Basalt fiber disc type tension adjusting device

A tension adjustment device and technology of basalt fiber, which are applied in manufacturing tools, glass manufacturing equipment and other directions, can solve the problems of insufficient adjustment and convenient disassembly, and achieve the effect of convenient disassembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

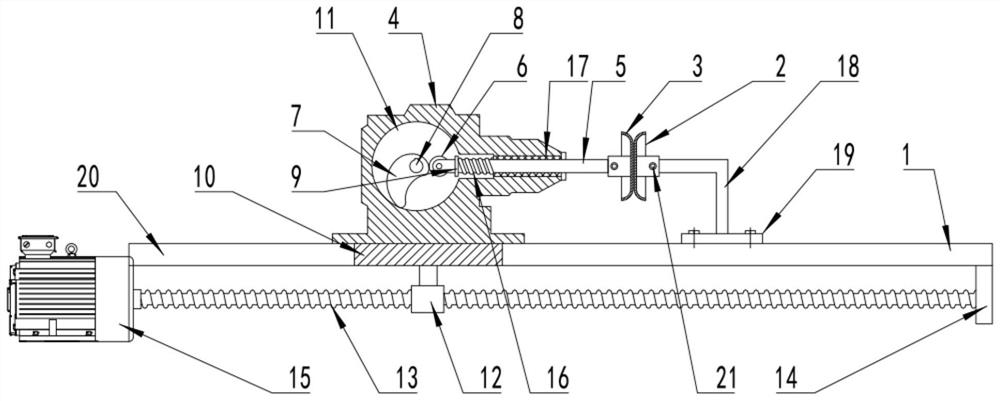

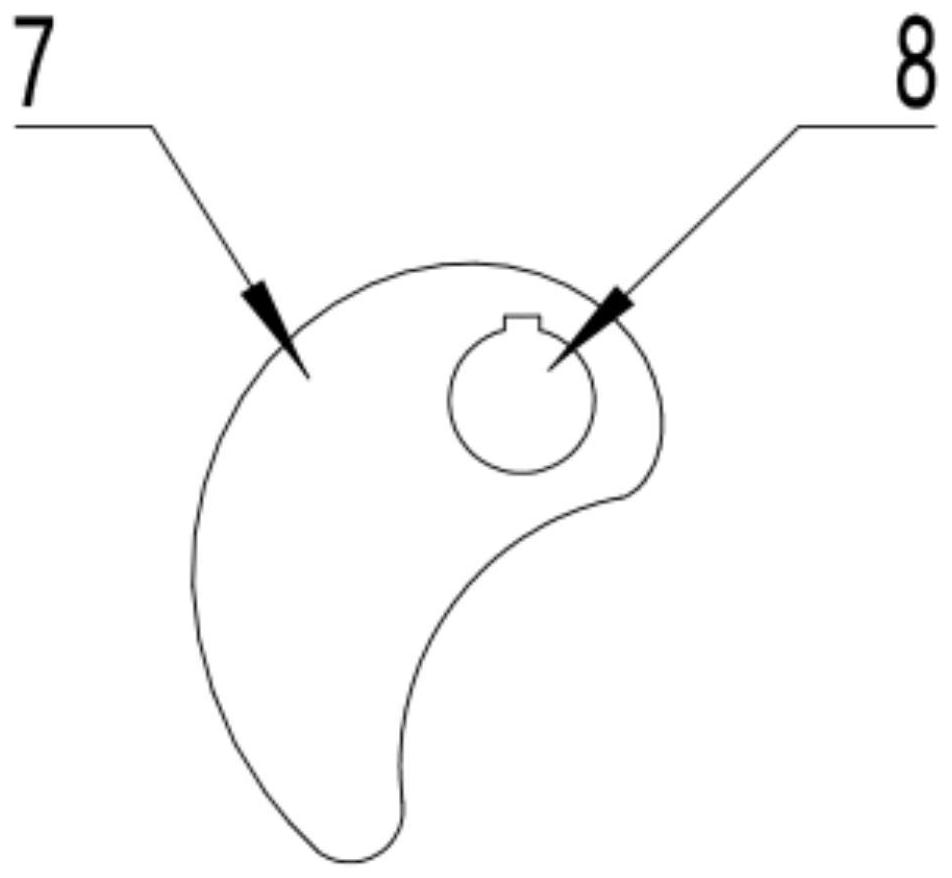

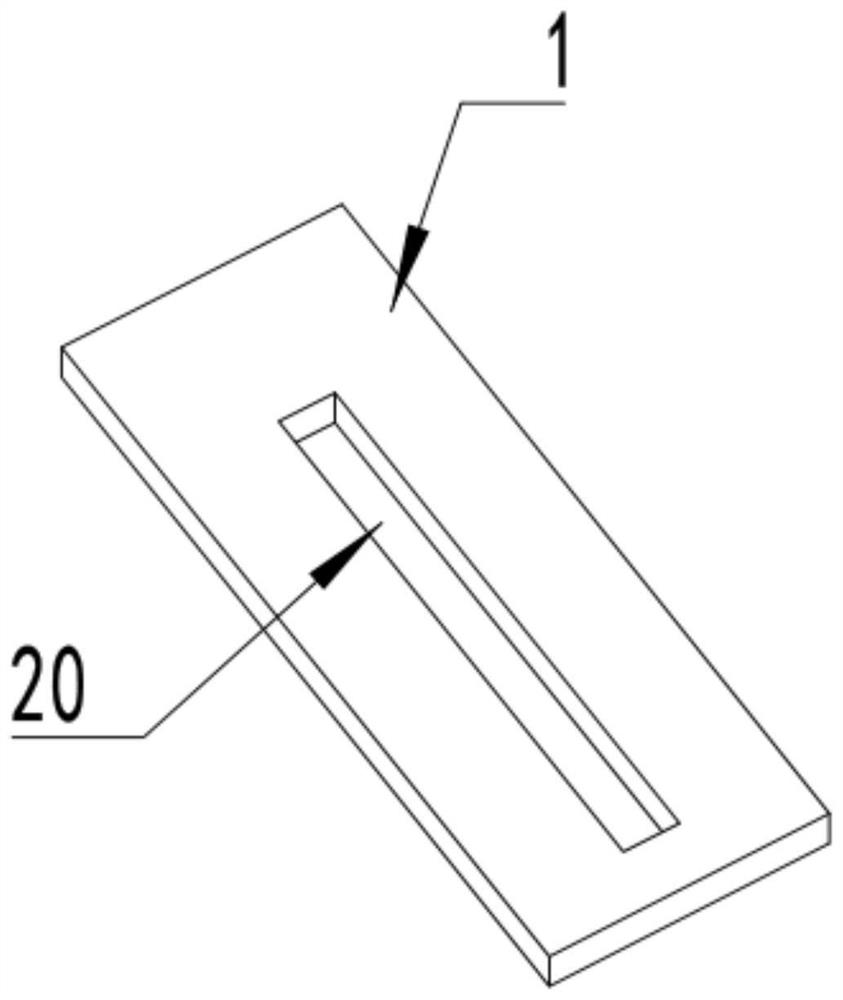

[0023]SeeFigure 1~3In the embodiment of the present invention, a basalt fiber disc-type tension adjusting device includes a table top 1, a fixed disc 2, a movable disc 3, an adjuster 4, and a driving mechanism that drives the adjuster 4 to move along a straight line. The center of the disc 2 is connected to the fixed rod 18 by a locking screw 21. The fixed rod 18 is fixed on the table 1 through a fixed seat 19 and bolts. The fixed disc 2 and the movable disc 3 are in opposite positions, and the movable disc 3 is locked The tightening screw 21 is fixed at the end of the movable rod 5. The movable rod 5 extends into the circular installation cavity 11 in the adjuster 4. The end of the movable rod 5 is equipped with a roller 6, and the wheel surface of the roller 6 is not When the regular rotating block 7 is in contact, the surface of the irregular rotating block 7 is smooth, and the distance from any point on the irregular rotating block 7 to its rotation center gradually increases an...

Embodiment 2

[0027]SeeFigure 1~3In the embodiment of the present invention, a basalt fiber disc-type tension adjusting device includes a table top 1, a fixed disc 2, a movable disc 3, an adjuster 4, and a driving mechanism that drives the adjuster 4 to move along a straight line. The center of the disc 2 is connected to the fixed rod 18 by a locking screw 21. The fixed rod 18 is fixed on the table 1 through a fixed seat 19 and bolts. The fixed disc 2 and the movable disc 3 are in opposite positions, and the movable disc 3 is locked The tightening screw 21 is fixed at the end of the movable rod 5. The movable rod 5 extends into the circular installation cavity 11 in the adjuster 4. The end of the movable rod 5 is equipped with a roller 6, and the wheel surface of the roller 6 is not When the regular rotating block 7 is in contact, the surface of the irregular rotating block 7 is smooth, and the distance from any point on the irregular rotating block 7 to its rotation center gradually increases an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com