Double-field coupled dewatering device and parameter optimization method

A dual-field coupling and dehydration device technology, which is applied in chemical instruments and methods, separation methods, electric/magnetic dehydration/emulsification, etc., can solve the problems that the results are difficult to meet the requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

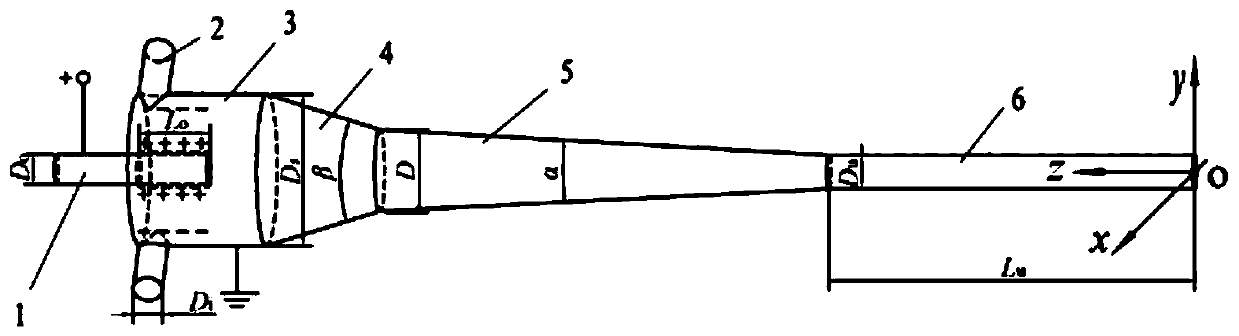

[0050] Such as figure 1 As shown, the double-field coupling dehydration device provided in this embodiment includes an overflow pipe, an inlet, a straight pipe section, a large cone section, a small cone section and an underflow pipe;

[0051] An overflow pipe and an inlet are arranged on the straight pipe section, the inlet is arranged on the outer wall of the straight pipe section, and the inlet is arranged tangent to the pipe wall of the straight pipe section, so that the liquid flow enters the straight pipe section according to a certain speed, and can be The flow rotates along the inner wall of the straight pipe section; the overflow pipe is arranged along the axial direction of the straight pipe section; It is connected with the large cone section, the other side of the large cone section is connected with the small cone section, and the other side of the small cone section is connected with the bottom flow pipe.

[0052] The outer wall of the overflow pipe is provided ...

Embodiment 2

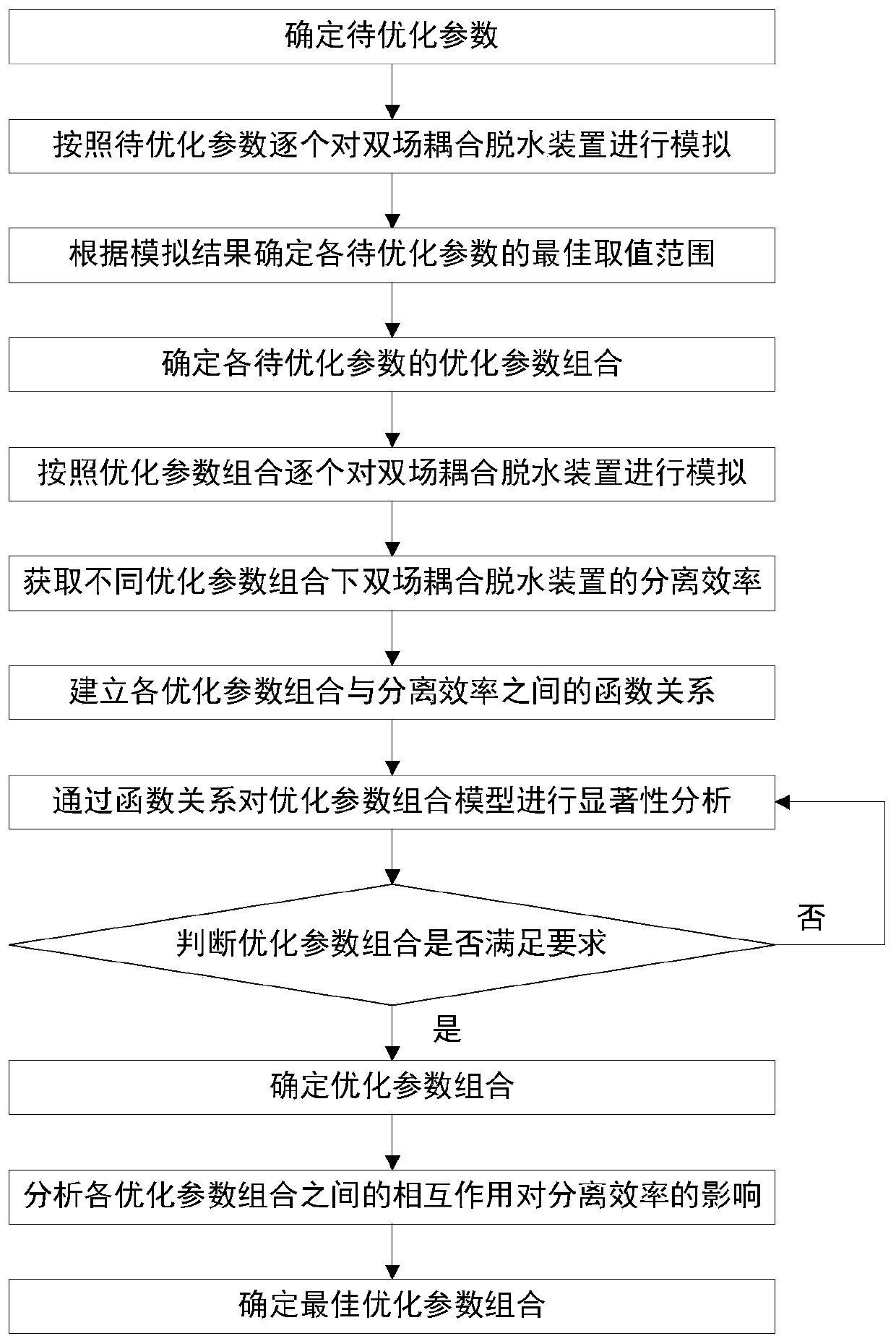

[0058] Such as figure 2 As shown, the parameter optimization method of the dual-field coupling dehydration device provided in this embodiment, this embodiment adopts the influence of a single parameter on the separation efficiency and the influence of the interaction between parameters on the separation efficiency, combined with the dual-field coupling numerical simulation As a result, the software Desing-Expert was used to analyze and obtain the optimal parameter combination of the double-field coupling dehydration device. The specific steps are as follows:

[0059] Determine the parameters to be optimized;

[0060]Simulate the dual-field coupling dehydration device one by one according to the parameters to be optimized; simulate the device under a certain setting condition;

[0061] Determine the optimal value range of each parameter to be optimized according to the simulation results; determine the optimal value range of each parameter by studying the influence of the cha...

Embodiment 3

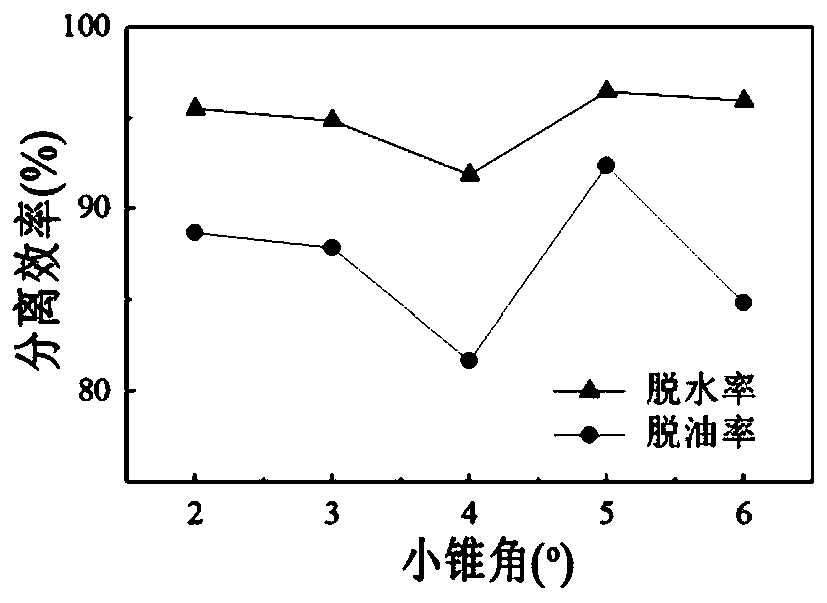

[0073] This embodiment takes the optimization of the cone segment structure of the dual-field coupling device as an example to illustrate the method of use

[0074] In this example, the waste oil emulsion is used as the background, and the double-field coupling dehydration device is used as the optimization object. The optimization range of each parameter is obtained through single-factor analysis, and the design-expert software is used to design the combination of parameters for each input factor. Combined with the double-field The output factors under each combination are obtained through coupling numerical simulation calculation, and then the parameter optimization model is obtained. According to the model, the optimal operation parameter combination of the double-field coupling dehydration device is obtained.

[0075] Such as figure 1 as shown, figure 1 It is a structural model of a double-field coupling dehydration device, which mainly includes a straight pipe section, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com