Demulsification dehydration apparatus for aged crude oil

A technology of aging crude oil and dehydration device, which is applied in the direction of mechanical dehydration/demulsification, dehydration/demulsification adjustment/control, etc., which can solve the problems of difficult effective dehydration, large difference in processing capacity, high processing cost, etc., and achieve improvement Demulsification efficiency and water droplet coalescence speed, improvement of processing capacity and work efficiency, and effect of reducing water content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

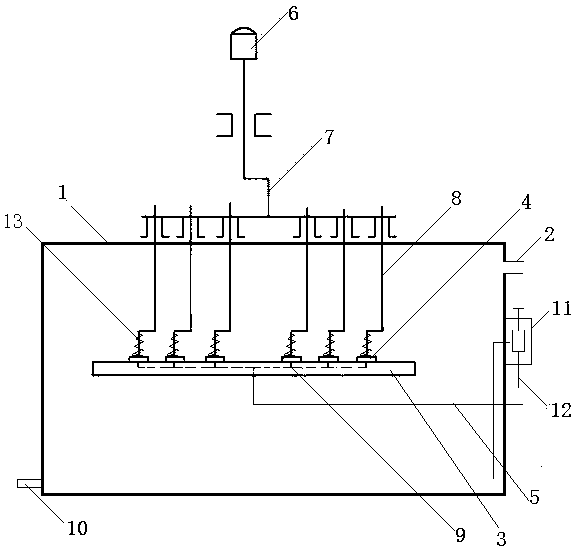

[0016] see figure 1 , the names of parts are as follows: box body 1, oil spill port 2, fixed end face 3, rotary end face 4, supporting liquid supply pipeline 5, motor 6, crank connecting rod machine 7, crank 8, liquid hole 9, active water inlet 10, Water level regulator 11, water overflow port 12, spring 13.

[0017] see figure 1 , a demulsification and dehydration device for aging crude oil, including a box 1, in which there is 80-90°C high-temperature active water (water with chemical demulsifier added), the box 1 has a high-temperature water inlet, and the water passes through the hot water The water pump circulates continuously to maintain the active water temperature in the tank at 80-90°C. There is an active water inlet 10 at the bottom of the box body 1, an oil overflow port 2, a water level regulator 11, and a water overflow port 12 at the top of the box body 1. There are multiple rotary rolling and rubbing demulsification mechanisms in the box body 1, and the number...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com