is gradually increased and then gradually decreased. The basalt fiber disc type tension adjusting device has the beneficial effects that the friction force between the fixed disc and the movable disc can be adjusted, and meanwhile, the adjuster can move, so that the basalt fibers are more convenient to disassemble and re-put on the production line.

Owner:贵州玄武岩新材料工程技术开发有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com