Parallel type internal and external combined shock absorber

A technology of parallel connection and shock absorber, which is applied in the direction of spring/shock absorber, low internal friction spring, vibration suppression adjustment, etc. It can solve problems such as not considering resonance and difficult to achieve vibration reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

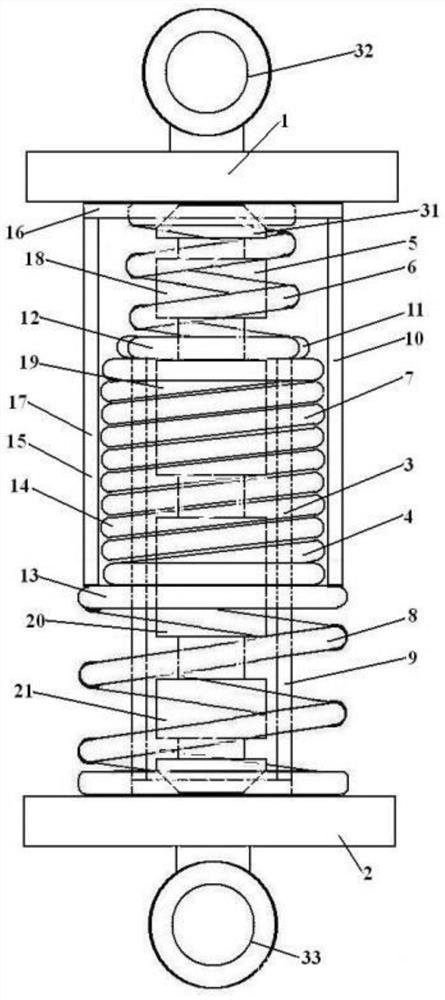

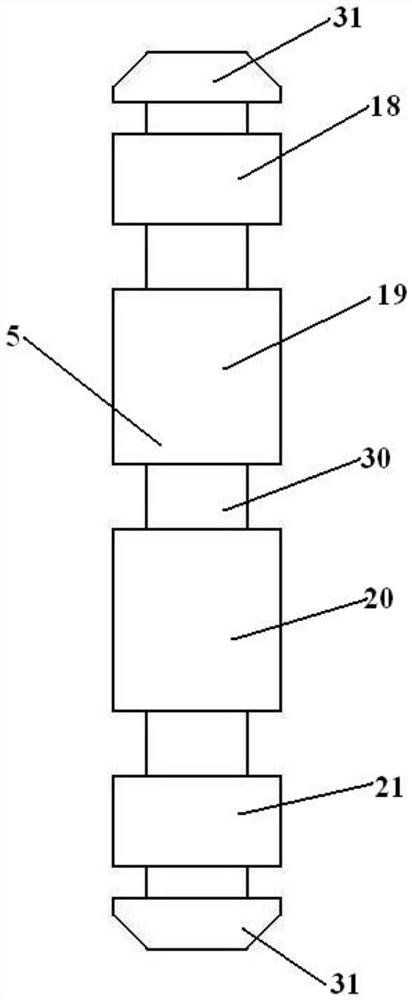

[0040] Such as figure 1 As shown, a parallel internal and external combined shock absorber is made, including an upper base plate 1, a lower base plate 2 and a damping main body 3, and the shock absorbing main body 3 is fixedly installed between the upper base plate 1 and the lower base plate 2, and the upper base plate 1 An upper seat hole 32 is fixedly installed above the base plate 1 , and a lower seat hole 33 is fixedly installed below the lower base plate 2 .

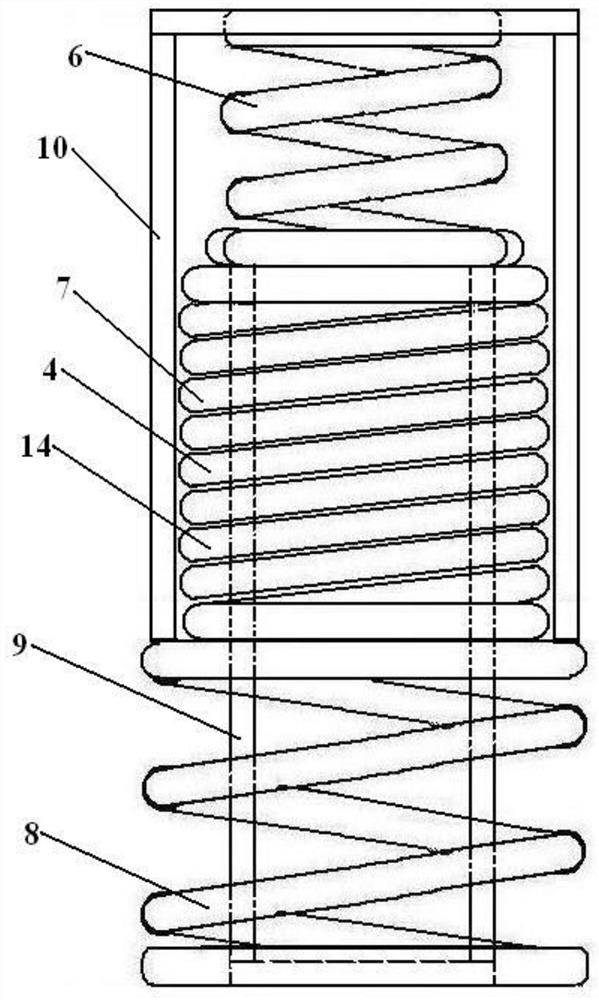

[0041] The external vibration damping mechanism 4 includes three sections of springs and two frame tubes 15, the three sections of springs are respectively small-diameter compression springs 6, medium-diameter extension springs 7 and large-diameter compression springs 8, and the two frame tubes 15 are respectively small-diameter Frame tube 9 and large-diameter frame tube 10; the outer diameter of described small-diameter compression spring 6 is less than the inner diameter of middle-diameter extension spring 7, and...

Embodiment 2

[0046] Such as Figure 4 As shown, on the basis of embodiment 1, the outer diameter of described small-diameter compression spring 6 is made equal to the inner diameter of middle-diameter extension spring 7, and the outer diameter of described middle-diameter extension spring 7 is made equal to large-diameter compression spring 8 inner diameter.

[0047] Make the free length Z1 of the small-diameter compression spring 6 , the free length Z2 of the middle-diameter extension spring 7 and the free length Z3 of the large-diameter compression spring 8 equal.

[0048] Add the length K1 of the small-diameter frame tube 9 to the sum of the length K2 of the large-diameter frame tube 10 to make it equal to the free length Z1 of the small-diameter compression spring 6 plus the free length Z3 of the large-diameter compression spring 8 plus twice the middle The sum of the free length Z2 of diameter extension spring 7, namely K1+K2=Z1+Z3+2Z2.

[0049] Make the adhesion length M1 of the sm...

Embodiment 3

[0054] As shown in each figure, the manufacturing method of the parallel internal and external combined shock absorber includes the following steps:

[0055] (1) Take three springs, the diameters of the three springs are different, and two of them are compression springs, and one is a tension spring, which are respectively small-diameter compression spring 6, medium-diameter tension spring 7 and large-diameter compression spring 8. The three springs are Both ends are respectively provided with a circle of seat ring; on the outer wall of the small diameter compression spring 6 right end seat ring, the outer annular limit stopper 11 is welded, and the outer annular limit stopper 11 is connected with the middle diameter tension spring 7 left end seat ring Welding, make the right end seat ring of small-diameter compression spring 6, the outer annular stopper 11 and the left end seat ring of medium-diameter extension spring 7 jointly form small-diameter seat ring 12; Weld the inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com