Damping oil pressure damper for steel structure connection nodes

A technology for connecting nodes and steel structures. It is used in underwater structures, infrastructure engineering, earthquake resistance, etc. to achieve the effects of reasonable structural design, energy dissipation and vibration, and increased damping.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

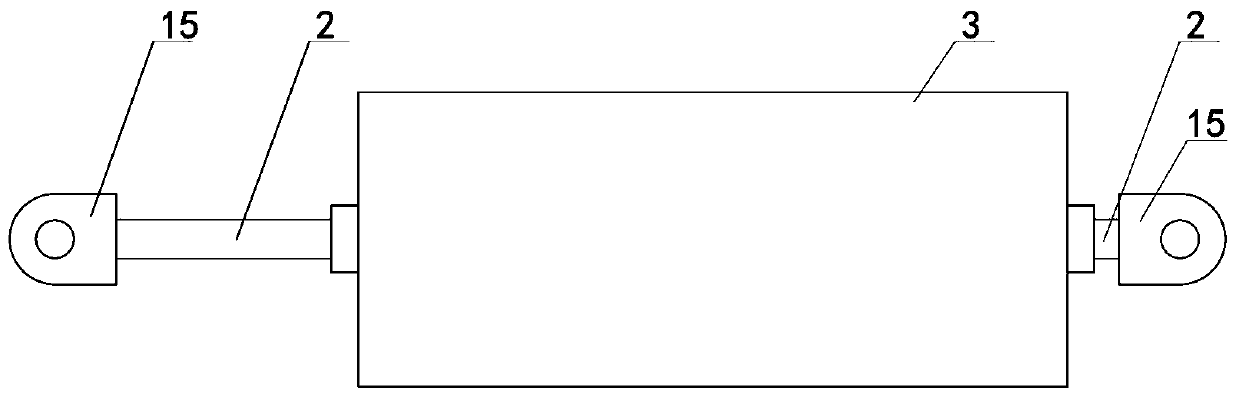

[0022] Embodiment 1: The first type of shock-absorbing oil pressure damper is mainly used in the connection position of the connection node of the steel structure. The damper includes a front tie rod 1, a rear tie rod 2 and a tubular node box 3, such as figure 1 As shown, the front and rear pull rods are also fixed with connecting seat 15. The shock-absorbing oil pressure damper can automatically adjust the change of oil resistance, thereby changing the vibration frequency and vibration amplitude of the node, and can effectively dissipate energy and reduce vibration.

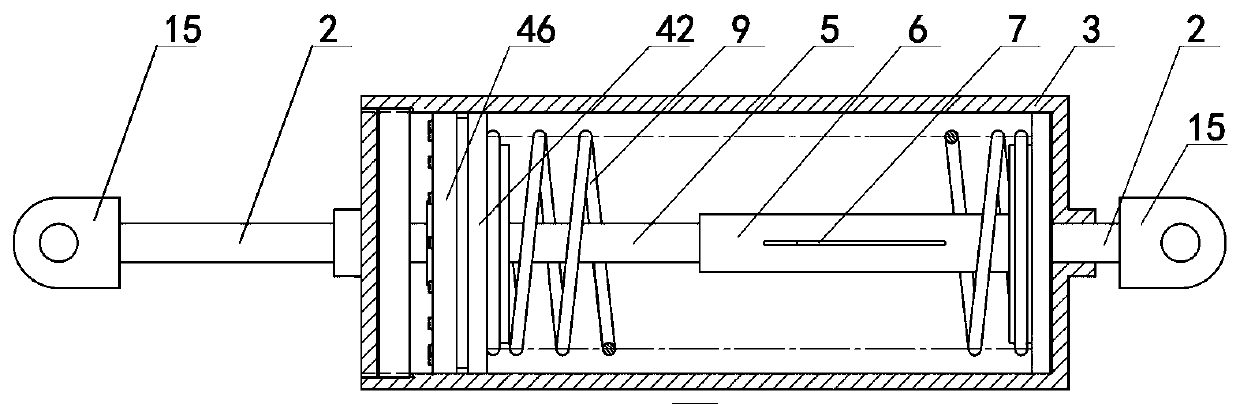

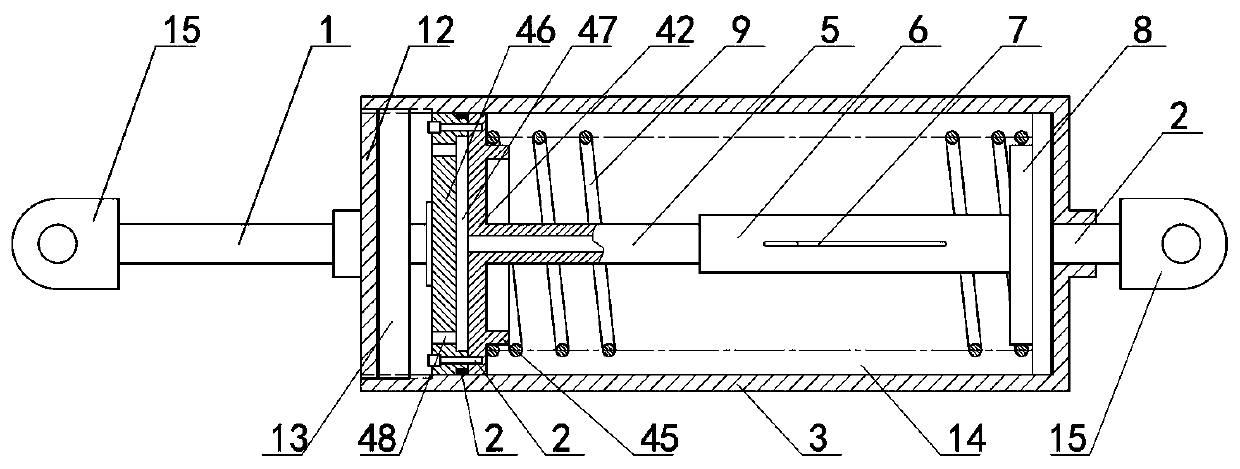

[0023] figure 2 with image 3 respectively figure 1 Schematic diagram of the internal structure of figure 2 with image 3 It can be seen that the node box is a closed structure, and its inner cavity is required to be filled with damping oil to form an oil cavity 14 .

[0024] Such as image 3 As shown, the front end of the oil chamber in the node box is matched with a piston body and additional componen...

Embodiment 2

[0028] Embodiment 2: The shock-absorbing oil pressure damper of the second steel structure connection node, such as Figure 4 As shown, it includes a front tie rod 1 , a rear tie rod 2 and a tubular node box 3 . Wherein, the node box is a closed structure, and its inner cavity is filled with damping oil to form an oil cavity 14 . The front tie rod and the rear tie rod go through the central holes of the two end walls of the node box.

[0029] Such as Figure 5 As shown, the middle part of the oil chamber in the node box 3 is matched with a piston body. There are dynamic spring seats on both sides of the piston body, and fixed spring seats are respectively arranged on the inner walls of both ends of the node box. Thrust springs are respectively connected between the moving spring seat and the fixed spring seat.

[0030] The specific structure of the piston body is as follows: Image 6As shown, it is a composite piston formed by docking and fixing two single pistons (piston ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com