Control parameter optimization control system and method of crude oil dehydration power supply

A crude oil dehydration and power control technology, which is applied in the field of variable-step self-optimizing control systems, can solve the problems of unstable crude oil dehydration effect, weak impact force of emulsion film, and production impact in oilfields, so as to improve oil-water separation effect and sedimentation. The effect of increased velocity and increased impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing:

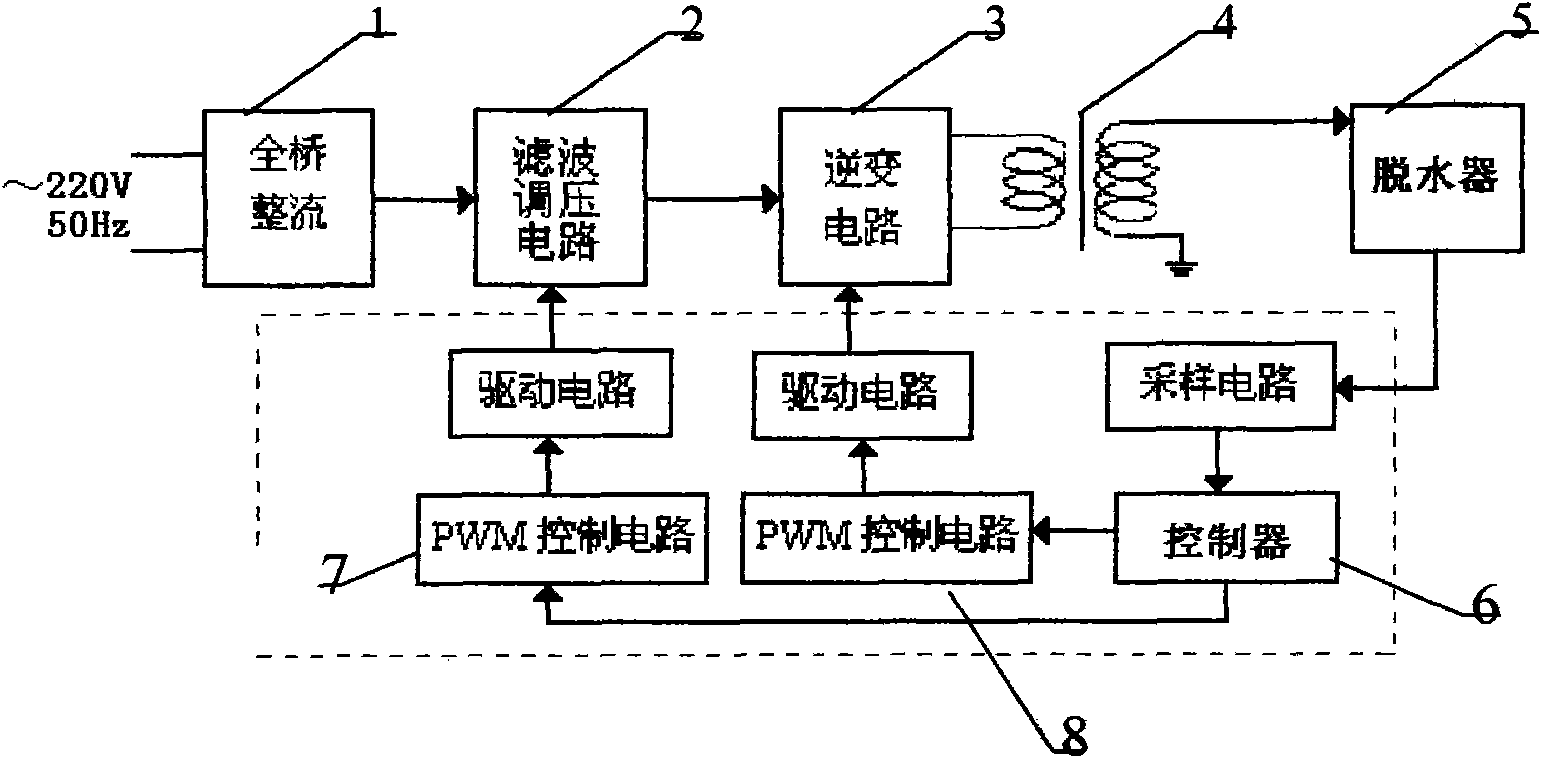

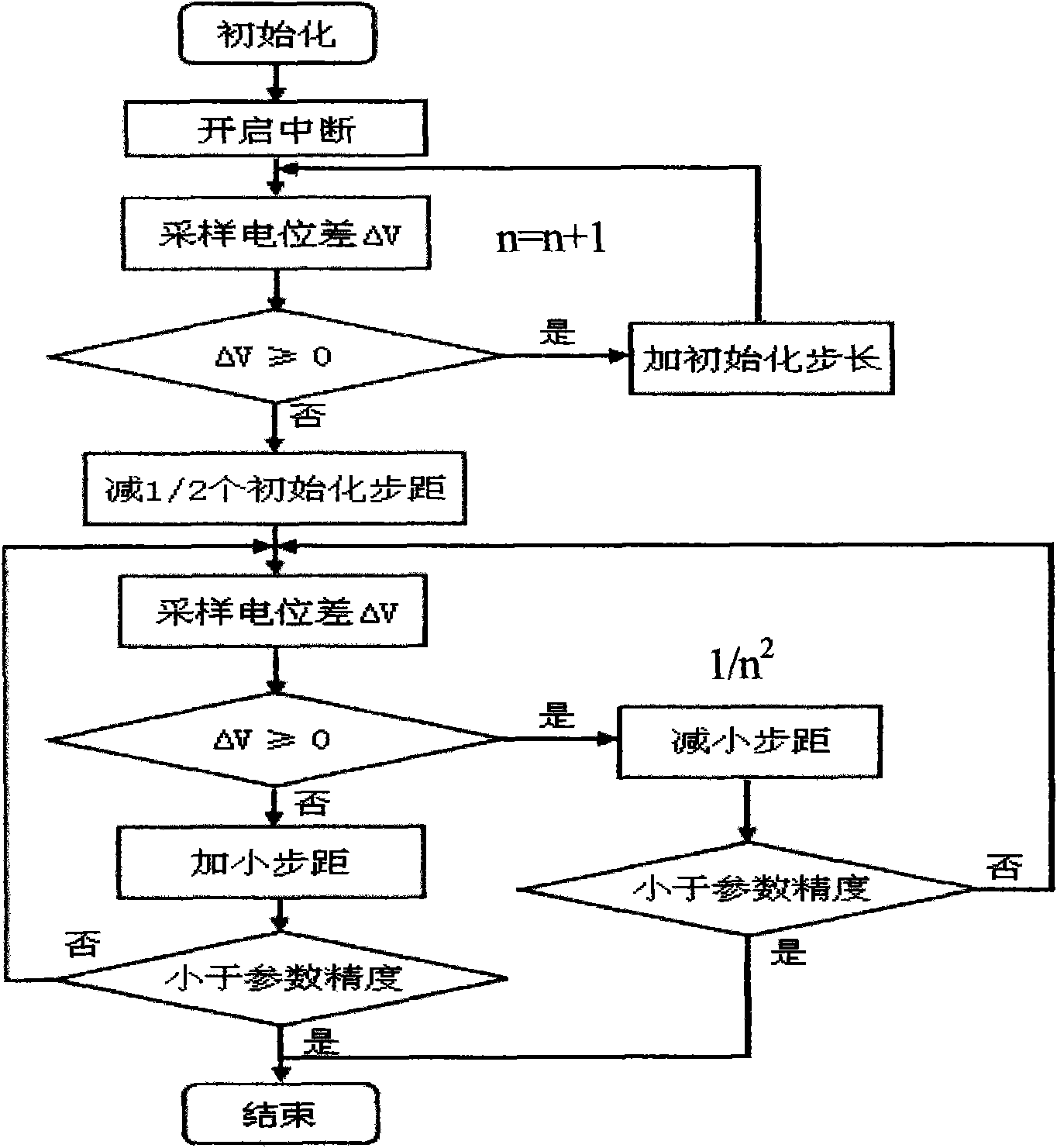

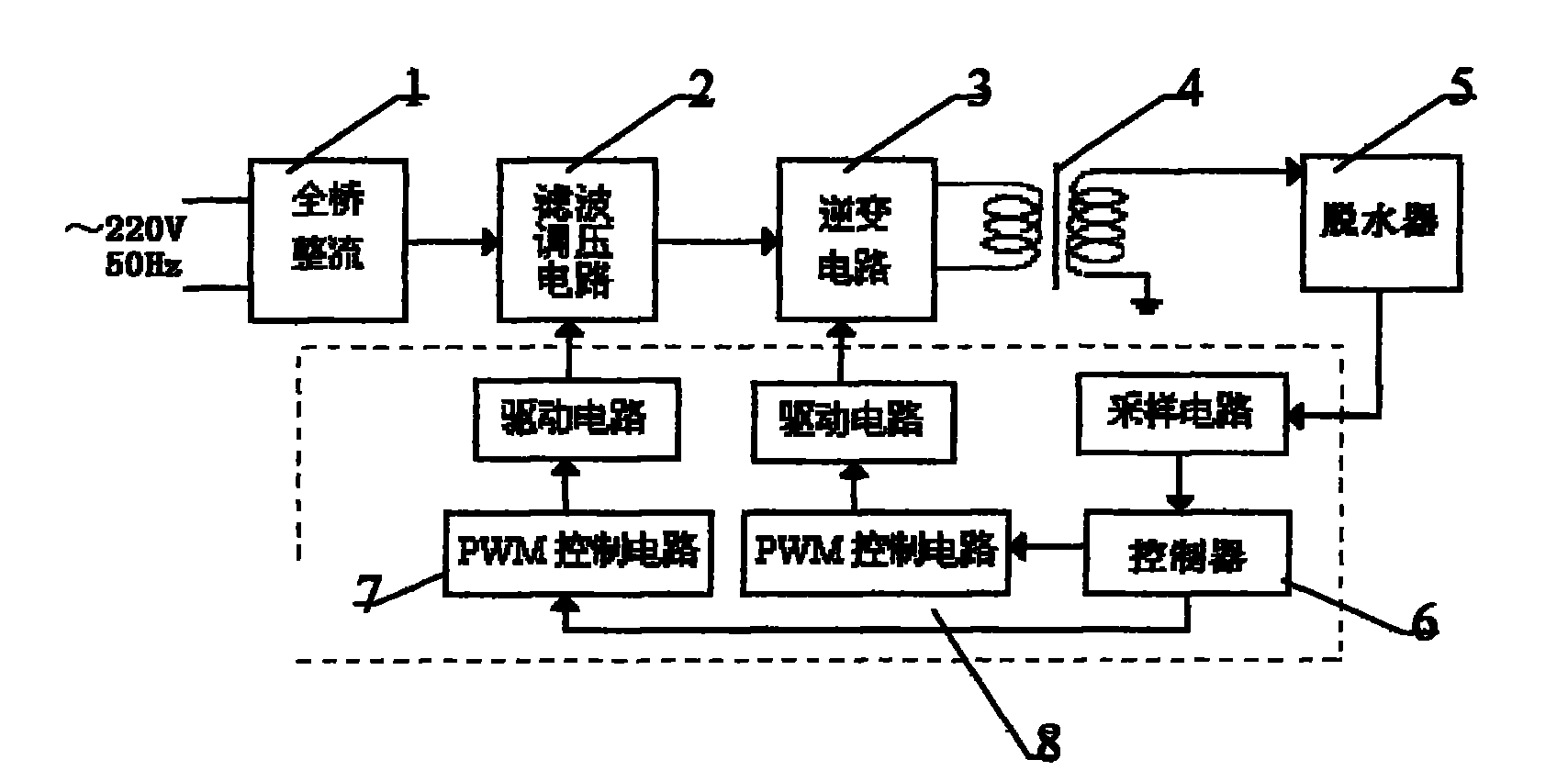

[0018] A crude oil dehydration power supply control parameter optimization control system, the main circuit of the power supply is composed of a rectifier circuit 1, a filter voltage regulating circuit 2, an inverter circuit 3, and a transformer 4 in sequence, wherein: the main circuit is also provided with a transformer The step size self-optimizing intelligent controller 6 samples the change of the moisture content of crude oil in the crude oil dehydrator through the sensor sampling circuit, converts the changed value into a voltage signal, and sends it to the controller 6. The comparison of two sampling values, the PWM control circuit 7 of the control part of the DC chopper voltage regulating circuit 2 controlled by the controller 6 and the PWM control circuit 8 of the control part of the inverter circuit 3 output the size of the PWM drive signal duty cycle , to control ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com