Crude oil electric dehydration dynamic visualization simulation device and method for preparing dehydrated crude oil by utilizing same

A simulation device, electric dehydration technology, applied in the direction of electric/magnetic dehydration/demulsification, dehydration/demulsification adjustment/control, etc., can solve the problem of large data differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

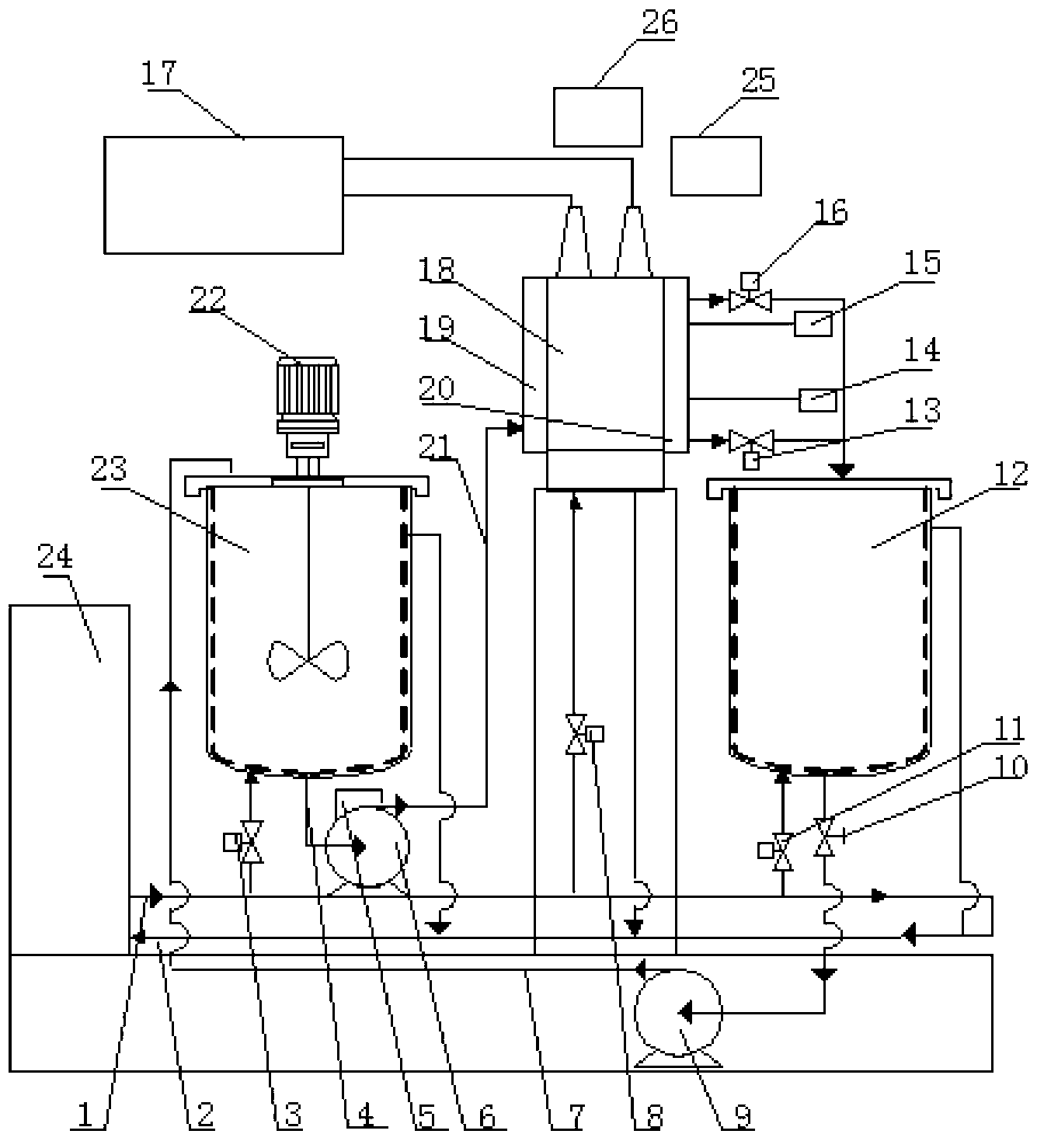

[0018] Specific Embodiment 1: The dynamic visualization simulation device for electric dehydration of crude oil in this embodiment includes: a high voltage power supply 17, a mold temperature controller 24, an emulsification and shear blending tank 23, a crude oil metering pump 6, a high voltage electric dehydrator 18, and a waste liquid tank 12. Circulation pump 9, characterized in that: the top of the high-voltage bushing 18-2 at the upper end of the high-voltage electric dehydrator 18 is connected to a high-voltage power supply 17, and the outlet of the emulsification shear blending tank 23 is connected to the inlet of the high-voltage electric dehydrator 18. A crude oil metering pump 6 is connected between them, and a crude oil flow controller 5 is arranged at the outlet of the crude oil metering pump 6. The inlet and outlet of the crude oil metering pump 6 pass through the crude oil delivery pipeline 21 and the liquid outlet 4 of the emulsification and shearing blending tan...

specific Embodiment approach 2

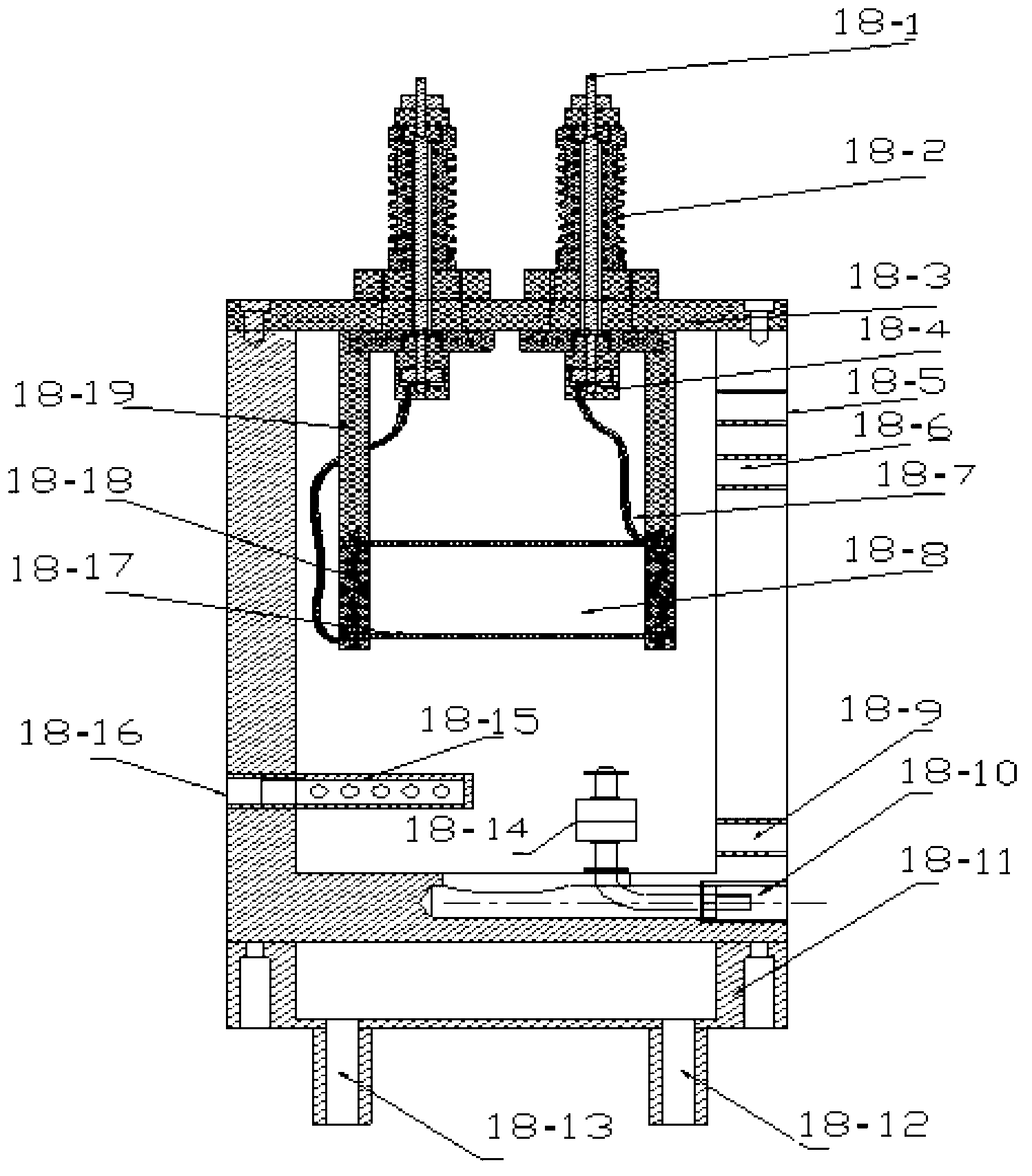

[0020] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the high-voltage electric dehydrator 18 includes: electrode guide rod 18-1, high-voltage bushing 18-2, high-voltage electric dehydrator upper cover 18- 3. Bushing connection protection cap 18-4, oil phase outlet 18-5, oil phase moisture content online detector interface 18-6, high voltage lead wire 18-7, electric field area 18-8, water phase moisture content online detector interface 18-9, water phase outlet 18-10, electric dehydrator insulation box 18-11, insulation box heat transfer oil inlet 18-12, insulation box heat transfer oil outlet 18-13, float switch 18-14, crude oil inlet buffer pipe 18-15, crude oil injection port 18-16, electric dehydrator horizontal hanging electrodes 18-17, horizontal hanging electrode spacing adjustment parts 18-18, horizontal hanging electrode insulating support parts 18-19, casing fasteners 18-24;

[0021]Wherein, the two electrode guide rod...

specific Embodiment approach 3

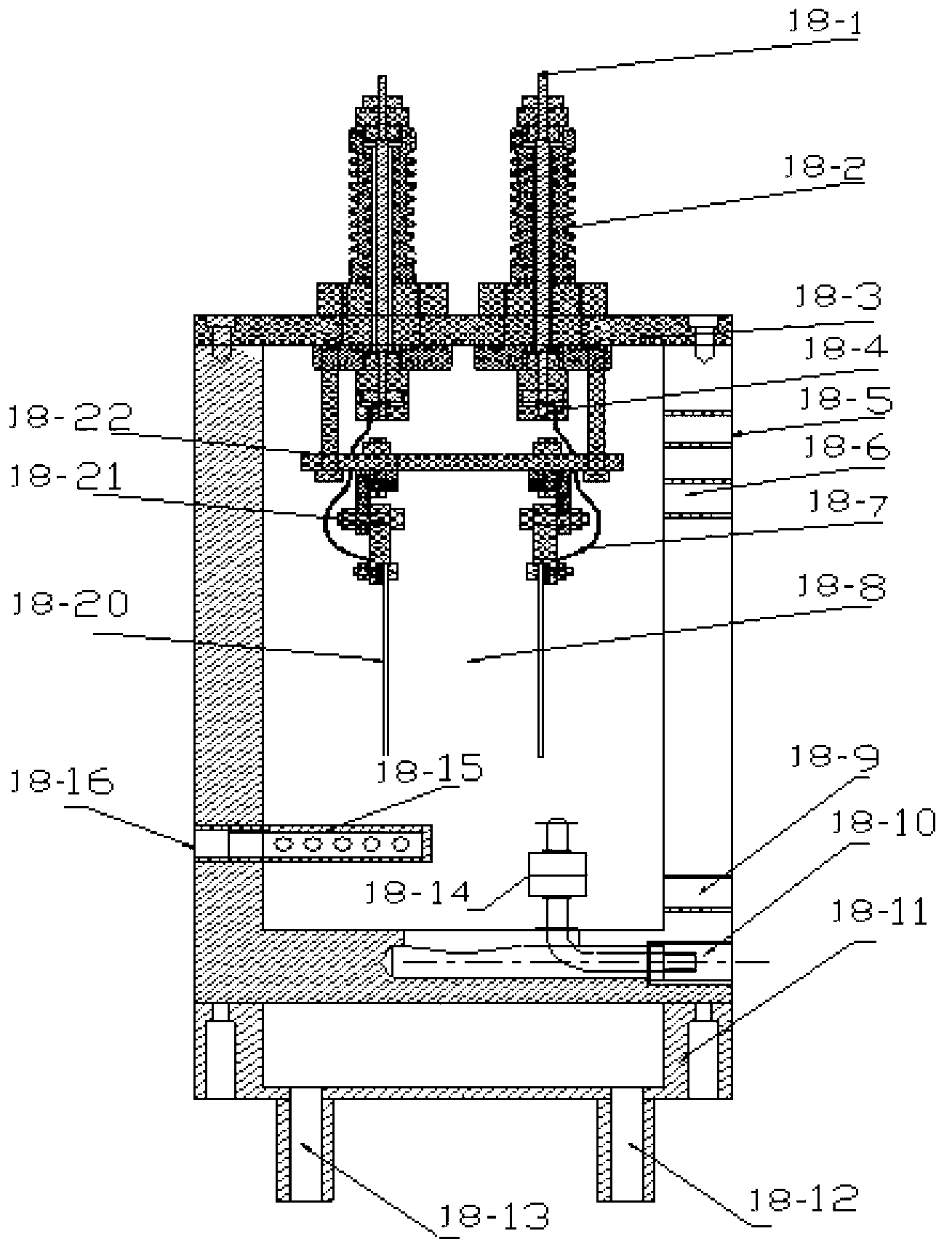

[0022] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is: the dynamic visualization simulation device for electric dehydration of crude oil, which is characterized in that the high-voltage electric dehydrator 18 includes: electrode guide rod 18-1 , High-voltage bushing 18-2, High-voltage electric dehydrator upper cover 18-3, Bushing connection protection cap 18-4, Oil phase outlet 18-5, Oil phase water content online detector interface 18-6, High voltage lead wire 18 -7. Electric field area 18-8, water phase water content online detector interface 18-9, water phase outlet 18-10, electric dehydrator insulation box 18-11, insulation box heat transfer oil inlet 18-12, insulation box heat transfer oil Outlet 18-13, float switch 18-14, crude oil inlet buffer pipe 18-15, crude oil injection port 18-16, electric dehydrator vertical electrode 18-20, vertical electrode connector 18-21, vertical electrode Plate spacing slideway plate 18-22, vertical electrode...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com