Tank dewatering sensing and valve control method and apparatus

a technology of sensing valve and dewatering method, which is applied in the direction of filtration separation, borehole/well accessories, separation process, etc., can solve the problems of complex fittings of density sensors, high cost of recovering oil from containment area, and reliability and accuracy of such a dewatering method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061]It is to be noted that the discussions contained in the “Background” section and that above relating to prior art arrangements relate to discussions of documents or devices which form public knowledge through their respective publication and / or use. Such should not be interpreted as a representation by the present inventor(s) or patent applicant that such documents or devices in any way form part of the common general knowledge in the art. References will be made later herein to Appendix A, B and C where:

[0062]Appendix A is a table showing kinematic viscosity of water and crude oil,

[0063]Appendix B is a table showing conductivity information for water and crude oil, and

[0064]Appendix C is a table showing density information for water and crude oil.

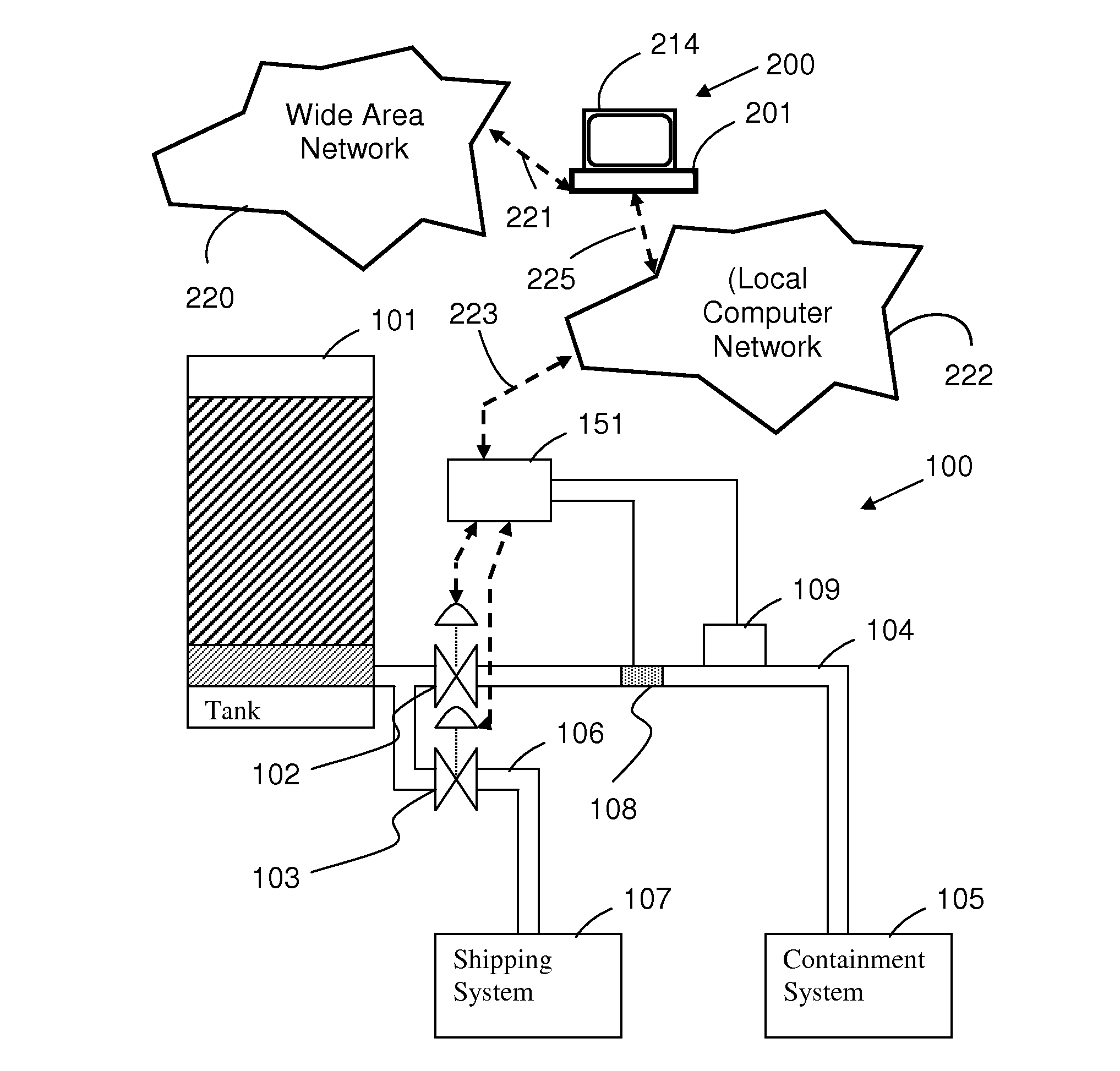

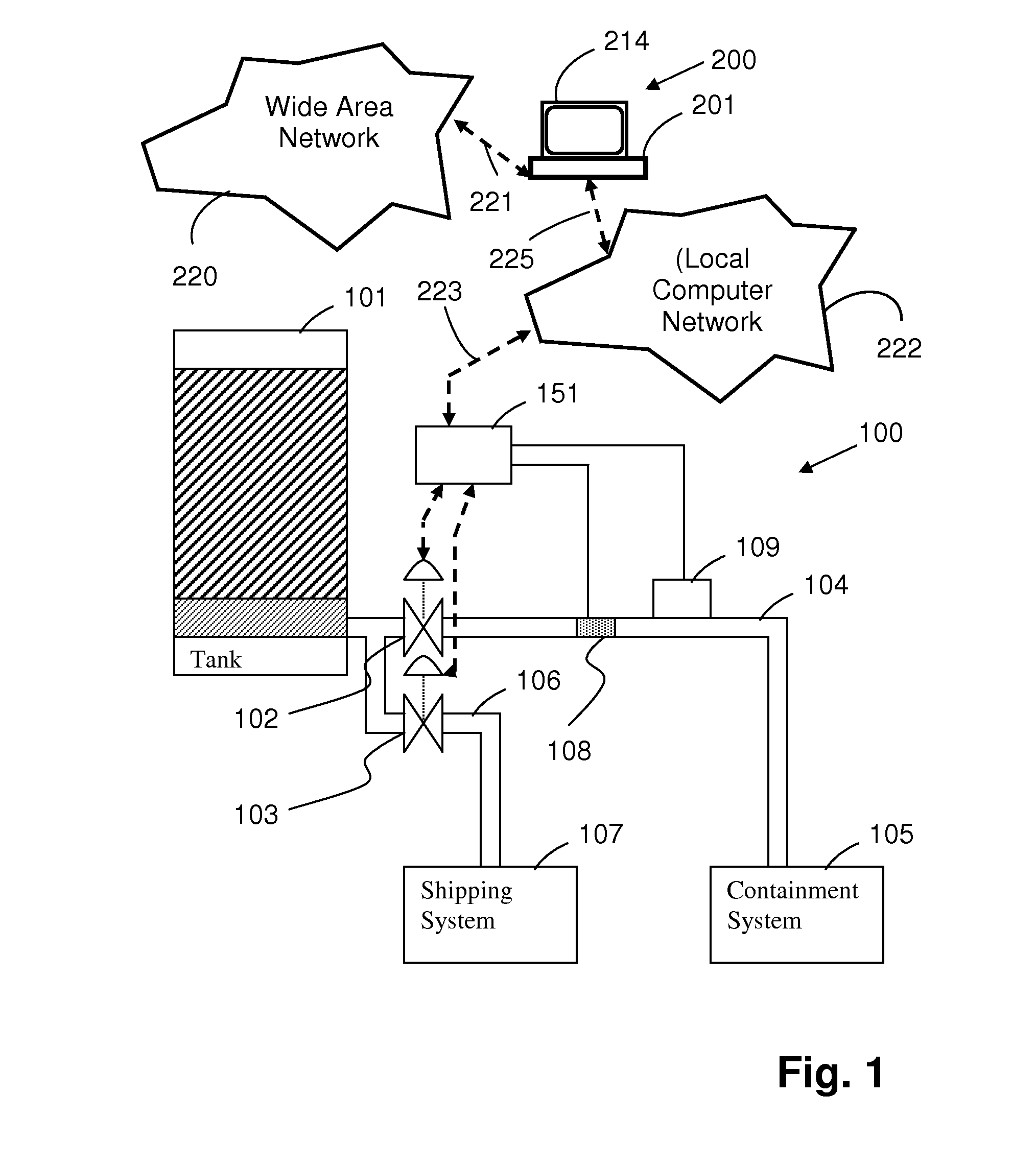

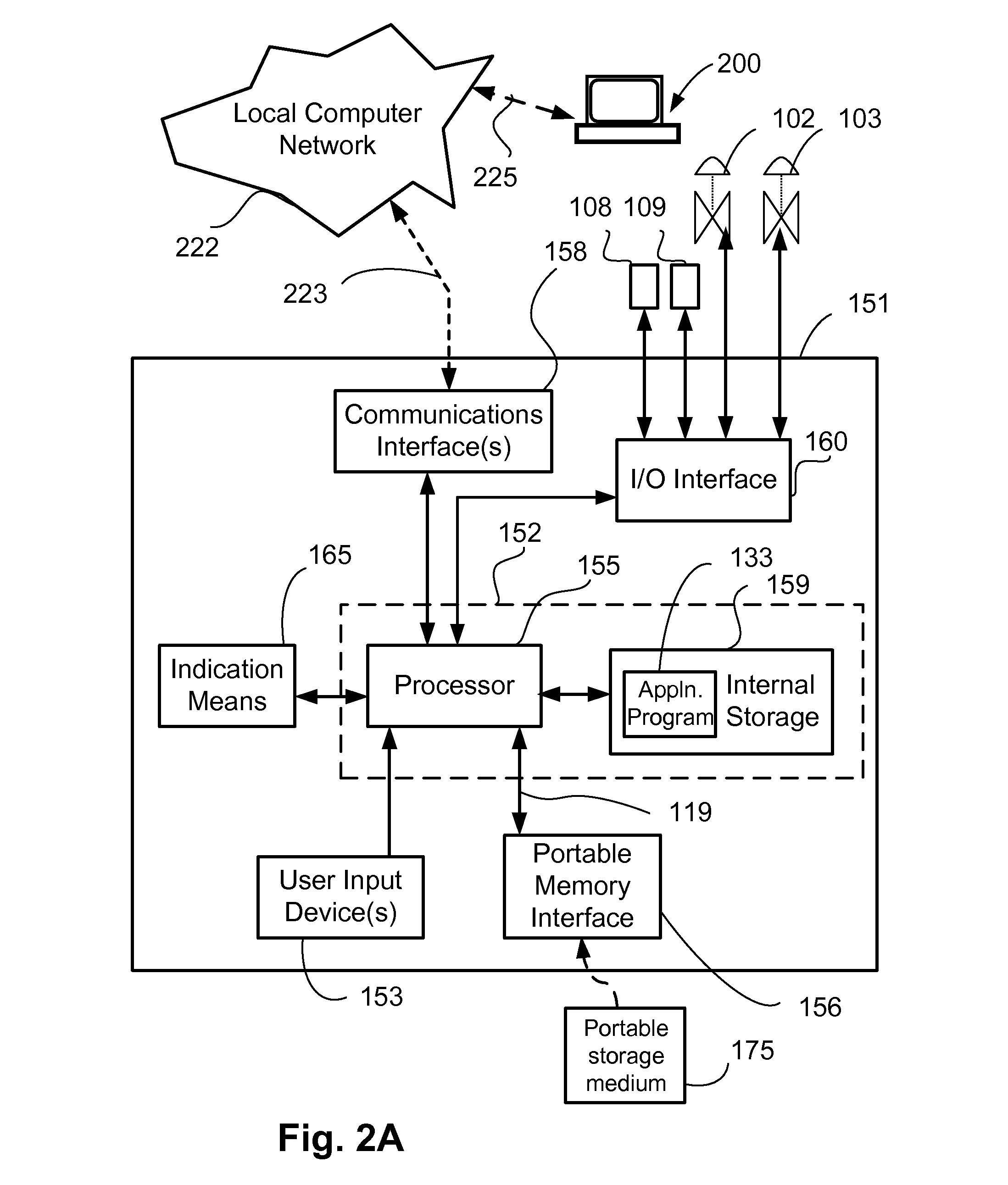

[0065]FIG. 1 shows a system 100 for dewatering a bulk-storage tank 101. The system 100 comprises two motorised valves 102 and 103. The valve 102 controls flow of liquid through a pipe 104 connecting the base of the tank 101 to a cont...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| kinematic viscosity | aaaaa | aaaaa |

| frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com