Device with a displaceable carriage and a linear guide

一种线性引导件、引导件的技术,应用在制造工具、轴和轴承、直线运动的轴承等方向,能够解决路径精度有限、妨碍精确加工、难拖板保持在特定位置等问题,达到精确移动和定位的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

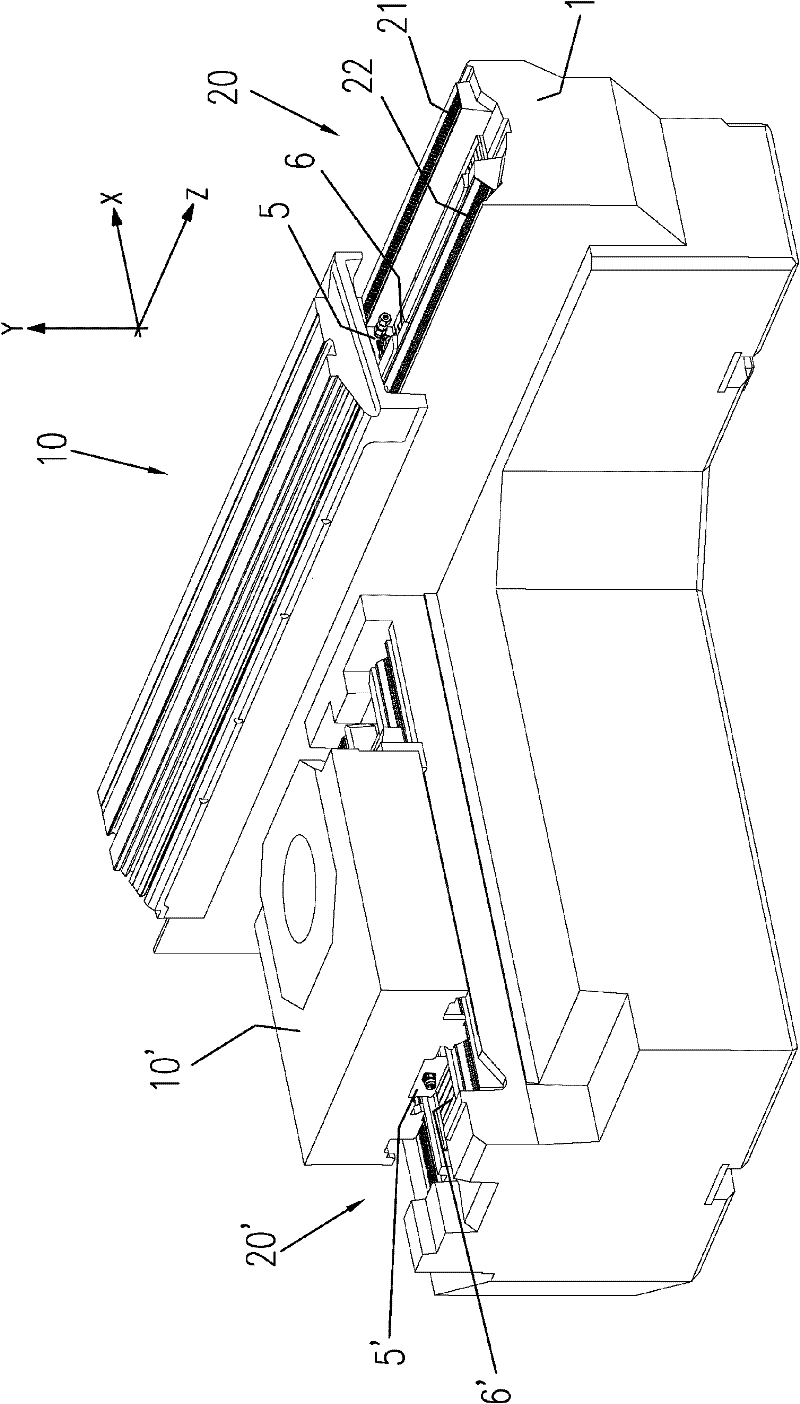

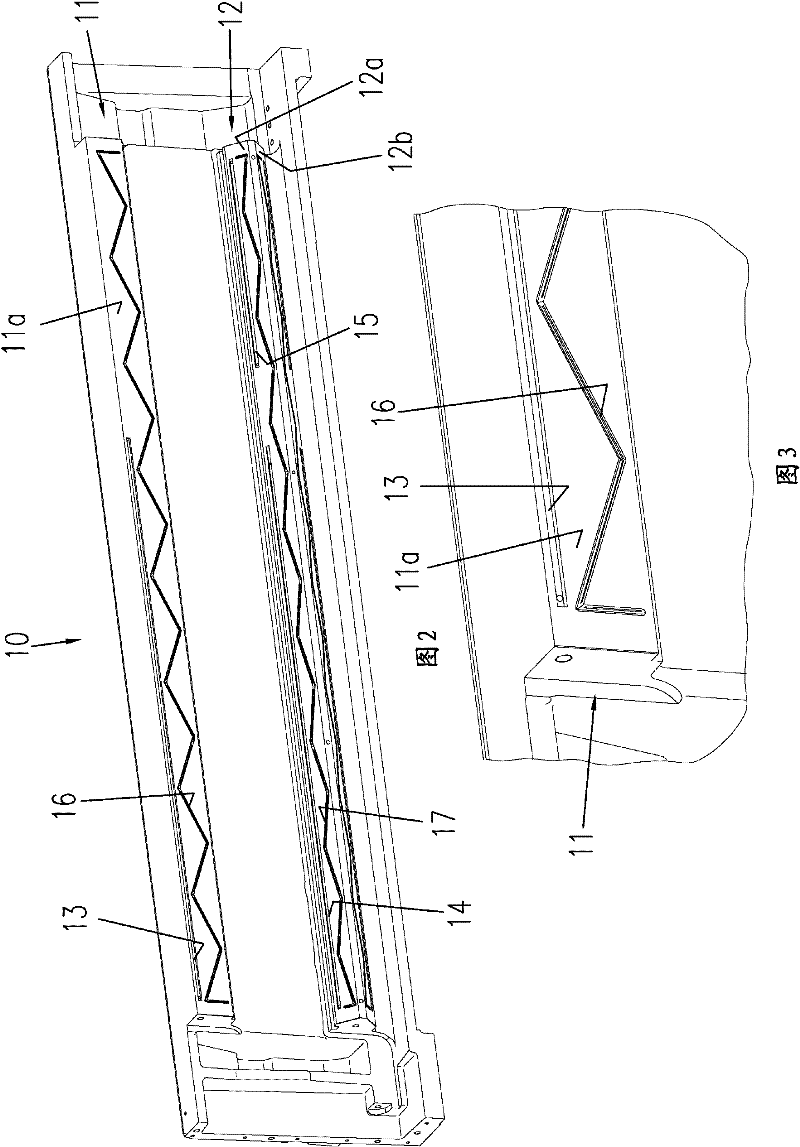

[0014] figure 1 The device is shown with a processing table 1 on which a carriage 10 is arranged. The carriage is movable along one axis, ie here the Z axis, the path of movement of which is defined by the linear guide 20 . In the present example, the linear guide 20 is implemented as a freely supported guide, ie it is not surrounded, for example in the form of figure 2 The V-flat guide shown, as figure 2 shown. Other guides are also conceivable, for example only V-shaped guides or only planar guides.

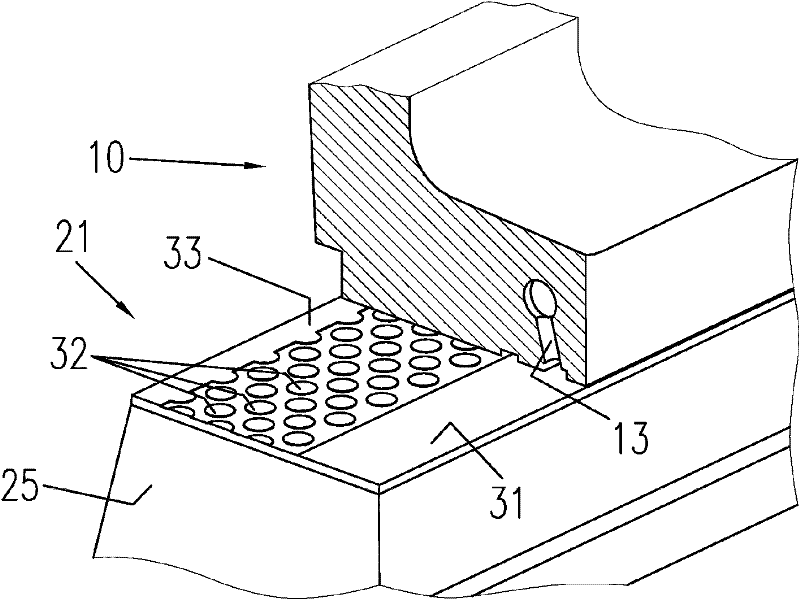

[0015] The linear guide 20 comprises two guide profiles 21 and 22 which extend in the direction of the movement axis Z. Each guide profile 21 and 22 is embodied, for example, such that it is integral with the machining table, or is attached to the machining table in the form of a separate rail. The carriage drive 5 and the carriage drive 6 for moving the carriage 10 are arranged between the guide contour 21 and the guide contour 22 . In this example, carriage drive 5 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com