Continuous rolling roll and its preparation method

A roll and roll body technology, which is applied in the field of continuous roll and its preparation, can solve the problems of difficult control of quality stability and achieve the effects of increasing service life, reducing hardness drop, and increasing the thickness of the working layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

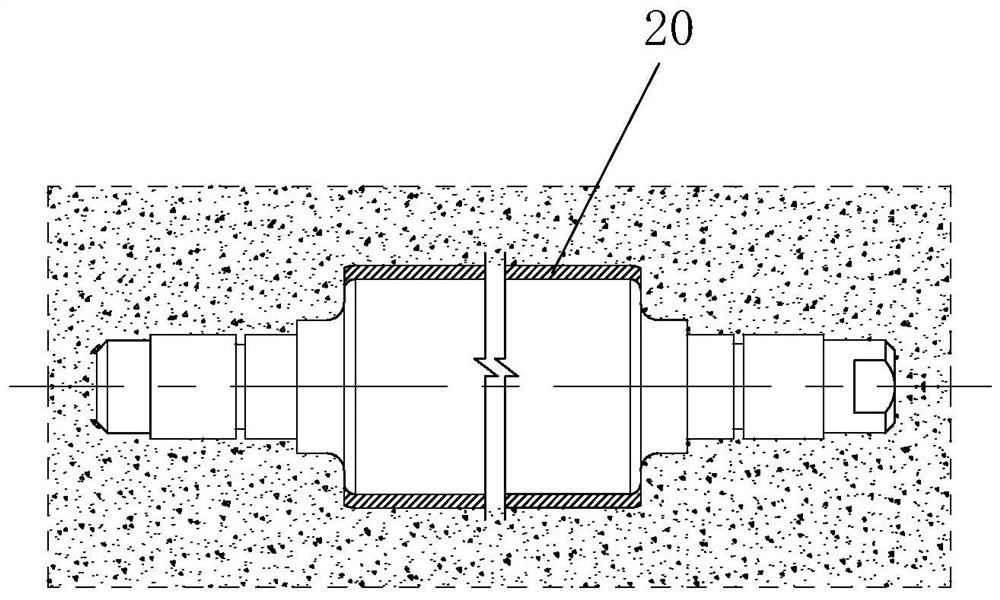

[0024] The continuous rolling roll in this embodiment includes a roll body, a journal on the transmission side, and a shaft head, and the roll body, the journal, and the shaft head are cast into an integral structure using hot-working die steel, and the hot-working die steel includes the following alloy Elements: C: 0.65%, Si: 0.30%, Mn: 0.5%, Cr: 5.3%, Ni: 1.5%, Mo: 0.30%, P≤0.03%, S≤0.03%, Fe balance.

[0025] The preparation method of the described continuous rolling roll of the present embodiment comprises the following steps:

[0026] Step 1, batching smelting: the composition of the hot work die steel is proportioned according to the following weight percentages: C: 0.65%, Si: 0.30%, Mn: 0.5%, Cr: 5.3%, Ni: 1.5%, Mo: 0.30%, P≤0.03%, S≤0.03%, Fe balance, smelting in an electric furnace after batching, and refining to obtain pure molten steel with qualified components;

[0027] Step 2, molding: After the molten steel is smelted to meet the requirements, it is taken out of...

Embodiment 2

[0033] The continuous rolling roll in this embodiment includes a roll body, a journal on the transmission side, and a shaft head, and the roll body, the journal, and the shaft head are cast into an integral structure using hot-working die steel, and the hot-working die steel includes the following alloy Elements: C: 0.70%, Si: 0.35%, Mn: 0.5%, Cr: 5.30%, Ni: 1.7%, Mo: 0.30%, P≤0.03%, S≤0.03%, Fe balance.

[0034] The preparation method of the described continuous rolling roll of the present embodiment comprises the following steps:

[0035] Step 1, batch smelting: the composition of the hot work die steel is proportioned according to the following weight percentages: C: 0.70%, Si: 0.35%, Mn: 0.5%, Cr: 5.30%, Ni: 1.7%, Mo: 0.30%, P≤0.03%, S≤0.03%, Fe balance, smelting in an electric furnace after batching, and refining to obtain pure molten steel with qualified components;

[0036] Step 2, molding: After the molten steel is smelted to meet the requirements, it is taken out of ...

Embodiment 3

[0042] The continuous rolling roll in this embodiment includes a roll body, a journal on the transmission side, and a shaft head, and the roll body, the journal, and the shaft head are cast into an integral structure using hot-working die steel, and the hot-working die steel includes the following alloy Elements: C: 0.70%, Si: 0.35%, Mn: 0.5%, Cr: 4.90%, Ni: 1.7%, Mo: 0.30%, P≤0.03%, S≤0.03%, Fe balance.

[0043] The preparation method of the described continuous rolling roll of the present embodiment comprises the following steps:

[0044] Step 1, batch smelting: the composition of the hot work die steel is proportioned according to the following weight percentages: C: 0.70%, Si: 0.35%, Mn: 0.5%, Cr: 4.90%, Ni: 1.7%, Mo: 0.30%, P≤0.03%, S≤0.03%, Fe balance, smelting in an electric furnace after batching, and refining to obtain pure molten steel with qualified components;

[0045] Step 2, molding: After the molten steel is smelted to meet the requirements, it is taken out of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com