Method for optimizing rotation parameters in mask rotary gluing

A technology of rotation parameters and optimization methods, which is applied in photoplate-making process coating equipment, patterned surface photoplate-making process, optics, etc., can solve the problems of low efficiency and high cost, and achieve the effect of reducing test cost and high efficiency of the method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0054]This embodiment takes the G11 generation mask as an example, the size of the G11 generation mask is 1620mm*1780mm*17mm, and the weight of the G11 generation mask substrate is >100Kg. refer to figure 1 , figure 1 It is the distribution map of the coating color difference on the mask plate substrate under normal spin coating process conditions. It can be seen that the color difference is relatively large, and it exists on the edge of the mask plate substrate, mostly in the shape of an approximate triangle or parabola.

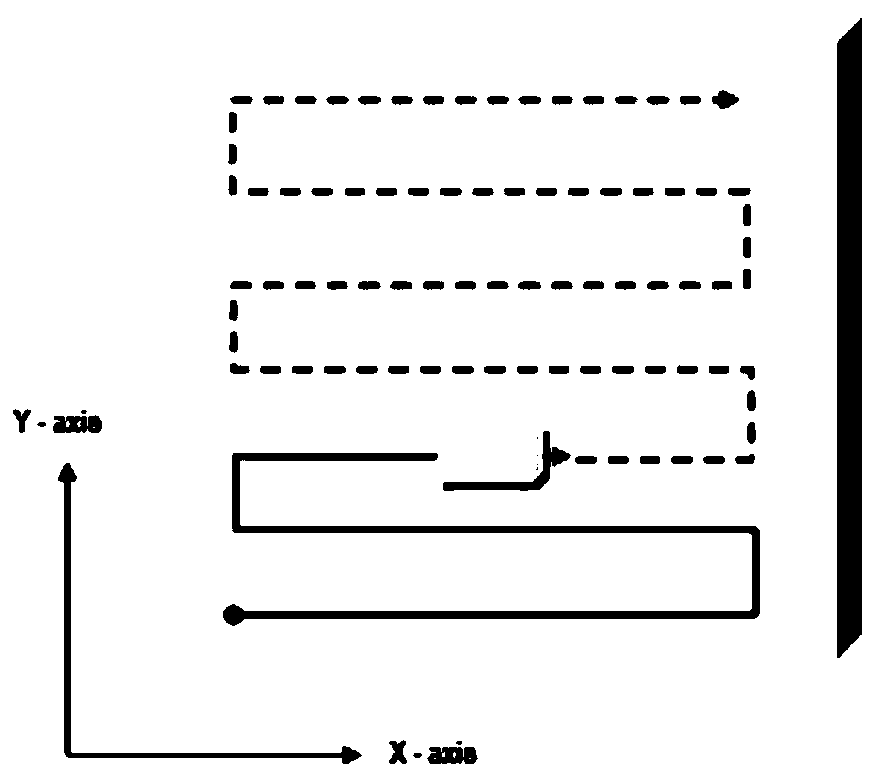

[0055] refer to figure 2 , image 3 and Figure 4 , rotation parameter optimization method in mask plate rotation gluing of the present invention, comprises the following steps:

[0056] S1 establishes the mask plate model, selects the rotation parameters that affect the mask plate spin coating process and the target parameters for evaluating the mask plate glue coating quality;

[0057] Wherein, the rotation parameter comprises the rotation speed rpm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com