Visual recognition detection pile dividing counting machine

A visual recognition and visual detection technology, applied in the field of visual recognition and detection stacking counting machines, can solve the problems of limited PCB automation, lack, slow speed, etc., and achieve the effect of satisfying industrialized automatic production and reasonable design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

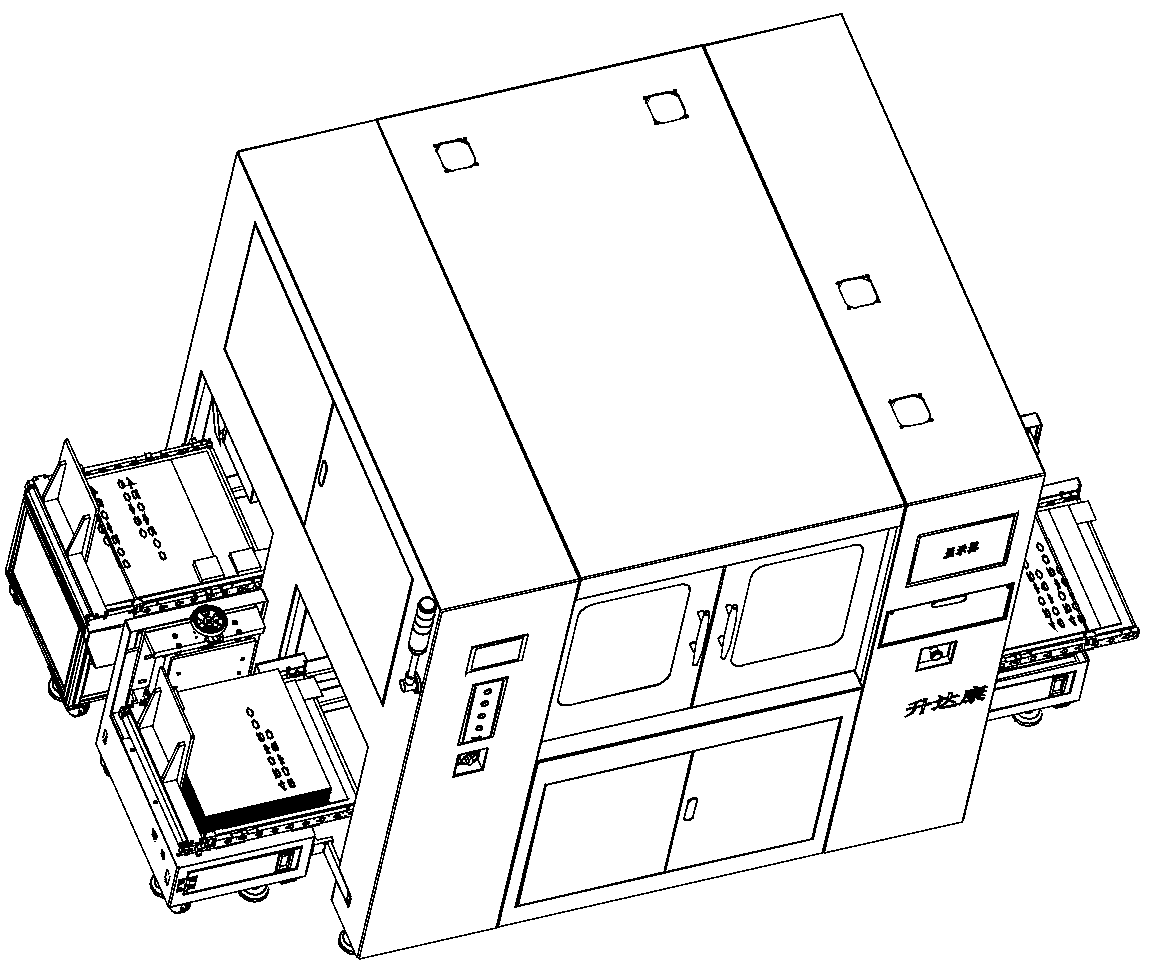

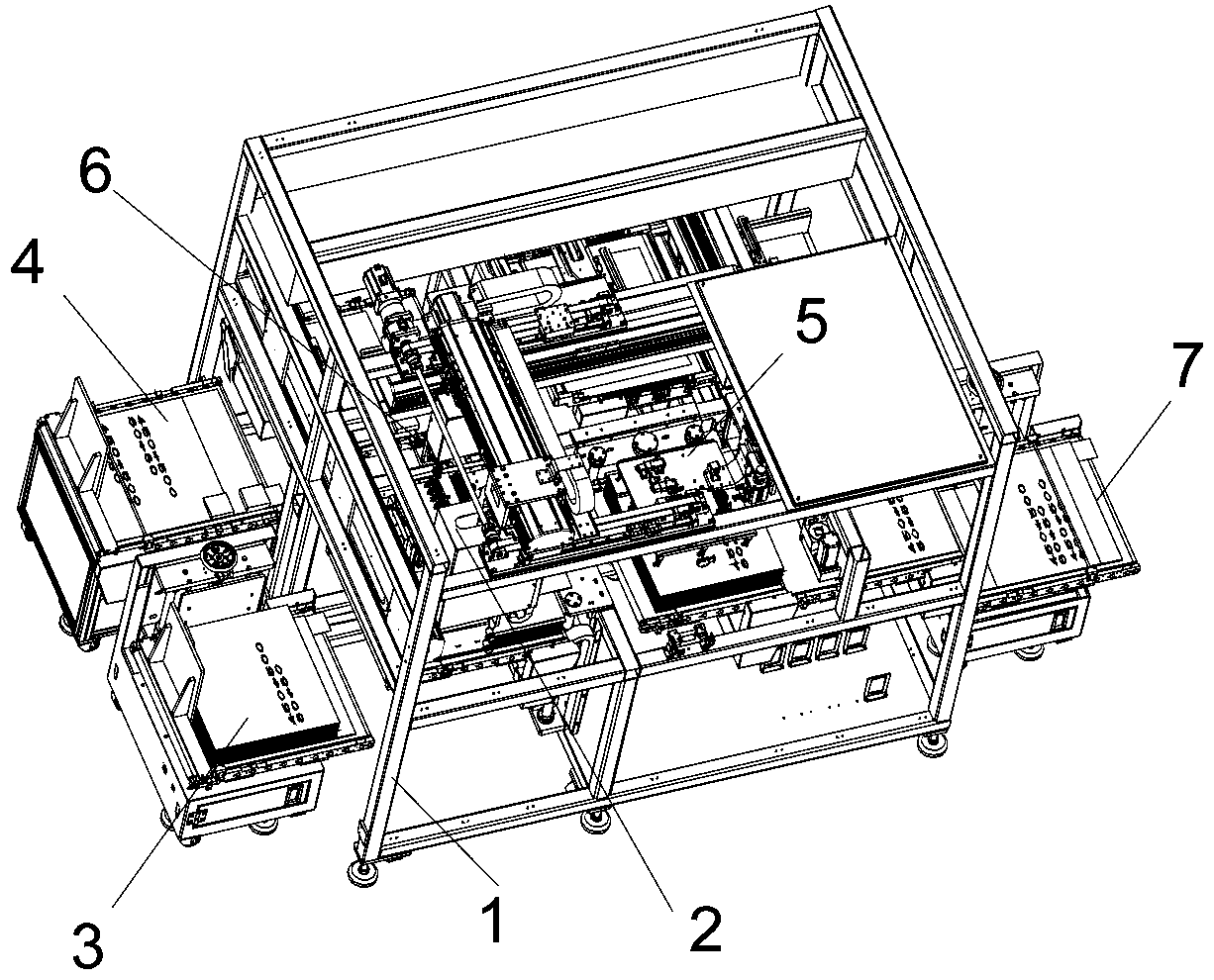

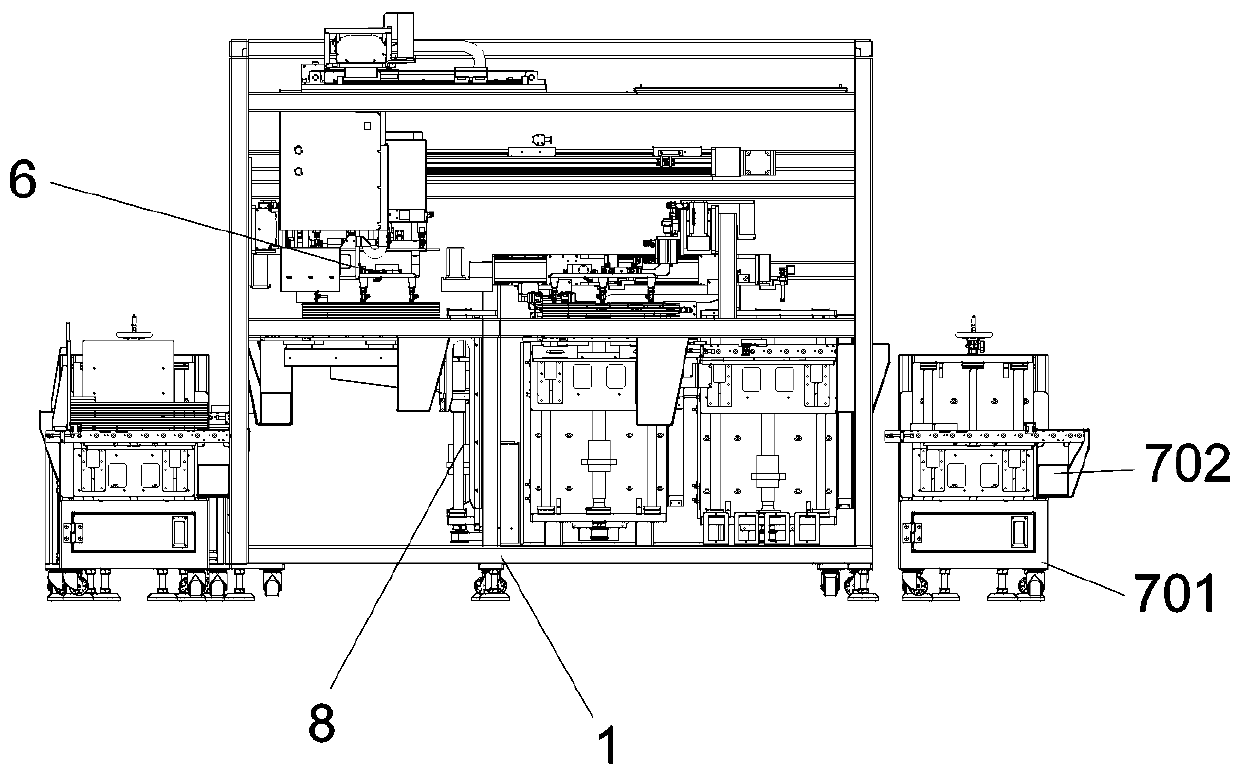

[0036] Such as Figure 1-9 As shown, it includes machine 1, controller, visual inspection component 2, PCB feeding device 3, NG discharging device 4, paper separation device 5, PCB grabbing device 6, PCB discharging device 7, NG discharging device The device 4 and the PCB discharge device 8 are both cart-type structures with the same structure; the machine table 1 is provided with a matching position for respectively cooperating with the PCB feeding device 3, the NG discharge device 4, and the PCB discharge device 7, and is installed on the Three sets of lifting mechanisms 8 in the matching position; the visual inspection component 2, the paper separating device 5, and the PCB grabbing device 6 are all installed on the top of the machine 1 through the bracket; the visual inspection component 2 is aligned with the PCB feeding device 3 ; The PCB grabbing device 6 is in alignment with the PCB feeding device 3 and the PCB discharging device 7; the NG discharging device 4 is also i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com