Device for generating circular oscillation or directional oscillation

A kind of equipment, circular technology, applied in the field of equipment that generates circular vibration or directional vibration, can solve the problem that there is no room for the unbalanced main body, and achieve simple and fast coupling stability, reduced manufacturing cost, and high compactness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

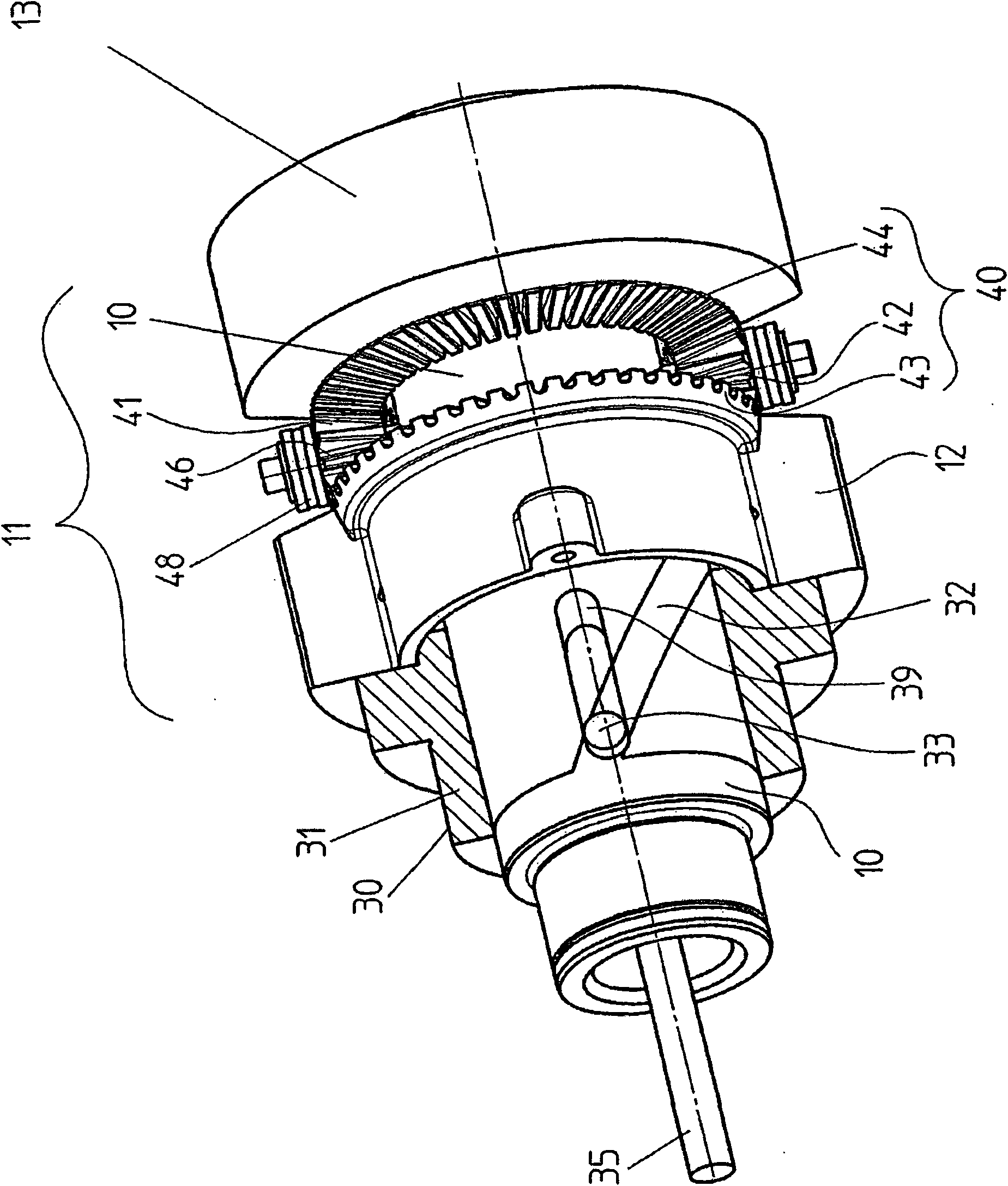

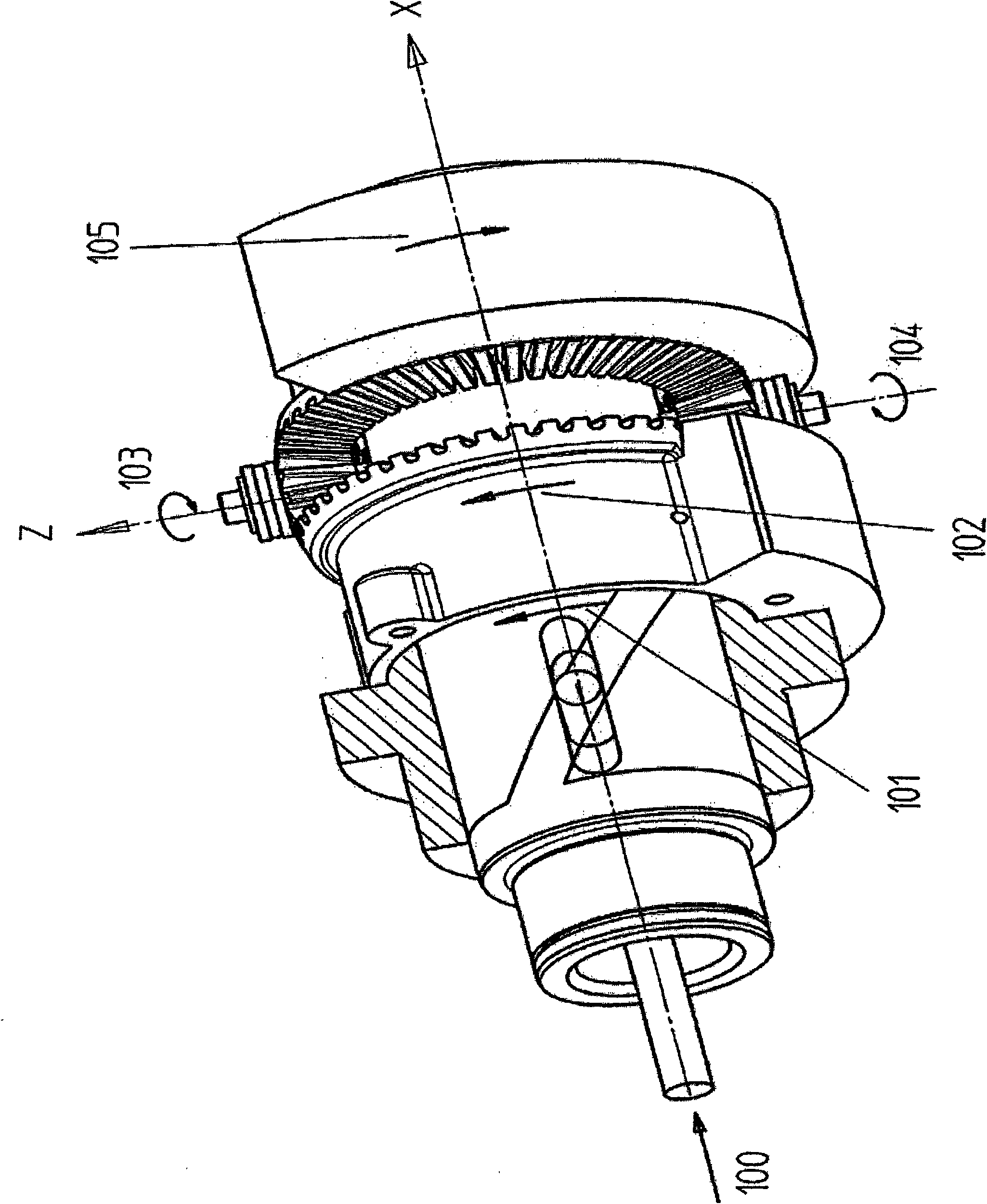

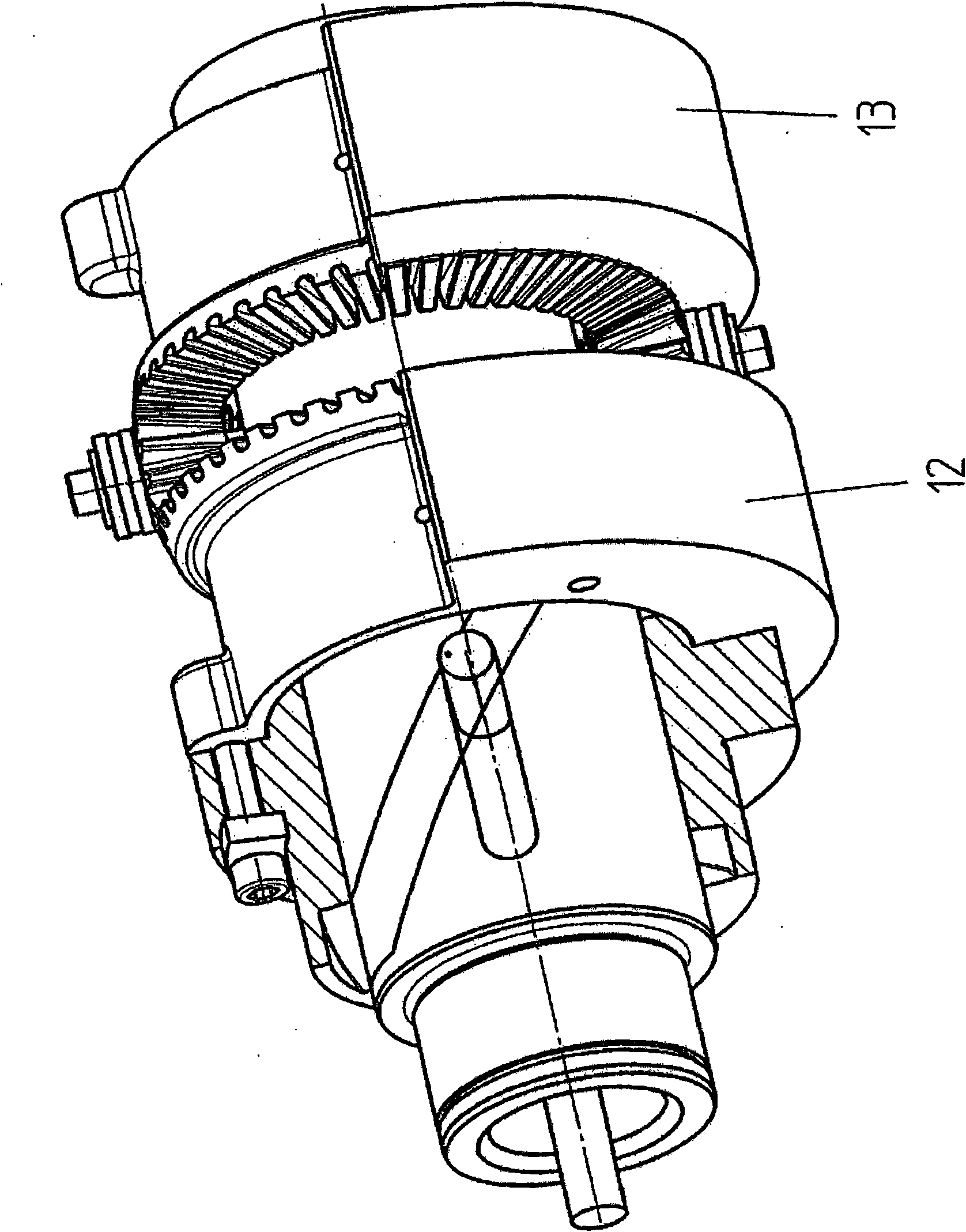

[0037]figure 1 A first unbalanced weight pair 11 of a first spindle 10 is shown, said first unbalanced weight pair 11 having unbalanced weights 12 , 13 . Located between the unbalanced weights 12 , 13 is a coupling 40 having two crown wheels 43 , 44 and a transmission medium 46 , in particular pinions 41 , 42 . The pinions 41 , 42 are symmetrical relative to the axis of rotation of the main shaft 10 and offset by 180°, they are rotatable on the transmission medium carrier 45 . Furthermore, axial bearings 48 are known and serve to absorb the centrifugal forces generated by the pinions 41 , 42 .

[0038] The adjusting unit 30 has an adjusting sleeve 31 , which is fixedly connected to the first unbalanced weight 12 with axial locking, for example via screws 36 , in a rotationally fixed manner. The inner wall of the adjustment sleeve 31 is provided with two helical grooves 32 offset by 180°. Engaging in the helical groove 32 is an adjustment pin 33 which is guided in an oblong h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com