Patents

Literature

140results about "Dewatering/demulsification regulation/control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

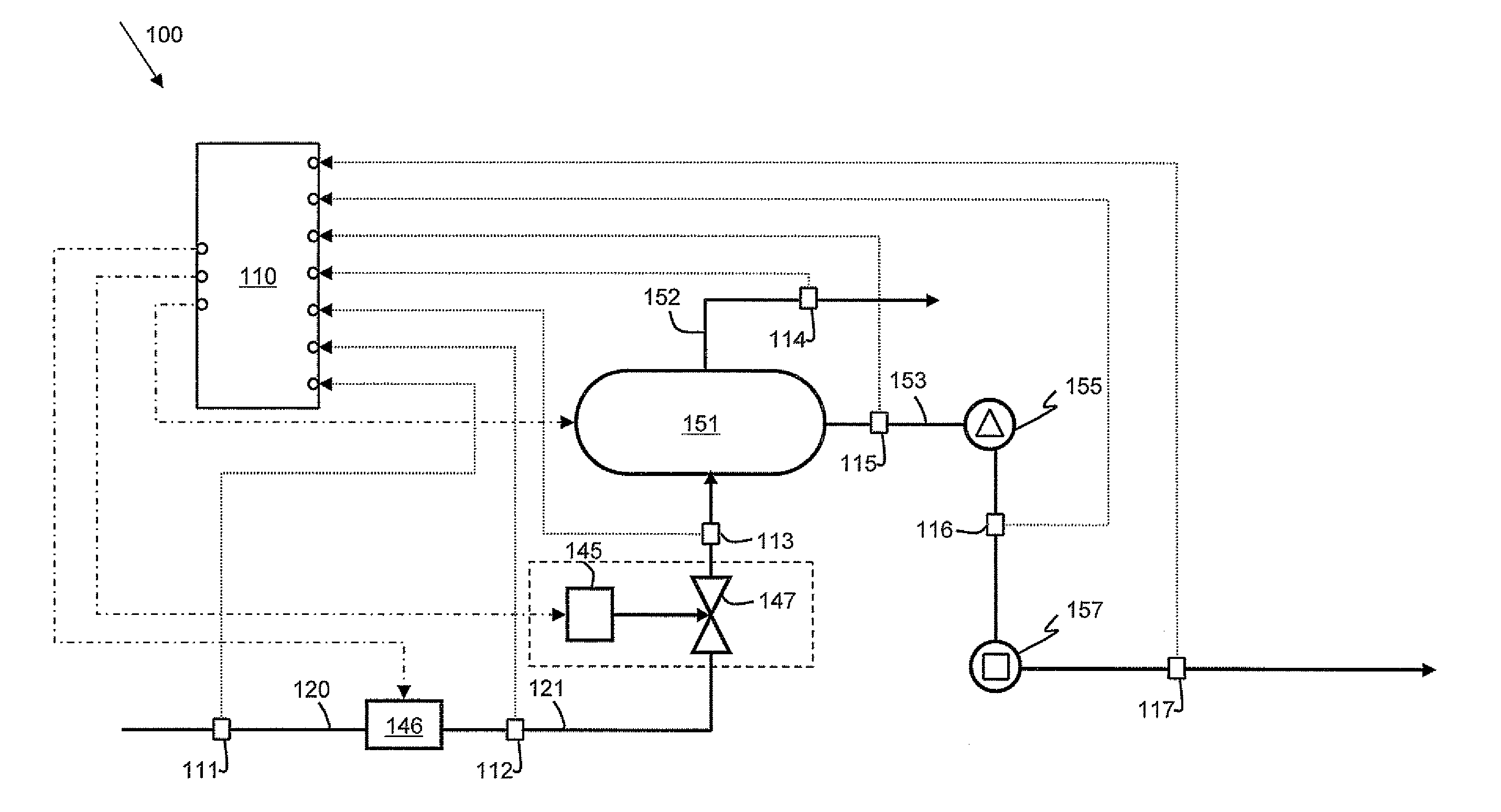

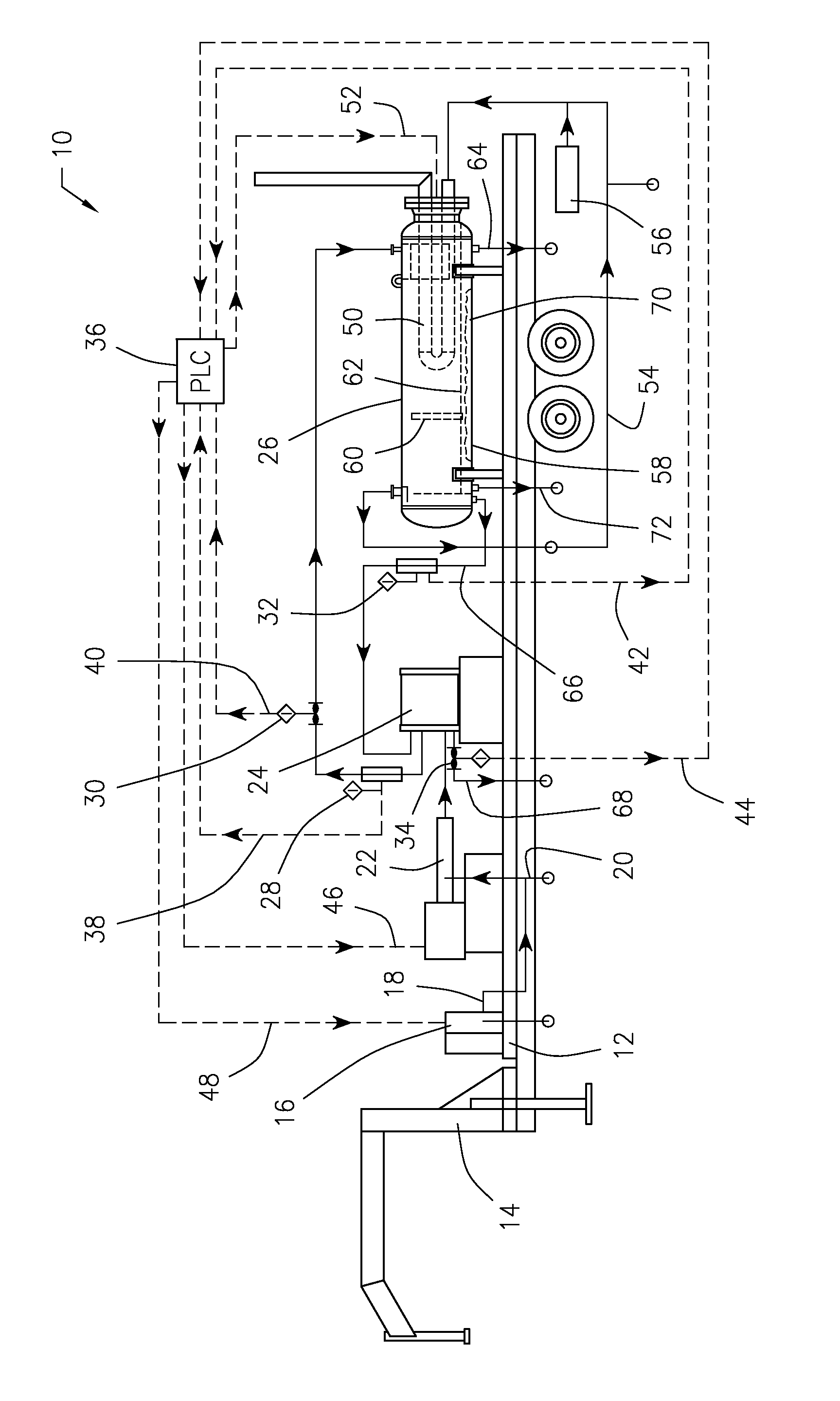

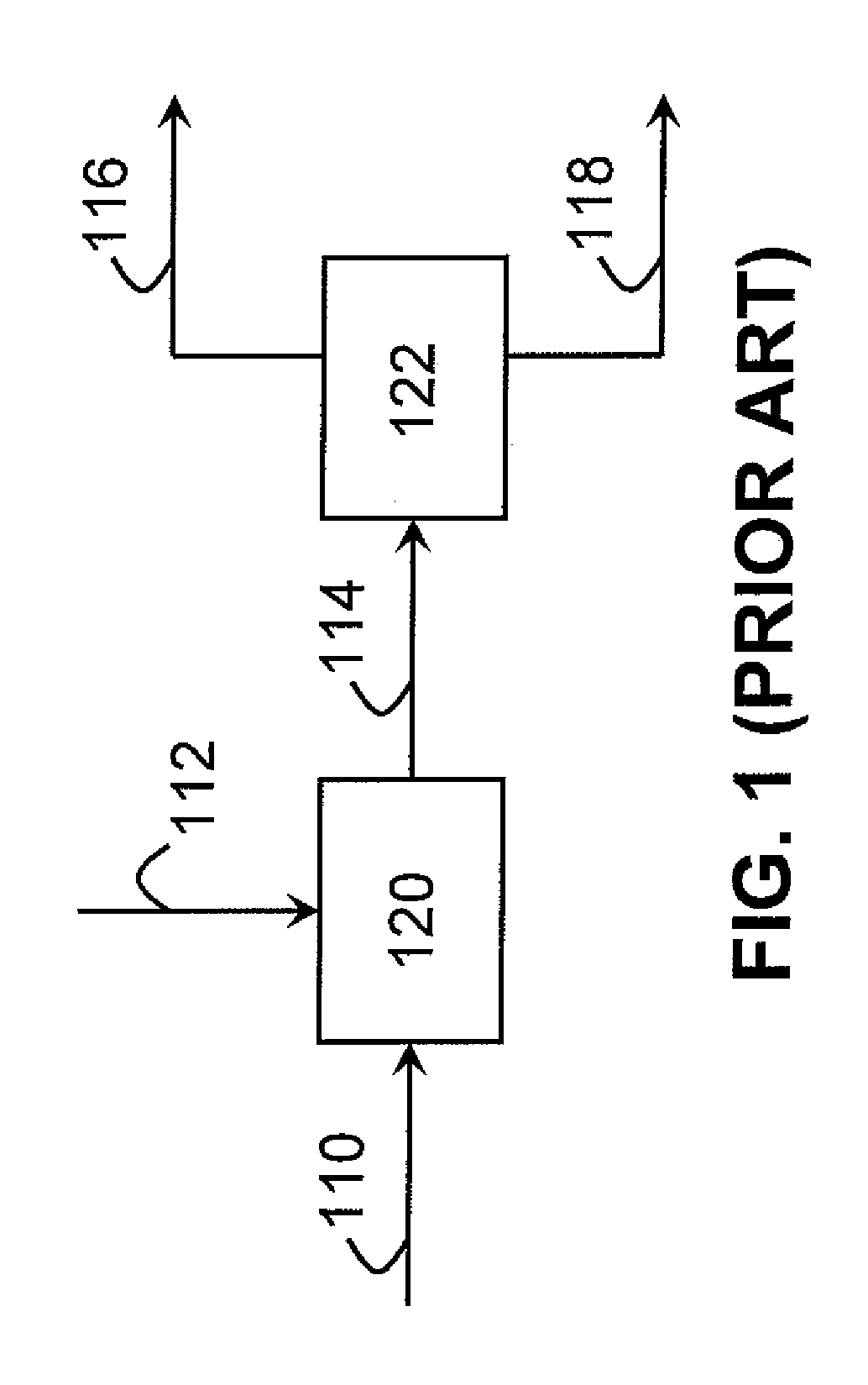

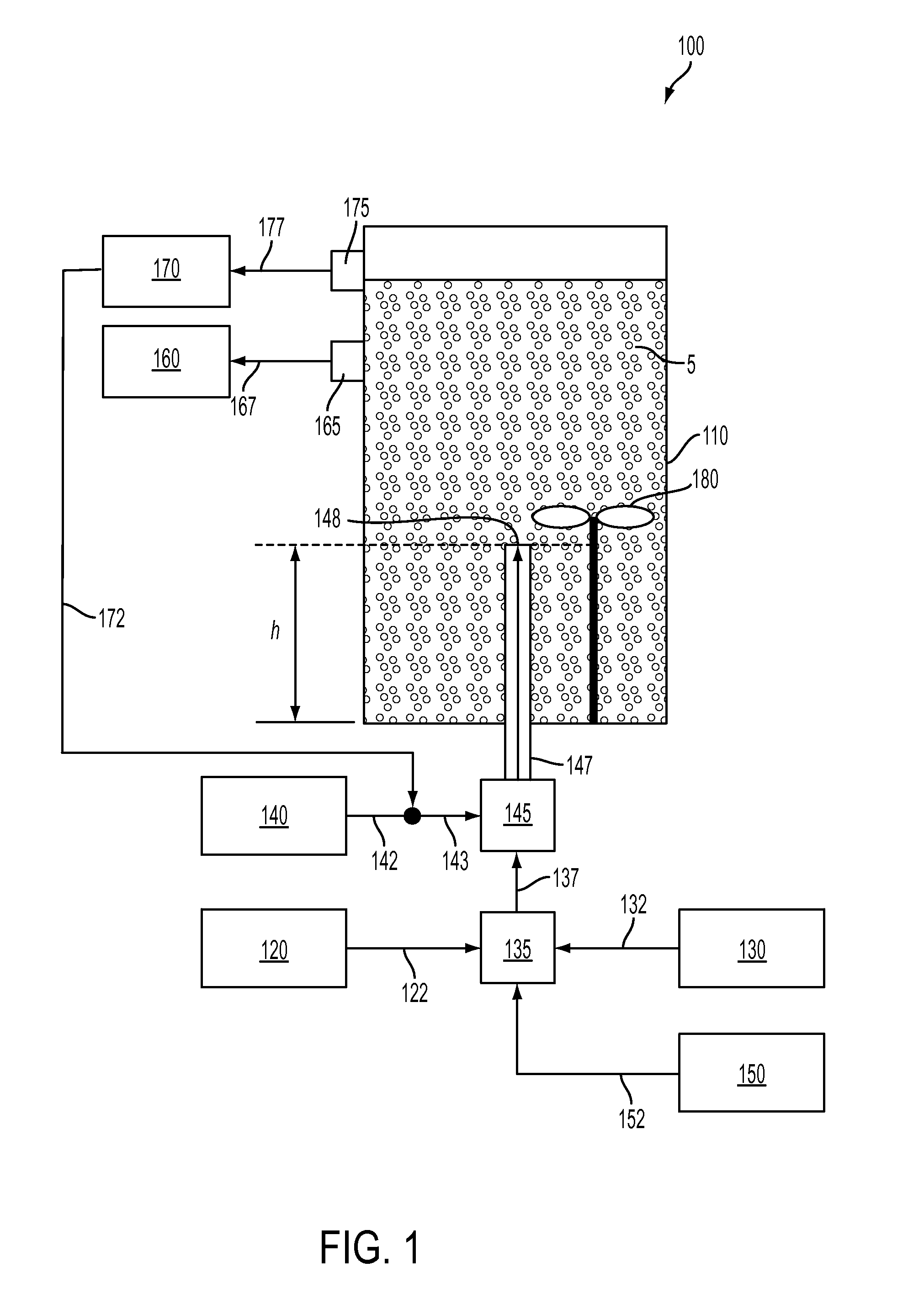

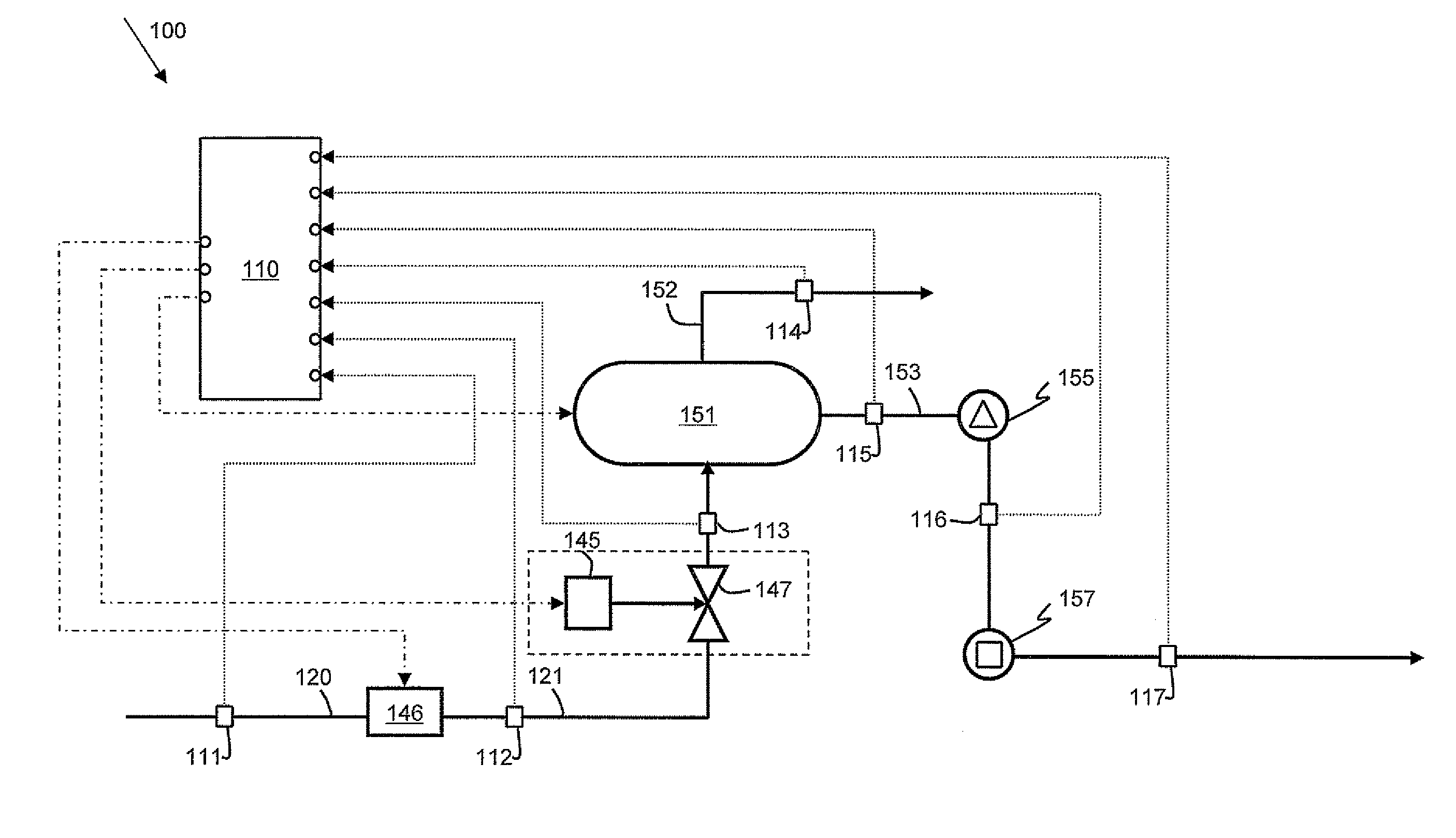

Dynamic demulsification system for use in a gas-oil separation plant

ActiveUS20130026082A1Low viscosityLiquid separation auxillary apparatusLiquid separation by electricityMicrowaveOil separation

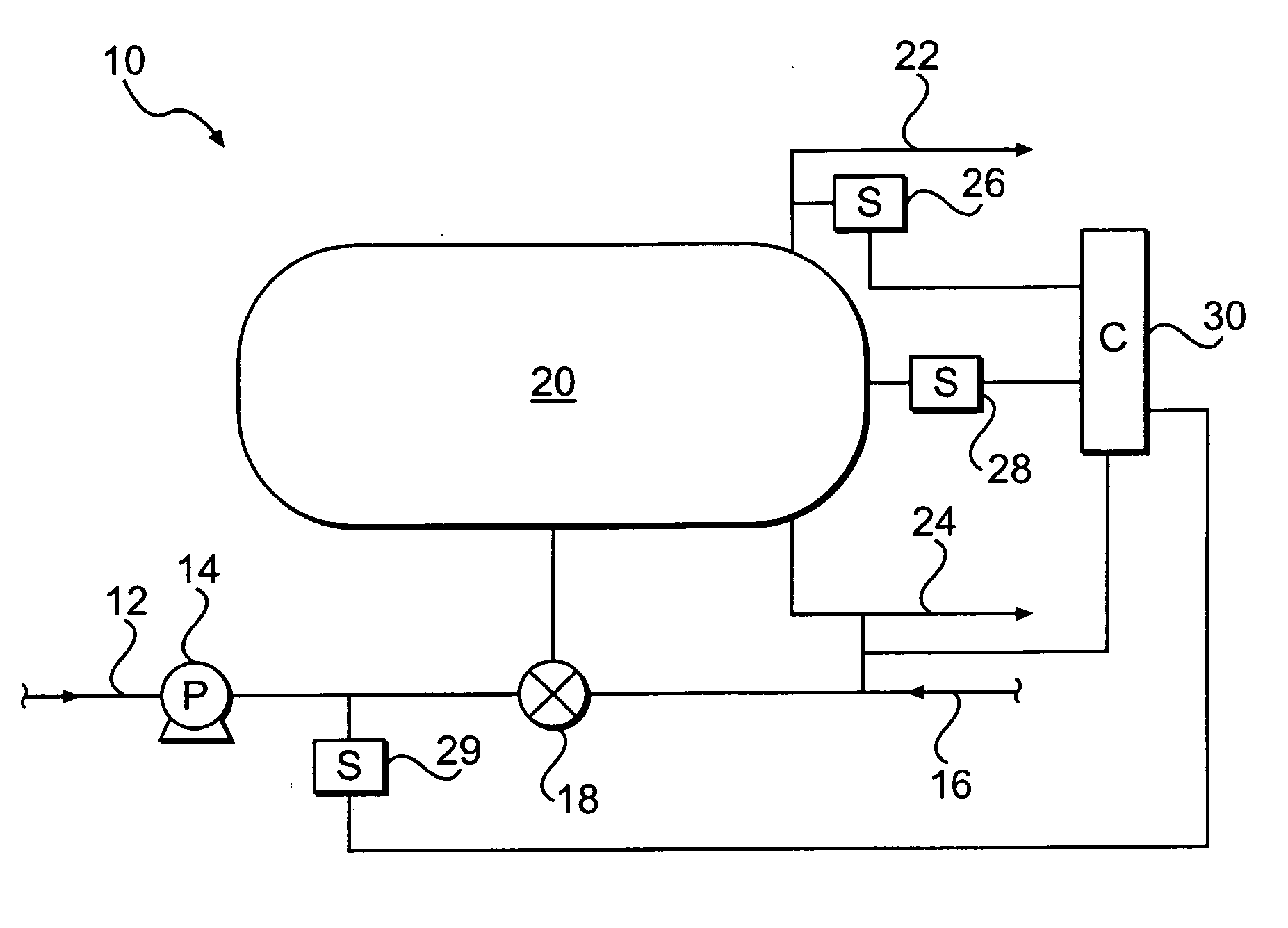

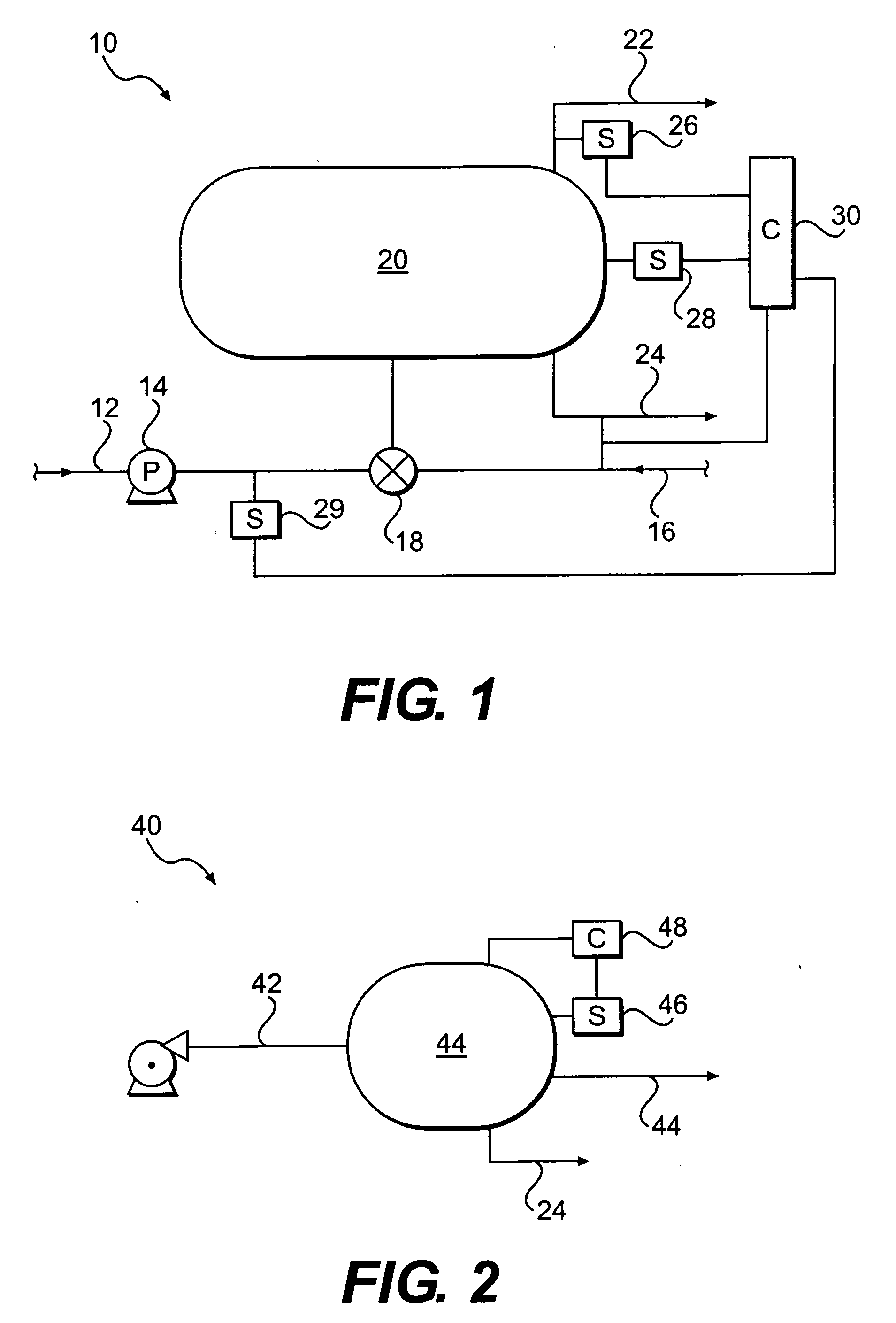

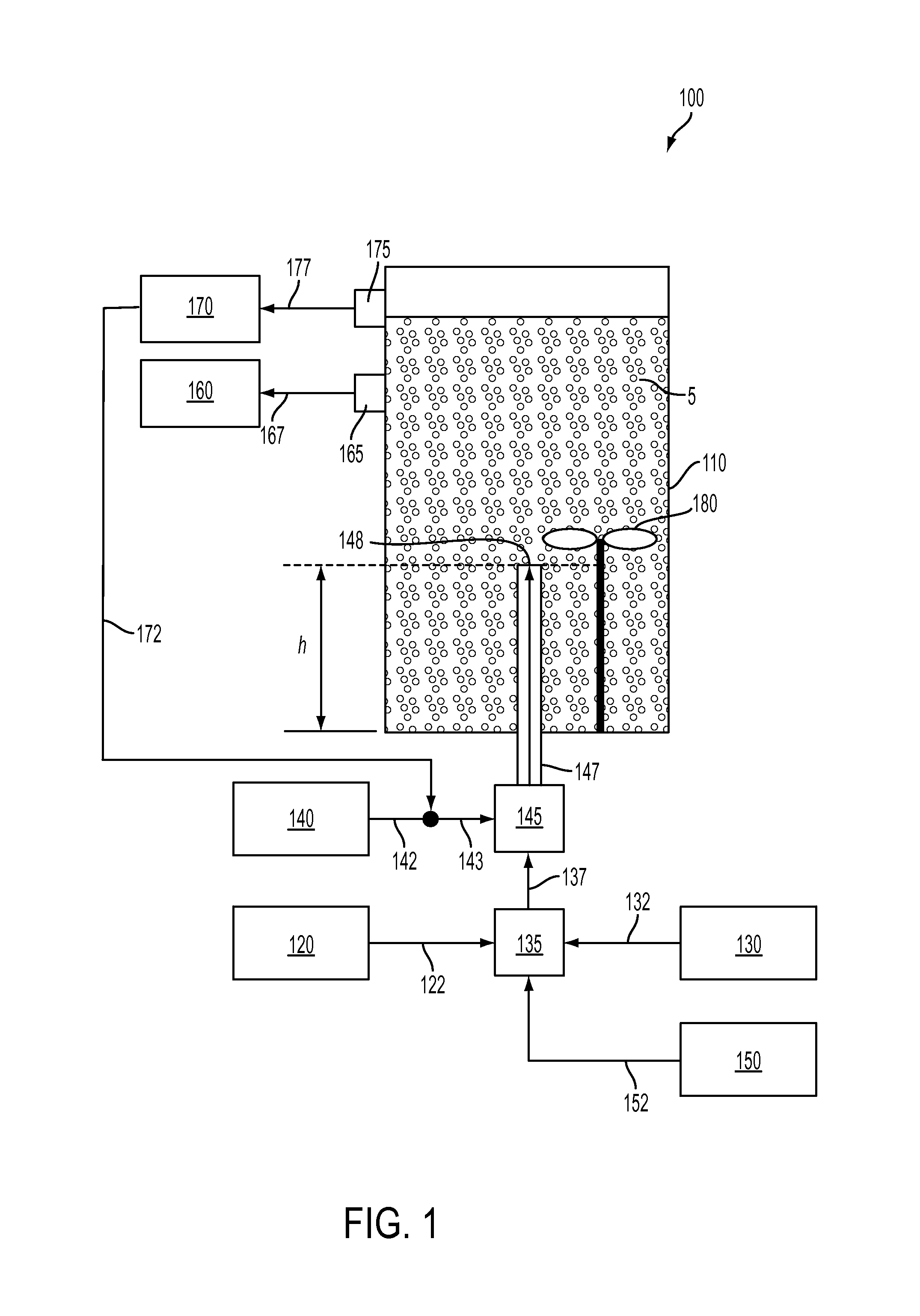

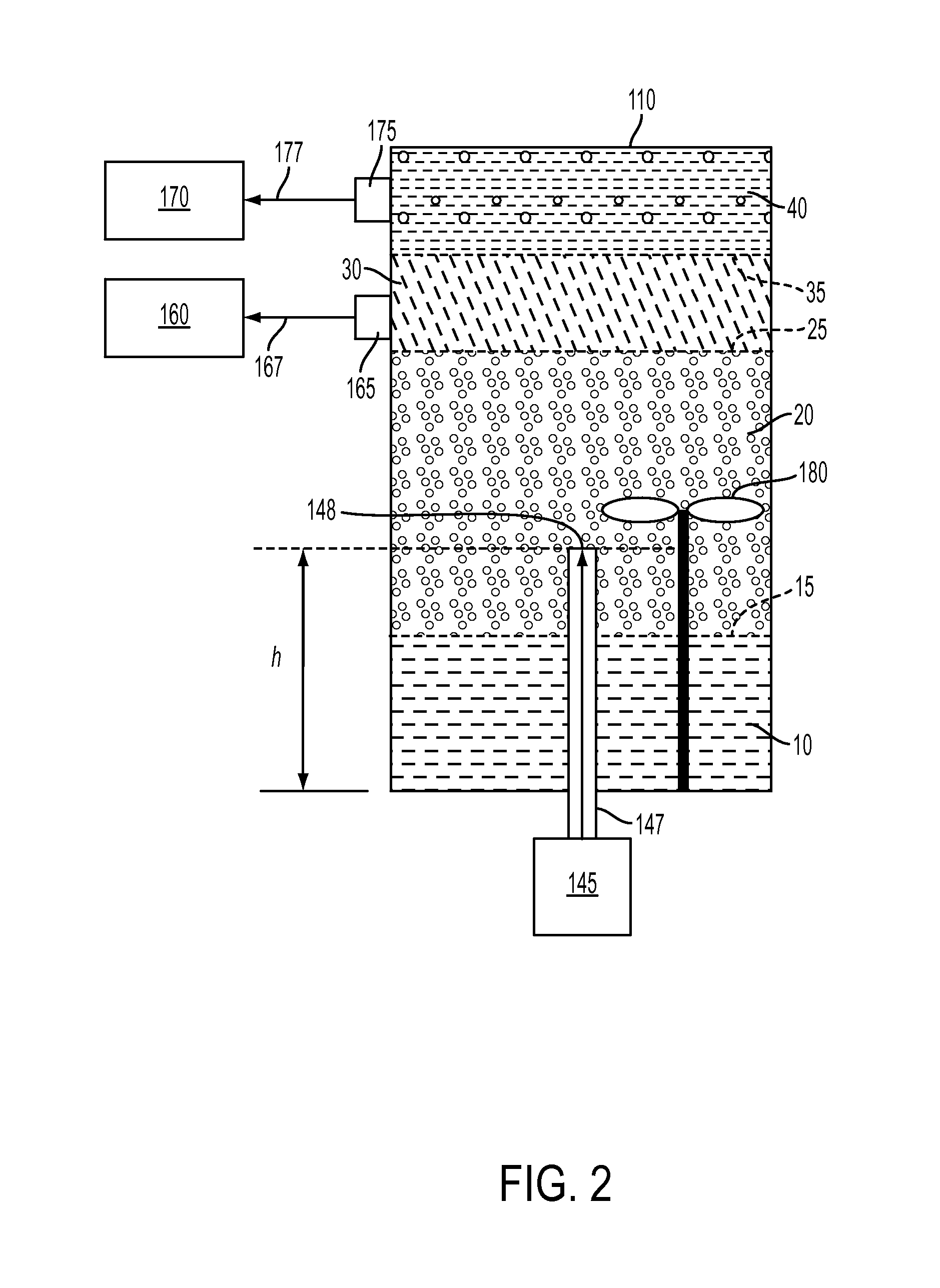

A dynamic water / oil demulsification system for a gas-oil separation plant (GOSP) includes:an in-line microwave treatment subsystem upstream of one or more of each of a dehydrator vessel, desalter vessel and / or water / oil separator vessel, each of which vessels receives a water-oil emulsion;sensors that monitor and transmit data corresponding to properties of the water-oil emulsion in or downstream of the respective vessel(s); anda processor / controller associated with the in-line microwave treatment subsystem that initiates the application of microwave energy to the emulsion(s) based on the data from the sensors.

Owner:SAUDI ARABIAN OIL CO

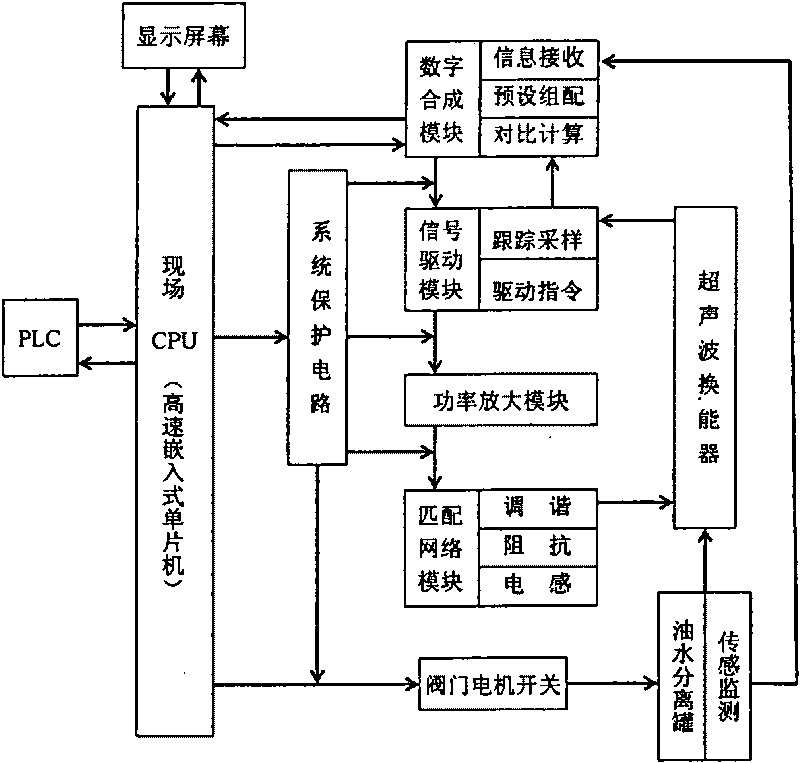

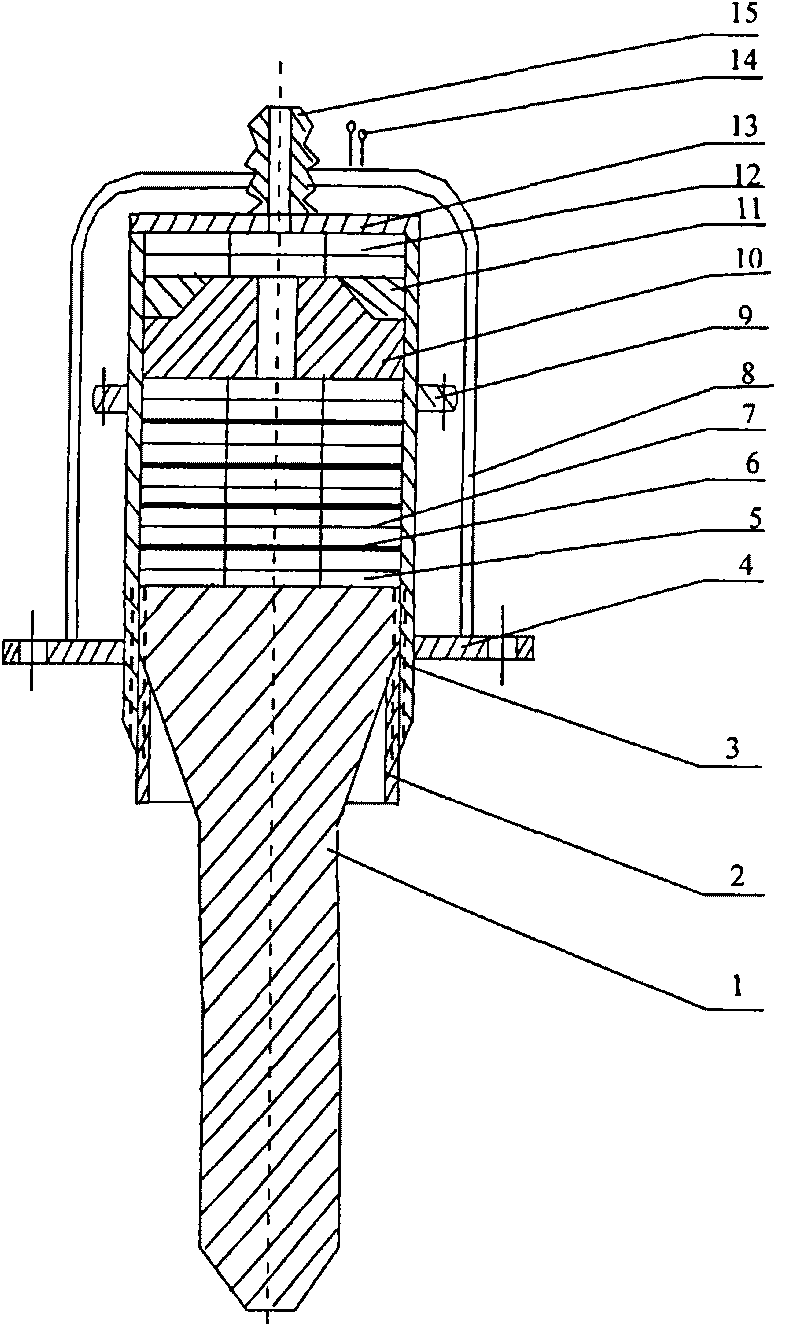

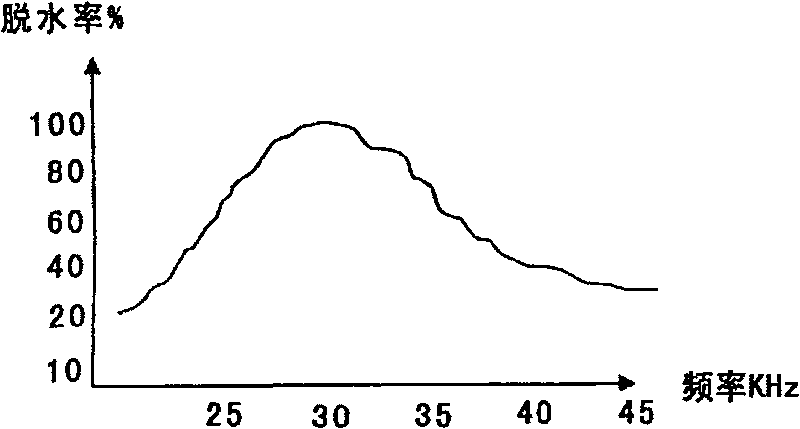

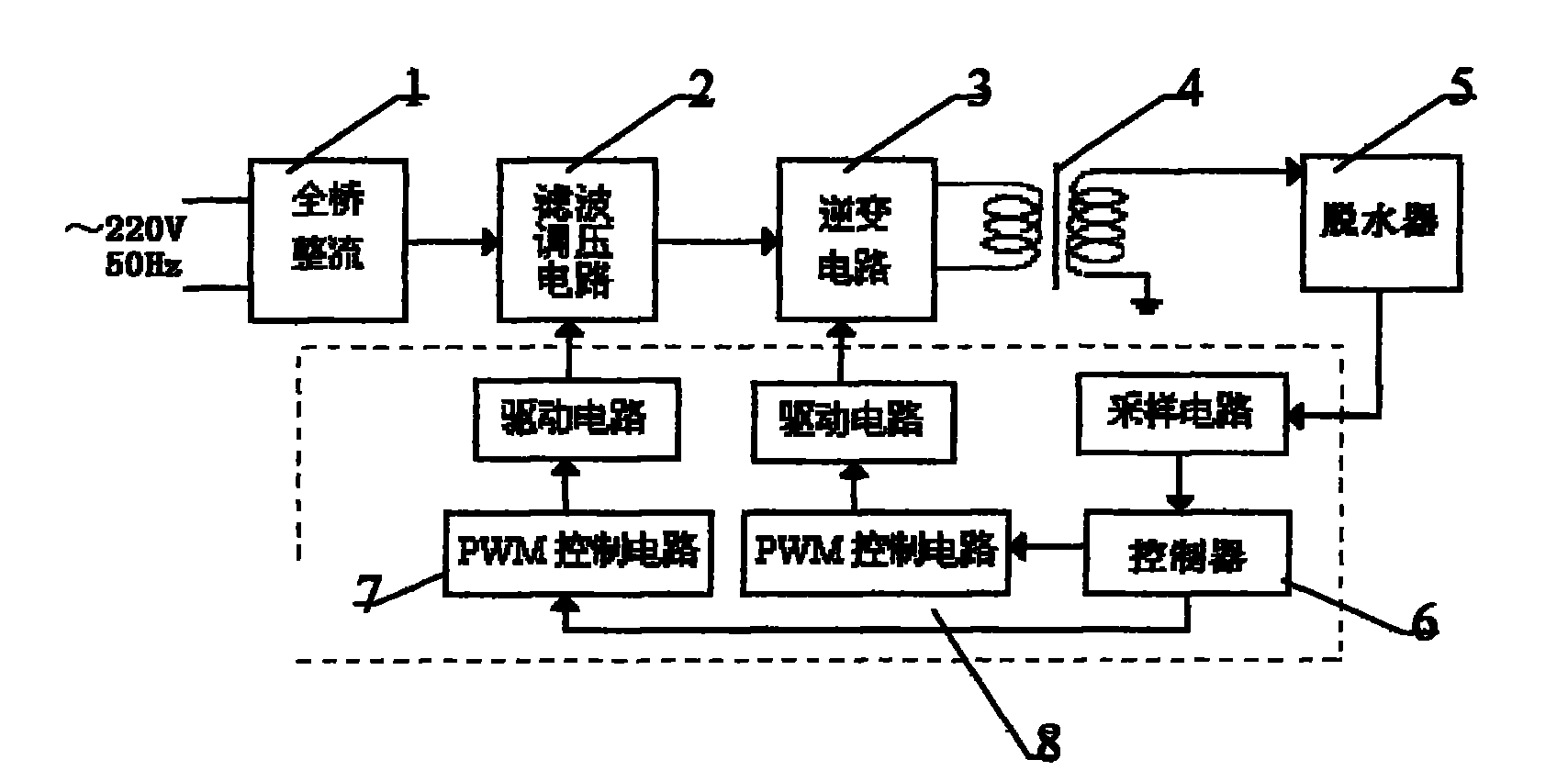

Crude oil ultrasonic emulsion breaking dehydrating device and emulsion breaking dehydrating method thereof

InactiveCN101724439AReal-time automatic tracking displayControl and adjust the function of running job parametersDewatering/demulsification with mechanical meansDewatering/demulsification regulation/controlChemical activityChemistry

The invention relates to an oil-water separating technology in petroleum crude oil extracting and refining industry, in particular to a crude oil ultrasonic emulsion breaking dehydrating device and emulsion breaking dehydrating method thereof. The invention, combining with the characteristic of ultrasonic wave and chemical activity effect of chemical demulsifier, breaks the stable structure of crude oil emulsion, causes the crude oil emulsion to be rapidly changed in structure and realizes less consumed electric quantity, low demulsifier usage amount, through oil water separation and separation on crude oil with extremely low content in water and sedimented muddy sand. The invention is mainly applicable to china oil stations and oil extracting centralized field in oil field; and the invention can be applied if the oil field can normally extract oil and requires crude oil emulsion breaking dehydrating treatment.

Owner:SIPING ZHONGKE TECH

Process for removing water from a water-containing crude oil

A process and apparatus for treating a crude oil containing water. An inlet introduces a flow of the crude oil into the apparatus, wherein at least a portion of the water is a vapor. A first separator disrupts the crude oil flow in order to separate at least a portion of the vapor from the crude oil to produce a treated oil. A heater heats the treated oil to produce a heated treated oil. Means for recycling a first amount of the heated treated oil from the heater to the inlet are provided. The first amount is at least sufficient to heat the crude oil to a temperature such that at least a portion of the water forms the vapor. At least one oil outlet removes the treated oil and at least one vapor outlet removes the vapor. Finally, means are provided for producing the flow of the crude oil. The process is preferably conducted using the apparatus.

Owner:FOREMOST UNIVERSAL

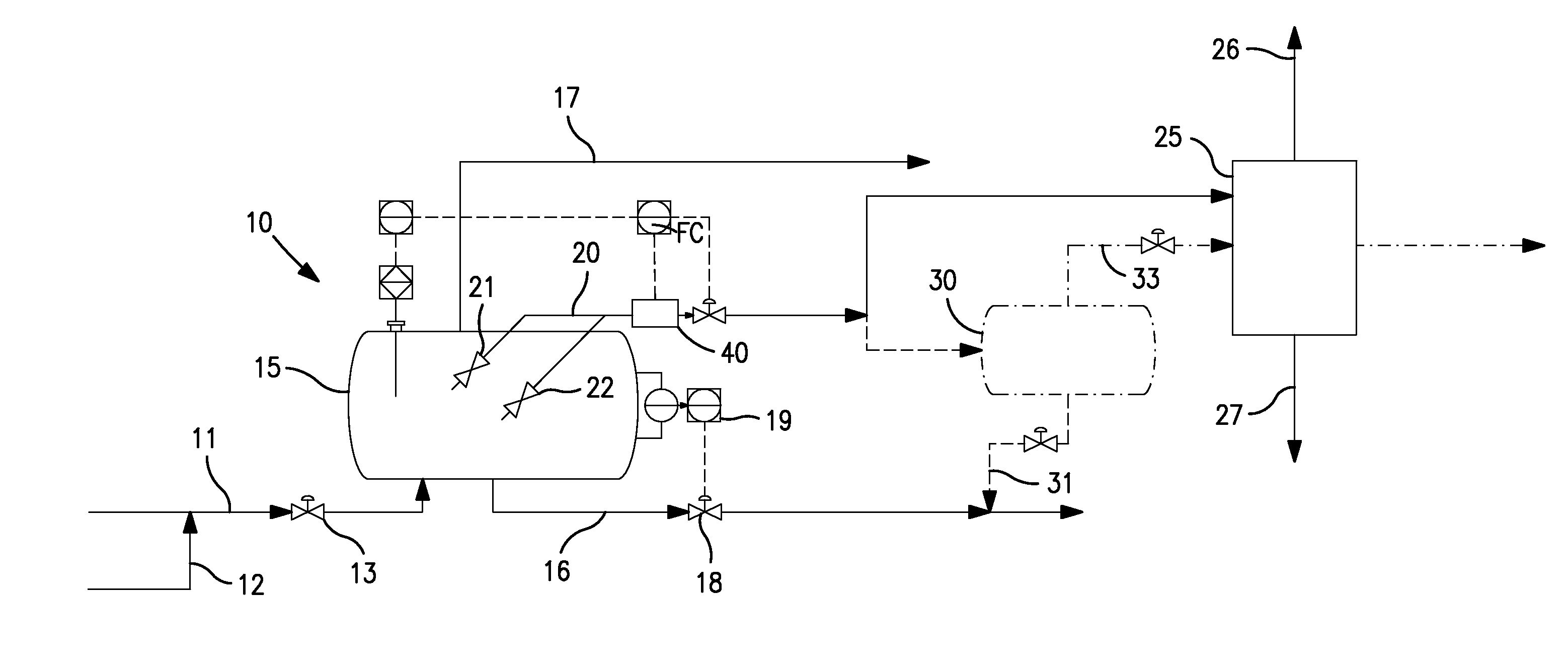

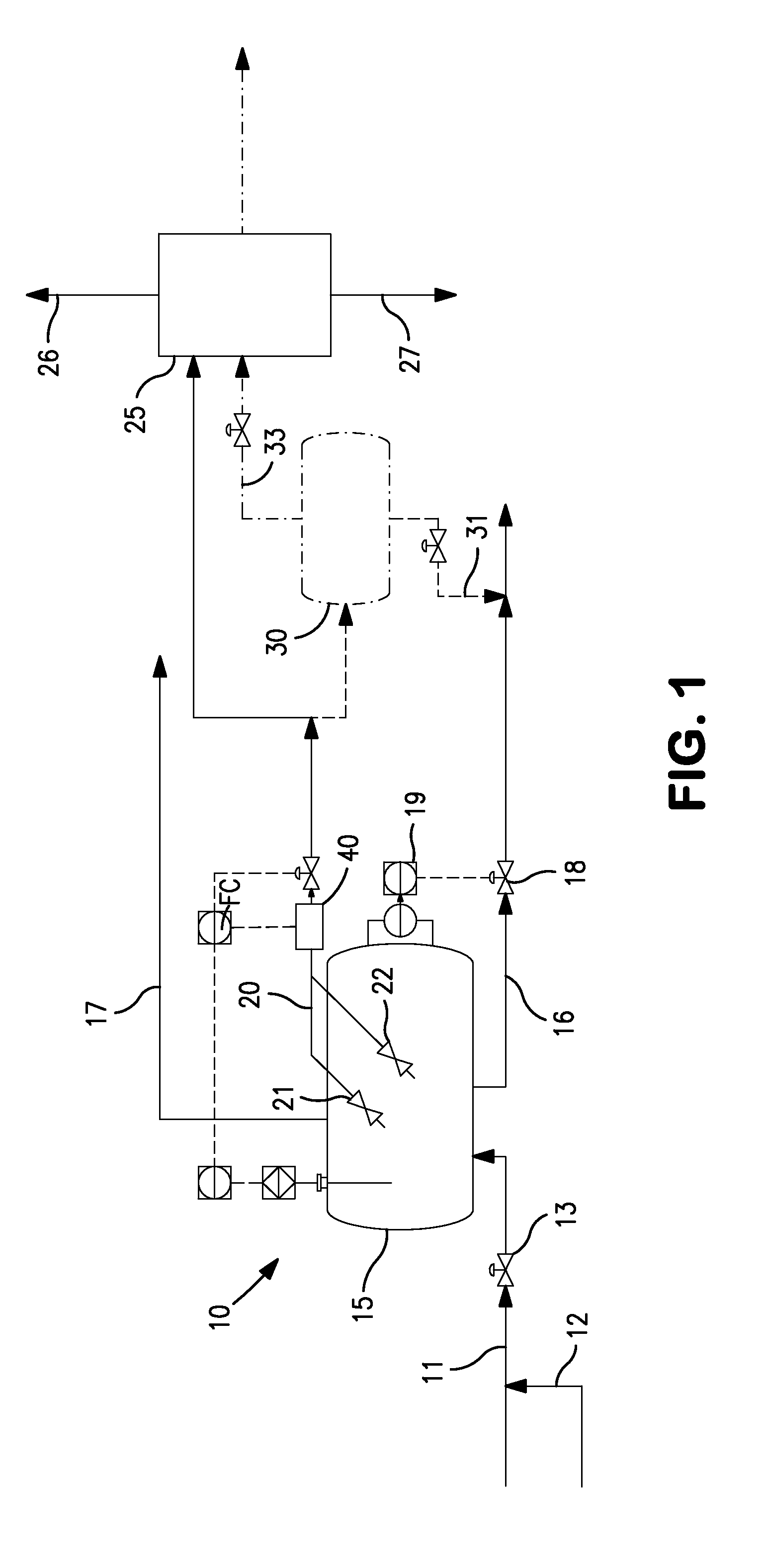

Local produced oil dehydrator

ActiveUS9157035B1Avoid necessityEasy to relocateDewatering/demulsification with chemical meansDewatering/demulsification with mechanical meansDemulsifierSediment

A portable, semi-portable, or permanent system for removing BS&W from crude oil at the local production or bulk storage site. A demulsifier is added to the crude as it enters a low shear pump which pumps the mixture through a plate and frame type heat exchanger where the incoming crude is preheated using outgoing heated and dehydrated crude. Then the incoming crude enters an oil-water separator where it is further heated by a secondary heater within the separator and passes through a special coalescing section. Water and basic sediment separate from the crude are discharged from the bottom of the separator. The heated dehydrated crude exits the separator, flows back through the heat exchanger where it is cooled as it preheats incoming crude, and then is pumped to clean oil storage. BS&W and flow monitors on the incoming crude and outgoing crude are used to control operation of the system.

Owner:BREAKTHROUGH ENGENUITY LLC +1

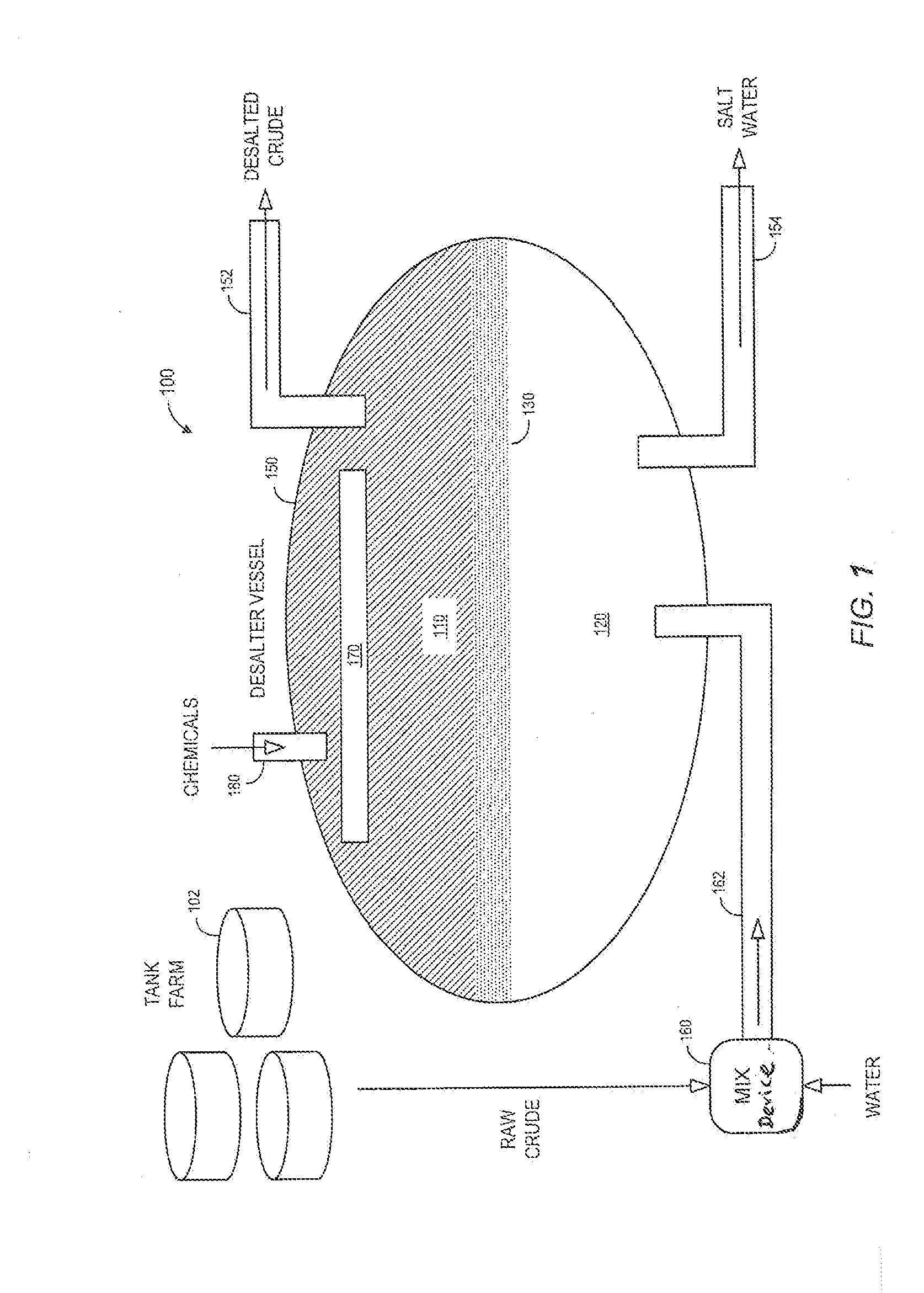

Devices And Processes For Deasphalting And/Or Reducing Metals In A Crude Oil With A Desalter Unit

ActiveUS20100089797A1Easy to processReduce dirtDewatering/demulsification with chemical meansDewatering/demulsification with mechanical meansDesalterWater soluble

This invention relates to devices and processes for removing asphaltenes and / or metals from crude oil to increase refinery processing of heavy materials. The desalters of this invention reduce and / or remove at least a portion of asphaltenes and / or metals form the crude oil. The separation occurs by mixing water with the crude oil to result in an aqueous phase having water and water soluble salts, an interface phase having asphaltenes and / or metals along with water, and a hydrocarbon phase having desalted, deasphalted and / or reduced metal crude oil.

Owner:BP CORP NORTH AMERICA INC

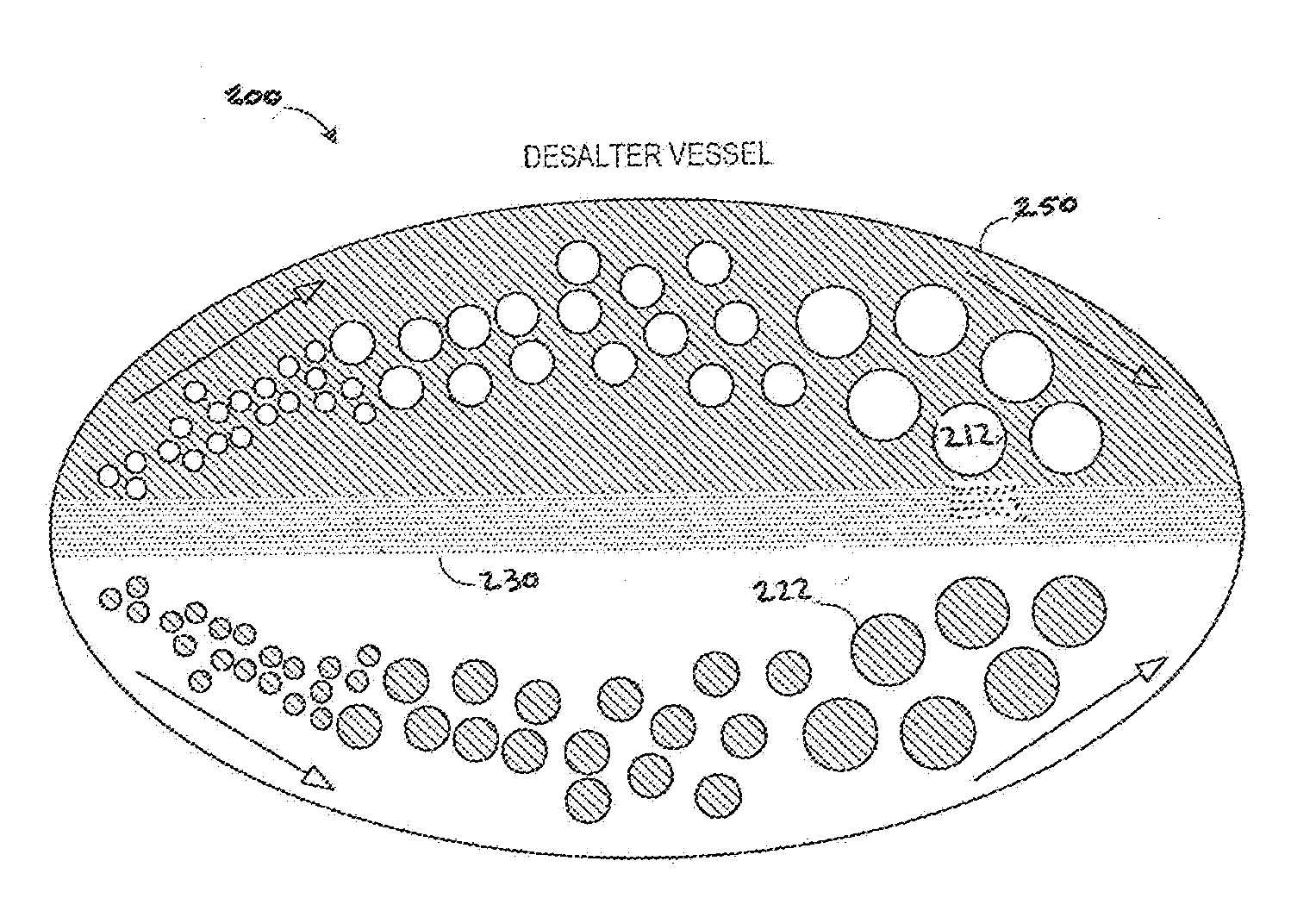

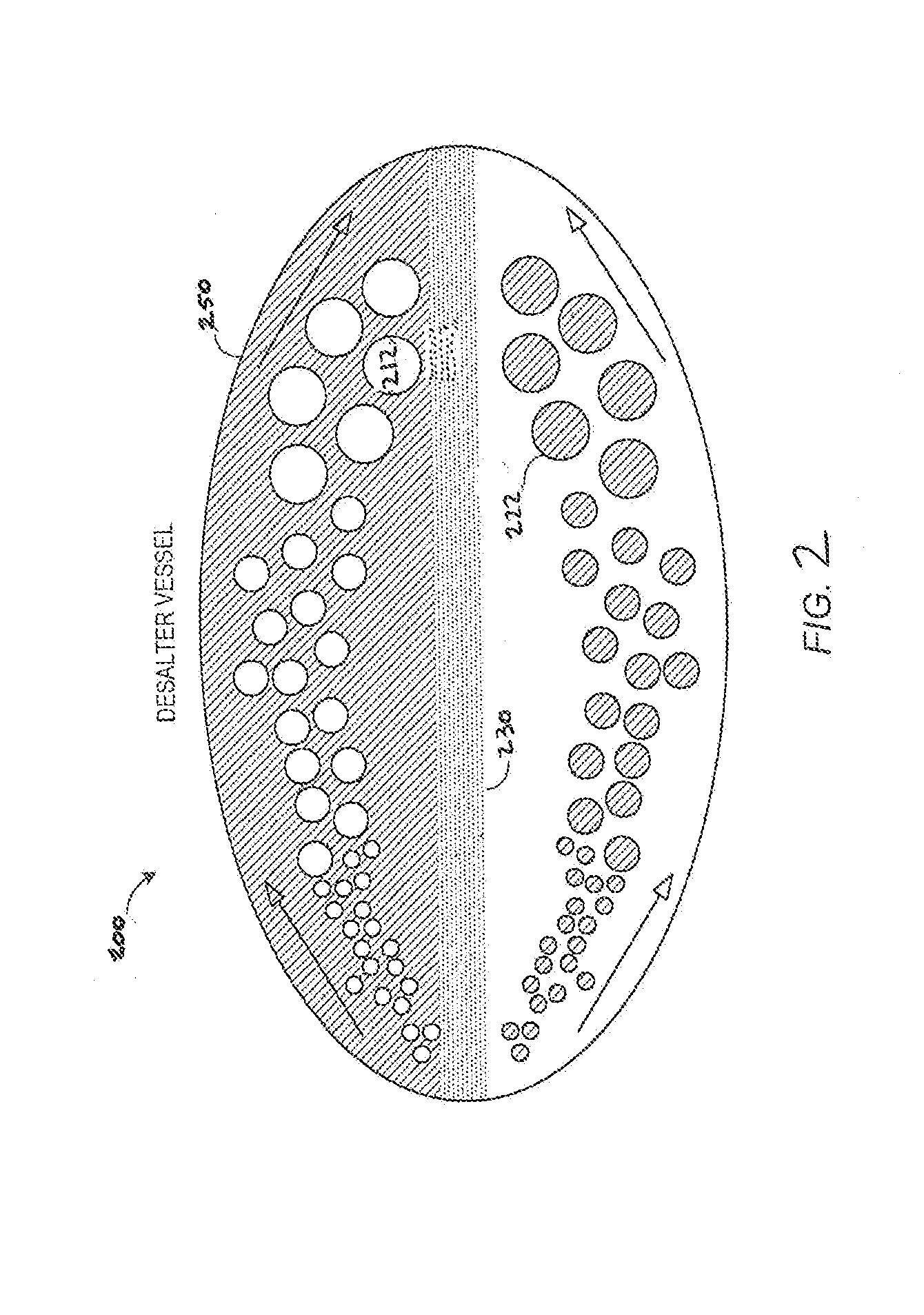

Separator for desalting petroleum crude oils having rag layer withdrawal

ActiveUS20140251874A1Minimal downtimeDewatering/demulsification with electric/magnetic meansRefining by water treatmentEmulsionAutomatic control

An improved separator for desalting petroleum crude oils which may be operated in a continuous manner under automatic control; the improved desalter is therefore well suited to modern refinery operation with minimal downtime. A portion of the emulsion layer is withdrawn from the desalter through external withdrawal ports according to the thickness and position of the emulsion layer with the selected withdrawal header(s) being controlled by sensors monitoring the position and thickness of the emulsion layer. The withdrawn emulsion layer can be routed as such or with the desalter water effluent to a settling tank or directly to another unit for separation and reprocessing.

Owner:EXXON RES & ENG CO

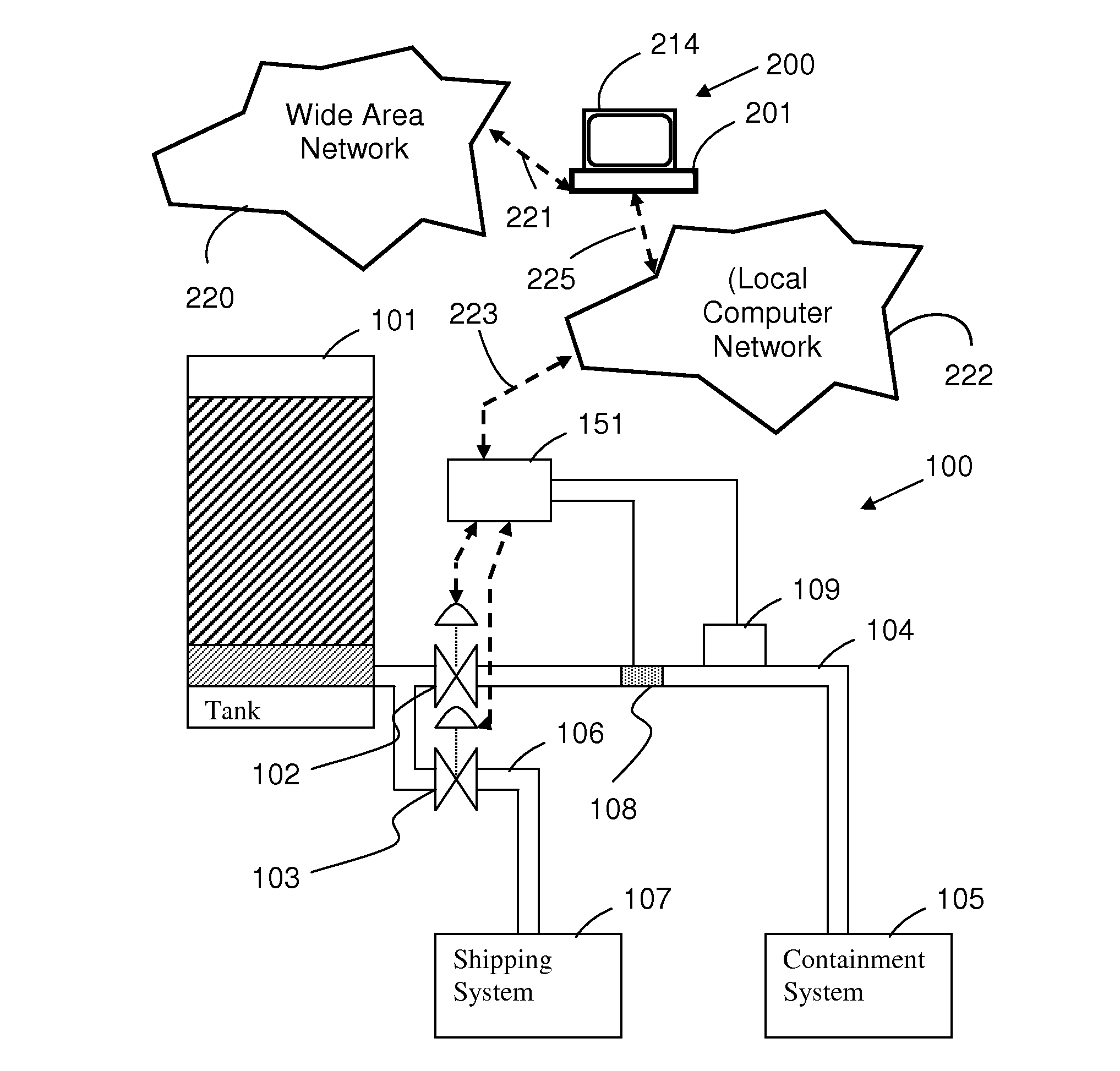

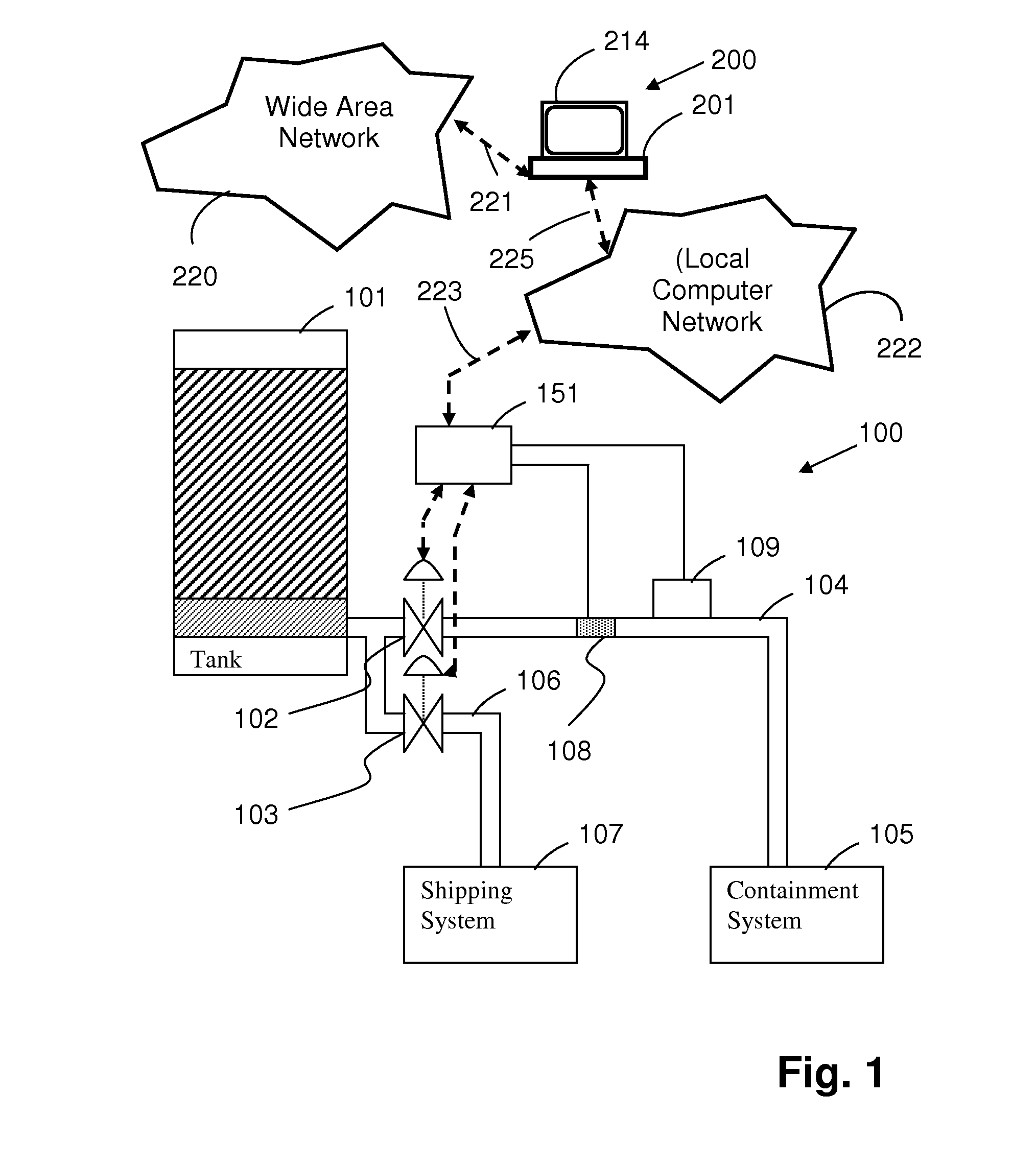

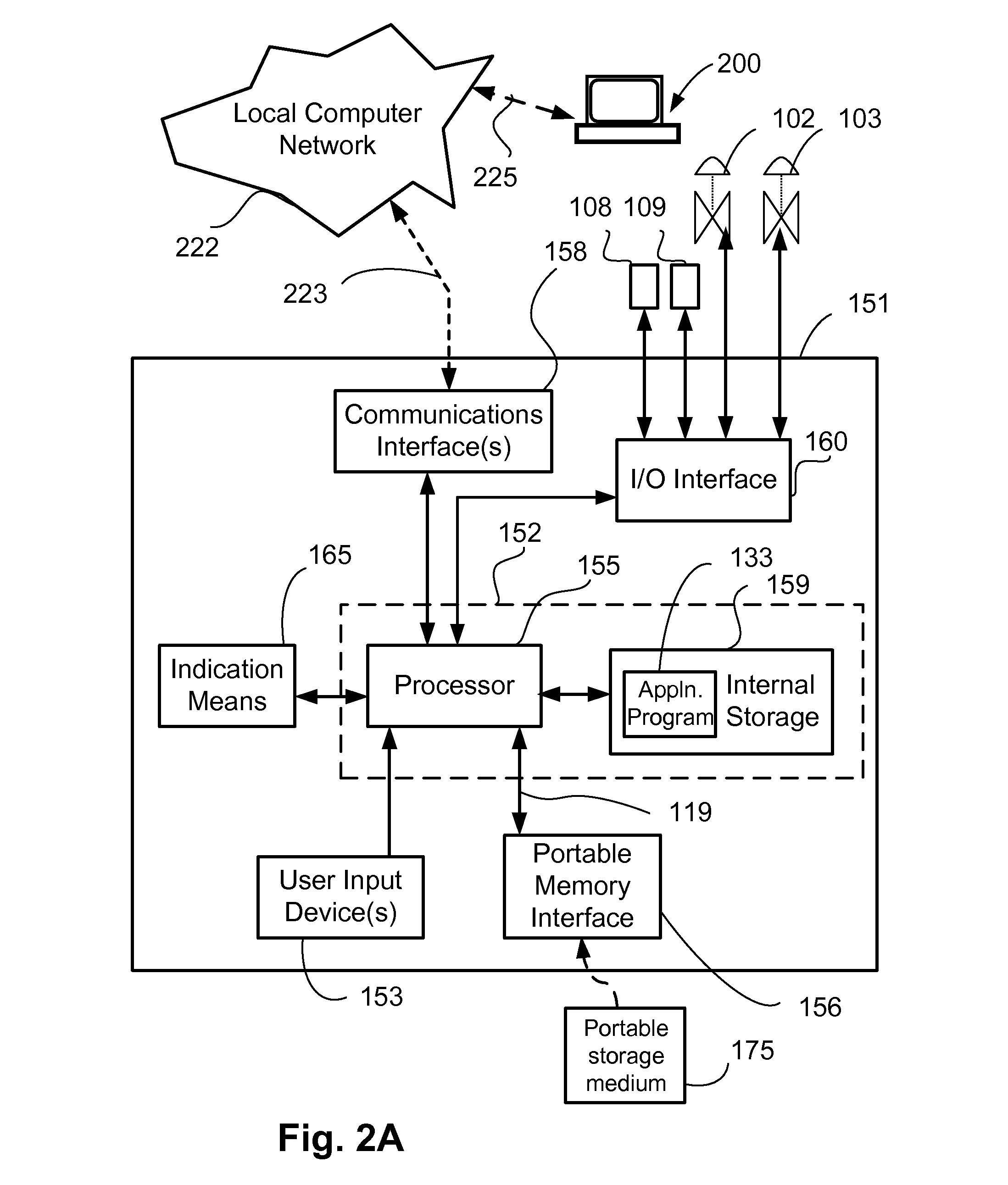

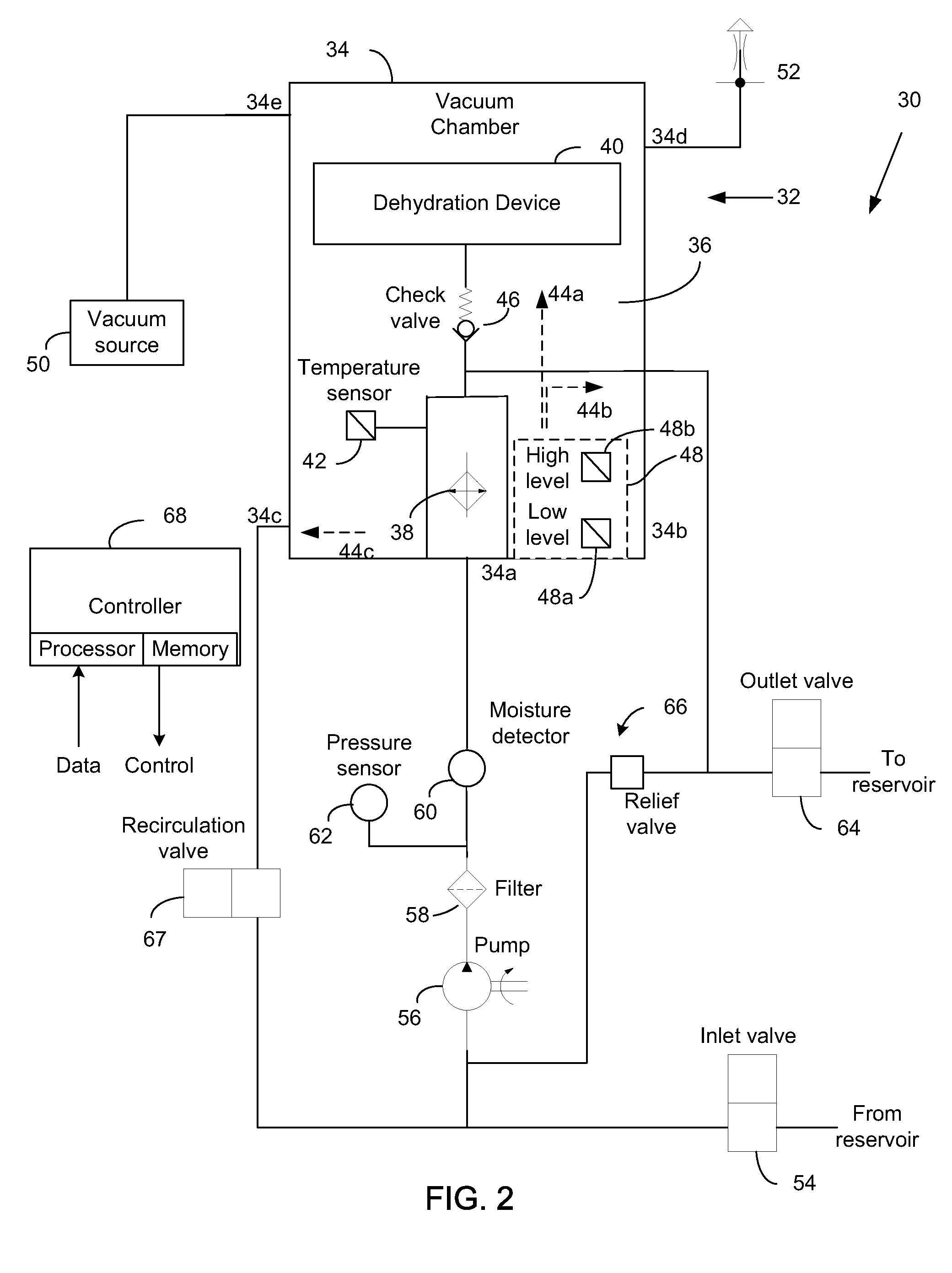

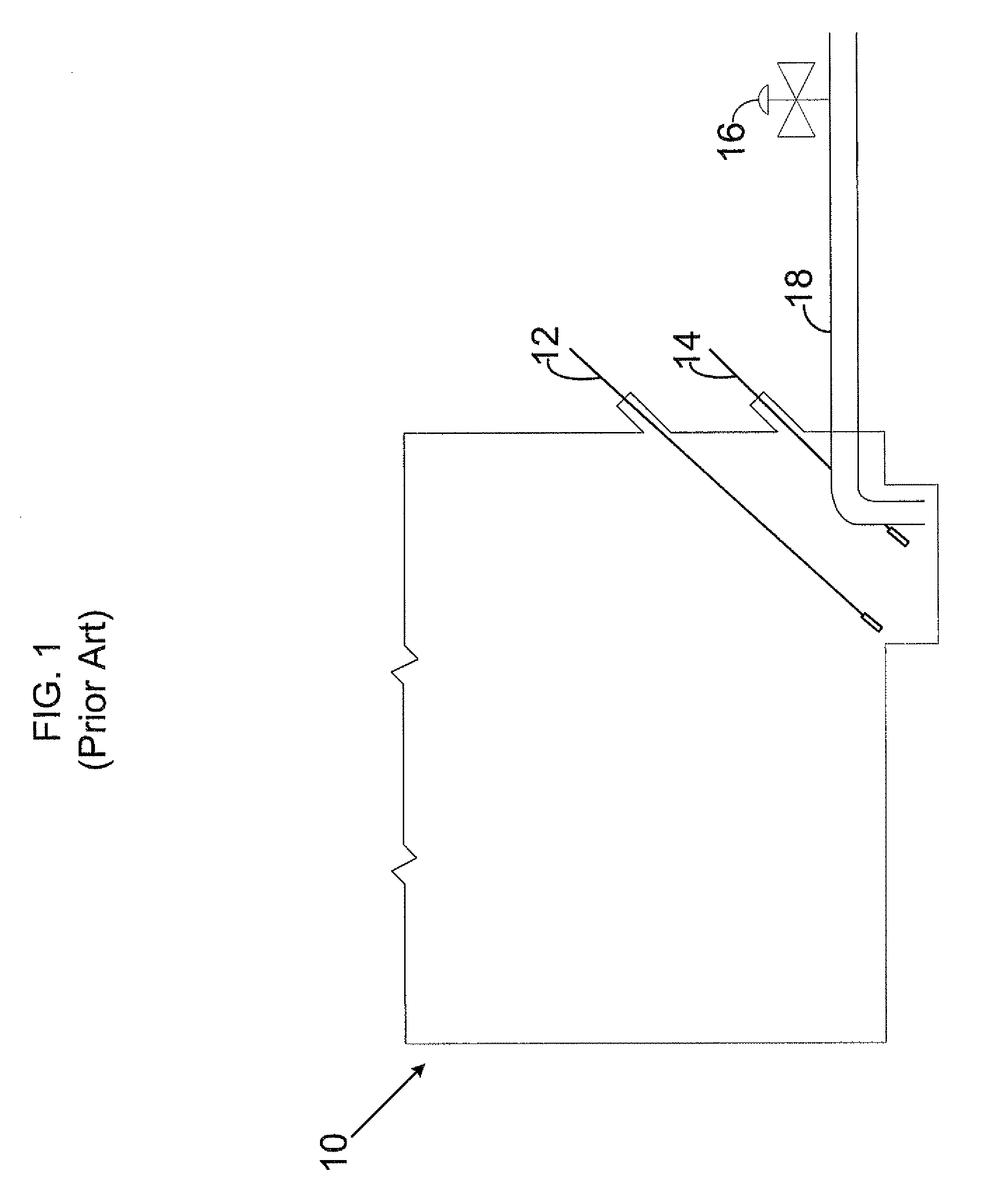

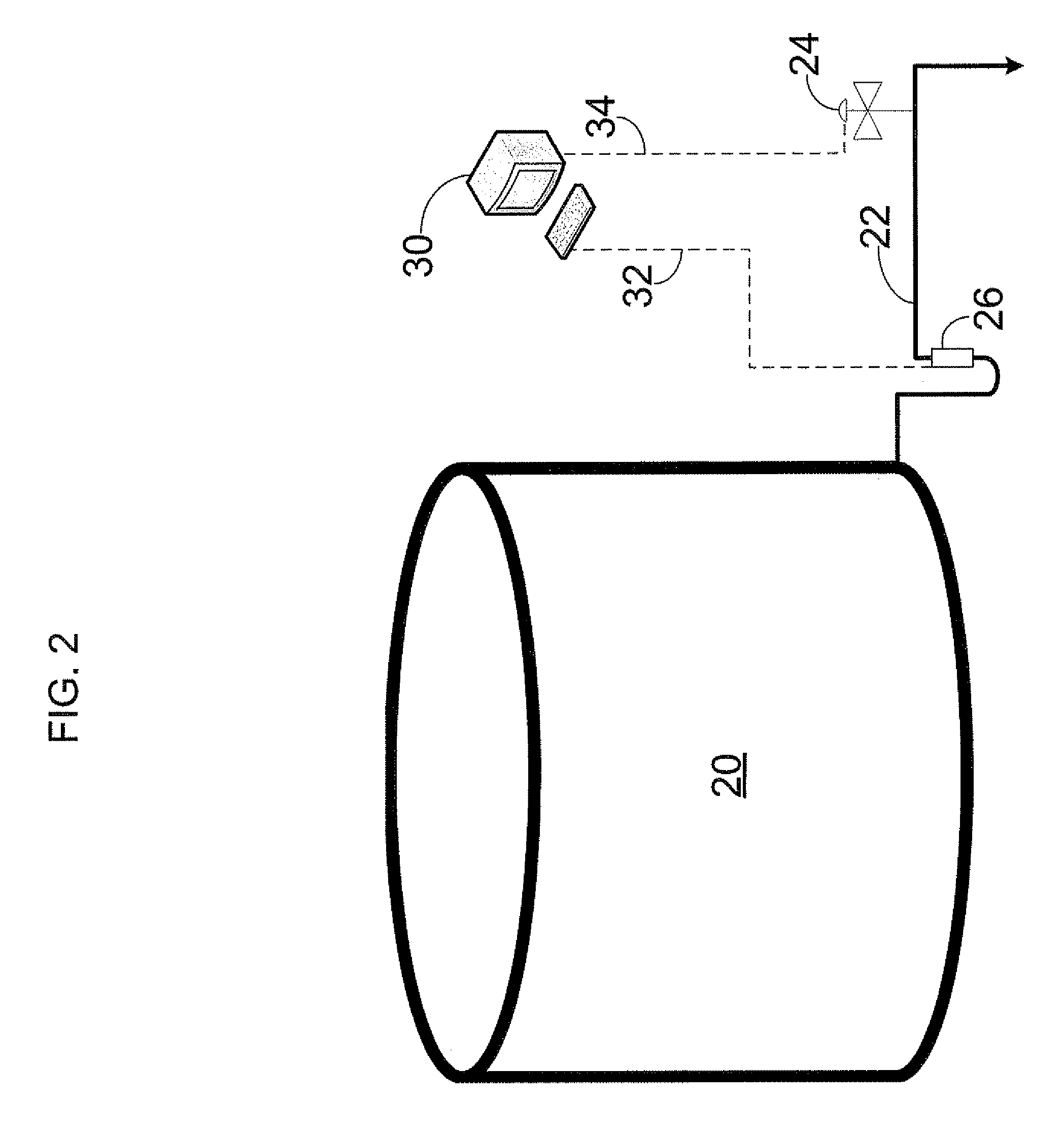

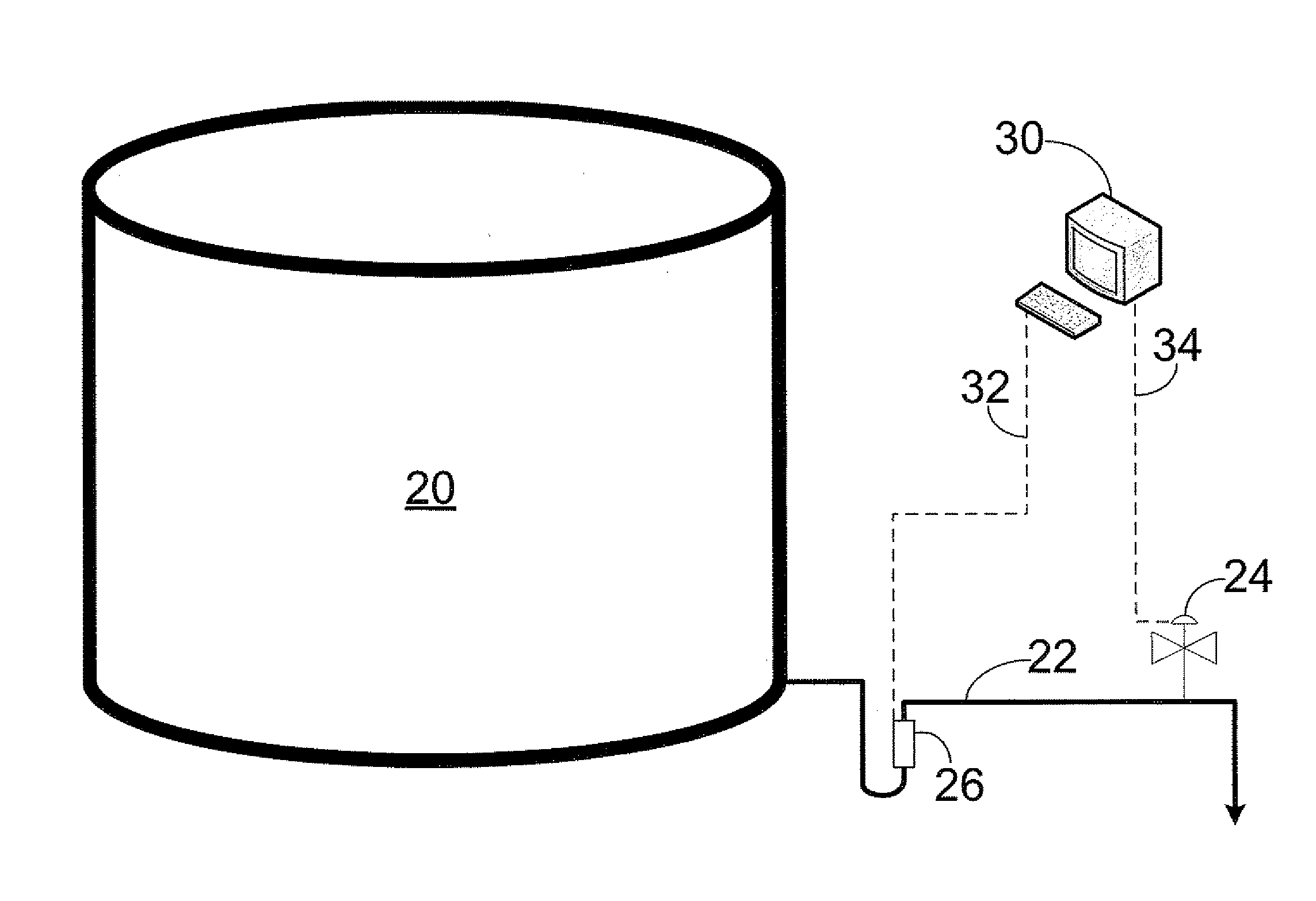

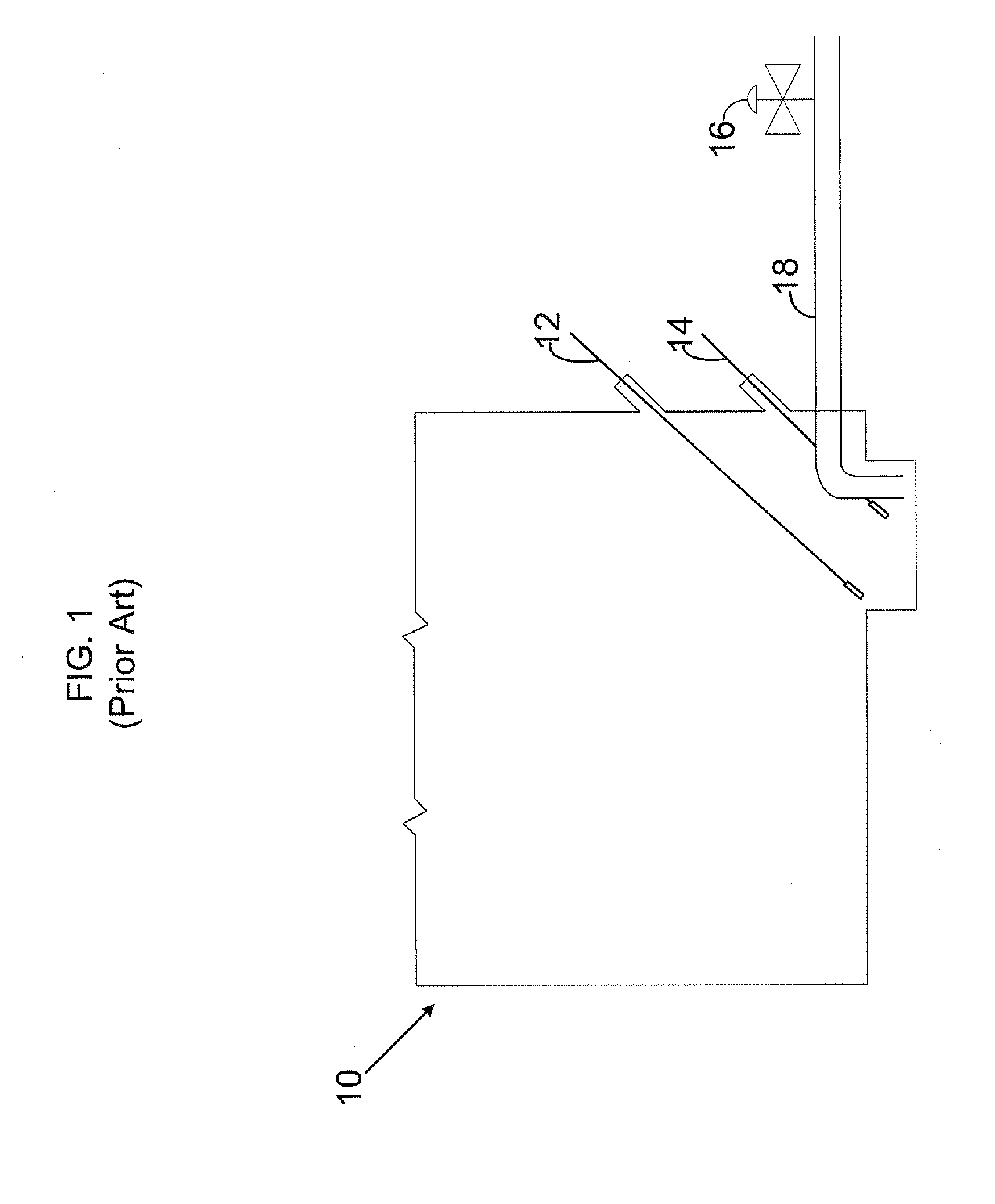

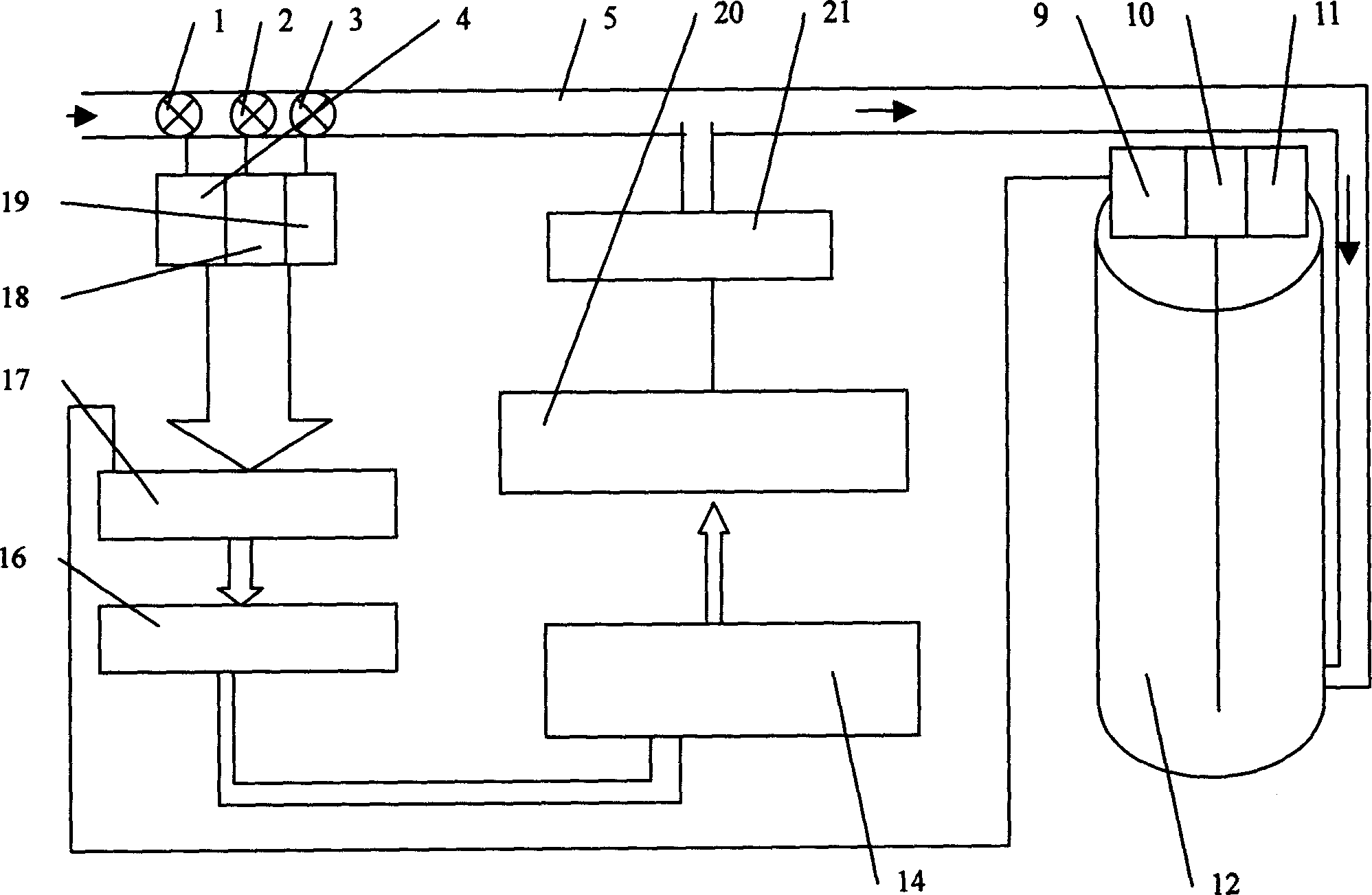

Tank dewatering sensing and valve control method and apparatus

InactiveUS20130082010A1Overcome disadvantagesLiquid separation auxillary apparatusSemi-permeable membranesControl systemWater flow

A system for separating water from crude oil includes a bulk-storage tank for storing unrefined crude oil, a first pipe for delivering water separated from crude oil in the bulk-storage tank to a containment system, a second pipe for delivering crude oil to a shipping system, a first valve for controlling flow in the first pipe, a second valve for controlling flow in the second pipe, and a control system for controlling operation of the first and second valves. The control system has a control device for controlling the first and second valves, an acoustic sensor array mounted on the first pipe for sensing a sound pressure level during flow of water through the first pipe, means for comparing the sensed sound pressure level with a predetermined sound pressure threshold level characterizing flow of oil-water mixture through the pipe, and a control device for closing the first valve and opening the second valve when the measured sound pressure level reaches the sound pressure threshold level.

Owner:SAUDI ARABIAN OIL CO

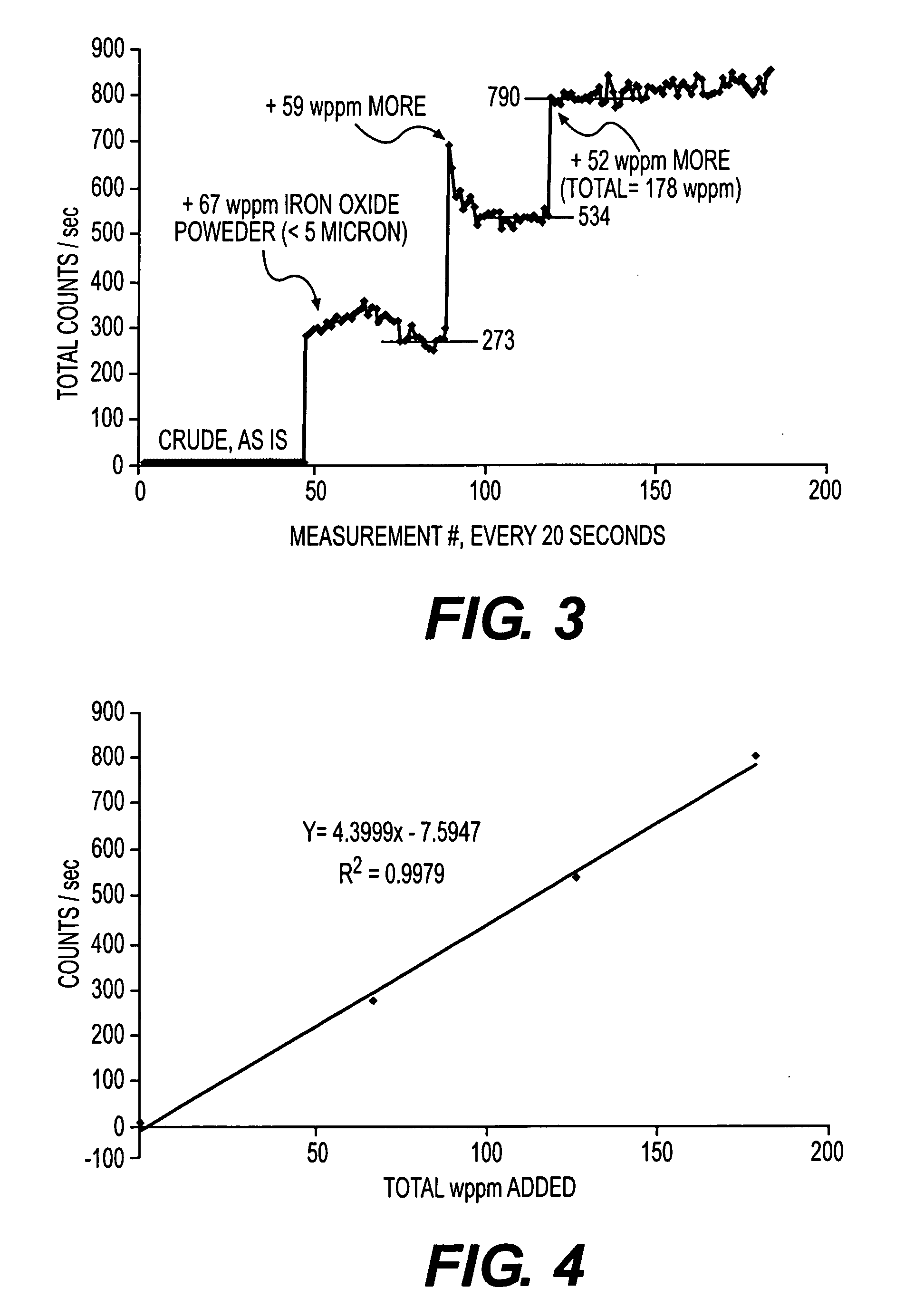

Focused beam reflectance measurement to optimized desalter performance and reduce downstream fouling

InactiveUS20100038286A1Improve performanceLiquid separation by electricityElectrostatic separationEngineeringDesalter

Performance of equipment, such as a desalter, in a refinery is monitored in real-time and on-line to minimize fouling of downstream equipment. Using an instrument to measure particles and droplets in-process allows monitoring of the various operations to optimize performance. Such measurement can also be used during crude oil blending to detect asphaltene precipitates that can cause fouling and can be used for monitoring other fouling streams.

Owner:GREANEY MARK A +3

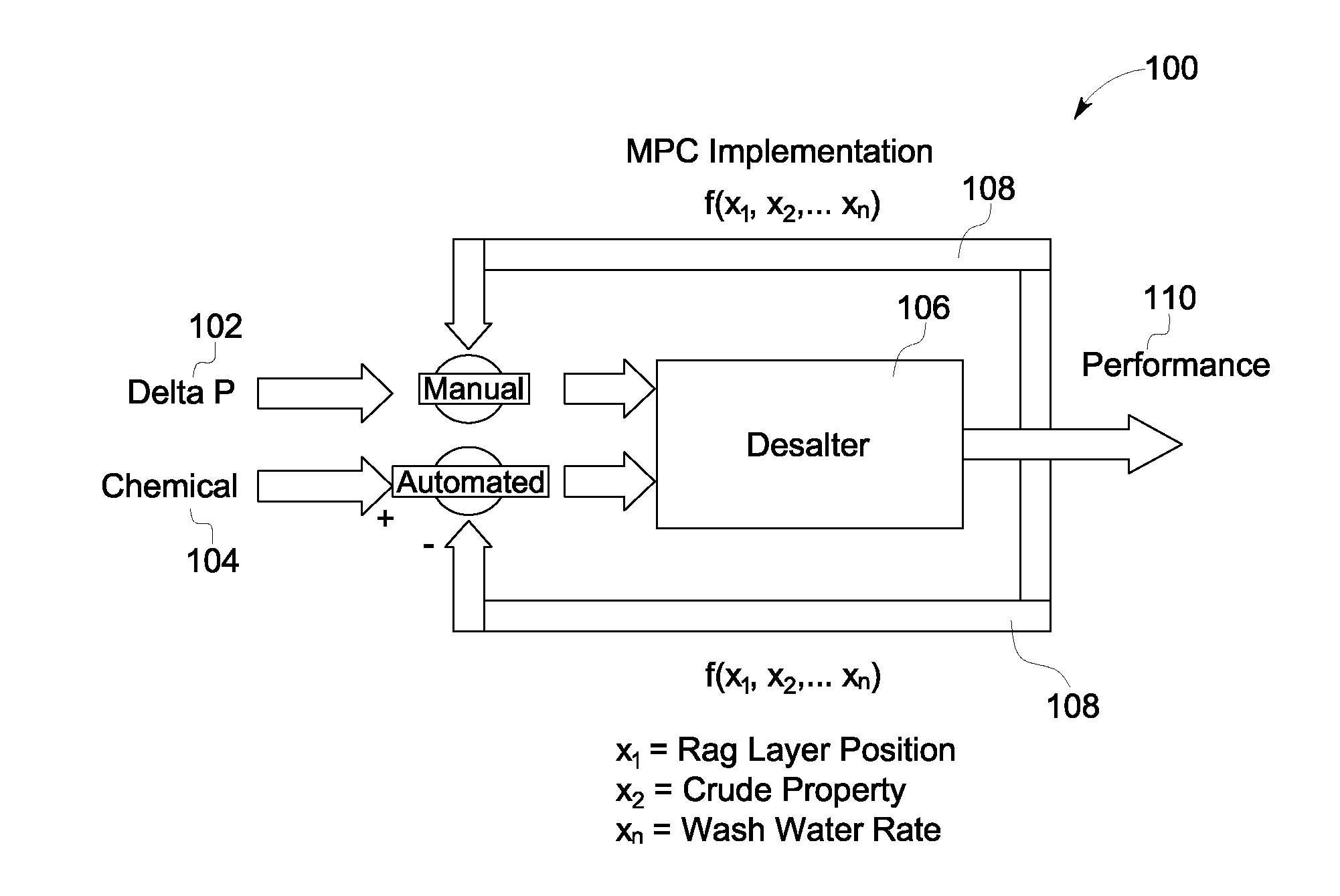

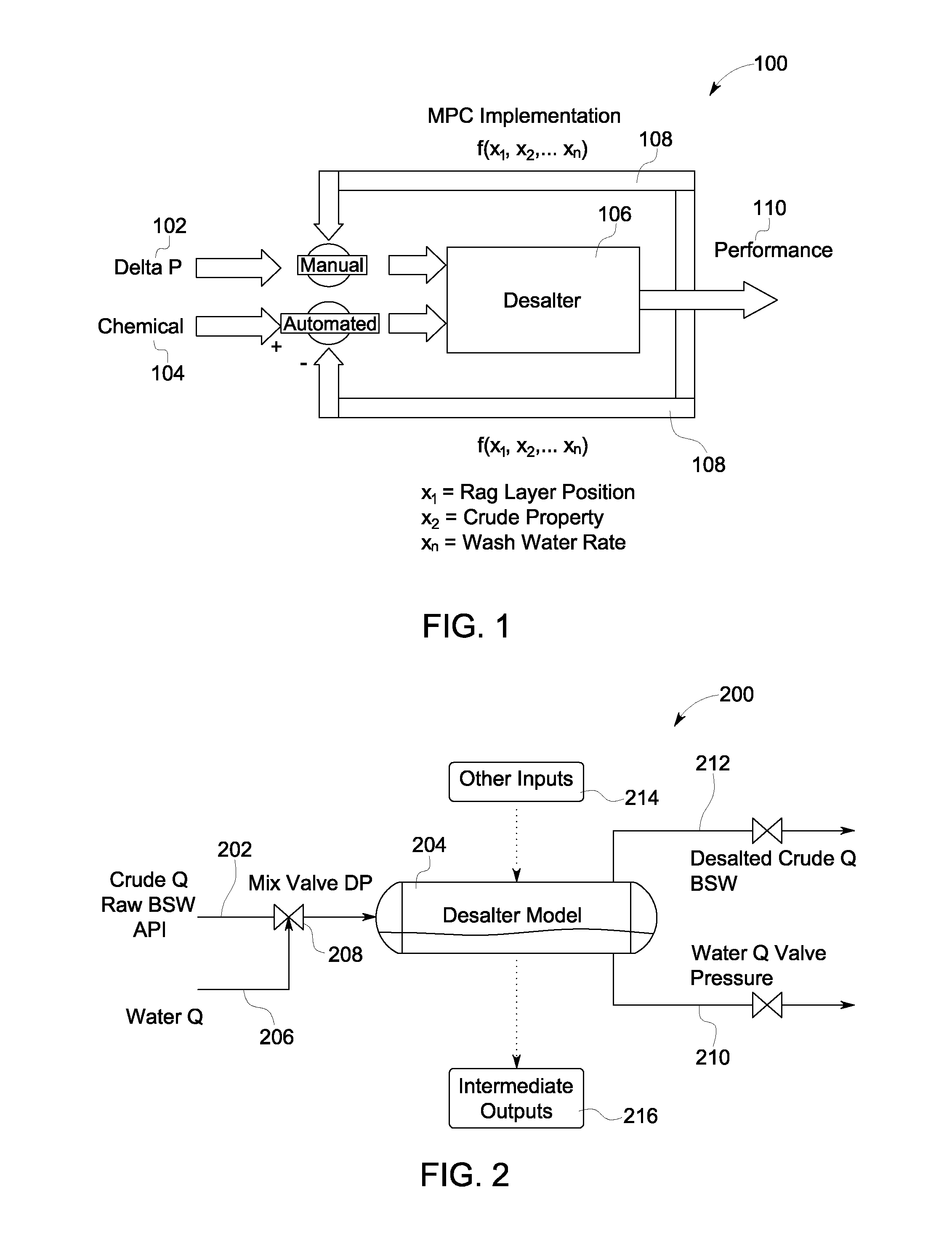

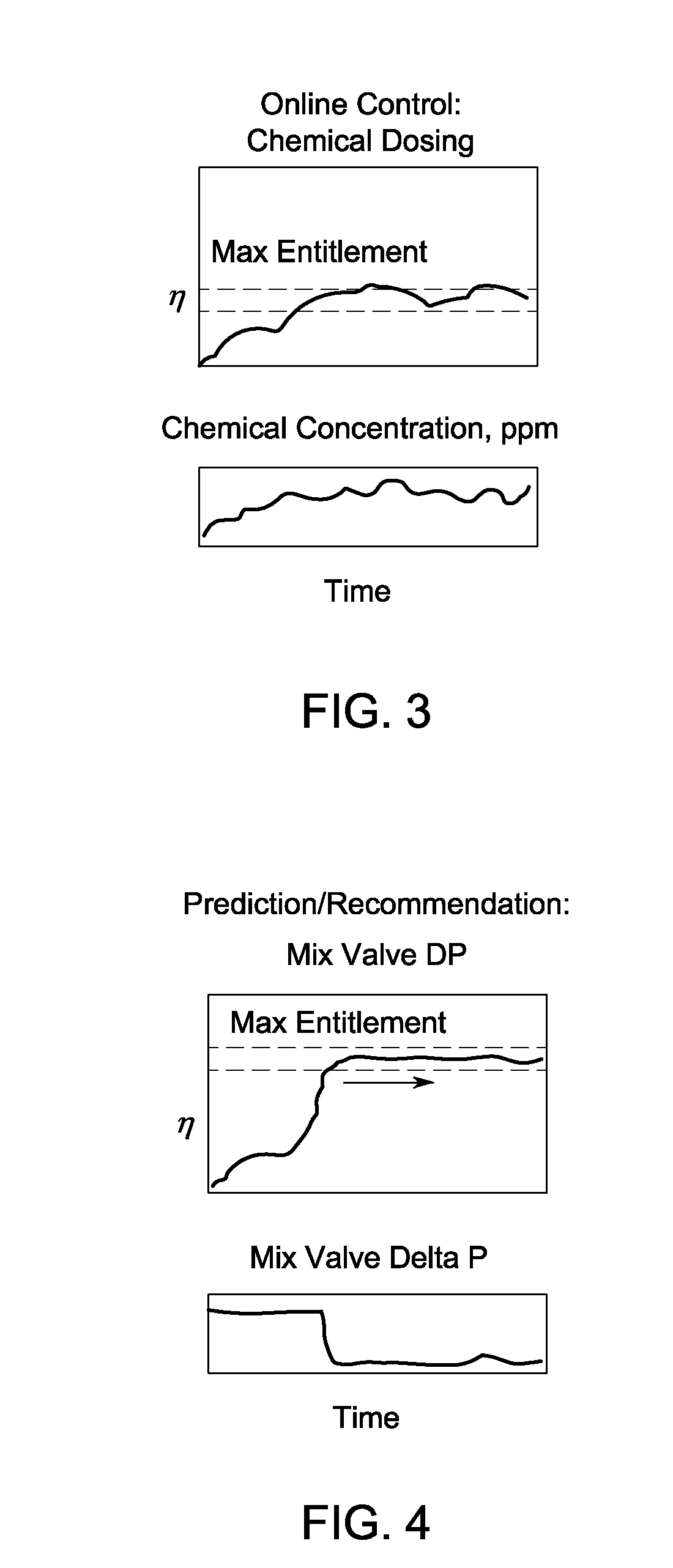

Advisory controls of desalter system

ActiveUS20150361350A1Dewatering/demulsification with chemical meansLiquid separation auxillary apparatusDemulsifierFirst principle

The present invention concerns a method of providing advisory controls for a desalter system. The method allows a user to continuously monitor performance of the desalter system, to continuously monitor position of the emulsion band (or rag layer), to control the emulsion band using demulsifiers, and to recommend to users how to maintain optimal pressure drop at the mixing device of the desalter system. This is achieved by using a first principles based model combined with a sensor to measure the position, quality and size of the emulsion band. The first principles based model takes into account the geometry of the desalter system, physical properties of the crude oil and water, as well as the operating conditions. Thus, the method provides users with sensing of an emulsion layer through direct measurements and also gives recommendations on appropriate corrective actions to be initiated during upsets.

Owner:BL TECH INC

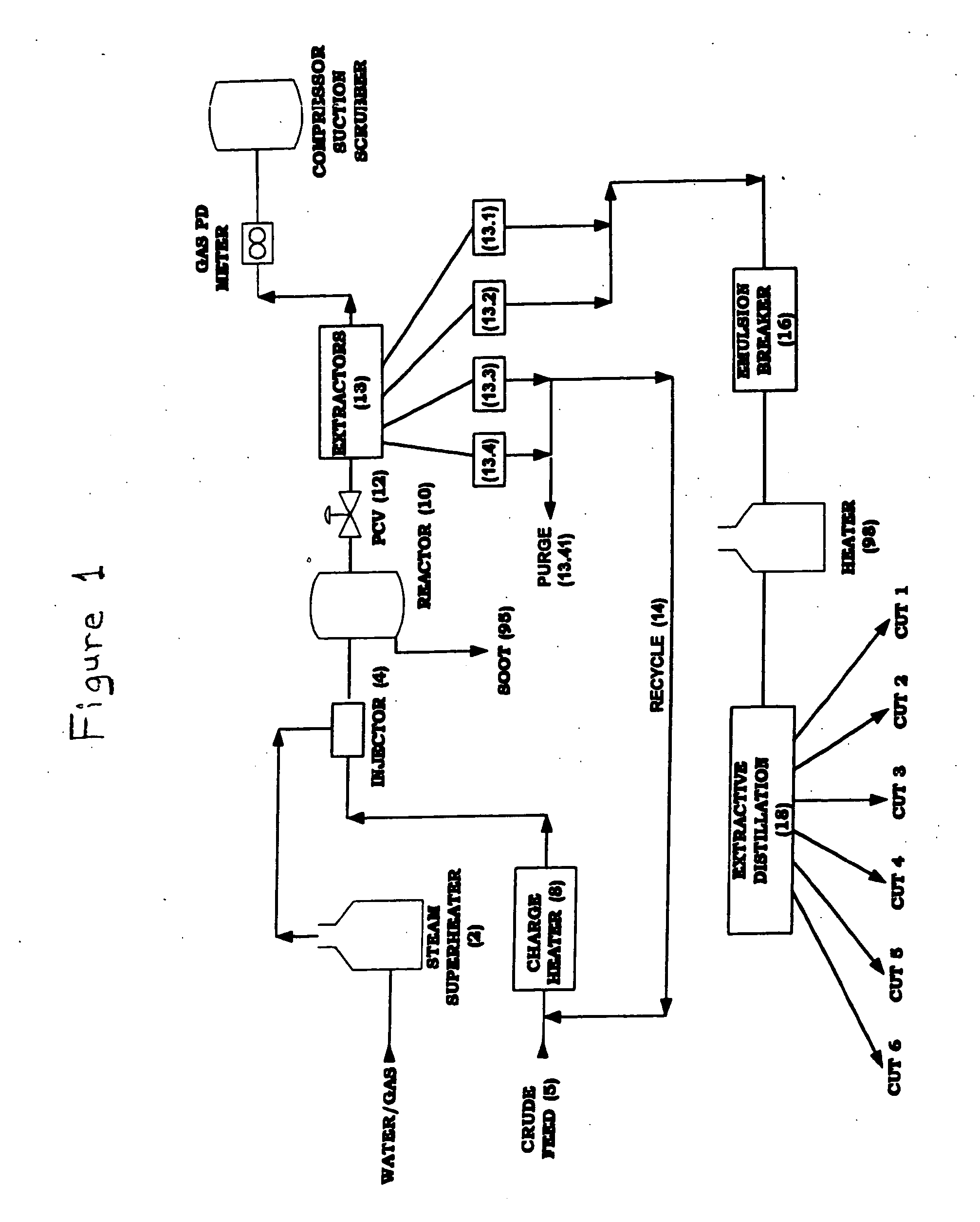

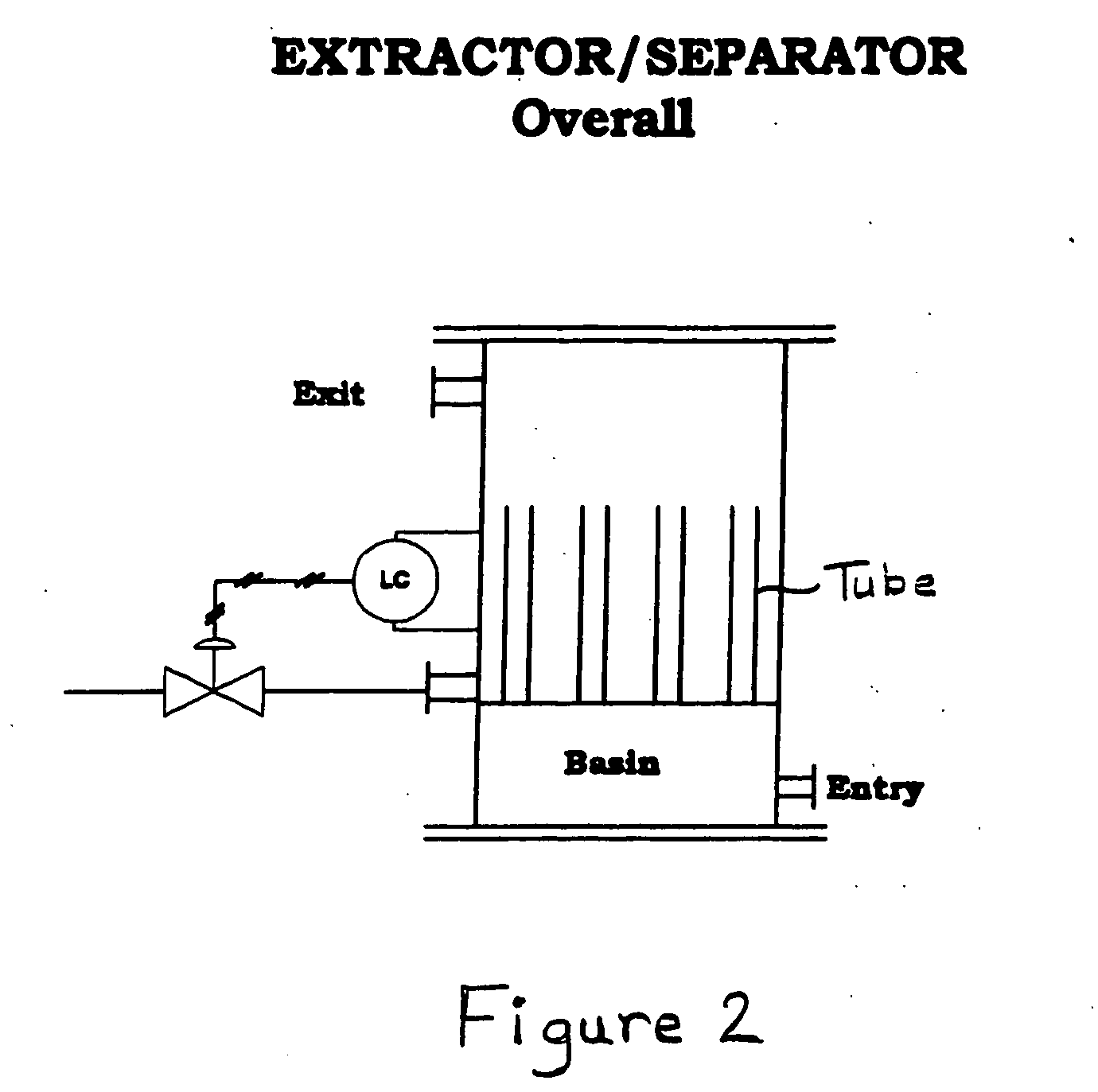

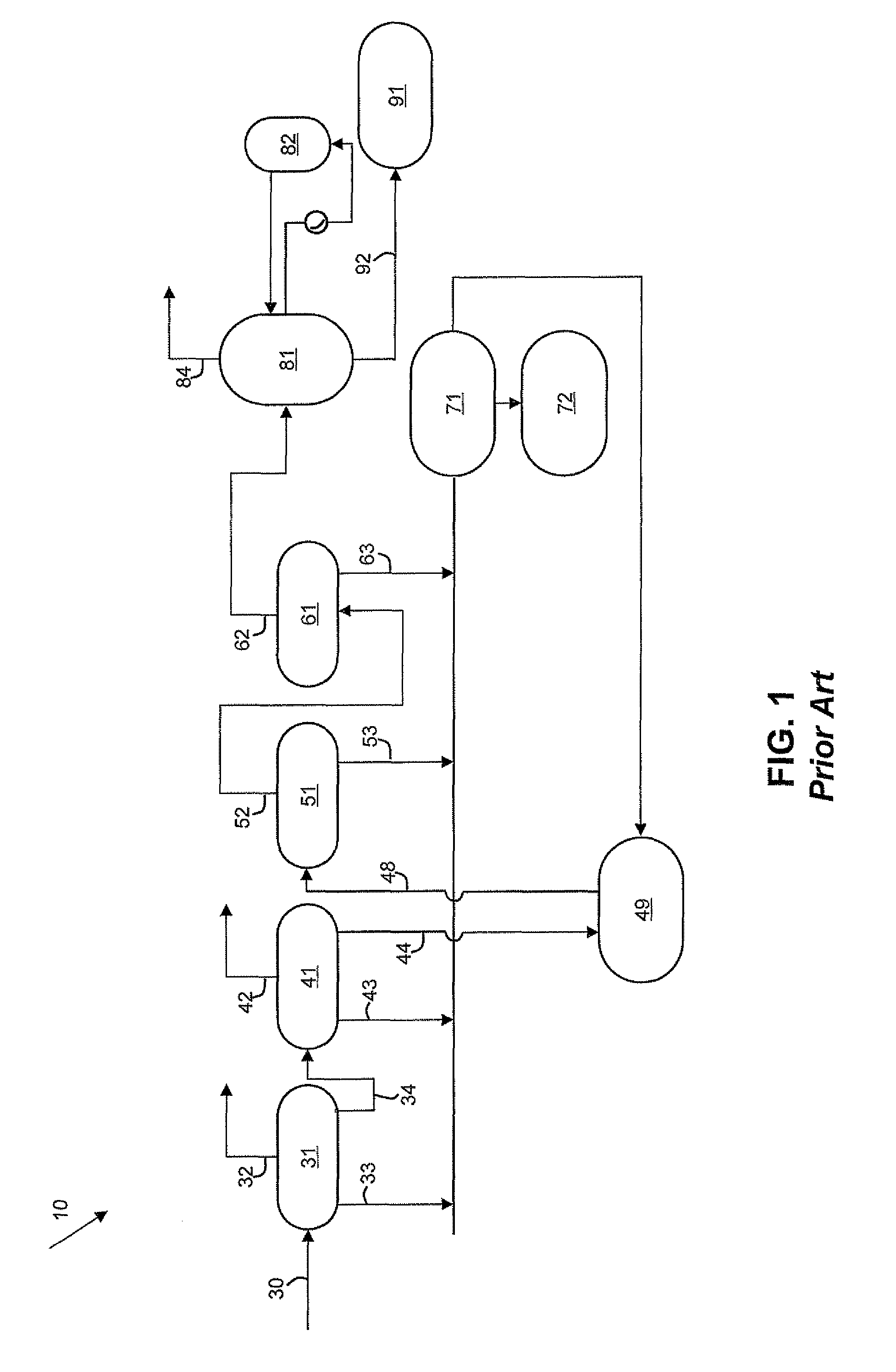

Deep conversion combining the demetallization and the conversion of crudes, residues or heavy oils into light liquids with pure or impure oxygenated compounds

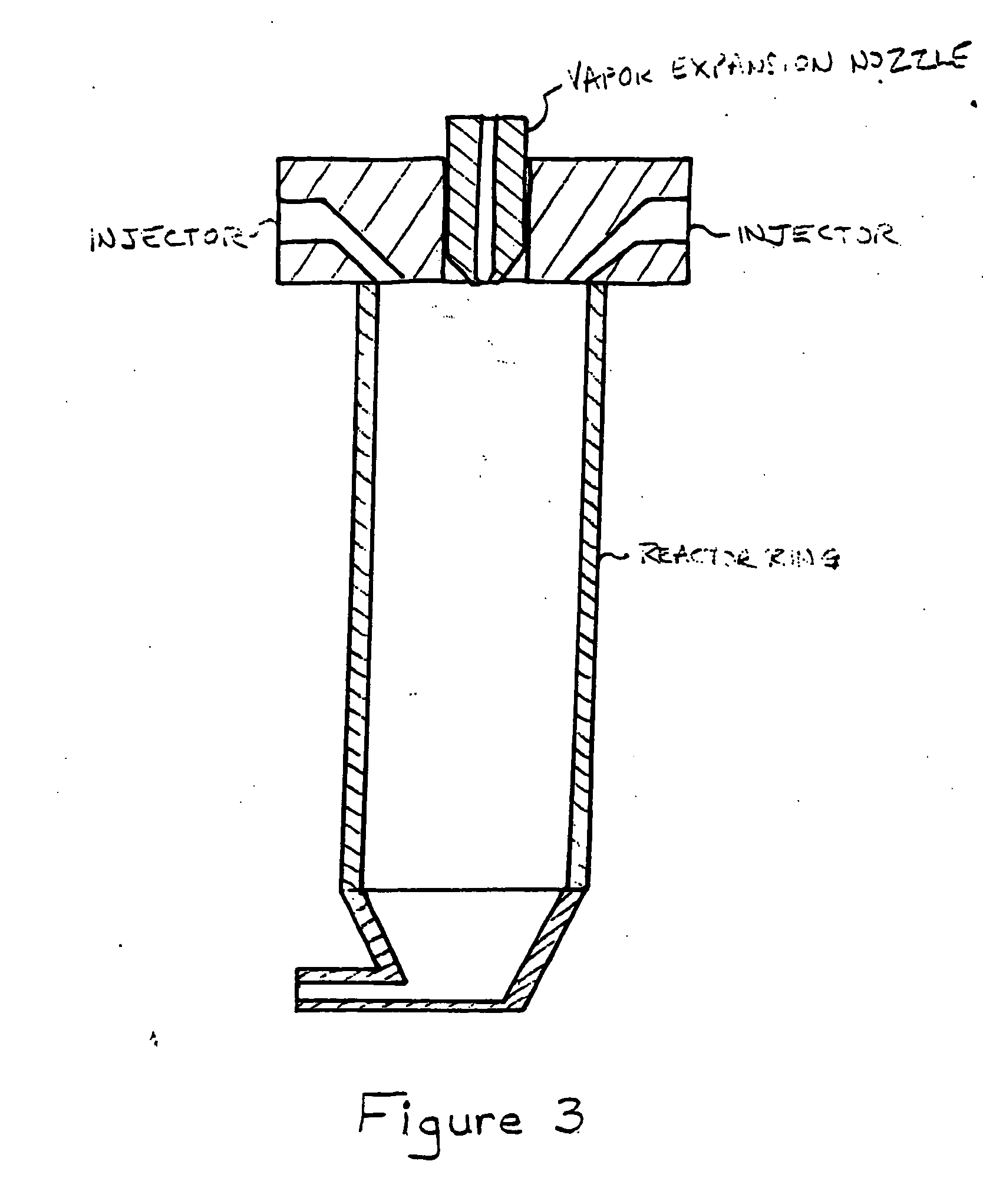

InactiveUS20050211602A1Thermal non-catalytic crackingDewatering/demulsification with mechanical meansSuperheaterFuel oil

A process for the conversion of hydrocarbons that are solid or have a high boiling temperature and may be laden with metals, sulfur or sediments, into liquids (gasolines, gas oil, fuels) with the help of a jet of gas pity superheated between 600 and 800° C. The process comprises preheating a feed 5 in a heater 8 to a temperature below the selected temperature of a reactor 10. This feed is injected by injectors 4 into the empty reactor 10 (i.e., without catalyst.) The feed is treated with a jet of gas or superheated stem from superheater 2 to activate the feed. The activated products in the feed are allowed to stabilize at the selected temperature and at a selected pressure in the reactor and are then run through a series of extractors 13 to separate heavy and light hydrocarbons and to demetallize the feed. Useful products appearing in the form of water / hydrocarbon emulsions are generally demulsified in emulsion breaker 16 to form water laden with different impurities. The light phase containing the final hydrocarbons is heated in heater 98 and is separated into cuts of conventional products, according to the demand for refining by an extractor 18 similar to 13.

Owner:WESCO ENERGY

Advisory controls of desalter system

InactiveUS20130024026A1Liquid separation auxillary apparatusSampled-variable control systemsDemulsifierProcess engineering

Owner:GENERAL ELECTRIC CO

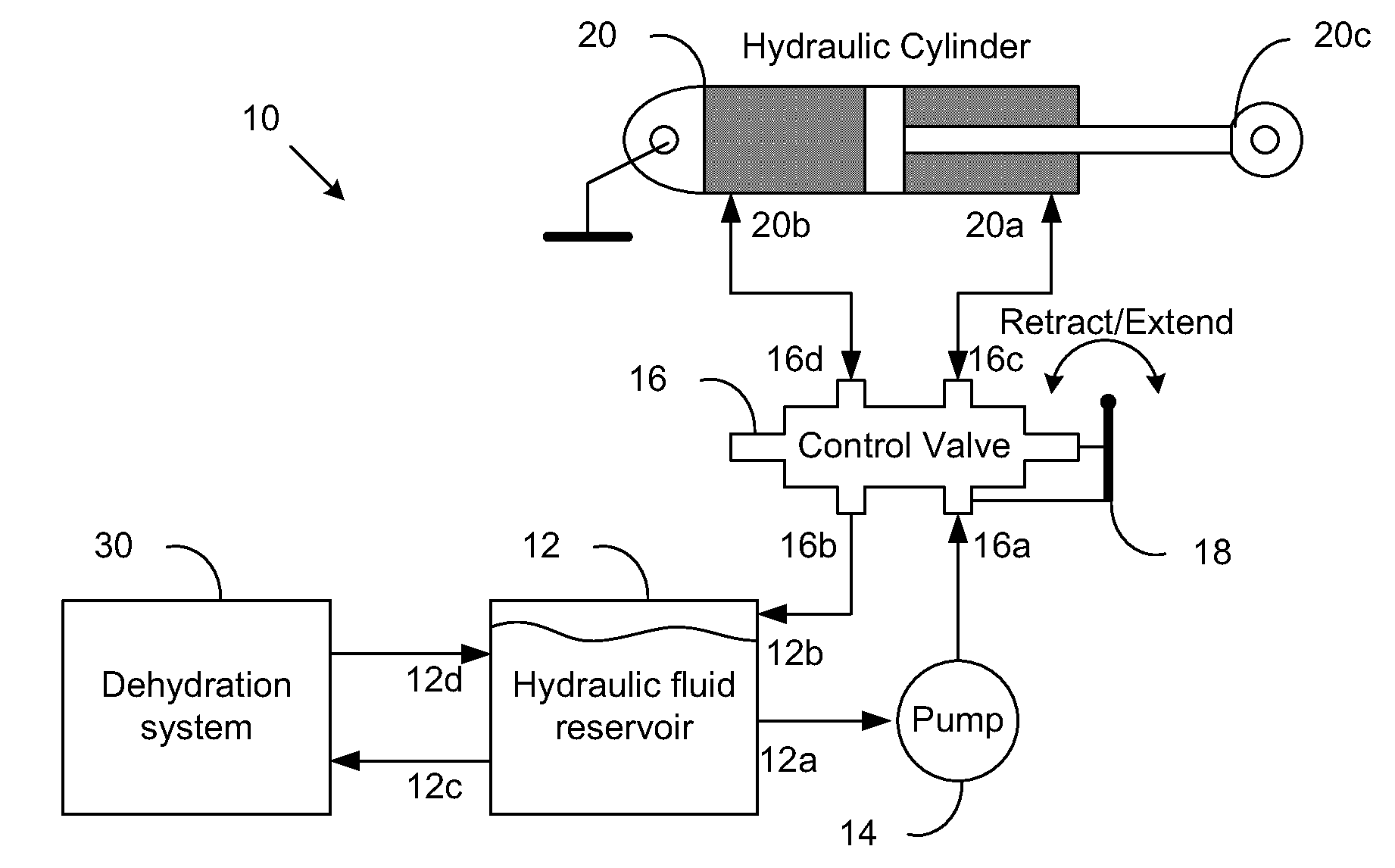

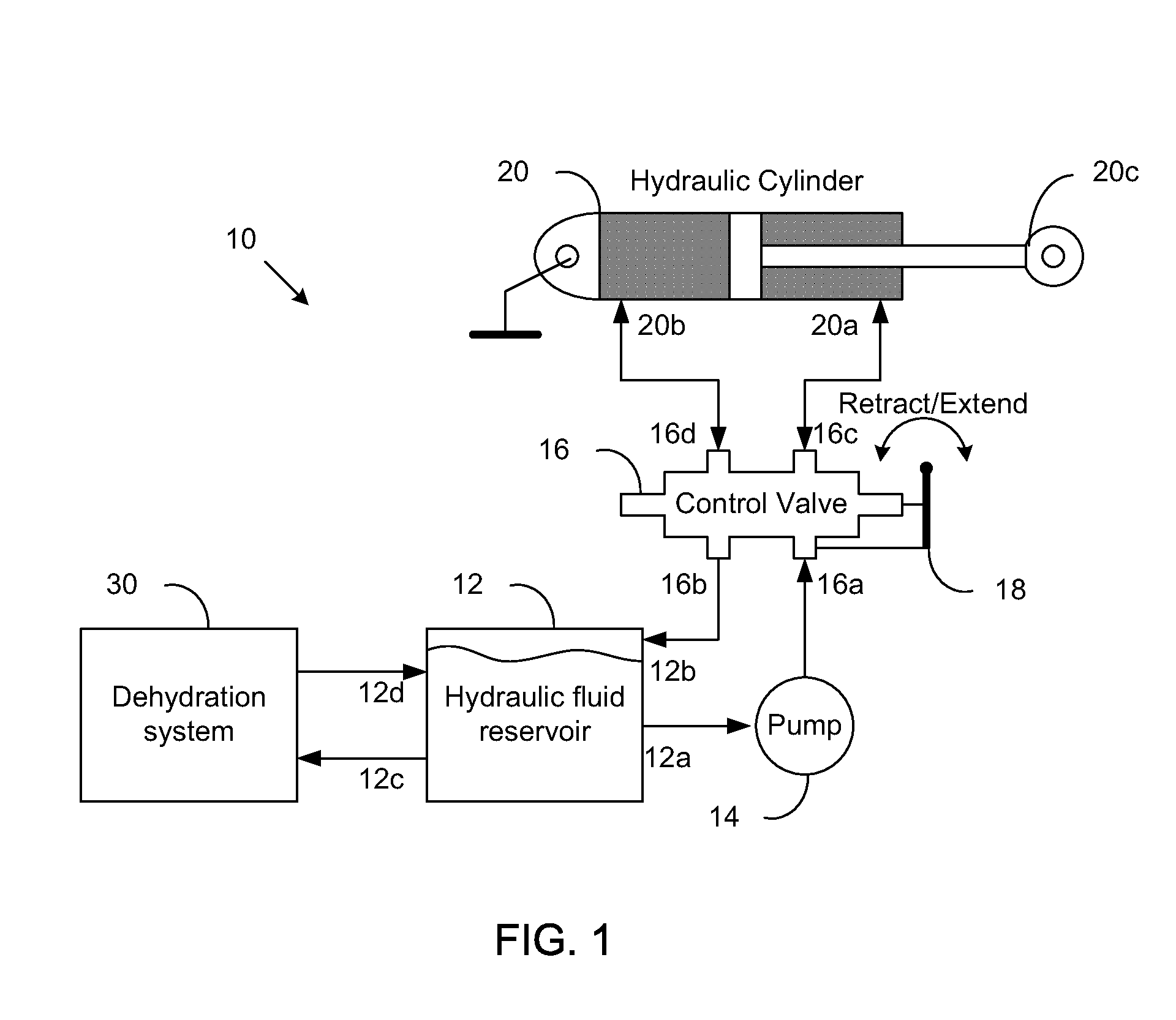

Offline filtration device and method

ActiveUS20150017020A1Easy to useLiquid separation auxillary apparatusDistillation regulation/controlFiltrationTemperature difference

An apparatus, system and method are provided for controlling fluid flow through a vacuum chamber of a dehydration system, the vacuum chamber having a temperature sensing device operative to measure a temperature of a fluid in the vacuum chamber. A temperature difference between a temperature setpoint for the fluid and the measured temperature of the fluid is determined, and fluid is recirculated through the vacuum chamber while the temperature difference is greater than a predetermined temperature difference. While the temperature difference is less than the predetermined temperature difference, the fluid is recirculated through the vacuum chamber for a predetermined time period, and upon the predetermined time period expiring inhibiting recirculation of the fluid through the vacuum chamber.

Owner:PARKER HANNIFIN CORP

Sound-velocity dewatering system

ActiveUS9086354B2Operating means/releasing devices for valvesDewatering/demulsification with mechanical meansSound energyControl system

A method and apparatus for an improved dewatering tank system that allows for safely controlling a water stream exiting the dewatering tank system. The apparatus can include a sound velocity detector, a control system, and a control element. The sound velocity detector can include a transducer, a detector, and a transmitter. The control system can include a computer and a program product. The apparatus can optionally include a dewatering tank, a drain line, and a controllable valve. The apparatus allows for transmitting sound energy through the water stream flowing in the drain lined that is connected to the dewatering tank, calculating the velocity of the sound energy as the sound energy travels through the water stream, monitoring the velocity of the sound energy for a period of time, and controlling the position of the controllable valve depending on the calculated velocity of the sound energy.

Owner:SAUDI ARABIAN OIL CO

Sound-Velocity Dewatering System

ActiveUS20120017998A1Material analysis using sonic/ultrasonic/infrasonic wavesOperating means/releasing devices for valvesSound energyControl system

Owner:SAUDI ARABIAN OIL CO

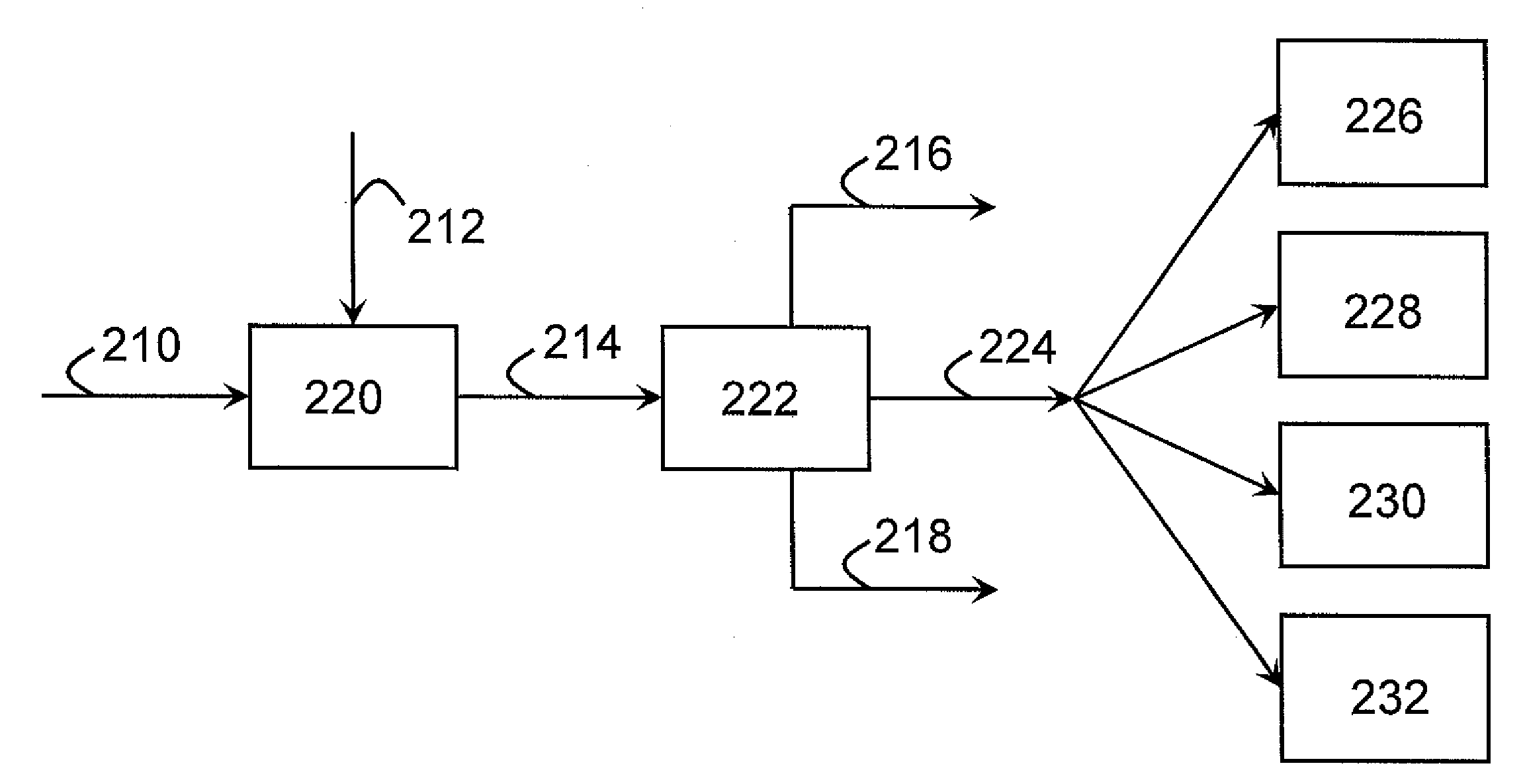

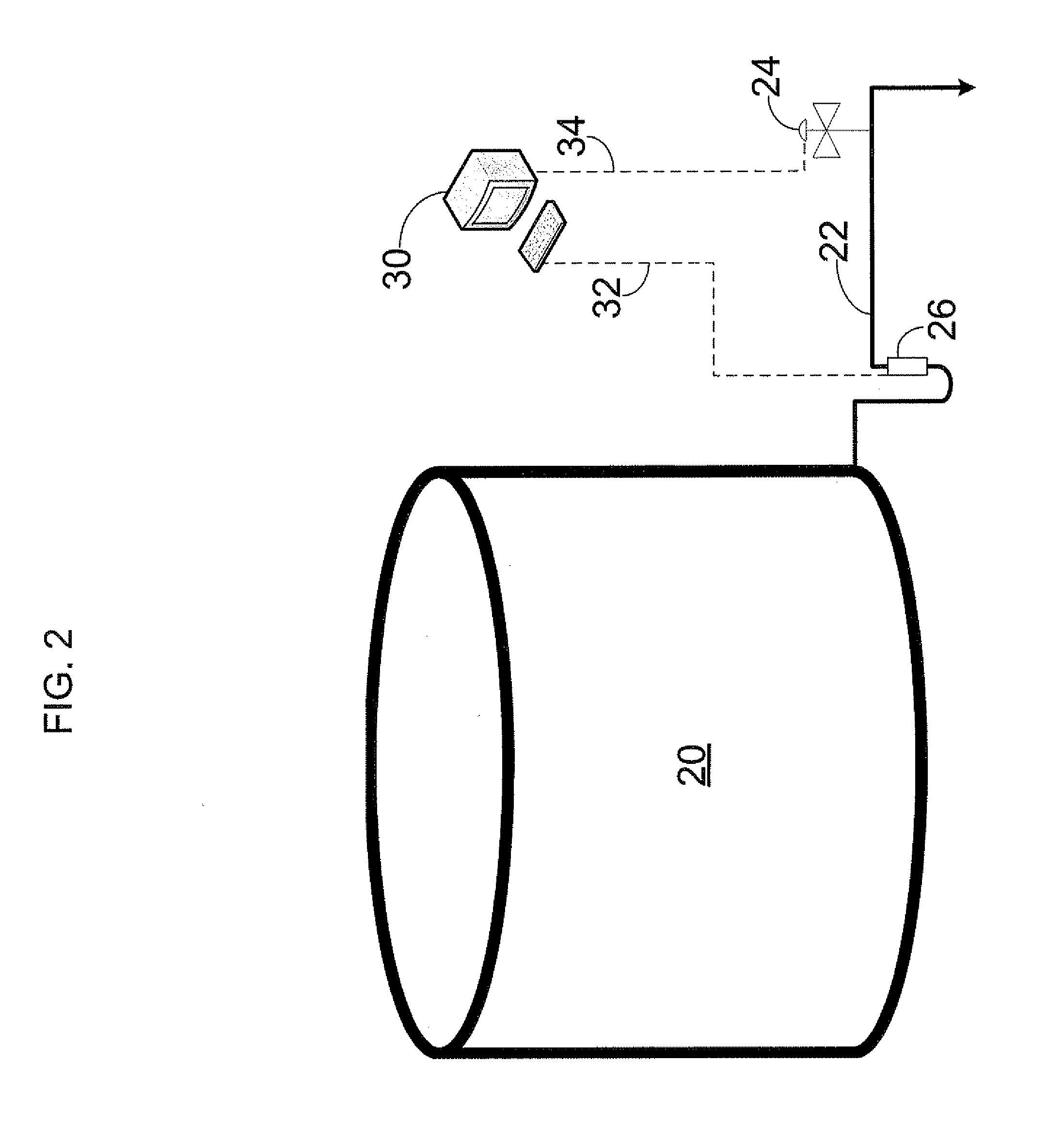

Automatic crude oil demulsification and dehydration device, and its control method

InactiveCN1769375AMeet the needs of industrialized automatic productionLiquid separation auxillary apparatusDewatering/demulsification regulation/controlState parameterData acquisition

The invention relates the crude oil automatic demulsifying dehydration apparatus and its controlling means, comprising the following characters: setting the flow monitoring probe or moisture percentage monitoring probe or temperature monitoring probe in the crude oil input pipe, fixing the medium layered condition monitoring instrument or oil spilling moisture percentage monitoring instrument or waste water oil length monitoring instrument on the storage tank, monitoring probe and monitoring instrument connected with data acquisition unit, the data acquisition delivering the characteristic parameter of pretreatment fluid in the oil pipeline and state parameter of treatment fluid in the storage tank to analysis of data processing unit by data line, the CPU of analysis of data processing unit dealing with the datas and exporting digit signal to data out control unit, and the electrical signal exported by data out control unit to control the demulsification apparatus.

Owner:WEIHAI HAIHER TECH

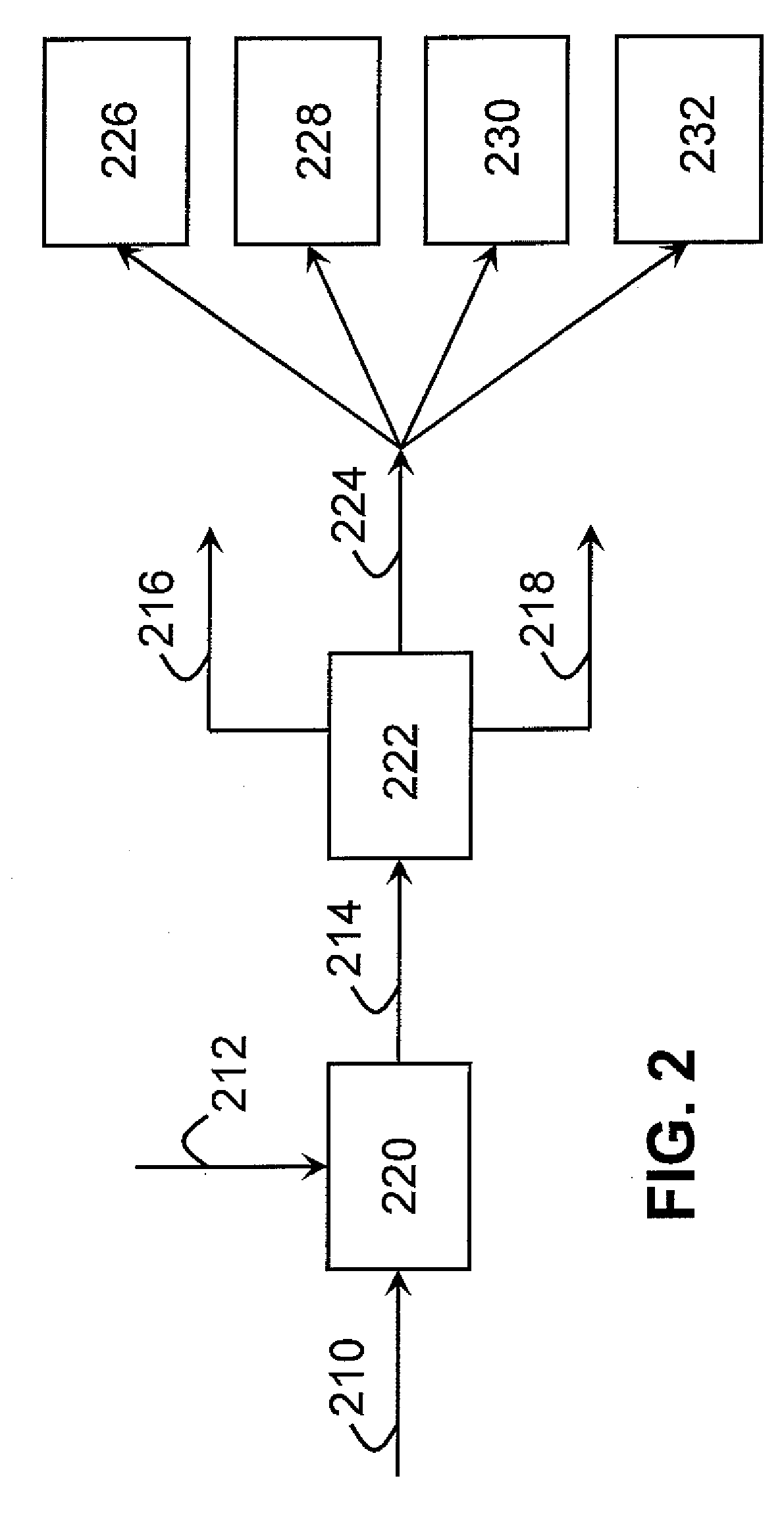

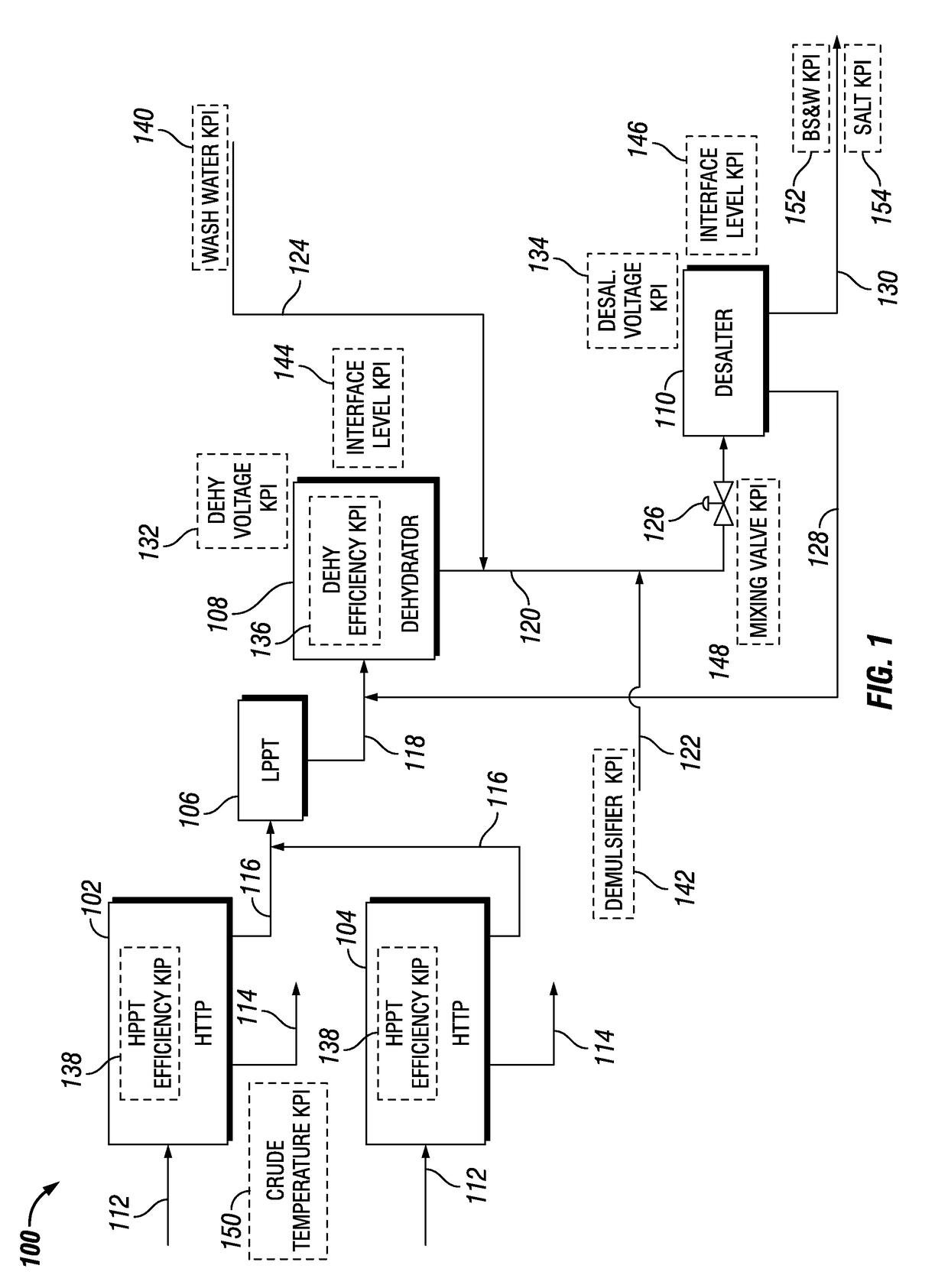

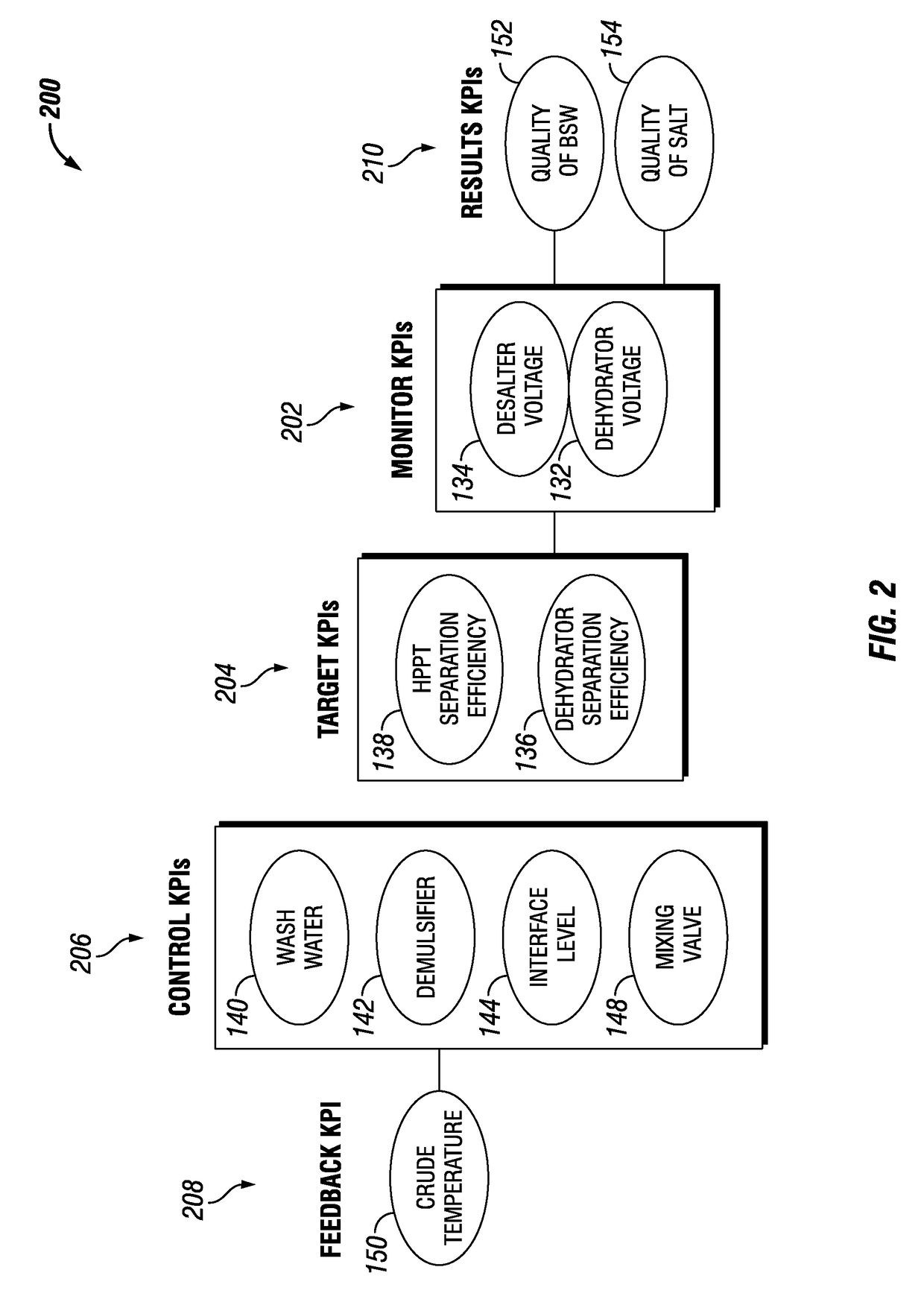

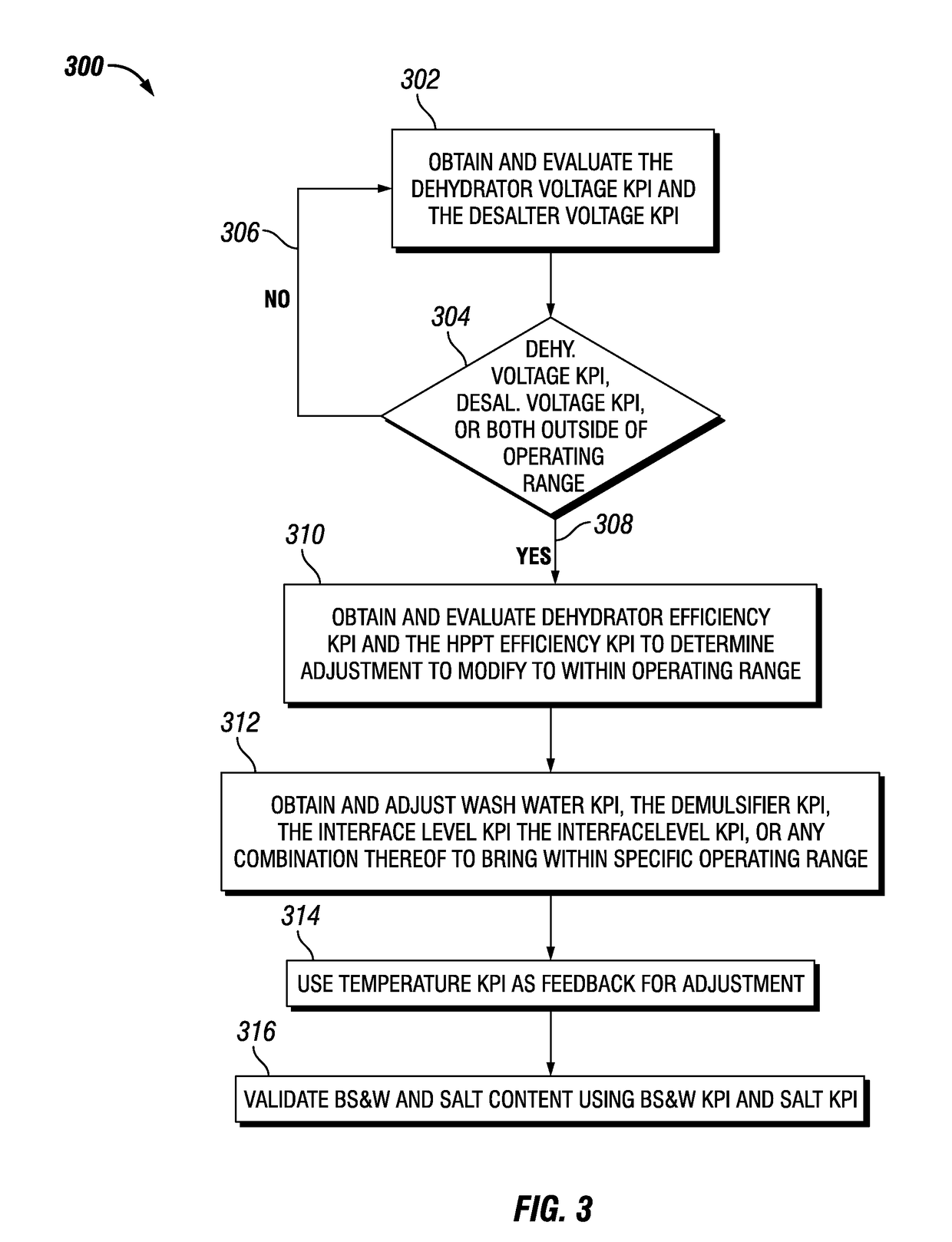

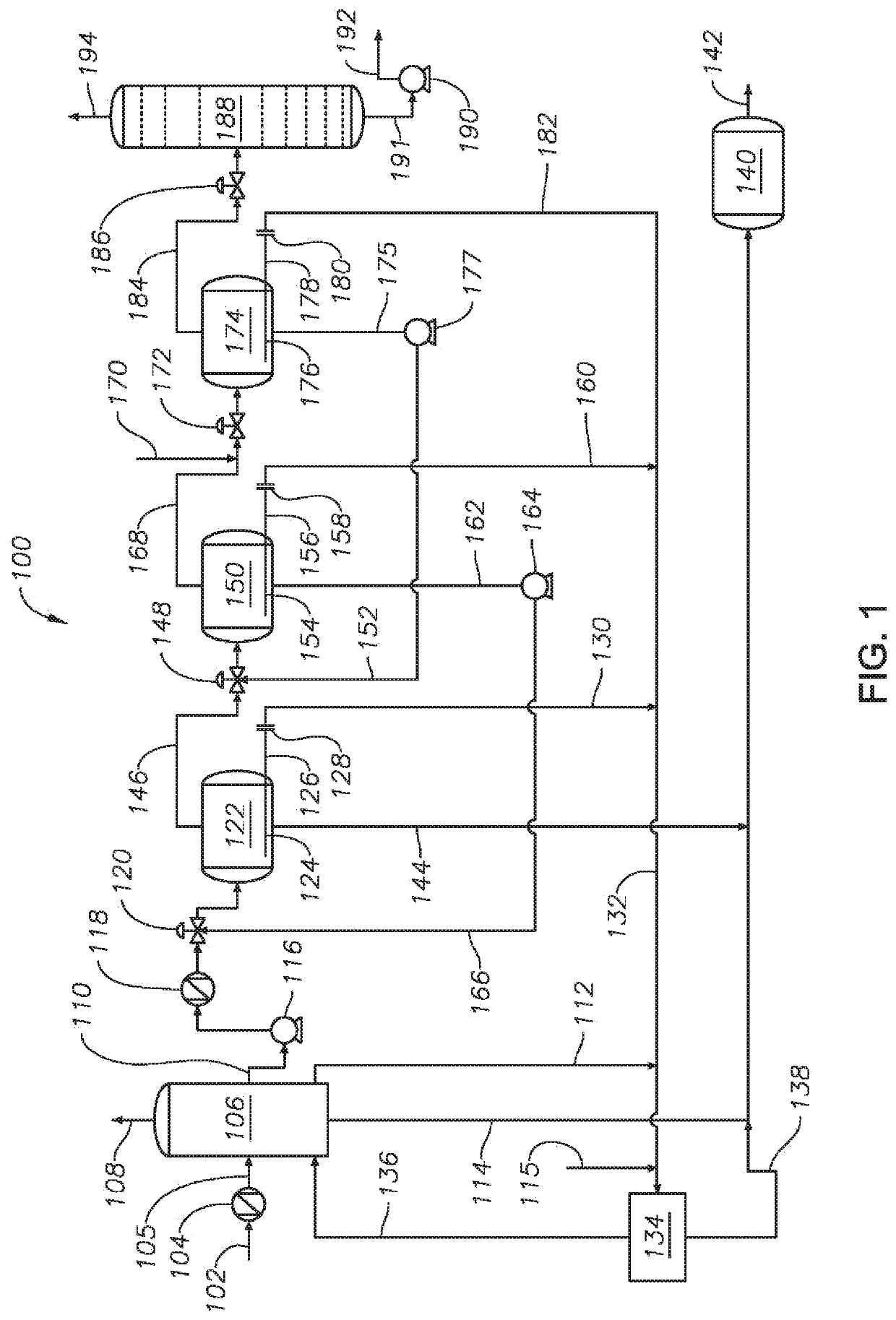

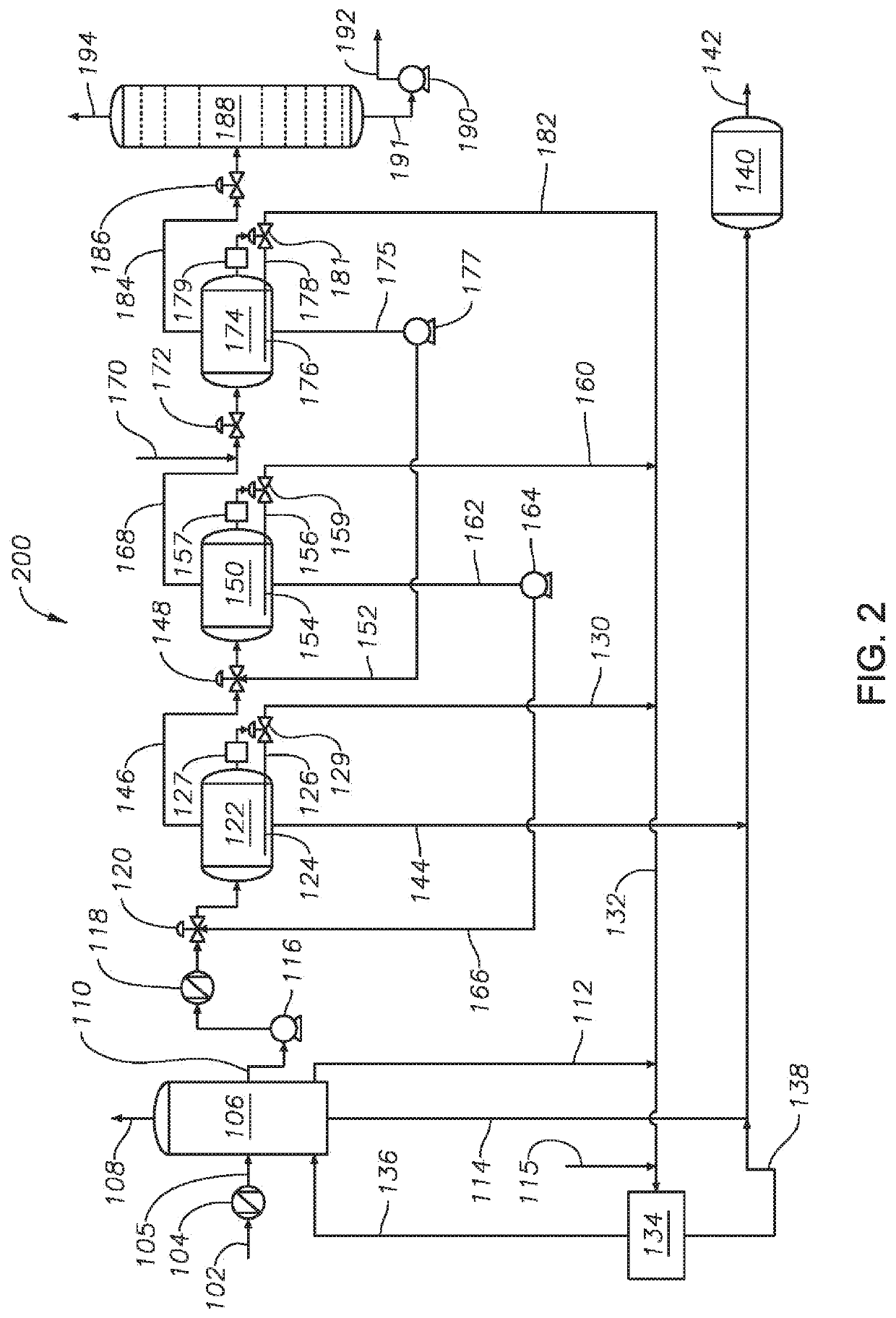

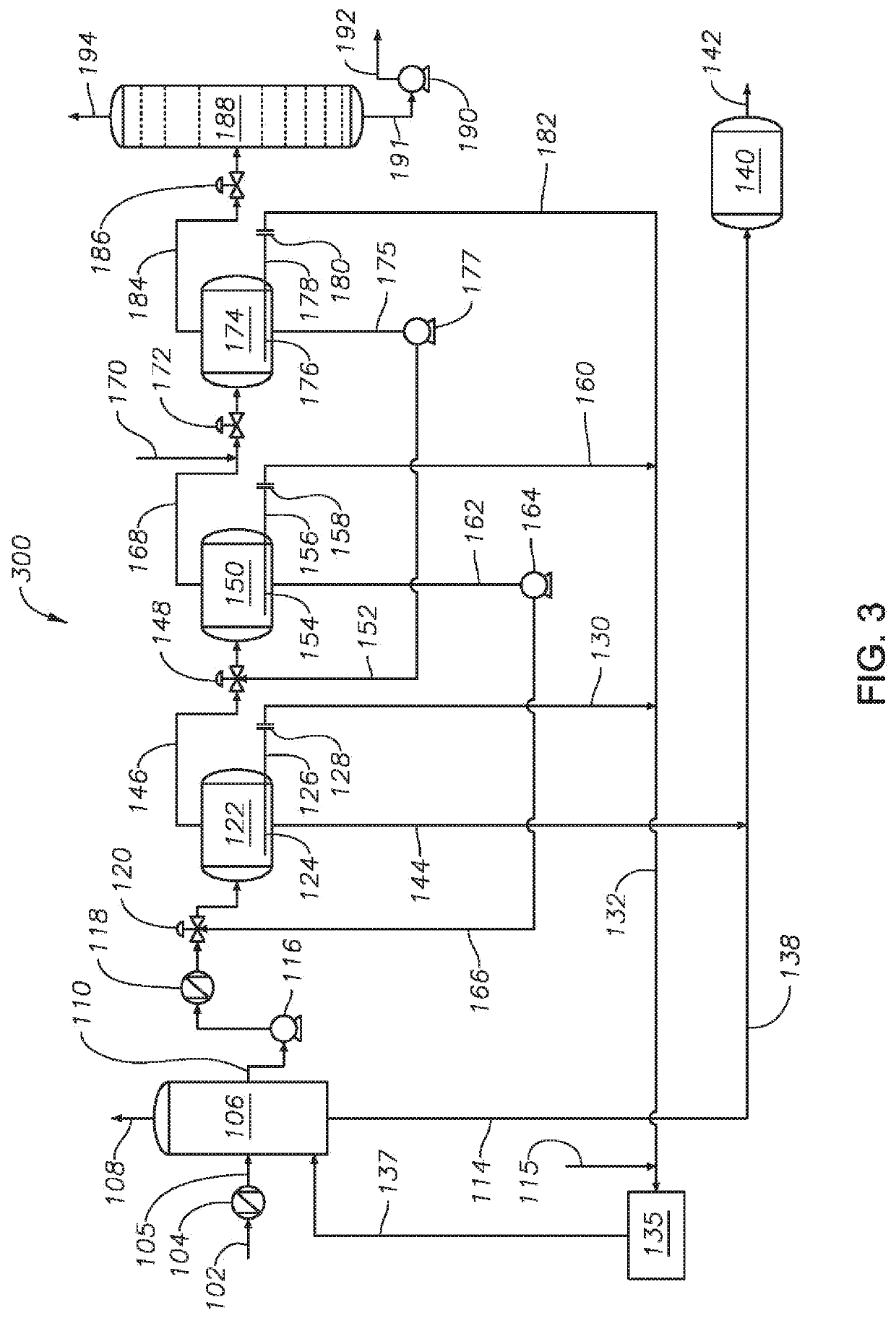

Methods and Systems for Proactively Monitoring Crude Quality Assurance

ActiveUS20190062645A1Liquid separation auxillary apparatusRefining by water treatmentDifferential pressureQuality assurance

Methods and systems to monitor and control crude oil processing with regards to crude oil specifications for bottom sediment & water (BS&W) and salt are provided. Crude oil processing may be monitored and controlled using key performance indicators (KPIs) that include the desalter voltage and dehydrator voltage as indicators of the BS&W and salt. In response to monitoring of the desalter voltage and dehydrator voltage, a high pressure production trap (HPPT) efficiency and a dehydrator separation efficiency may be controlled via adjustment of a wash water percentage, a demulsifier dosage, a dehydrator interface level, a desalter interface level, and a differential pressure across a mixing valve.

Owner:SAUDI ARABIAN OIL CO

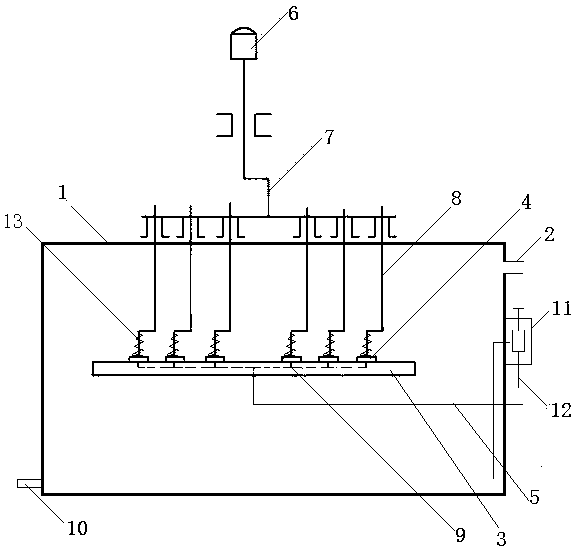

Demulsification dehydration apparatus for aged crude oil

PendingCN109722274ARealize demulsification and dehydrationAchieve separationDewatering/demulsification with mechanical meansDewatering/demulsification regulation/controlOil waterEngineering

The invention relates to the field of oil field crude oil treatment, particularly to a demulsification dehydration apparatus for aged crude oil. The demulsification dehydration apparatus comprises a box body, wherein a constant temperature circulation system for providing high temperature active water is arranged in the box body, the upper portion of the box body is provided with an oil overflow port, at least a rotary rolling kneading demulsification mechanism is arranged in the box body, each rotary rolling kneading demulsification mechanism has a fixed end surface and a relatively fixed endsurface rotary end surface, the two end surfaces cooperatively perform rotary motion, the fixed end surface has an aged crude oil inlet hole and a matched liquid supply pipeline, and the rotary end surface is supplied with rotary power by a mechanical transmission device, and is provided with a spring applying mechanism. According to the present invention, the aged oil mechanical treatment deviceis provided, the oil-water separation is achieved, the demulsification dehydration of the aged oil is effectively achieved, the utilization rate of the recovered crude oil is improved, and the purposes of cost reduction, yield increase and efficiency increase are achieved.

Owner:通化市远通石油机械有限责任公司

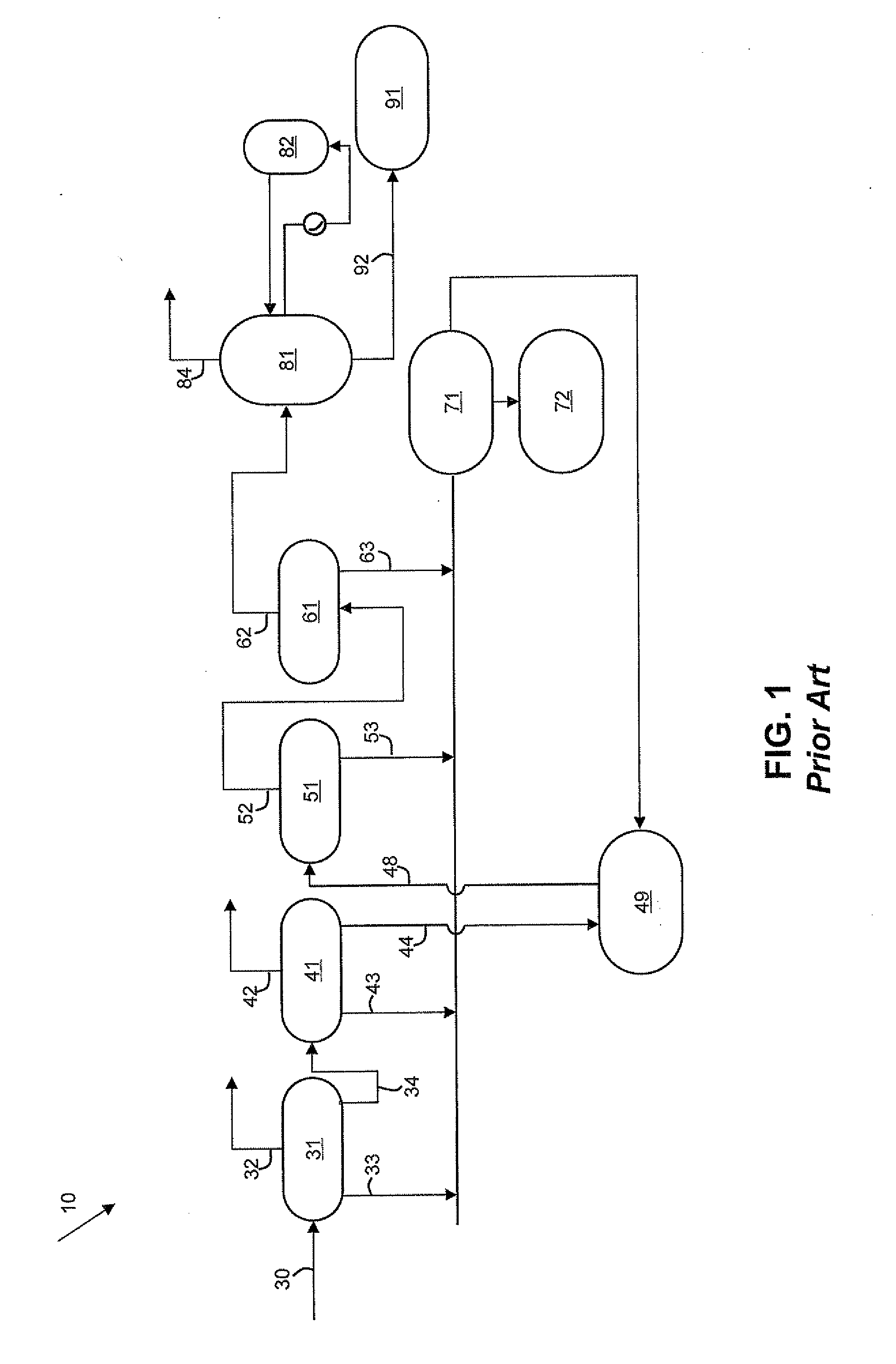

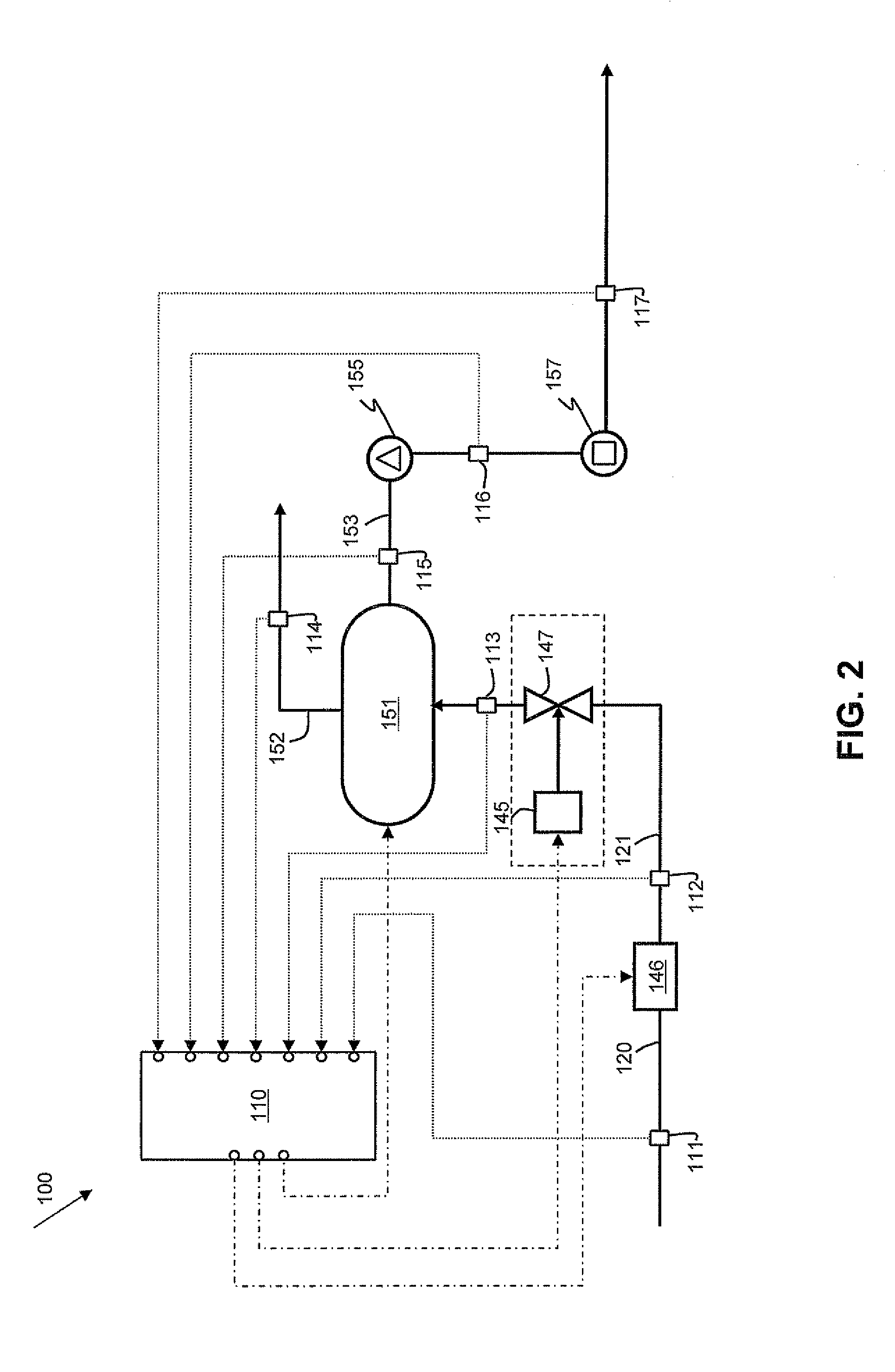

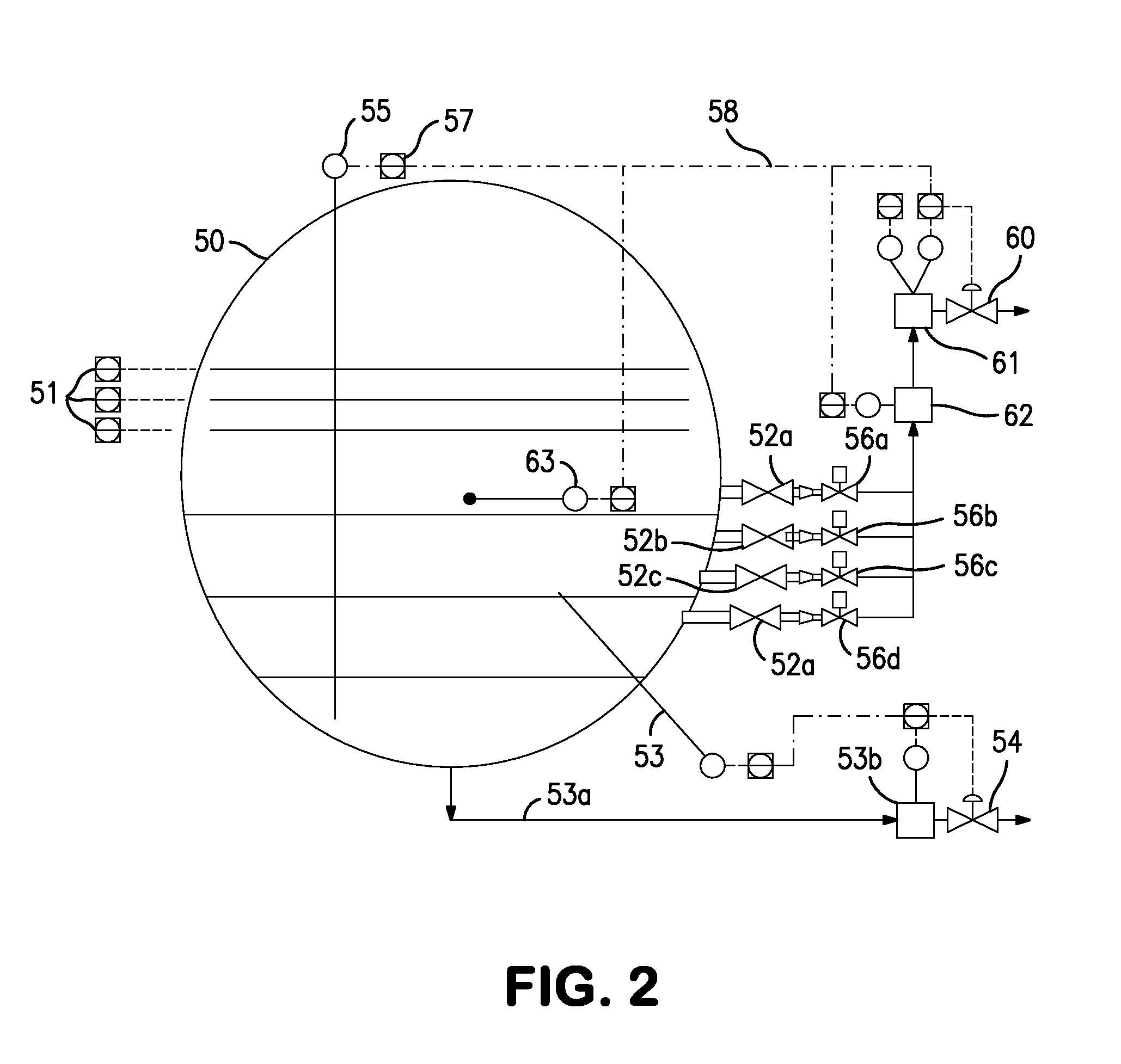

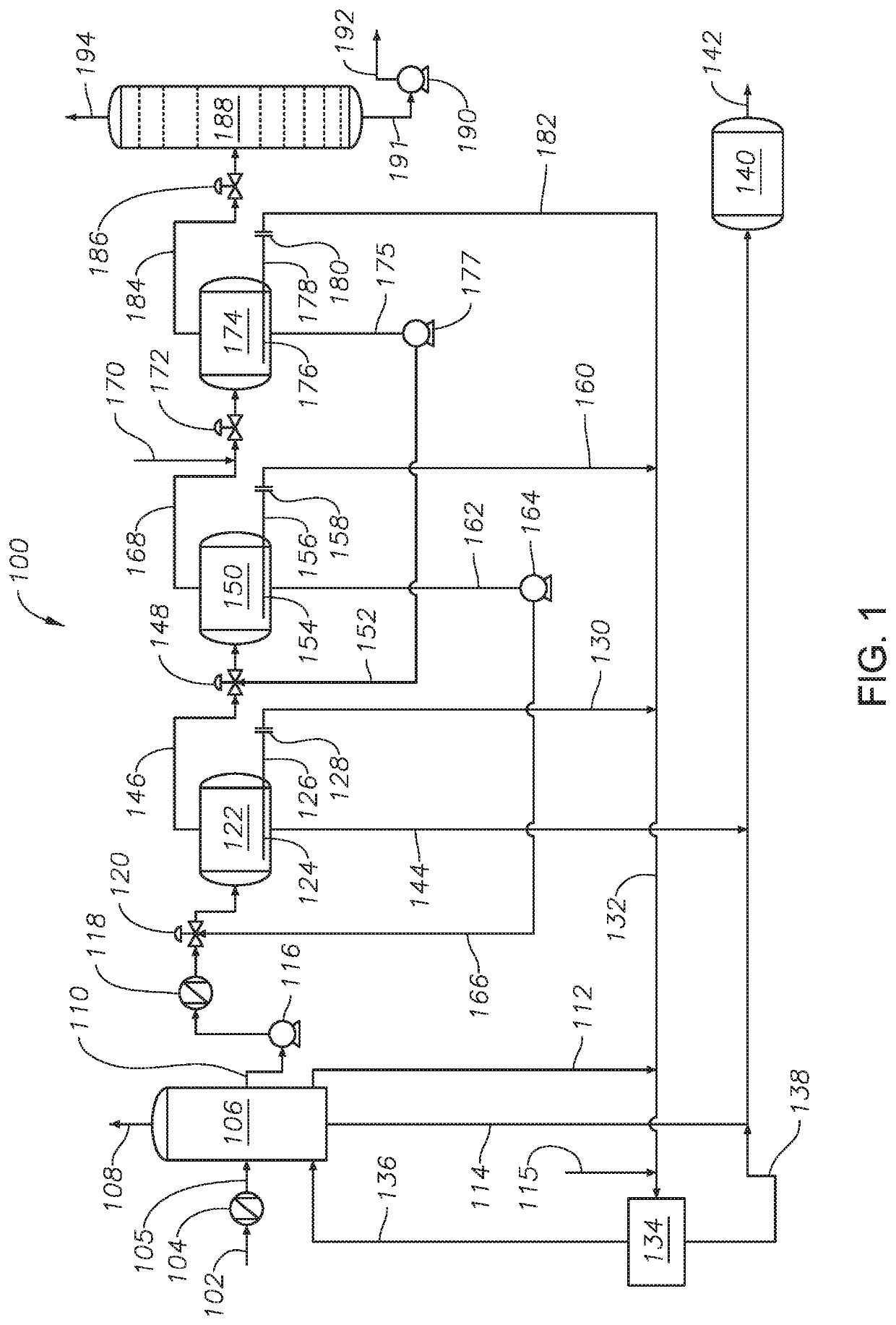

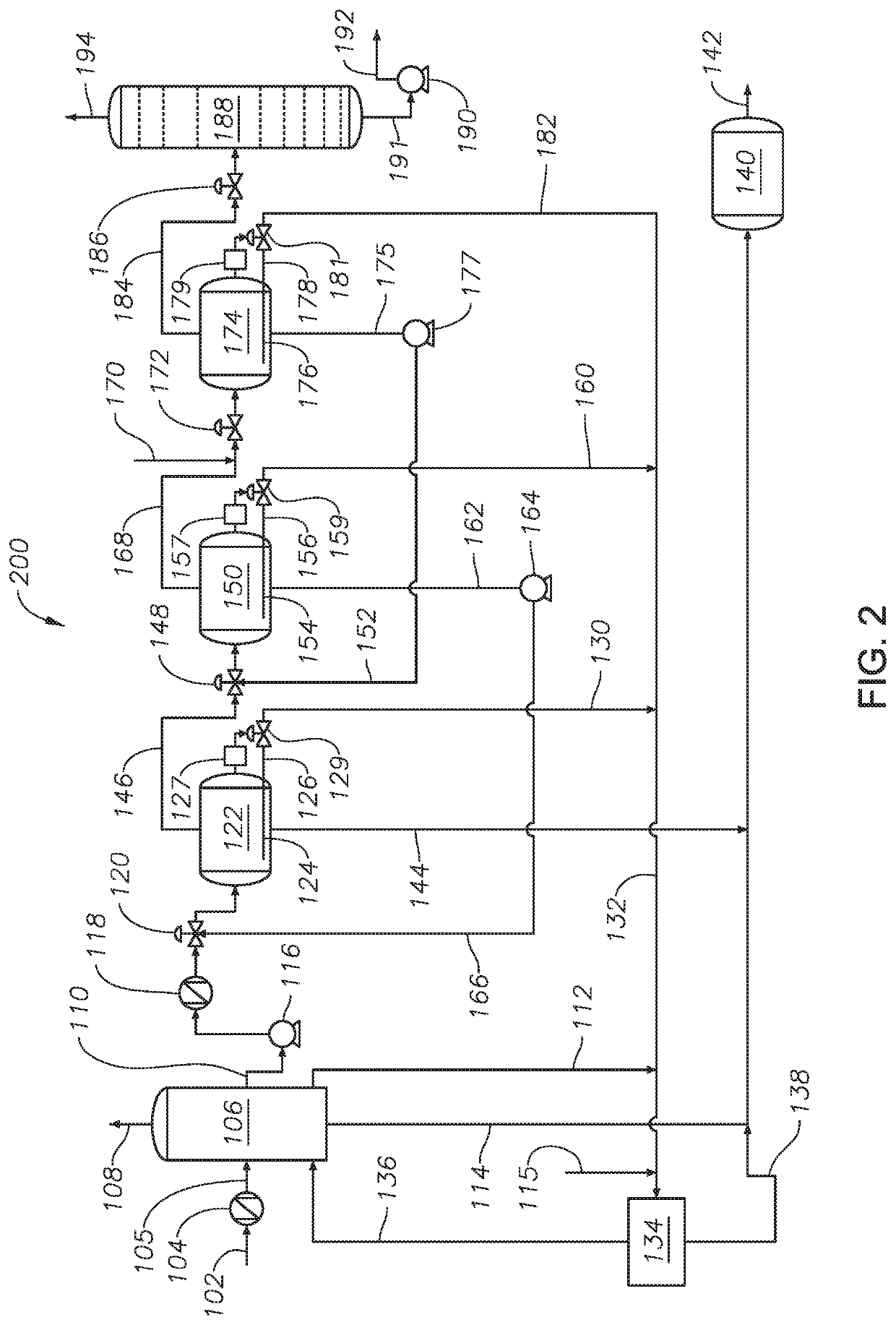

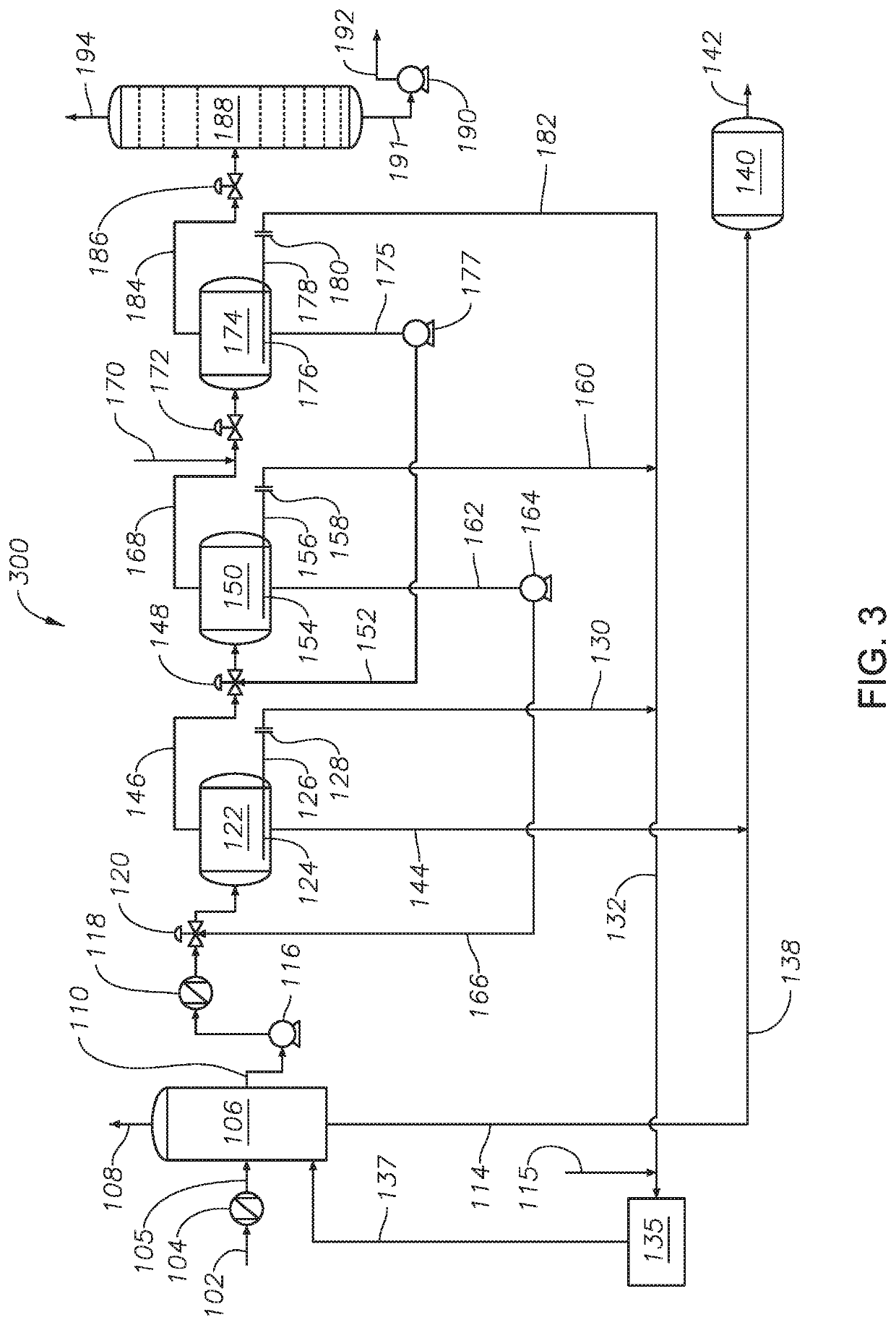

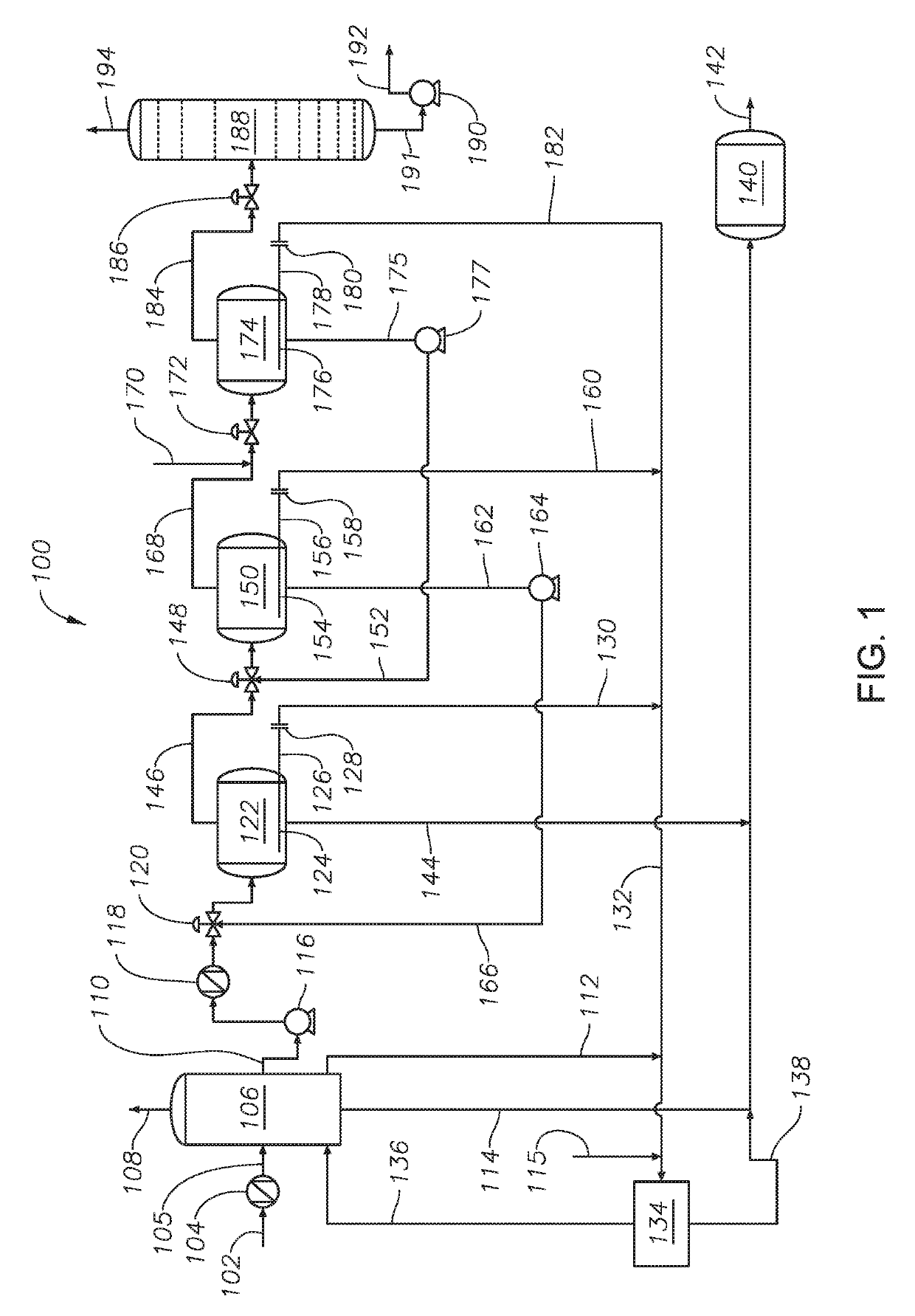

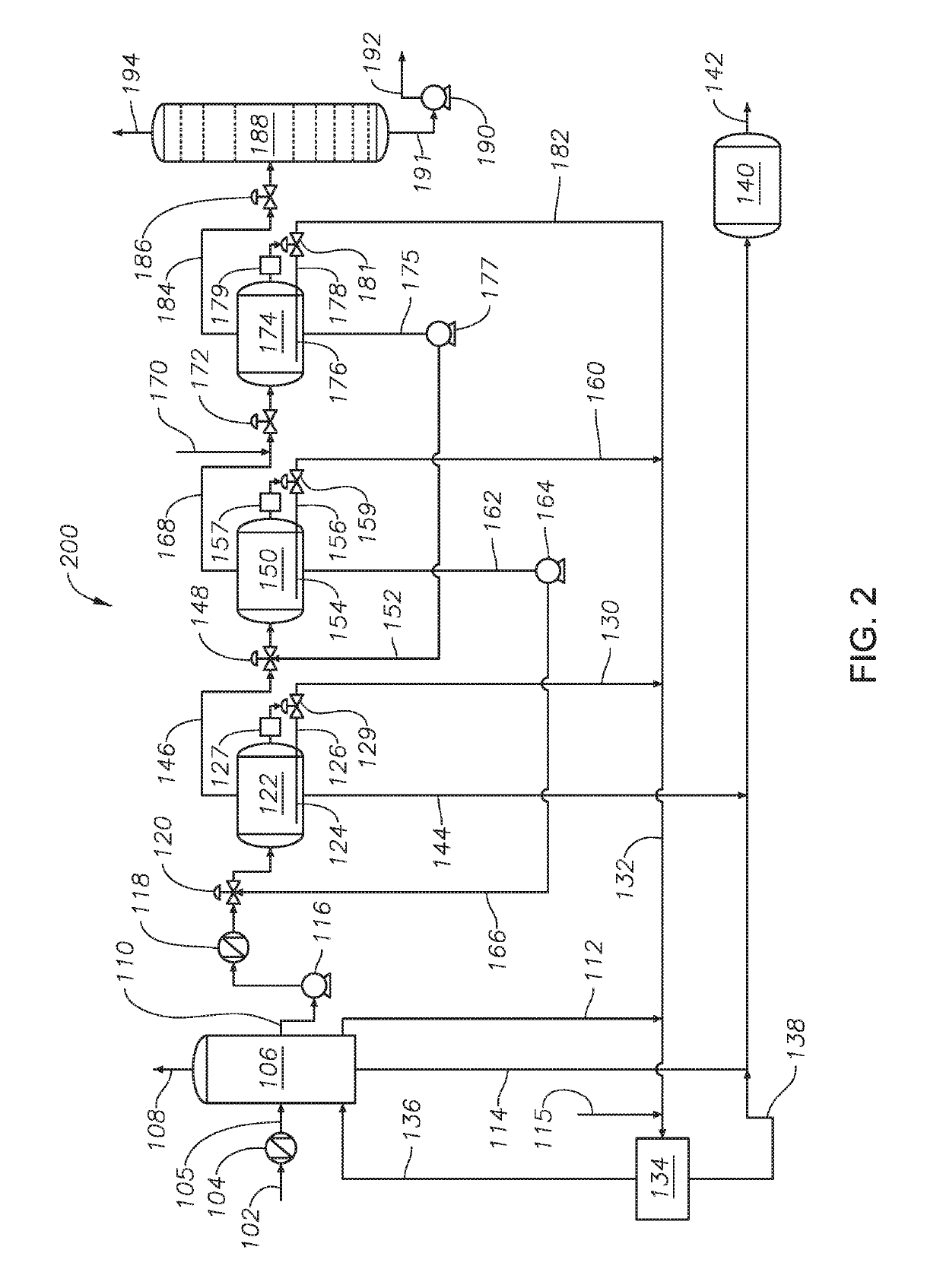

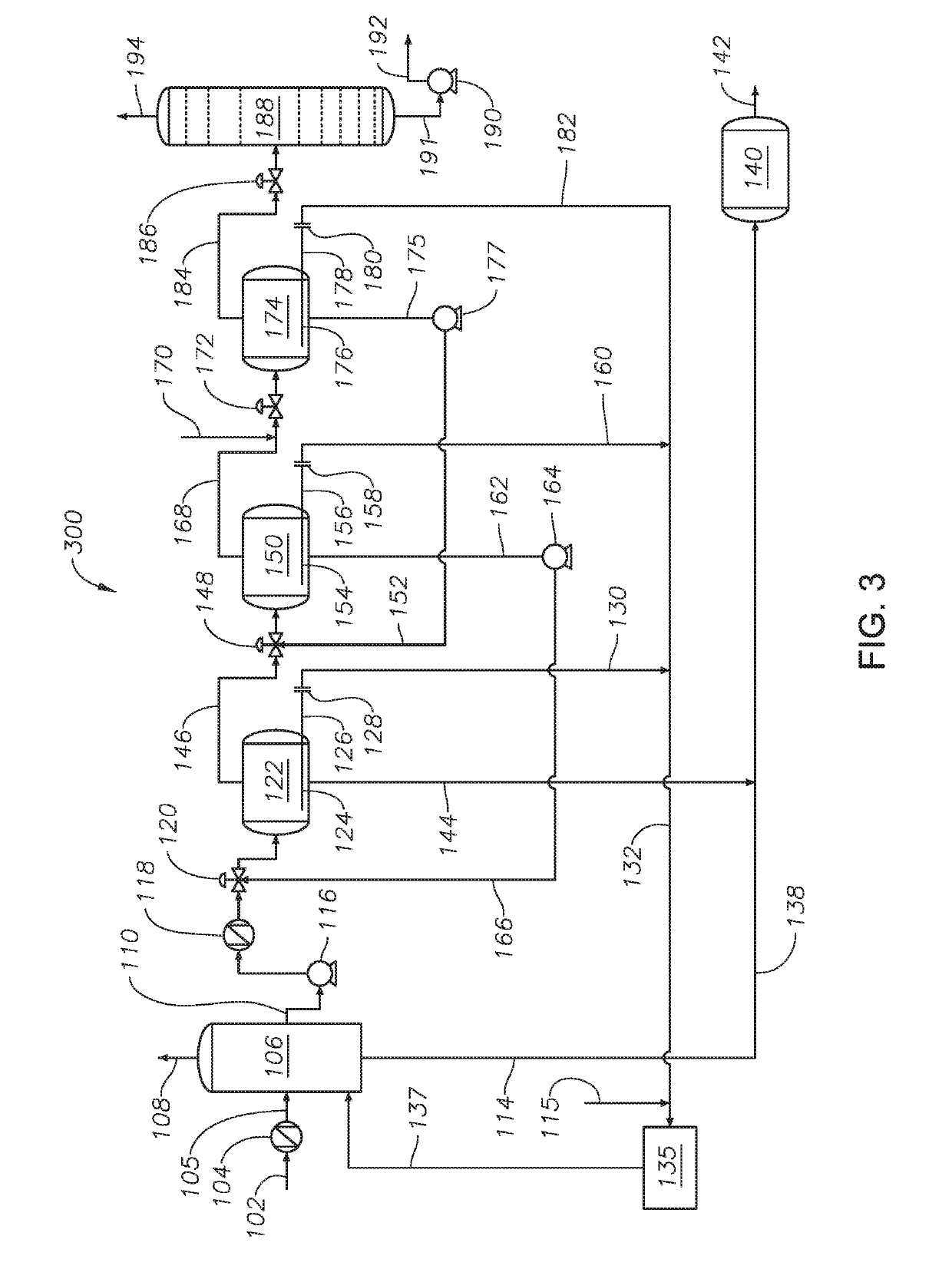

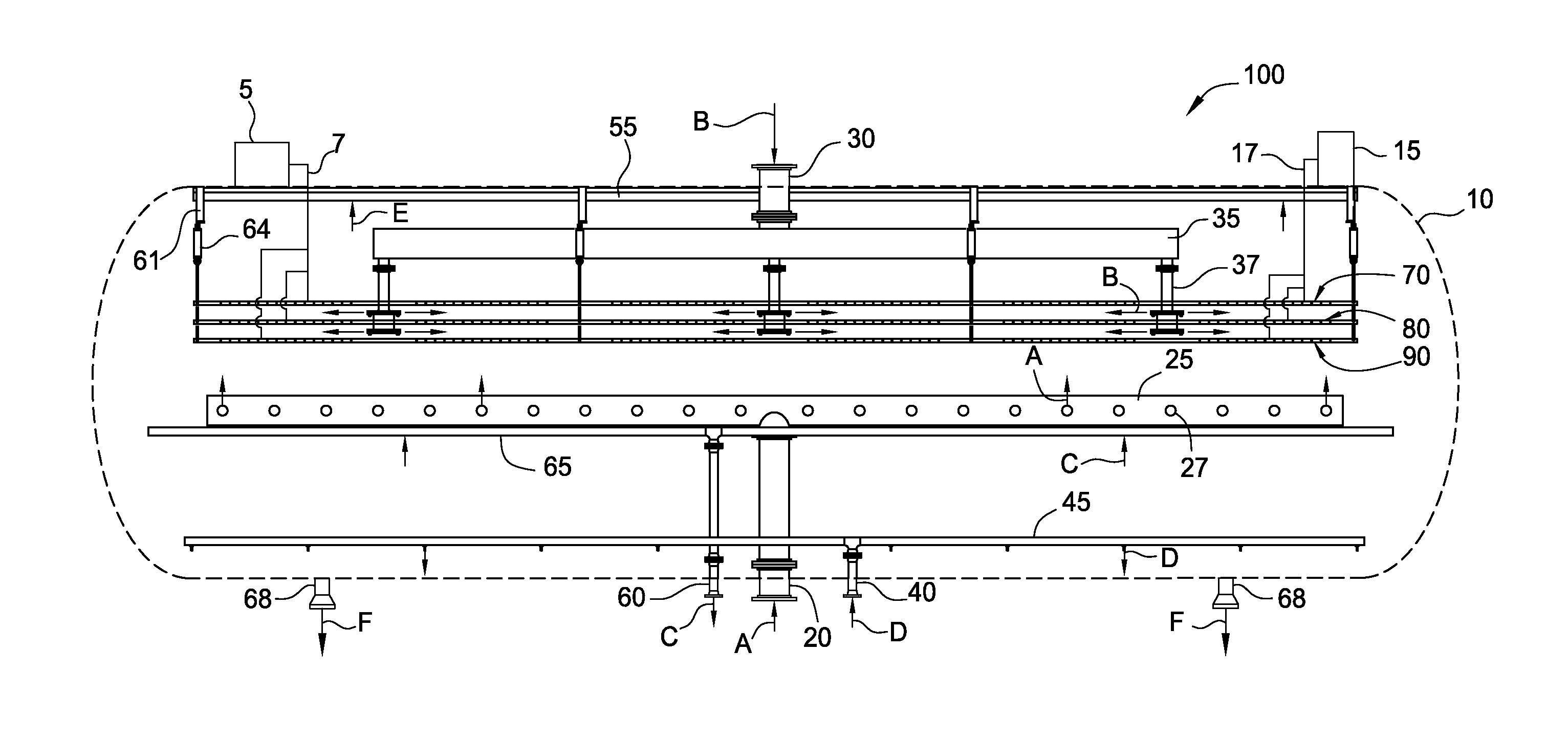

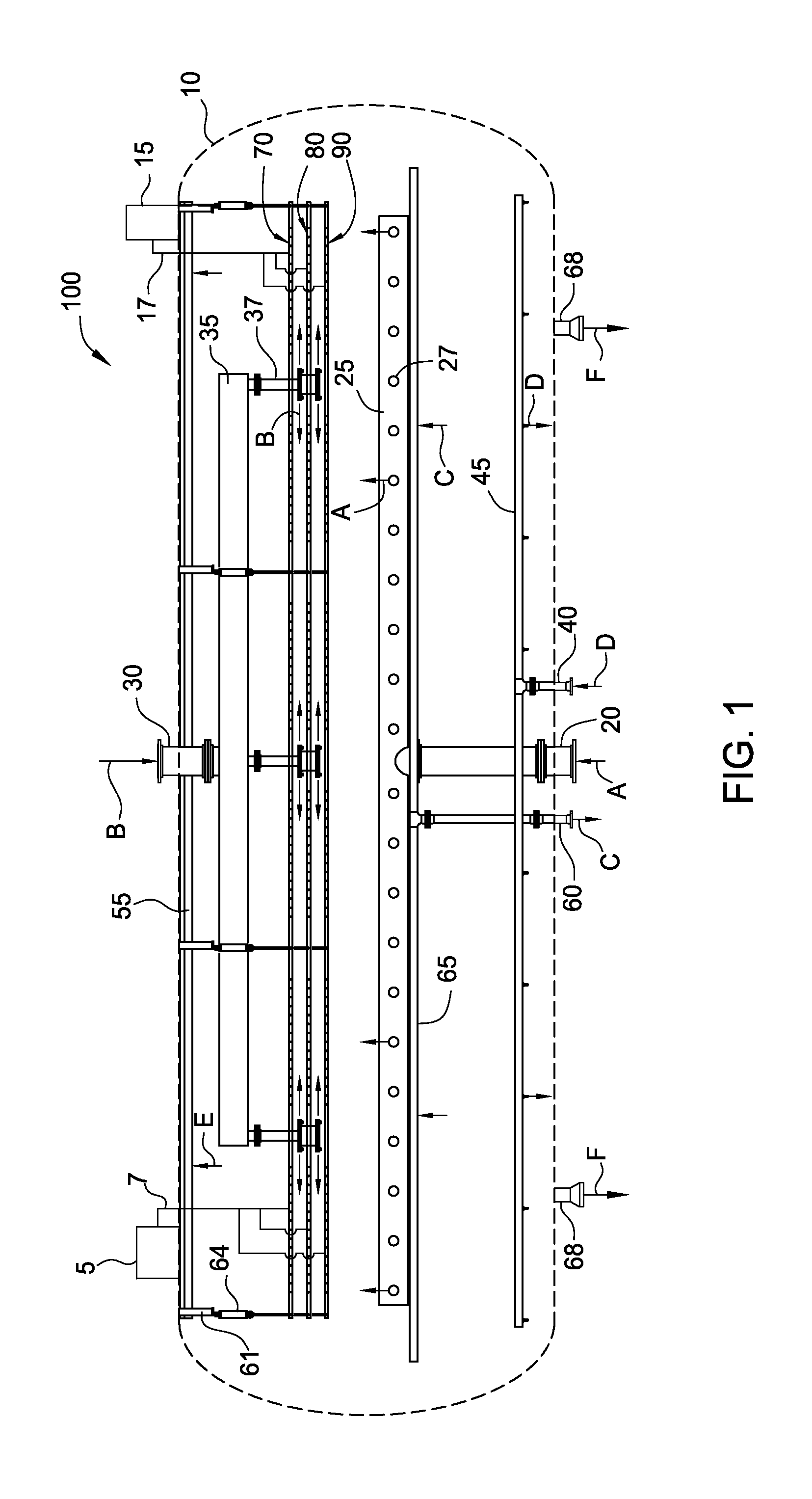

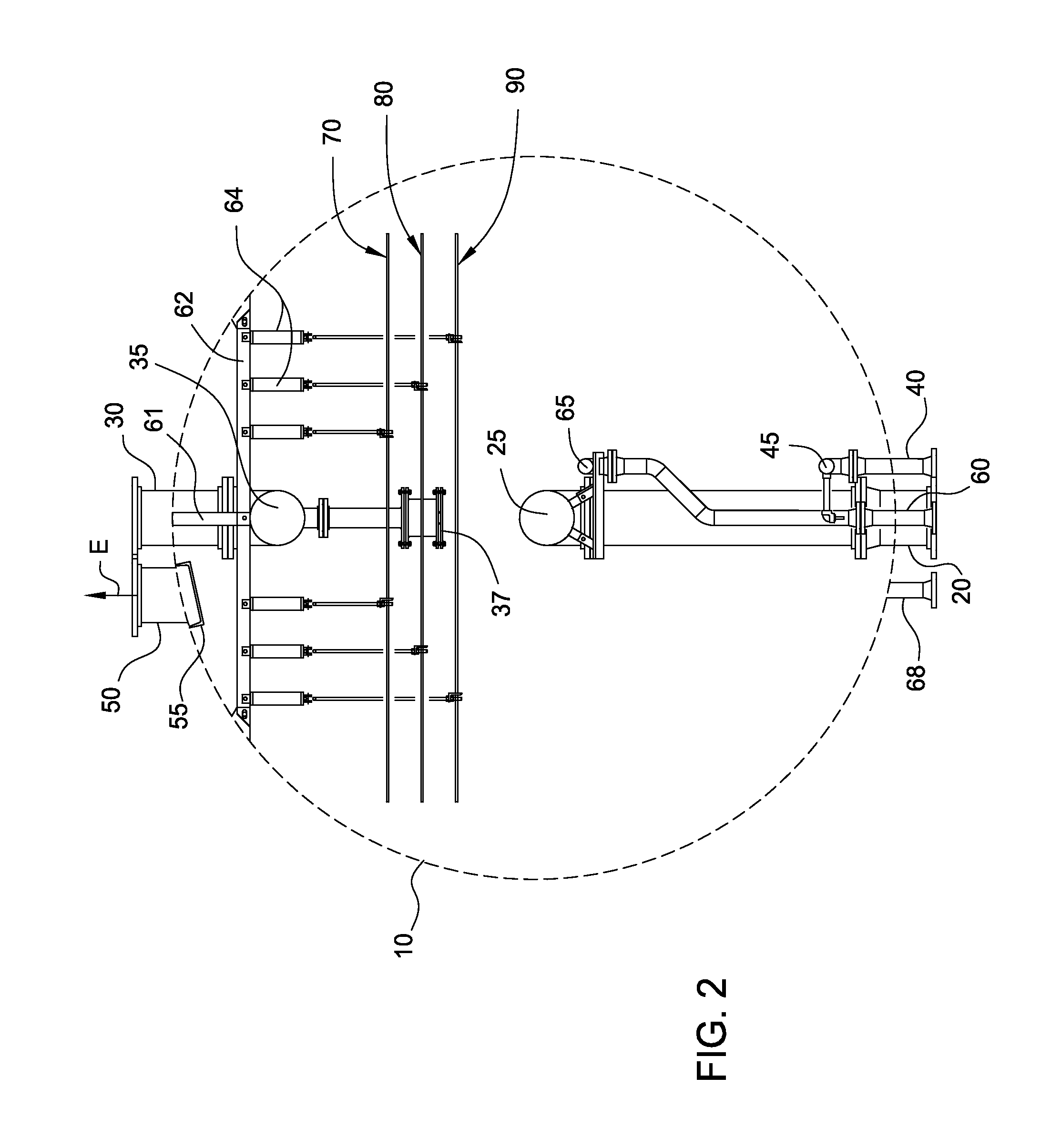

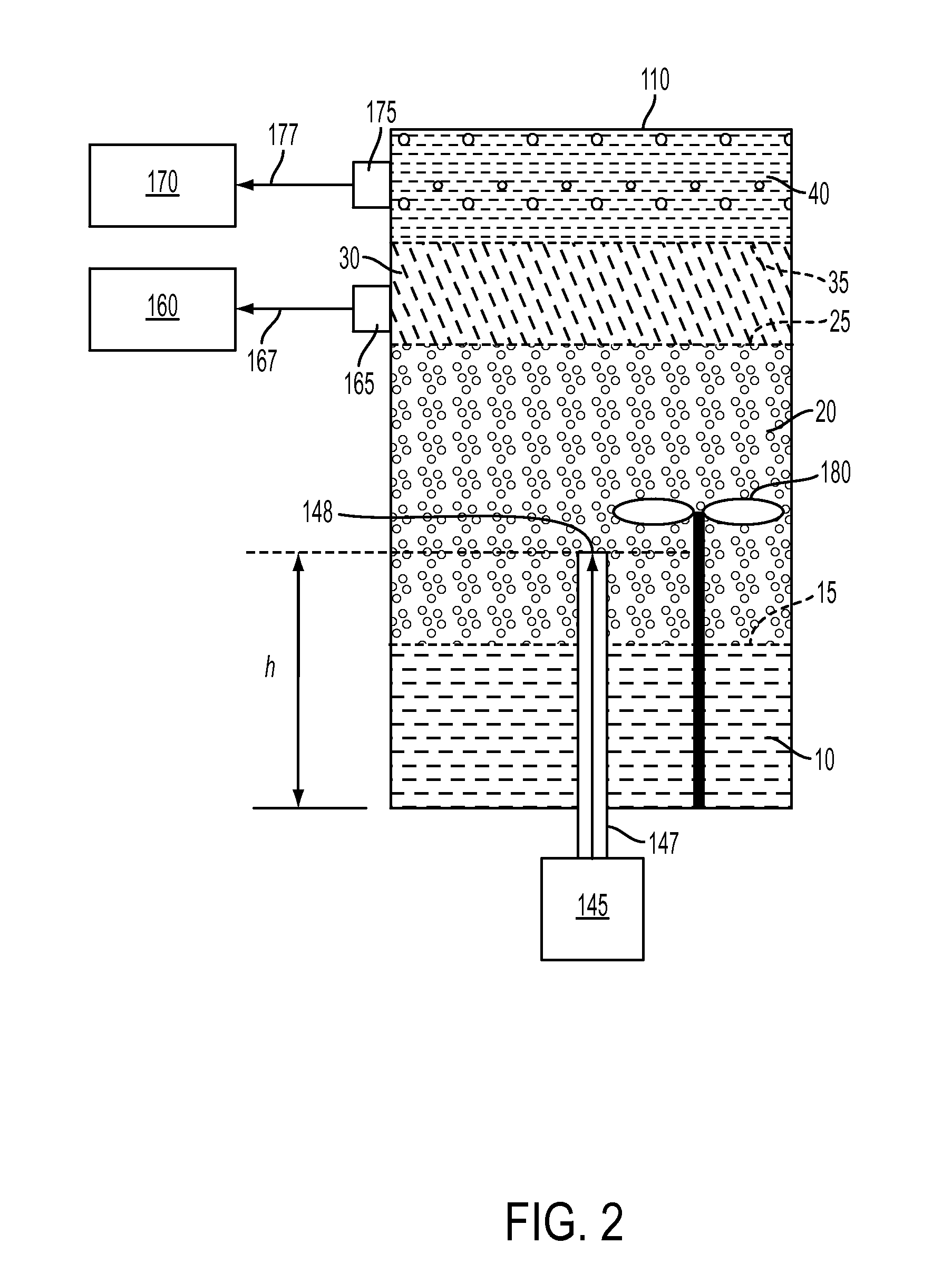

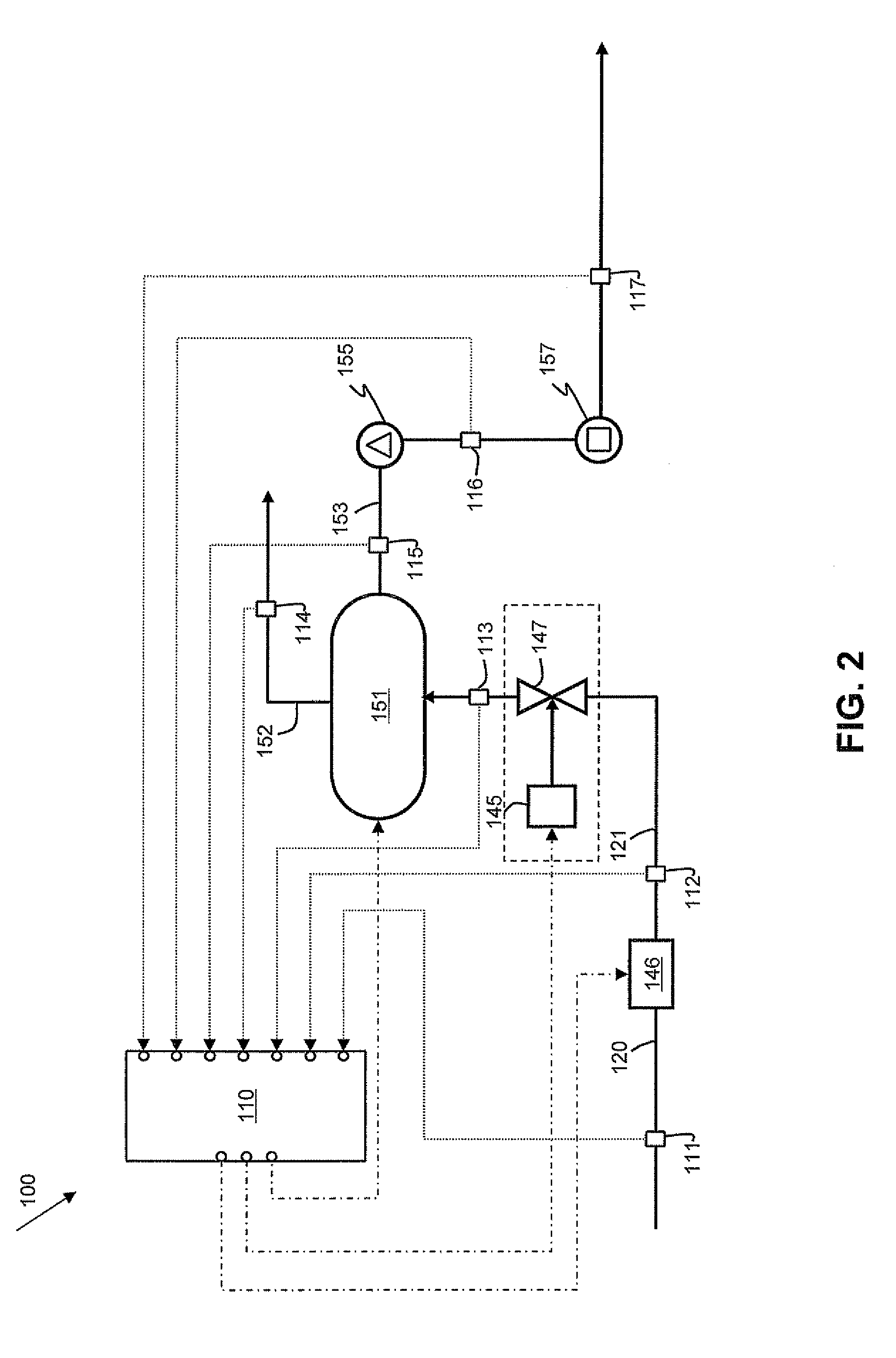

Gas oil separation plant systems and methods for rag layer treatment

ActiveUS10513663B2Effective controlEliminate effectiveFatty/oily/floating substances removal devicesLiquid separation by electricityOil separationTreatment system

Systems and methods for treating a rag layer in a gas oil separation plant. The method includes withdrawing the rag layer from a vessel proximate an oil water interface; conveying the rag layer to a separation device, the separation device operable to effect electrostatic coalescence on the rag layer to separate oil and water; and recycling separated oil from the separation device back to the gas oil separation plant process.

Owner:SAUDI ARABIAN OIL CO

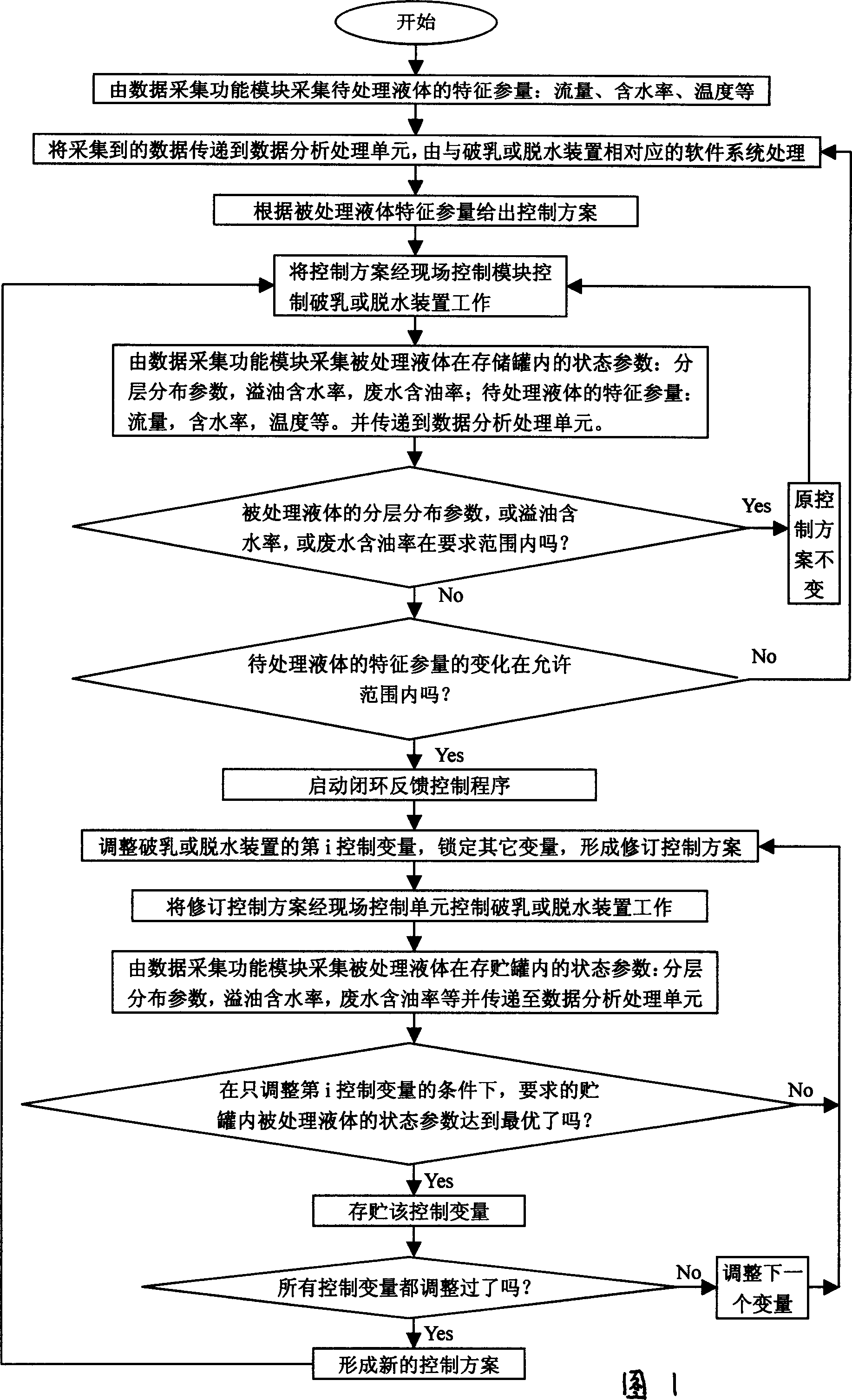

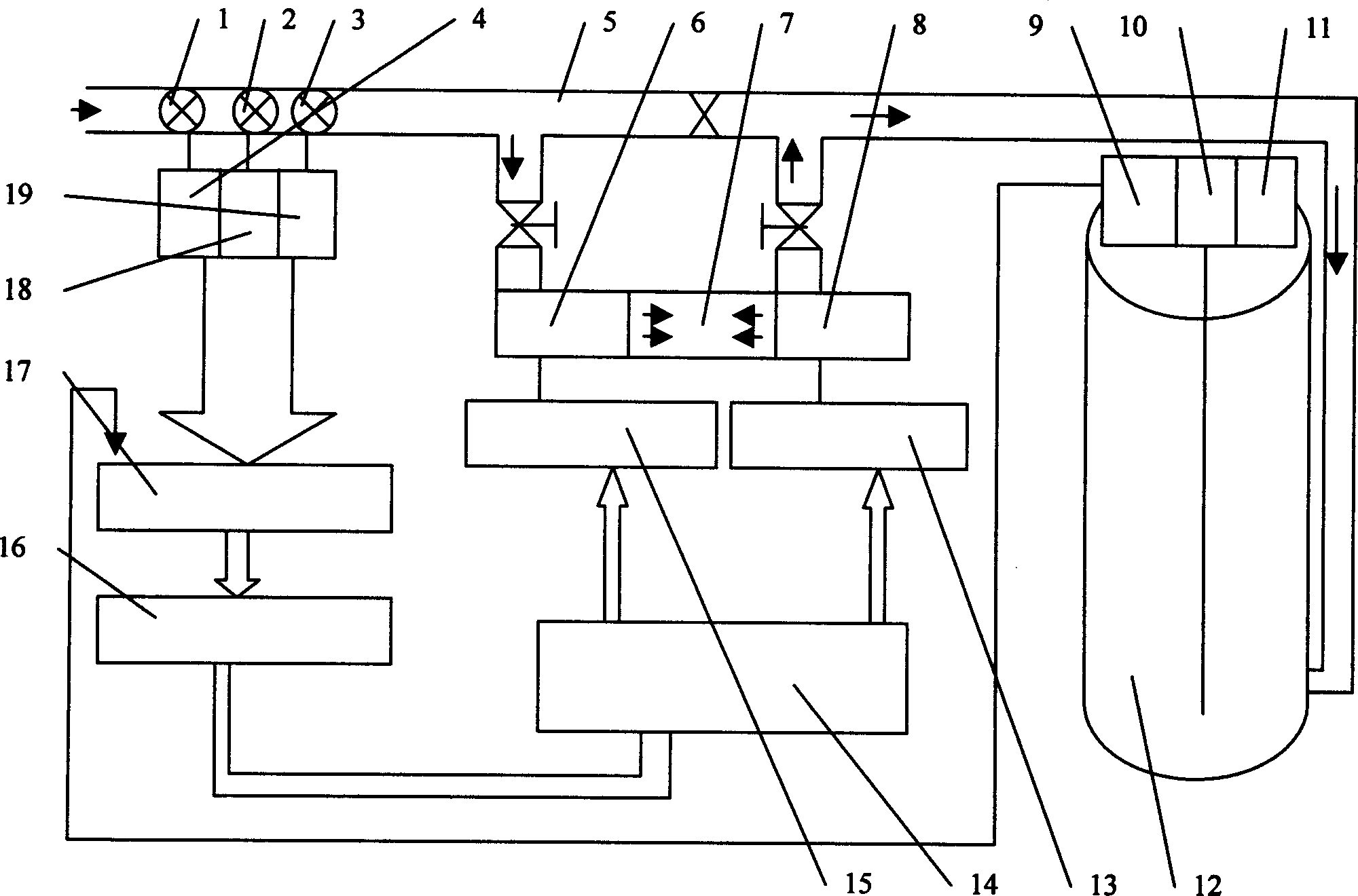

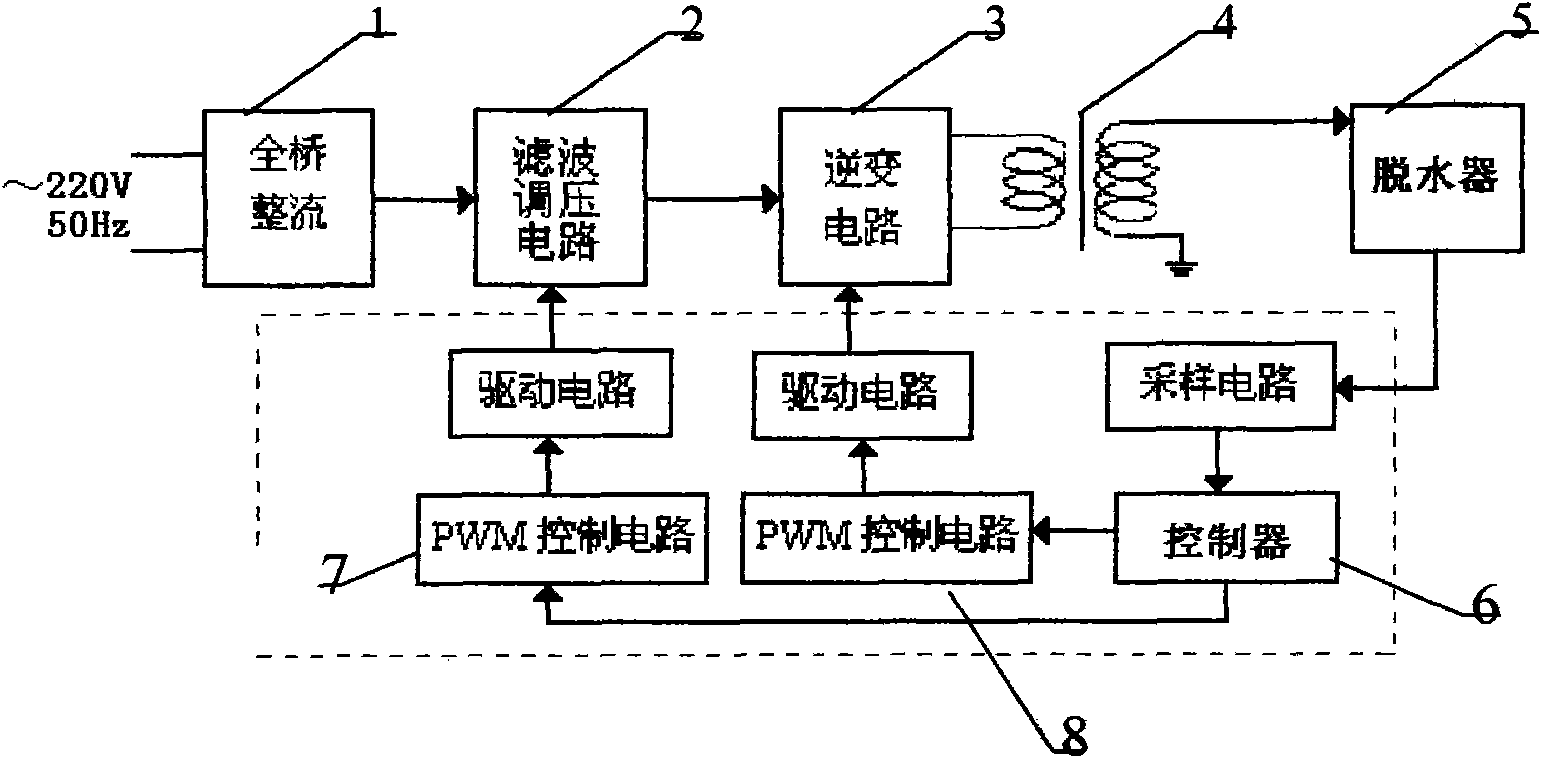

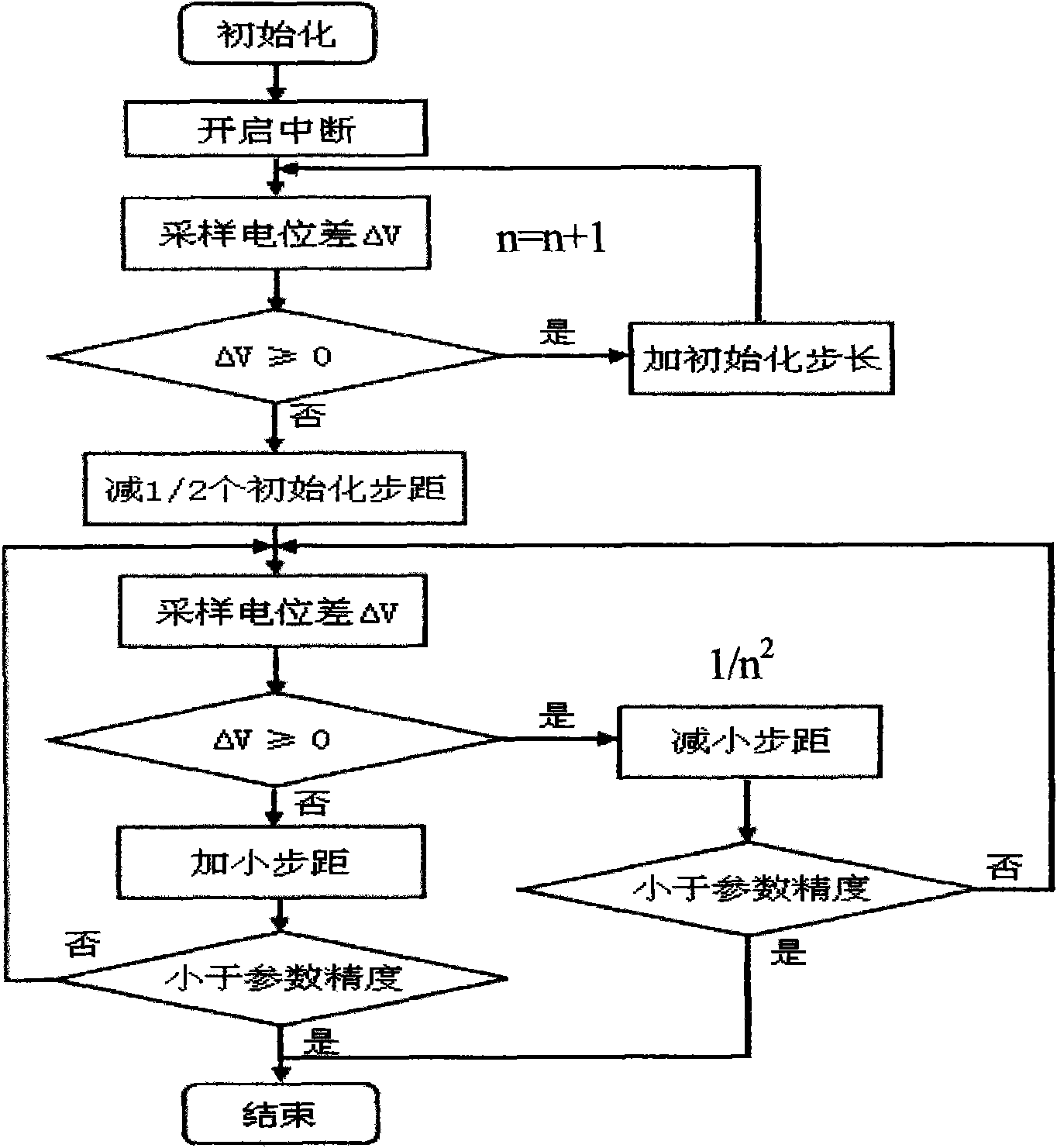

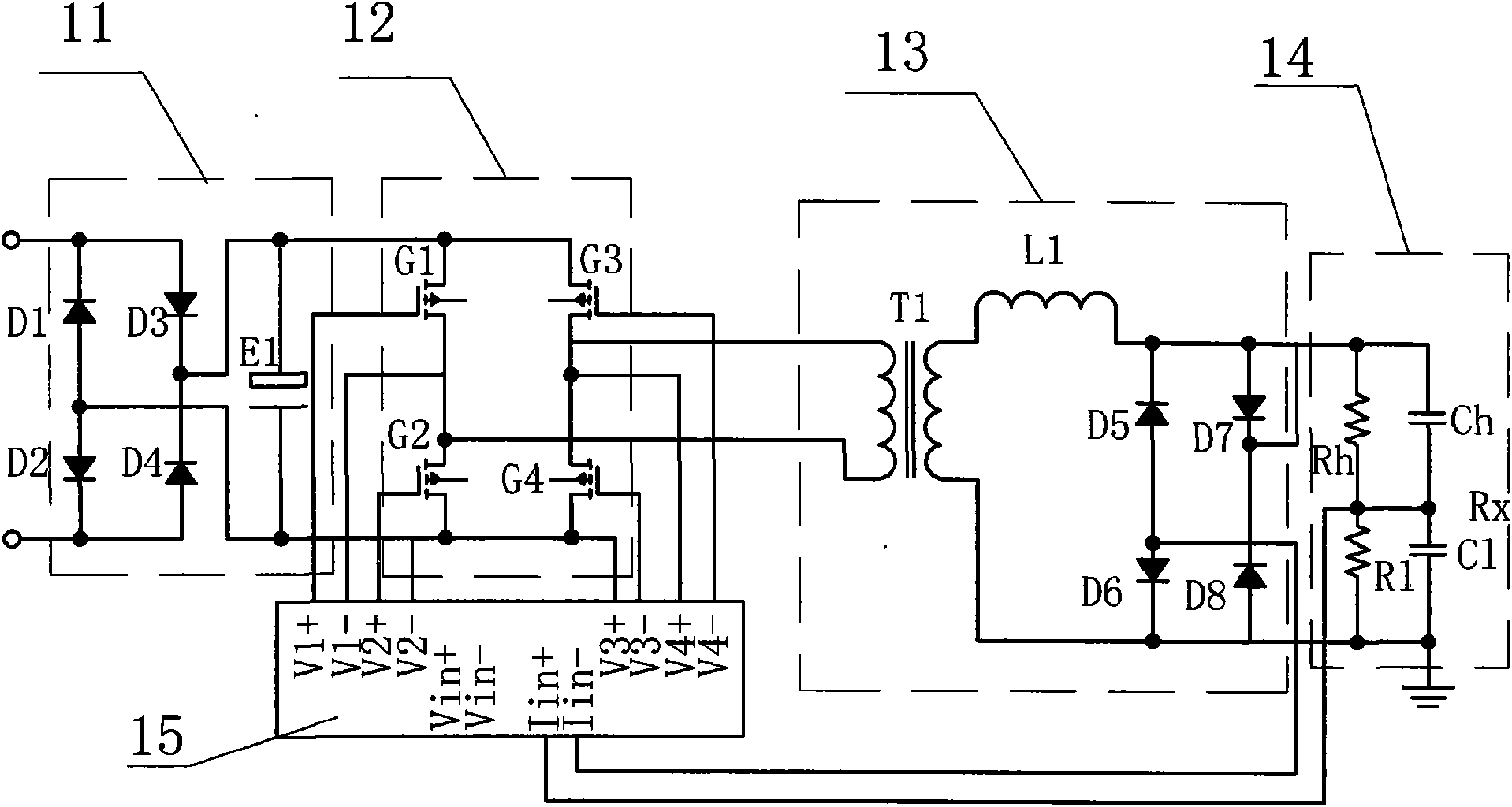

Control parameter optimization control system and method of crude oil dehydration power supply

InactiveCN102005936ABig impactIncrease the sedimentation rateDewatering/demulsification with electric/magnetic meansDewatering/demulsification regulation/controlHigh pressureMoisture

The invention relates to a control parameter optimization control system and method of a crude oil dehydration power supply, aiming at solving the problems that the crude oil moisture content is high home and abroad and the dehydration effect needs to be improved. Aiming at improving the crude oil dehydration efficiency, a control parameter optimization control system of crude oil dehydration power supply is designed in the invention. With respect to different properties of crude oil emulsion, the power supply parameter optimization intelligent control system adopts a variable-step length self-optimizing control method with the self-learning function, can be used for adjusting and self-optimizing the power control parameter, is beneficial to effectively exerting the function of high-pressure field stress inside the moisture crude oil, and ensures that the sedimentation rate of water drops in the crude oil is greatly increased so that the oil-water separation effect is improved.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

Gas oil separation plant systems and methods for rag layer treatment

ActiveUS20190211274A1Effective controlEliminate effectiveFatty/oily/floating substances removal devicesLiquid separation by electricityOil separationOil water

Systems and methods for treating a rag layer in a gas oil separation plant. The method includes withdrawing the rag layer from a vessel proximate an oil water interface; conveying the rag layer to a separation device, the separation device operable to effect electrostatic coalescence on the rag layer to separate oil and water; and recycling separated oil from the separation device back to the gas oil separation plant process.

Owner:SAUDI ARABIAN OIL CO

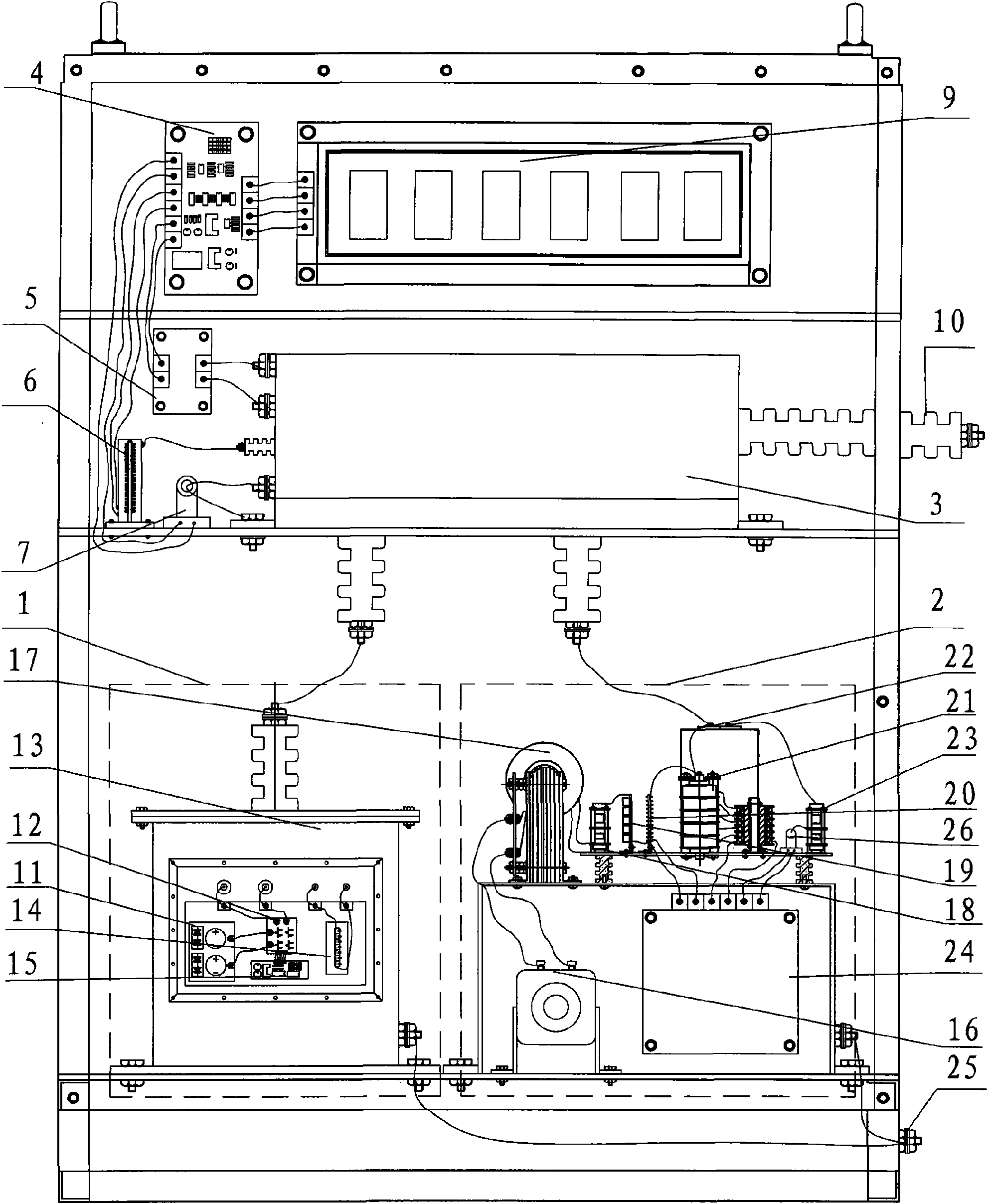

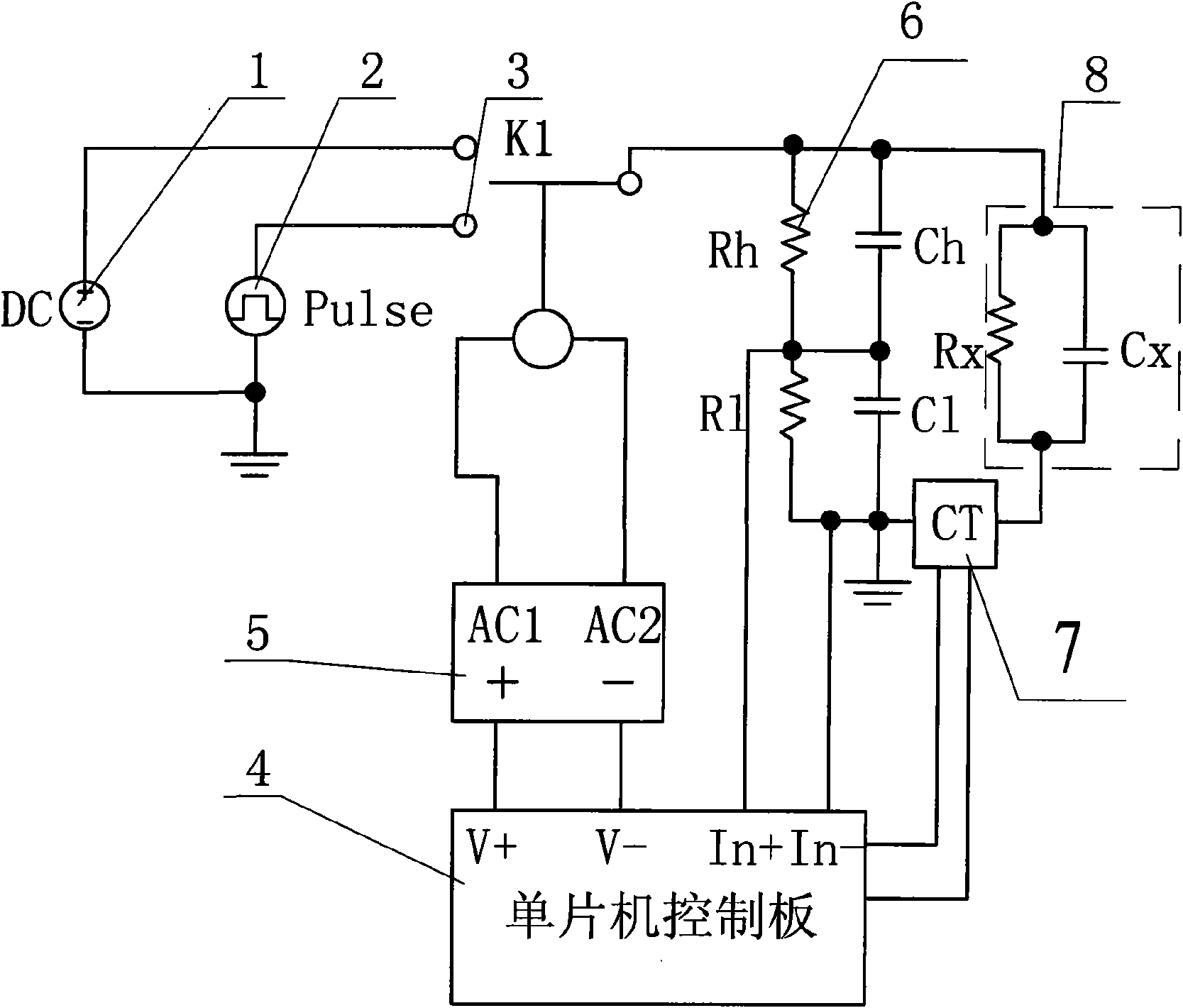

Combined type crude oil electric dewatering high-voltage power source and controlling device thereof

InactiveCN101550353AStable dehydration electric fieldElectric field stabilizationLiquid separation by electricityDewatering/demulsification with electric/magnetic meansMicrocontrollerCurrent sensor

The invention relates to a combined type crude oil electric high-voltage dewatering power source and a controlling device thereof and aims to solve the problems that the prior electric dewatering device has heavy control current, unstable high-voltage electric field, and the like. The combined type crude oil electric dewatering power source and the controlling device thereof comprise a high-voltage direct current generator (1), a high-voltage pulse generator (2) and a control circuit, wherein the high-voltage direct current generator and the high-voltage pulse generator are respectively connected with a grounding terminal (2), and after being connected in parallel, the high-voltage direct current generator and the high-voltage pulse generator are connected with a high-voltage switch (3); the high-voltage switch is connected with a high-voltage switch driver (5) which is connected with a single chip controlling plate (4); the single chip controlling plate is connected with a high-voltage divider A (6), a current sensor (7) and a measurement display window (9); the high-voltage voltage divider A and the current sensor are connected with the high-voltage switch; and the output of thehigh-voltage switch is connected onto a dewatering container (8) through a high-voltage sleeve pipe (10). The invention serves as the power source and the controlling device for dewatering the crude oil.

Owner:HARBIN UNIV OF SCI & TECH

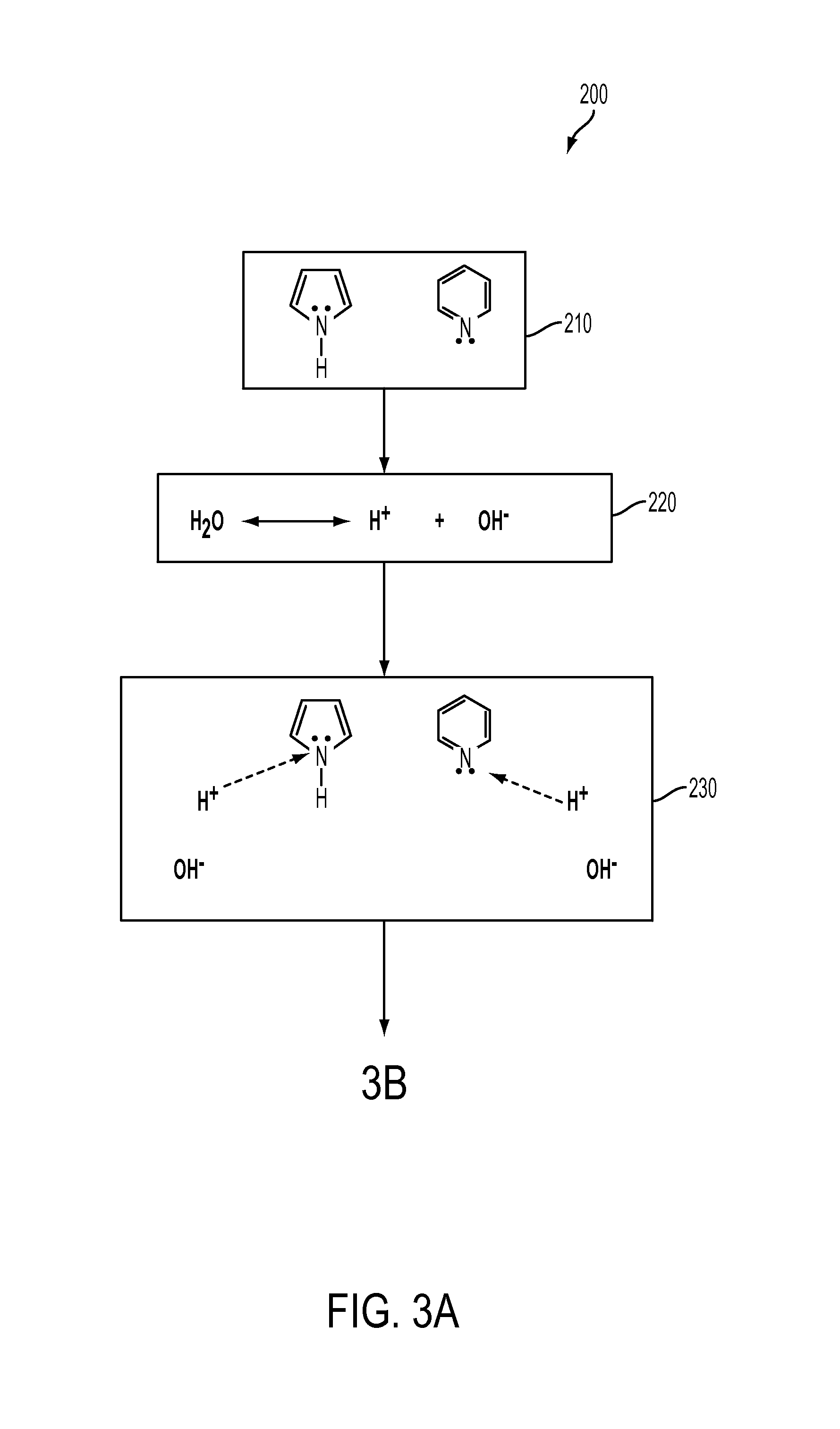

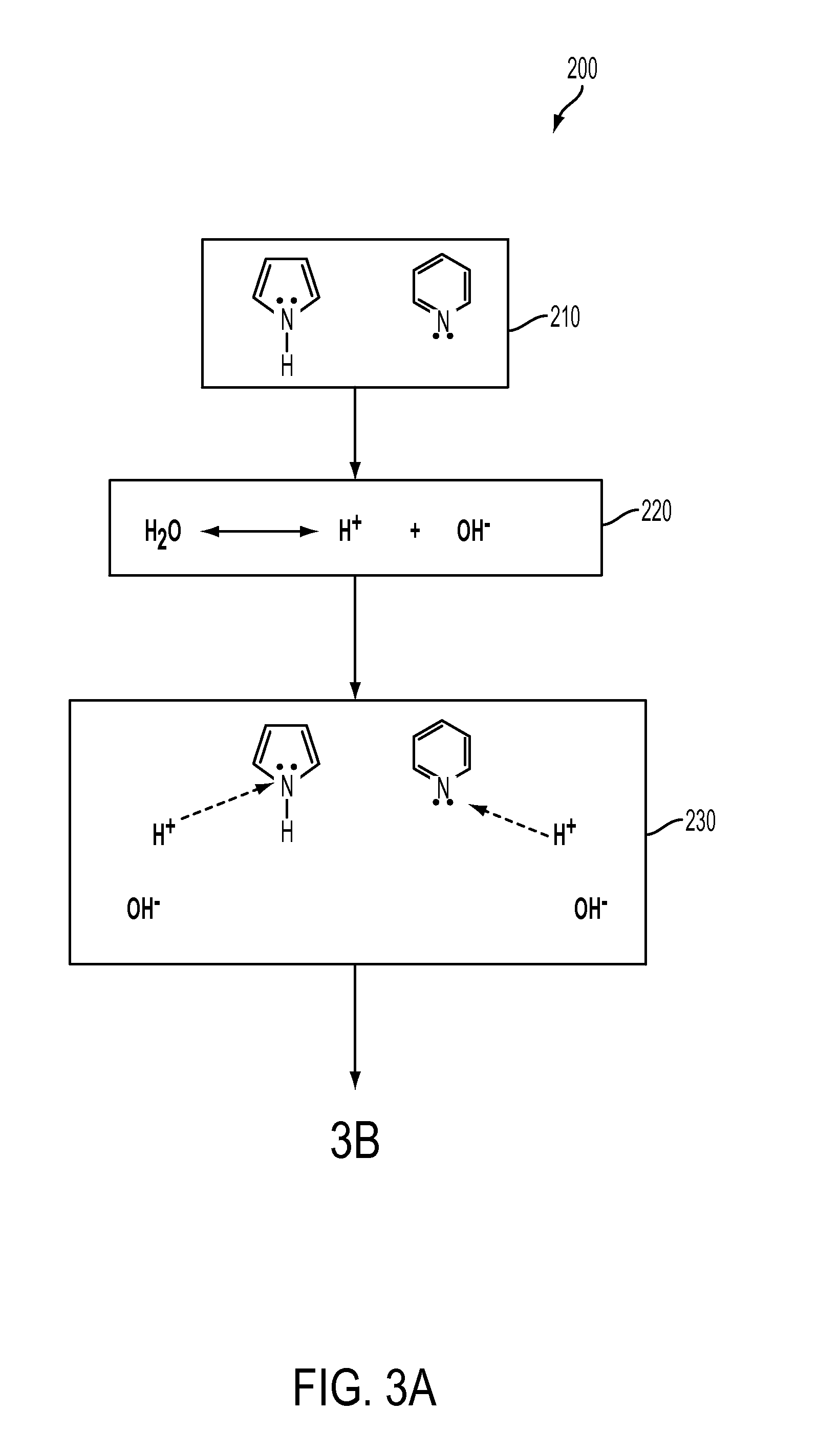

Demulsification of emulsified petroleum using carbon dioxide and resin supplement without precipitation of asphaltenes

ActiveUS9169446B2Promote ruptureDewatering/demulsification with chemical meansTreatment with plural serial refining stagesOil phasePetroleum

Methods for demulsifying an emulsified petroleum source having a predetermined resin-to-asphaltene ratio without substantial aggregation or precipitation of asphaltenes may include adding a resin supplement to the emulsified petroleum source to form a resin-supplemented emulsion having a resin-to-asphaltene ratio above a predetermined critical value. An acidic-to-basic ratio of acidic functional groups to basic functional groups in the supplemented emulsion may be adjusted to be from about 0.25 to about 4.0. The resin-supplemented emulsion may be contacted with carbon dioxide to form an initial mixture having an emulsified oil phase and an emulsified aqueous phase. The initial mixture may be stabilized to facilitate rupture of the resin-supplemented emulsion, to cause phase separation, and to allow removal of a separated oil phase. The resin-to-asphaltene ratio being above the predetermined critical value in the supplemented emulsion maintains asphaltene suspension during demulsification, such that asphaltene agglomeration and precipitation are avoided.

Owner:SAUDI ARABIAN OIL CO

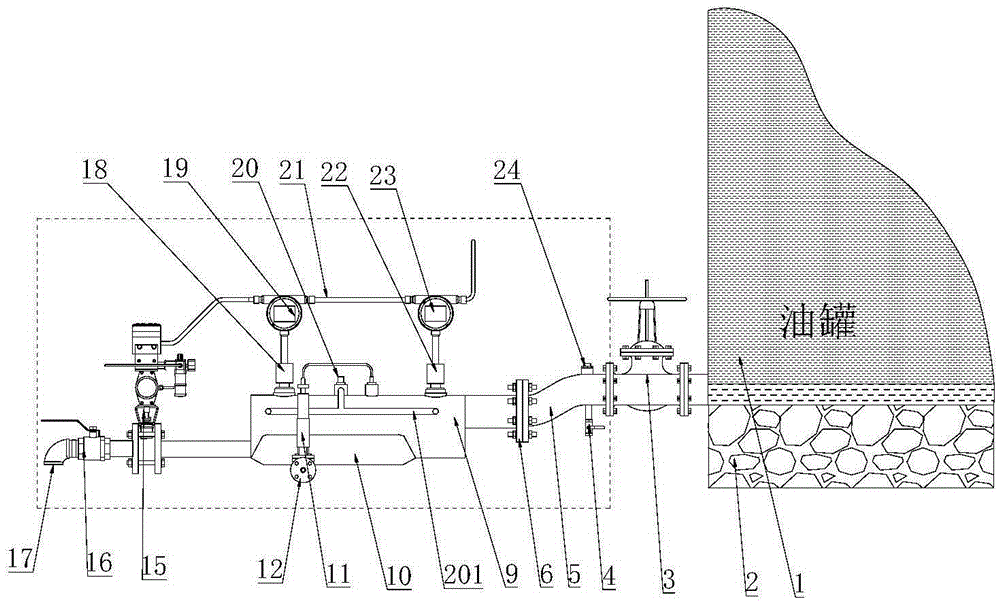

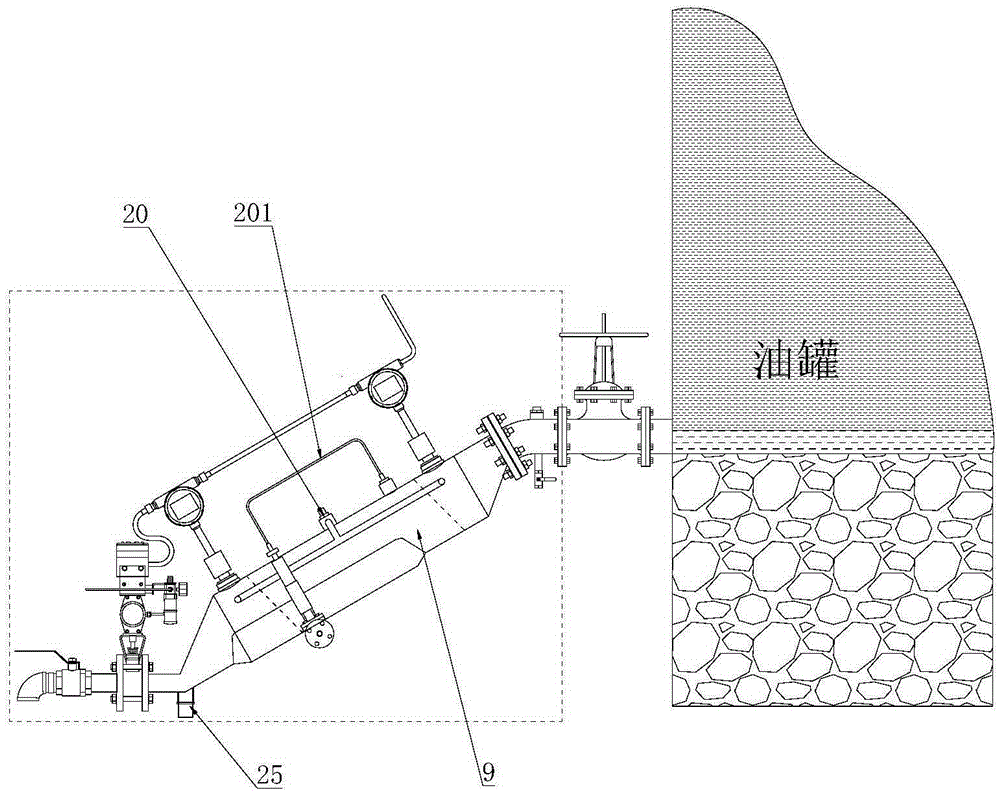

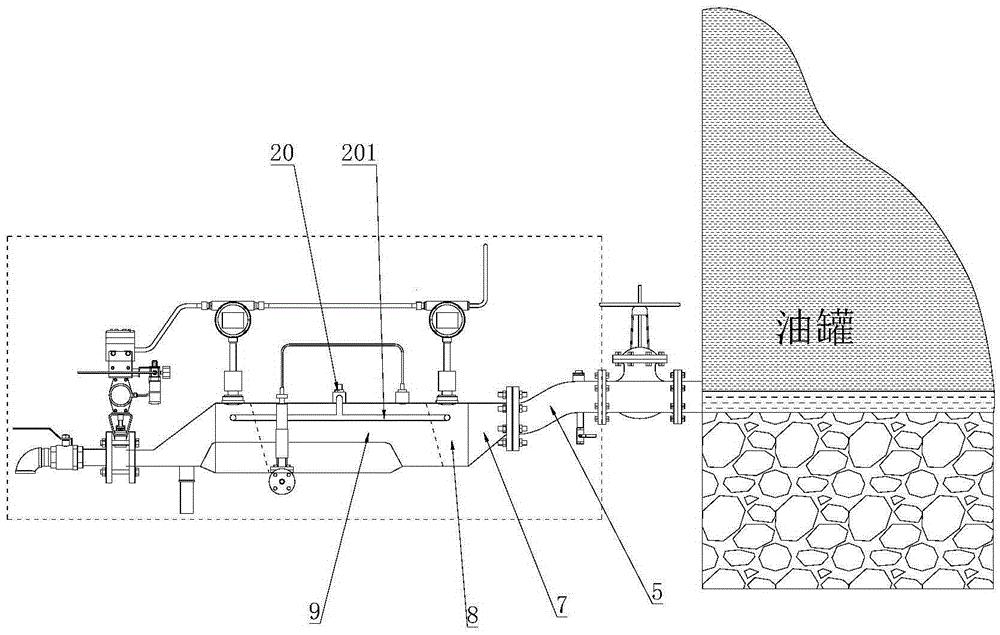

Novel pipeline-type automatic dehydrater for oil tank

ActiveCN105419857AEasy to cleanAvoid inaccurate detection and oil leakage problemsDewatering/demulsification regulation/controlPulp and paper industryPollution

The invention discloses a novel pipeline-type automatic dehydrater for an oil tank. The novel pipeline-type automatic dehydrater comprises a dewatering pipeline, a first sensor arranged on the dewatering pipeline, a first controller and a dewatering valve, wherein the first controller is used for controlling opening or closing of the dewatering valve according to data detected by the first sensor; a first mounting part and a second mounting part are arranged at the two ends of the dewatering pipeline respectively; a cleaning pipeline is arranged in the dewatering pipeline; a cleaning pipeline inlet is formed in the dewatering pipeline; through the cleaning pipeline, a cleaning solution is introduced into the first sensor; the first mounting part is communicated with a water outlet of the oil tank; the second mounting part is not higher than the first mounting part. Through reasonable arrangement of the dewatering pipeline, impurities in the oil tank can flow out of the oil tank through the dewatering pipeline; the cleaning pipeline is arranged in the dewatering pipeline to realize cleaning of the sensor, so that the cleaning of the sensor is facilitated, and a problem that a dehydrater cannot work normally, which is caused by the fact that monitoring data is influenced due to pollution to the sensor is avoided.

Owner:GUANGZHOU DAY WO AUTOMATION IND

Electric field regulating and controlling method for crude oil dehydration device

InactiveCN102517070AAdjust in timeMeet the actual control needsDewatering/demulsification with electric/magnetic meansDewatering/demulsification regulation/controlWater contentChemical industry

The invention discloses an electric field regulating and controlling method for a crude oil dehydration device, which relates to a method for recovering an electric field to normal only by performing electrical property regulation on a crude oil emulsion in the electric dehydration device without changing a front section flow or a medicament. In the method, the change of the electrical property of the emulsion in the electric dehydration device is adjusted rapidly according to the change of a dielectric constant, an additive is regulated in time, a dielectric constant is recovered, the electric field is recovered, and the practical control requirement of electric field indexes in field production is met, so that normal running of the electric dehydration device is ensured, the water content of exported purified oil is up to or lower than an exportation standard, and the requirement of normal production is met. Meanwhile, control indexes can be provided for processes such as primary and secondary sedimentation at a front section, thermal sedimentation process and the like, and appropriate water content of crude oil containing emulsified water entering the electric dehydration device is ensured. The method is suitable for the technical field of chemical industry.

Owner:SOUTHEAST UNIV

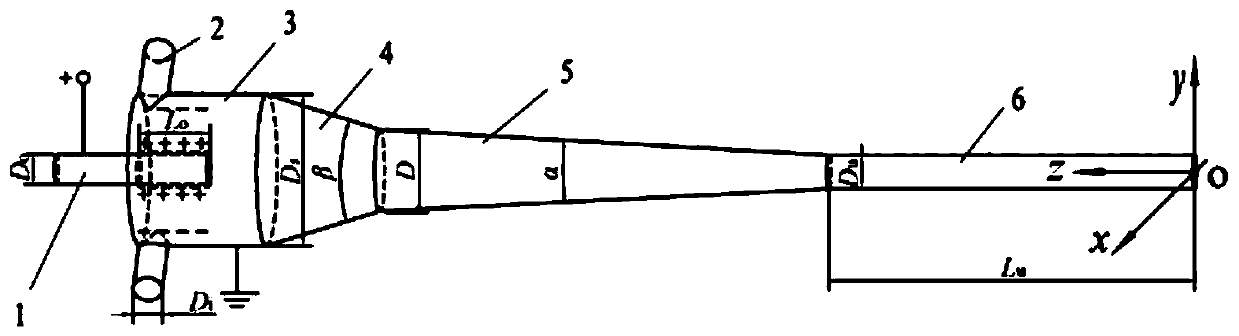

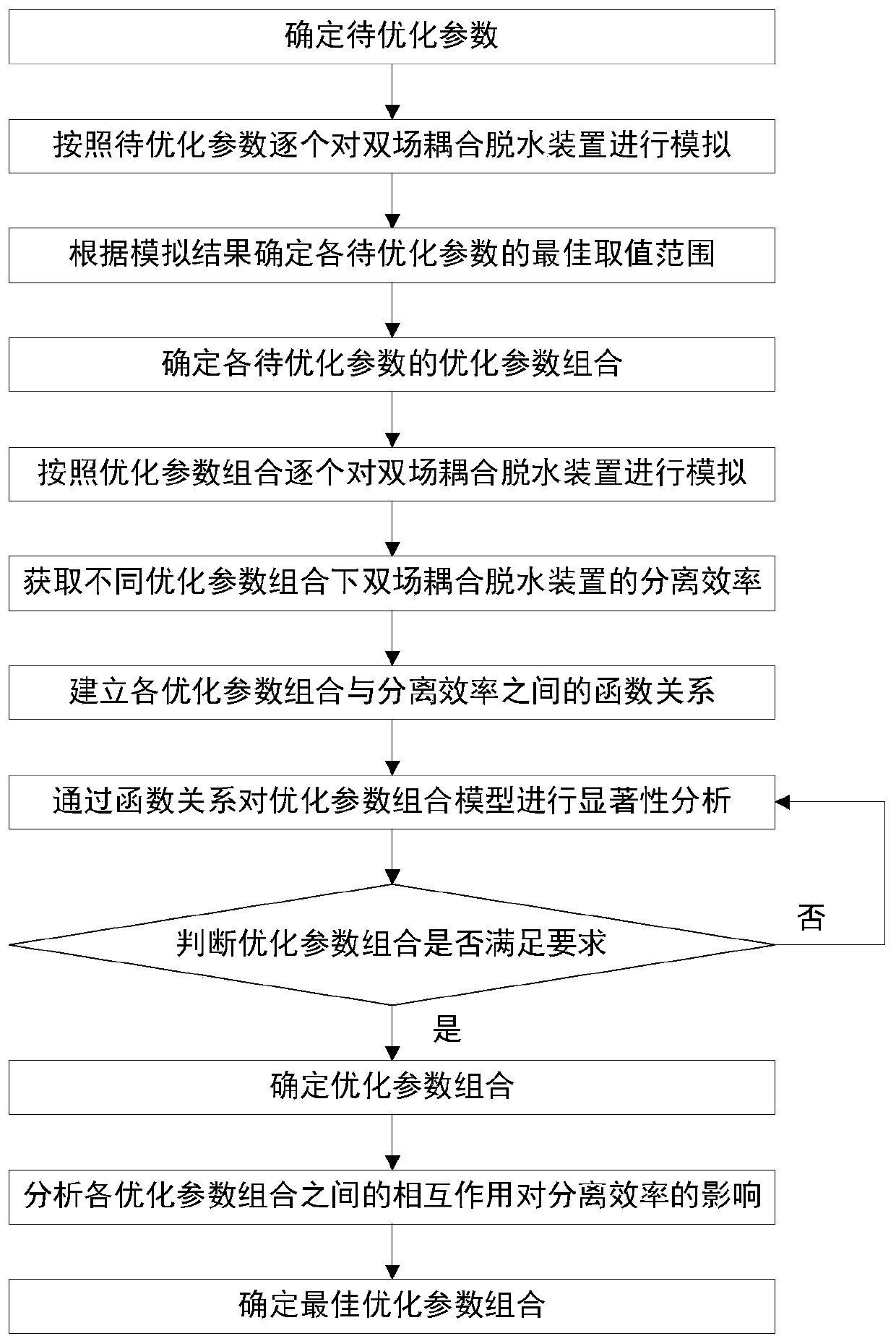

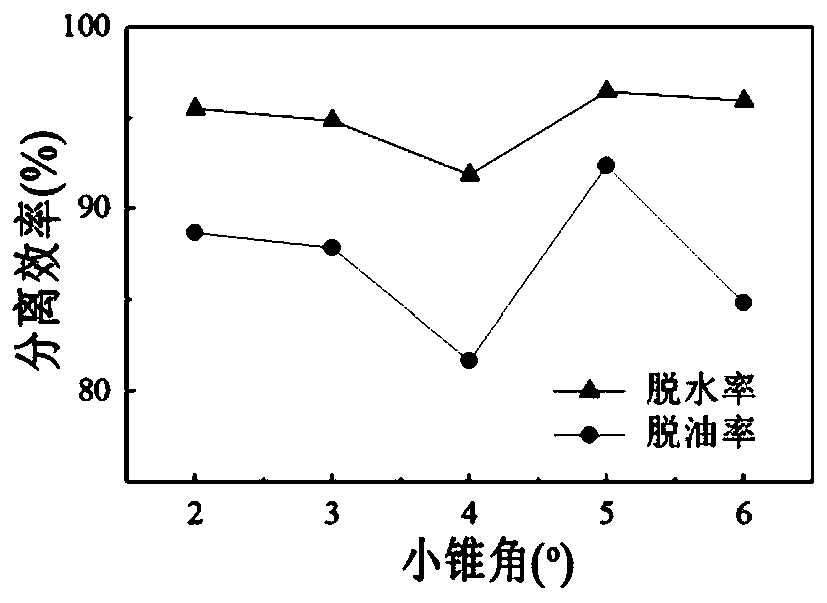

Double-field coupled dewatering device and parameter optimization method

ActiveCN109868157ABest parameter combinationAchieve combinatorial optimizationDewatering/demulsification with mechanical meansLiquid separation by electricityCouplingCombinatorial optimization

The invention discloses a double-field coupled dewatering device and a parameter optimization method. The parameter optimization method comprises the steps that firstly, parameters to be optimized aredetermined; the double-field coupled dewatering devices are simulated one by one; the optimum ranges of the parameters to be optimized are determined according to the simulation results; then the optimum parameter combination of the parameters to be optimized is determined; the double-field coupled dewatering devices are simulated one by one; the separation efficiency of the double-field coupleddewatering device is obtained under different combinations of optimization parameters; and the optimum combination of optimization parameters is determined according to the separation efficiency. Through simultaneously considering the influence of single parameter on separation efficiency and the influence of the interaction between parameters on separation efficiency, and combining with the numerical simulation results of double-field coupling, the combined optimization of structure parameters or operation parameters of the double-field coupled dewatering device can be realized by using Desing-Expert software for analysis. The method can provide a reasonable solution to the parameter matching problem of the coupled dewatering device, and the optimum parameter combination of the double-field coupled dewatering device is obtained.

Owner:CHONGQING TECH & BUSINESS UNIV

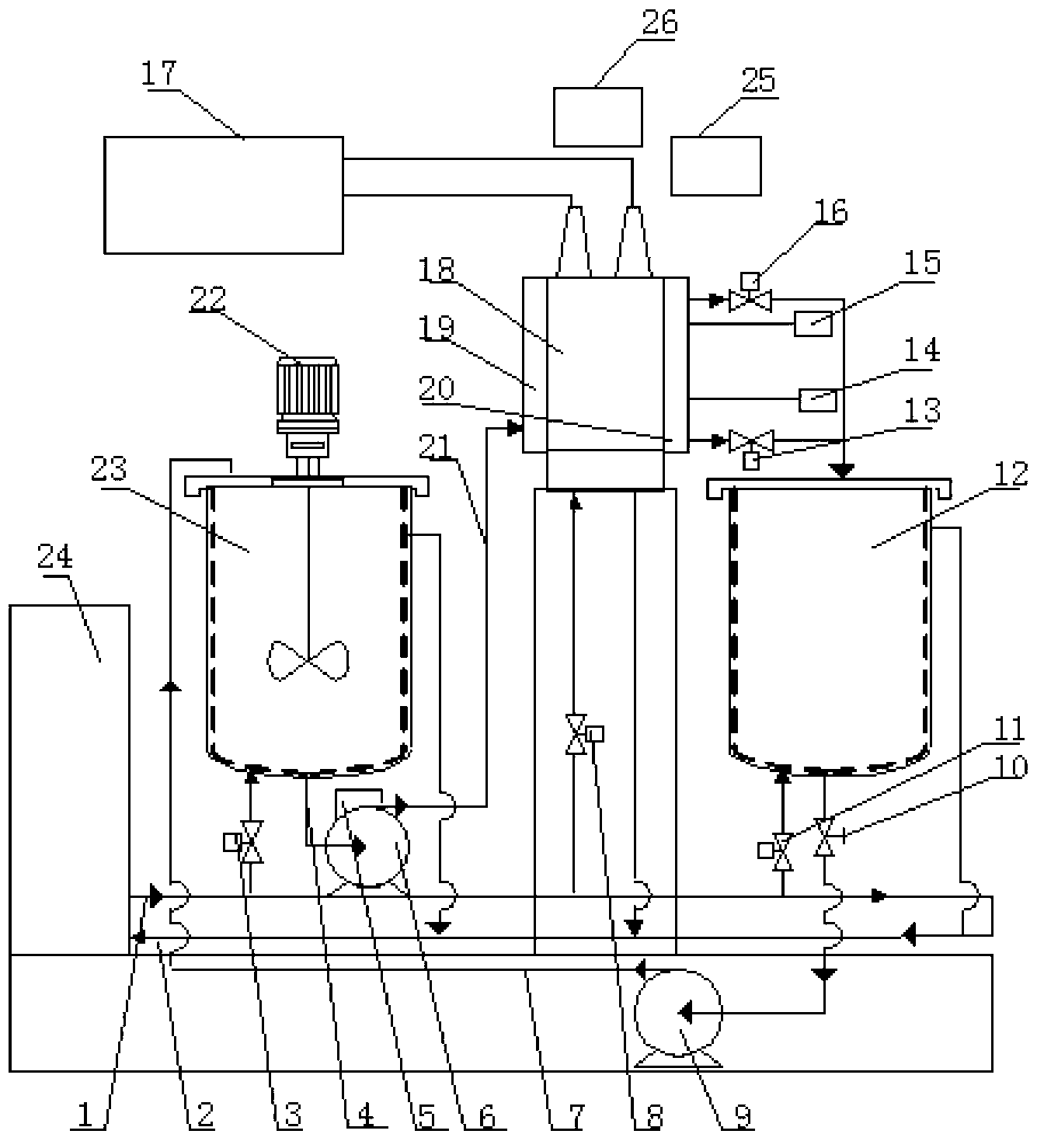

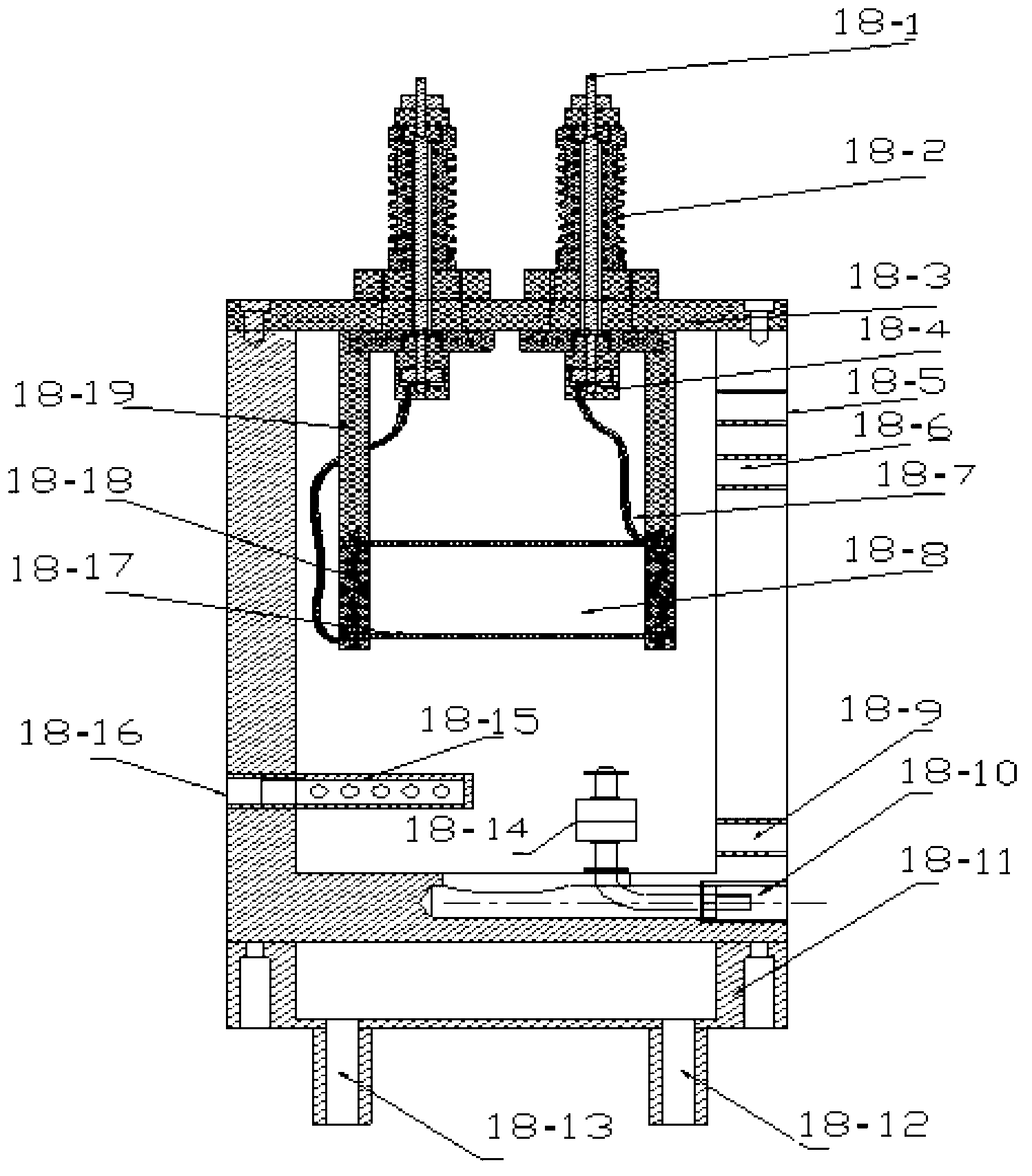

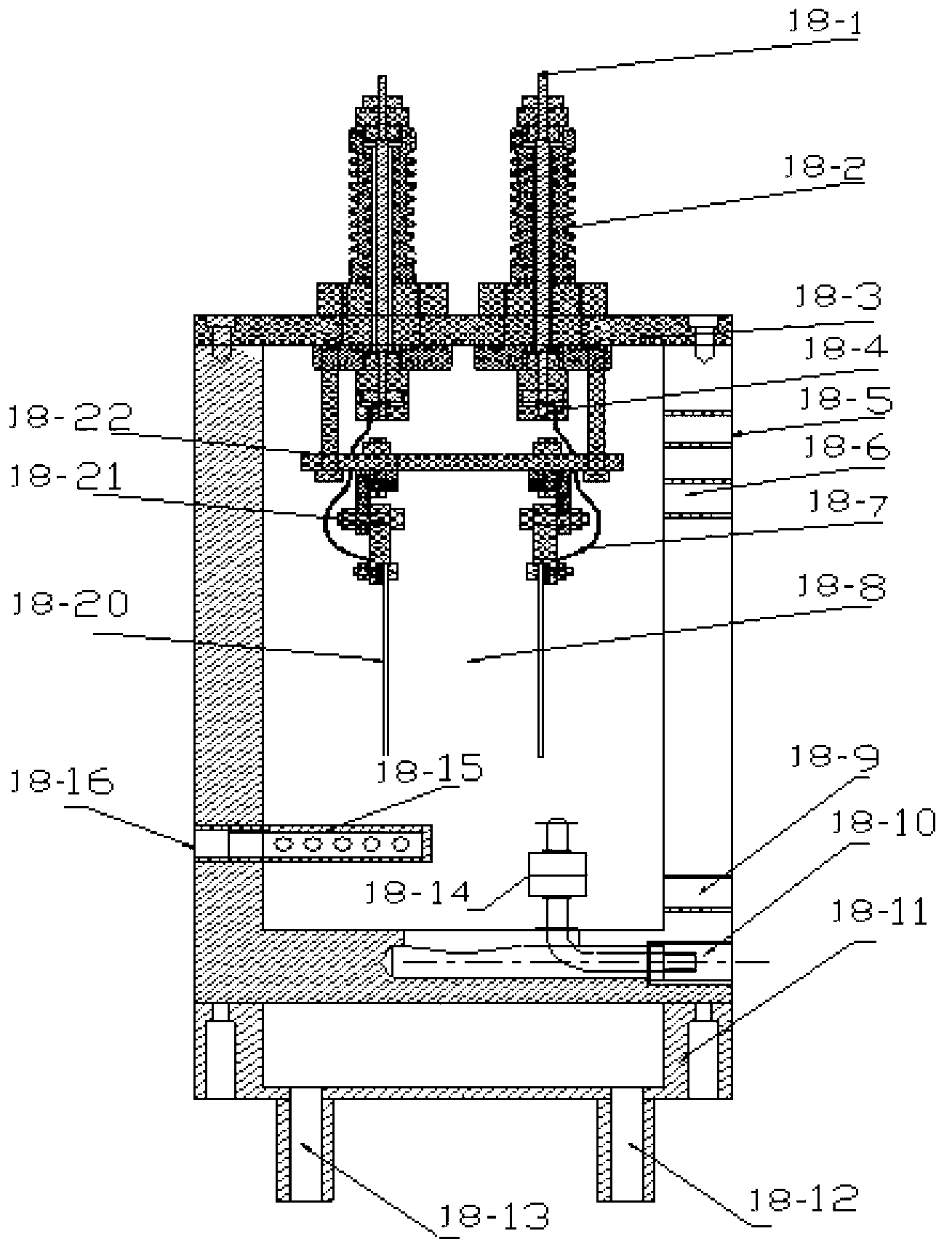

Crude oil electric dehydration dynamic visualization simulation device and method for preparing dehydrated crude oil by utilizing same

InactiveCN103059909AChange outputAdjust the size of the electric fieldDewatering/demulsification with electric/magnetic meansDewatering/demulsification regulation/controlHigh pressureMixing tank

The invention discloses a crude oil electric dehydration dynamic visualization simulation device and a method for preparing dehydrated crude oil by utilizing the same and relate to the technical field of high voltage and insulation. The device and the method are used for mainly solving the problem that experimental data obtained by the existing laboratory crude oil electric dehydration device and data used in an actual production have large difference. The device comprises a high voltage power supply, a mold temperature machine, an emulsion shear mixing tank, a crude oil metering pump, a crude oil flow controller, a high-voltage dehydrator, a waste liquid tank and a circulation pump. The method for preparing the dehydrated crude oil by utilizing the crude oil electric dehydration dynamic visualization simulation device comprises the following steps: 1, adding crude oil to the emulsion shear mixing tank; and 2, carrying out electric dehydration. The method can be used for accurately controlling crude oil dehydration parameters, analyzing dehydration rules and summarizing optimum dehydration parameters which have important guiding significance for selection of high voltage power supply parameters and polar plate spacing in an electric dehydrator, and can be used for preparing the dehydrated crude oil.

Owner:HARBIN UNIV OF SCI & TECH

Desalter/dehydrator system

A desalter / dehydrator system that comprises a pressure vessel, and first and second distribution headers disposed within the pressure vessel. The first distribution header is configured to inject an oil / water emulsion at a location within an electric field generated within the pressure vessel. The second distribution header is configured to inject the oil / water emulsion at a location below an electric field generated within the pressure vessel.

Owner:FORUM US

Demulsification of emulsified petroleum using carbon dioxide and resin supplement without precipitation of asphaltenes

ActiveUS20150184085A1Promote ruptureInhibition of agglomerationDewatering/demulsification with chemical meansTreatment with plural serial refining stagesOil phasePetroleum

Methods for demulsifying an emulsified petroleum source having a predetermined resin-to-asphaltene ratio without substantial aggregation or precipitation of asphaltenes may include adding a resin supplement to the emulsified petroleum source to form a resin-supplemented emulsion having a resin-to-asphaltene ratio above a predetermined critical value. An acidic-to-basic ratio of acidic functional groups to basic functional groups in the supplemented emulsion may be adjusted to be from about 0.25 to about 4.0. The resin-supplemented emulsion may be contacted with carbon dioxide to form an initial mixture having an emulsified oil phase and an emulsified aqueous phase. The initial mixture may be stabilized to facilitate rupture of the resin-supplemented emulsion, to cause phase separation, and to allow removal of a separated oil phase. The resin-to-asphaltene ratio being above the predetermined critical value in the supplemented emulsion maintains asphaltene suspension during demulsification, such that asphaltene agglomeration and precipitation are avoided.

Owner:SAUDI ARABIAN OIL CO

Dynamic demulsification system for use in a gas-oil separation plant

ActiveUS9555345B2Liquid separation auxillary apparatusLiquid separation by electricityMicrowaveOil separation

A dynamic water / oil demulsification system for a gas-oil separation plant (GOSP) includes:an in-line microwave treatment subsystem upstream of one or more of each of a dehydrator vessel, desalter vessel and / or water / oil separator vessel, each of which vessels receives a water-oil emulsion;sensors that monitor and transmit data corresponding to properties of the water-oil emulsion in or downstream of the respective vessel(s); anda processor / controller associated with the in-line microwave treatment subsystem that initiates the application of microwave energy to the emulsion(s) based on the data from the sensors.

Owner:SAUDI ARABIAN OIL CO

Desalting plant systems and methods for enhanced tight emulsion crude oil treatment

ActiveUS20200255748A1Effective controlEliminate effectiveLiquid separation auxillary apparatusFatty/oily/floating substances removal devicesDesalinationOil separation

Systems and methods for treating a rag layer in a gas oil separation plant. The method includes withdrawing the rag layer from a vessel proximate an oil water interface, conveying the rag layer to a separation device, and recycling separated oil from the separation device back to the gas oil separation plant process.

Owner:SAUDI ARABIAN OIL CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com