Patents

Literature

43results about How to "Change the vibration amplitude" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

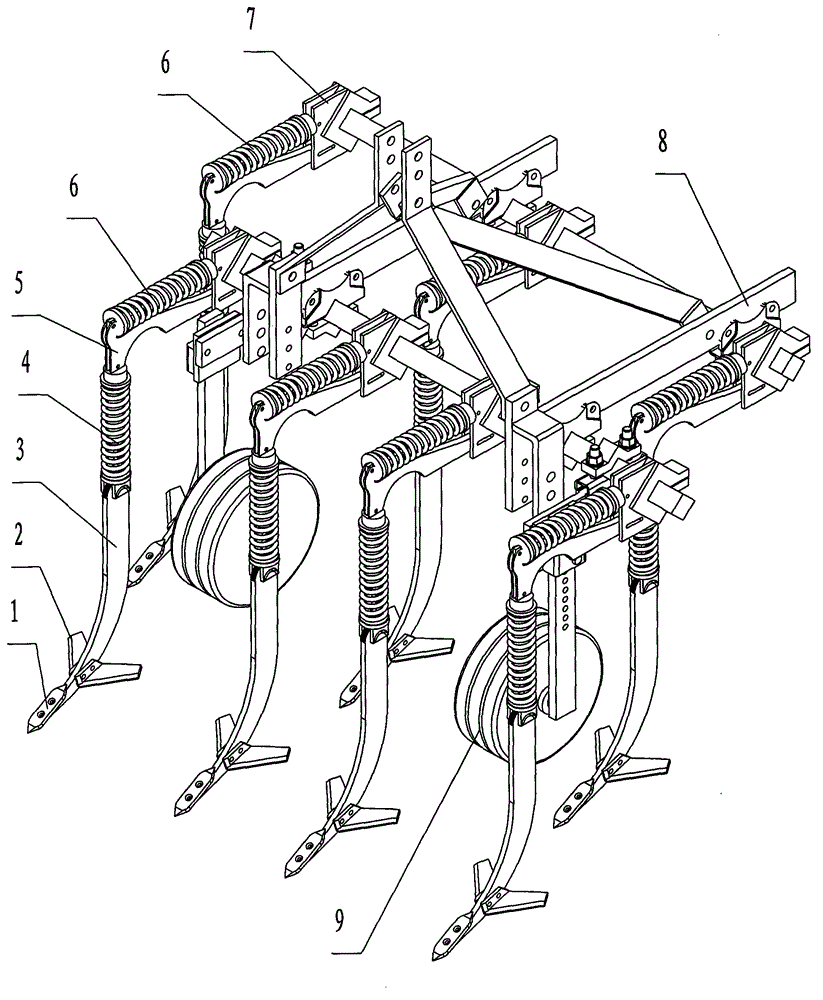

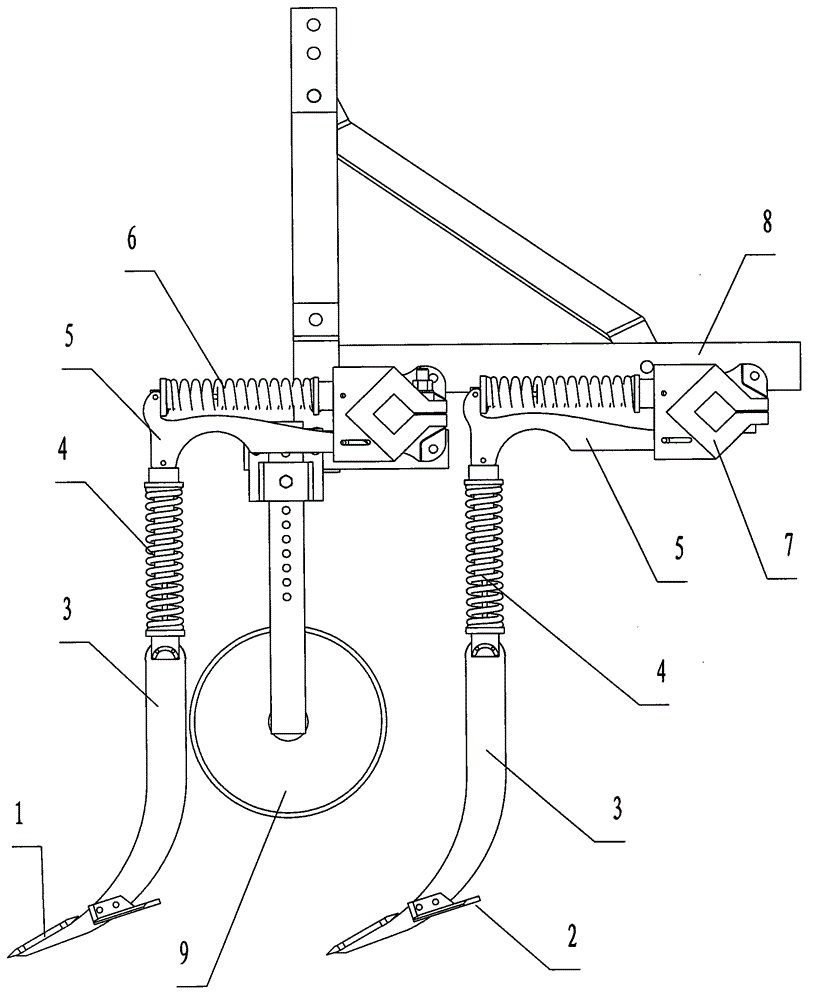

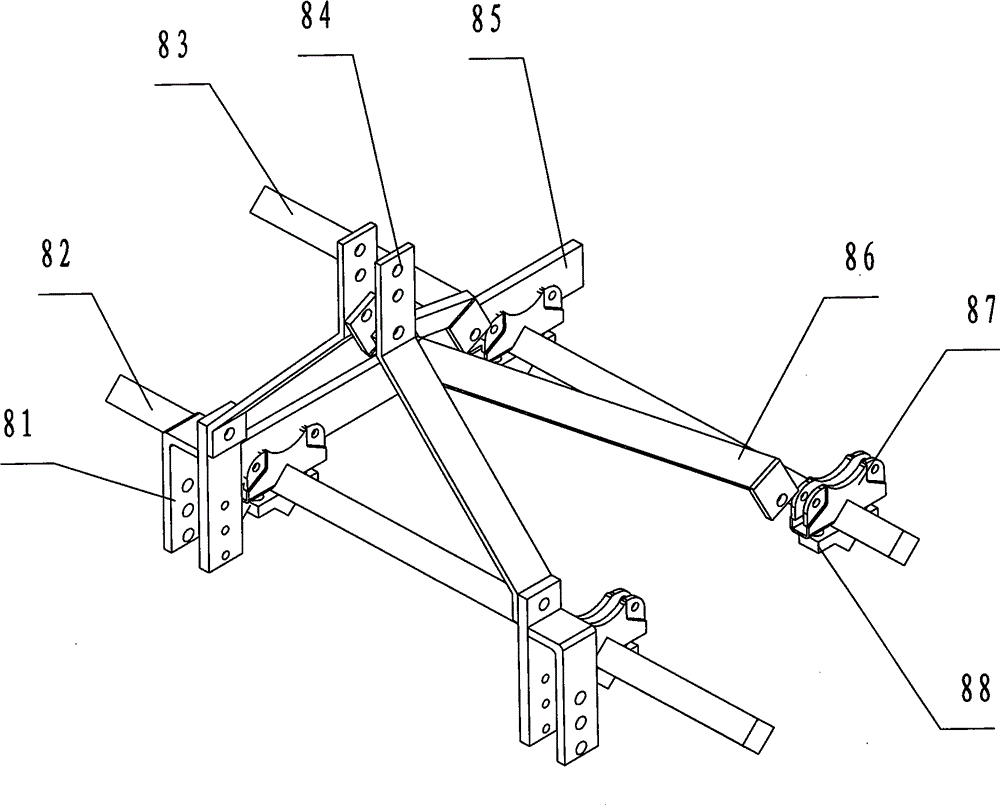

Hydraulic self-induced vibration subsoiler

InactiveCN104604365AAdjust the entry depthReduce physical discomfort and other problemsPloughsAgricultural engineeringTractor

The invention relates to a hydraulic self-induced vibration subsoiler. The hydraulic self-induced vibration subsoiler is characterized by comprising a machine frame and a subsoiling device, wherein the subsoiling device is arranged at the bottom of the machine frame, the machine frame is composed of suspension pair plates, a front beam, a rear beam, an inclined traction rod, a cross beam, a cross traction rod, U-shaped groove fixing pieces and V-shaped locking pieces, and the subsoiling device is composed of shovel points, shovel wings and shovel handles. According to the hydraulic self-induced vibration subsoiler, the stretch and retraction amount of vibration springs is controlled and adjusted through hydraulic oil, the embedded depths of all subsoiling shovels are effectively adjusted, in this way, the tilling depth consistency is guaranteed during subsoiling, and the overall vibration which causes discomfort of a driver of a tractor and the like and is generated due to inconsistency of shake of mechanisms of the subsoiler is reduced; compared with a non-vibration subsoiler and a one-way vibration subsoiler under the same condition, during work, the traction resistance is remarkably reduced; to sum up, the hydraulic self-induced vibration subsoiler can reduce resistance and save energy and is good in operation effect and high in adaptability.

Owner:SHIHEZI UNIVERSITY

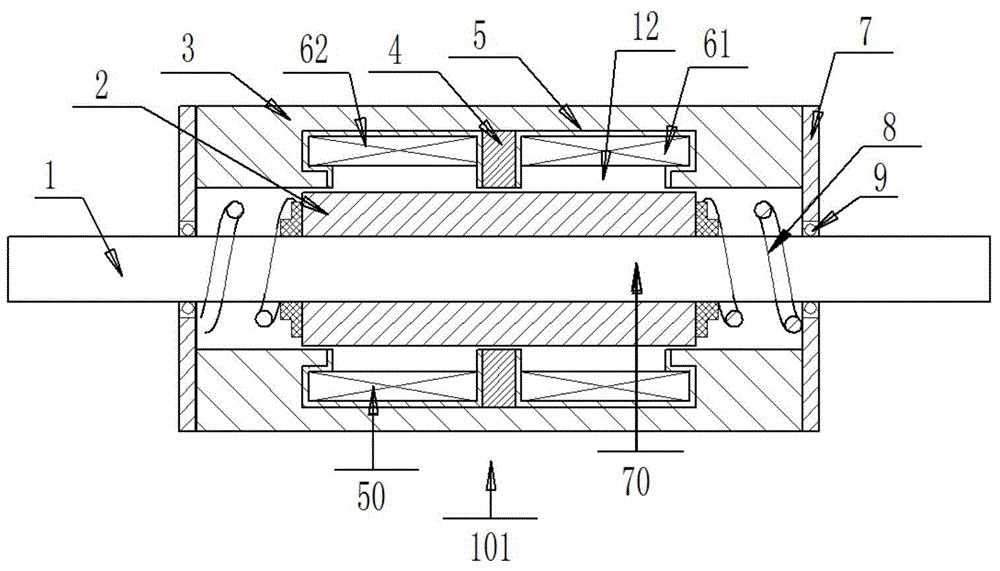

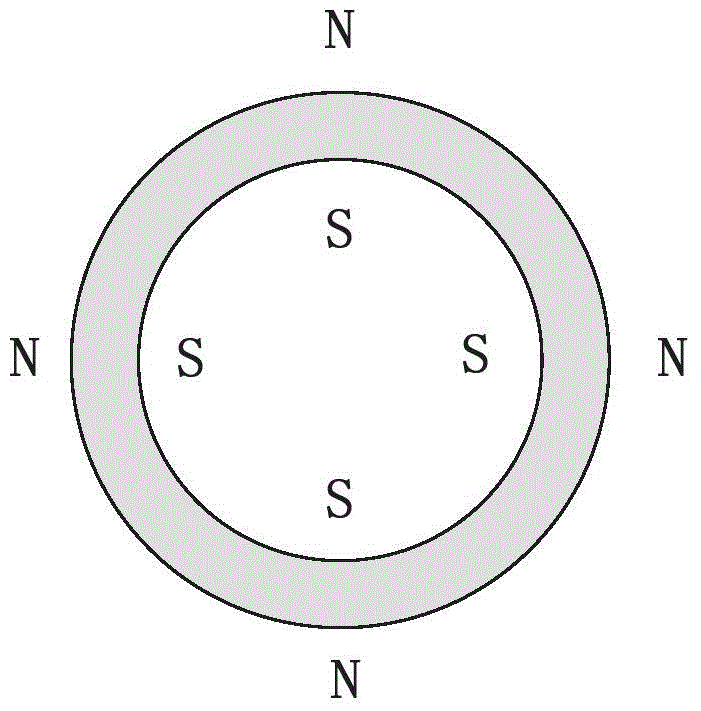

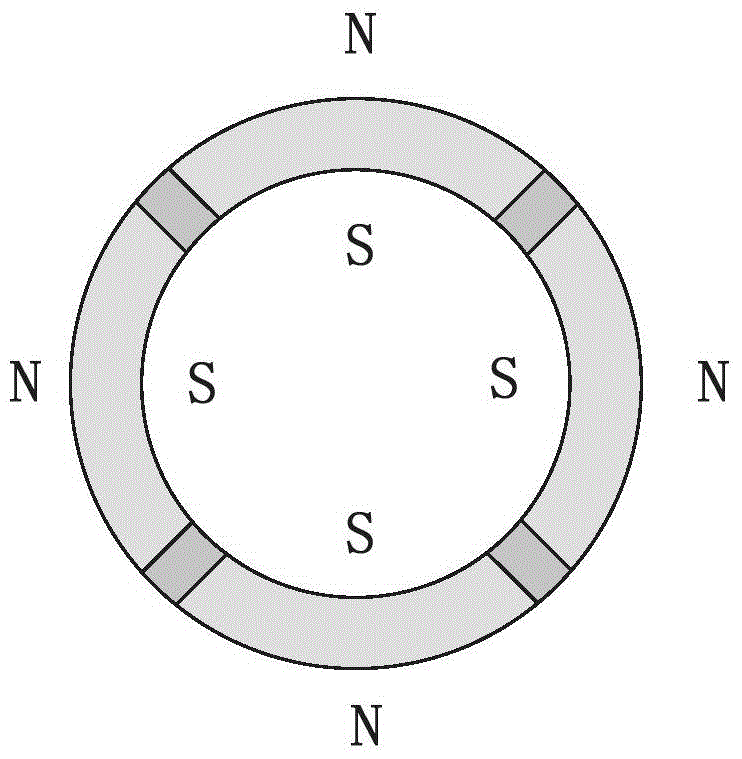

Permanent-magnetic linear oscillation motor and motor-driven equipment

ActiveCN104702078ALight in massFast dynamic responseMagnetic circuit stationary partsMechanical energy handlingPhysicsStator

The invention provides a permanent-magnetic linear oscillation motor. The permanent-magnetic linear oscillation motor comprises a mover portion and a stator portion. The mover portion comprises a shaft and a mover iron core, and the mover iron core is installed and fixed on the shaft. The stator portion comprises a primary iron core, a permanent magnet, a coil former, a first coil and a second coil. The primary iron core is provided with a groove used for accommodating the permanent magnet, the coil former, the first coil and the second coil. The first coil and the second coil are symmetrically arranged on the coil former relative to the permanent magnet. When the first coil and the second coil are powered on, a magnetic field is generated, and therefore the mover portion is driven to reciprocate along the axial direction of the shaft. The invention further relates to a piece of motor-driven equipment. According to the permanent-magnetic linear oscillation motor and the motor-driven equipment the mover portion is lighter in weight and fast in dynamic response, the permanent magnet is not liable to lose magnetism, and the motor can run more reliably.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

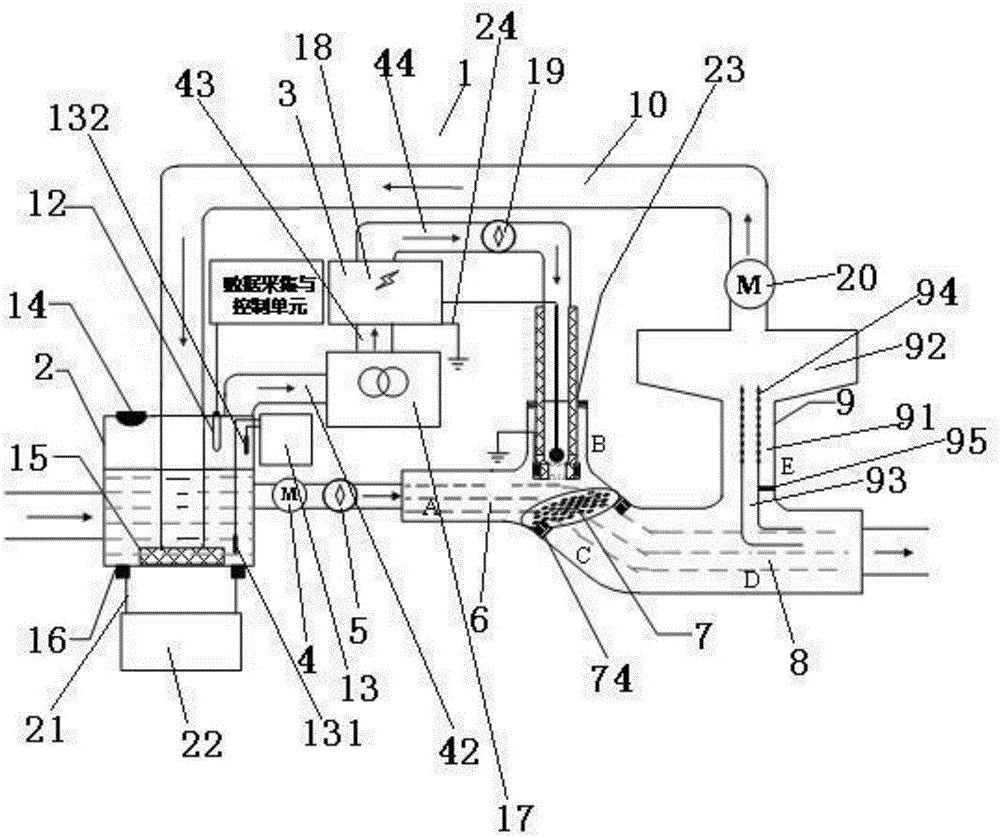

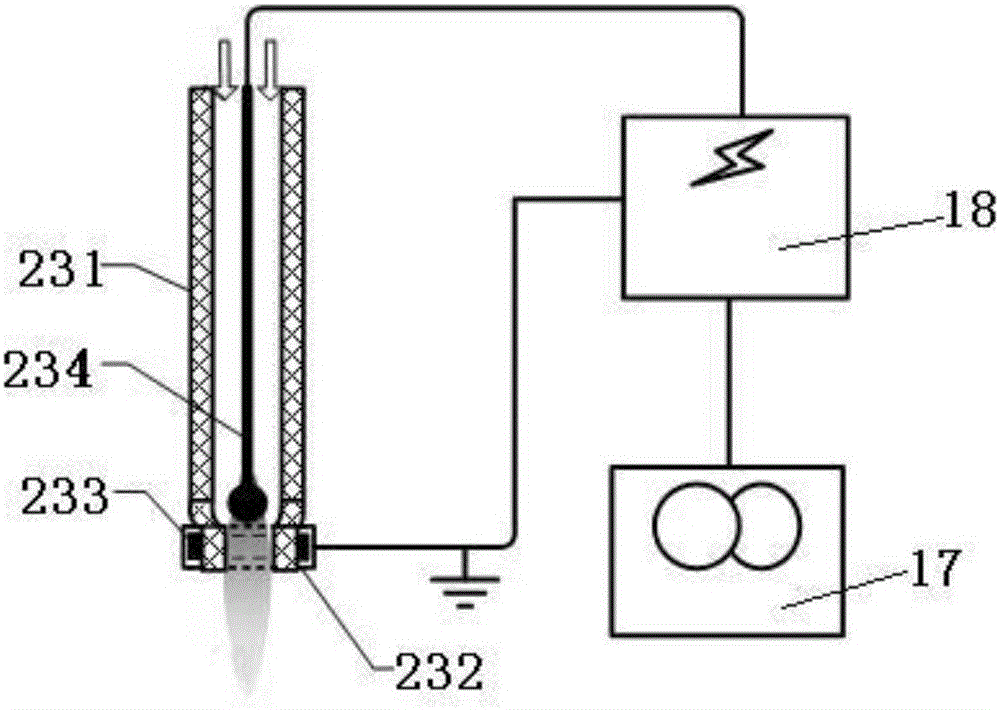

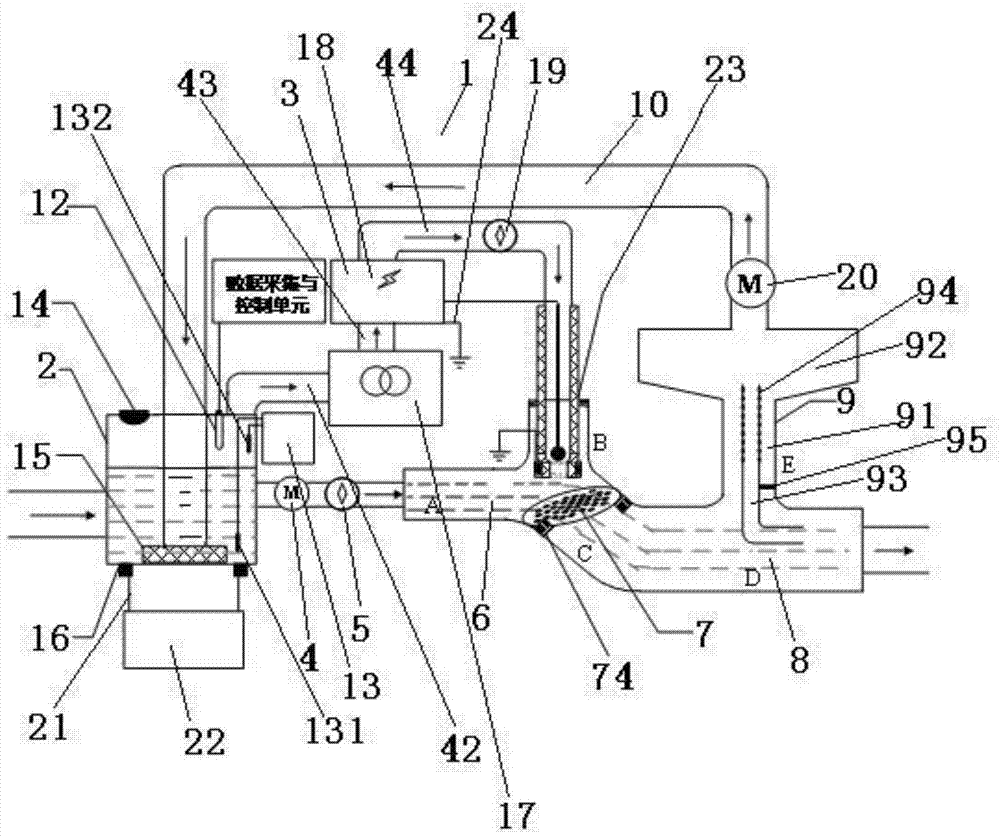

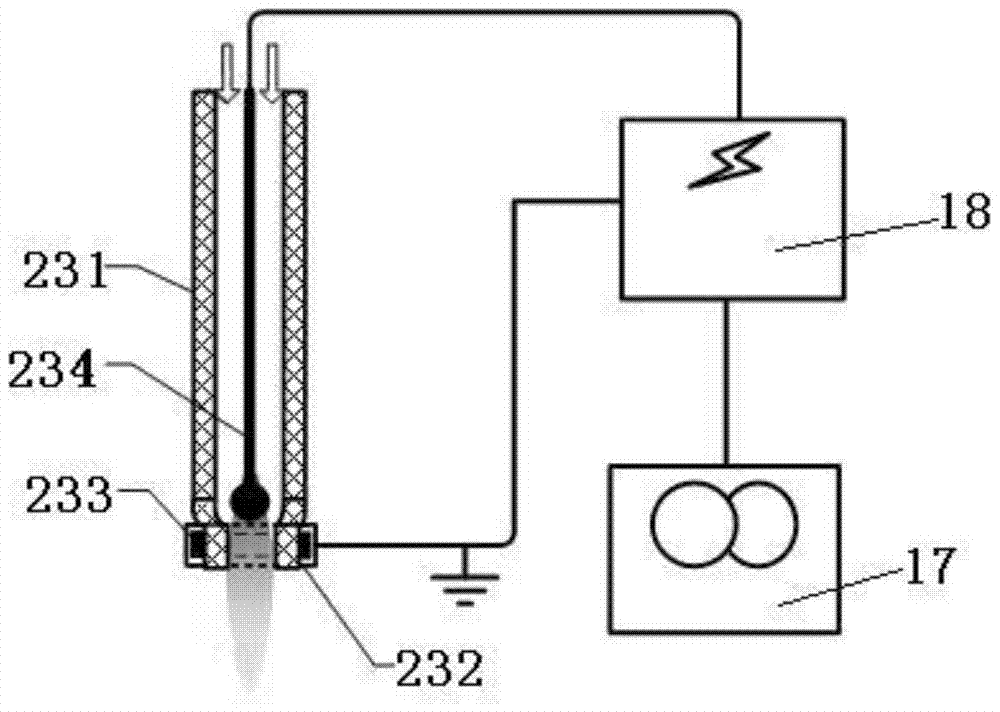

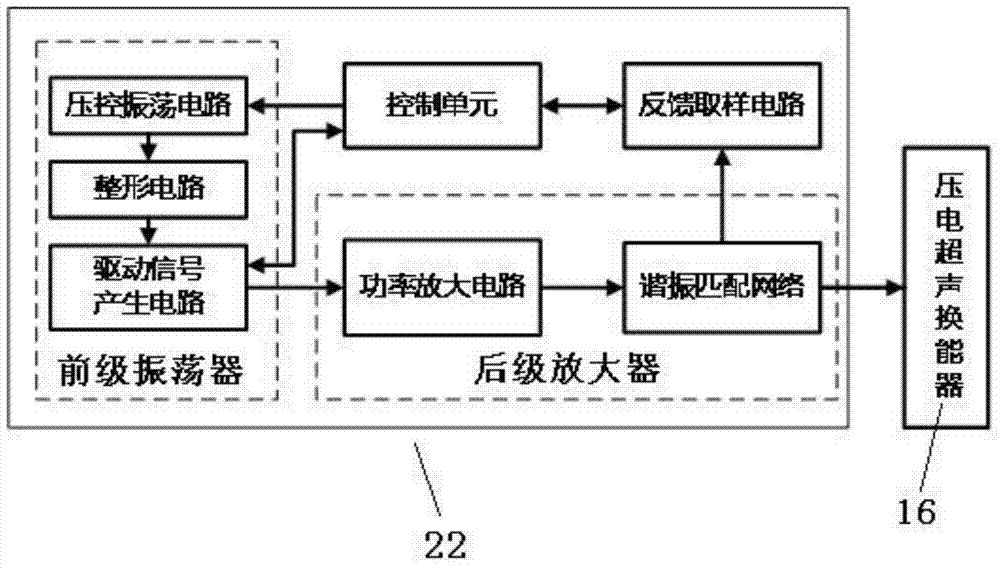

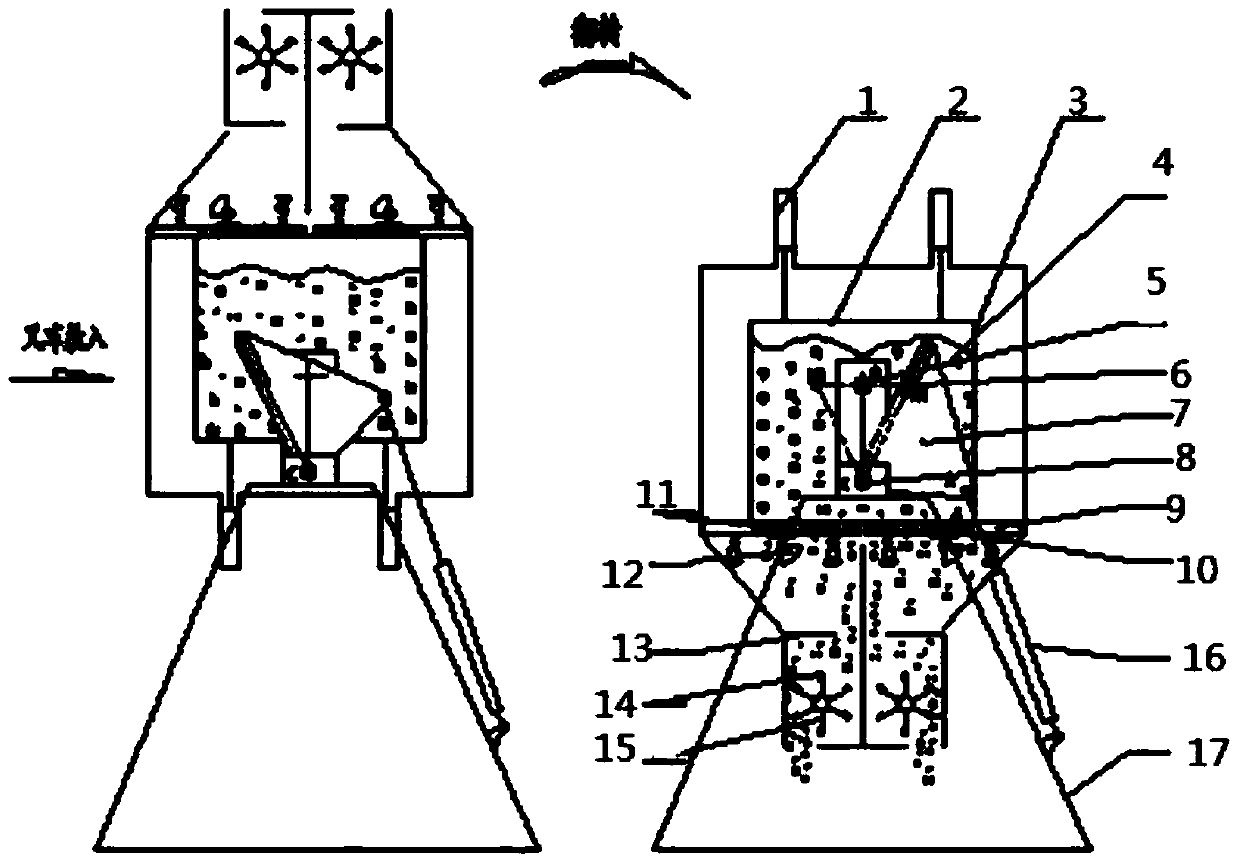

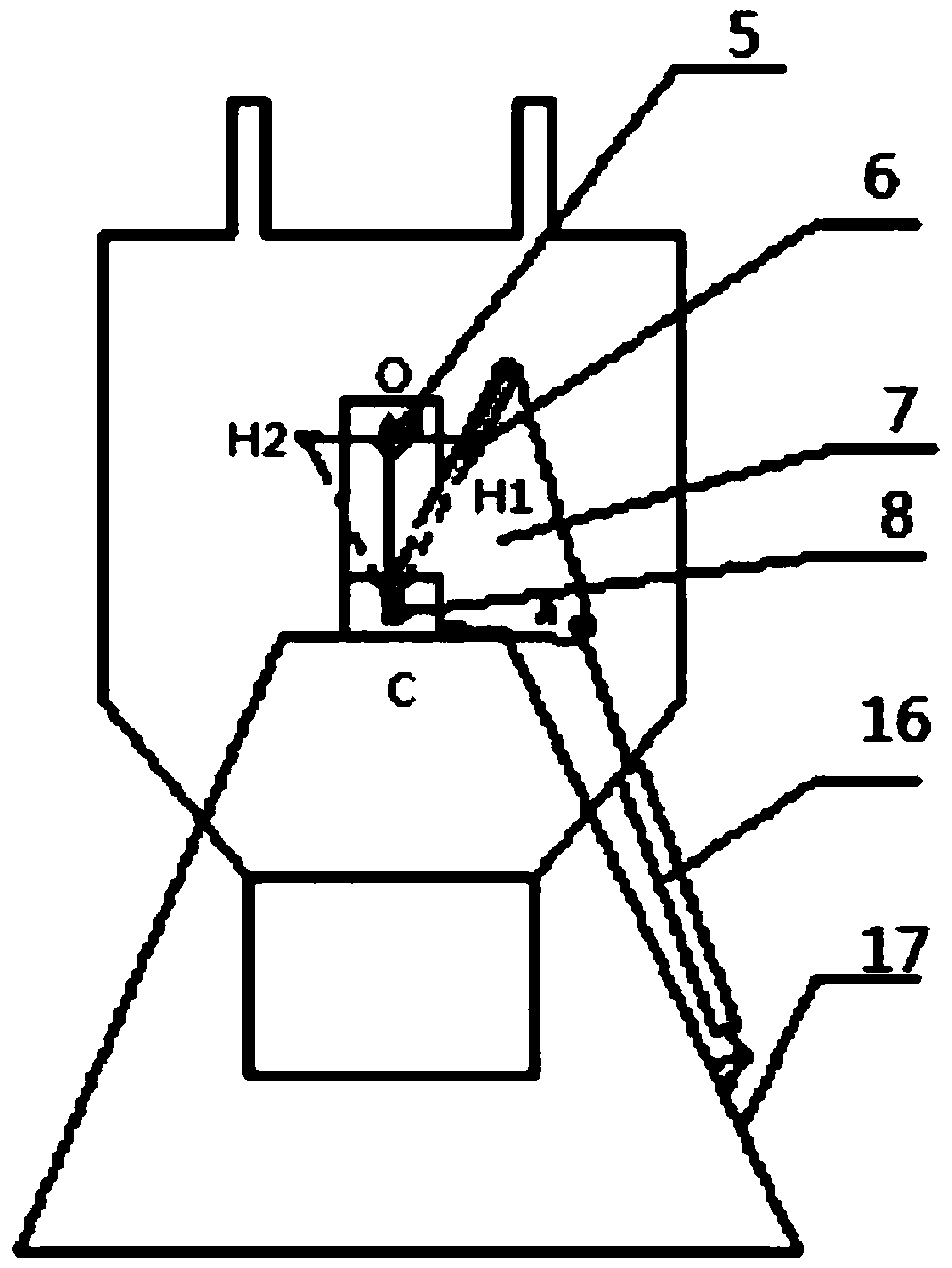

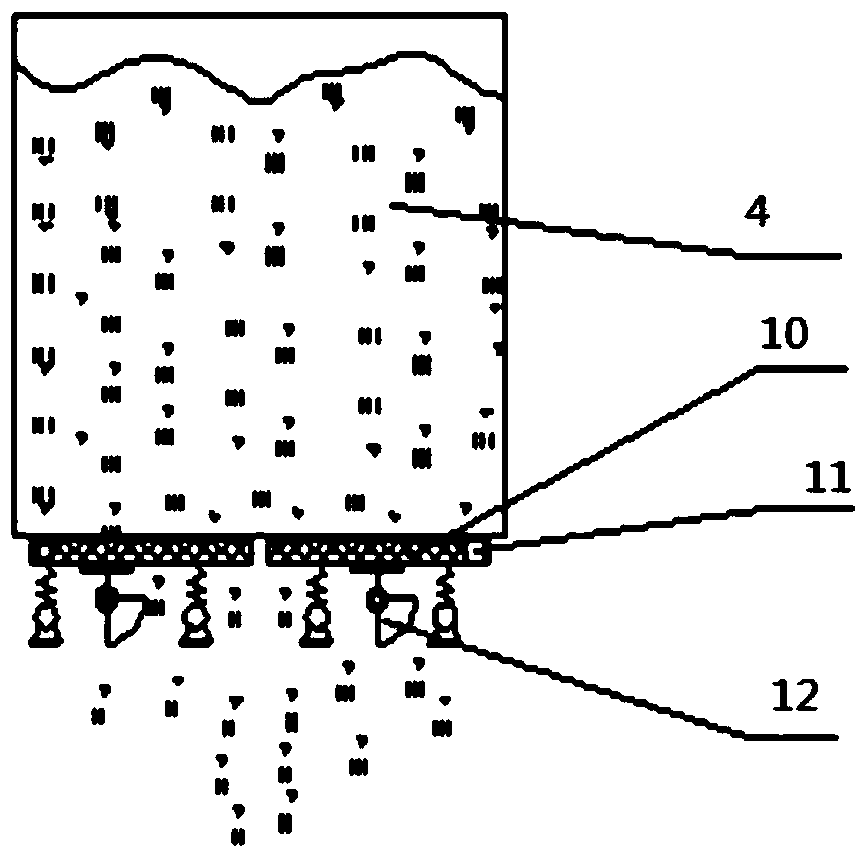

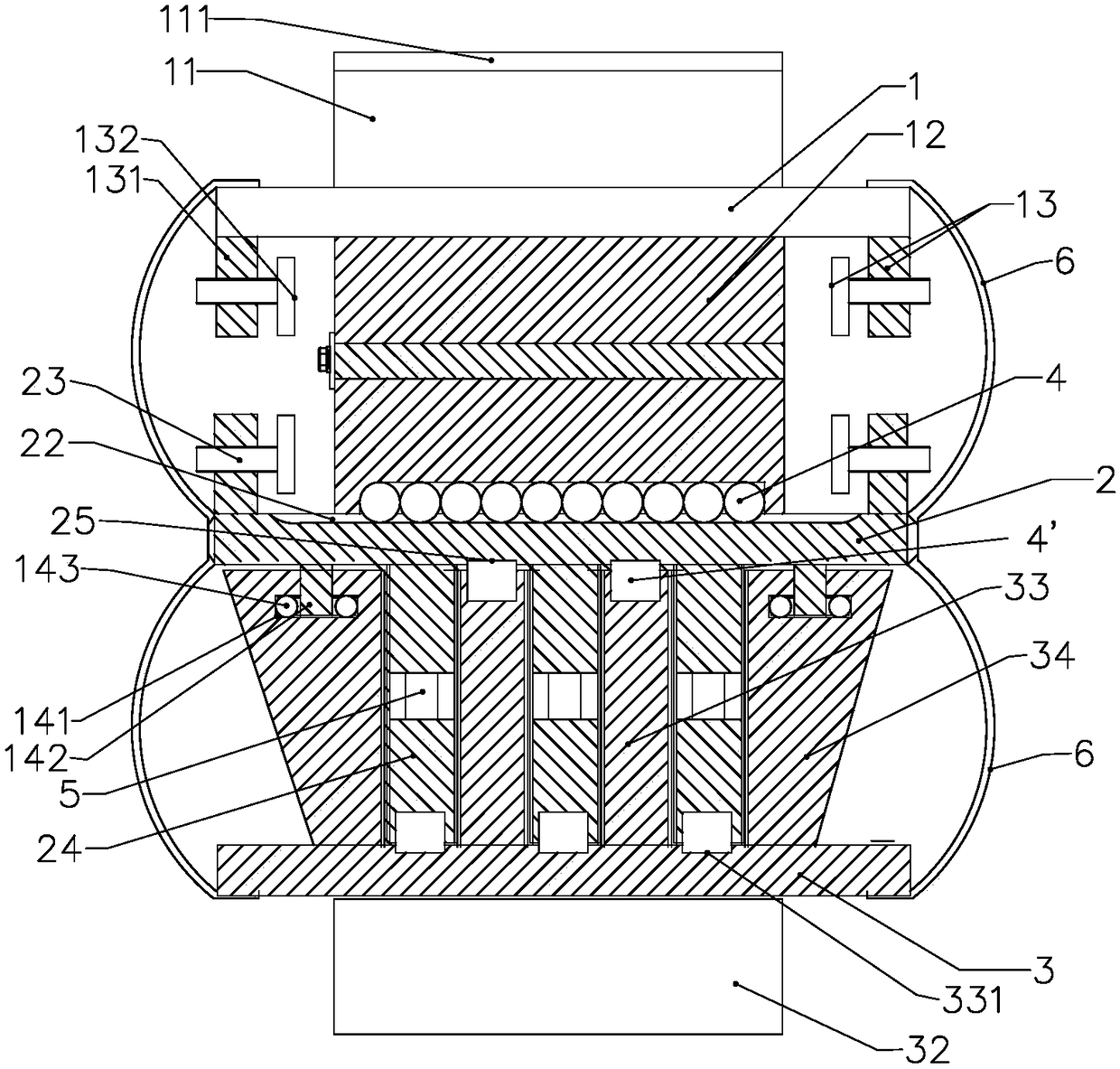

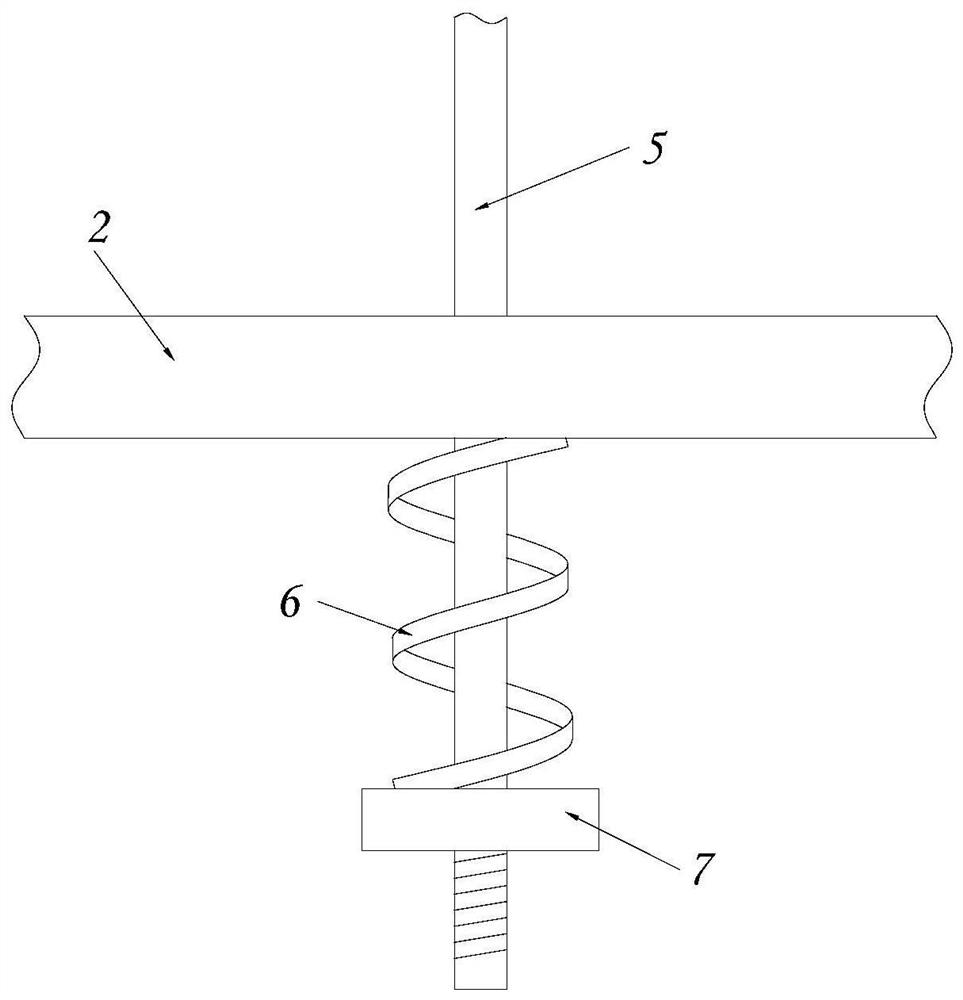

Plasma and ultrasonic and catalysis combined cascading style water treatment device

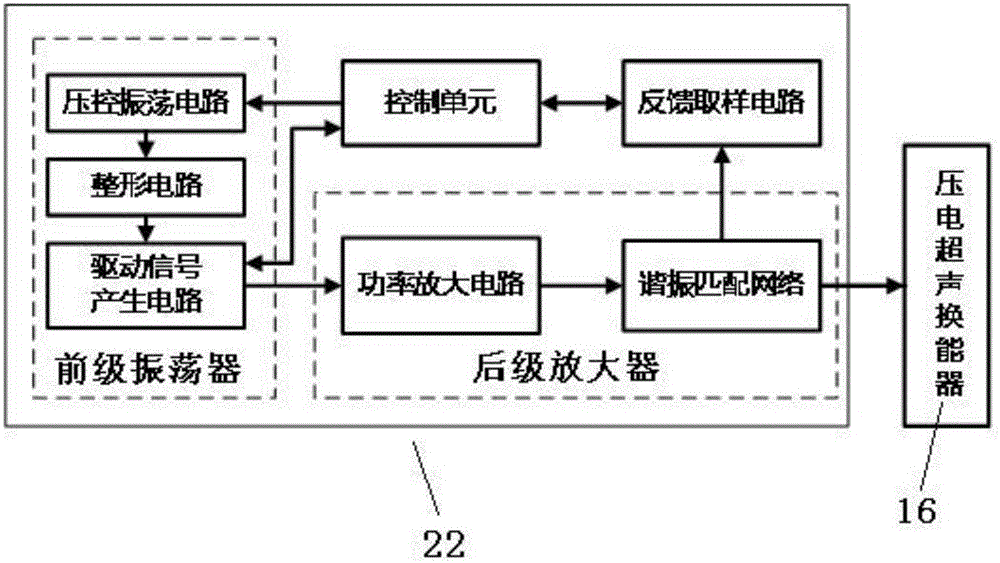

ActiveCN105130046AImprove degradation efficiencyIncrease the number ofMultistage water/sewage treatmentHigh energyPlasma generator

The present invention discloses a plasma and ultrasonic and catalysis combined cascading style water treatment device characterized by comprising a water treatment unit (1), the water treatment unit (1) comprises an ultrasonic ozone united reactor (2) and a plasma generator (3), a water outlet of the ultrasonic ozone united reactor (2) is connected with a water inlet of a Y-type reactor (6) by a liquid pump (4) and a liquid flow meter (5), the top of the ultrasonic ozone united reactor (2) is in communication with the plasma generator (3) through a second gas circulation pipe (42). The plasma and ultrasonic and catalysis combined cascading style water treatment device treats wastewater by comprehensive utilization of ultrasound, ozone, plasma, TiO2 catalysis and other methods; in addition, the plasma and ultrasonic and catalysis combined cascading style water treatment device also overcomes the problems of large floor area, high energy consumption, long single treatment time and low utilization of active materials in plasma, and the like of wastewater treatment devices in the prior art.

Owner:南通河海大学海洋与近海工程研究院

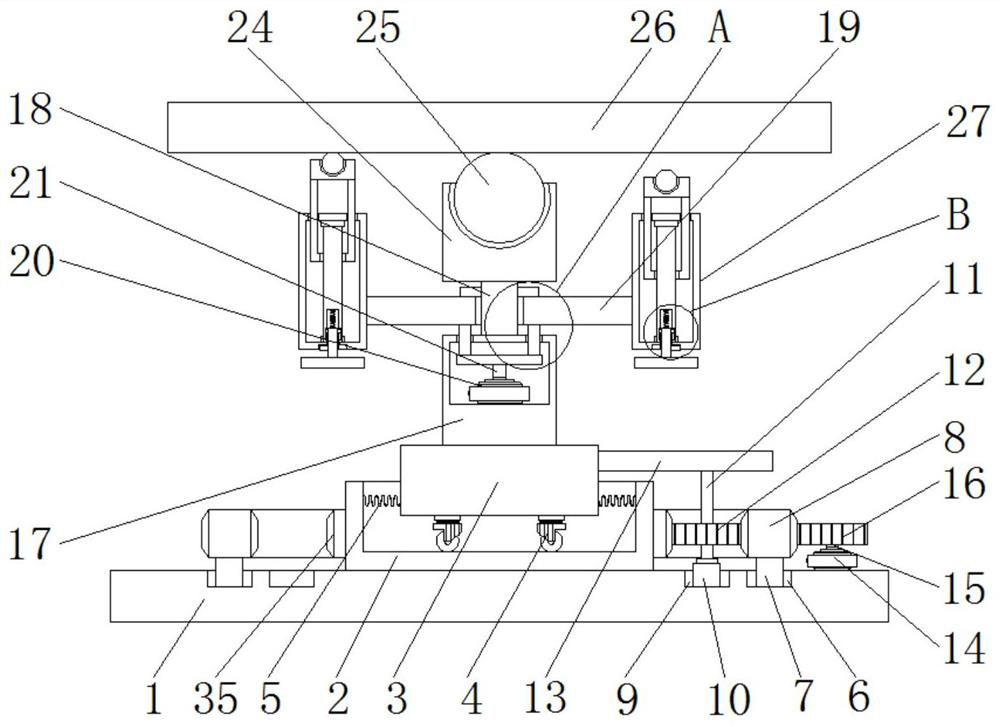

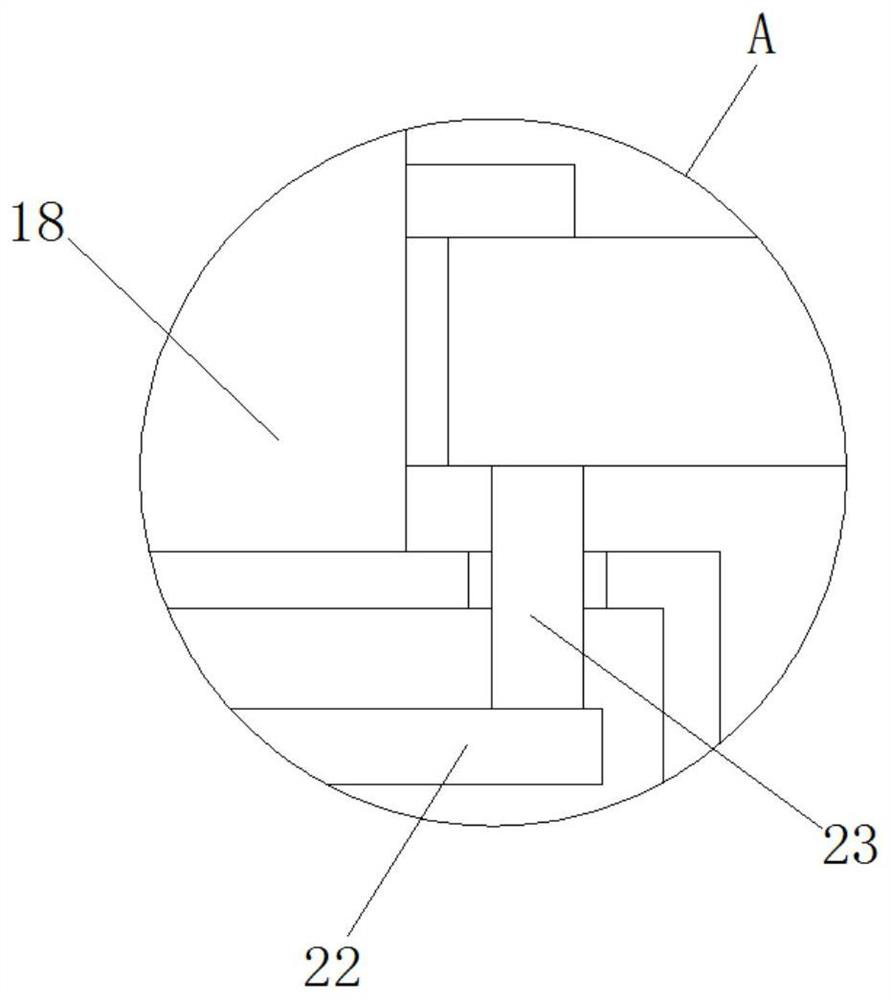

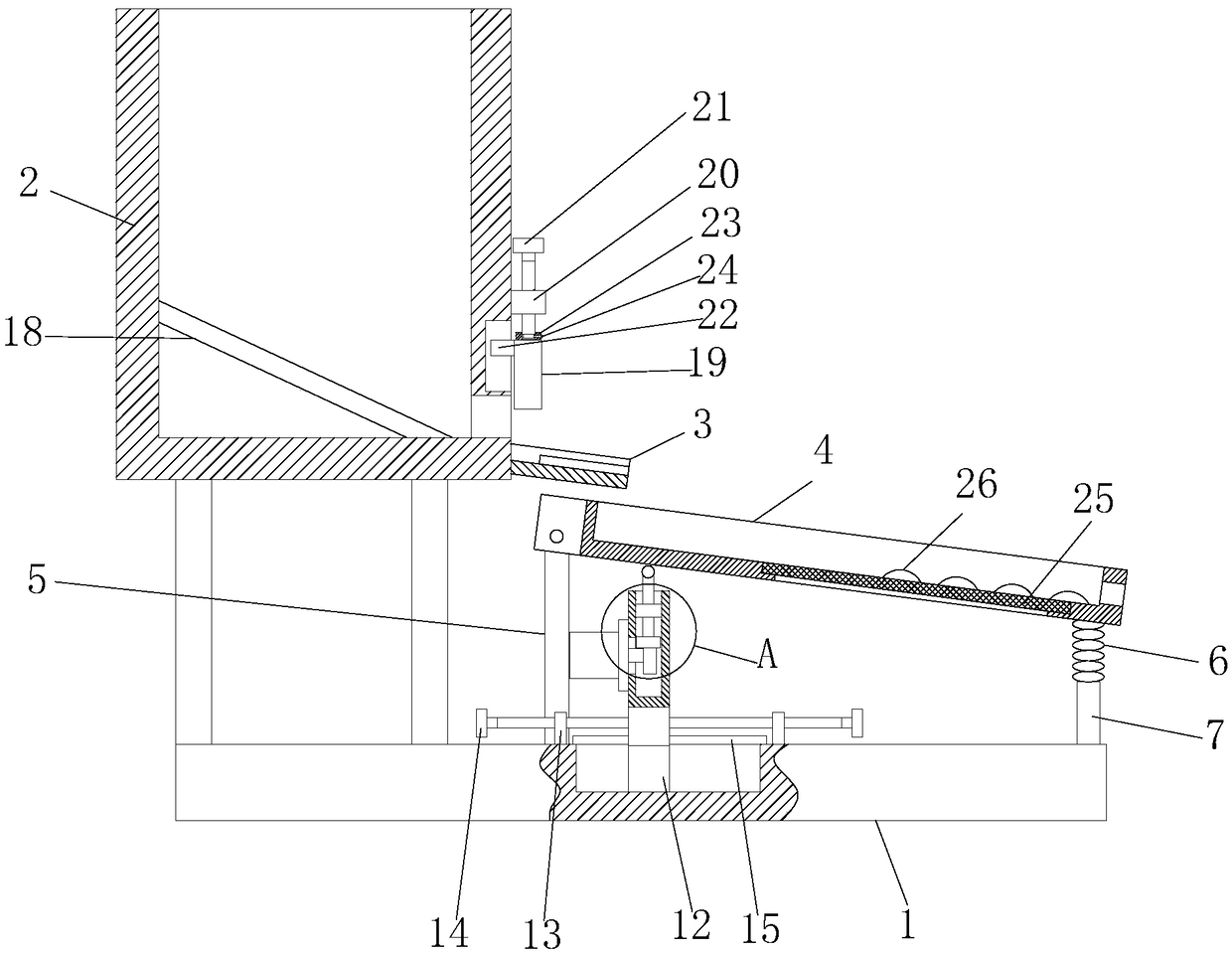

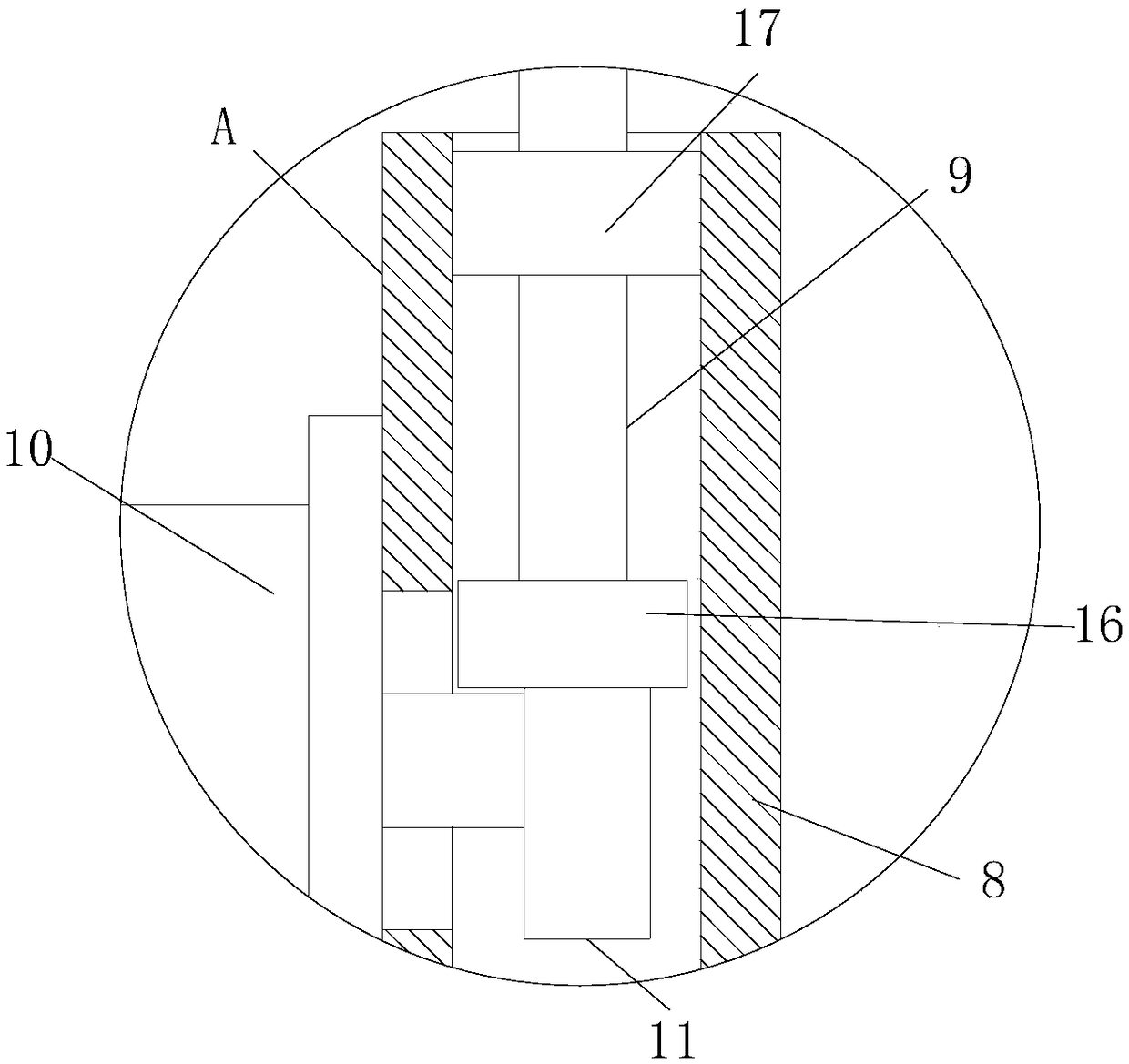

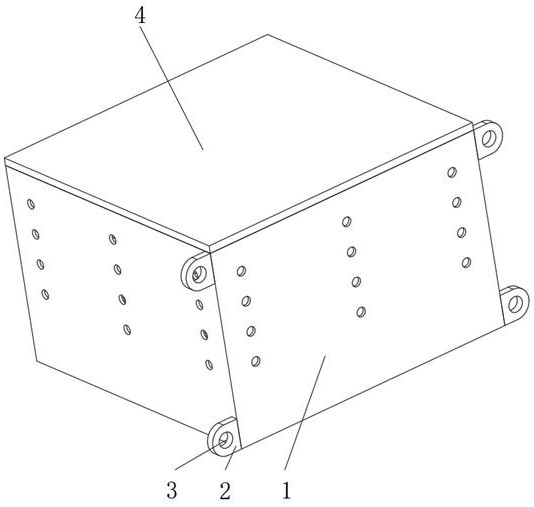

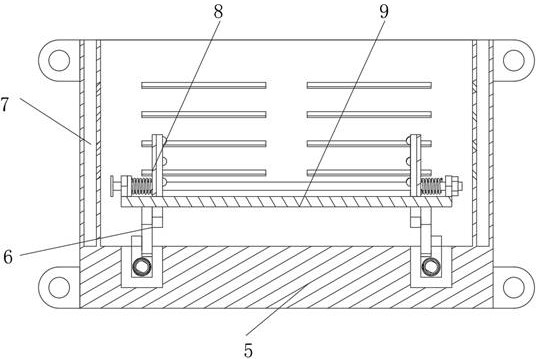

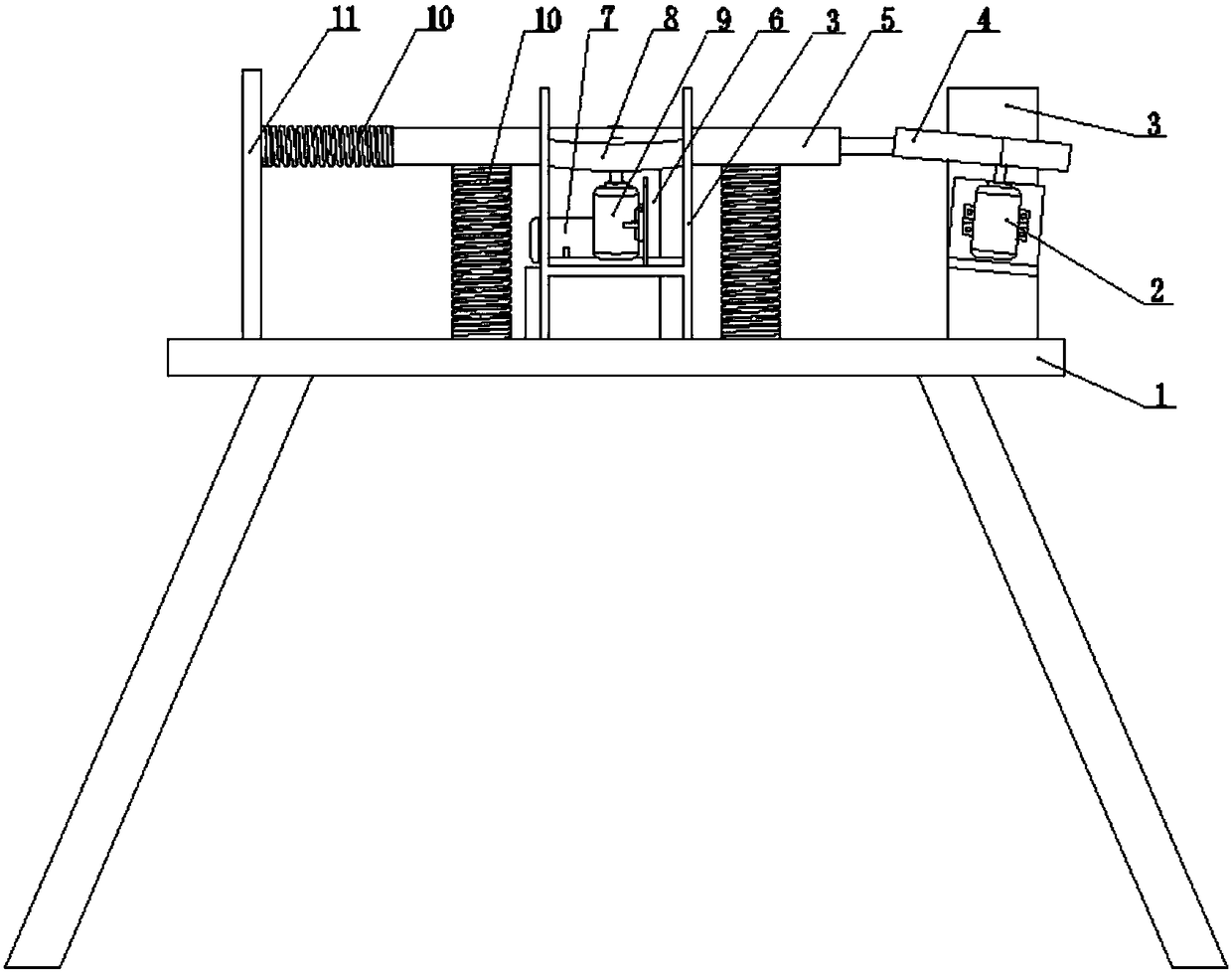

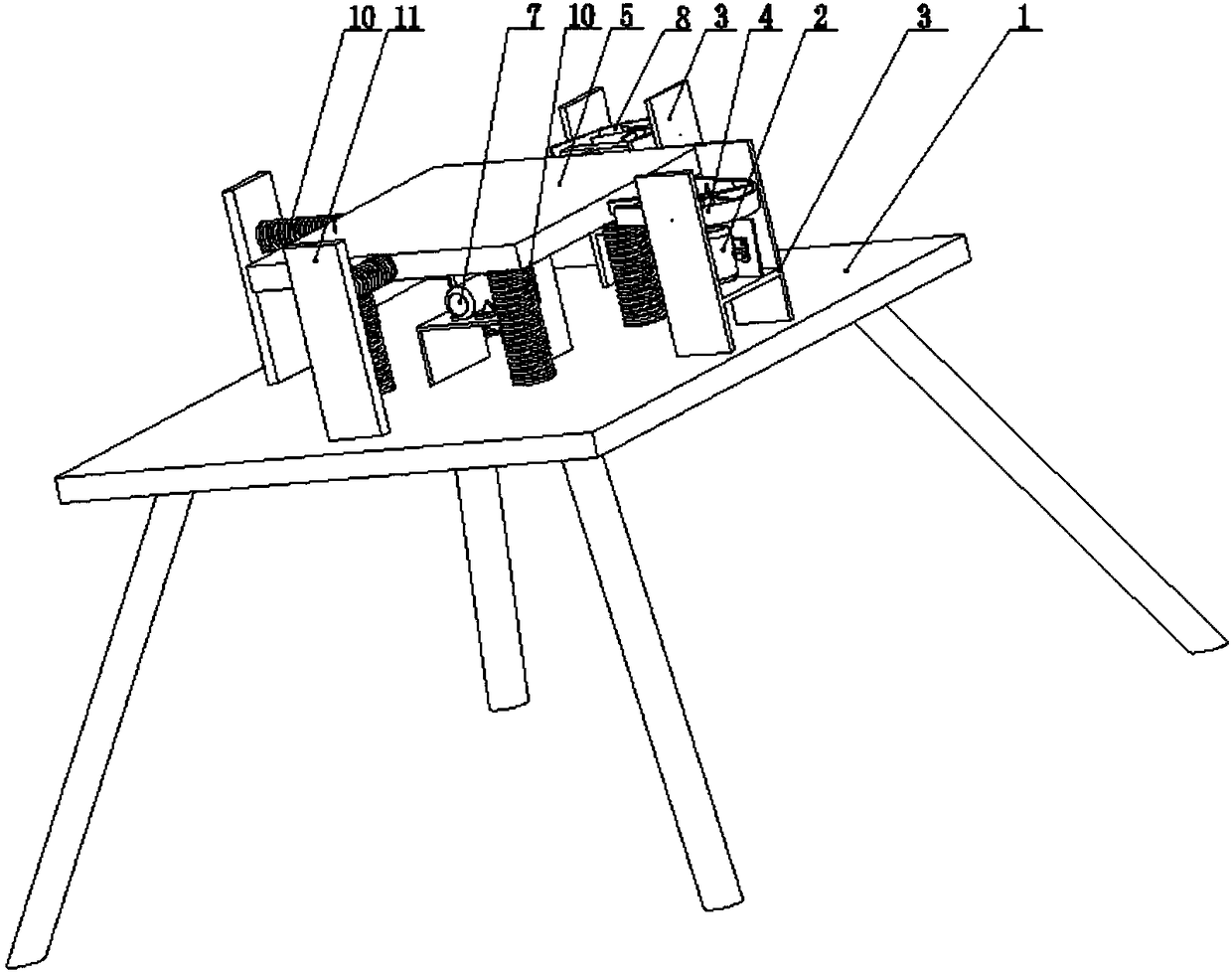

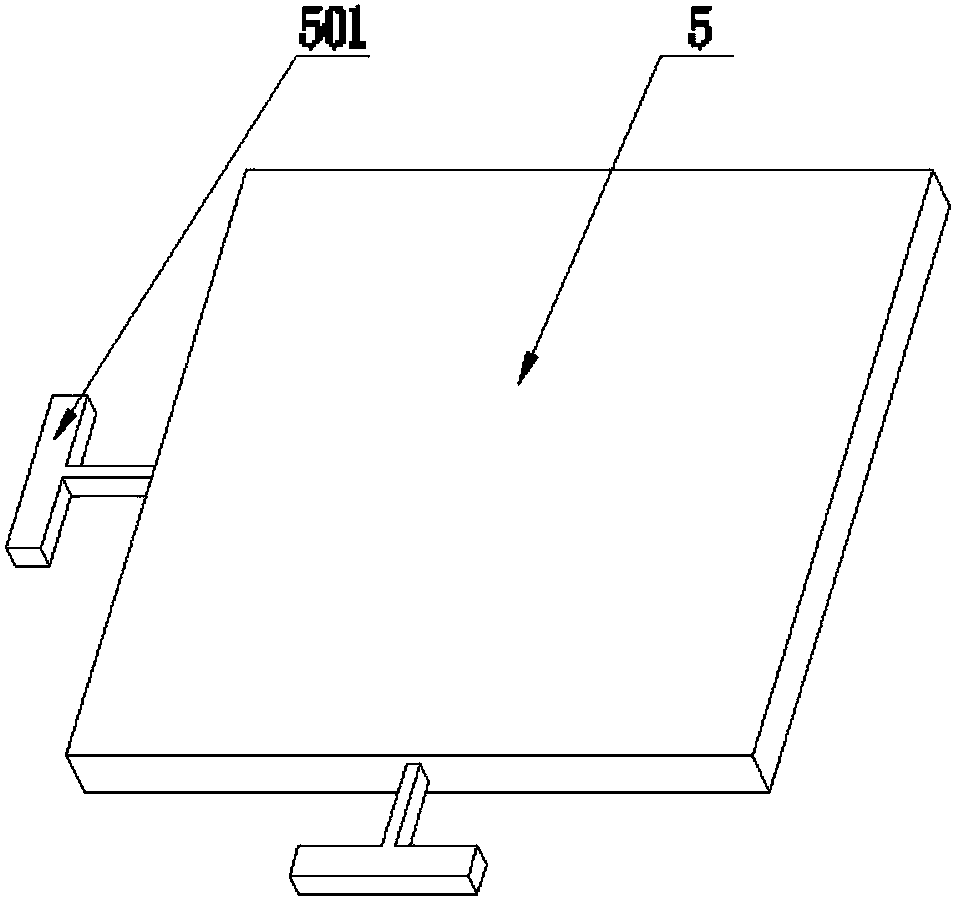

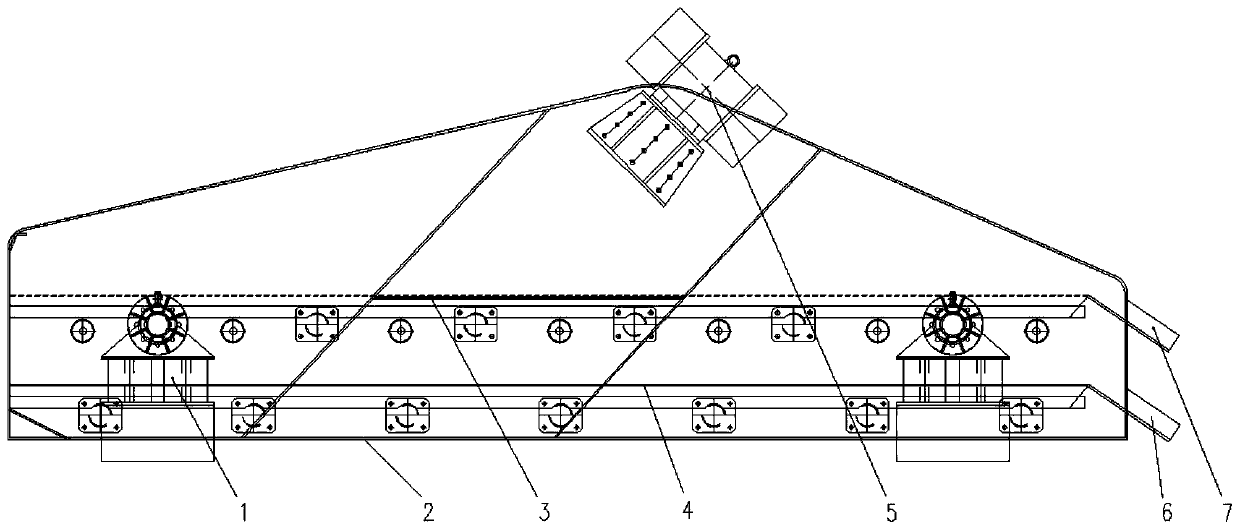

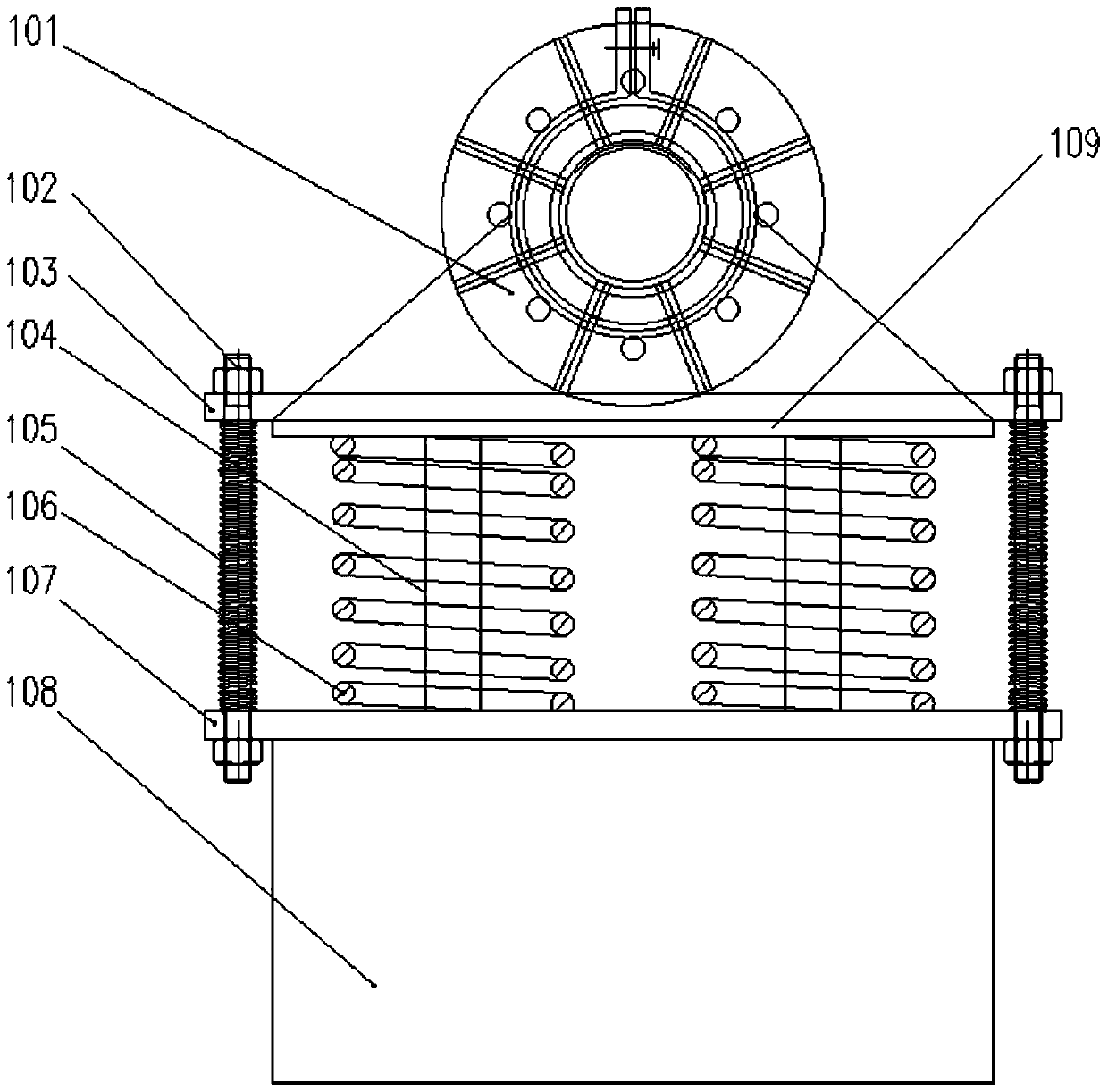

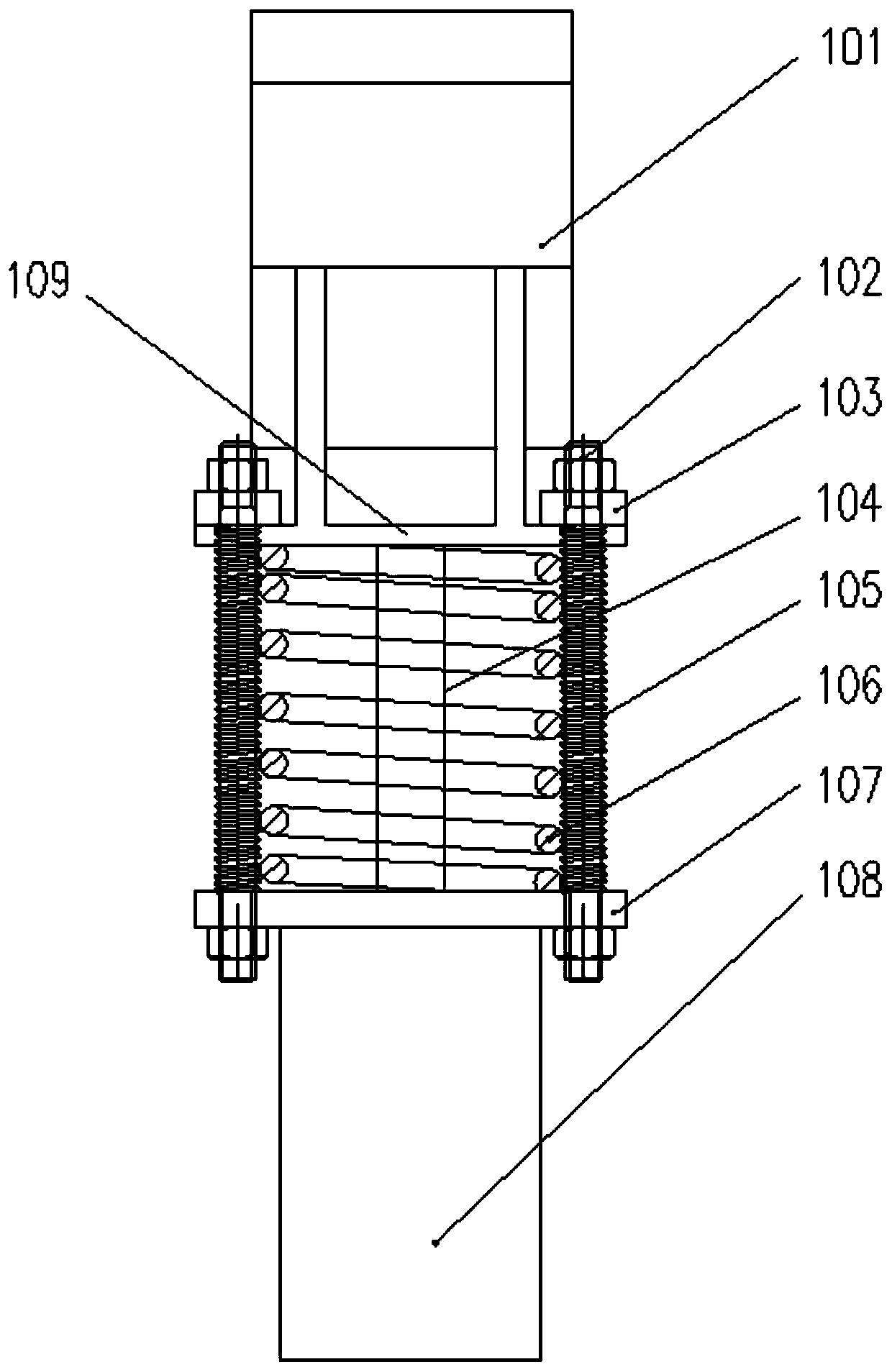

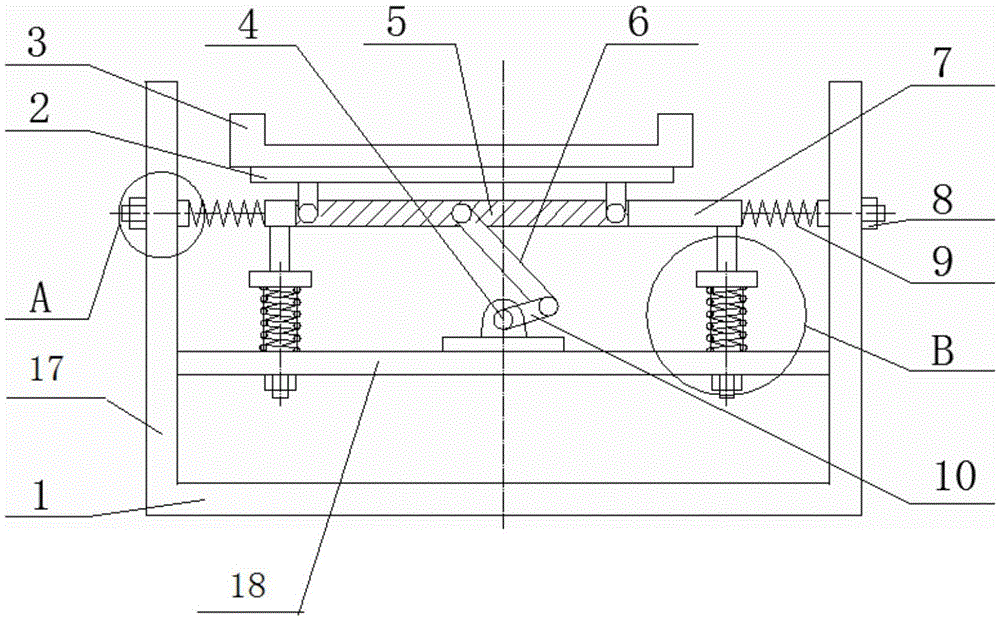

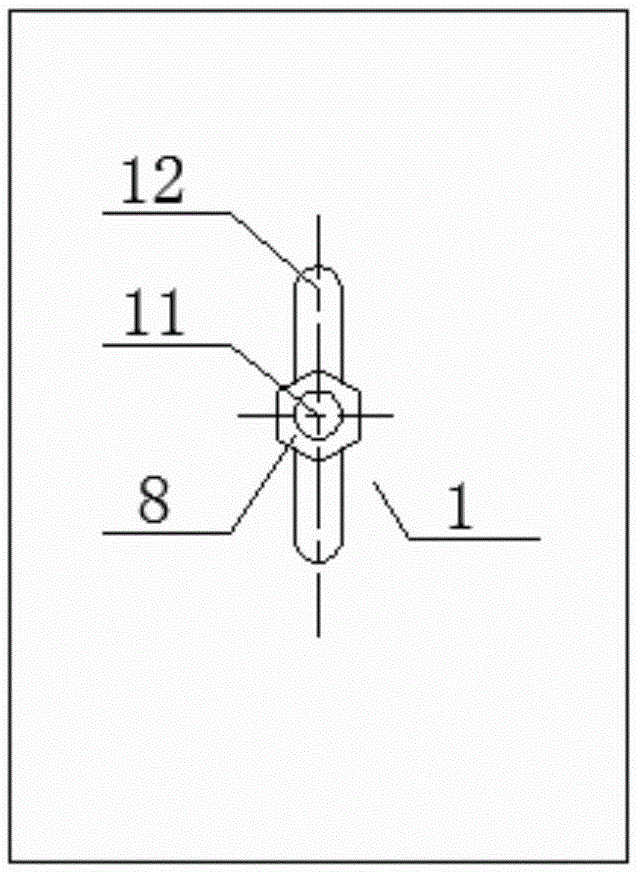

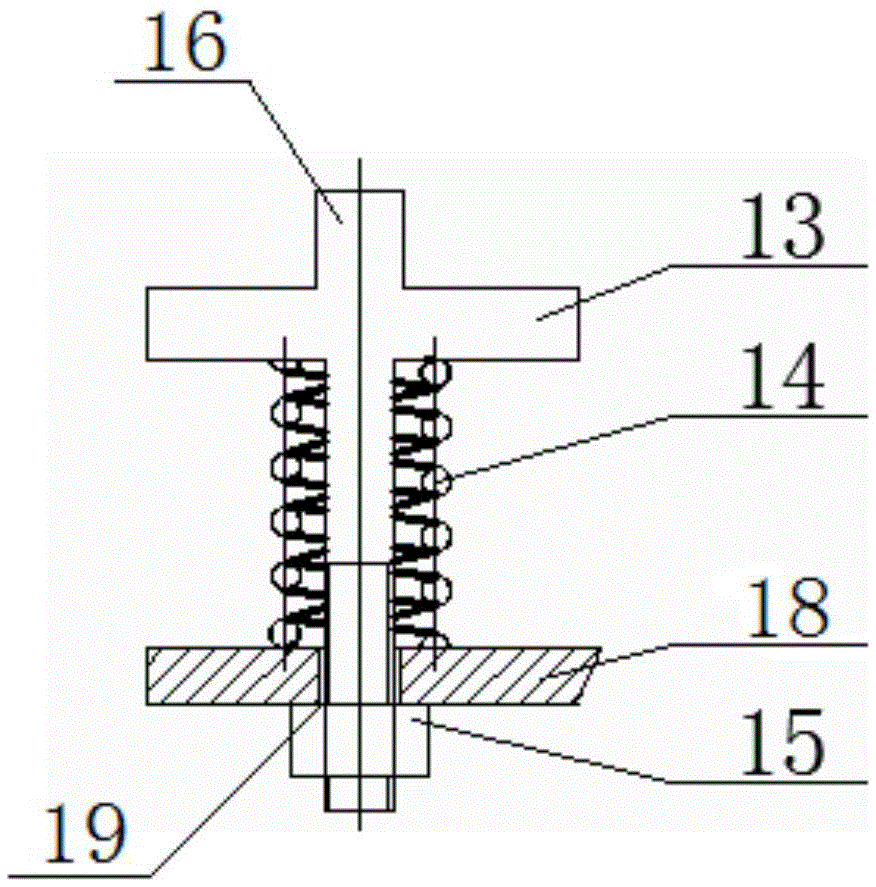

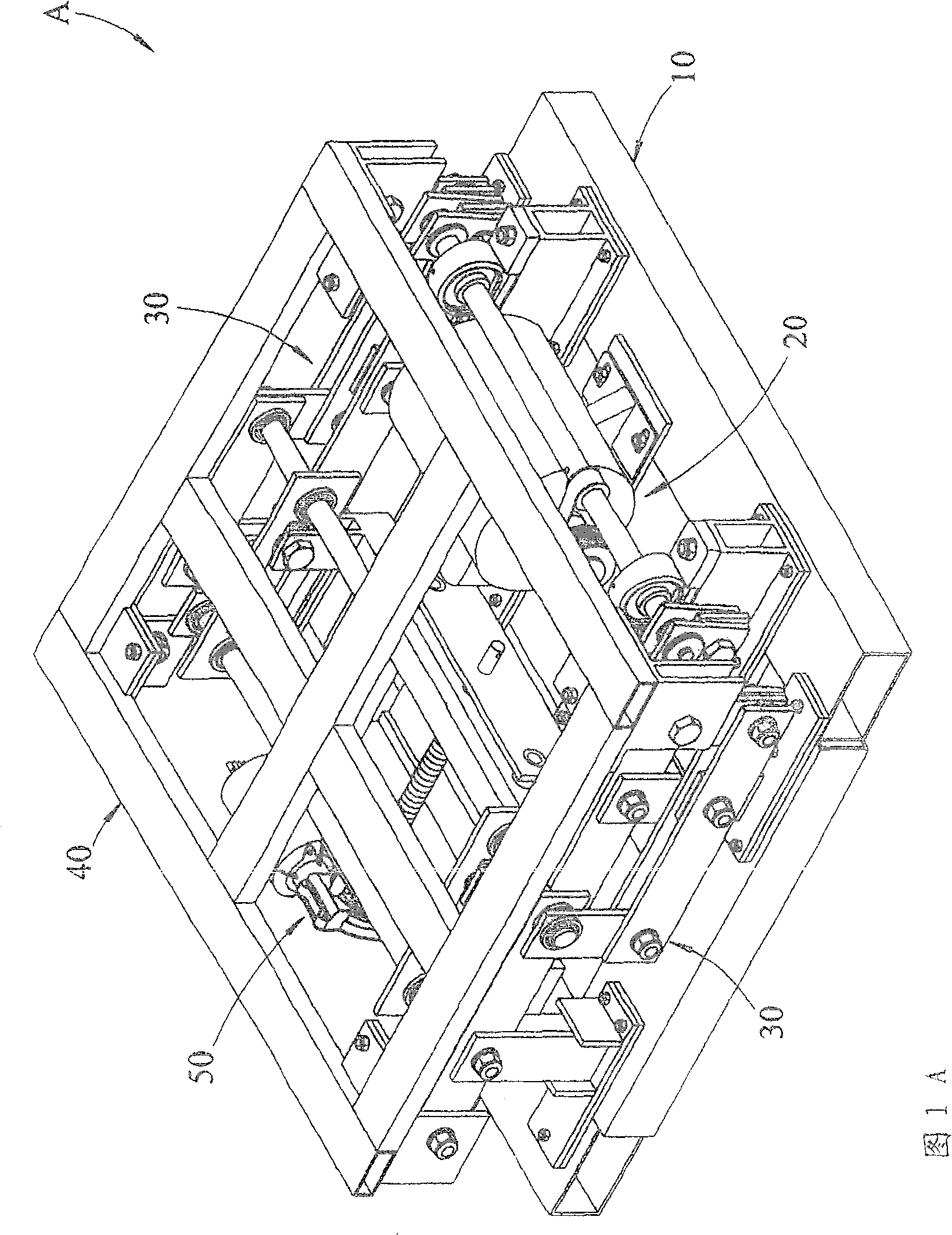

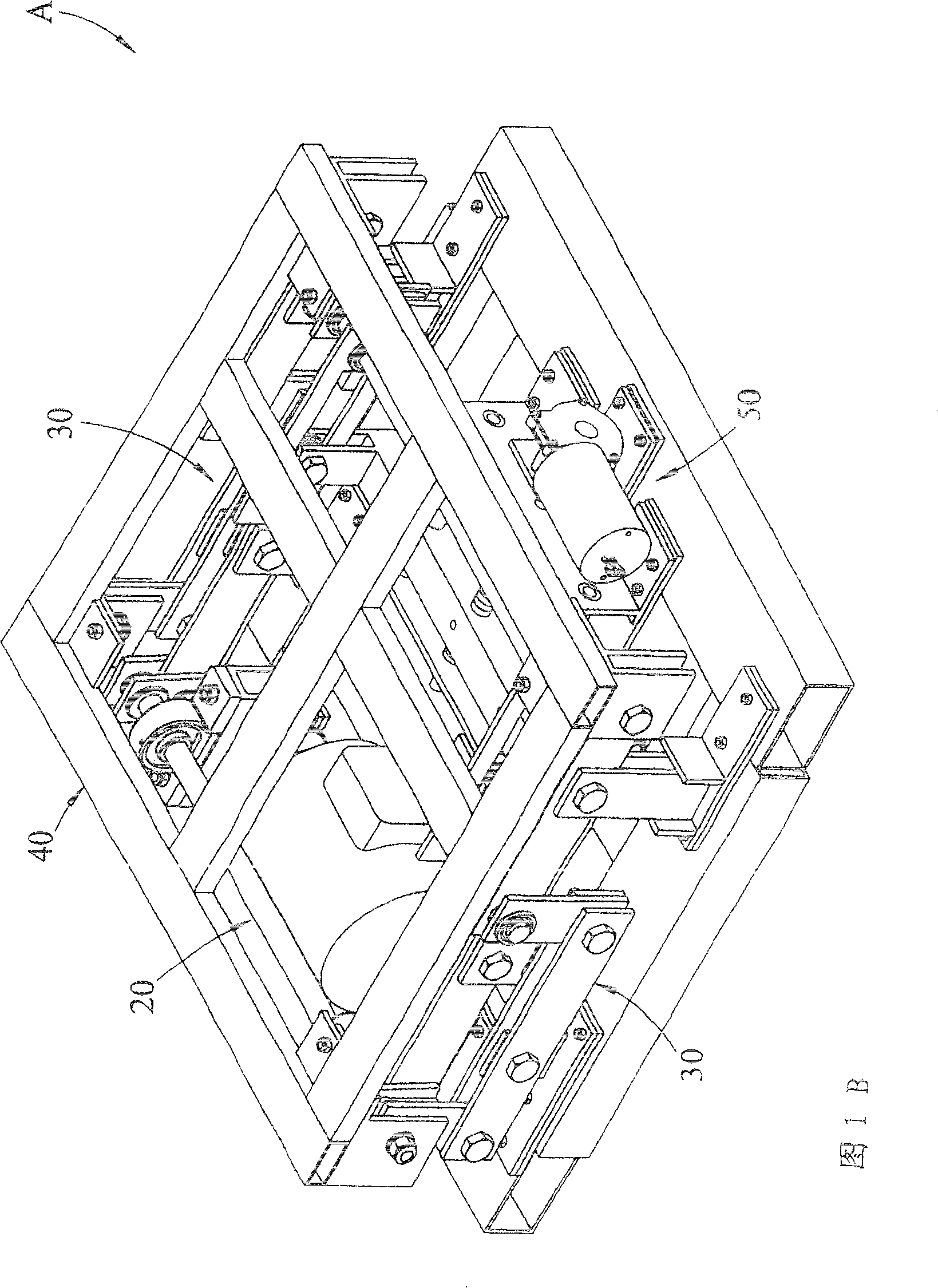

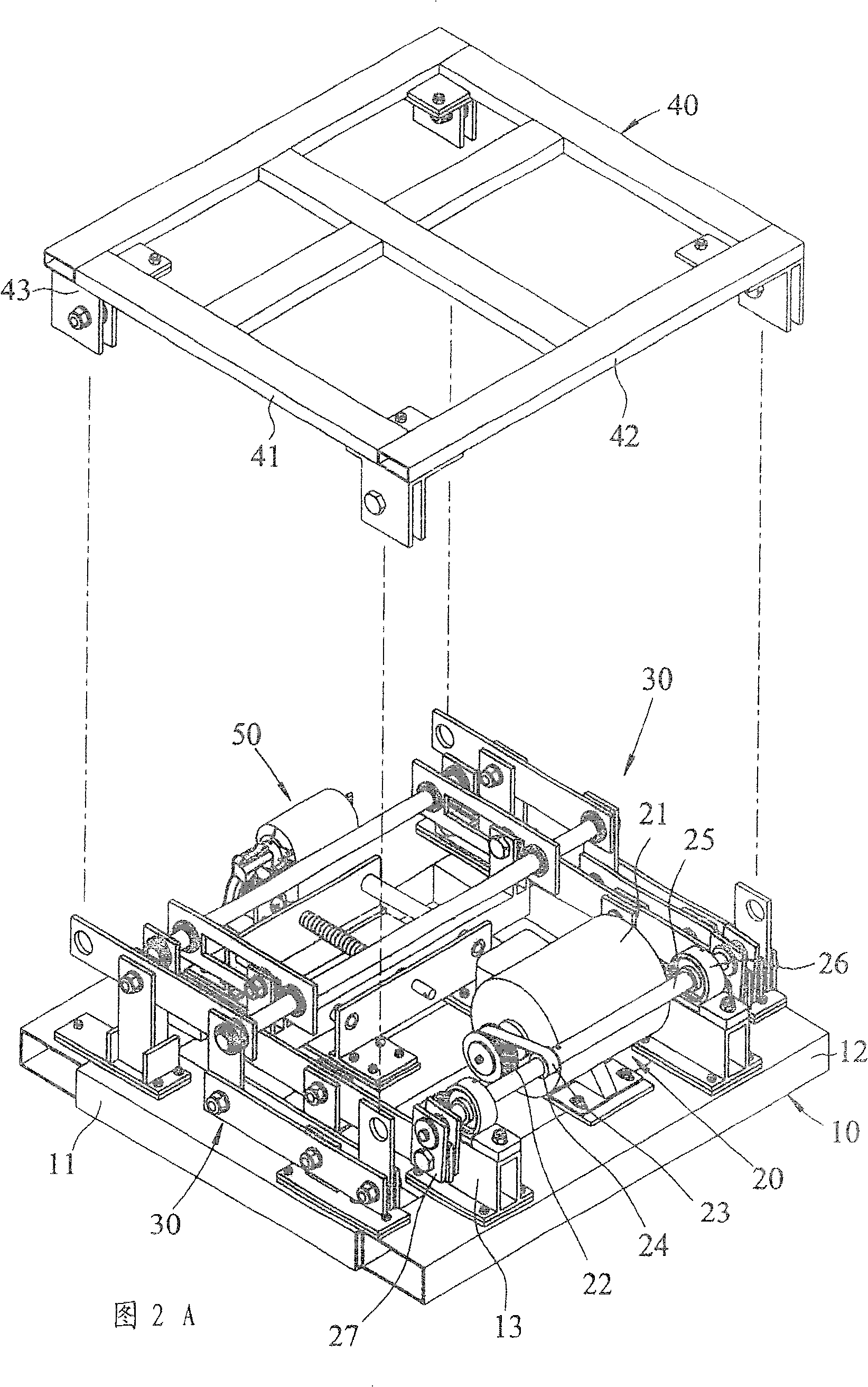

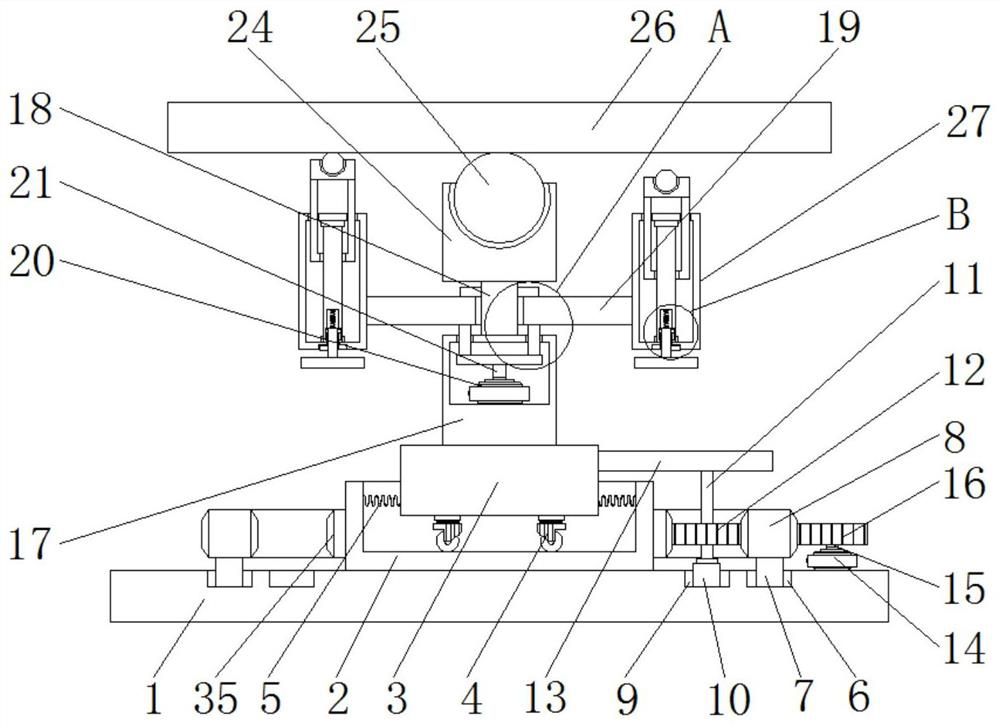

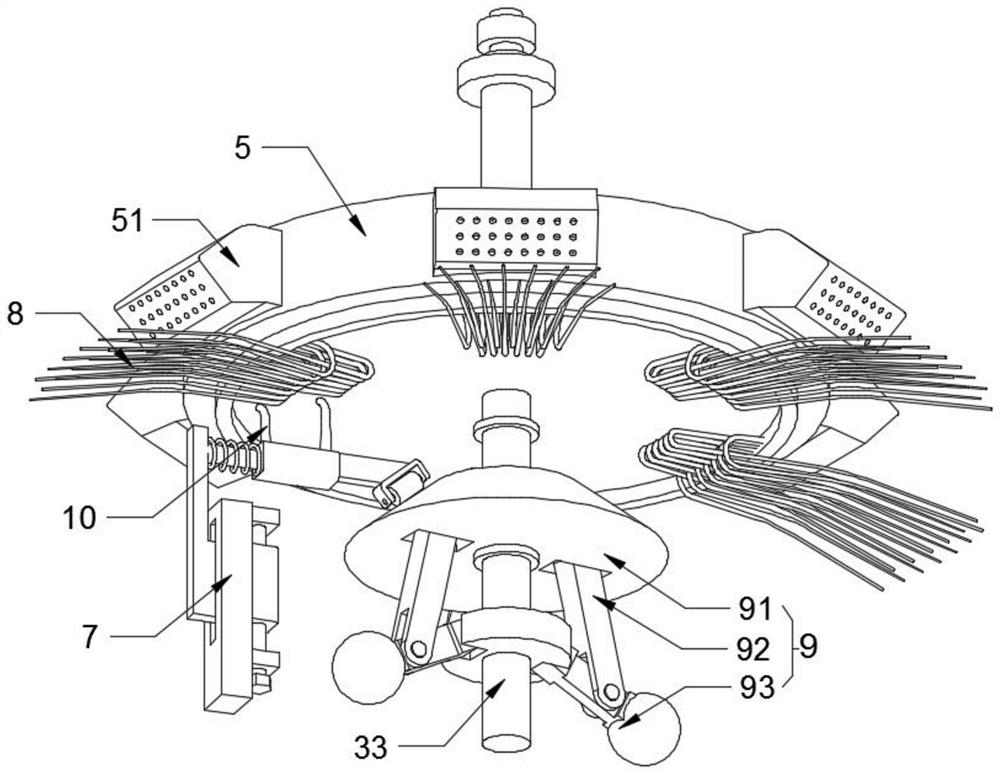

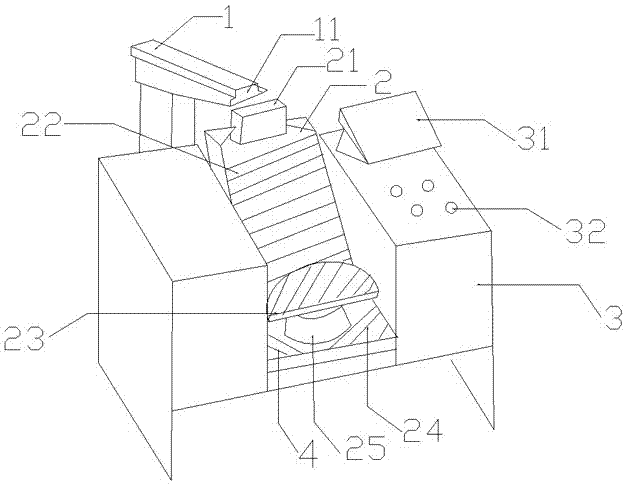

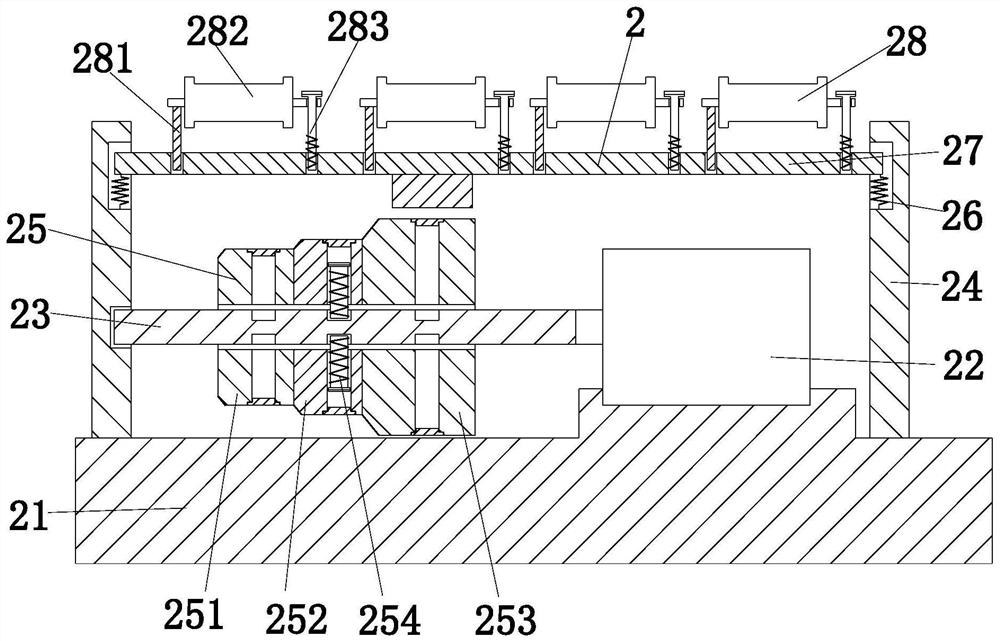

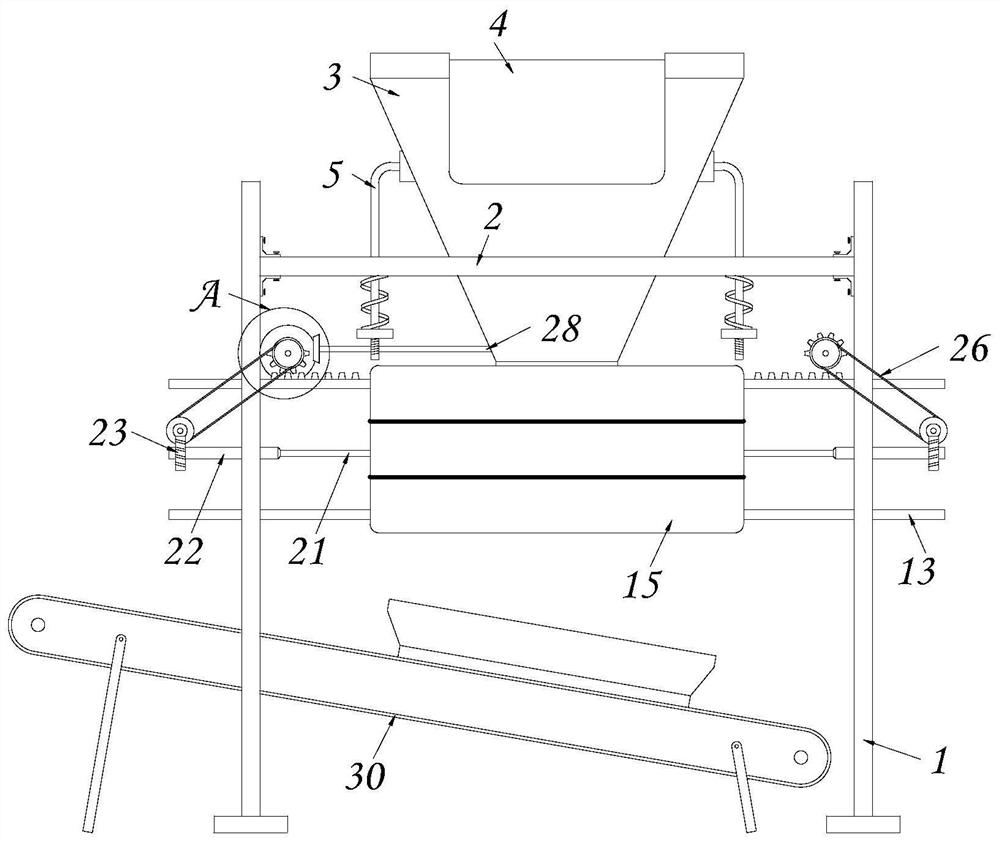

Three-degree-of-freedom thermal fatigue testing device used for metal bellows of vehicle exhaust system

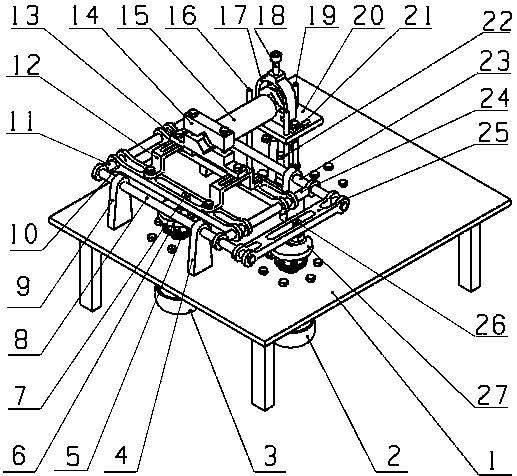

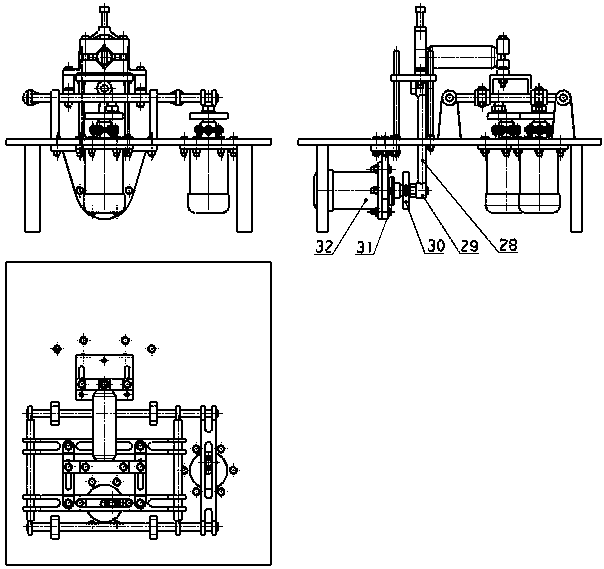

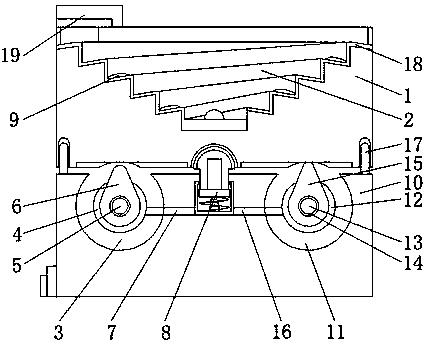

InactiveCN105510011AAchieve independenceChange the vibration amplitudeMachine part testingVibration testingThermal fatigueThree degrees of freedom

The invention discloses a three-degree-of-freedom thermal fatigue testing device used for a metal bellows of a vehicle exhaust system, and the three-degree-of-freedom thermal fatigue testing device belongs to the field of vehicle component performance detection. The three-degree-of-freedom thermal fatigue testing device is composed of driving motors, a transmission mechanism and a clamping mechanism. The three-degree-of-freedom thermal fatigue testing device achieves movement of the metal bellows in one direction, and can achieve combined movement in two or three directions. The integral structure of the three-degree-of-freedom thermal fatigue testing device is connected in ways of: both ends of the bellows are fixed on a vibration mechanism by means of V-shaped blocks, and the distance between the V-shaped blocks can be changed by adjusting fastening bolts, so as to achieve thermal fatigue tests on bellows of different sizes; the driving motors in three directions are fixed under a test bench; the transverse driving motor and the longitudinal driving motor are connected with crank wheels through couplers and drive sliding chute connecting rods and polished rods to move along brackets, such that transverse and axial movement of a vibration end of the bellows are achieved; and the vertical driving motor pushes the clamping mechanism to move along a vertical polished rod up and down through a crank rocker mechanism, thereby achieving vertical direction of the vibration end of the bellows.

Owner:CHANGCHUN UNIV OF TECH

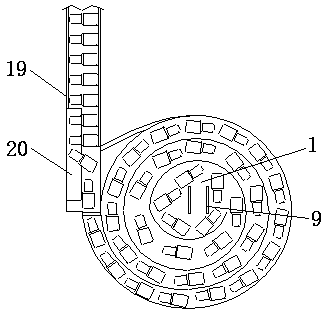

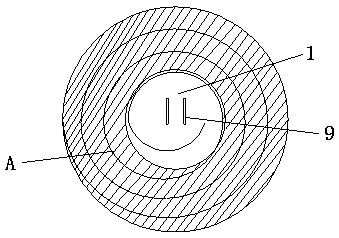

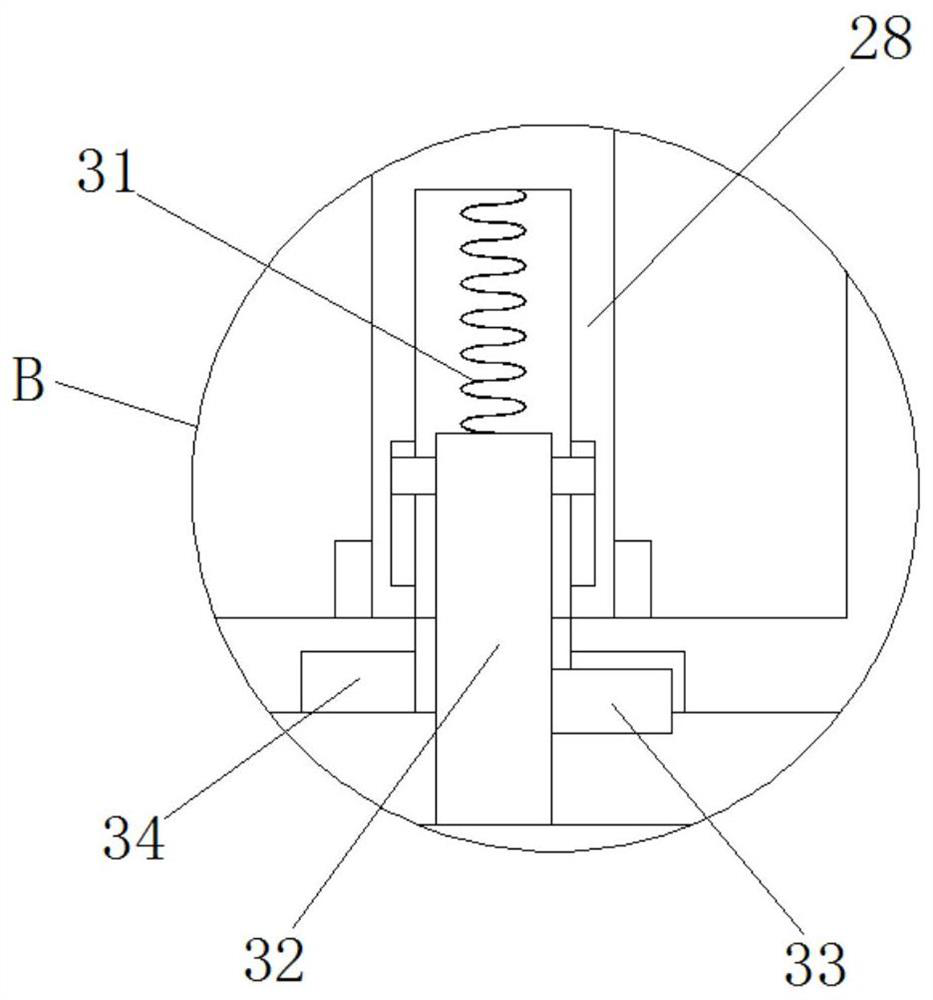

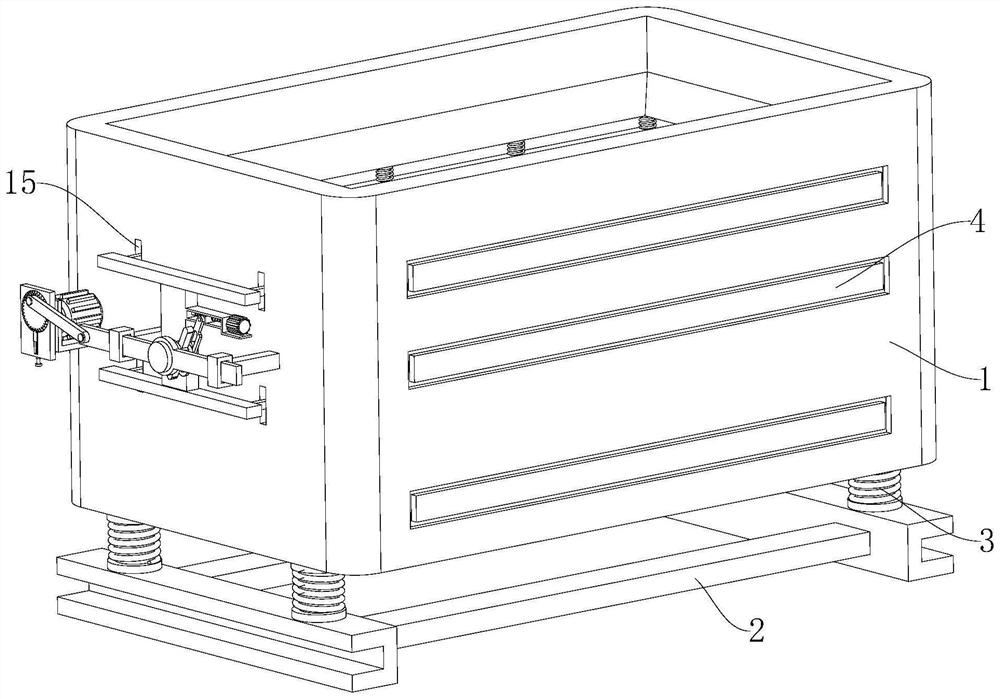

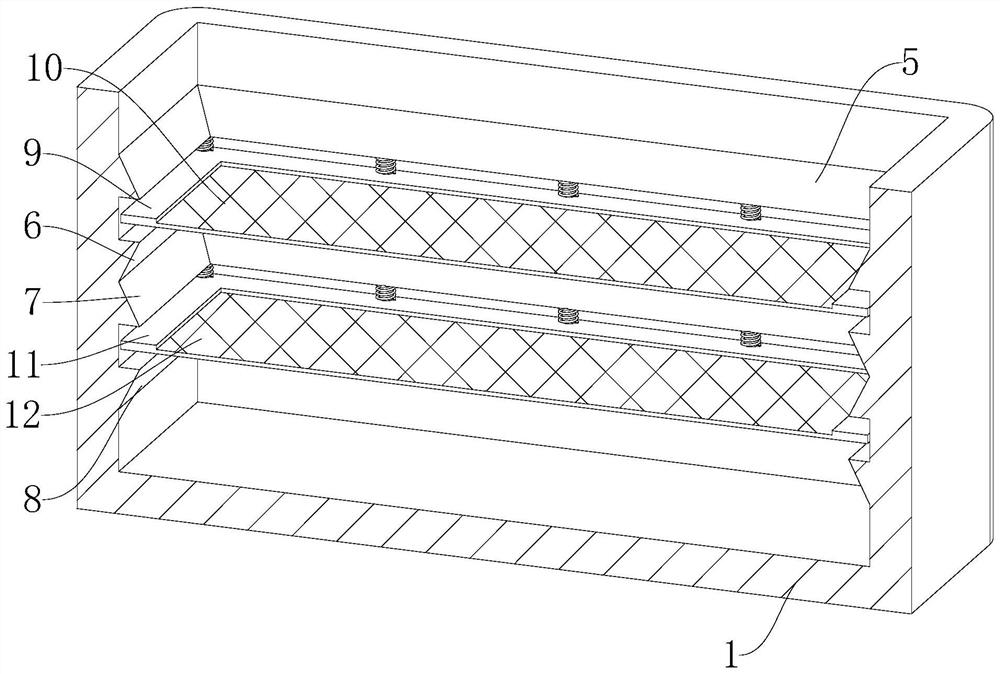

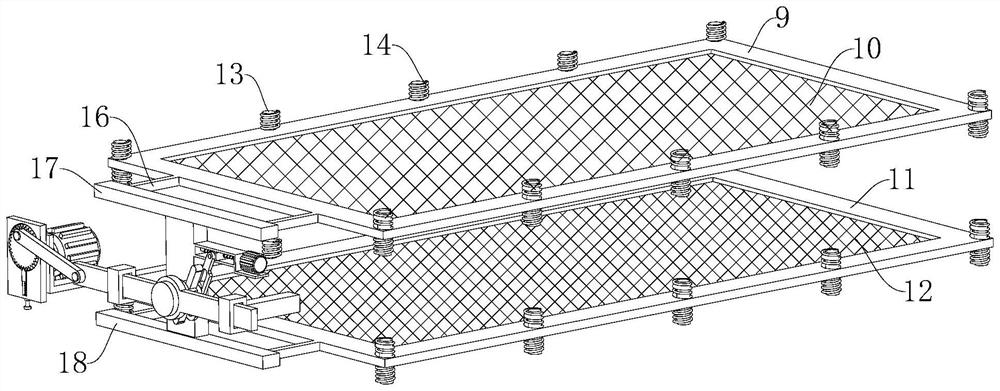

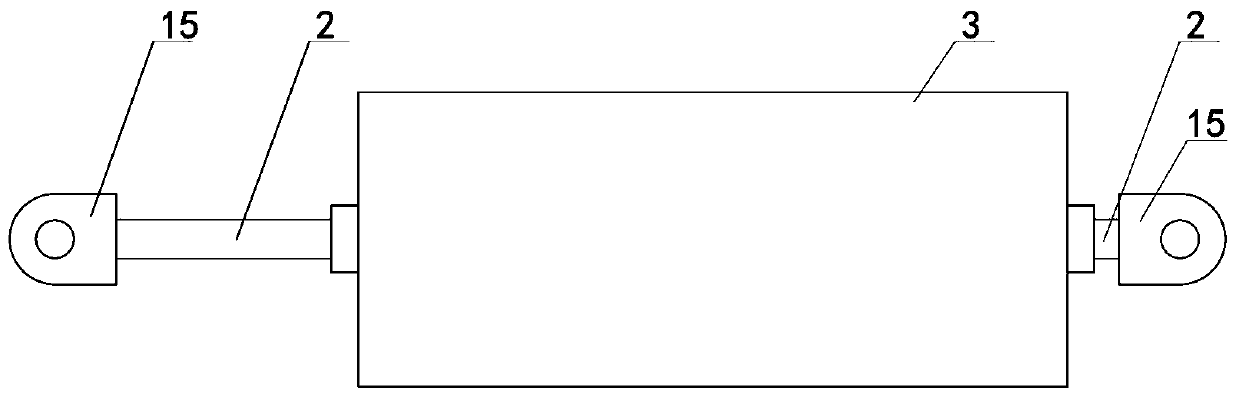

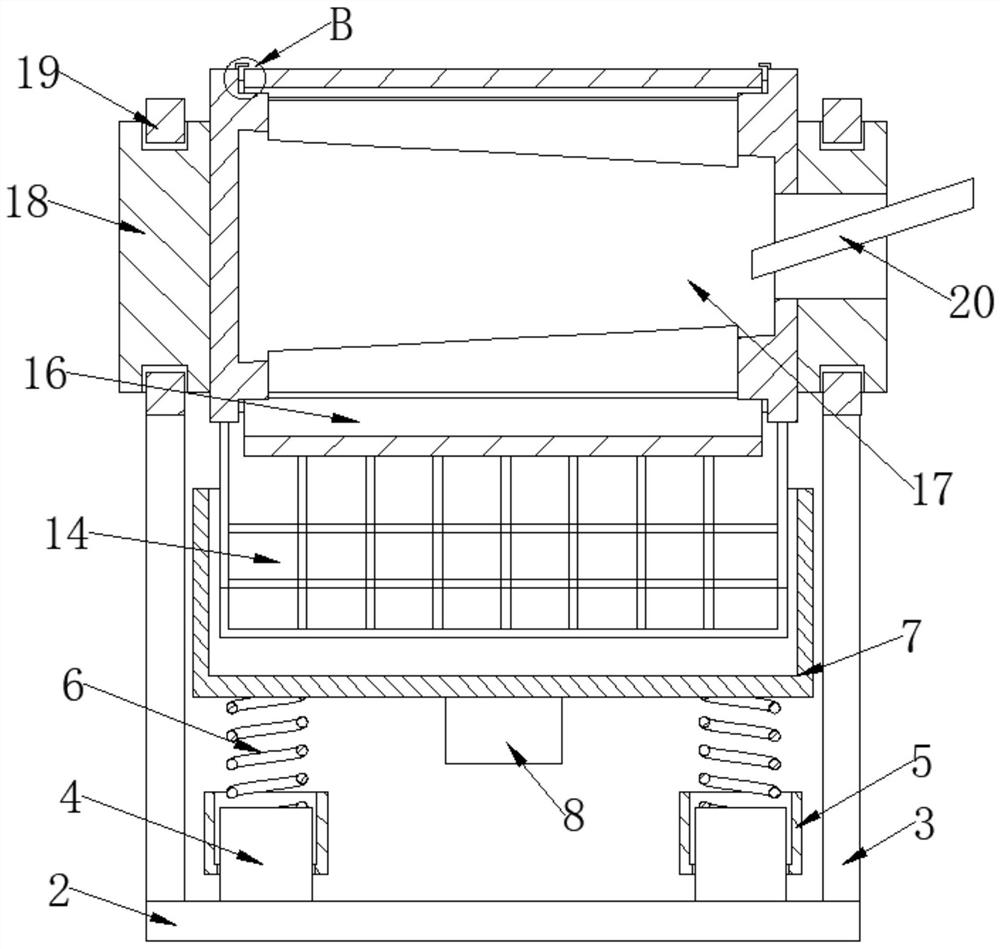

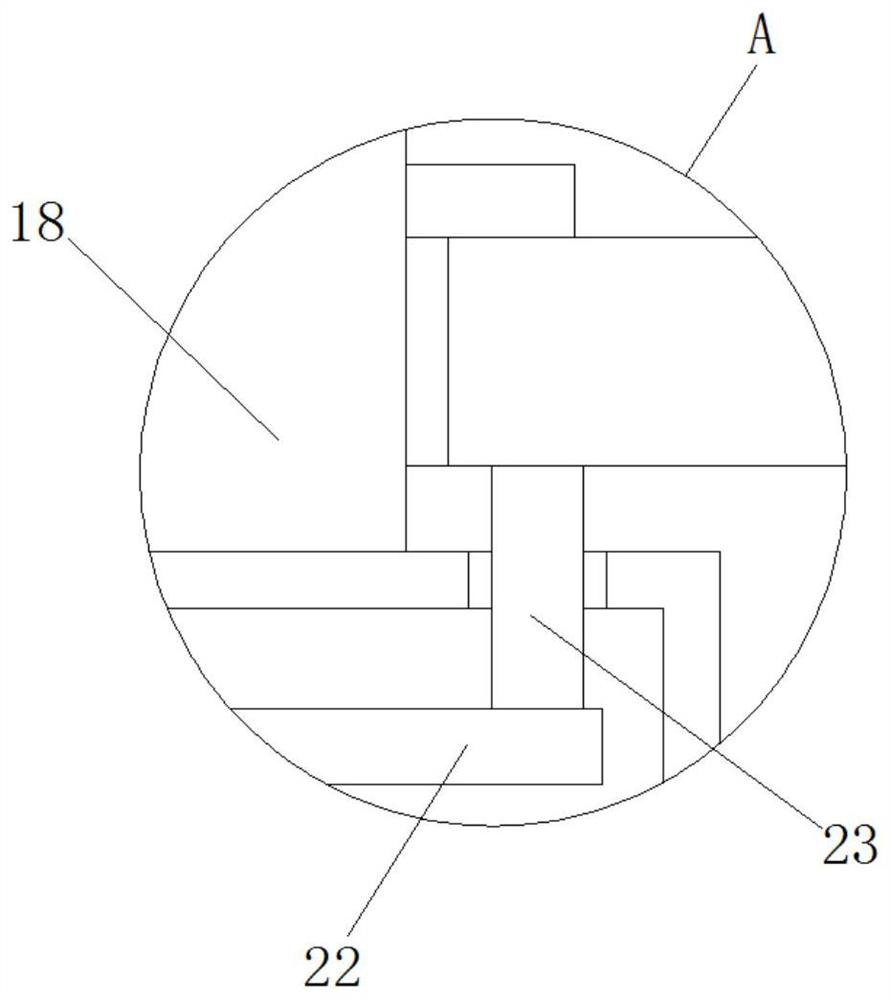

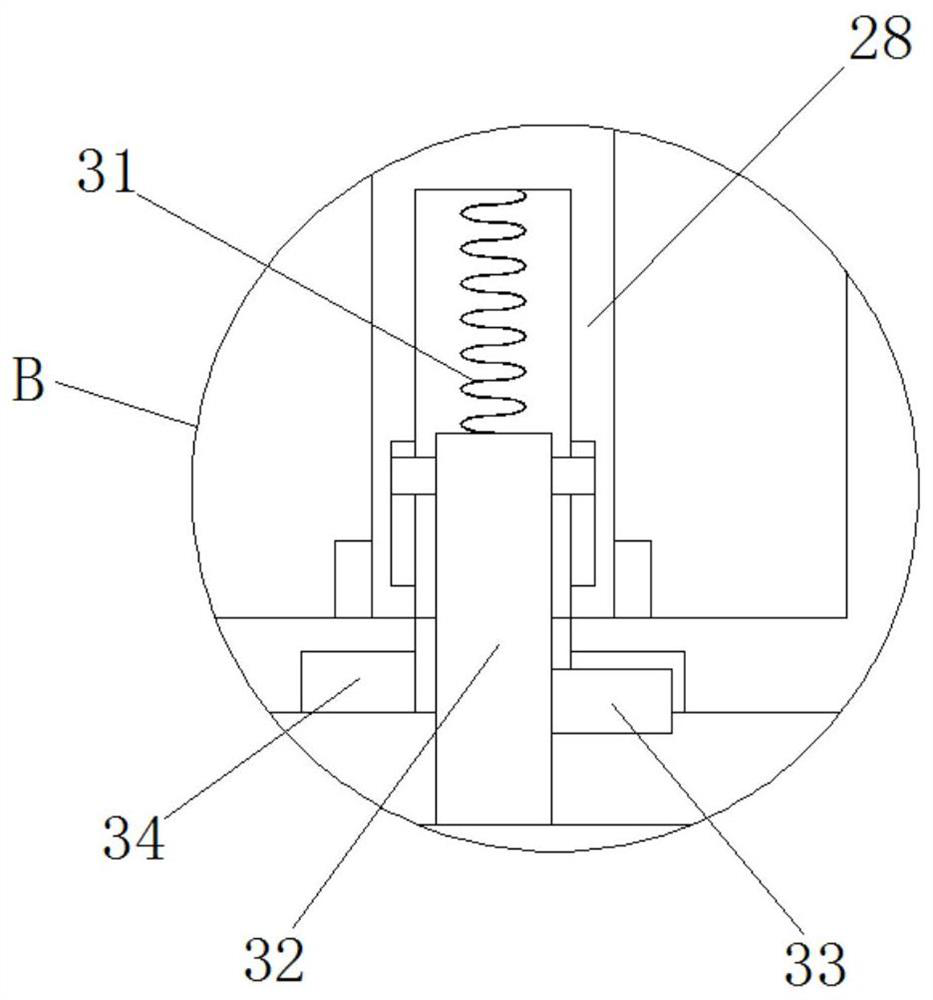

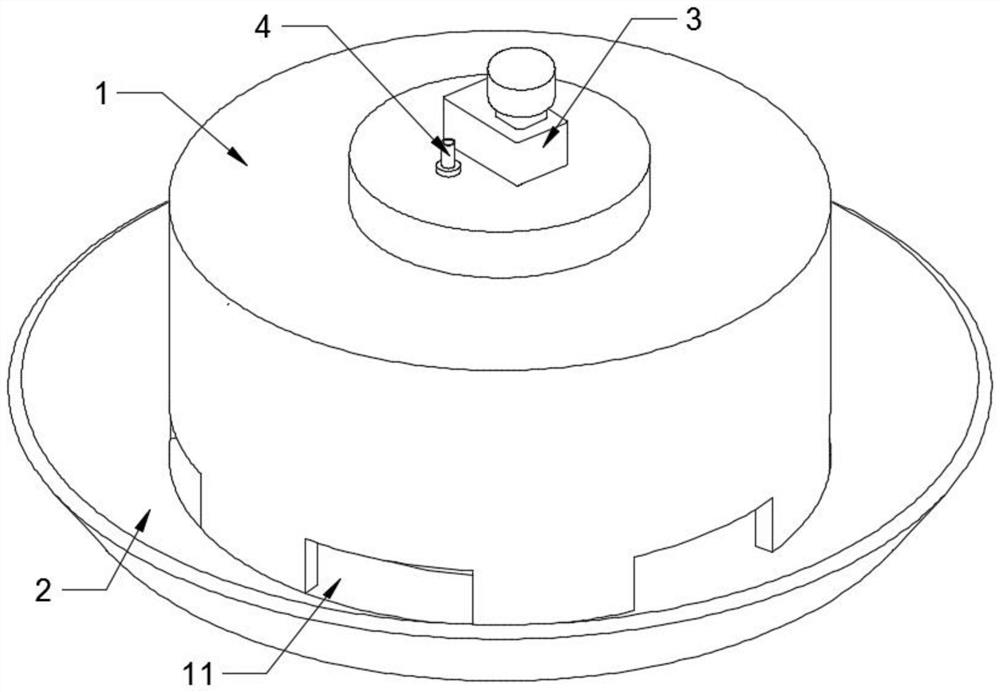

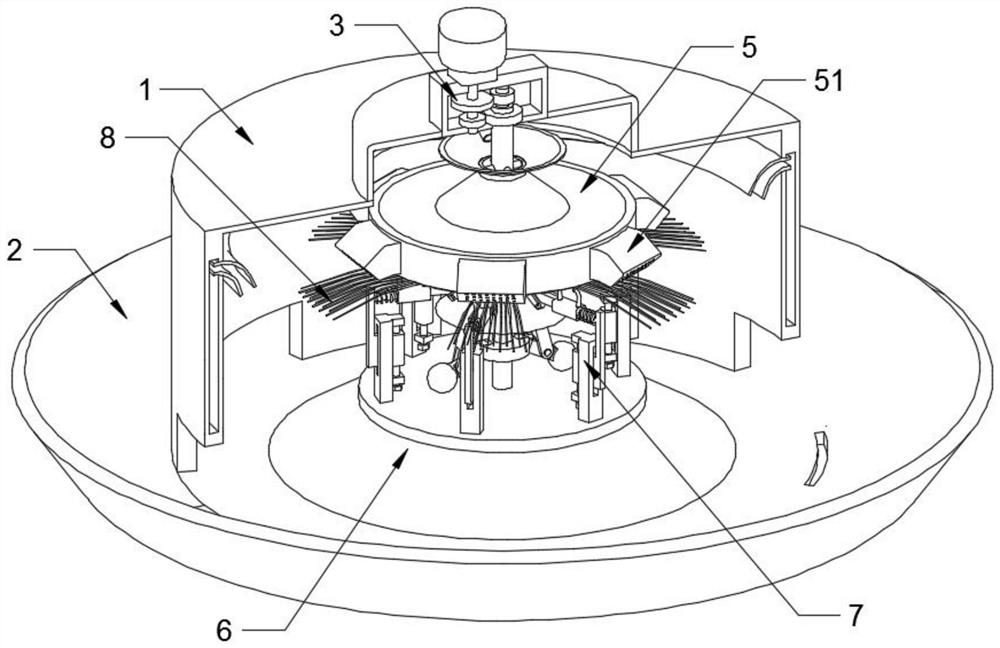

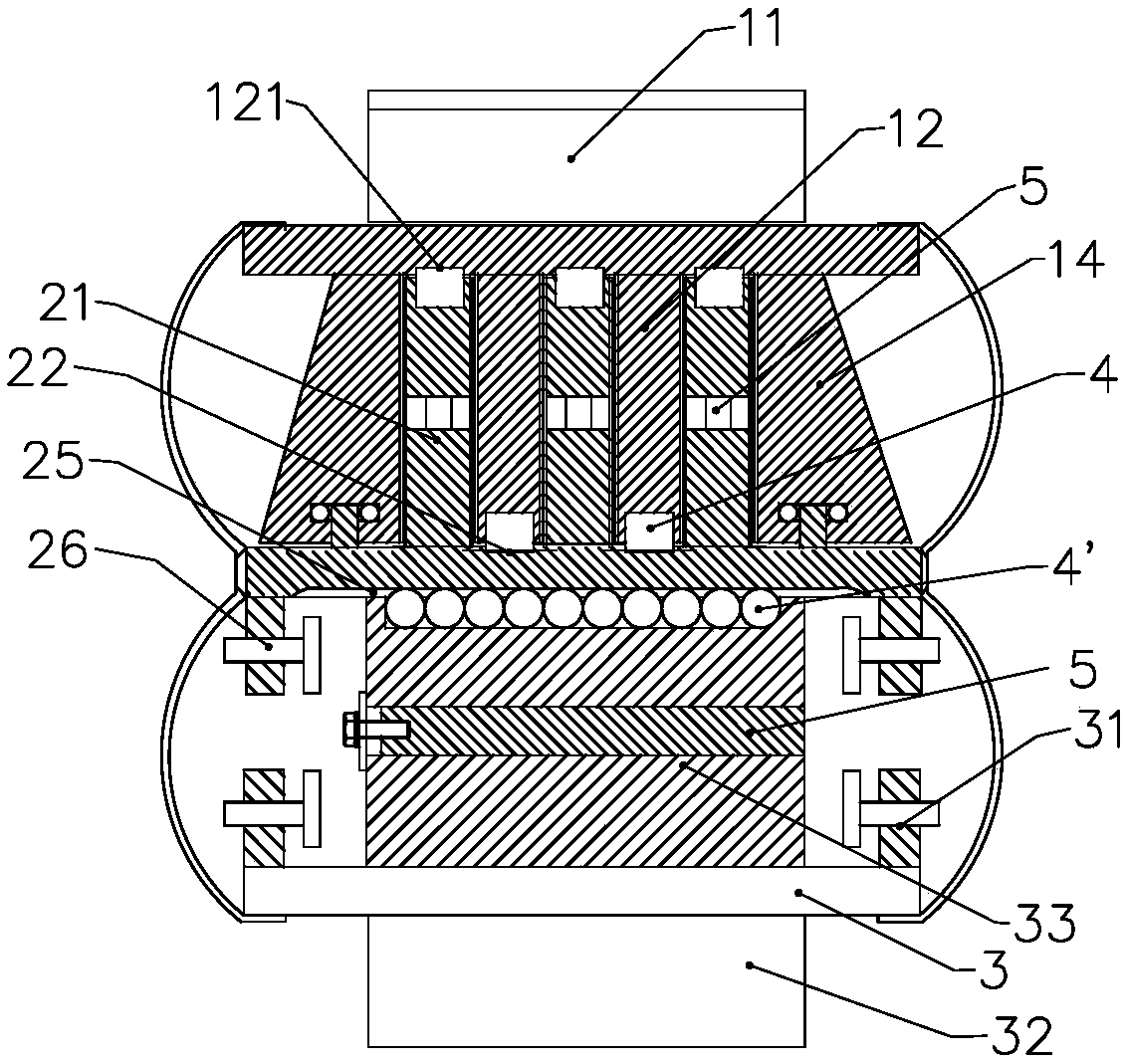

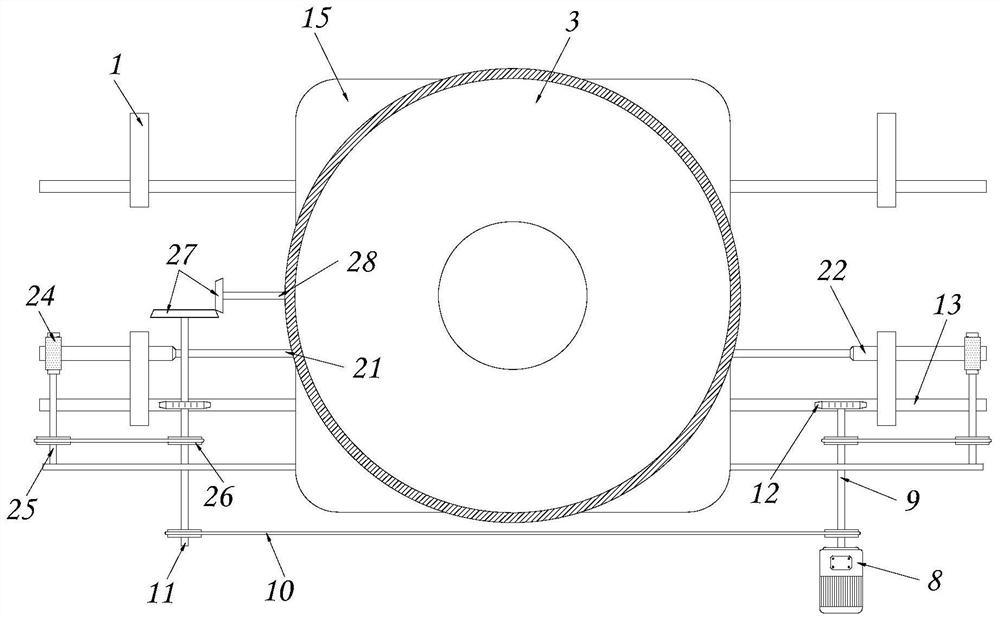

Multidimensional vibration sorting system with intelligent frequency modulation

ActiveCN111230569AReduce collisionReduce direct collisionMetal working apparatusVibration amplitudeEngineering

The invention discloses a multidimensional vibration sorting system with intelligent frequency modulation. The multidimensional vibration sorting system comprises a vibration plate, a base plate, a vibration mechanism and gravity sensors; the gravity sensors act on the vibration plate and recognize the gravity change at a specified position on the vibration plate; the vibration mechanism has two or more vibration frequencies, and / or has two or more vibration amplitudes, and / or has two or more vibration modes; and the vibration mechanism drives the vibration plate, and when the gravity sensorsrecognize that the gravity at the specified position on the vibration plate has a specified change, the vibration frequencies and / or vibration amplitudes and / or vibration modes of the vibration mechanism are switched. In the multidimensional vibration sorting system, by arranging the vibration plate, a circular groove, an elastic paint layer and a high-elastic baffle, collision between accessoriesand the wall surface of the circular groove and collision between the accessories can be conveniently prevented during vibration sorting of the accessories in the vibration plate, and wear of precision accessories is prevented; and as the gravity sensors act on the vibration mechanism, gathering and mutual collision of the precision accessories are reduced, and wear caused by mutual collision ofthe precision accessories is reduced.

Owner:福建新峰科技有限公司

Anti-seismic experiment device for assembled bridge engineering

ActiveCN111638029AChange the vibration amplitudeIn line with the actual useBridgesVibration testingElectric machineryEarthquake resistant

The invention discloses an anti-seismic experiment device for assembled bridge engineering. The device comprises a base, a movable seat and a first mounting bin, wherein a fixed bin is fixed to the middle of the top of the base, a second gear ring is mounted on the outer side of the fixed bin, the movable seat is arranged in the fixed bin, and first annular sliding grooves are formed in the two sides of the top of the base. According to the anti-seismic experiment device for the assembled bridge engineering, the first gear is in meshed connection with the second gear ring and a first gear ring; the first gear ring and a second gear are in meshed connection; a first motor drives a second rotating shaft to rotate; a first rotating shaft can continuously perform planetary motion along with the first rotating shaft, and then the movable seat is driven to shake in multiple directions, so that a multi-direction vibration experiment can be performed once, a bridge model on the placement platecan be driven to further vibrate in multiple directions, the actual use condition is better met, and a more comprehensive experiment can be performed.

Owner:DALIAN JIAOTONG UNIVERSITY

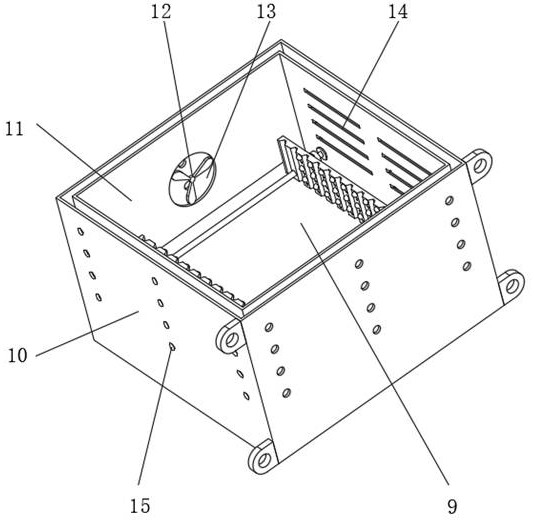

Material screening device

The invention discloses a material screening device which comprises a box body, an end cover, a screen mesh and a vibrating motor, wherein the end cover is mounted at the top end of the box body; a feed opening is formed in the end cover; a discharge opening is formed in the tail end of the box body; the vibrating motor is mounted at the bottom end of the box body; the box body is fixed on a support through support pillars at the four corners of the box body; elastic elements are arranged between the support pillars and the box body; vertical parallel screen plates are arranged on two inner sides of the box body and are connected with each other through screen mesh tightening devices; each screen mesh tightening device comprises a bolt, a fastening screw matched with the bolt and a baffle plate fixed on the edge of the screen mesh; the fastening screws penetrate through the baffle plates to be fastened with the screen plates and the bolts. The material screening device has the benefits as follows: the structure is designed reasonably and compactly; the end cover is opened and closed conveniently by a control valve so as to facilitate maintenance and adjustment inside the box body; the amplitude of vibration is changed by adjusting the screen mesh tightening device; springs have a vibration reduction effect so as to meet the requirements of enterprises.

Owner:孙海兵

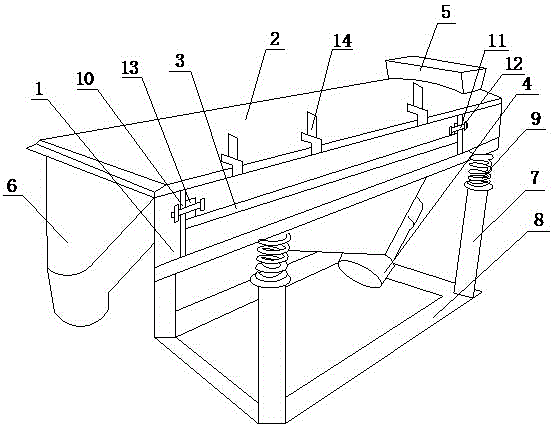

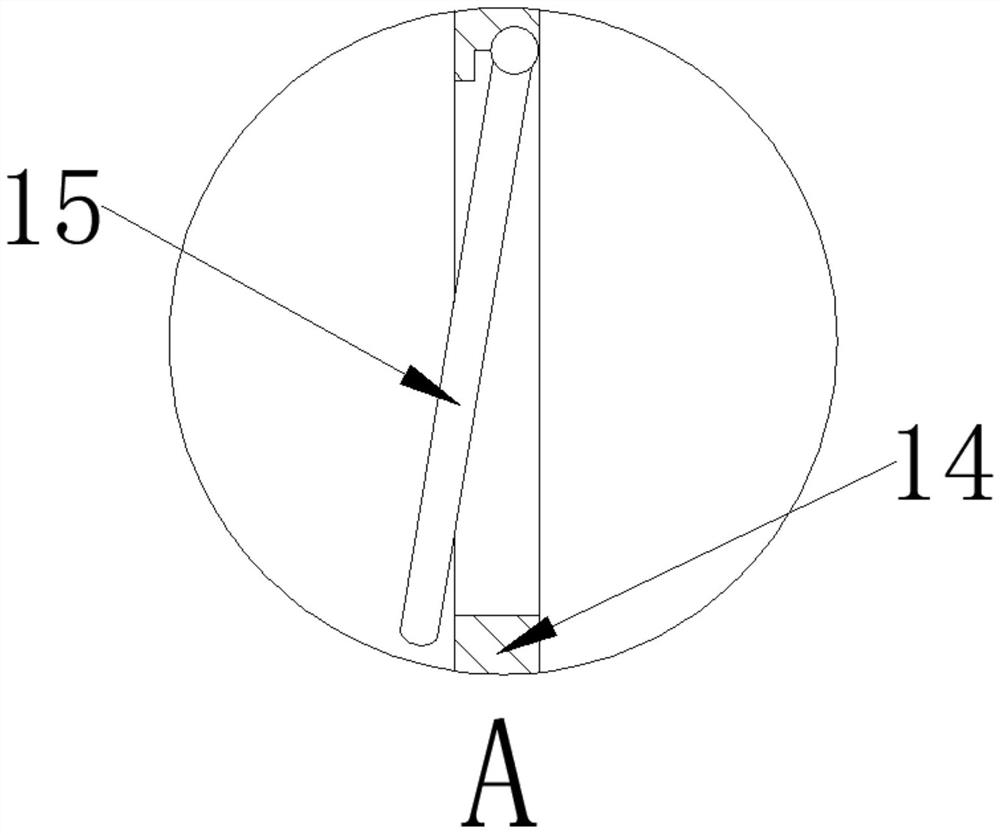

Crop seed screening equipment

InactiveCN109433595AUniform particle sizeGuaranteed germination rateSievingScreeningGranularityEngineering

The invention discloses a crop seed screening equipment. The equipment comprises a base, wherein a hopper is arranged on the left side of the top of the base, a vibrating screening device is arrangedon the right side of the top of the base, and a discharging mechanism and a flow guide plate are arranged on the lower portion of the right side of the hopper; the screening device comprises a screenframe and a driving mechanism, the left end of the screen frame is rotatably connected with the base through frame columns, and the bottom of the right end of the screen frame is connected with the upper surface of the base through a plurality of tension springs; the driving mechanism comprises a driving seat, an ejecting rod, a driving motor, and a cam, wherein the ejecting rod is arranged on thedriving seat in a sliding mode, the driving motor is arranged on the driving seat, and the cam is arranged on an output shaft of the driving motor and is used for driving the ejecting rod; and an adjusting mechanism used for left-right adjusting the driving mechanism is arranged on the base. According to the equipment, the seed screening speed can be increased, the screened seeds are uniform in granularity, and the germination rate of seeds in the soil is guaranteed; and meanwhile, the vibration force of the screening equipment can be changed, so that the screening equipment is suitable for the use by the seeds with the different granularities.

Owner:重庆市开州区金昇农业开发有限公司

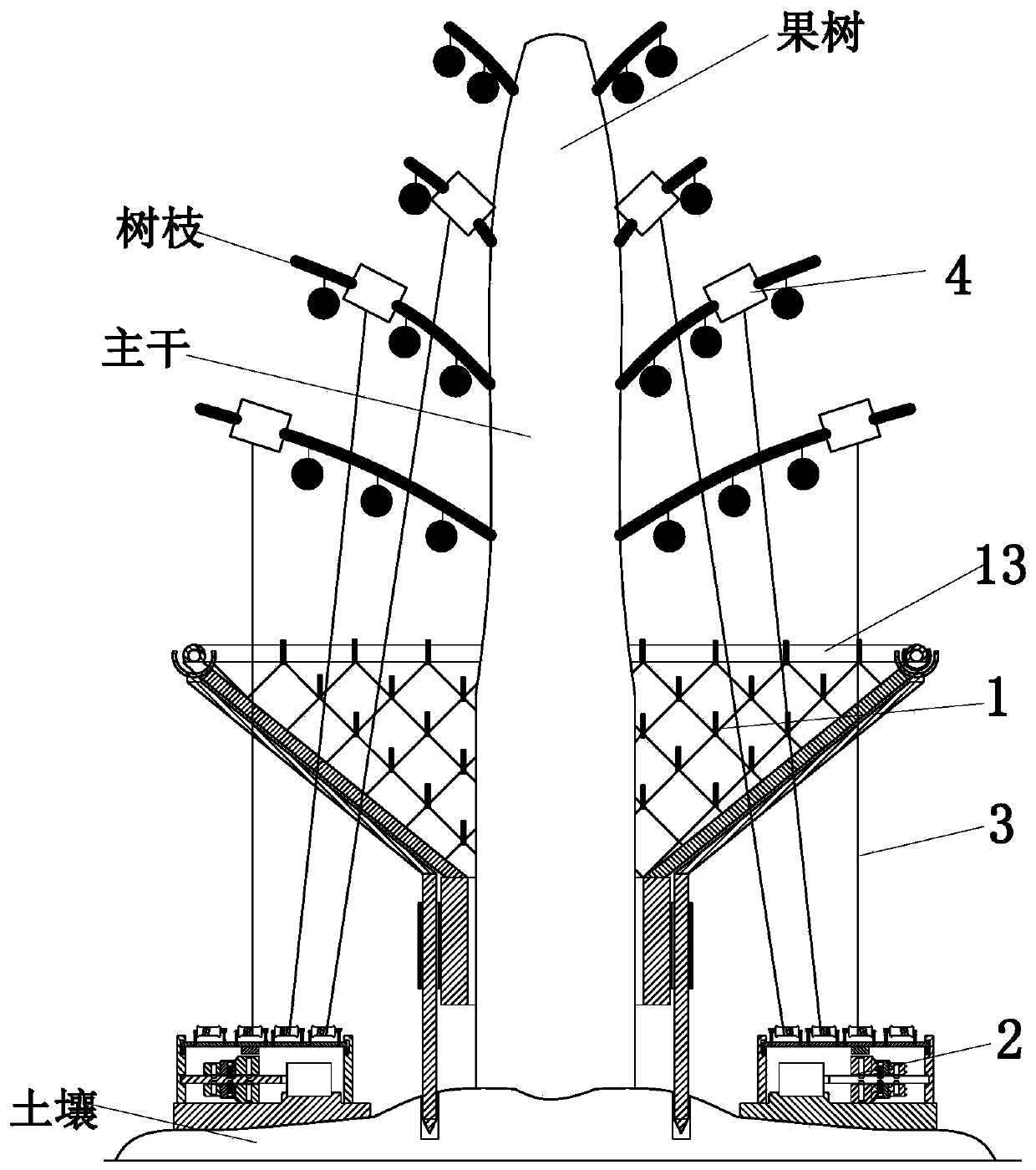

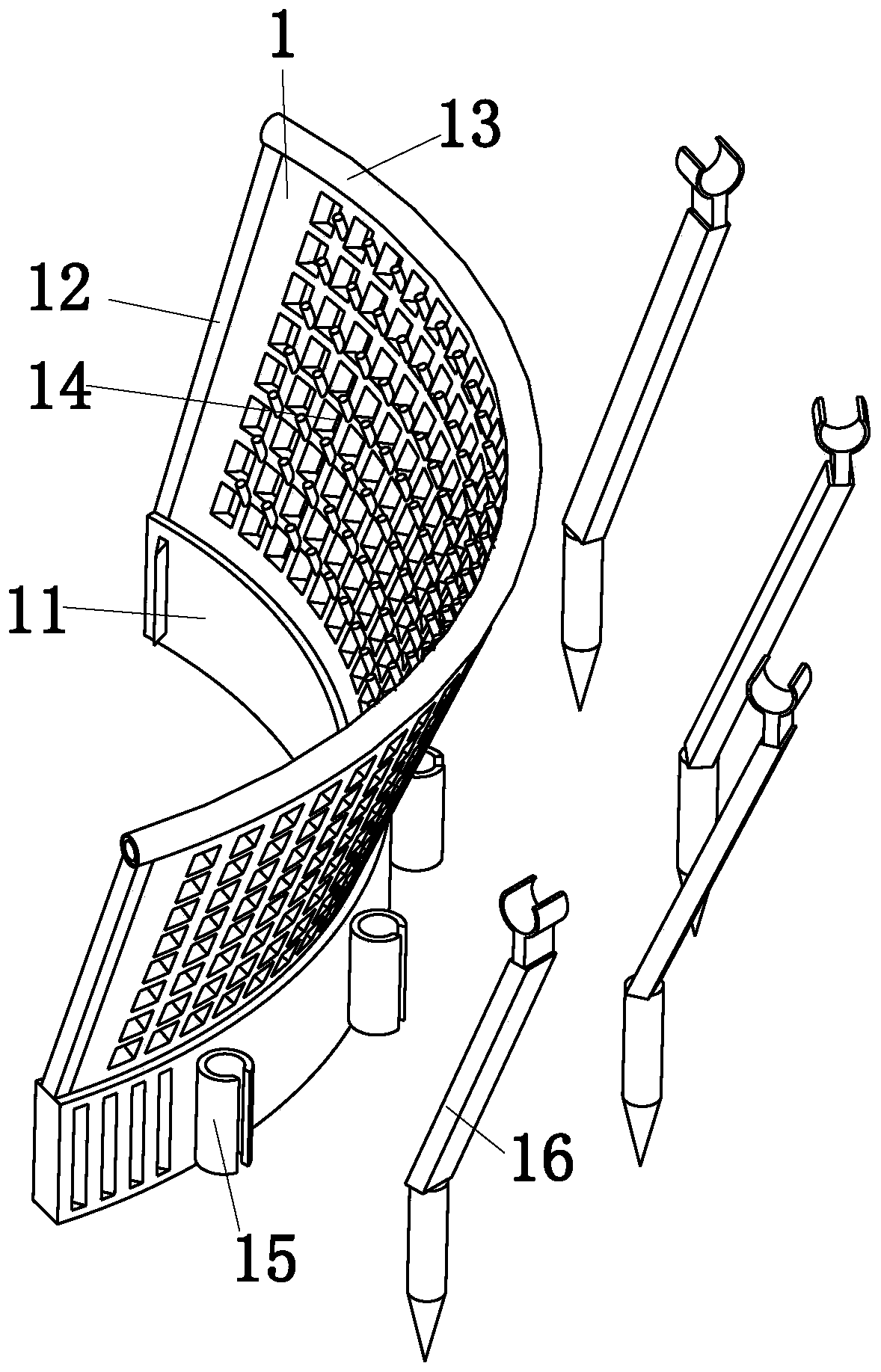

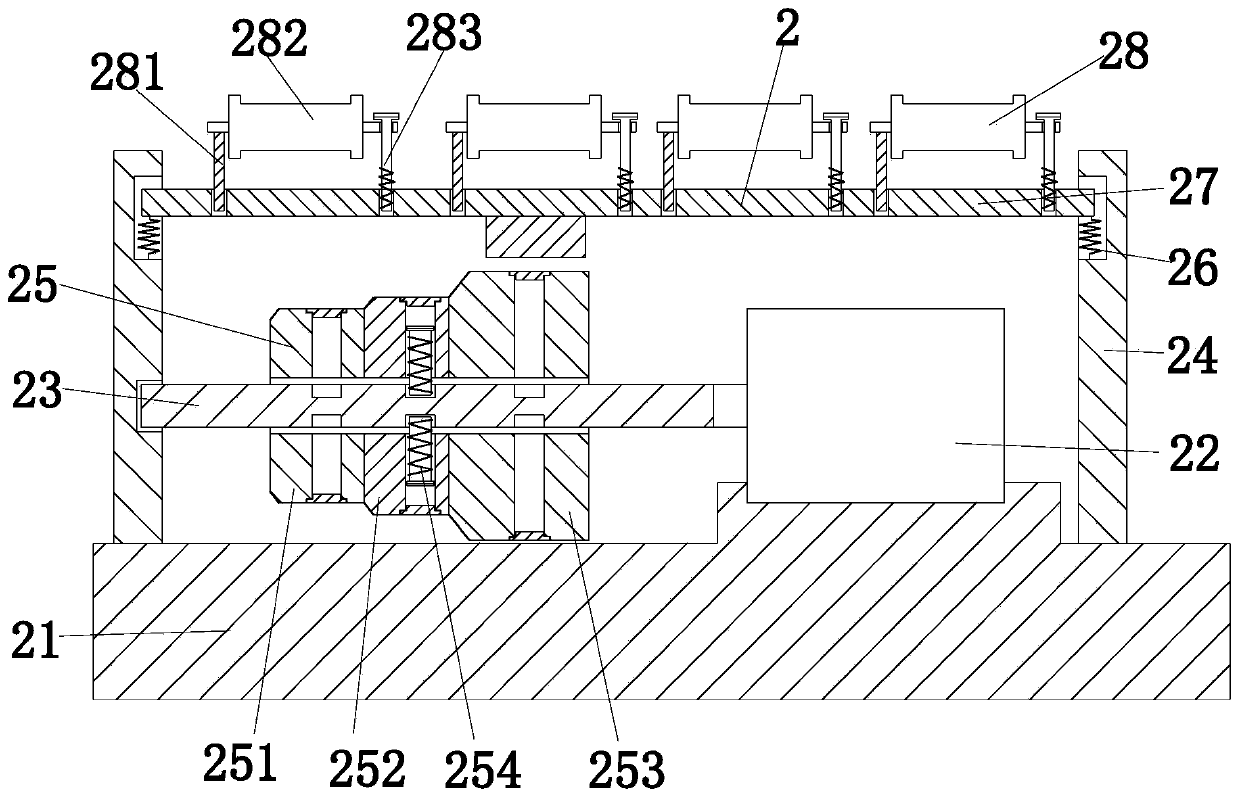

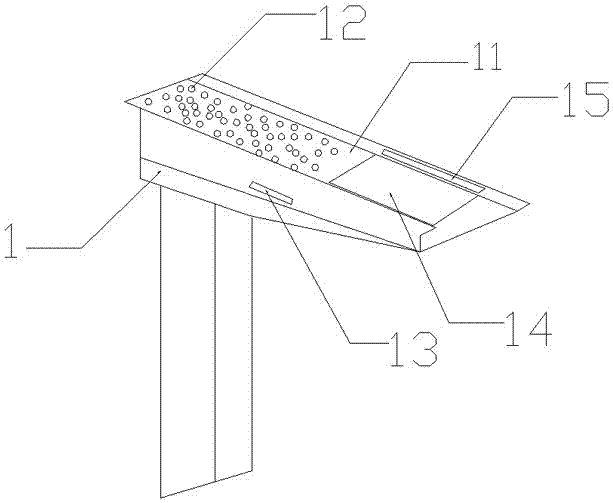

Fruit picking machine for agricultural planting and use method

The invention relates to a fruit picking machine for agricultural planting and a use method. The machine comprises a supporting discharging net, a vibration device, a traction rope and a wrapping frame; the vibration device is arranged on the outer side of the supporting discharging net, and the upper portion of the vibration device is connected with the wrapping frame through the traction rope. Accordingly, the problems can be solved that in the picking process, fruits are knocked off through a bamboo pole, part of branches are likely to be broken, the time for the broken branches growing again is long, the yield of the next year is likely to be affected, in the falling process, due to the fact that the force of manual rod swinging is large and different, part of immature fruits are likely to be knocked off, then fruit waste is caused, the fallen fruits are likely to fall into the ground due to the fact that the fruits are not received in time or not received stably, thus the fruit skin is damaged, and the fruit quality and harvest yield are affected.

Owner:安徽普渡智慧农业装备有限公司

Multi-stage screening vibration type coal separator

InactiveCN114308648AChange the vibration amplitudeImprove screening efficiencySievingScreeningVibration amplitudeMotor drive

The multistage screening vibration type coal picker comprises a box body, a base is arranged below the box body, the box body and the base are connected through a shock absorber, and a first upper protrusion, a first lower protrusion, a second upper protrusion and a second lower protrusion are sequentially and fixedly connected to the inner surface wall of the box body from top to bottom. A second motor drives a rectangular plate to rotate, a gear and the rectangular plate rotate synchronously, the connecting end of a transmission rod and the gear is driven to rotate around the geometric center of the rectangular plate, a sliding rod is pulled to reciprocate left and right, a second sliding block slides, a vertical plate, a first screen and a second screen are driven to reciprocate up and down, and raw coal particles are vibrated and screened; the first motor drives the threaded rod to rotate, so that the nut base moves, the swing rod is driven to move, the first sliding block and the second sliding block rotate, when the sliding rods move by the same displacement, the vibration amplitude of the first screen and the vibration amplitude of the second screen are changed, and the screening efficiency and the screening effect of the first screen and the screening effect of the second screen are improved.

Owner:潘金茹

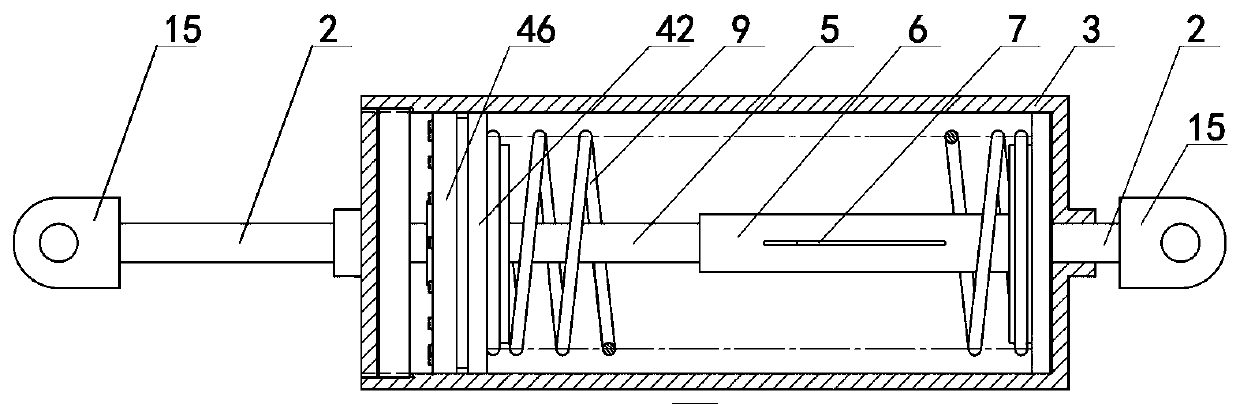

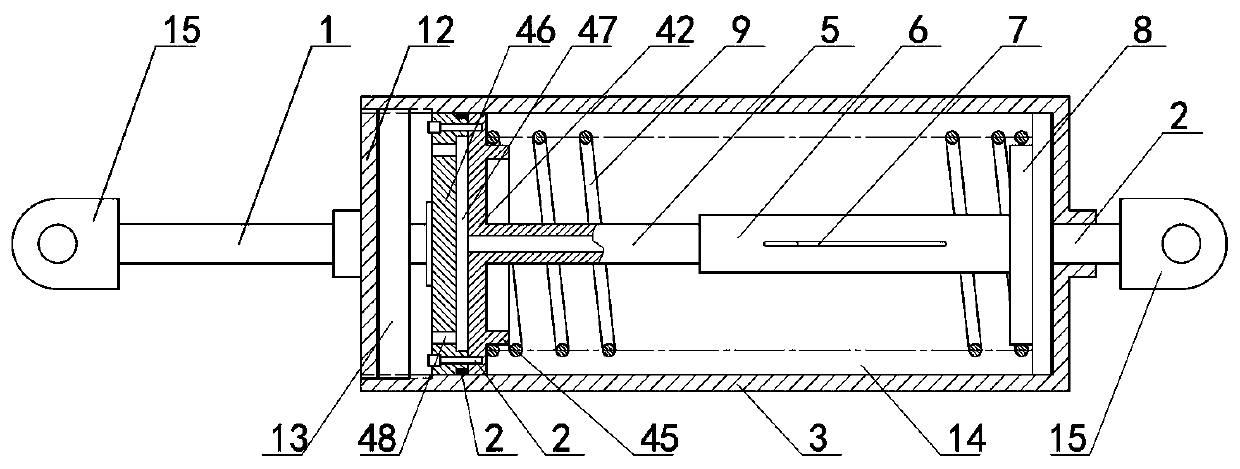

Damping oil pressure damper for steel structure connection nodes

ActiveCN111270661AChange vibration frequencyChange the vibration amplitudeArtificial islandsProtective buildings/sheltersMechanicsPiston

The invention discloses a damping oil pressure damper for connection nodes in a steel structure, which comprises a front pull rod, a rear pull rod and a tubular node box, wherein the node box is of aclosed structure, the inner cavity of the node box is filled with damping oil to form an oil cavity, the middle of the oil cavity in the node box is sleeved with a piston body in a matched manner, andthrust springs are respectively connected between a movable spring seat and a fixed spring seat on two sides of the piston body; a sliding pipe is axially fixed at the axial center position of the piston body, two ends of the sliding pipe are respectively matched and sleeved in sliding sleeves at the two ends and are capable of sliding, and strip-shaped oil-saving holes are formed in the side surfaces of the sliding sleeves at the two ends. According to the invention, when the front pull rod and the rear pull rod of the node box are pulled or compressed, the piston body inside the node box can be driven to move in the axial direction, and then the sliding pipe is driven to slide in the sliding sleeve, so that oil resistance change adjustment can be automatically carried out, vibration frequency and vibration amplitude of the nodes are changed, and energy can be effectively dissipated and vibration can be reduced.

Owner:CHINA NAT OFFSHORE OIL CORP +2

Power supply waterproof device for reconnaissance robot

InactiveCN113059590AImprove cooling effectImprove cooling efficiencyManipulatorPower conversion systemsEngineeringMechanical engineering

The invention discloses a power supply waterproof device for a reconnaissance robot, and relates to the technical field of reconnaissance robots. The problem of heat dissipation is solved. The power supply waterproof device specifically comprises a shell, the shell comprises a base and a side wall, a damping seat is connected to the outer wall of the top of the base through a damping mechanism, and a fixing mechanism is arranged on the outer wall of the top of the damping seat. The side wall comprises an outer side wall and an inner side wall, and three sets of second heat dissipation holes at equal intervals are formed in the inner wall of the outer side wall. Two sets of first heat dissipation holes are formed in the inner walls of the inner side walls, the first heat dissipation holes are designed in an inclined mode from inside to outside, the first heat dissipation holes are formed between the two adjacent sets of second heat dissipation holes, planar projections of the first heat dissipation holes and planar projections of the second heat dissipation holes are completely not overlapped, and active heat dissipation holes are formed in the inner wall of one of the inner side walls. The internal power supply is relatively open to the outside, heat dissipation is facilitated, and the heat dissipation efficiency can be improved by arranging an active heat dissipation fan.

Owner:章余

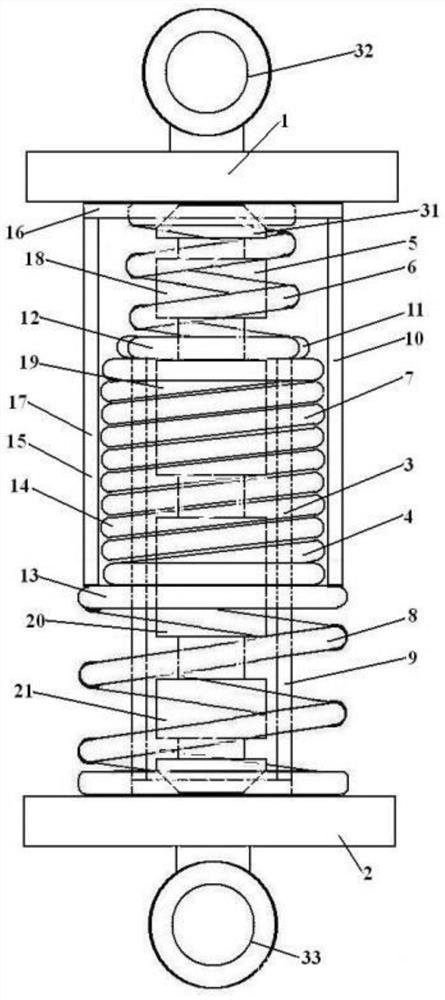

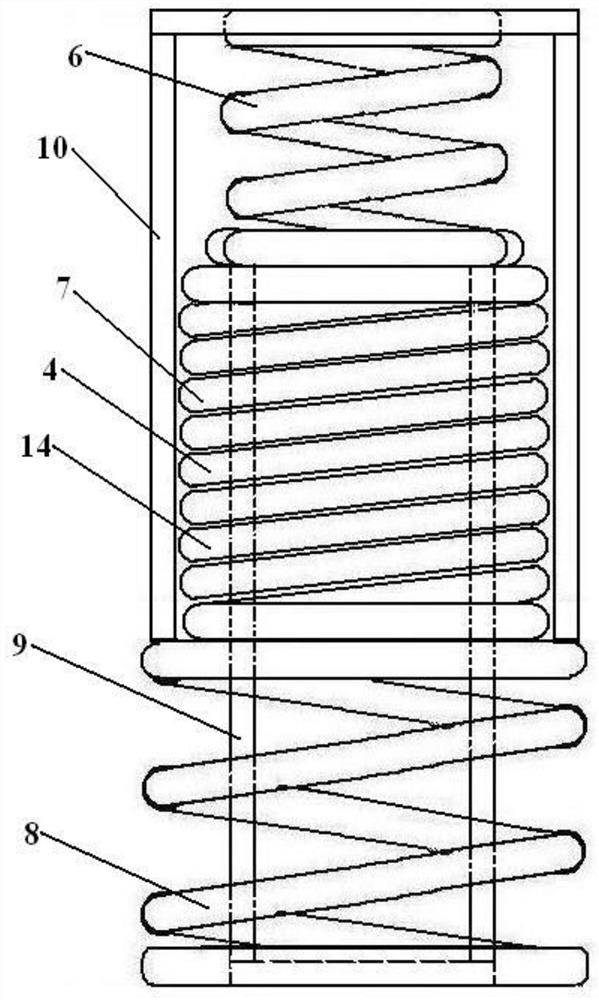

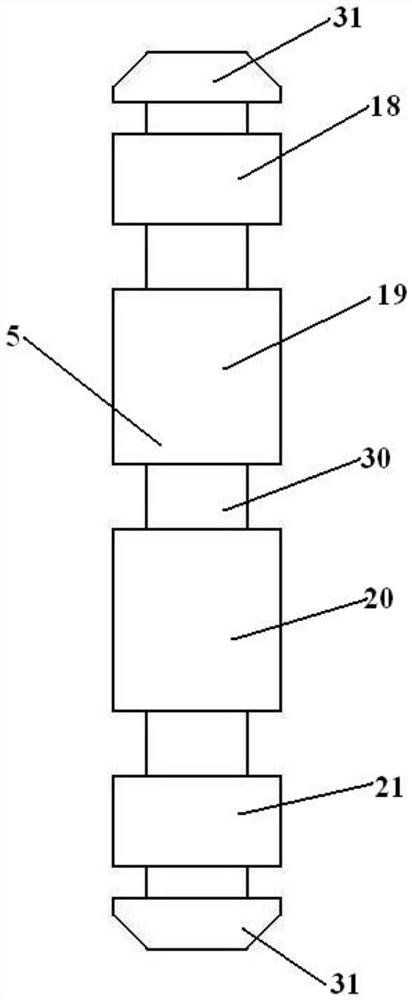

Parallel type internal and external combined shock absorber

ActiveCN113417966AChange the direction of dampingChange vibration frequencyFlywheelsLow internal friction springsInerterEngineering

The invention discloses a parallel type internal and external combined shock absorber, and belongs to the technical field of auto parts. The parallel type internal and external combined shock absorber comprises an upper base plate, a lower base plate and a shock absorption body, wherein the shock absorption body comprises an external connection shock absorption mechanism and an internal connection shock absorption mechanism; the external connection shock absorption mechanism comprises a small-diameter pressure spring, a medium-diameter tension spring and a large-diameter pressure spring which jointly form a tandem type large-small-diameter tension-compression spring, and a small-diameter frame cylinder and a large-diameter frame cylinder are inserted into the tandem type large-small-diameter tension-compression spring in a sleeving mode to form the external connection shock absorption mechanism; the internal connection shock absorption mechanism is formed by sequentially connecting a first damper, a first inerter, a second inerter and a second damper in series; and the internal connection shock absorption mechanism is sleeved with the external connection shock absorption mechanism to form the shock absorption body, and the shock absorption body is fixedly connected between the upper base plate and the lower base plate to form the parallel type internal and external combined shock absorber. The parallel type internal and external combined shock absorber has the beneficial effects that the vibration frequency can be mixed, the frequency and the amplitude are induced to be converted, the vibration is converted into low-frequency vibration, the vibration in the running process of the automobile is continuously reduced, and the riding comfort of the automobile is improved.

Owner:徐庆利

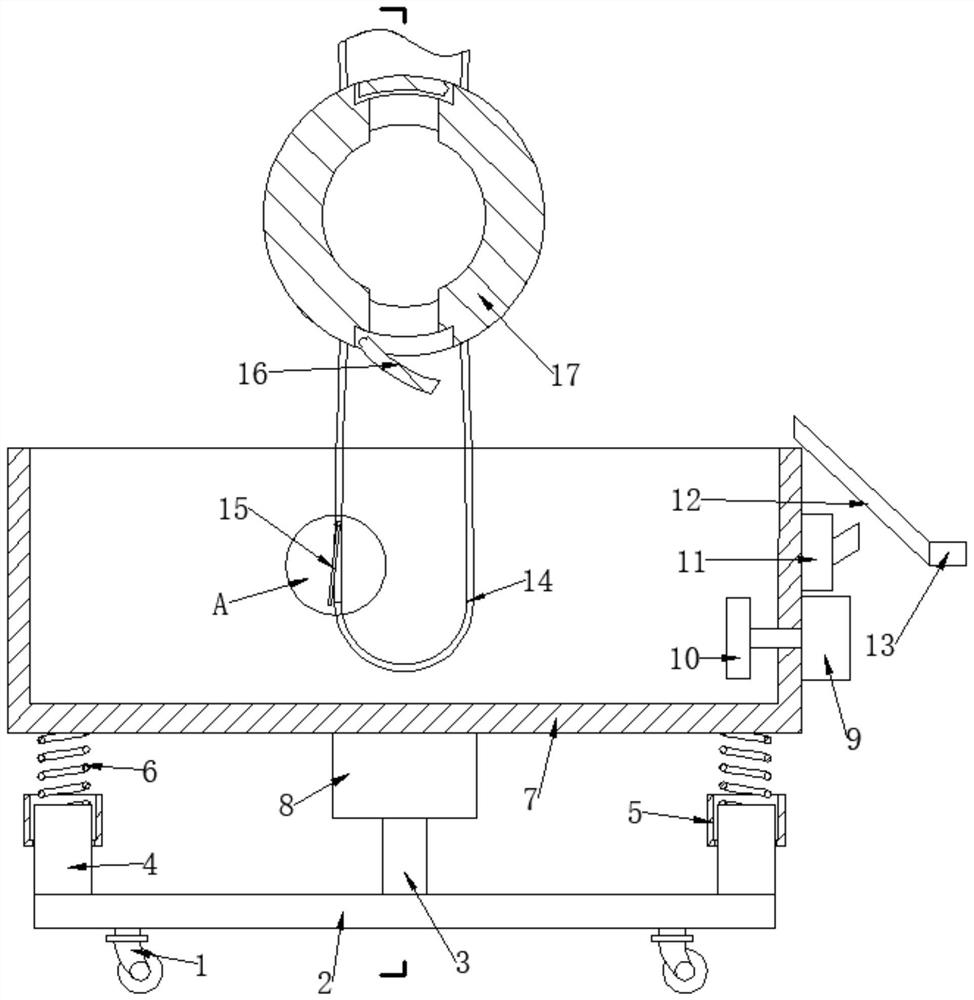

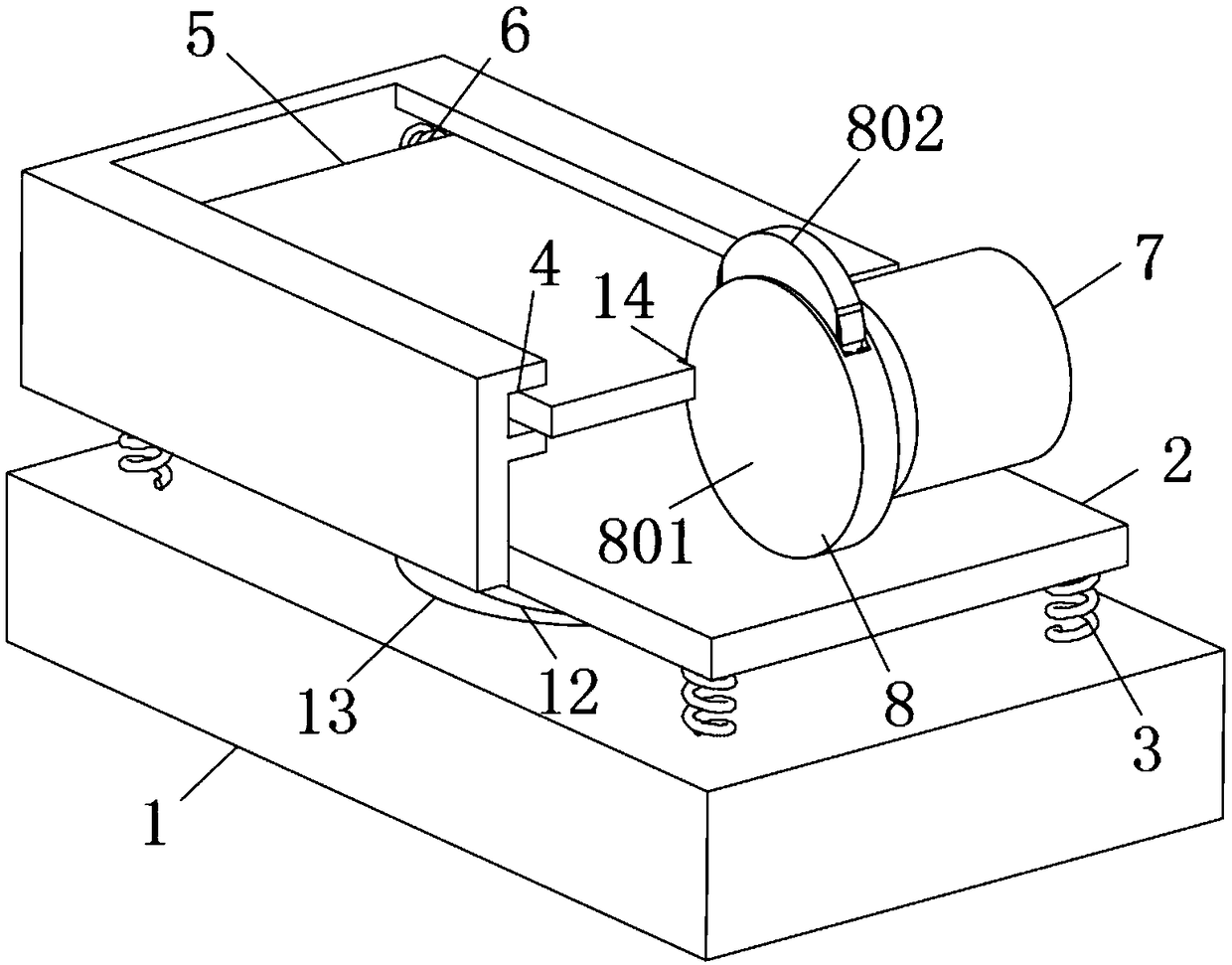

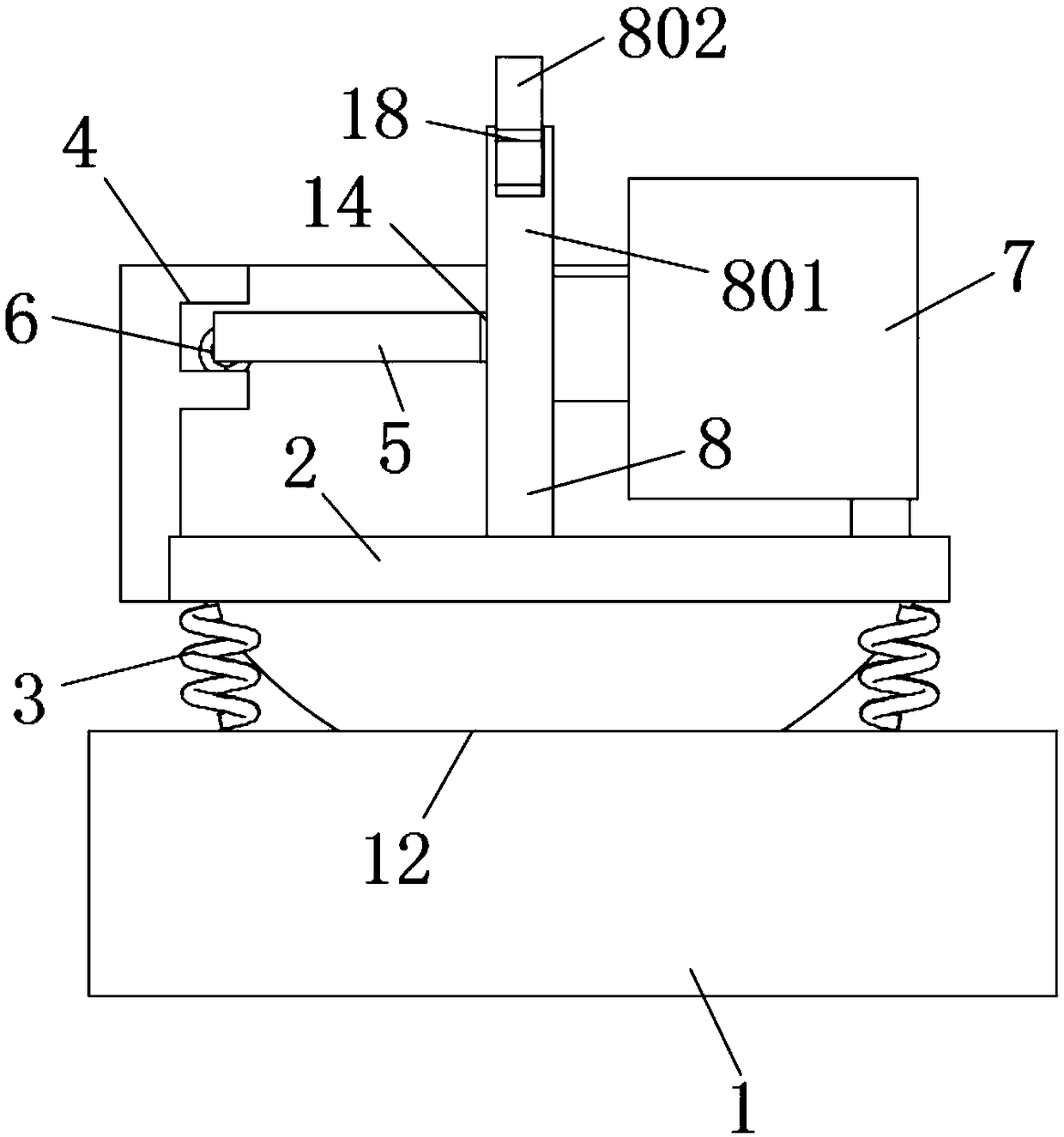

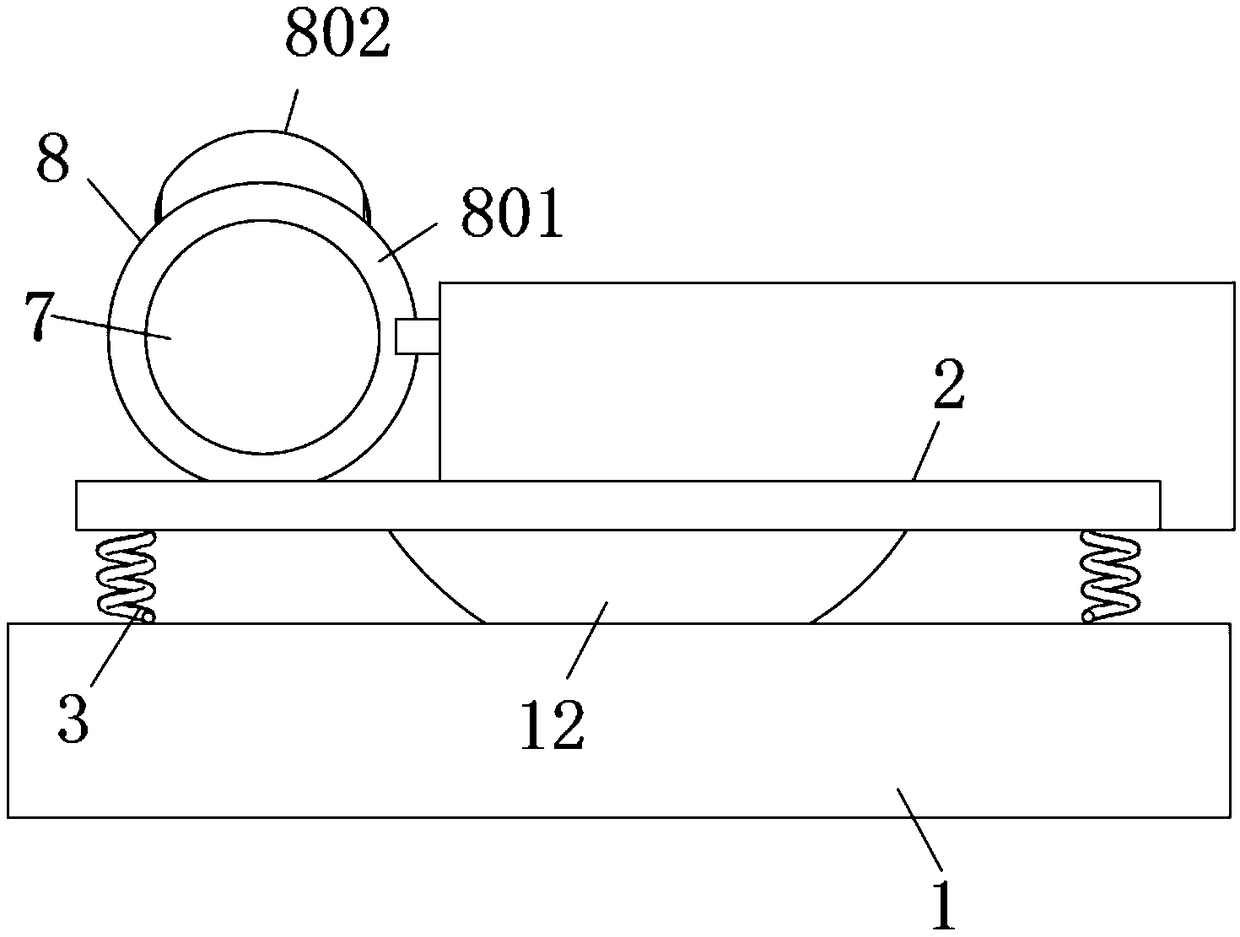

A Random Vibration Test Bench

InactiveCN106679920BFully simulate the actual situation of field operationsChange the vibration amplitudeVibration testingEngineeringFan blade

The invention relates to a random vibration type test bed. A vibration platform is supported on a bracket through springs; shock excitation devices are respectively arranged along X direction, Y direction and Z direction of the vibration platform; a shell of each shock excitation device has a hollow chamber structure; one side of the shell is opened; a fan blade is arranged in the shell; the fan blade is driven by a motor; a spherical roller is arranged in the shell; the shock excitation devices along the X direction and the Y direction respectively act on the vibration platform through force transferring guide rods along the X direction and the Y direction; the shock excitation device along the Z direction is vertically arranged under the vibration platform and directly acts on the vibration platform; the springs along the X direction, the Y direction and the Z direction are used for supplying restoring forces to the vibration platform. The fan blade is rotated for striking the spherical roller, so that the spherical roller can irregularly random strike in each shock excitation device, a random unbalancing inertia force is generated and acts on the vibration platform and the vibration platform can generate random vibration along all-dimensional directions.

Owner:CHINA AGRI UNIV

Coating machine for pharmacy

InactiveCN111759735AImprove efficiencyChange the vibration amplitudePharmaceutical product form changeCoatingsPharmacyEngineering

The invention discloses a coating machine for pharmacy, and relates to the field of coating machines. The coating machine comprises a feeding structure used for receiving a previous process and a conveying mechanism used for connecting a next process, and is also provided with a fixed support structure and a coating execution mechanism, so that the device can be directly connected with an upper / lower process of drug production to perform coating work; other procedures are not needed, and the efficiency is higher; a stirring mechanism is arranged on the side face of a coating pool; a spring isarranged below the coating pool; coating liquid in the coating pool can be in a non-static state through the stirring mechanism and the spring so that the coating liquid can be kept uniform, and meanwhile the coating effect can be better in the continuous stirring process of the coating liquid; furthermore, a reinforcing sleeve is further arranged, the position, exposed out of the reinforcing sleeve, of the spring can be changed by adjusting the position, relative to the spring, of the reinforcing sleeve, and then the vibration amplitude of the spring can be changed.

Owner:桂海国

A cascade water treatment device combining plasma, ultrasound and catalysis

ActiveCN105130046BImprove degradation efficiencyIncrease the number ofMultistage water/sewage treatmentHigh energyPlasma generator

The invention discloses a cascaded water treatment device combining plasma, ultrasound and catalysis, which is characterized in that it includes: a water treatment unit (1), and the water treatment unit (1) includes an ultrasonic ozone combined reactor (2) and The plasma generator (3), the water outlet of the ultrasonic ozone combined reactor (2) is connected to the water inlet of the Y-shaped reactor (6) through the liquid pump (4) and the liquid flow meter (5); the ultrasonic The top of the combined ozone reactor (2) communicates with the plasma generator (3) through a second gas circulation pipeline (42). The invention provides a cascaded water treatment device combining plasma, ultrasound and catalysis, which comprehensively utilizes ultrasound, ozone, plasma, TiO 2 Catalysis and other methods are used to treat sewage; in addition, it also overcomes the problems of large footprint, high energy consumption, long single treatment time and low utilization rate of active substances in plasma in the prior art.

Owner:南通河海大学海洋与近海工程研究院

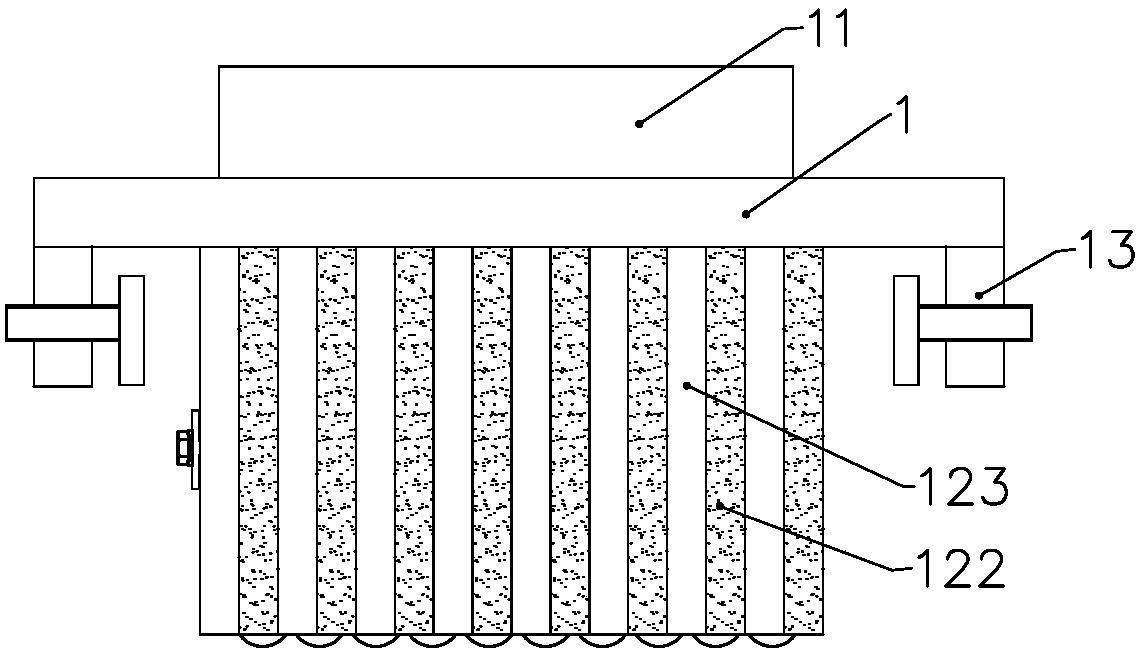

Amplitude-adjustable screening equipment for shield construction muck treatment

InactiveCN111420873AChange the vibration amplitudeAmplitude adjustmentSievingScreeningVibration amplitudeClassical mechanics

The invention belongs to the technical field of shield construction muck treatment, and particularly relates to amplitude-adjustable screening equipment for shield construction muck treatment. The problem that the treatment capacity and adaptability of a vibration screening device can be reduced when the vibration screening device adopts the same amplitude in the prior art is solved. According tothe technical scheme of the invention, the amplitude-adjustable screening equipment for shield construction muck treatment comprises a screening equipment box body (2), wherein a screen mesh (3), a spring assembly (1) and a vibrating device (5) are arranged in the vibrating screening equipment box body (2), and an amplitude adjusting device is arranged in the spring assembly (1). According to theamplitude-adjustable screening equipment for shield construction muck treatment, the vibration amplitude of the spring assembly can be changed, so that the vibration amplitude of the screening equipment can be adjusted, the screening equipment can work under different vibration amplitudes, the treatment capacity and the adaptability of the screening equipment are improved, and the screening equipment is suitable for treating shield construction muck.

Owner:CHINA RAILWEY ENG SERVICE CO LTD

Shaker

InactiveCN104646281BImplement location changesThe role of control screeningSievingScreeningVibration attenuationVibration amplitude

The invention relates to a vibrating screen. The vibrating screen comprises a foundation support, a horizontal vibration attenuation mechanism, a vertical supporting mechanism, a horizontal guide rail, a bracket and a motor, wherein the foundation support is provided with a horizontal supporting part and vertical supporting parts, and the vertical supporting parts are arranged on two ends of the horizontal supporting part; the horizontal vibration attenuation mechanism is connected with the vertical supporting parts of the foundation support; the vertical supporting mechanism is connected with the horizontal supporting part of the foundation support; the horizontal guide rail is respectively connected with the vertical supporting parts and the horizontal supporting part of the foundation support through the horizontal vibration attenuation mechanism and the vertical supporting mechanism; the bracket is used for fixing a screen assembly, and the bracket can be movably fixed on the horizontal guide rail through a slide block; the motor is installed on the foundation support, and a rotating shaft of the motor is connected with the slide block through a crank linkage mechanism. According to the vibrating screen of the invention, a spring is uniformly stressed, the service life is prolonged, and the vibration amplitude of the screen assembly can be conveniently adjusted.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Equipment table for engine tilt experiment

ActiveCN108827636AHigh vibration frequencyIncrease shaking frequencyEngine testingElectric machineryEngineering

The invention provides an equipment table for an engine tilt experiment, and the equipment table comprises an equipment platform. The surface of the equipment platform is movably provided with a support plate, and the bottom surface of the support plate is fixedly connected with the upper end of a support spring. The lower end of the support spring is fixedly connected with the surface of the equipment platform. Two sides of the surface of the support plate are integrated with two groups of vertical plates, and the inner sides of the two vertical plates are provided with two groups of chutes in an embedded manner. When the equipment table is in use, an engine is installed on an engine installation plate, a motor is started, and the output shaft of the motor rotates to drive a cam device torotate, and then the cam device rotates to drive the engine installation plate to slide back and forth in the chutes. The vibration frequency of the engine installation plate is increased through a vibration spring, and the cooperation of a hemisphere with a hemisphere groove enables the support plate to swing in multiple directions on the surface of the equipment platform, thereby achieving themore real simulation of the swinging conditions of the engine in a driving process of an automobile. The support spring achieves the supporting of the four corners of the support plate.

Owner:林梅仙

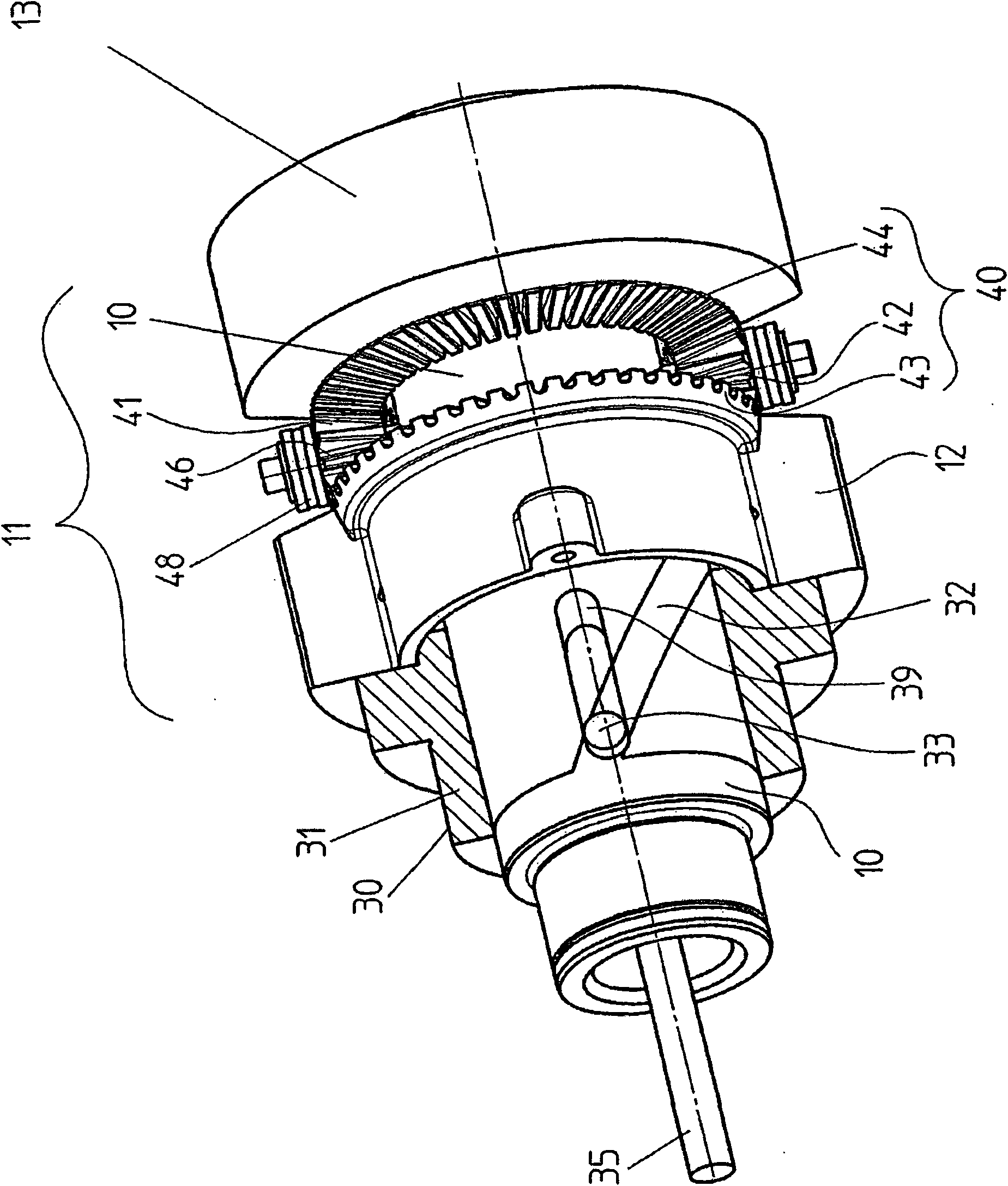

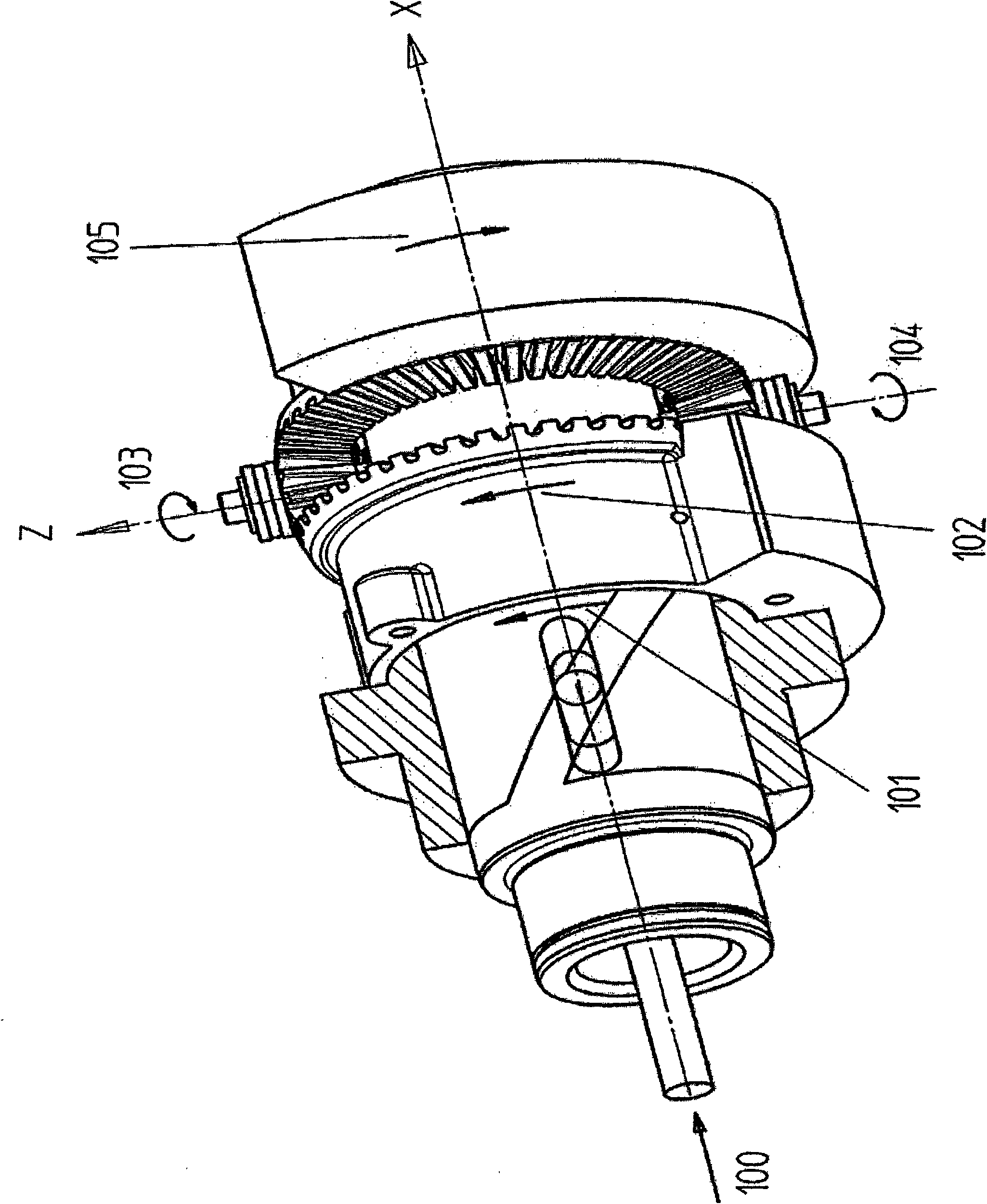

Device for generating circular oscillation or directional oscillation

InactiveCN101961710AChange the vibration amplitudeSimple and quick adjustabilityMechanical apparatusMechanical vibrations separationCouplingClassical mechanics

Owner:BOMAG

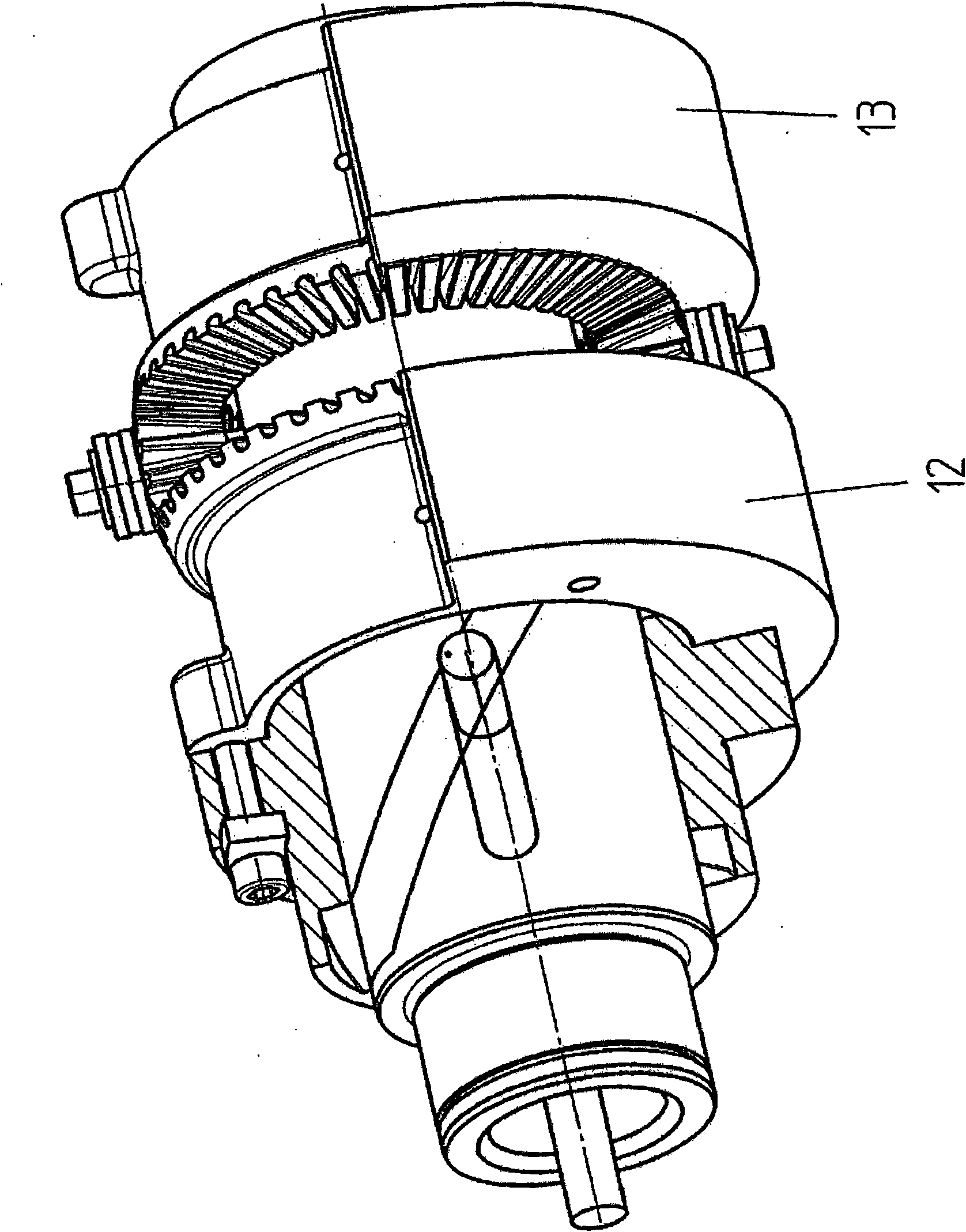

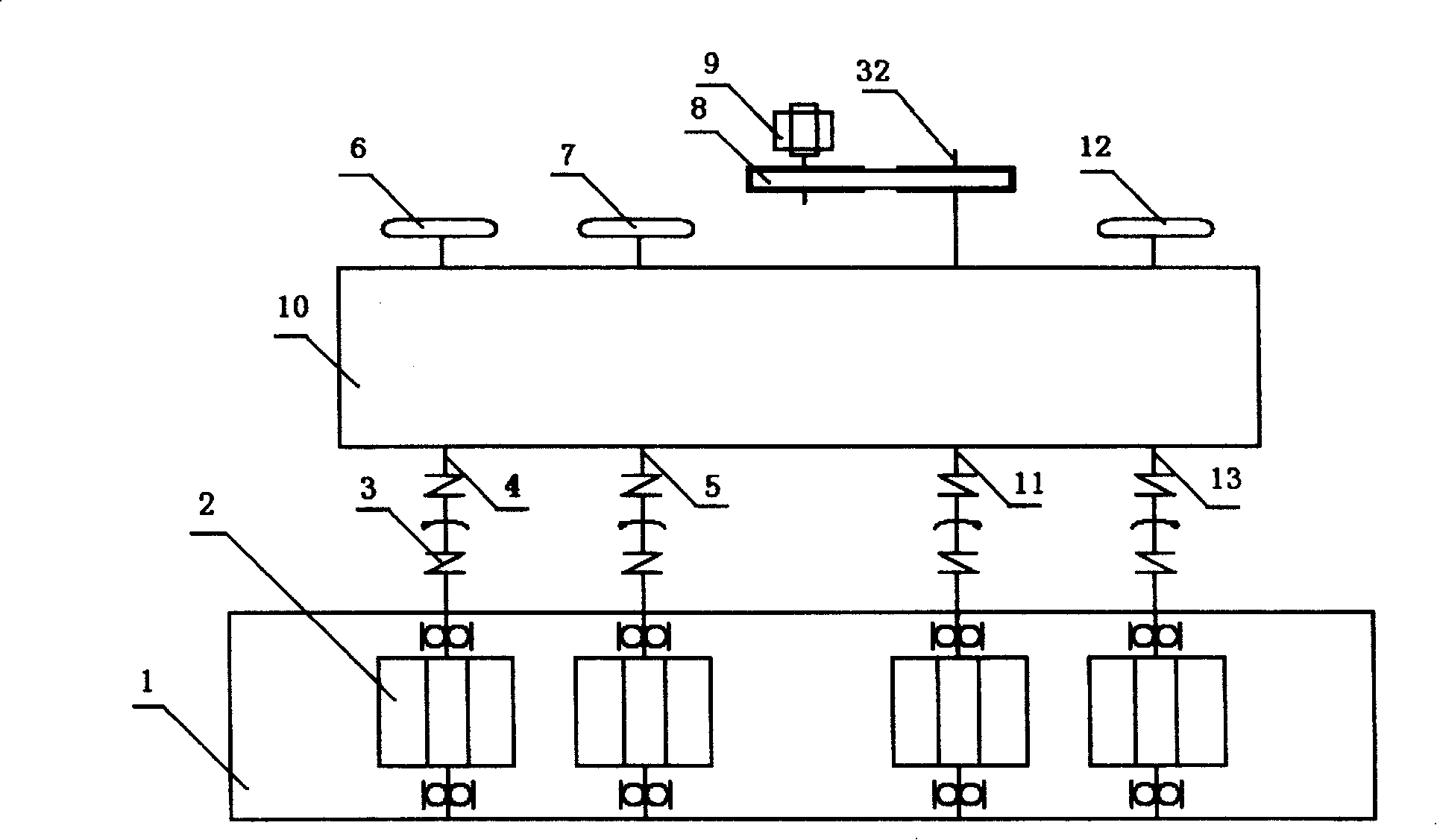

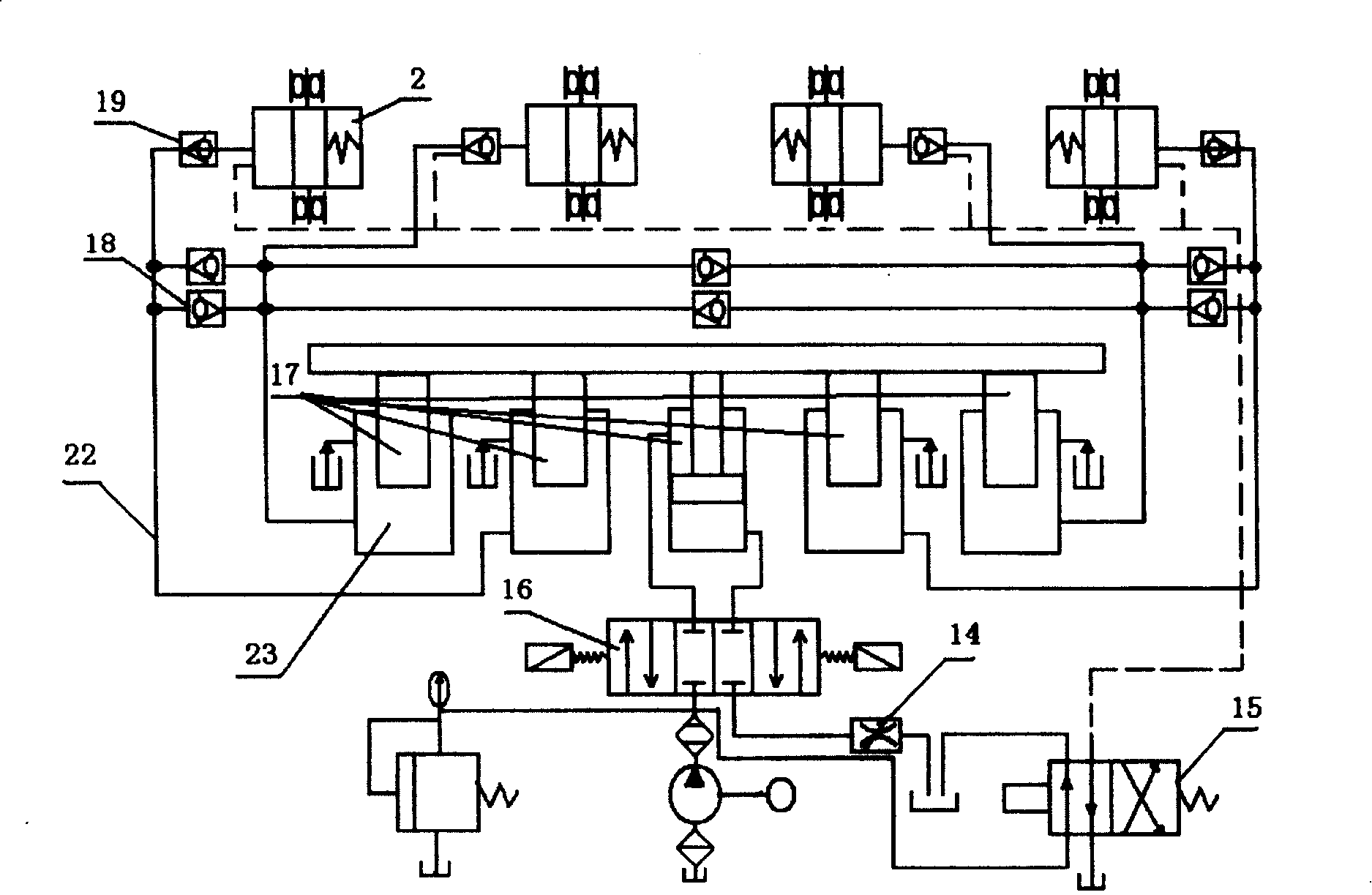

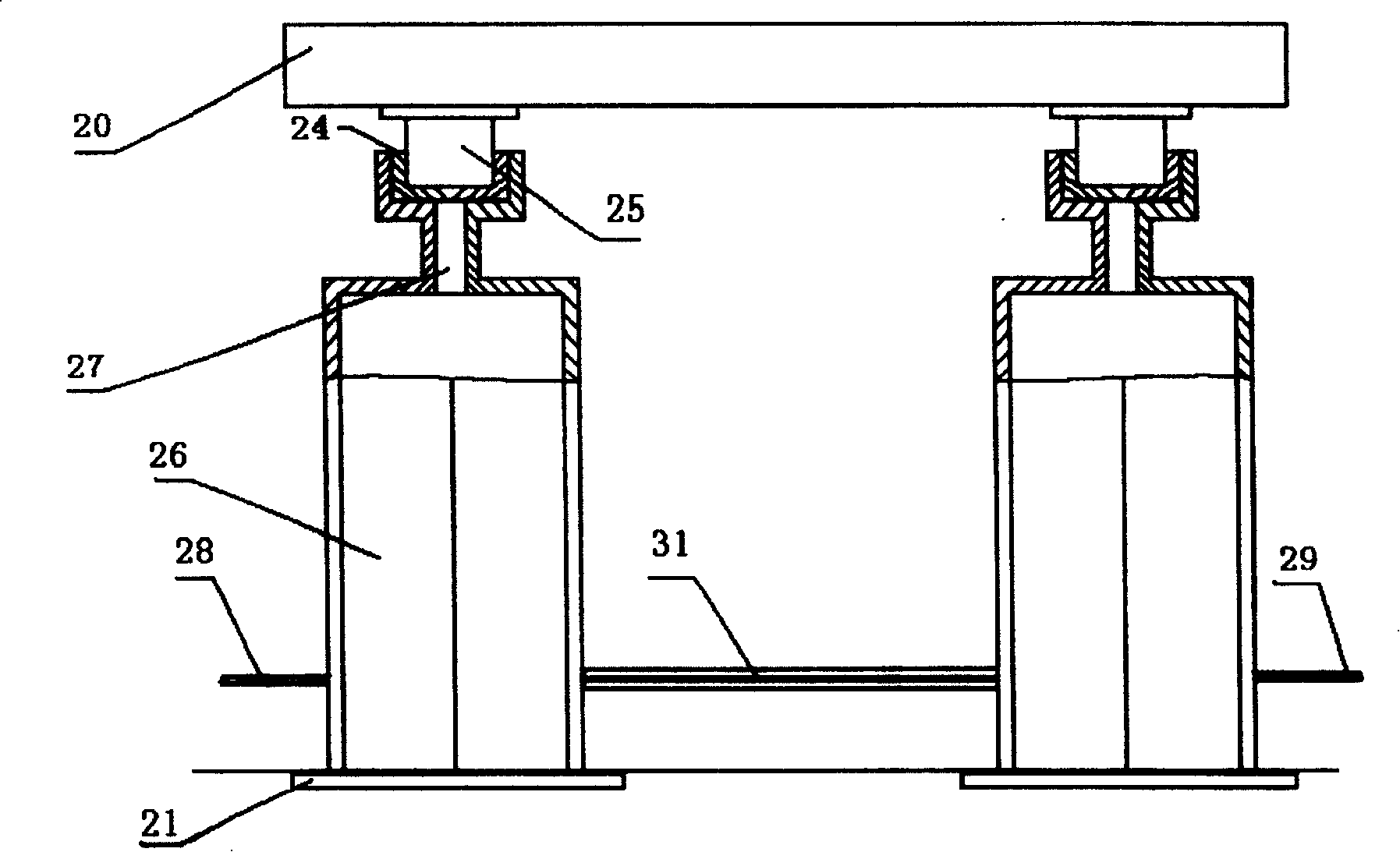

Simulated test platform system for mechanical structure vibration resistant performance

InactiveCN100408993CGood vibration isolationChange the vibration amplitudeVibration testingAir springEngineering

The present invention relates to a mechanical structure antivibration property simulation testing platform system. Said system includes platform supporting mechanism formed from four air spring supporting mechanisms, vibration exciting mechanism formed from four rotary oil cylinders and pilot-controlled non-return valves, hydraulic control mechanism, flexible couplers and driving device. Said invention also provides the concrete structure of the above-mentioned every component, and provides their connection mode.

Owner:沈光新

Whole body vibration training apparatus with linearly variable vibration amplitude

InactiveCN100528266CAchieve the effects of whole body vibration trainingChange the vibration amplitudeChiropractic devicesMechanical energy handlingVibration amplitudeWhole body

The invention relates to a whole-body vibration training device capable of linearly changing the vibration amplitude. Its composition at least includes a base, a swing connecting rod group and a driving mechanism. The swing connecting rod group is assembled on the base, and it is provided with a Driving mechanism, and the driving mechanism can drive the connecting rod formed by several swinging connecting rods to move, through the drive of the motor, an eccentric transmission shaft drives the swinging connecting rod group to generate linear vibration during the swinging process, and cooperates with the speed of the motor so that The upper support frame produces up and down displacements of various frequency vibrations; in addition, an adjustment device can be installed between the swing link group and the base, which can change the fulcrum position of a swing link group, thereby changing the swing range of the swing link group According to this, the swing link group can be driven by the driving mechanism and its vibration amplitude can be changed linearly to achieve the effect of whole body vibration, and produce many functions such as stimulating organs, improving muscle strength, and promoting blood circulation. The whole is innovative and practical sex.

Owner:B GREEN TECH

An anti-seismic experimental device for assembled bridge engineering

ActiveCN111638029BIn line with the actual useAdjustable inclinationBridgesVibration testingBridge engineeringGear wheel

The invention discloses an anti-seismic experimental device for assembled bridge engineering, which comprises a base, a movable seat and a first installation warehouse, a fixed warehouse is fixed at the middle position on the top of the base, and a second installation warehouse is installed on the outside of the fixed warehouse. Two toothed rings, and a movable seat is arranged inside the fixed warehouse, and a first annular chute is opened on both sides of the top of the base. This kind of anti-seismic experimental device for assembled bridge engineering is through the meshing connection between the first gear and the second gear ring and the first gear ring, and the meshing connection between the first gear ring and the second gear, so that the second When a motor drives the second rotating shaft to rotate, it can make the first rotating shaft continue to do planetary motion, and then drive the movable seat to shake in multiple directions, so that multi-directional vibration experiments can be carried out in a single time, and the bridge model on the placement plate can be further multiplied. Azimuth vibration, so that it is more in line with the actual use situation, and more comprehensive experiments can be carried out.

Owner:DALIAN JIAOTONG UNIVERSITY

Base metal particle forming equipment

The invention relates to the technical field of base metal particle manufacturing, in particular to base metal particle forming equipment which comprises a forming chamber with a driving device arranged at the top, a centrifugal disc connected with the driving device is arranged in the forming chamber and suspended and comprises a centrifugal chamber, and the edge of the centrifugal chamber penetrates through a plurality of end shells. A plurality of fine holes are formed in the end face of the end shell, a plurality of elastic steel needles extending in the radial direction of the centrifugal chamber are arranged at the bottom of the end shell, the ends of the elastic steel needles are fixedly connected with the centrifugal chamber, a deflector rod connected with the forming chamber is arranged below the elastic steel needles and makes contact with the elastic steel needles, and a feeding pipe for injecting molten metal into the centrifugal chamber penetrates through the top of the forming chamber. Flying-out metal liquid drops are conducted through the elastic steel needle arranged at the end of the end shell, the rotating elastic steel needle is shifted through the shifting rod to generate high-frequency vibration, the metal liquid drops are further crushed and refined, and the forming size of metal particles is finer.

Owner:SUZHOU VOCATIONAL UNIV

A pulverizer and a method for pulverizing materials using the pulverizer

ActiveCN105057070BChange speedChange the vibration amplitudeGrain treatmentsHydraulic cylinderEngineering

Owner:北钢联(北京)重工科技有限公司

Intelligent food packing device

InactiveCN107082125APrevent food from getting wetReduce mistakesPackage sterilisationSolid materialFood packagingFood sterilization

The invention discloses an intelligent food packaging device, which comprises a vibrating feeding mechanism, a packaging mechanism and an automatic weighing mechanism. Several pores, the cavity of the vibrating feeding mechanism is provided with a temperature control device, one end of the guide trough is provided with a disinfection area, and the subpackaging mechanism is composed of a feeding hanging bag material opening, a slope concave backrest Plate, supporting plate, material storage platform and electromagnet. The automatic weighing mechanism is equipped with a circuit control mechanism. The beneficial effects are as follows: through the ultraviolet disinfection lamp and the temperature control device in the vibrating feeding mechanism, food disinfection can be realized; through the setting of the upper limit value and the lower limit value, the vibration amplitude of the vibrating feeding mechanism can be changed to reach the set value The vibration frequency of the vibrating feeding mechanism is reduced to reduce the error of food falling continuously; the outer surface of the vibrating feeding and sub-packaging mechanism is provided with a flexible rubber sleeve to avoid damage to fragile food.

Owner:江苏保灵食品有限公司

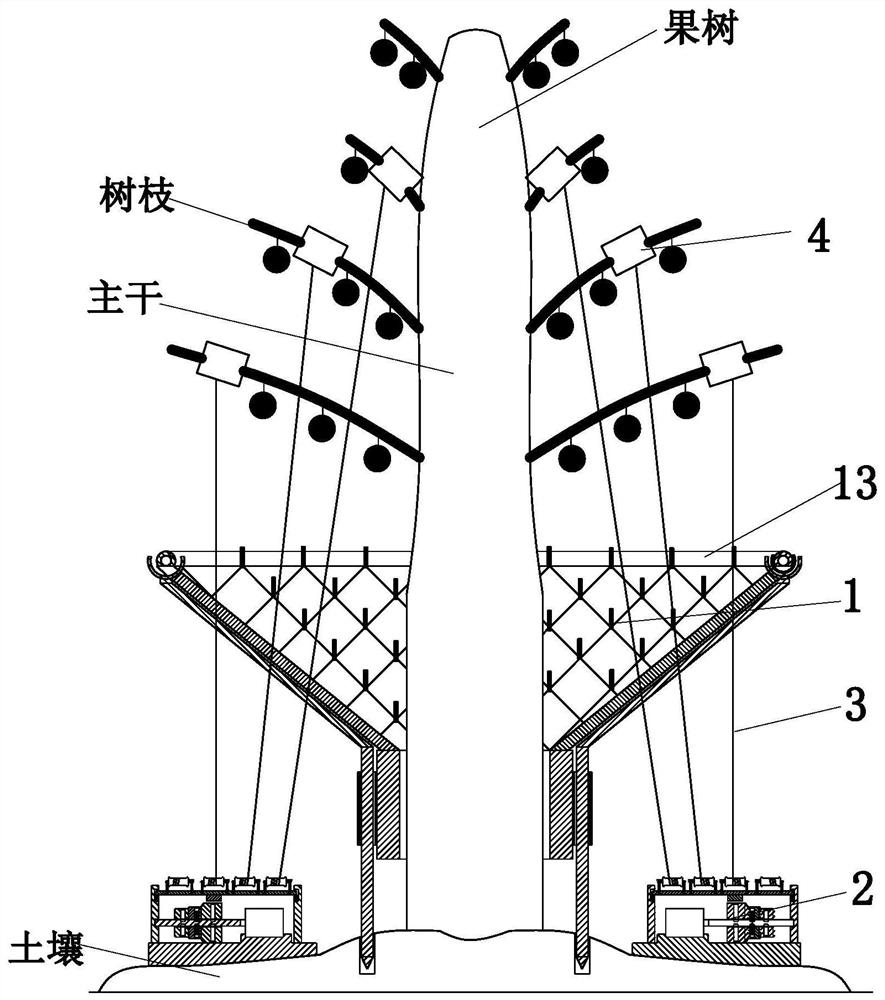

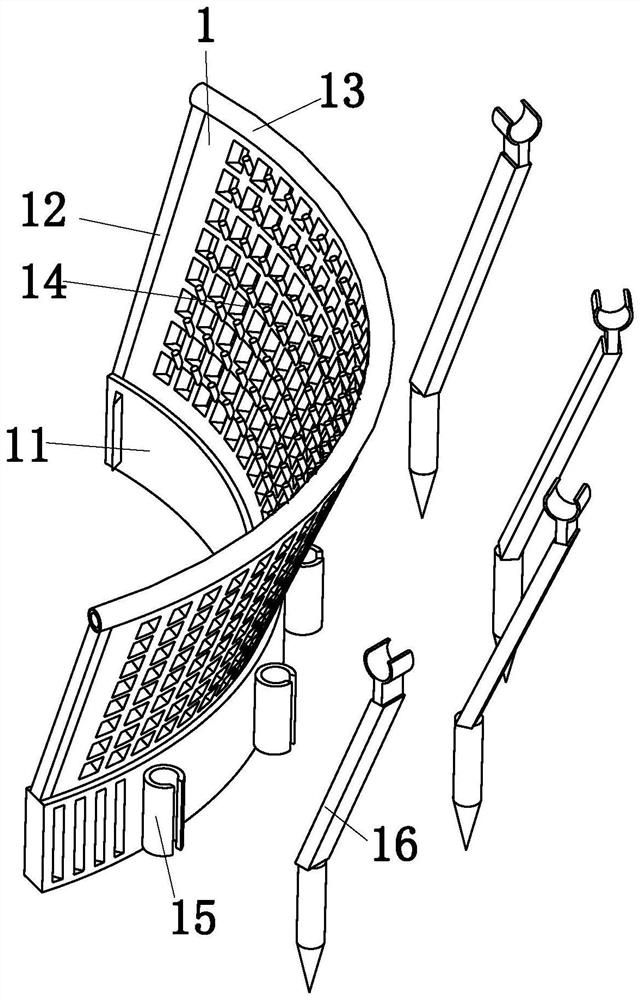

A fruit picker for agricultural planting and its use

ActiveCN110574552BAvoid crushing situationsImprove qualityPicking devicesAgricultural engineeringMechanical engineering

The invention relates to a fruit picking machine for agricultural planting and a use method. The machine comprises a supporting discharging net, a vibration device, a traction rope and a wrapping frame; the vibration device is arranged on the outer side of the supporting discharging net, and the upper portion of the vibration device is connected with the wrapping frame through the traction rope. Accordingly, the problems can be solved that in the picking process, fruits are knocked off through a bamboo pole, part of branches are likely to be broken, the time for the broken branches growing again is long, the yield of the next year is likely to be affected, in the falling process, due to the fact that the force of manual rod swinging is large and different, part of immature fruits are likely to be knocked off, then fruit waste is caused, the fallen fruits are likely to fall into the ground due to the fact that the fruits are not received in time or not received stably, thus the fruit skin is damaged, and the fruit quality and harvest yield are affected.

Owner:安徽普渡智慧农业装备有限公司

Anti-overturning high-voltage transmission line tower

ActiveCN106168078BChange vibration frequencyChange the vibration amplitudeTowersDamping functionEngineering

The invention discloses an anti-overturning high-tension transmission line iron tower used for solving the problem that an iron tower is prone to overturning. The iron tower comprises an iron tower body and a transition part, and the middle portions of the iron tower body are disconnected and movably connected through the transition part, with buffering and damping functions, on the corner. The transition part comprises a first plate, a second plate and a third plate which are arranged in parallel from top to bottom, wherein the portion between the first plate and the second plate and the portion between the second plate and the third plate are each designed to be a buffering structure with a brake structure. As the lower middle portions of the iron tower are disconnected and provided with the transition part, the portion prone to bending in the iron tower shifts in the horizontal direction in the presence of the transition part, in the shifting process, vibrating energy is consumed through effective friction, vibrating frequency and amplitude are changed, bending is avoided, the method of increasing the use amount of profile steel to improve strength traditionally is changed, and the seismic resistance is improved by 40% without changing the steel amount.

Owner:连云港强连铁塔制造有限公司

Material adhesion preventing feeding system for potassium calcium magnesium sulfate bagging

ActiveCN114084388ASolve the problem of easy blocking of the discharge portReduce manufacturing costSievingScreeningSulfateControl engineering

The invention discloses a material adhesion preventing feeding system for potassium calcium magnesium sulfate bagging, which is provided with a supporting frame, wherein a mounting plate is fixed on the inner side of the supporting frame through bolts. The material adhesion preventing feeding system comprises a supporting rod, a motor, a vibrating screen and a movable cylinder, wherein the supporting rod is welded to the side surface of a feeding hopper, and a damping spring is wound around the outer side of the supporting rod; the motor is installed on the side of the supporting frame through bolts, and a motor shaft is connected to the end of the motor; the vibrating screen is movably installed below the feeding hopper, a protection box is fixed to the inner wall of the vibrating screen, and a cam is movably arranged in the protection box; and the movable cylinder is arranged at the end of a guide rod in a sleeving manner, and a worm gear is fixed at the end of the movable cylinder. According to the material adhesion preventing feeding system for potassium calcium magnesium sulfate bagging, the scheme that the original unused loading machine feeding is changed into the feeding by using a forklift with a small shovel is adopted in the feeding hopper, so that the problem that a discharging port is easily blocked due to too much loading machine feeding is solved, and the production cost is greatly reduced.

Owner:ZHANJIANG PORT (GRP) CO LTD

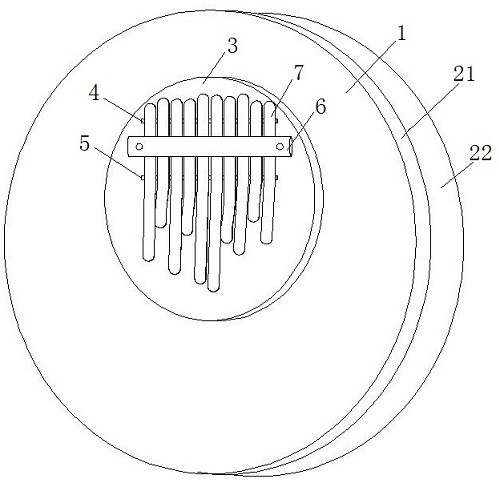

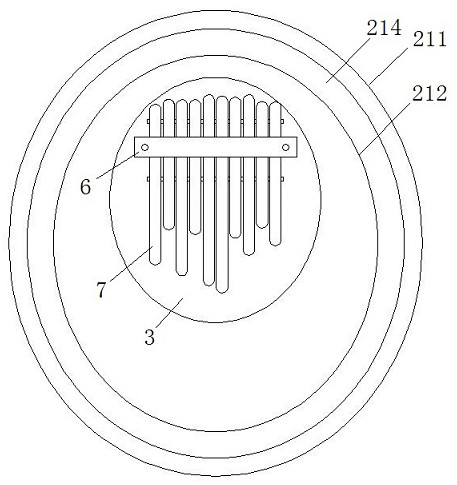

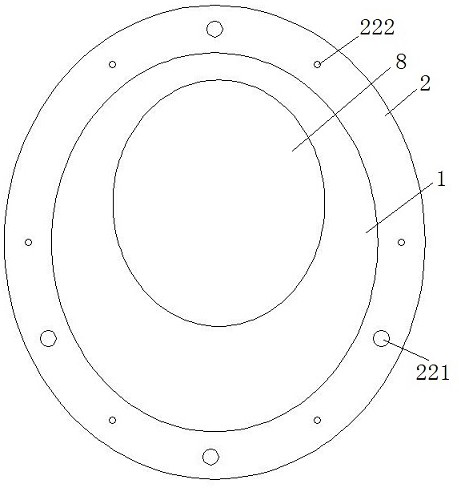

Novel thumb piano

The present invention discloses a novel thumb piano, sounding piano pieces are installed on a membrane structure or drum skin, the thumb piano comprises a piano body whole body and a piano support fixed to the piano body whole body, and elastic pieces used for playing music are installed on the piano support; the piano body whole body comprises a drum skin arranged on the top surface and a main support which is fixed on the lower side of the drum skin and used for supporting the drum skin. The drum skin is fixedly connected with the main support in a closed manner to form a sound cavity with a downward opening. According to the invention, the drum skin is arranged, so that when a player plays the elastic pieces with a thumb and vibrates the elastic pieces, the vibration of the elastic pieces drive the bottom plate and the drum skin to vibrate at the same time, and the sound made by the thumb piano is vigorous, melodious and more loud; furthermore, when the thumb piano is held by a hand for playing, a sound cavity is formed between the drum skin and the main support, so that sound waves generated by the drum skin during vibration can touch the inner wall of the sound cavity and then return to the air, the sound waves rotate in the sound cavity, and a simulated echo state is formed; and therefore, the sound made by the thumb piano is more lively, mellow and pleasant to hear.

Owner:ROYALSOUND MUSIC INSTR MFR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com