Automatic crude oil demulsification and dehydration device, and its control method

A technology of demulsification device and dehydration device, which is applied in the directions of dehydration/demulsification regulation/control, immiscible liquid separation, liquid separation auxiliary equipment, etc. The effect of industrial automatic production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

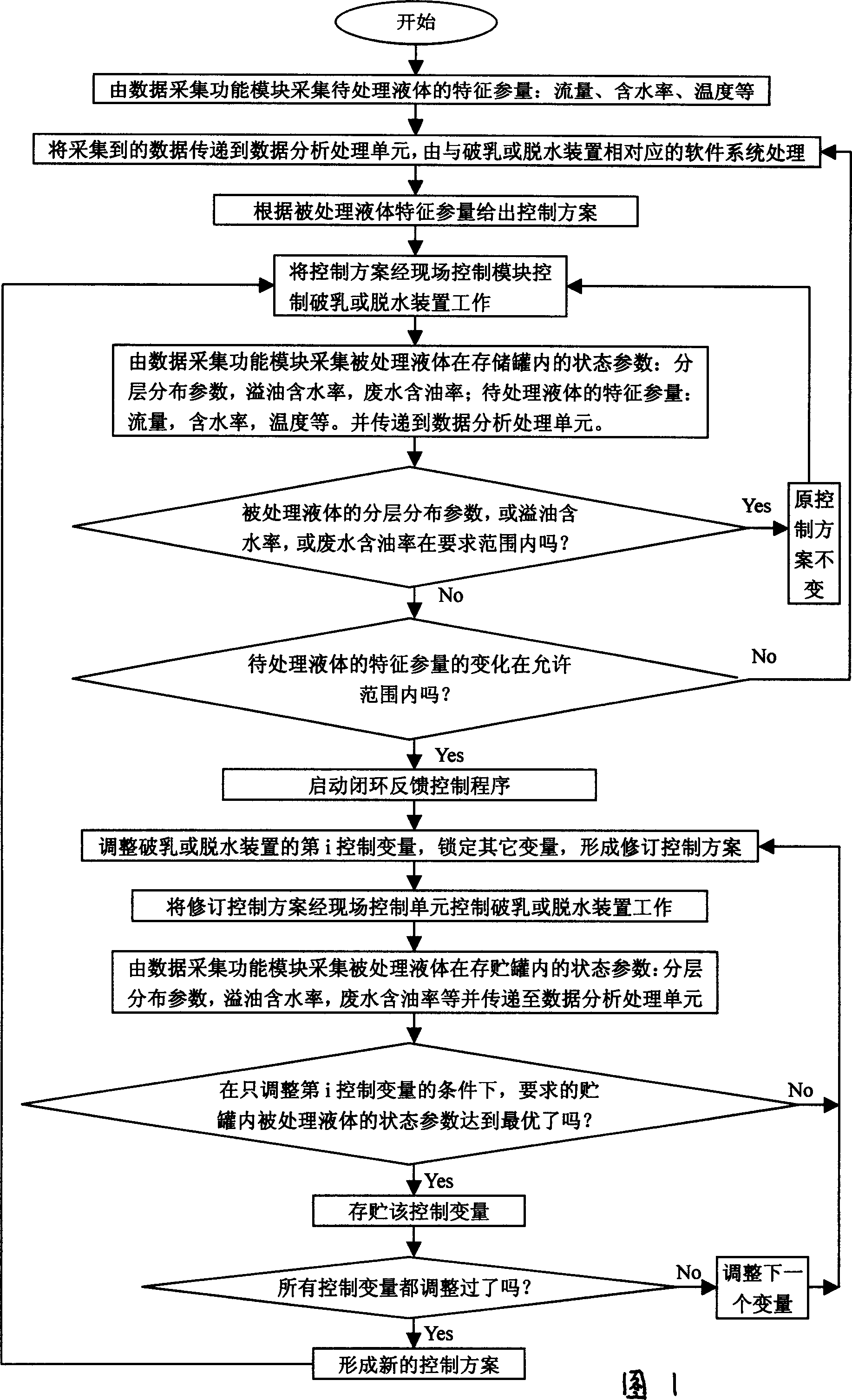

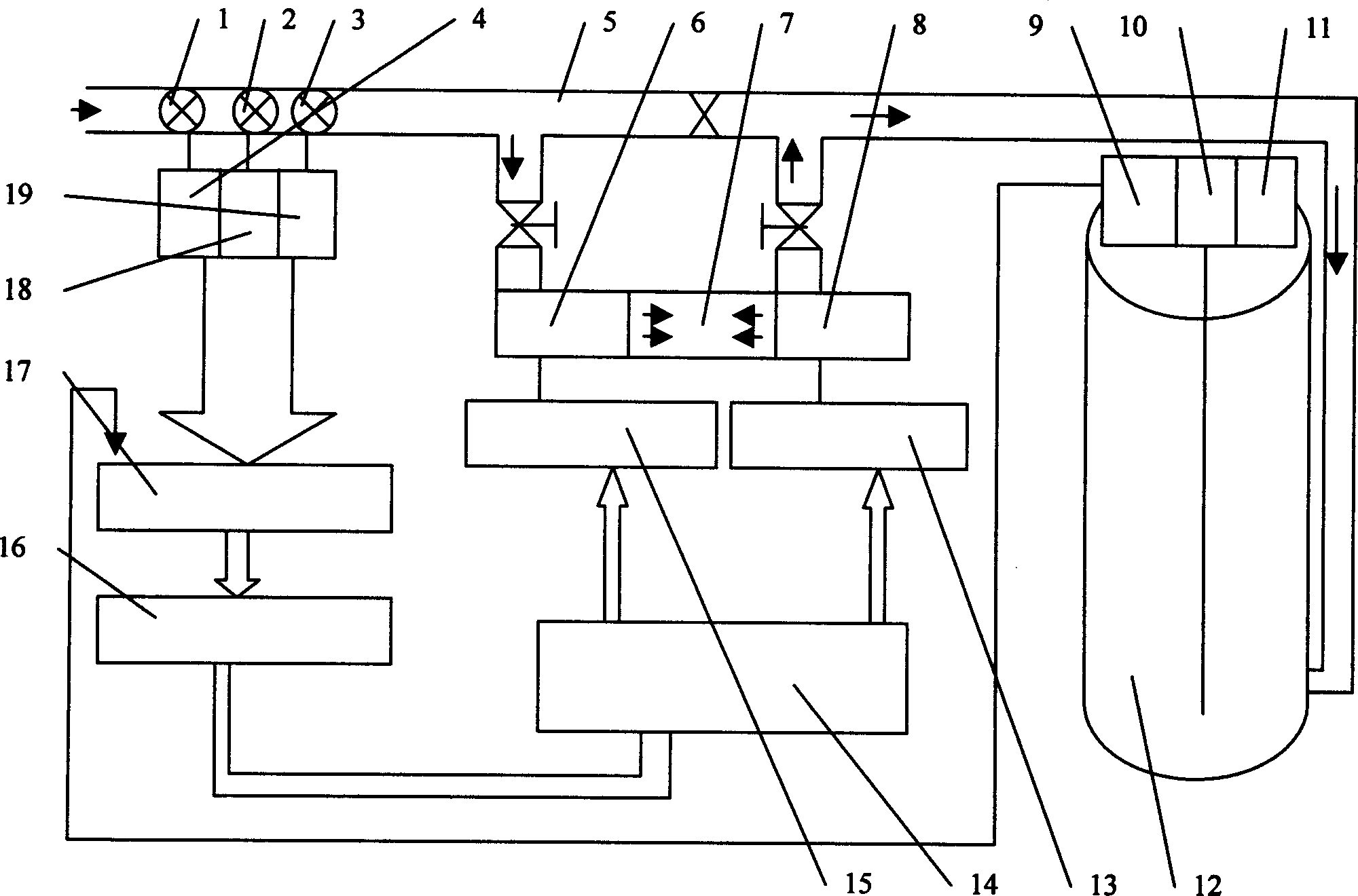

[0023] figure 1, figure 2 As shown, the demulsification device is connected between the crude oil input pipeline 5 and the storage tank 12. The demulsification device adopts an ultrasonic demulsification device. Composition, its structure is known to those of ordinary skill in the art, ultrasonic generator 15, ultrasonic generator 13 are electrically connected with data output control unit 14, and crude oil input pipeline 5 is provided with flow monitoring probe 1 and moisture content monitoring probe 2 , the temperature monitoring probe 3, the flow monitoring probe 1 and the moisture content monitoring probe 2, the temperature monitoring probe 3 respectively through the flow monitoring instrument 4 and the moisture content monitoring instrument 18, the temperature monitoring instrument 19 is electrically connected with the data acquisition unit 17, the storage tank 12 There are mixed storage medium stratification monitoring instrument 9 and oil spill water content monitoring ...

Embodiment 2

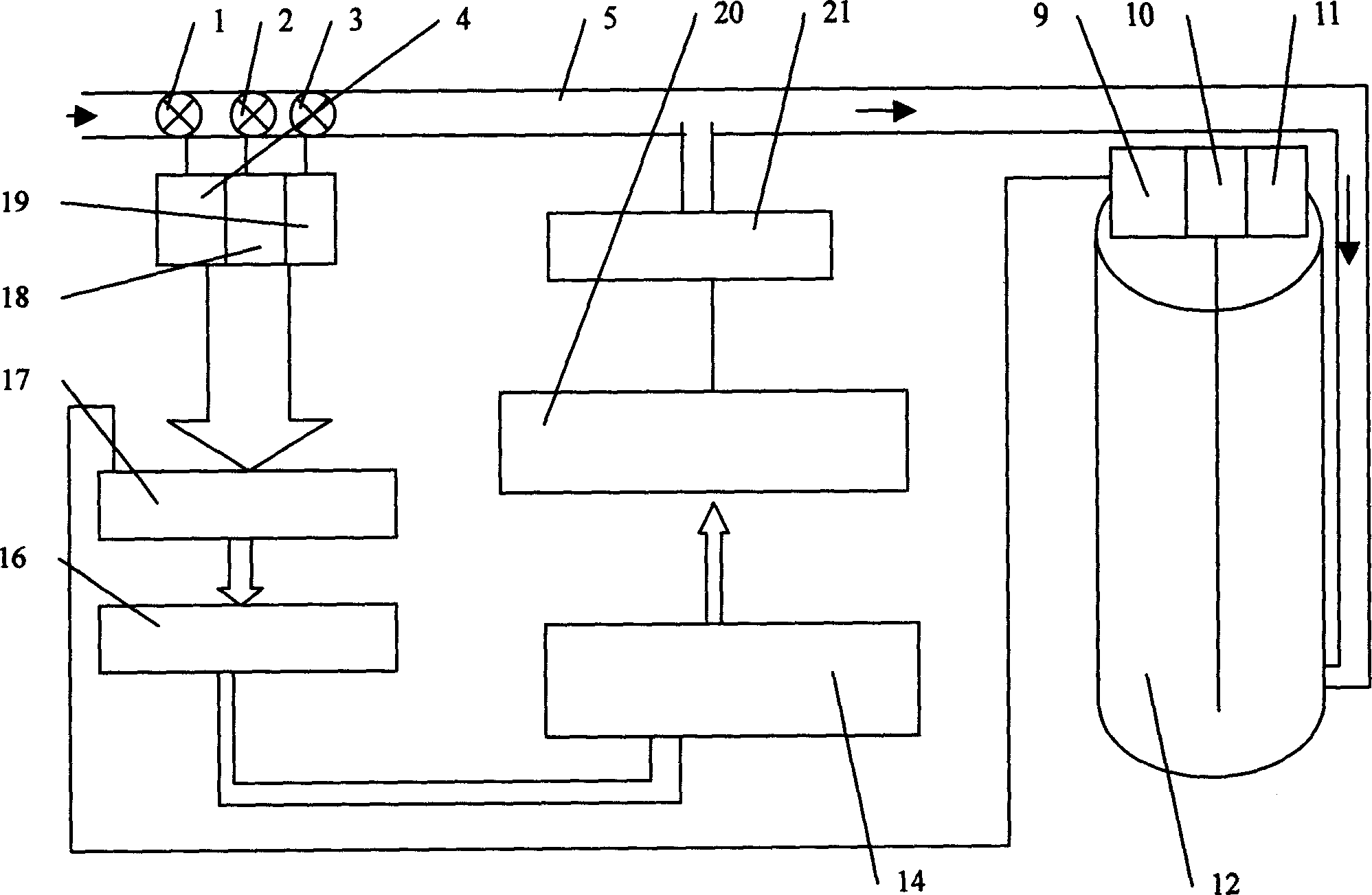

[0030] Embodiment two: the characteristic parameters of the liquid to be treated in the crude oil pipeline 5 can only collect one or any two of flow, water content, temperature (or a combination of parameters containing at least one of the above parameters), and flow monitoring corresponding to this Probe 1, moisture content monitoring probe 2, temperature monitoring probe 3 and flow monitor 4, moisture content monitoring instrument 18, temperature monitoring instrument 19 also only use one or any two. Similarly, the state parameters of the treated liquid in the storage tank 12 can also only collect one or any two of the oil-water layer distribution value, the water content of oil spill and the oil content of waste water (or a combination of parameters containing at least one of the above parameters) , mixed storage medium stratification condition monitor 9 and oil spill water content monitor 10, waste water oil content monitor 11 also just use one or any two thereupon. The co...

Embodiment 3

[0035] Figure 1, figure 2 As shown, the structure of the automatic demulsification device in this embodiment is the same as that in Embodiment 1.

[0036]The control method implemented in this embodiment is aimed at the situation that the characteristic parameters (flow, water content, temperature) of the liquid to be treated fluctuate greatly: the data acquisition unit 17 first passes through the flow monitor 4, the water content monitor 18, the temperature monitor 19 and The flow monitoring probe 1, the water content monitoring probe 2 and the temperature monitoring probe 3 connected thereto collect the flow rate, water content and temperature characteristic parameters of the liquid to be treated in the crude oil input pipeline 5, and the data acquisition unit 17 passes the received data through After sequence processing, it is converted into a digital signal convenient for system processing and transmission and passed to the data analysis and processing unit 16. The CPU of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com