Base metal particle forming equipment

A particle forming and base metal technology, which is applied in the field of base metal particle forming equipment, can solve the problems of low processing precision, large particle size, unevenness, etc., and achieve the effects of fine forming size, increased centrifugal compression, and expanded application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The liquid metal is formed into splash droplets by rotating centrifugal method, and the droplets are refined with high-frequency vibration. The specific operations are as follows:

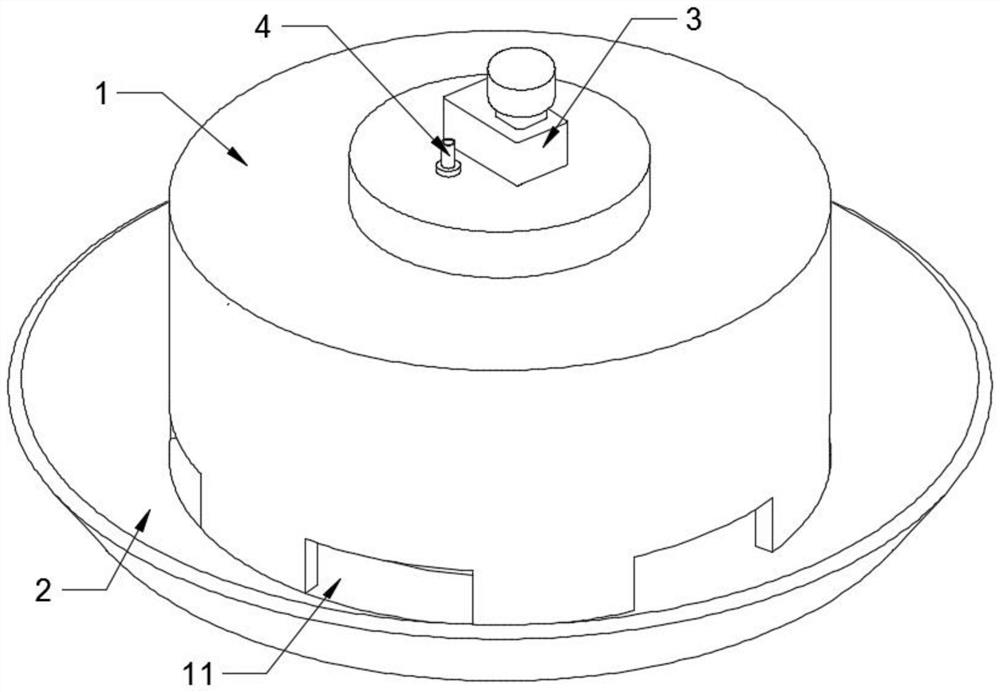

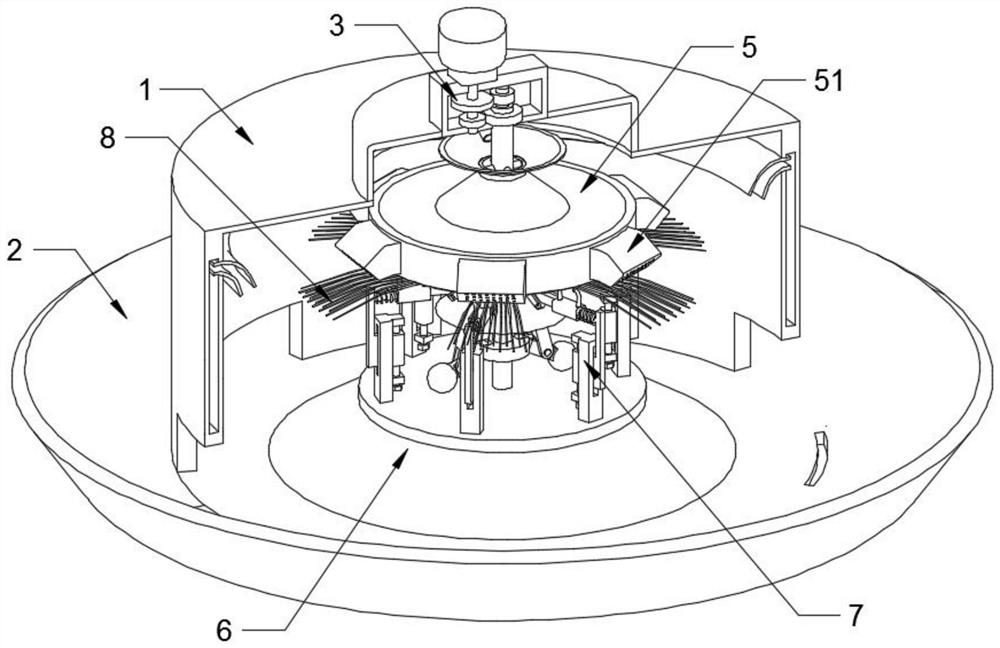

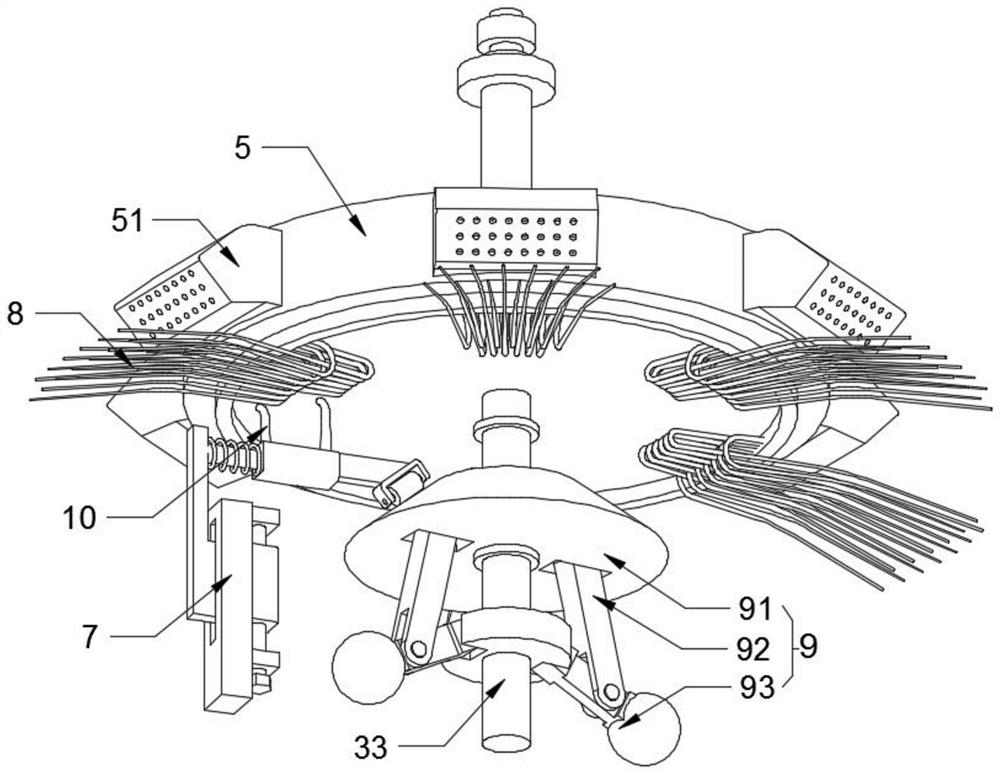

[0035] like figure 1 , figure 2 and image 3 As shown, a base metal particle forming equipment includes a forming chamber 1 with a driving device 3 at the top, a centrifugal disc 5 connected to the driving device 3 is arranged inside the forming chamber 1, the centrifugal disc 5 is suspended, and the centrifugal disc 5 includes a centrifugal chamber 53. The edge of the centrifugal chamber 53 passes through a plurality of end shells 51, the end surface of the end shell 51 has a number of pores, and the bottom of the end shell 51 is provided with a number of elastic steel needles 8 extending radially along the centrifugal chamber 53. The end is fixedly connected to the centrifugal chamber 53 , a lever 10 connected to the molding chamber 1 is arranged below the elastic steel needle 8 , the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com