Novel pipeline-type automatic dehydrater for oil tank

A pipeline type, dehydrator technology, applied in the field of dehydrators, can solve the problems of large maintenance and inaccurate monitoring, and achieve the effect of accurate and effective dehydration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

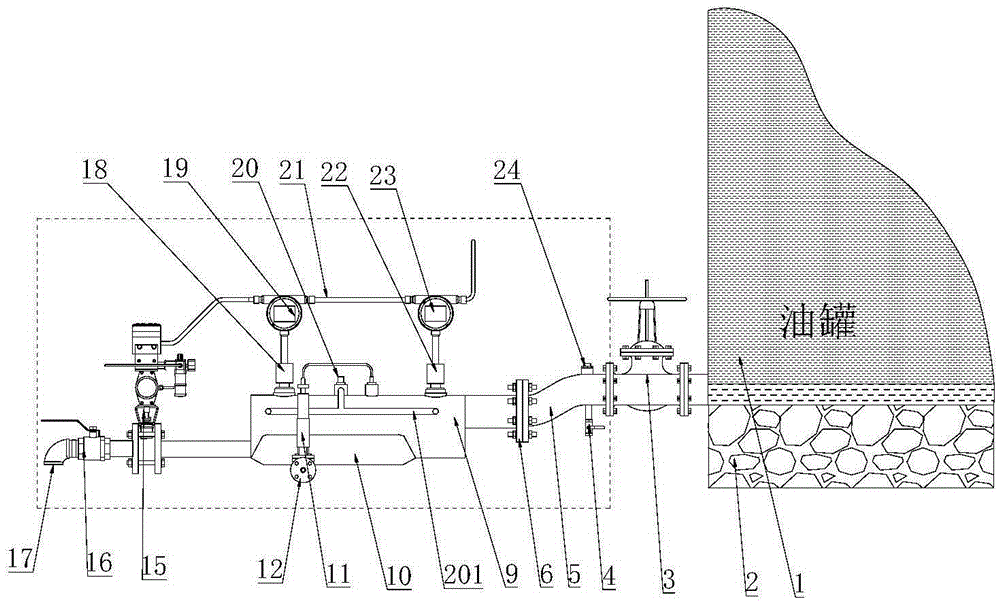

[0036] Such as figure 1 As shown, the novel pipeline type oil tank automatic dehydrator of the present invention includes a dehydration pipeline 9, a first sensor 22 arranged on the dehydration pipeline 9, a second sensor 18, and a first sensor connected to the first sensor 22. The controller 23, the second controller 19 connected to the second sensor 18, and the dehydration valve 15 for controlling the switch of the dehydration pipeline 9, the first sensor 22 and the second sensor 18 detect the oil and water passing through the dehydration pipeline 9 Proportion. The first controller 23 and the second controller 19 jointly control the opening and closing of the dehydration valve 15 according to the monitoring data fed back by the first sensor 22 and the second sensor 18 respectively.

[0037] Both ends of the dehydration pipeline 9 are respectively provided with a first mounting flange 6 and a second mounting flange, and one end of the first mounting flange 6 is connected to ...

Embodiment 2

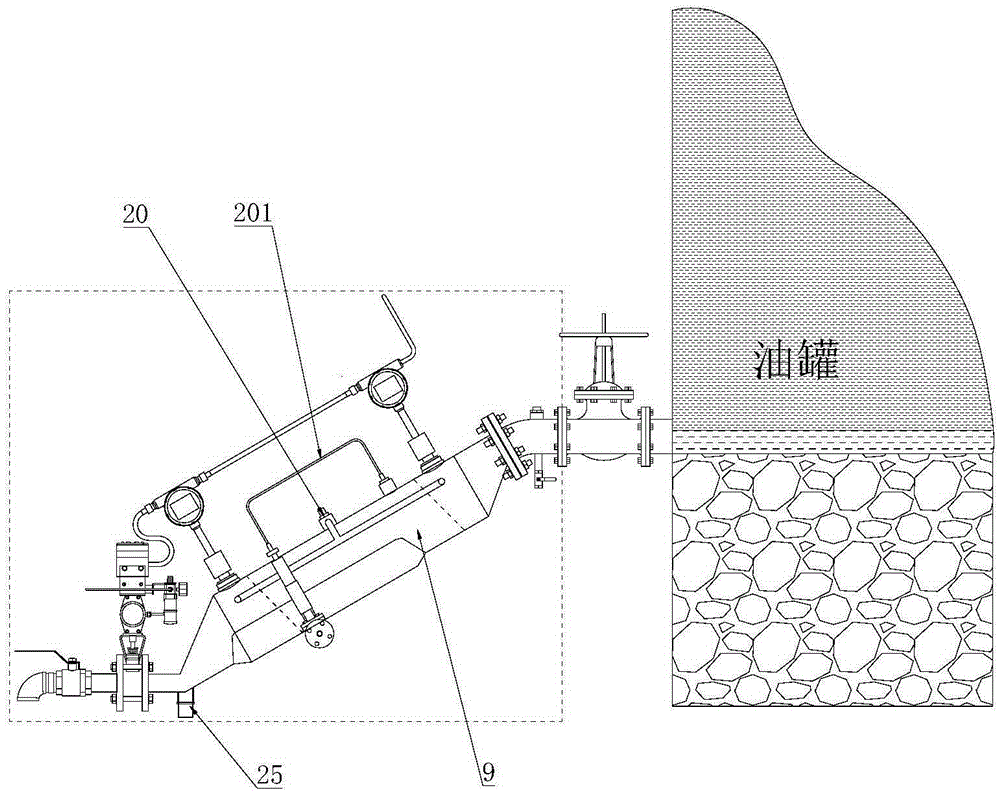

[0049] Such as figure 2 As shown, in this embodiment, except that the dehydration pipeline 9 is installed obliquely, other structures and working principles are the same as those in Embodiment 1. The dehydration pipeline 9 in this embodiment is installed obliquely, and the two ends of the dehydration pipeline 9 are respectively provided with eccentric big and small ends, and the eccentric big and small heads are integrally formed with the dehydration pipeline 9, and the small end of the eccentric big and small head is connected to the mounting flange connect. The first installation flange is connected with the oil tank 1 and is at a higher position, and the second installation flange is at a lower position for discharging water discharged through the dehydrator.

Embodiment 3

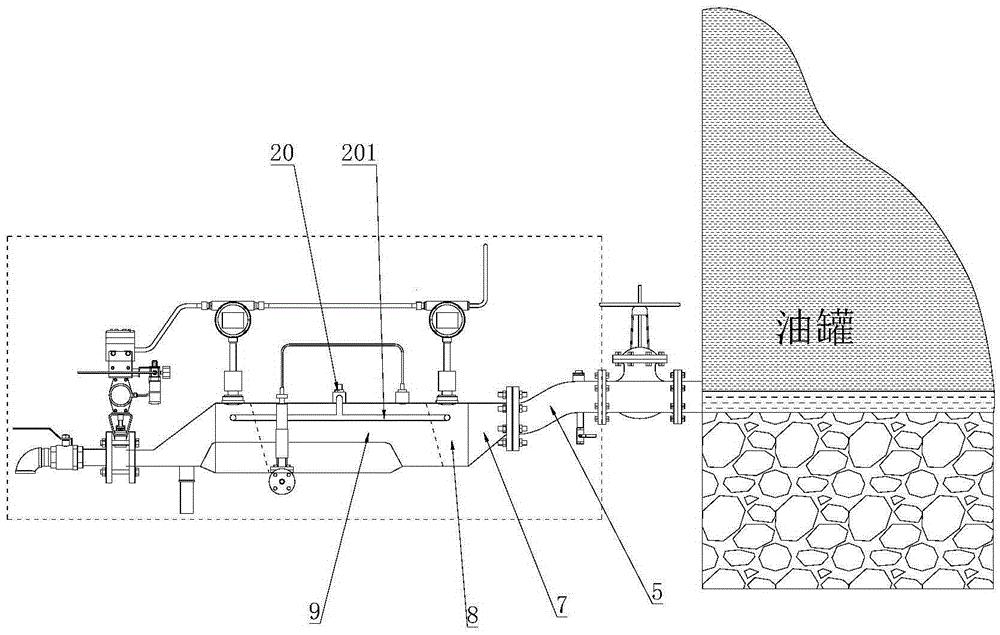

[0051] Such as image 3As shown, the new pipeline type oil tank automatic dehydrator described in this embodiment, except for the structure of the dehydration pipeline, other structures and working principles are the same as those in Embodiment 1, and the two ends of the dehydration pipeline 9 are respectively provided with first Eccentric small head 7, second eccentric small head 14, the dehydration pipeline 9 is horizontally arranged, one end of the small head of the first eccentric small head 7 is connected with the first mounting flange 6, the second eccentric small head 14 One end of the small head is connected with the second mounting flange.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com