Patents

Literature

126results about "Hydrocarbon dewatering" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Refinery desalter improvement

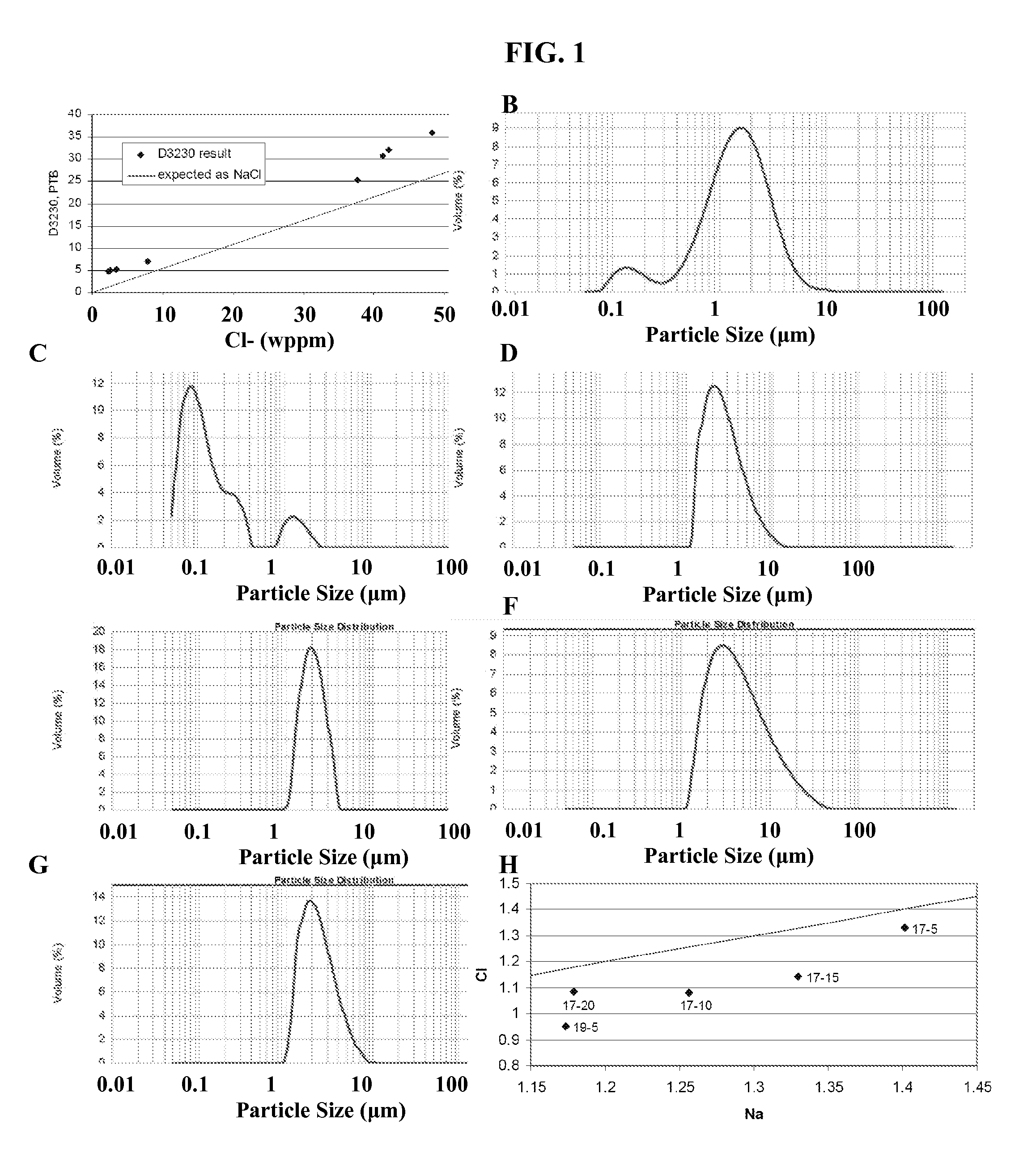

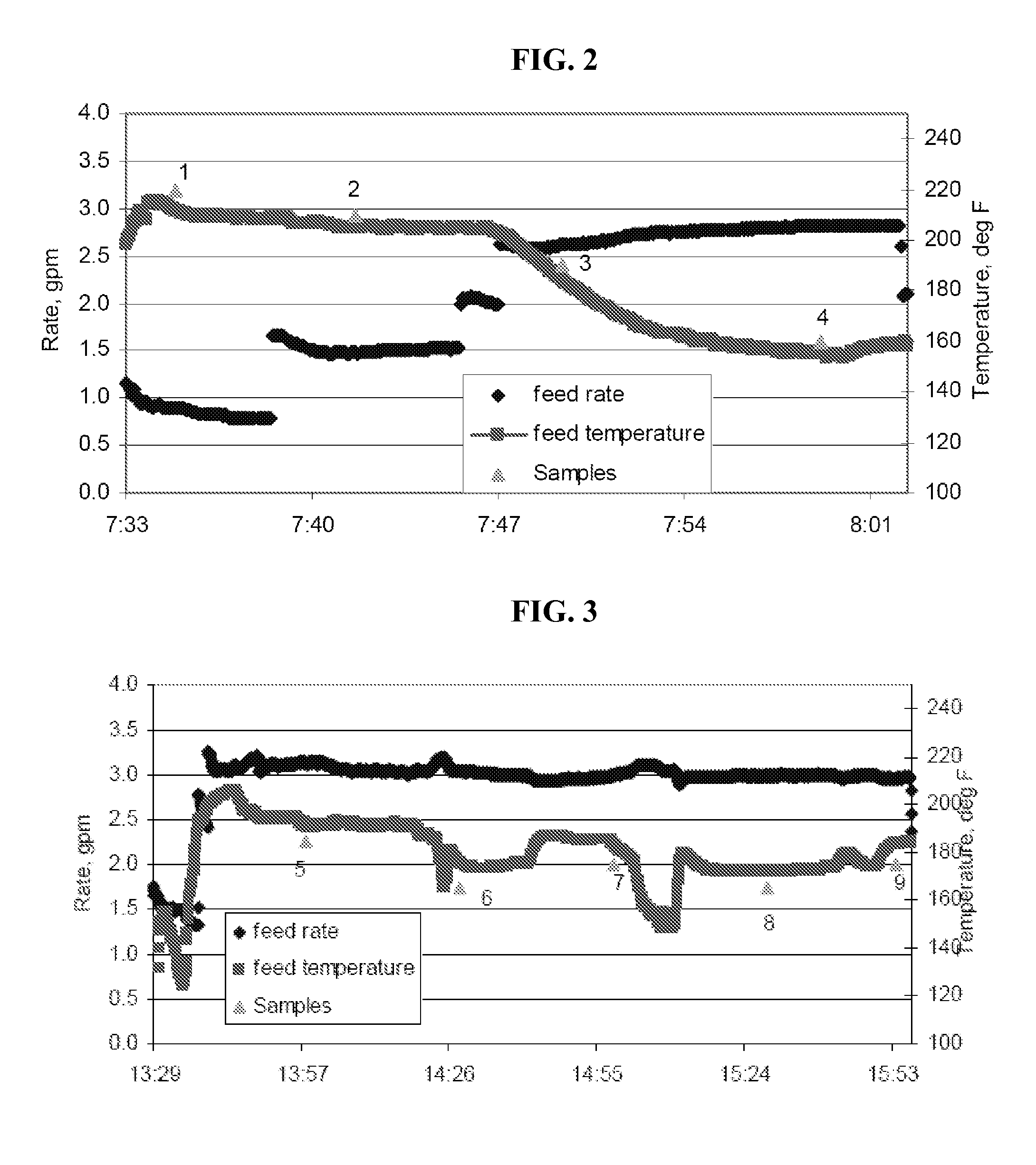

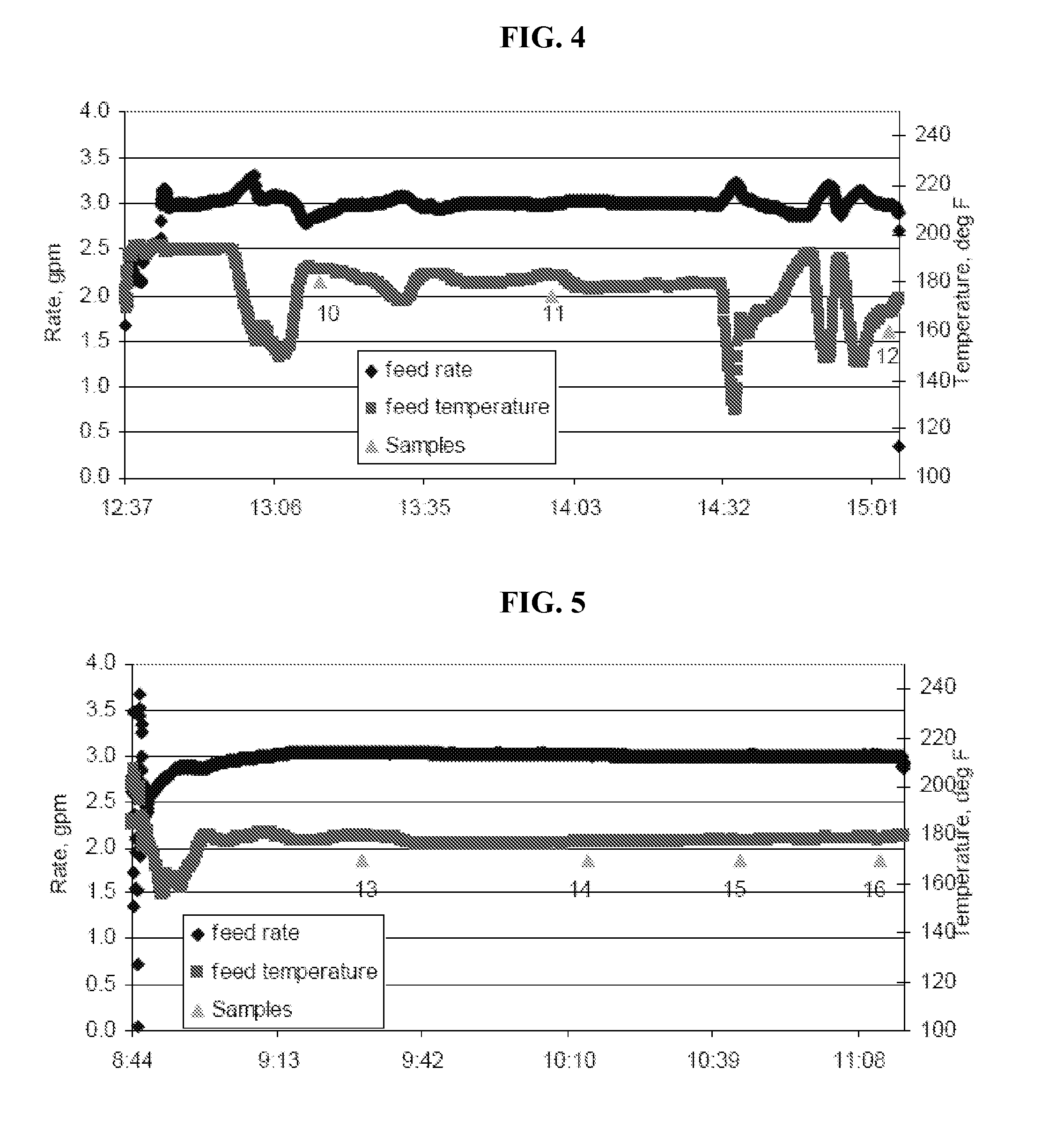

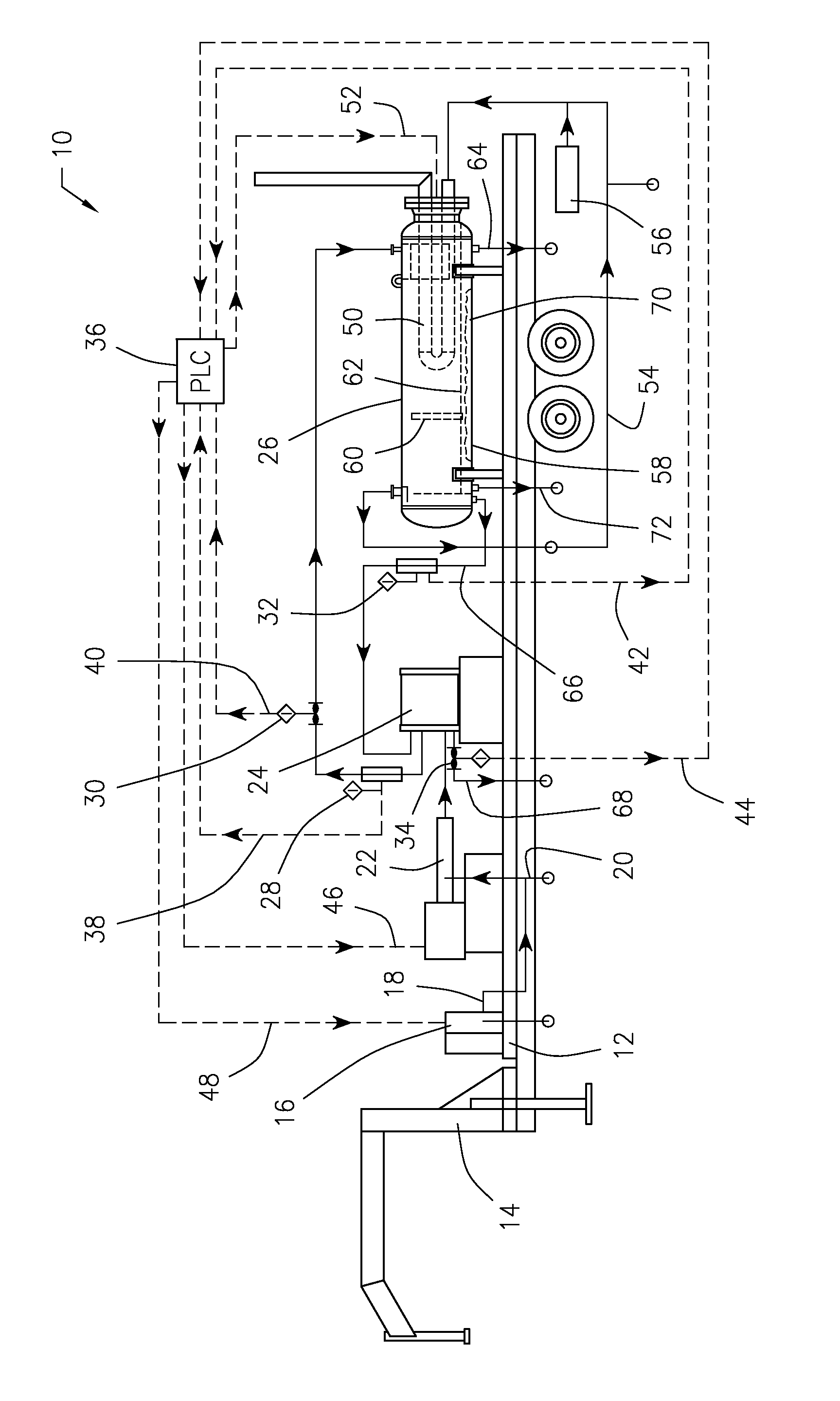

ActiveUS20120024758A1Increase capacityEasy to separateDewatering/demulsification with mechanical meansRefining by water treatmentDesalinationDesalter

The invention relates to improved methods of desalting hydrocarbon feeds using a separator with a stacked disk centrifuge to separate an emulsified oil and water rag layer. This method is effective for desalting heavy, high ionic, and non-traditional crude oils.

Owner:PHILLIPS 66 CO

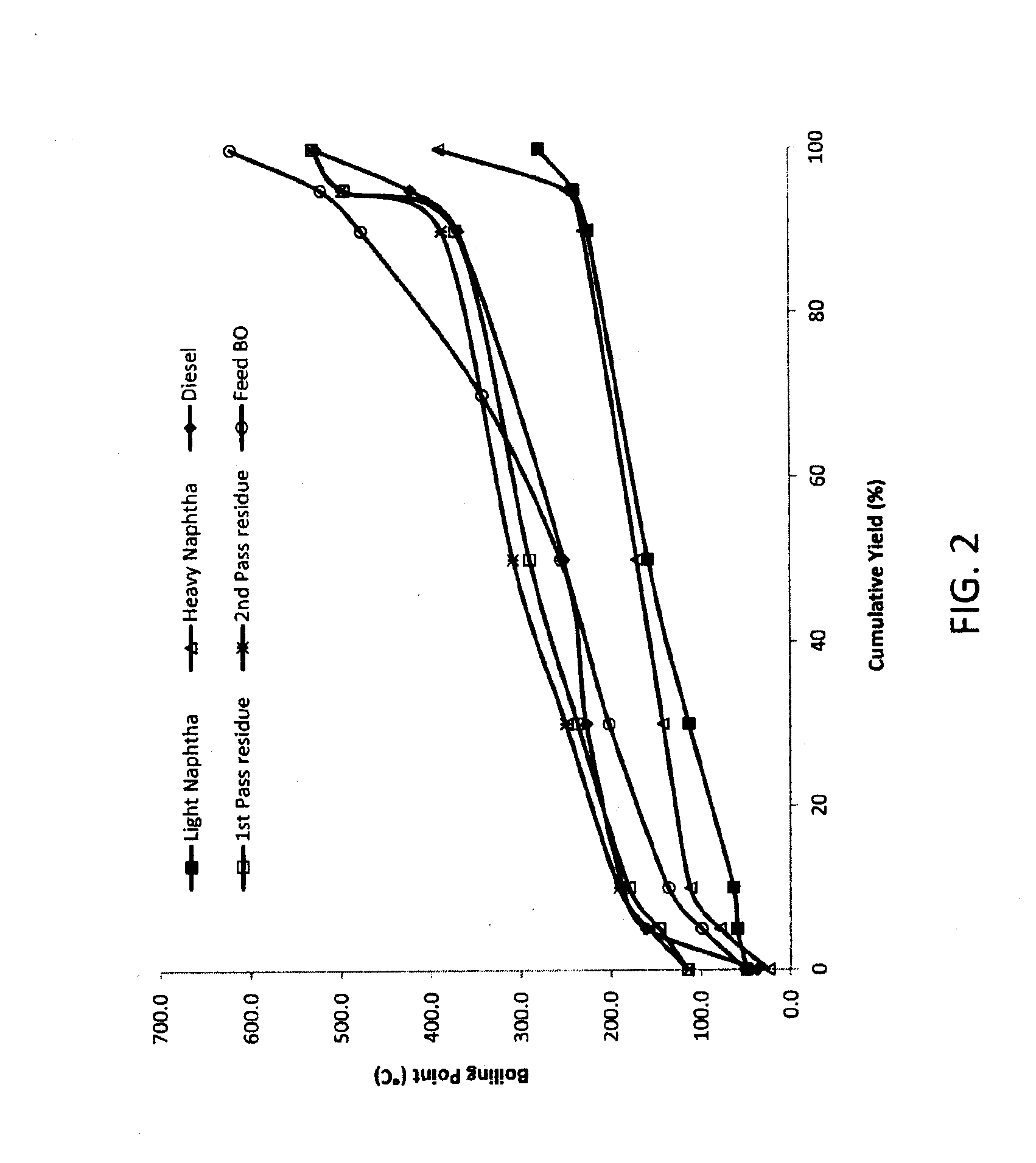

Method for upgrading an oil, a fuel product and a hydrocarbon product fraction

InactiveUS20130105356A1Stability of mixtures prepared in accordanceImprove stabilityTreatment with plural serial stages onlyLiquid carbonaceous fuelsBoiling point

Pyrolysis oil is upgraded by evaporating water from a mixture of the pyrolysis oil and a hydrocarbon having an atmospheric boiling point of at least 130° C. The method yields a de-watered pyrolysis oil mixture.

Owner:SHELL OIL CO

Process for removing water from a water-containing crude oil

A process and apparatus for treating a crude oil containing water. An inlet introduces a flow of the crude oil into the apparatus, wherein at least a portion of the water is a vapor. A first separator disrupts the crude oil flow in order to separate at least a portion of the vapor from the crude oil to produce a treated oil. A heater heats the treated oil to produce a heated treated oil. Means for recycling a first amount of the heated treated oil from the heater to the inlet are provided. The first amount is at least sufficient to heat the crude oil to a temperature such that at least a portion of the water forms the vapor. At least one oil outlet removes the treated oil and at least one vapor outlet removes the vapor. Finally, means are provided for producing the flow of the crude oil. The process is preferably conducted using the apparatus.

Owner:FOREMOST UNIVERSAL

Local produced oil dehydrator

ActiveUS9157035B1Avoid necessityEasy to relocateDewatering/demulsification with chemical meansDewatering/demulsification with mechanical meansDemulsifierSediment

A portable, semi-portable, or permanent system for removing BS&W from crude oil at the local production or bulk storage site. A demulsifier is added to the crude as it enters a low shear pump which pumps the mixture through a plate and frame type heat exchanger where the incoming crude is preheated using outgoing heated and dehydrated crude. Then the incoming crude enters an oil-water separator where it is further heated by a secondary heater within the separator and passes through a special coalescing section. Water and basic sediment separate from the crude are discharged from the bottom of the separator. The heated dehydrated crude exits the separator, flows back through the heat exchanger where it is cooled as it preheats incoming crude, and then is pumped to clean oil storage. BS&W and flow monitors on the incoming crude and outgoing crude are used to control operation of the system.

Owner:BREAKTHROUGH ENGENUITY LLC +1

Diesel oil dewatering process and apparatus

The invention provides a diesel dehydration method, including the following steps: cyclone separation is carried out to the diesel obtained by a hydrocracking process, so as to obtain purified diesel with the water content being reduced to below 40mg / kg. The invention further provides a diesel dehydration unit. The method and the device have high separation efficiency, high adaptability, small occupied area and easy maintenance.

Owner:SHANGHAI HUACHANG ENVIRONMENT PROTECTION

SAGD (steam-assisted gravity drainage) super-heavy oil high-temperature flash-evaporation dehydration method

ActiveCN101735849ALess waterShort processDewatering/demulsification with chemical meansHydrocarbon dewateringDiluentThree-phase

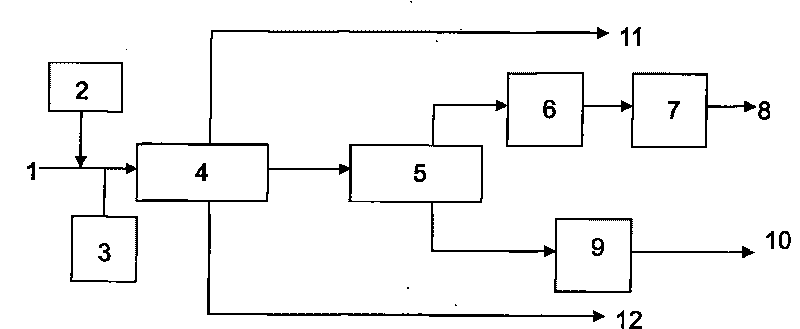

The invention relates to an SAGD (steam-assisted gravity drainage) high-temperature crude oil flash-evaporation dehydration method, which ensures that crude oil reaches crude oil index requirements after a produced liquid is dehydrated by utilizing the characteristic of high per se temperature (larger than 140 DEG C) of SAGD super-heavy oil and adopting a high-temperature flash-evaporation method. A process flow implemented by the method comprises a chemical feeder, a high-temperature sampling device, a three-phase separator, a flash-evaporation dehydrator, a clean water tank, a sewage exportation pump, a sewage exportation pipeline, a heavy oil exportation pump, a crude oil exportation pipeline, a natural gas exportation pipeline and the like. The method solves the problems of low utilization rate of crude oil energy, high diluent consumption, high power consumption, and poor economic performance existing in a traditional dehydration technology; and the SAGD high-temperature crude oil flash-evaporation dehydration method can be widely applied to the gathering and transportation dehydration treatment of heavy steam-assisted gravity drainage crude oil.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

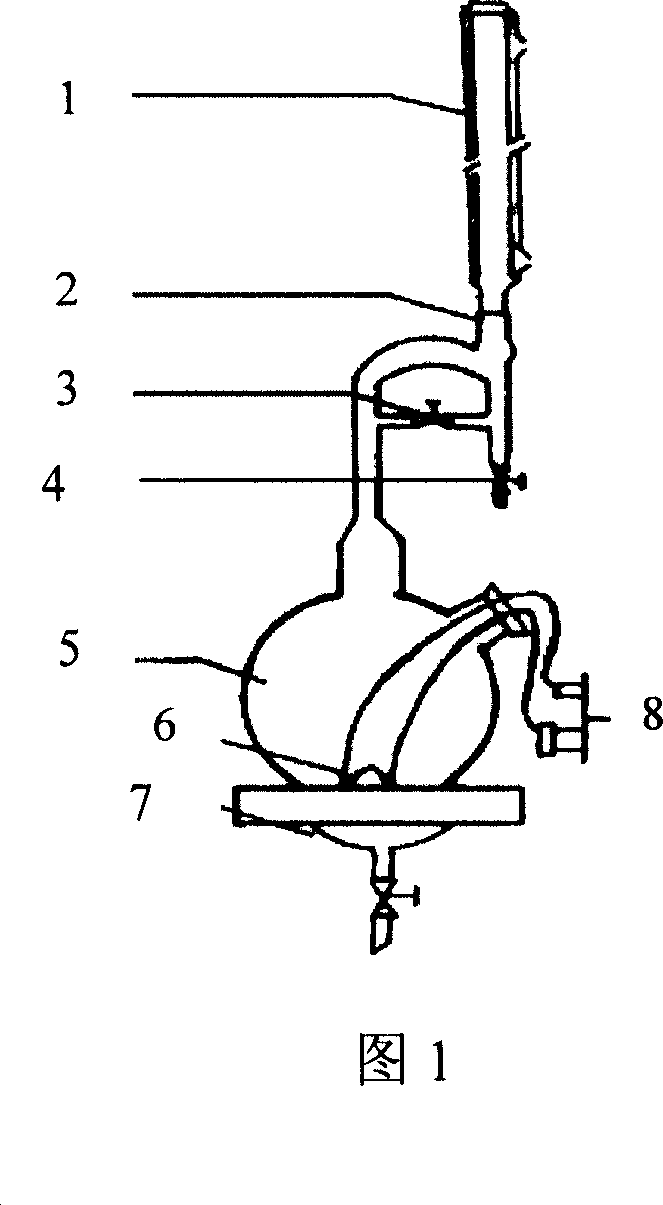

Distillation dewatering set and its dewatering process using it

ActiveCN1986061AAvoid drippingAvoid bumpingLaboratory glasswaresHydrocarbon dewateringWater vaporDistillation

The present invention provides a kind of distillation dewatering set and its dewatering process. The distillation dewatering set includes one distilling flask, one distilling column with heater, and one condensator. During distillation dewatering with the distillation dewatering set, the distilling column may be heated with the heater, so as to avoid condensation of water vapor in the distilling column and avoid explosive boiling in the distilling flask caused by condensed water dropping.

Owner:CHINA PETROLEUM & CHEM CORP +1

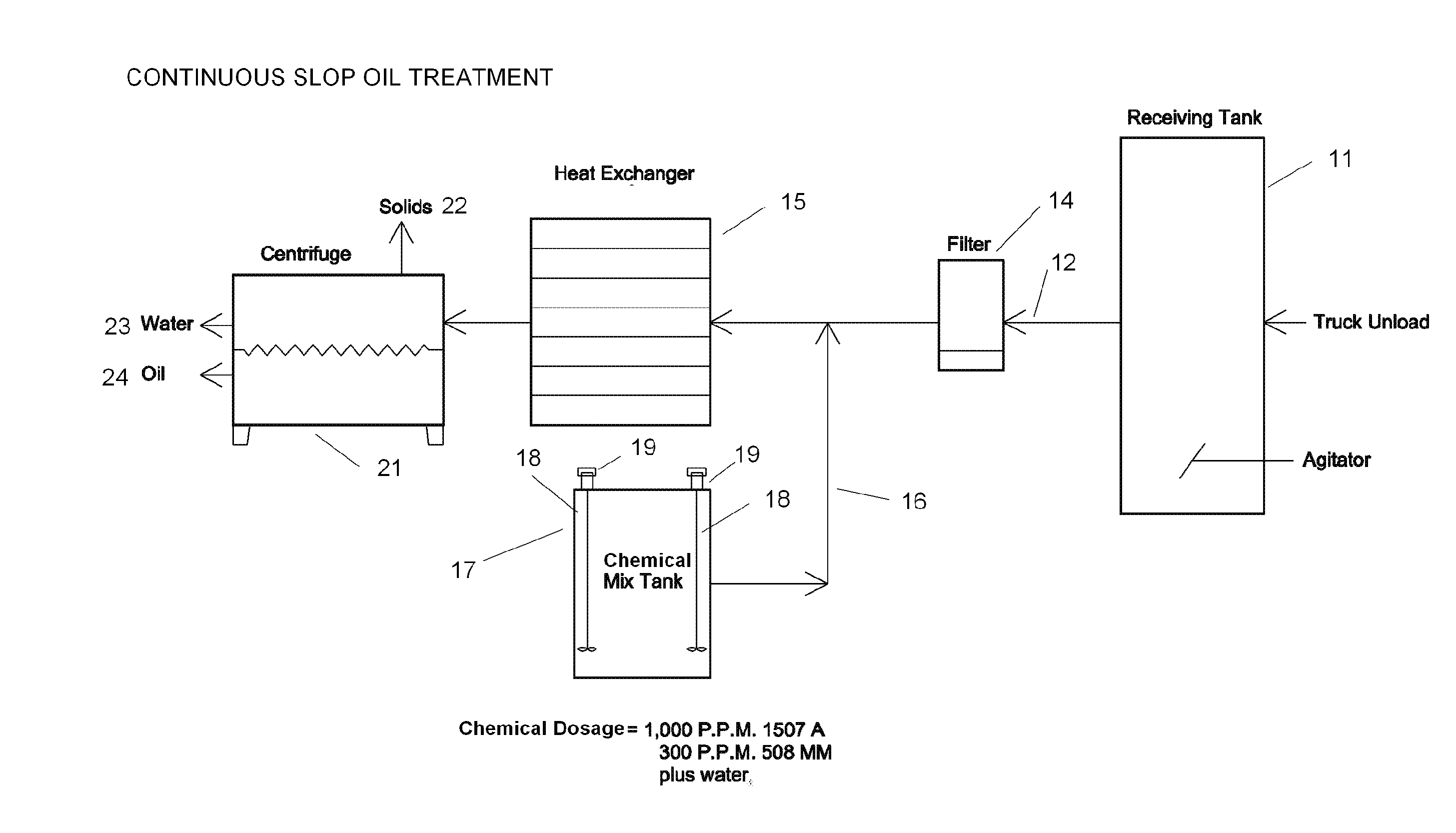

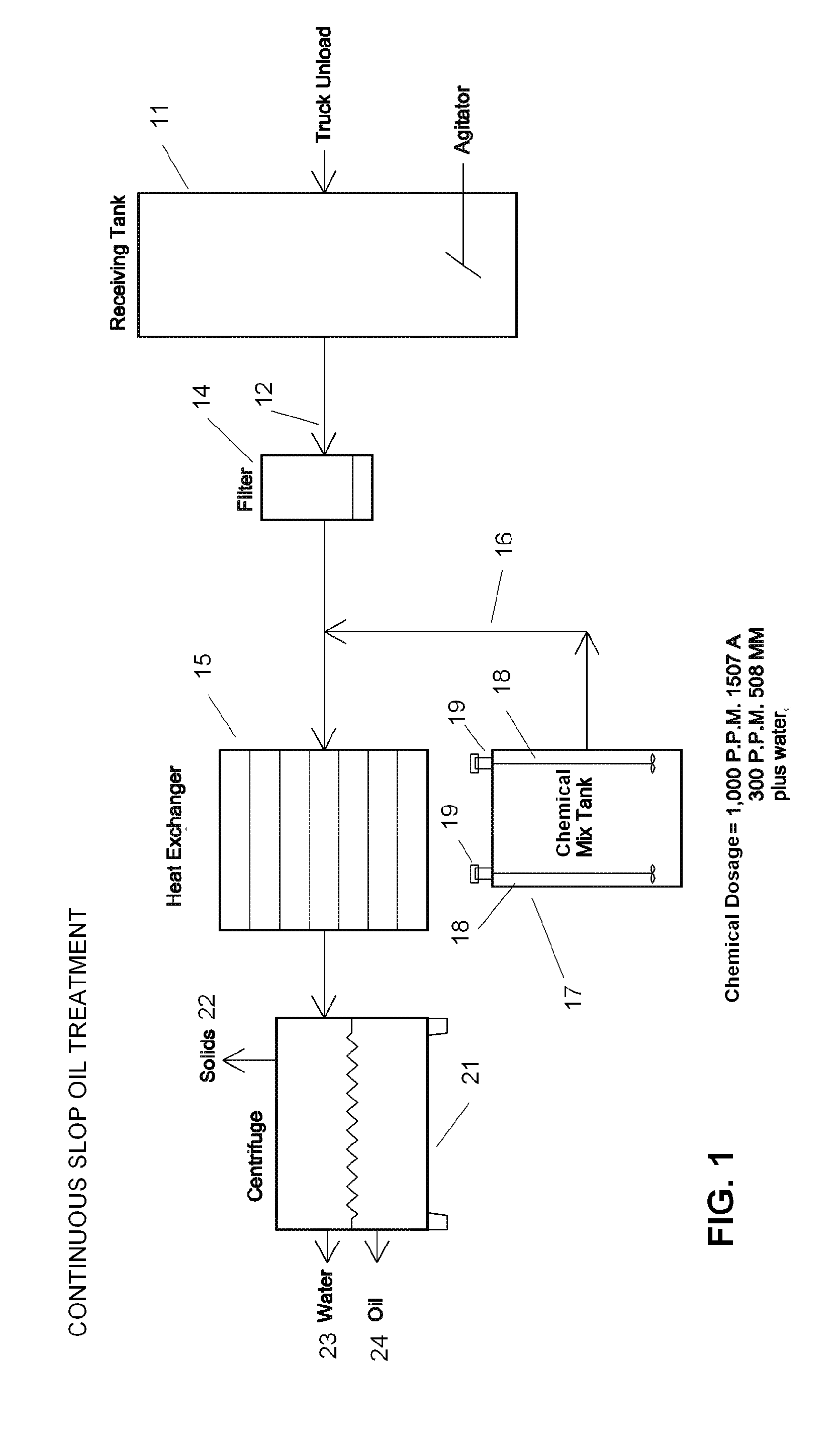

Processes for recycling sag-d process water and cleaning drill cuttings

InactiveUS20110174695A1Centrifugal force sediment separationSettling tanks heating/coolingSludgeSewage

A method of treating slop oil and slops from the SAG-D (steam assisted gravity-drainage) very heavy oil-bitumen crude oil production in such locations as Alberta and Saskatchewan provinces in Canada, Russia, Venezuela, Saudi Arabia, and Kern County, Calif., involves mixing the slop oil and slops with chemicals to help separate out water from the slop oil and slops.

Owner:MALCERA

Integrated Gas Oil Separation Plant for Crude Oil and Natural Gas Processing

ActiveUS20180066194A1Low costReduce expenditureDewatering/demulsification with electric/magnetic meansLiquid hydrocarbon mixture recoveryNatural-gas processingOil separation

Systems and methods of integrated gas oil separation are disclosed. Systems include a high pressure production trap (HPPT), a low pressure production trap (LPPT), a low pressure degassing tank (LPDT), a first knockout drum (KOD) fluidly coupled to the LPDT and operable to accept an atmospheric pressure off-gas from the LPDT, an atmospheric pressure compressor fluidly coupled to the first KOD and operable to compress the atmospheric pressure off-gas to introduce the atmospheric pressure off-gas from the LPDT into the LPPT inlet feed stream, a second KOD fluidly coupled to the LPPT and operable to accept a low pressure off-gas from the LPPT, and a low pressure compressor fluidly coupled to the second KOD and operable to compress the low pressure off-gas to introduce the low pressure off-gas from the LPPT into the crude oil inlet feed stream.

Owner:SAUDI ARABIAN OIL CO

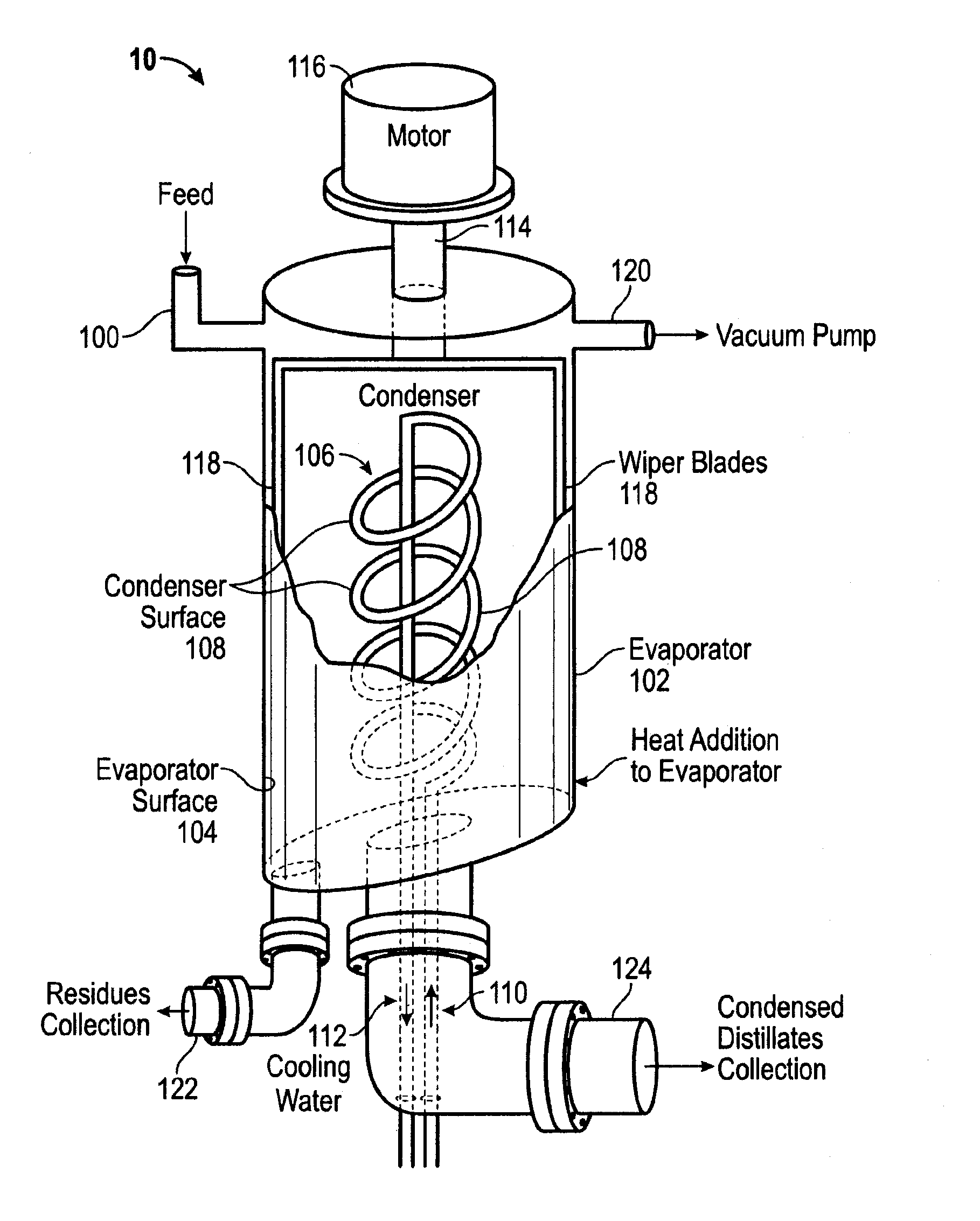

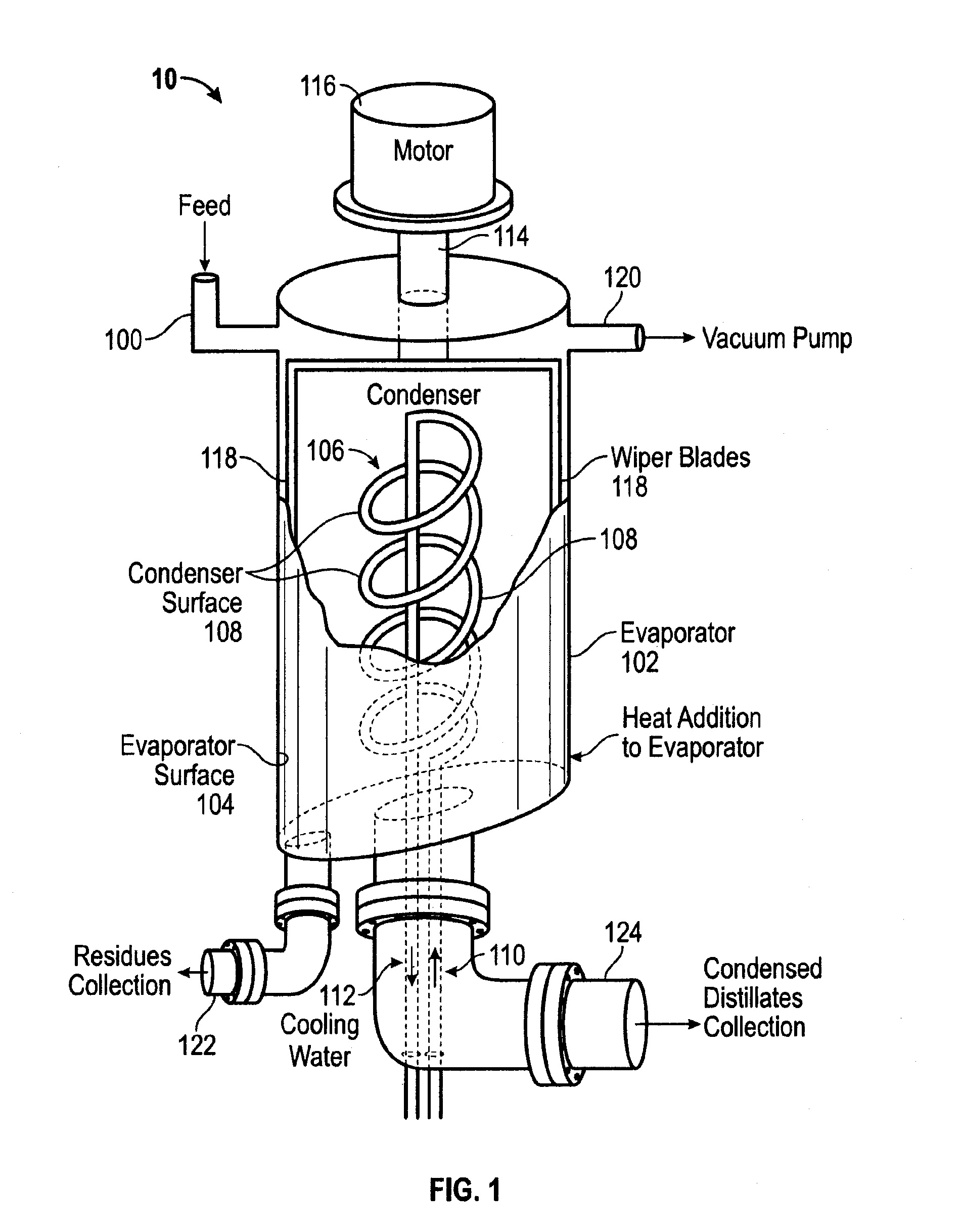

Bio-Oil Fractionation

Disclosed is a process / system for the fractionation of bio-oil, produced from the thermo-catalytic conversion of biomass, into boiling point fractions. The fractionation of the bio-oil is performed using molecular distillation under conditions which minimize the thermal stress to the bio-oil and fractions obtained therefrom.

Owner:MARD INC

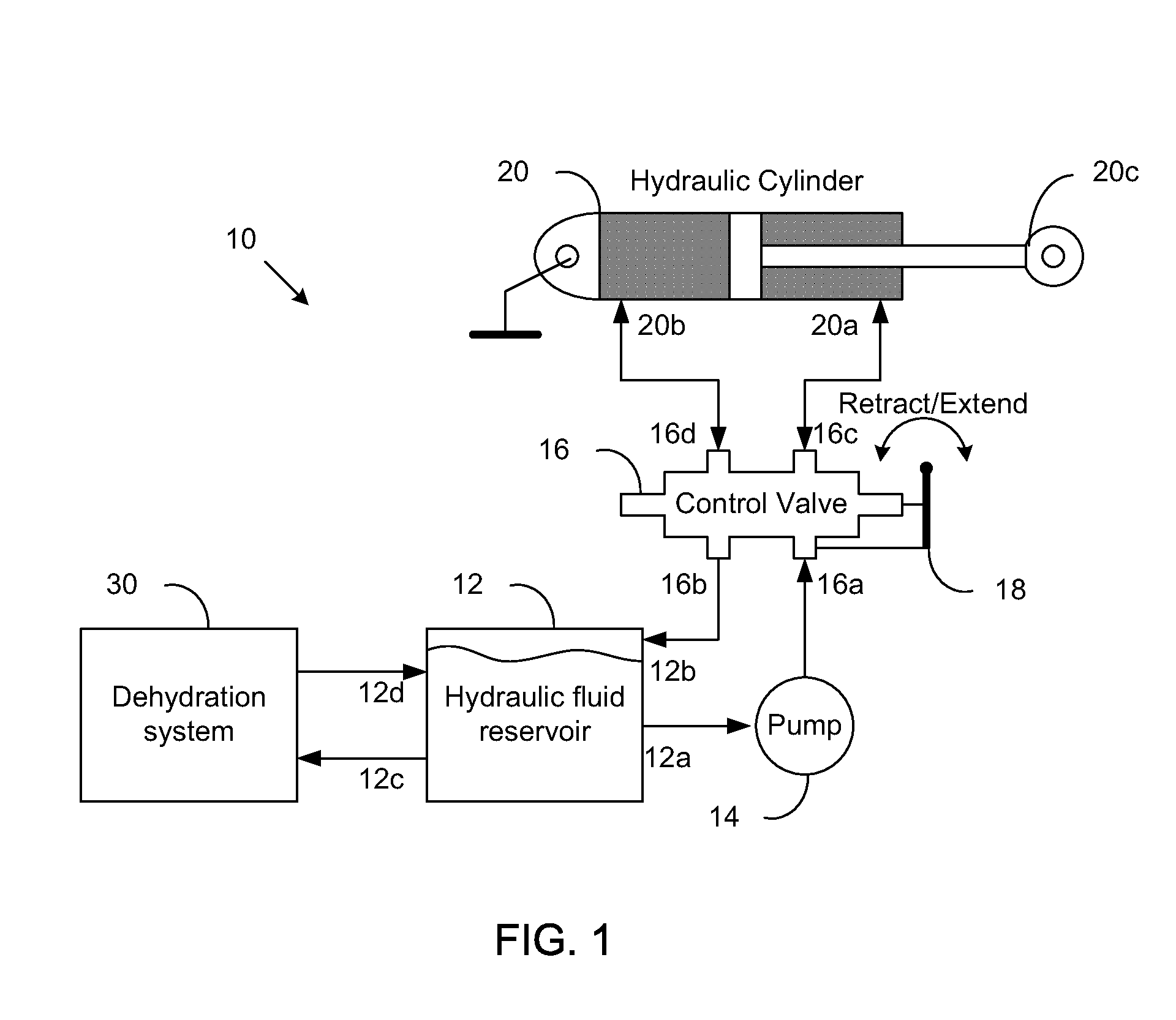

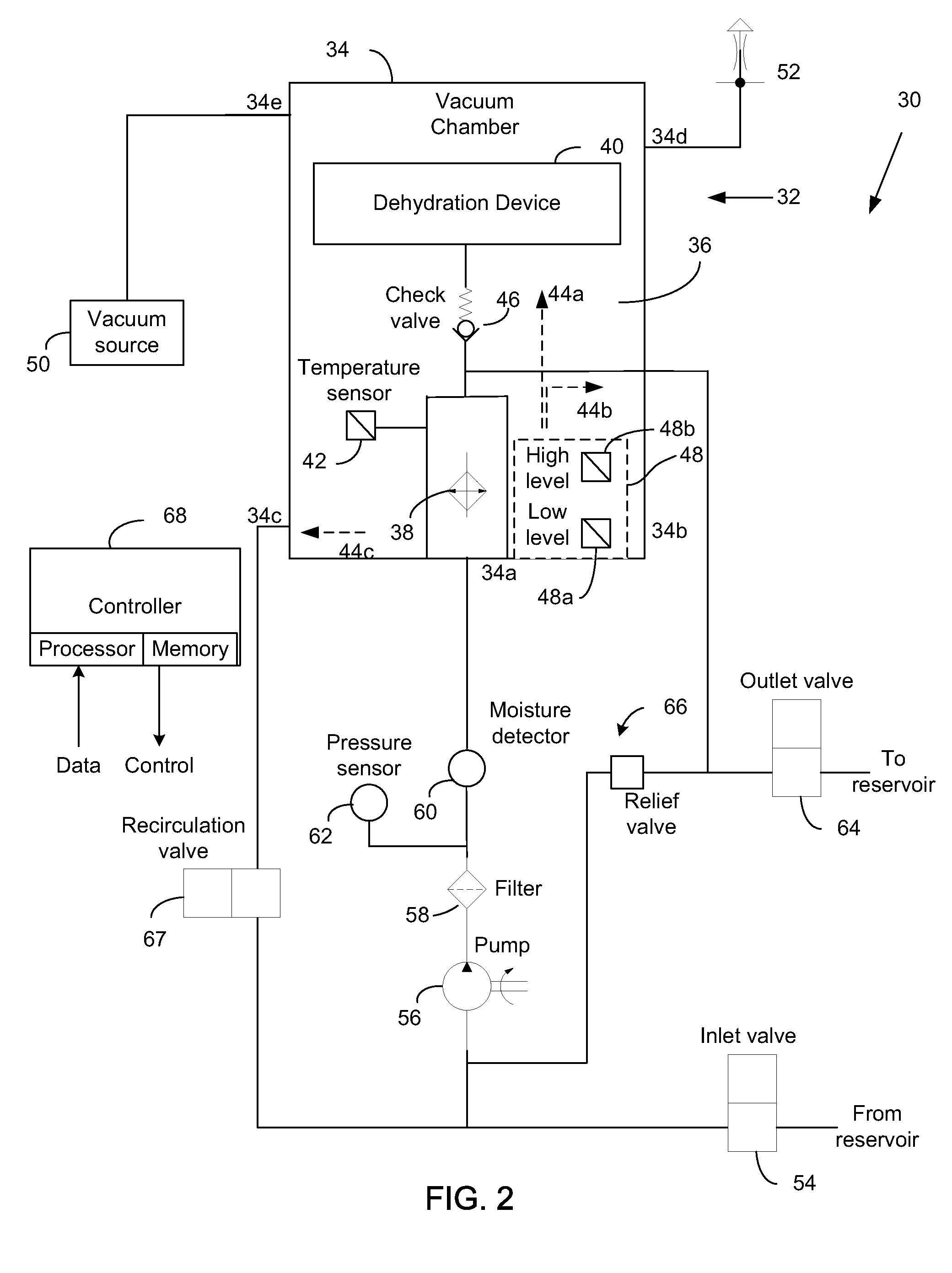

Offline filtration device and method

ActiveUS20150017020A1Easy to useLiquid separation auxillary apparatusDistillation regulation/controlFiltrationTemperature difference

An apparatus, system and method are provided for controlling fluid flow through a vacuum chamber of a dehydration system, the vacuum chamber having a temperature sensing device operative to measure a temperature of a fluid in the vacuum chamber. A temperature difference between a temperature setpoint for the fluid and the measured temperature of the fluid is determined, and fluid is recirculated through the vacuum chamber while the temperature difference is greater than a predetermined temperature difference. While the temperature difference is less than the predetermined temperature difference, the fluid is recirculated through the vacuum chamber for a predetermined time period, and upon the predetermined time period expiring inhibiting recirculation of the fluid through the vacuum chamber.

Owner:PARKER HANNIFIN CORP

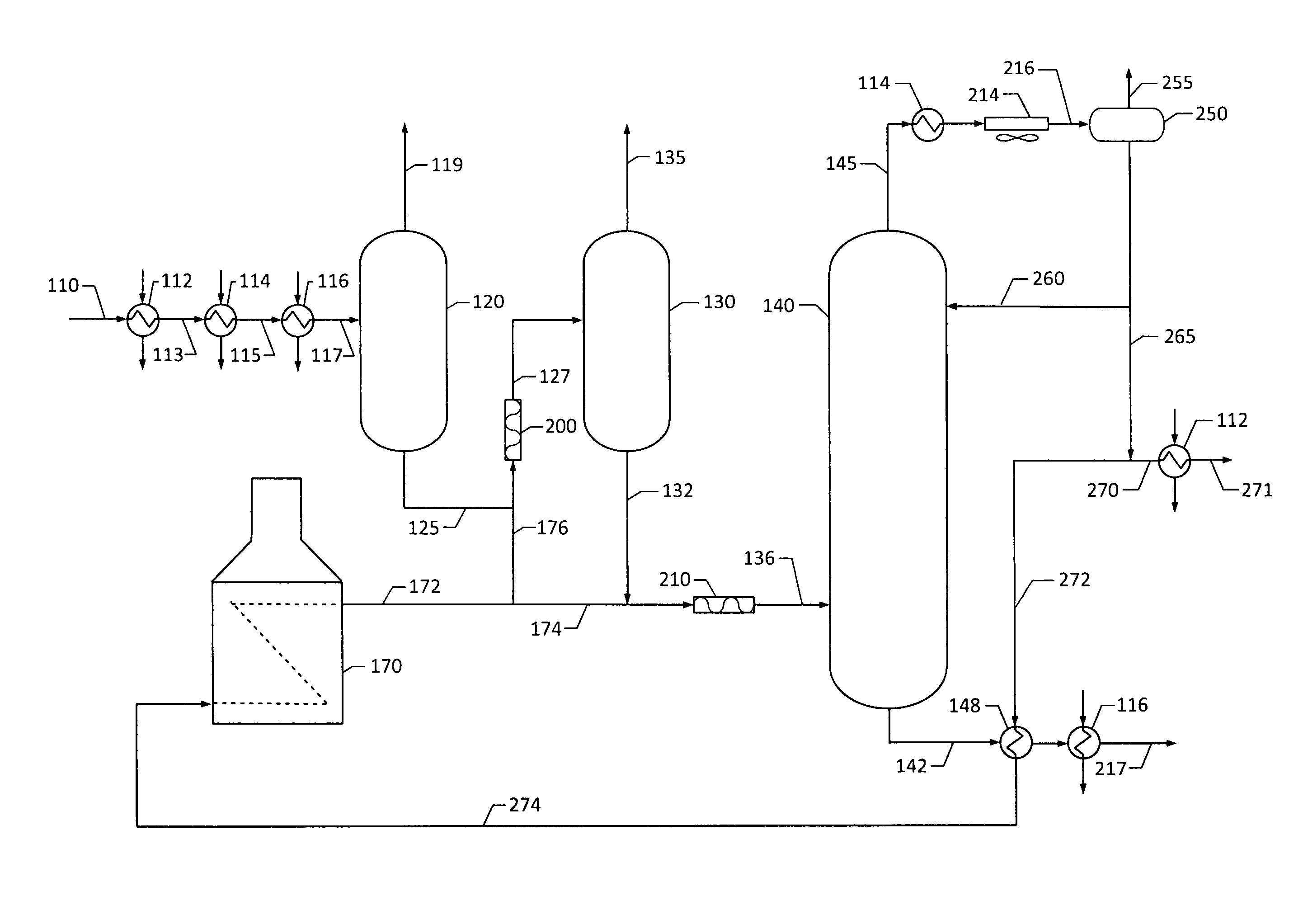

Re-refining used motor oil

A process for re-refining used lubricating oil (ULO) having thermally unstable additives. ULO is heated by mixing with superheated lubricant boiling range hydrocarbons recovered and recycled from the process. The mixture of ULO feed and superheated hydrocarbons is charged to a vacuum column, producing an overhead vapor free of unstable additives and a residual fraction, containing additives. The overhead vapor is condensed to produce an overhead liquid of lubricant boiling range hydrocarbons, a portion of which is recovered as a product and a portion of which is recycled. The overhead liquid free of unstable additives, may be superheated without fouling to produce superheated fluid which can heat the ULO feed sufficiently to permit fractionation. Superheating may occur in a fired heater or preferably in a heat exchanger to prevent high temperatures and cracking of recycled liquid. Mixing of superheated fluid and ULO feed may occur in a pipe in fully developed turbulent flow, and preferably via an inline mixer. Energy efficiency is improved by heat exchanging ULO feed with product streams.

Owner:APPLIED MICROCURRENT TECH LTD +1

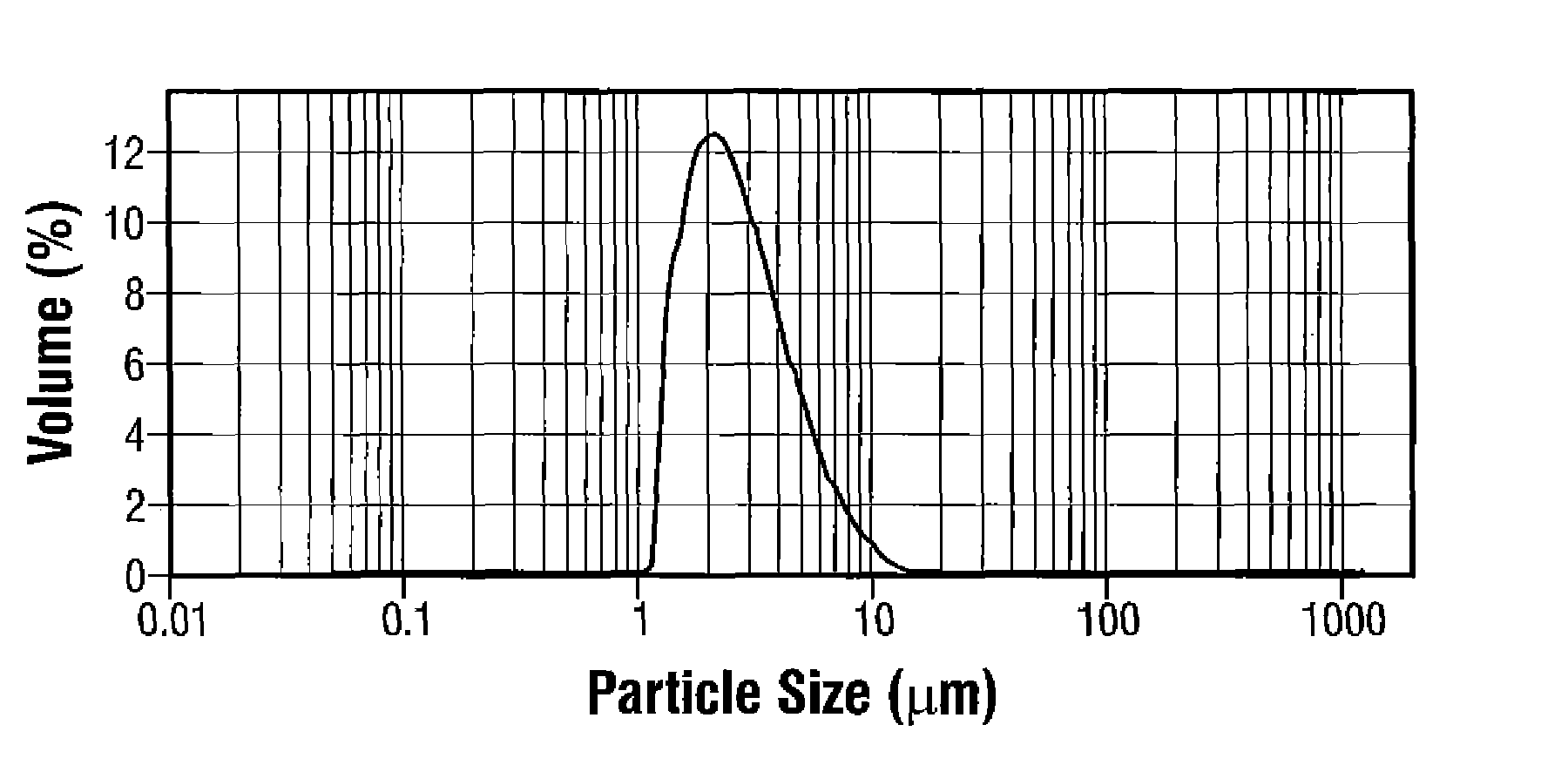

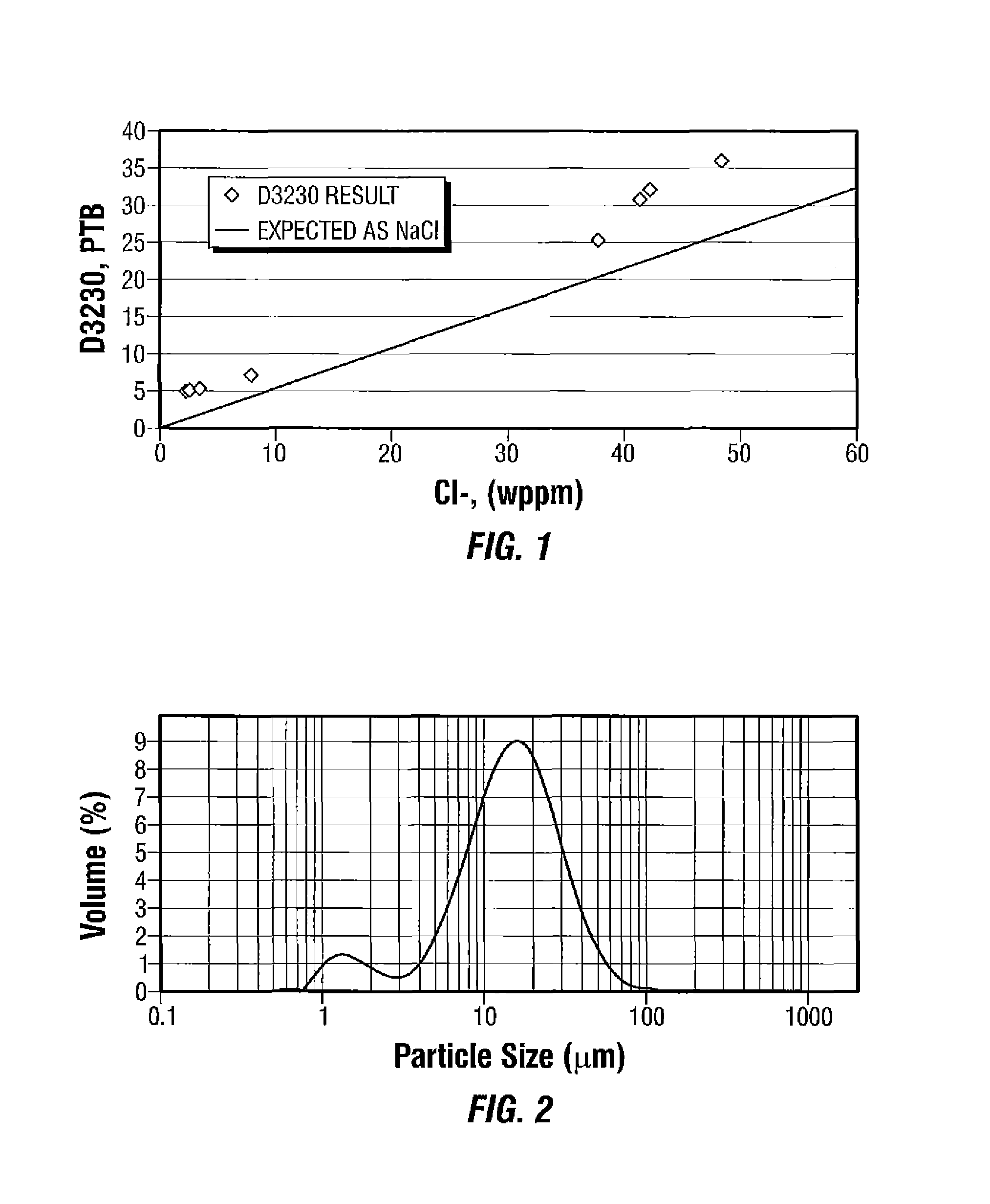

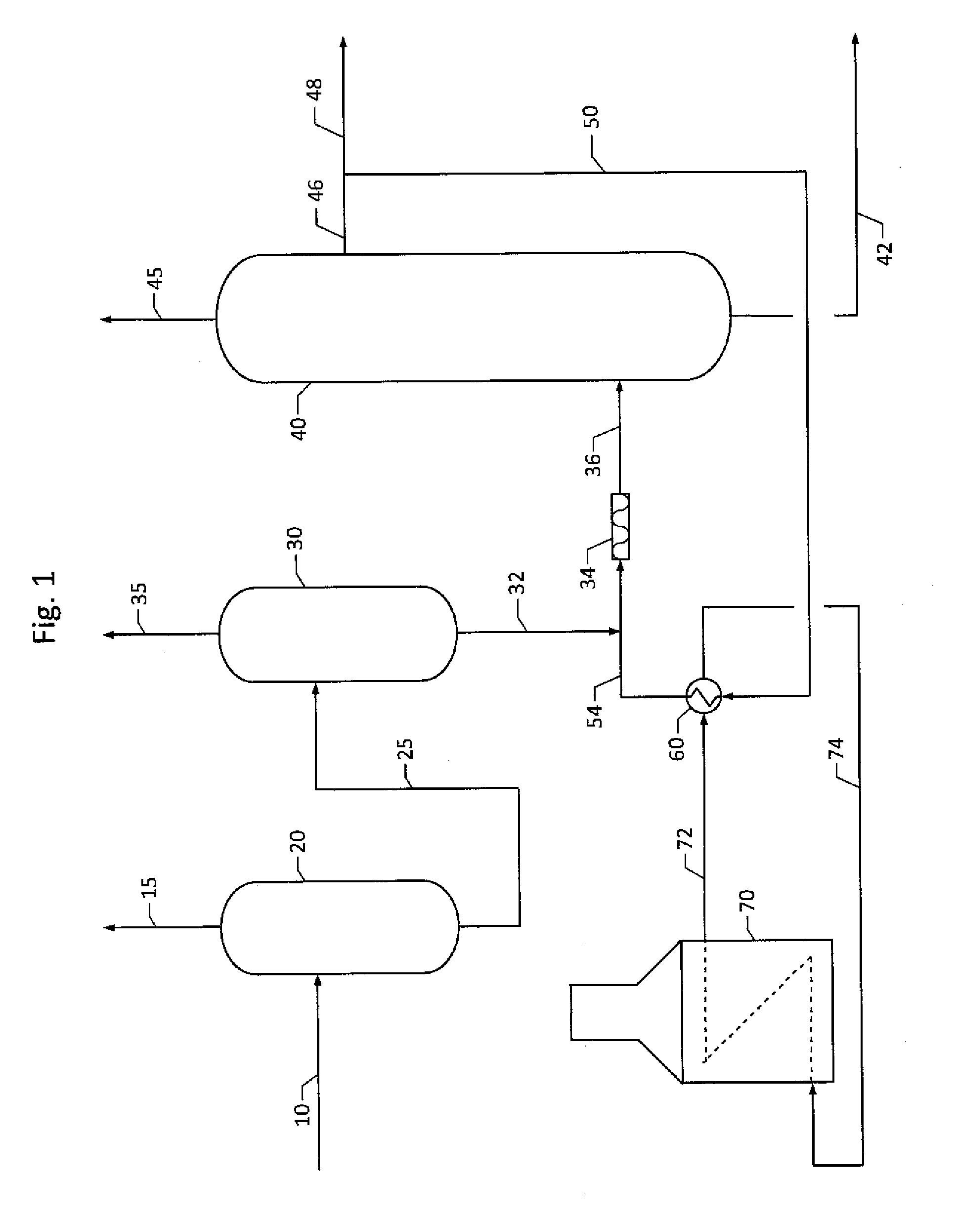

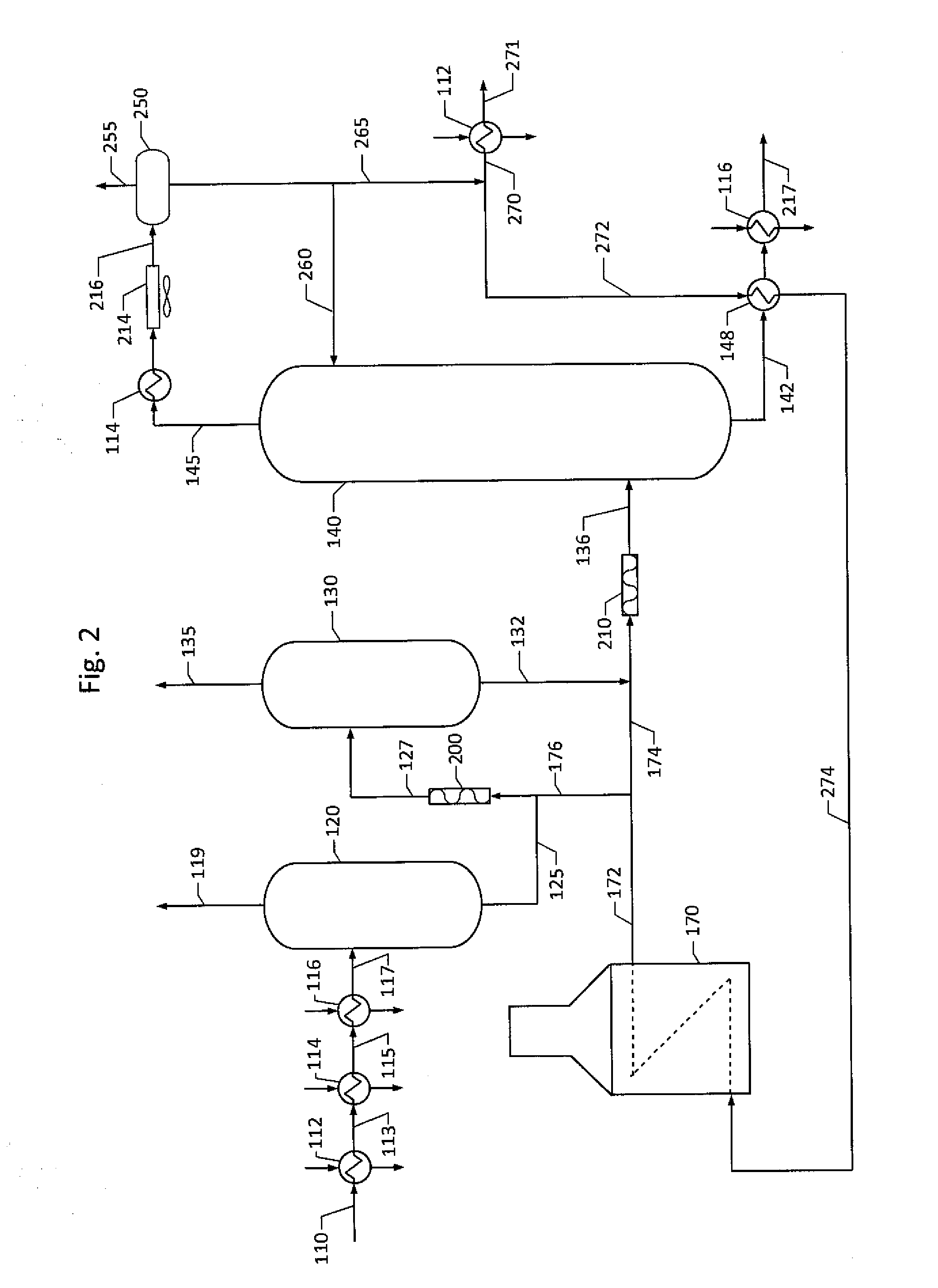

Refinery desalter improvement

ActiveUS8747658B2Increase capacityEasy to separateDewatering/demulsification with chemical meansDewatering/demulsification with mechanical meansDesalterImproved method

The improved methods relate to desalting hydrocarbon feeds using a separator with a stacked disk centrifuge to separate an emulsified oil and water rag layer. This method is effective for desalting heavy, high ionic, and non-traditional crude oils.

Owner:PHILLIPS 66 CO

Distillation of used motor oil with distillate vapors

A process and apparatus for re-refining used lubricating oil (ULO) having thermally unstable additives such as zinc compounds. ULO is mixed with a superheated distillate which may be a recycle stream, an outside stream, or combination, then charged to a vacuum flash or fractionator, to produce an overhead vapor and a residual fraction comprising additives and / or decomposition products thereof. Overhead vapor is condensed to yield a liquid lubricant boiling range product. Superheating may occur in a fired heater, heat exchanger or combination. Mixing of superheated fluid and ULO may occur in a pipe in turbulent flow and / or an in line mixer. Energy efficiency is improved by heat exchanging ULO feed with vapor or liquid product streams. An aromatic rich and thermally stable outside stream such as FCC LCO can be readily superheated. Recovered lubricant boiling range material can be recycled, used as a lube stock or for FCC feed.

Owner:WTL TECH LLC

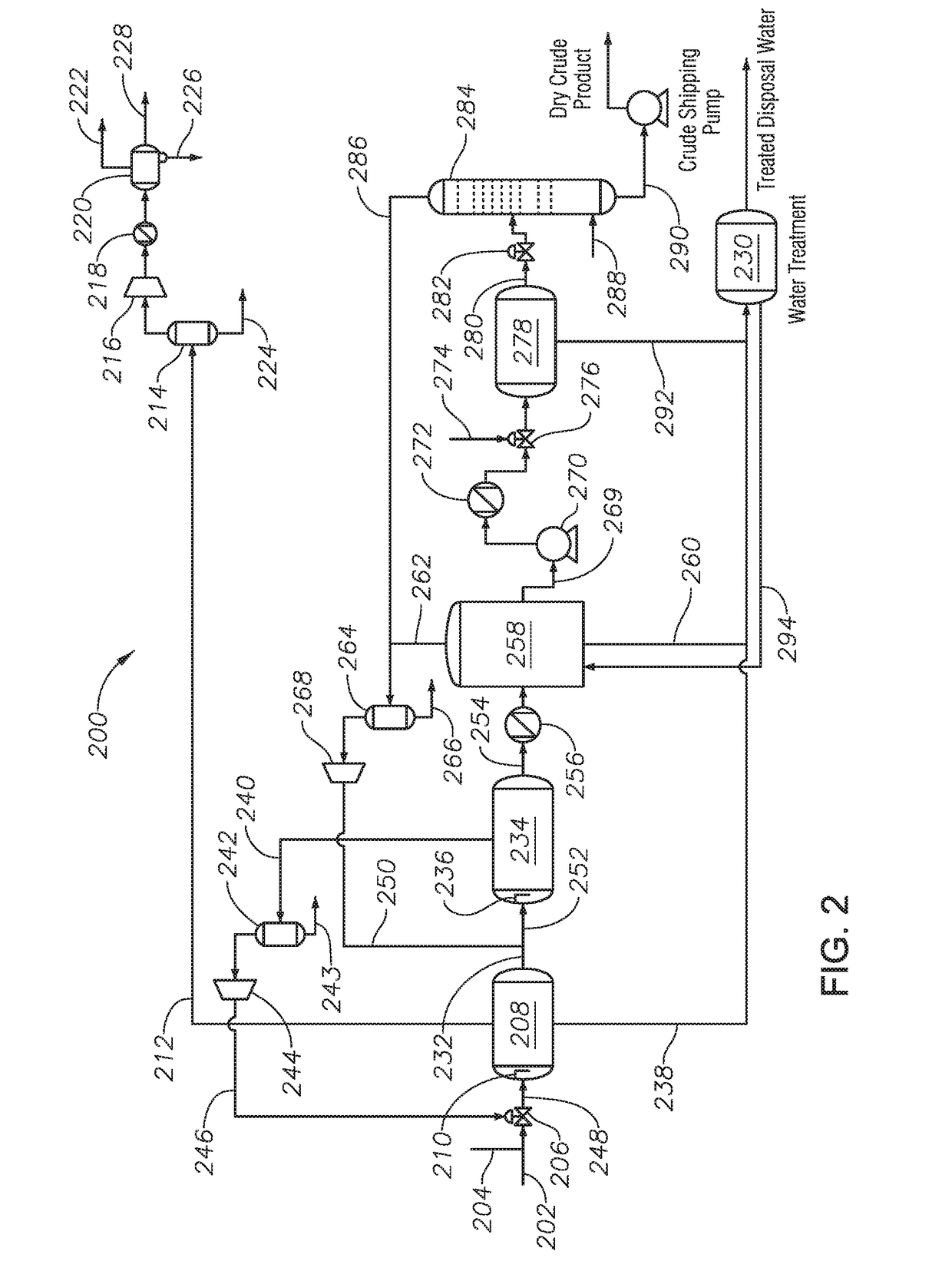

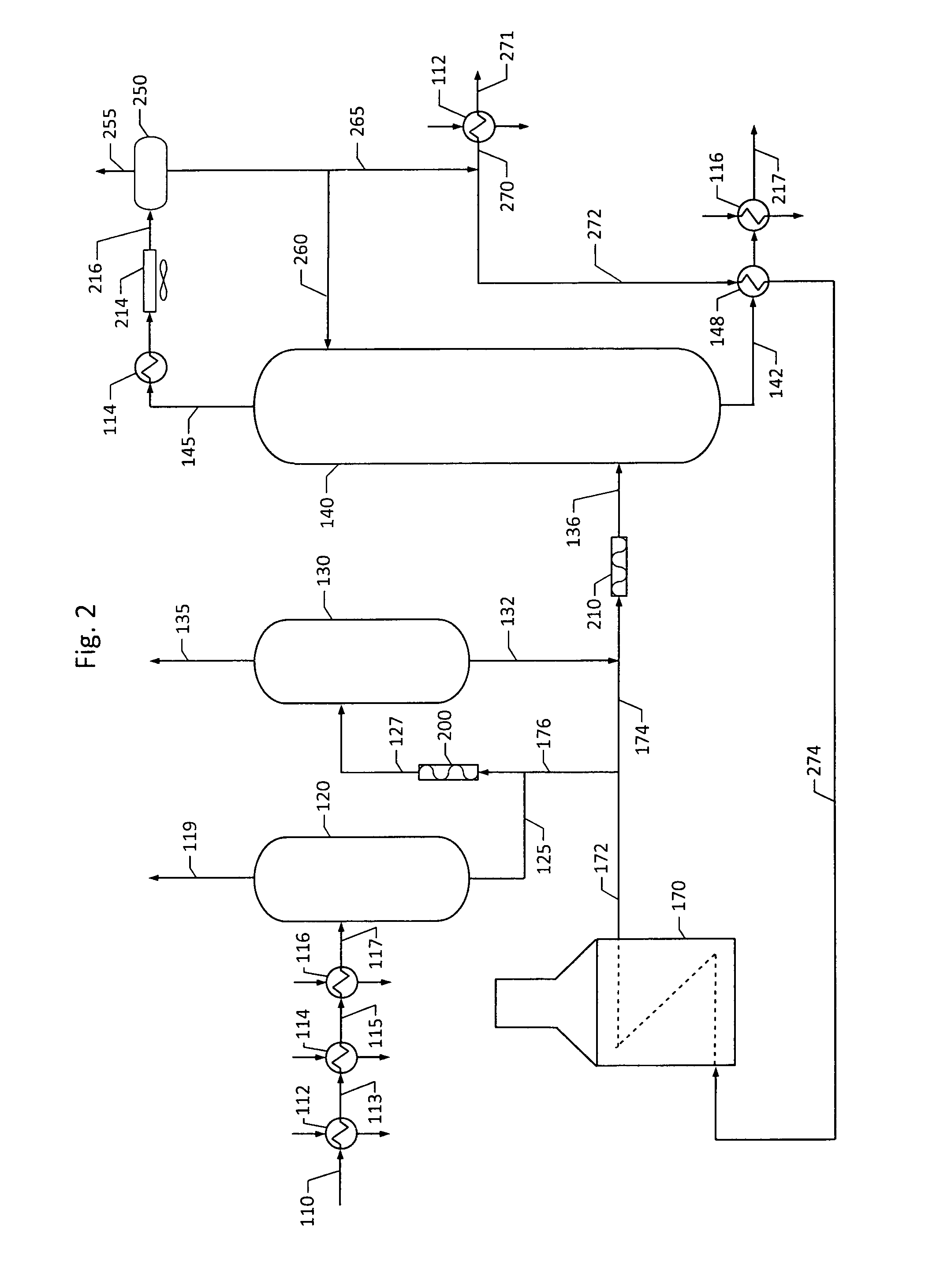

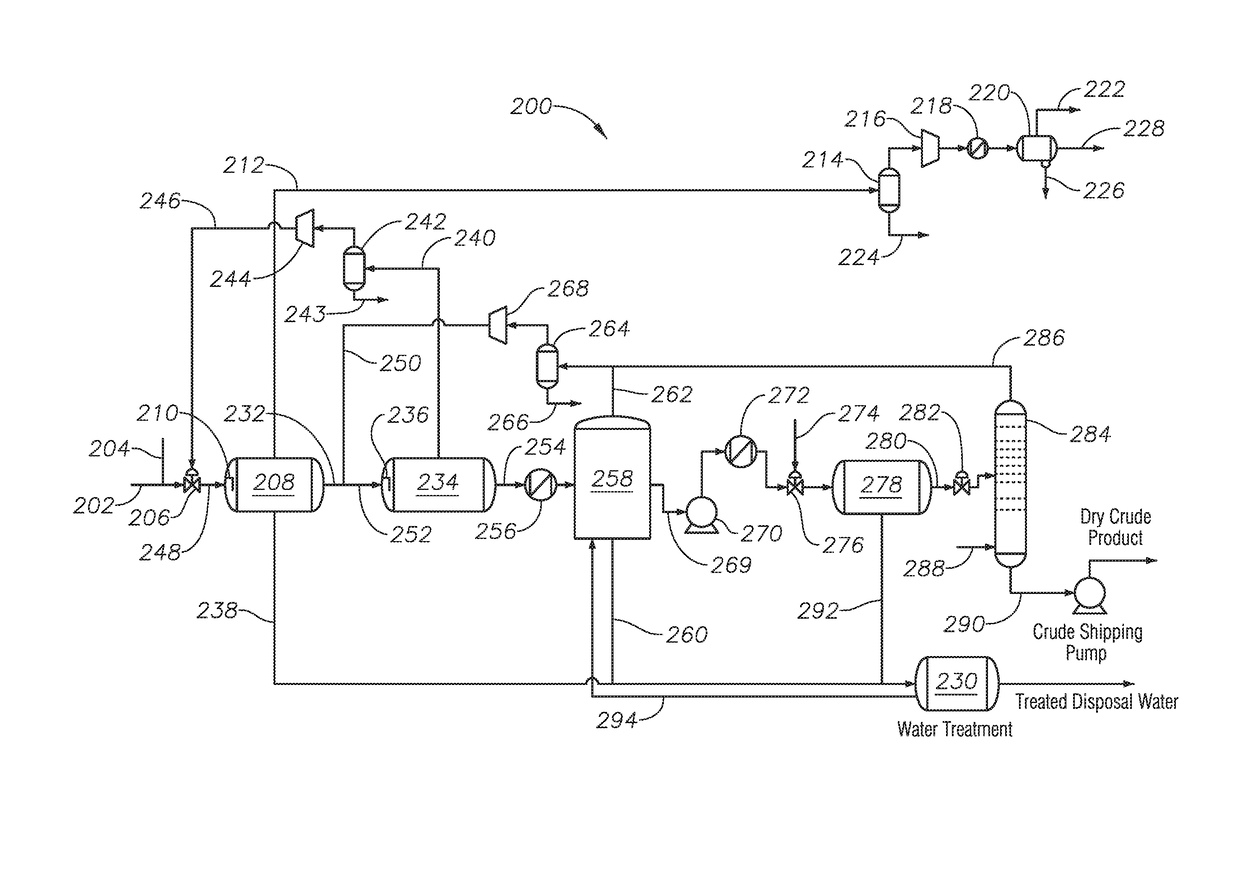

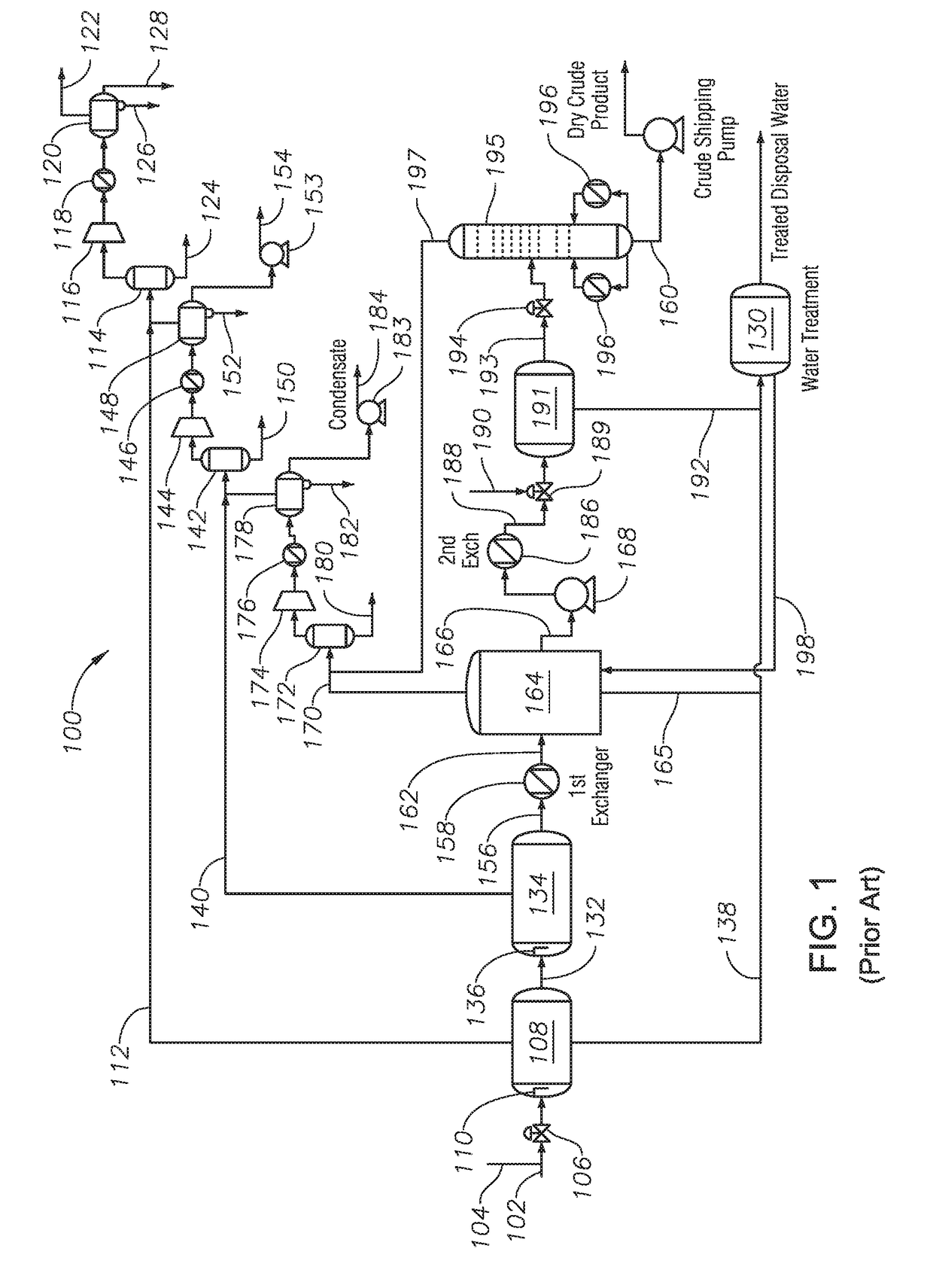

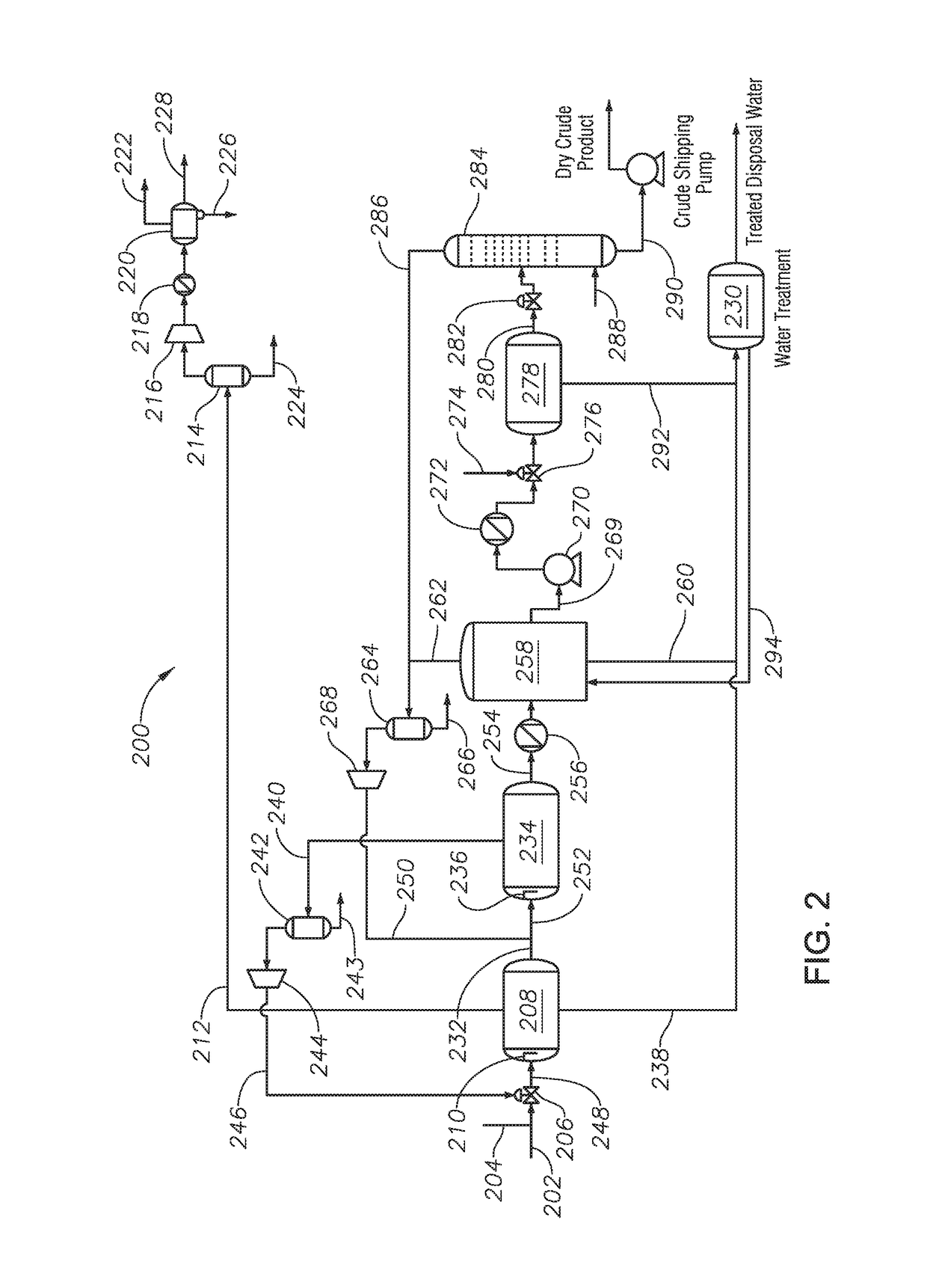

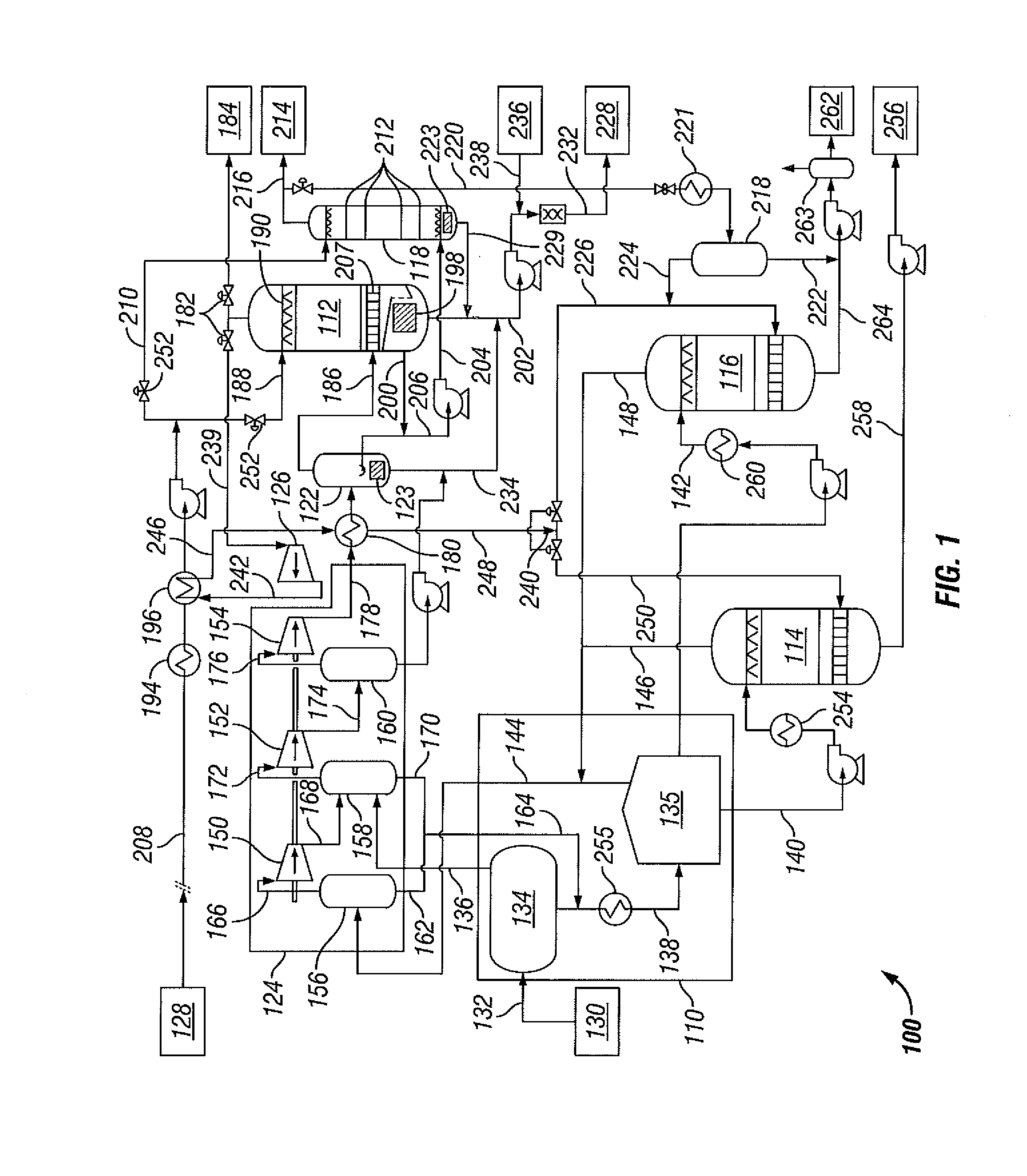

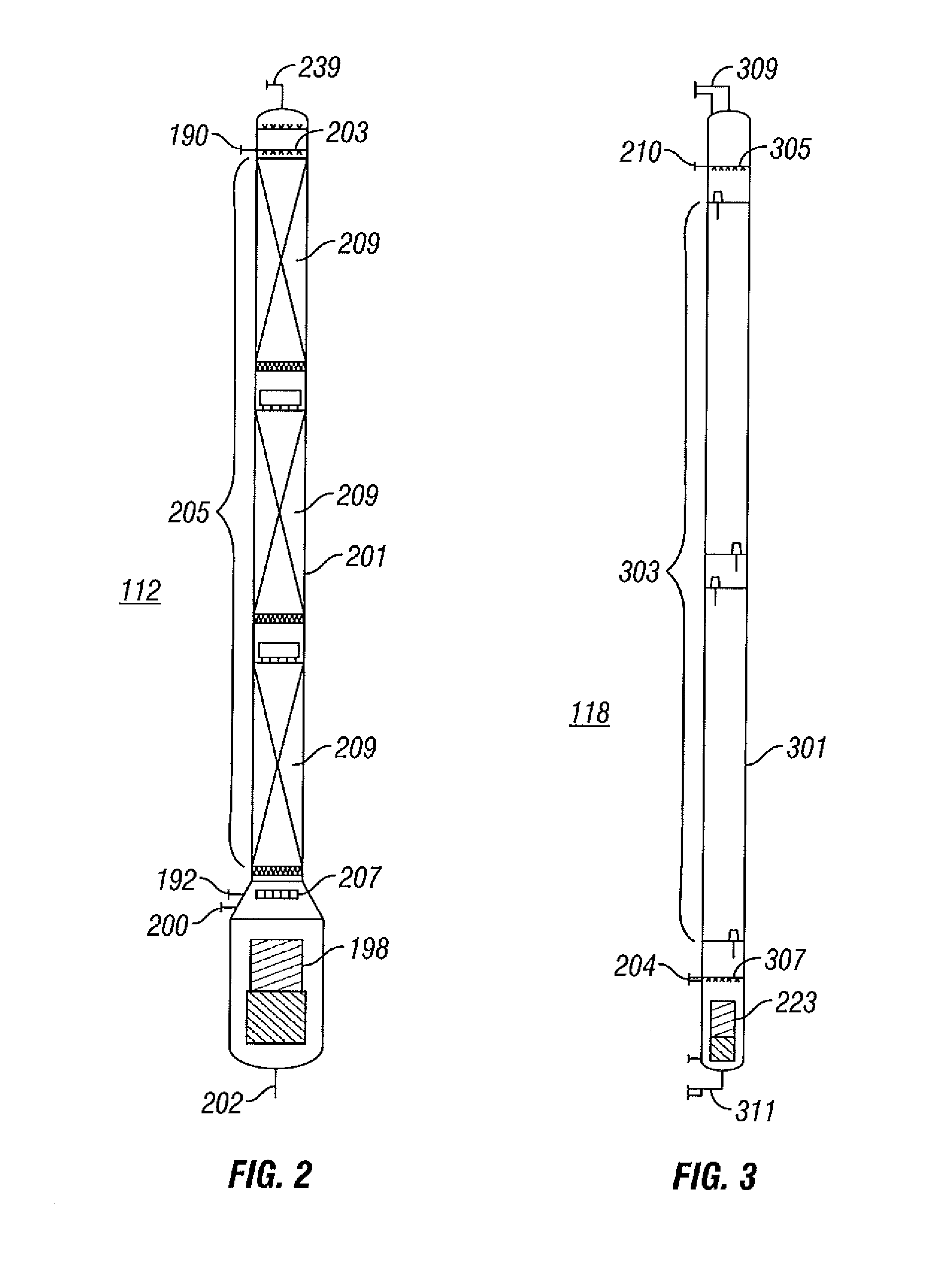

Integrated gas oil separation plant for crude oil and natural gas processing

ActiveUS10023811B2Low costReduce expenditureDewatering/demulsification with electric/magnetic meansLiquid hydrocarbon mixture recoveryNatural-gas processingAtmospheric air

Systems and methods of integrated gas oil separation are disclosed. Systems include a high pressure production trap (HPPT), a low pressure production trap (LPPT), a low pressure degassing tank (LPDT), a first knockout drum (KOD) fluidly coupled to the LPDT and operable to accept an atmospheric pressure off-gas from the LPDT, an atmospheric pressure compressor fluidly coupled to the first KOD and operable to compress the atmospheric pressure off-gas to introduce the atmospheric pressure off-gas from the LPDT into the LPPT inlet feed stream, a second KOD fluidly coupled to the LPPT and operable to accept a low pressure off-gas from the LPPT, and a low pressure compressor fluidly coupled to the second KOD and operable to compress the low pressure off-gas to introduce the low pressure off-gas from the LPPT into the crude oil inlet feed stream.

Owner:SAUDI ARABIAN OIL CO

Low-volatile liquid vacuum dehydrating method and device

InactiveCN104069652ASolve the problem of difficult to discharge the vacuum tankReduce volumeVacuum condensationLiquid degasificationWater dischargeProduct gas

Owner:王文兵

Method for processing sludge pyrolytic oil

InactiveCN101875848AEasy to operateLow costVacuum distillationHydrocarbon dewateringOil processingSludge

The invention relates to a method for processing sludge pyrolytic oil, comprising the following steps: 1) distilling and dewatering sludge pyrolytic oil containing water; 2) separating the distilled water and quasi-gasoline components; and 3) performing reduced pressure distillation on the dewatered oil to obtain fractions at different temperature stages. Oily matters generated by sludge pyrolysis is distilled and dewatered in a distiller, and the distillation condition is that water in the pyrolytic oil is distilled out at the temperature of 120-130 DEG C maintained for 1-3min. A dewatering and distilling device, a continuous or intermittent reduced pressure distillation device and a vacuum receiving and separating device utilized in the invention all can adopt equipment used in the raw oil processing procedure, as long as the requirements of dewatering, reduced pressure distillation and receiving and separating fractions can be satisfied. The method provided by the invention has simple operation and low cost, and provides necessary conditions for subsequent high performance fuel applications.

Owner:TIANJIN UNIV

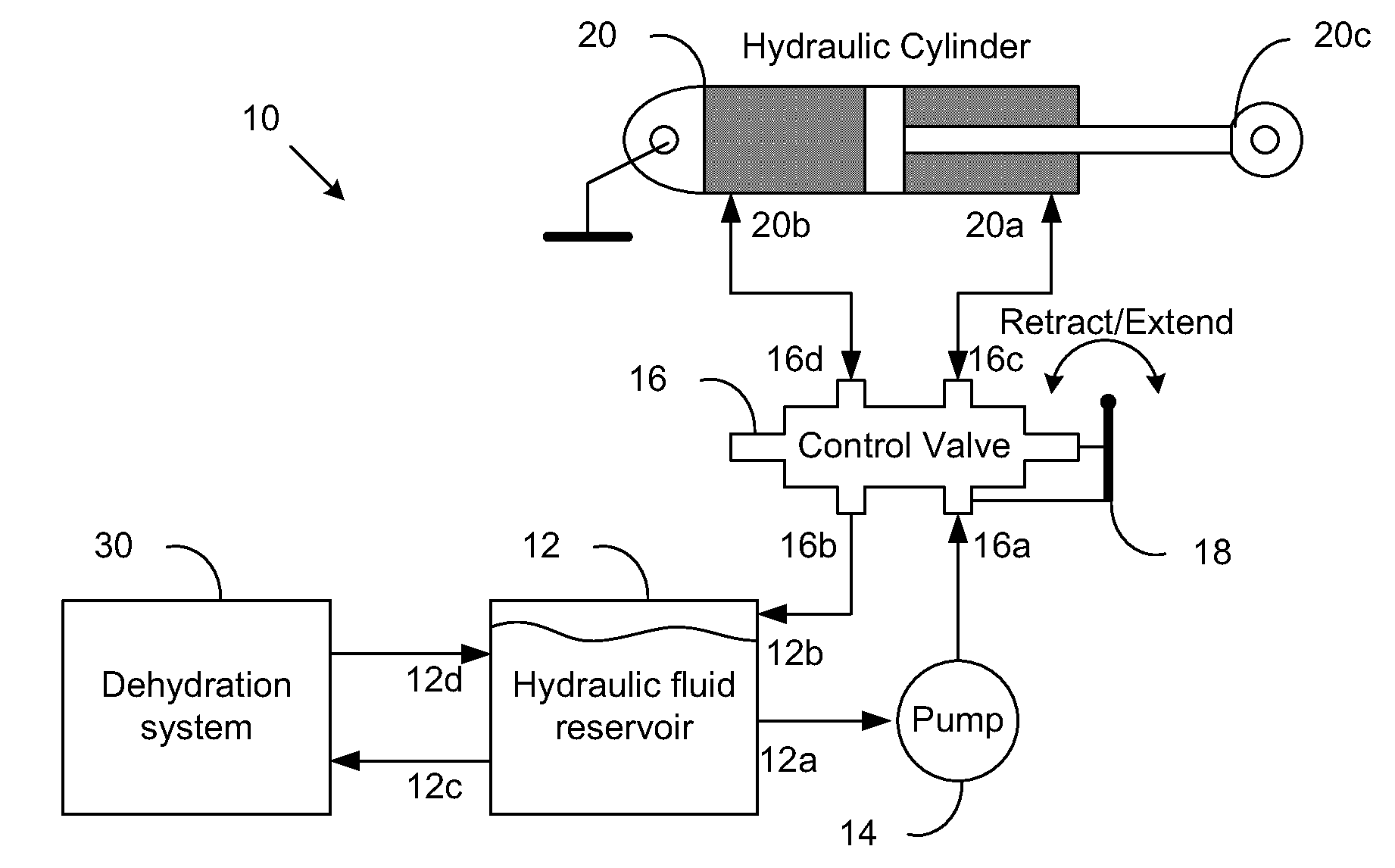

Method for recovering hydrocarbon fluids using a hydraulic fracturing process

ActiveUS20130248175A1Waste water treatment from quariesDewatering/demulsification with mechanical meansLiquid waterFilter media

A method for recovering and treating hydrocarbon fluids using a hydraulic fracturing process wherein a fluid stream containing liquid or gaseous hydrocarbon species or both, produced water, suspended solids, and dissolved contaminants is recovered from a well. and hydrocarbon species are separated from the fluid stream to produce a second fluid stream comprising liquid water, which is then directed to a filter medium and essentially all of the second fluid stream passes through the medium to produce a permeate stream and a filter cake, and the filter cake is separated from the medium and disposed of separately.

Owner:DUPONT SAFETY & CONSTR INC

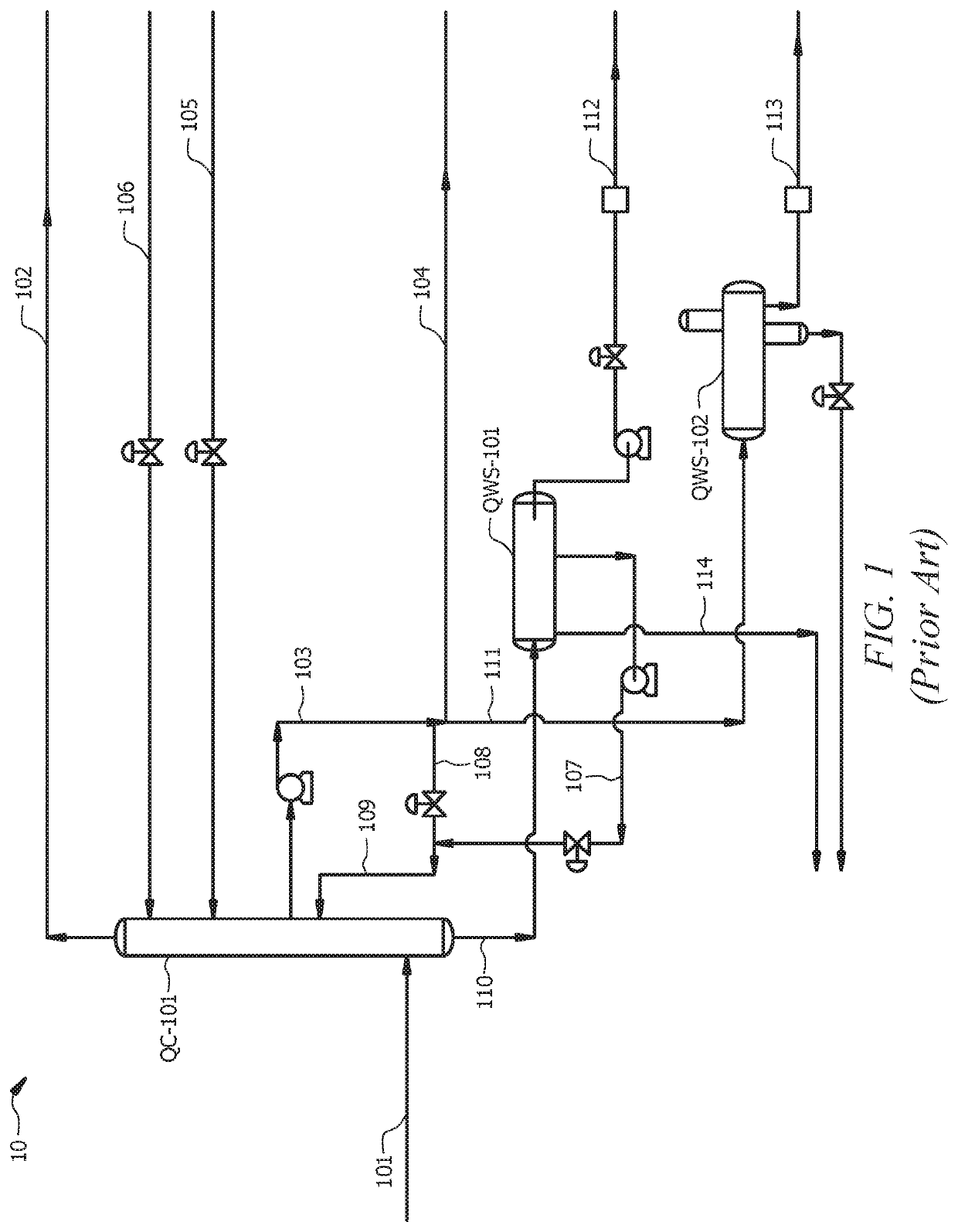

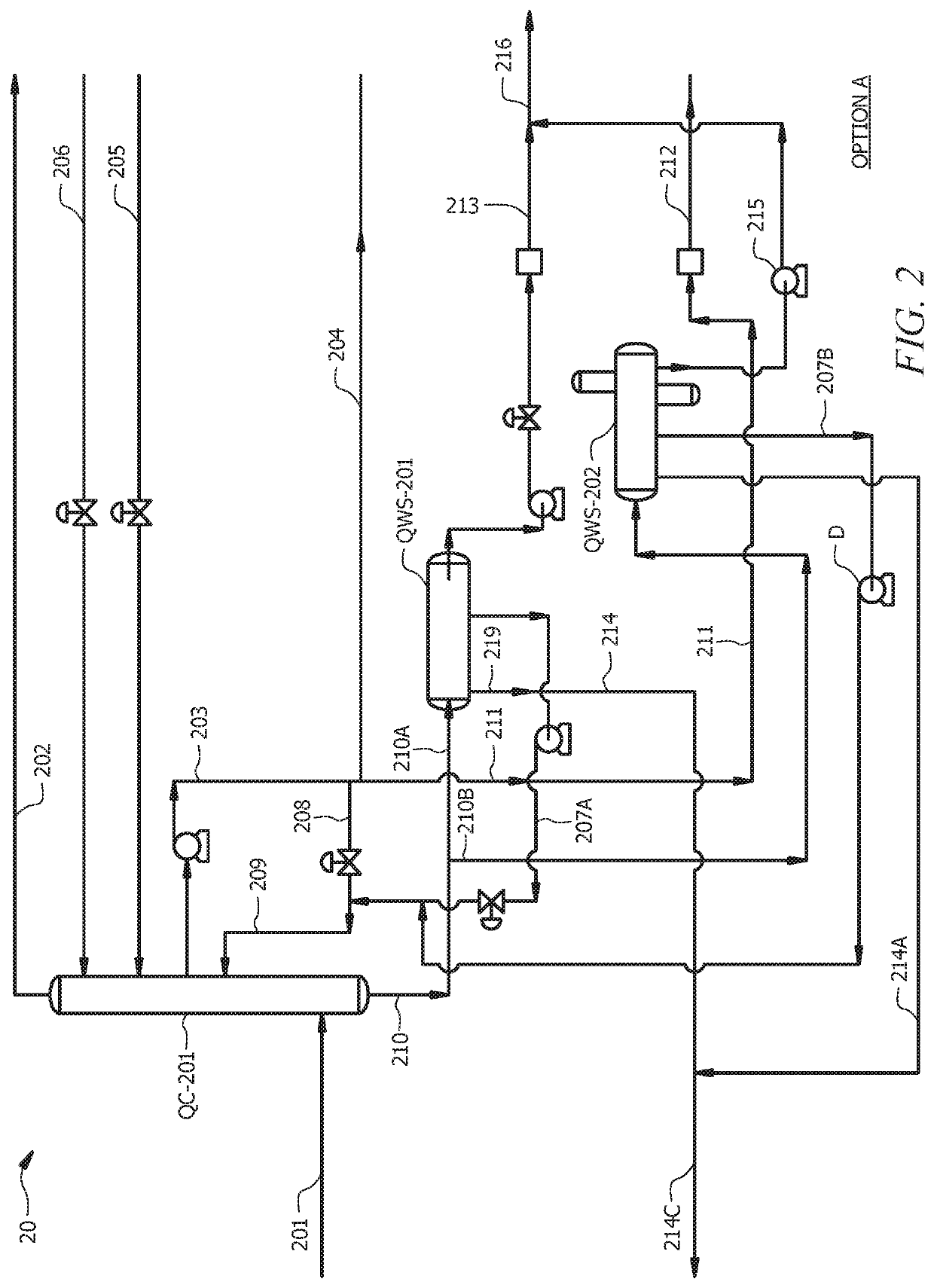

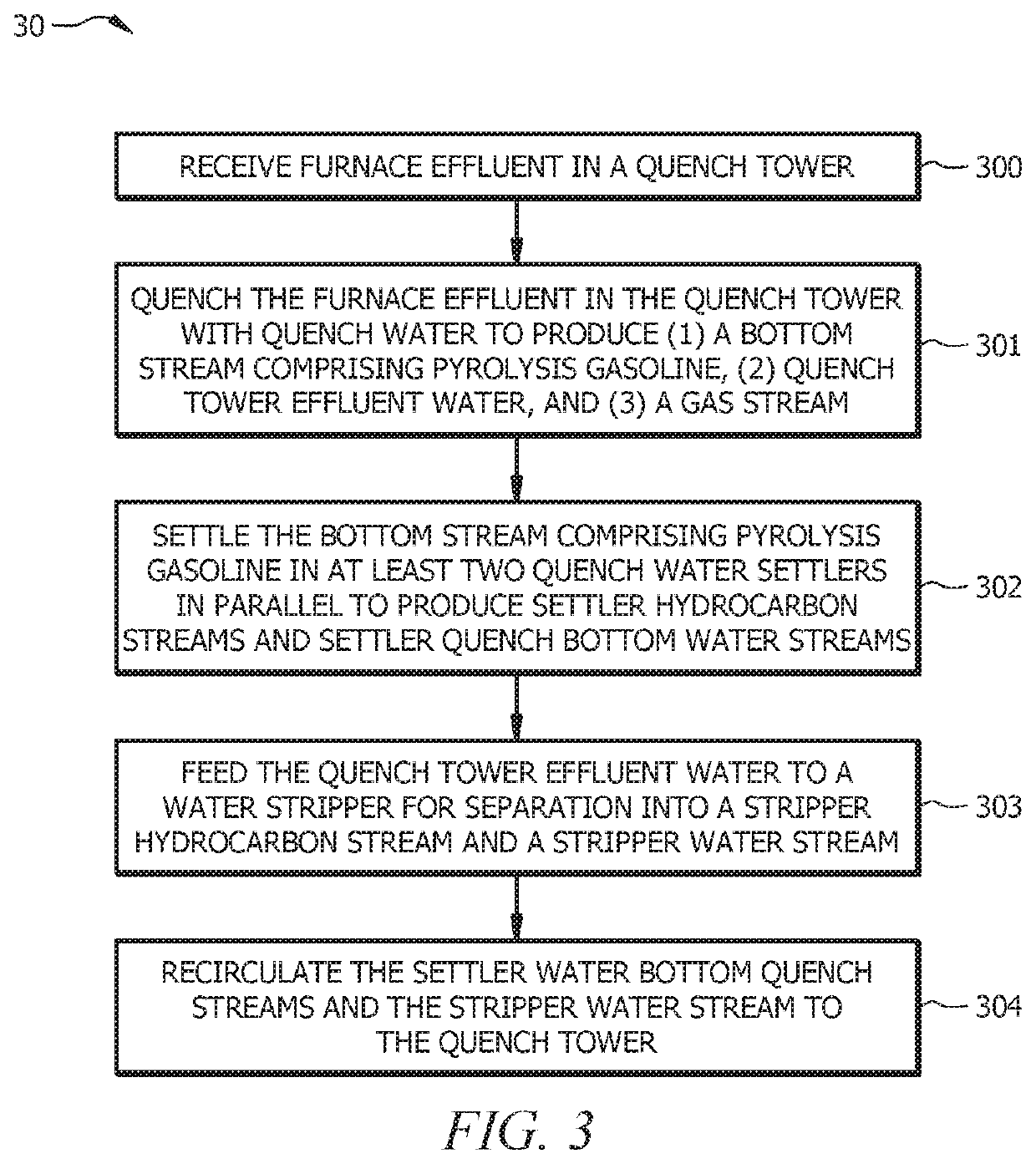

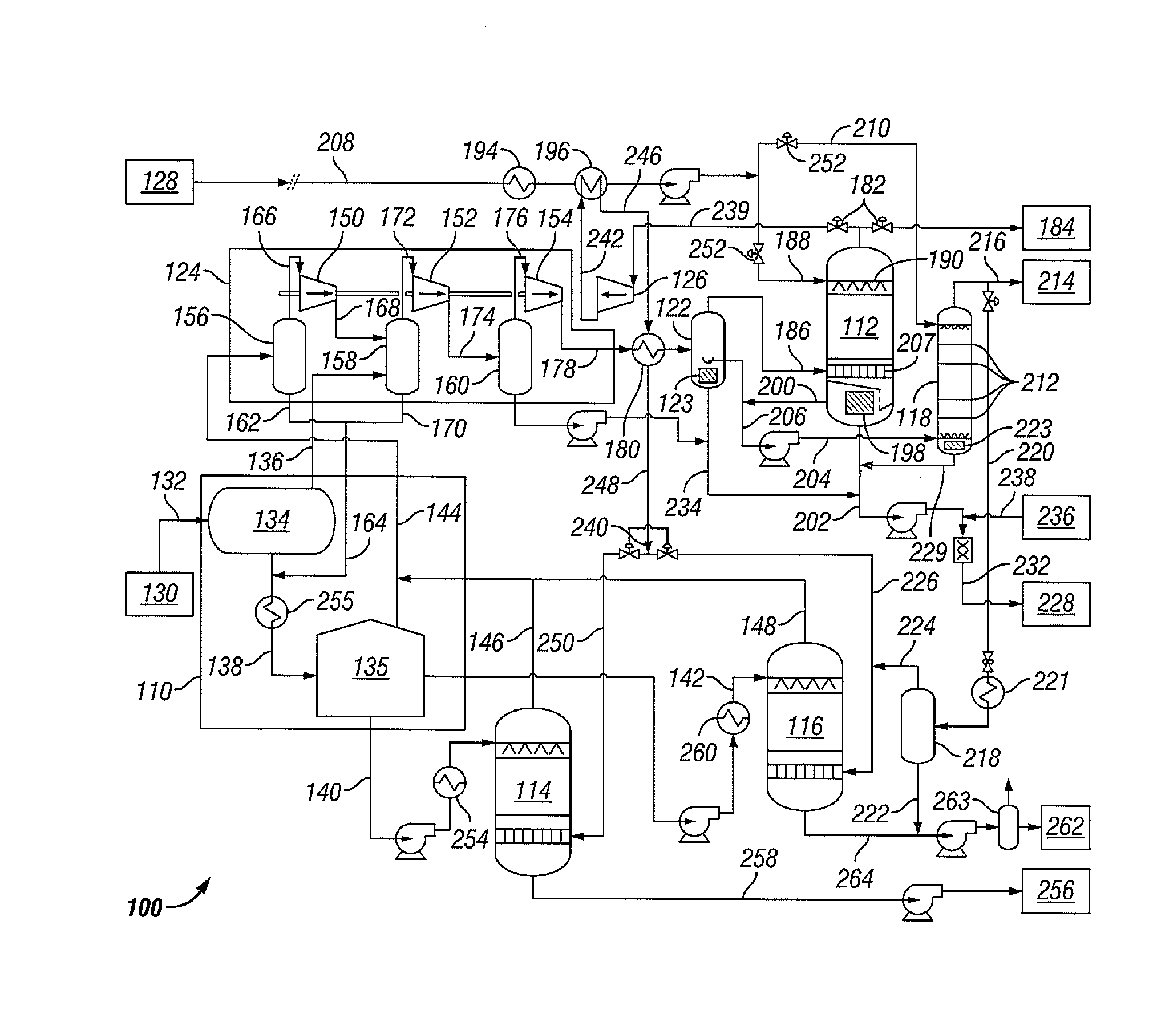

Steam quench performance improvement

ActiveUS20190375992A1Reduce and limit occurrenceImprove oil/water separationThermal non-catalytic crackingLiquid degasificationTarWater flow

Methods that reduce fouling of equipment in a quench water recycling loop of a steam cracker quench system by separating tar from water in the quench water recycling loop. The methods may include settling a bottom stream comprising pyrolysis gasoline, from a quench tower, in at least two quench water settlers in parallel, each of the quench water settlers producing a settler hydrocarbon stream and a settler bottom quench water stream. The methods may also include mixing a bottom stream comprising pyrolysis gasoline, from a quench tower, with quench tower effluent water to form a combined stream. The method may further include settling the combined stream in at least two quench water settlers in parallel to produce settler hydrocarbon streams, settler bottom quench water streams, and settler process water streams.

Owner:SABIC GLOBAL TECH BV

Systems and method for separating dimethyl ether from oil and water

ActiveUS20140338904A1Gas treatmentLiquid degasification with auxillary substancesAlkanePhysical chemistry

A system is provided for removing dimethyl ether (DME) from oil, water or brine and gas that includes a gas-oil-water separation module, a DME absorber, a water stripper, a liquid-liquid extractor, a water source, and an oil stripper, and a process is provided for separating DME from a mixture of DME, crude oil, water or brine, and a gas containing alkane hydrocarbons. A DME lean oil containing at most 1 ppmwt may be produced by the process.

Owner:SHELL USA INC

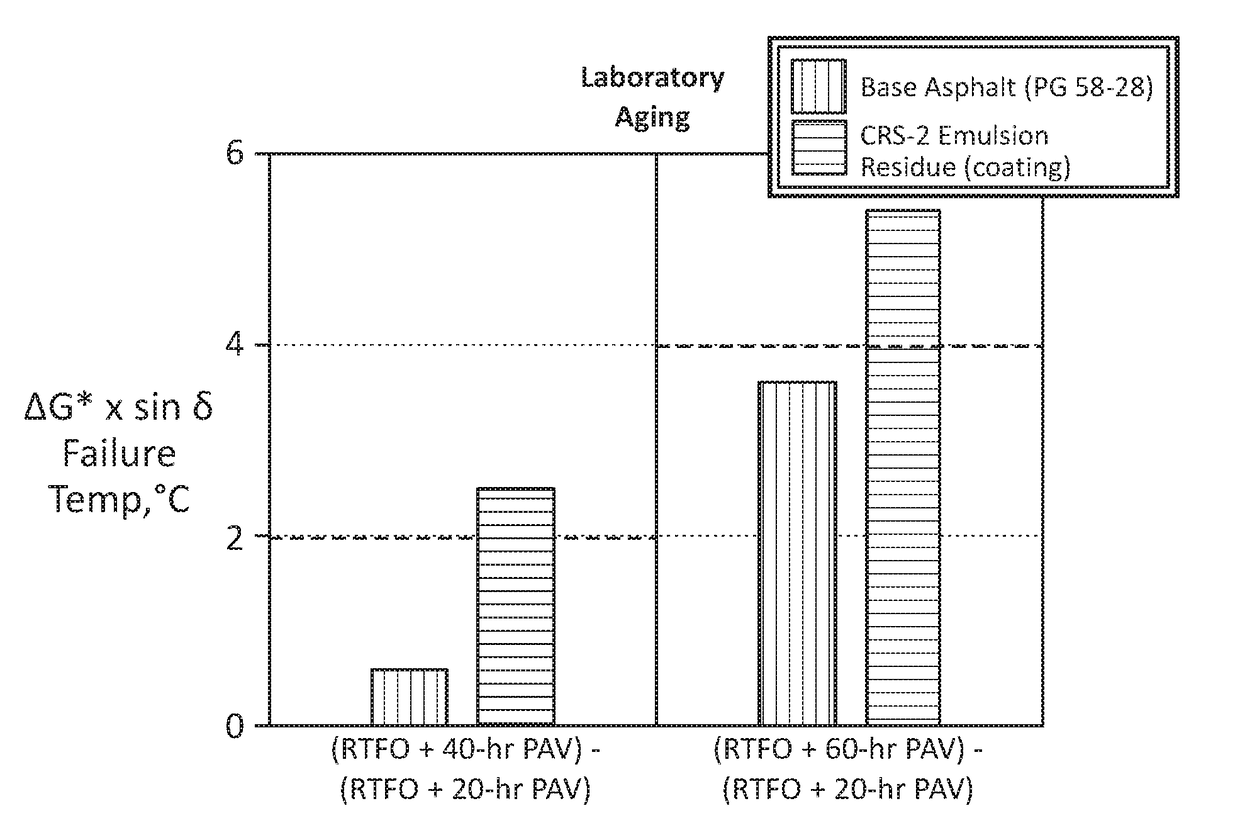

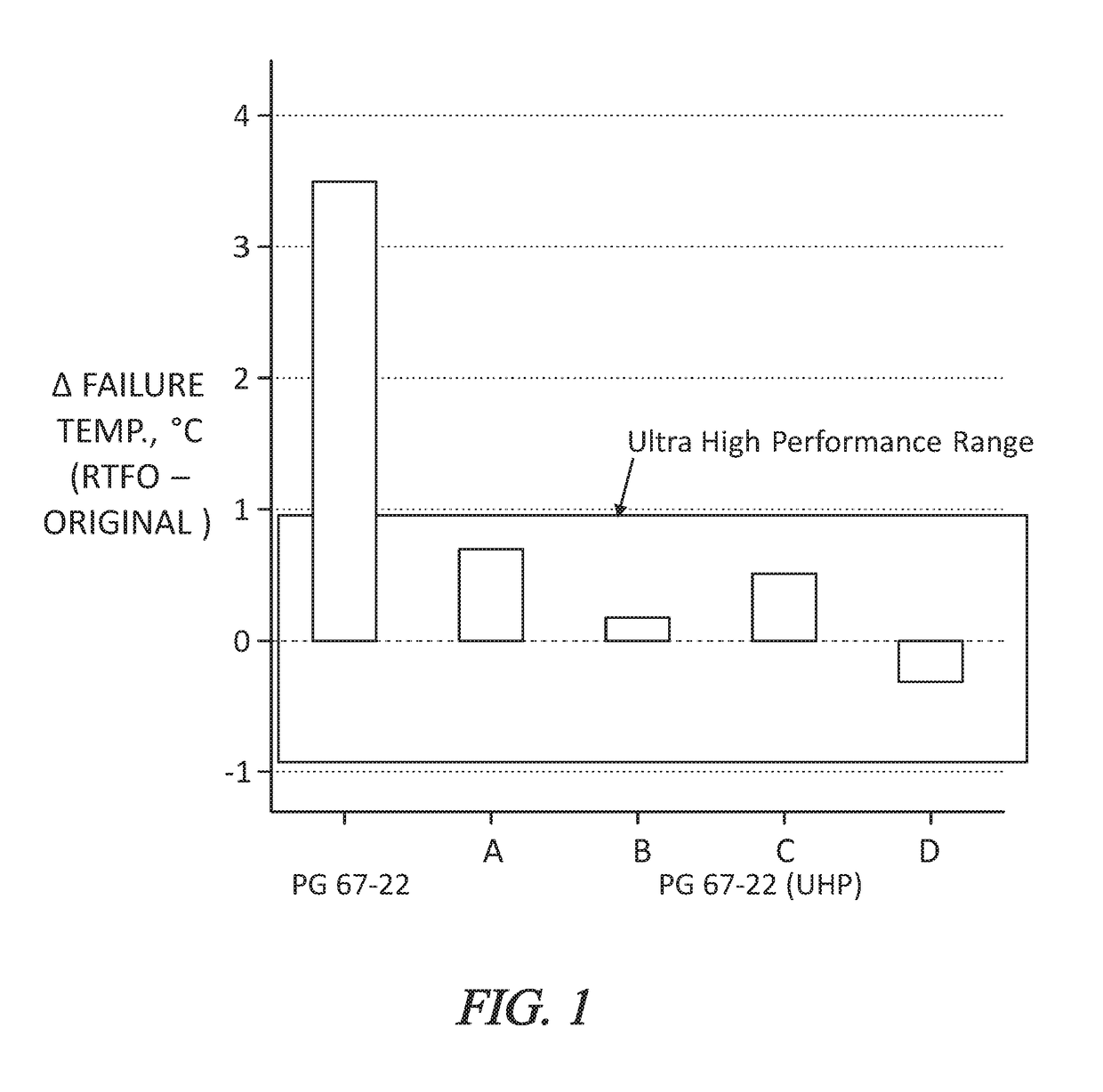

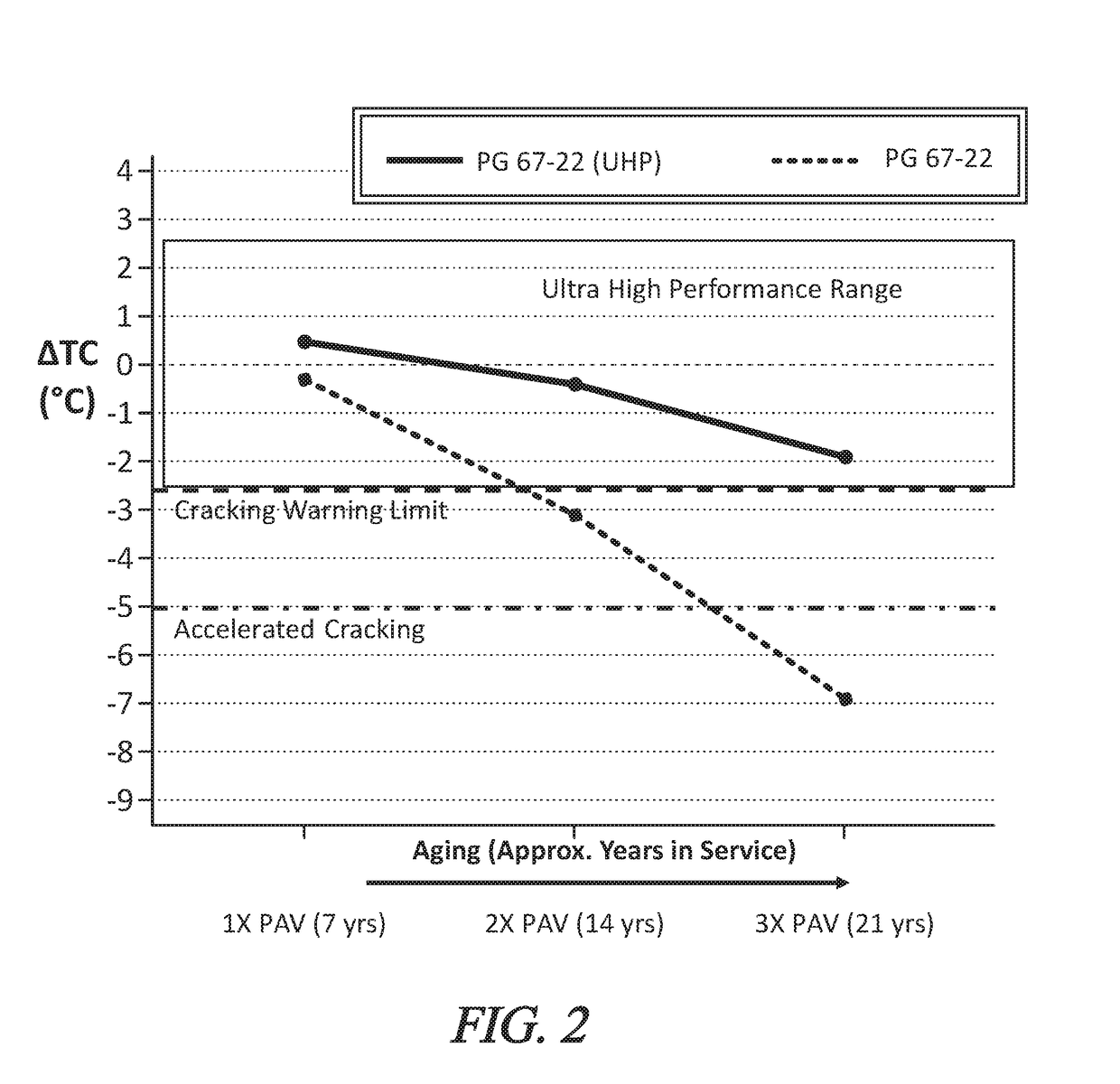

Age resistant coatings and methods for treating roadway substrates

Aging resistant emulsified asphalt compositions and related methods of preparing and applying the same for use in asphalt treatment and paving applications. The aging resistant emulsified asphalt compositions can include an aging resistant asphalt composition, emulsifier, and water. The resulting residue formed when the emulsified asphalt composition has cured is aging resistant and can be resistant to age-induced cracking even after simulated aging of 14 years and 21 years. Appropriate use of emulsifiers in some embodiments can further improve aging resistance in the residues.

Owner:BLACKLIDGE EMULSIONS

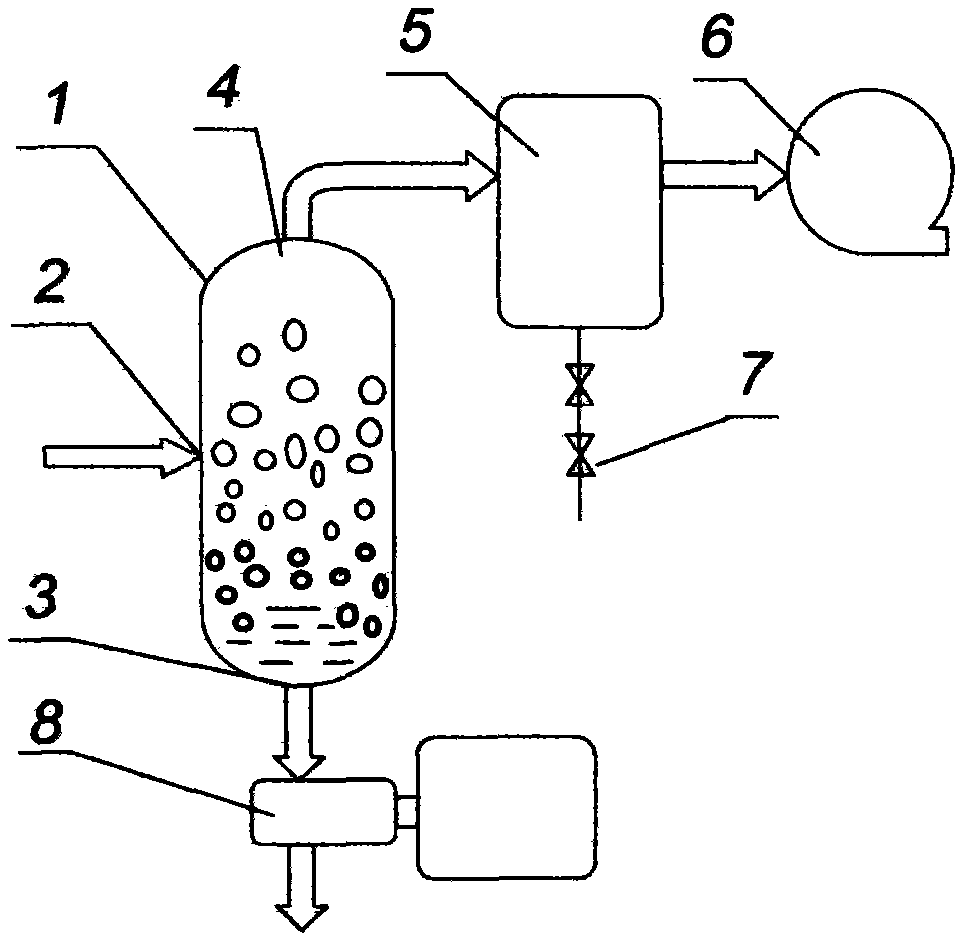

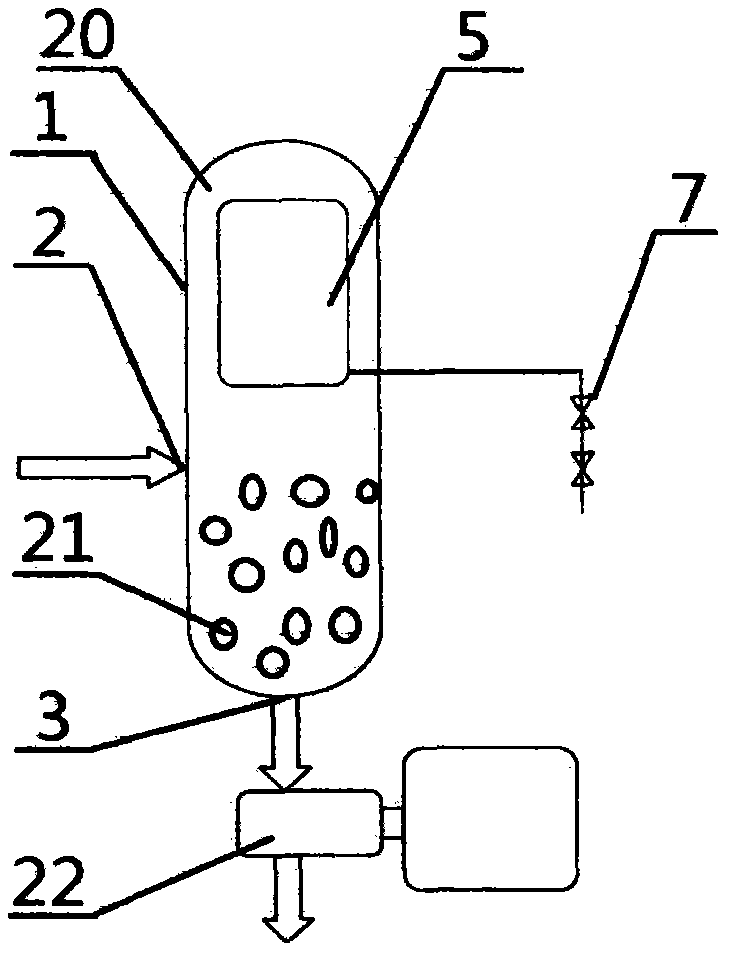

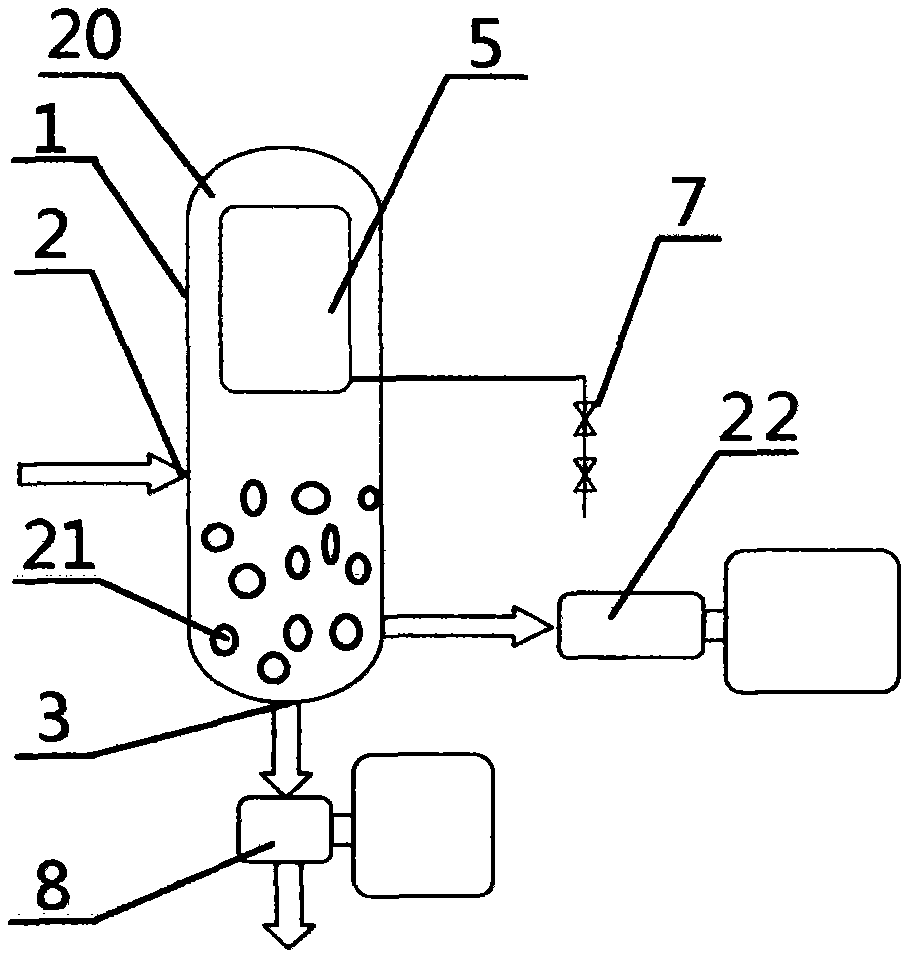

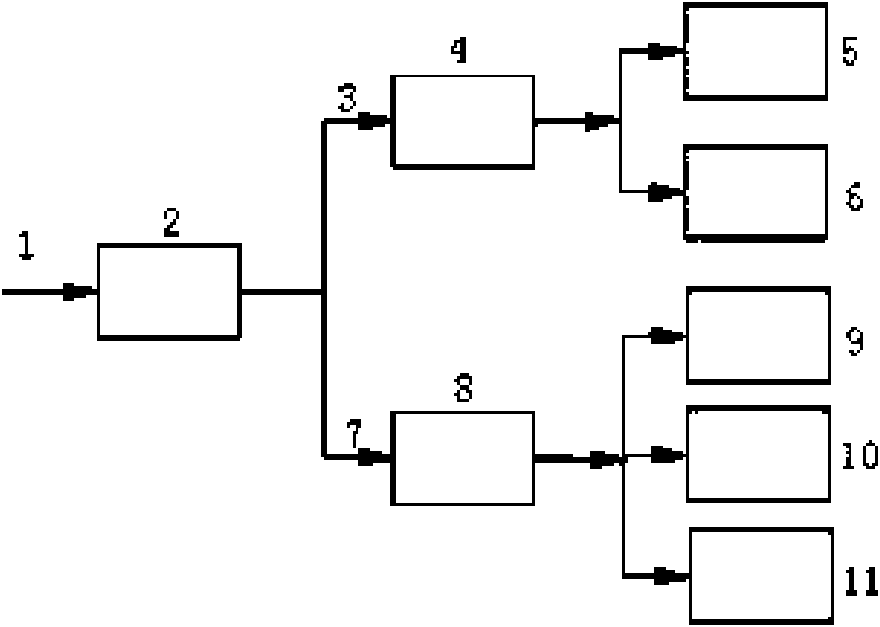

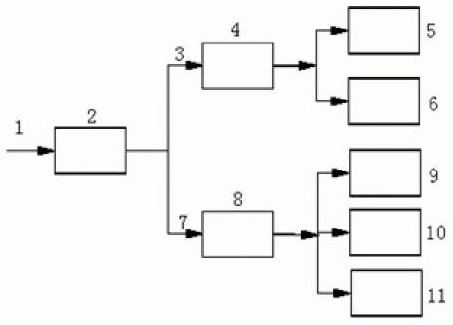

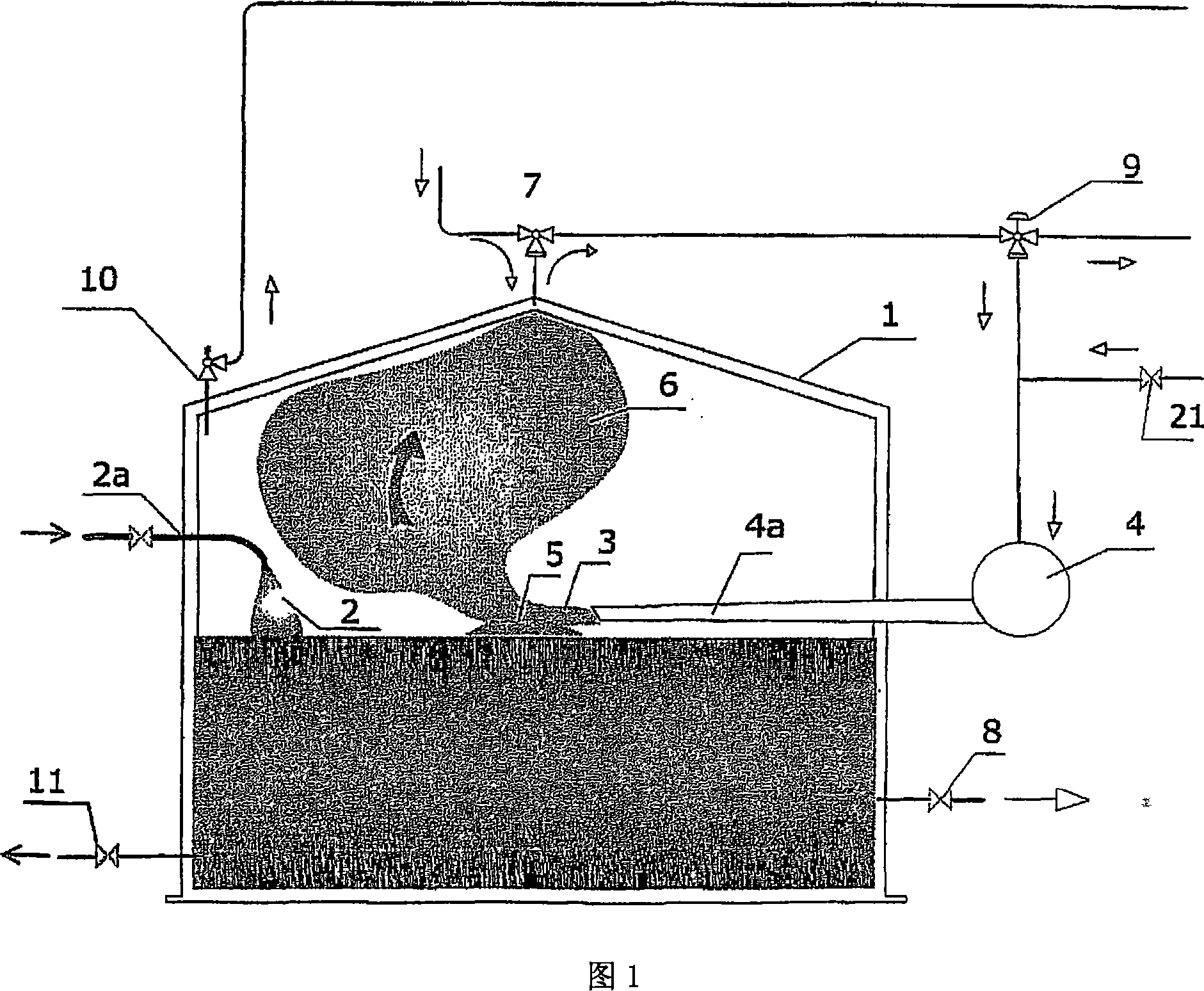

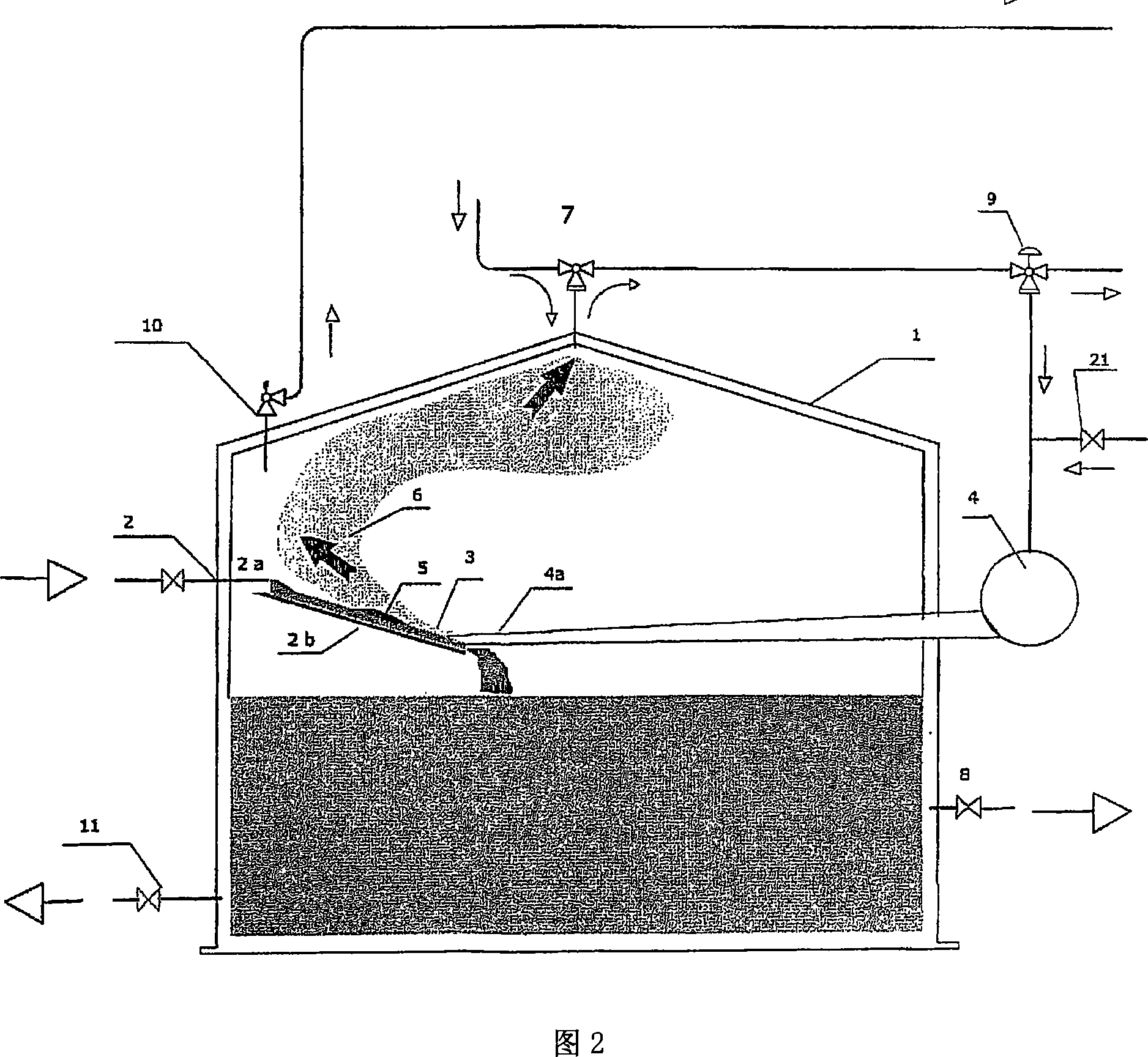

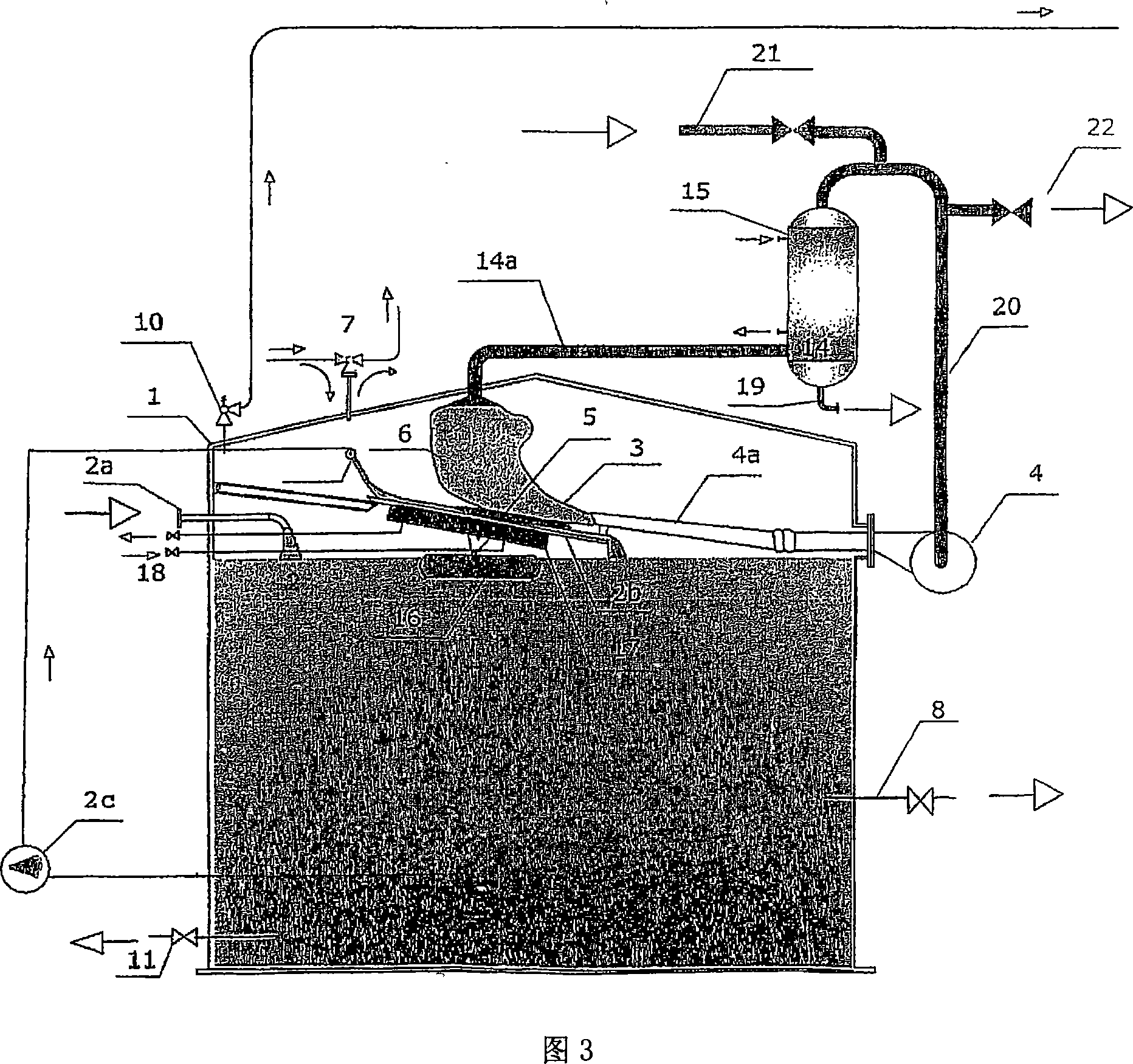

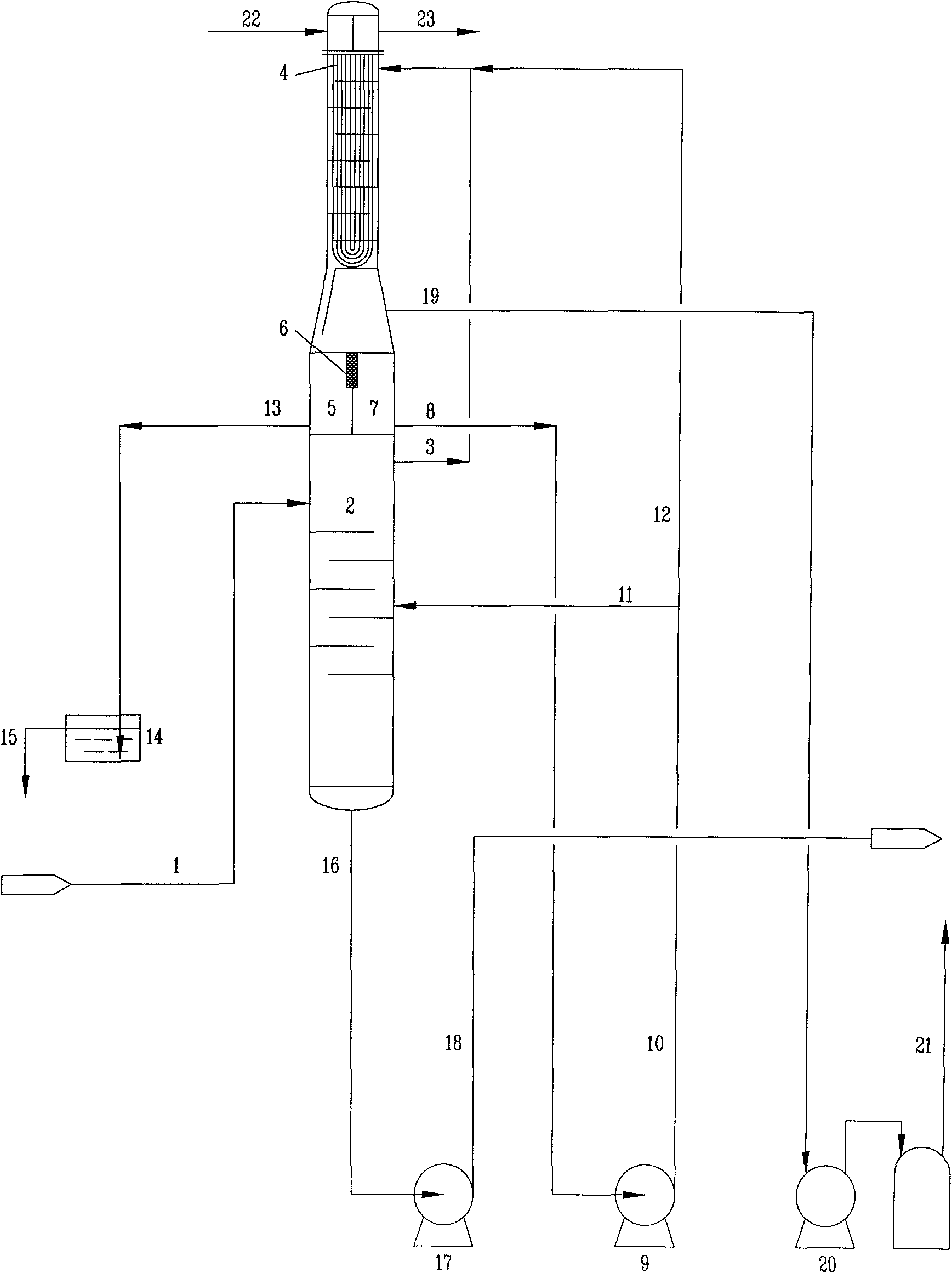

Process and device for separation of liquids emulsified in mixtures of liquids and gases dissolved in mixtures of liquids and gases by localized pressure reduction

InactiveCN101227959AIdeal end productLiquid degasification with auxillary substancesHydrocarbon distillation control/regulationEmulsionDistillation

A process, and a device for implementing the process, for separation of fluids in emulsion and / or in solution, and / or for low pressure distillation, in particular of water and / or gaseous hydrocarbons dissolved in crude petroleum, and / or for separation of crude petroleum droplets emulsified in water, so as to obtain water with the necessary characteristics for its injection without pollution of underground aquifers, and / or when the mixture is dominant in crude petroleum, acceleration of the settling of the water in the lower part of the mixture, and / or for low pressure distillation of crude petroleum. The method creates a localized zone (5) of reduced pressure on part of the free surface of a liquid (2) to be processed, within a closed processing tank (1), without the overall pressure inside the closed processing tank being affected.

Owner:PARTEX SERVICES PORTUGAL - SERVICOS PARA A IND PETROLIFERA

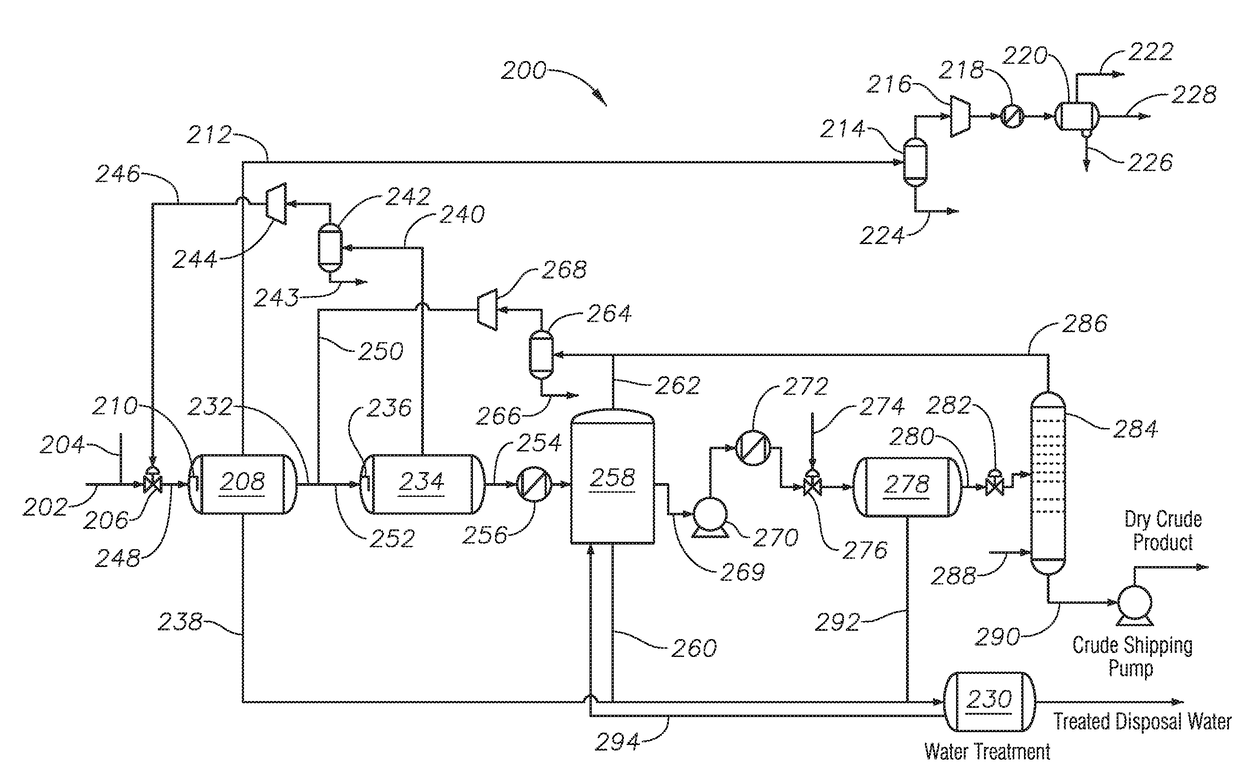

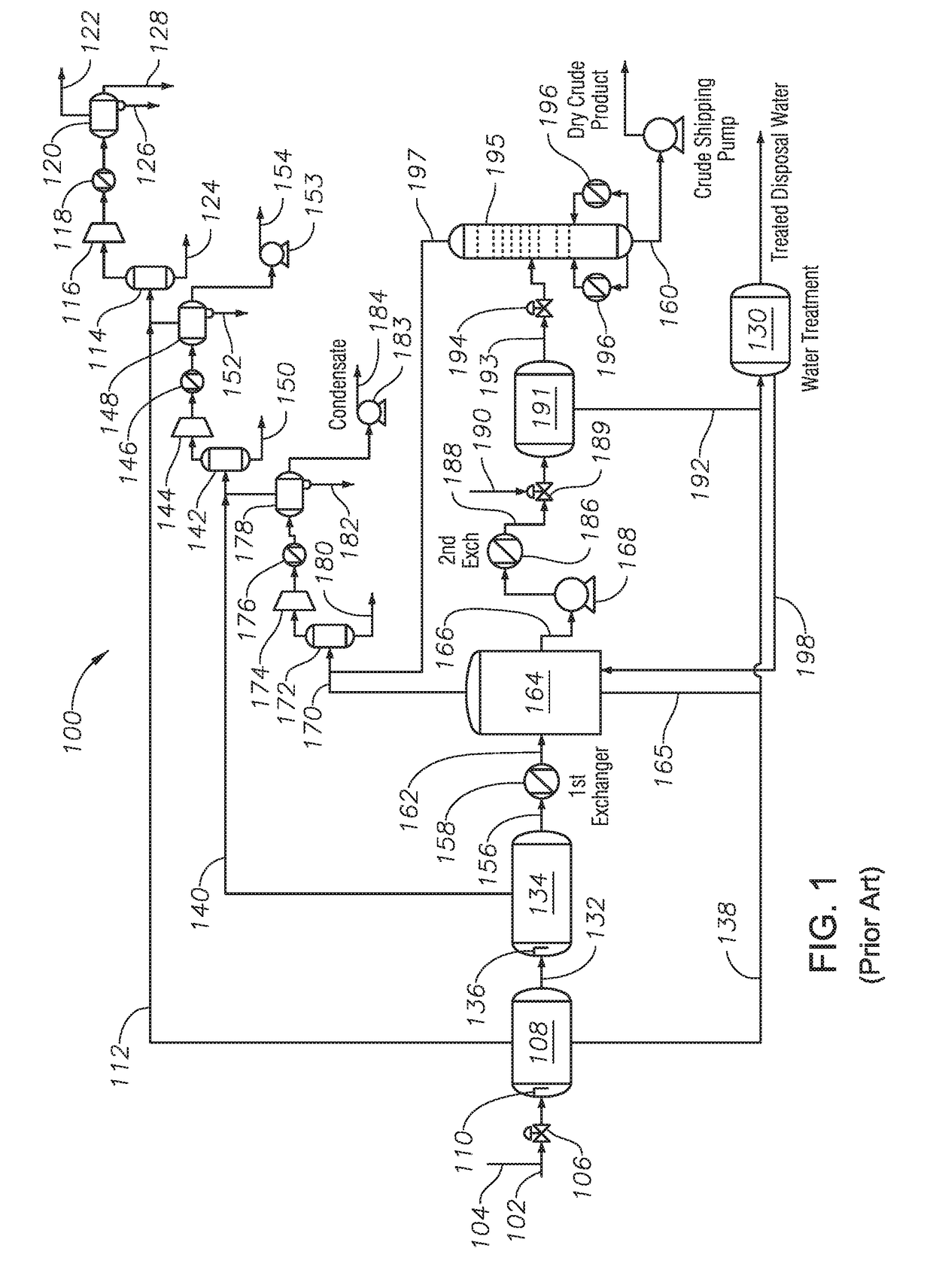

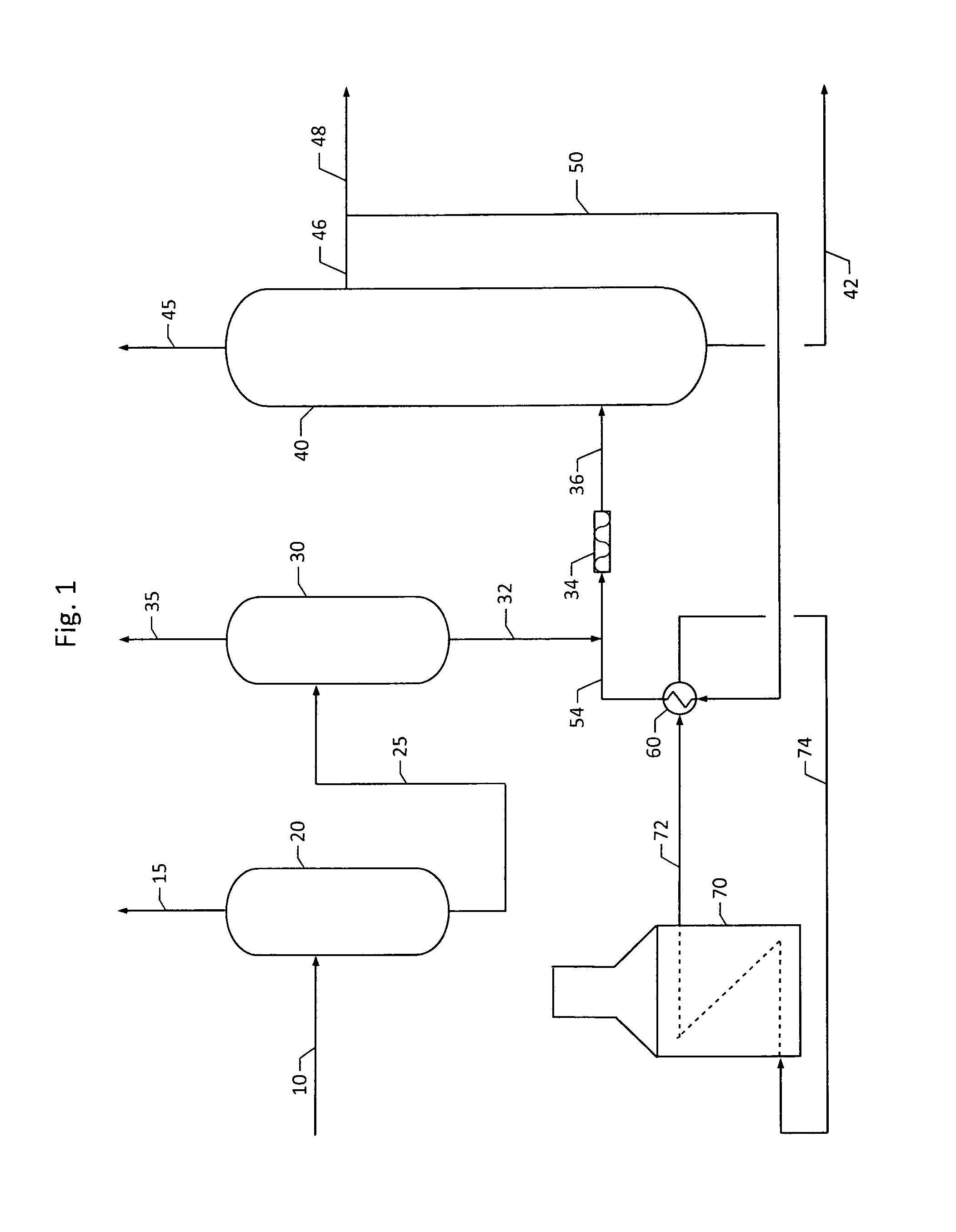

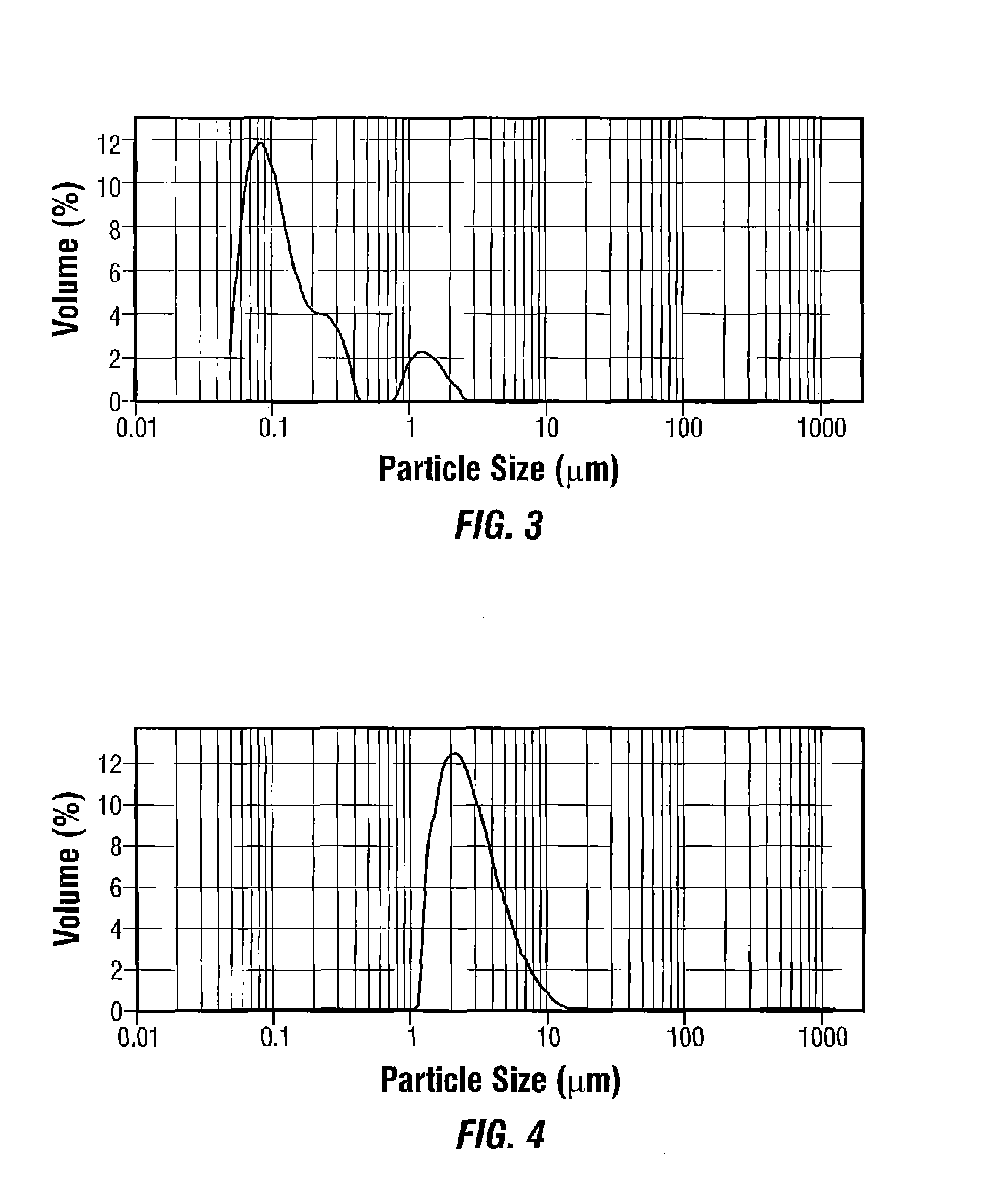

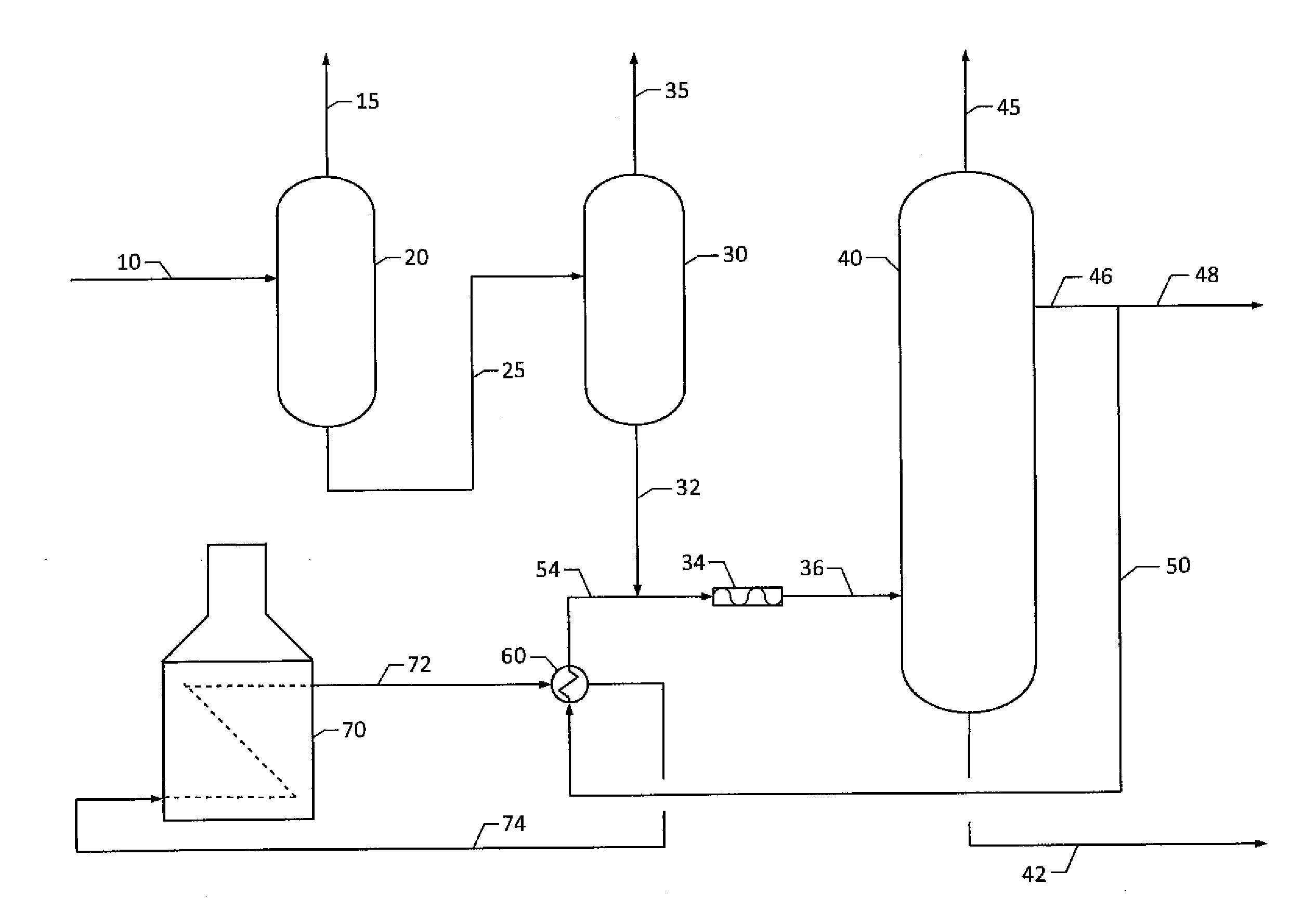

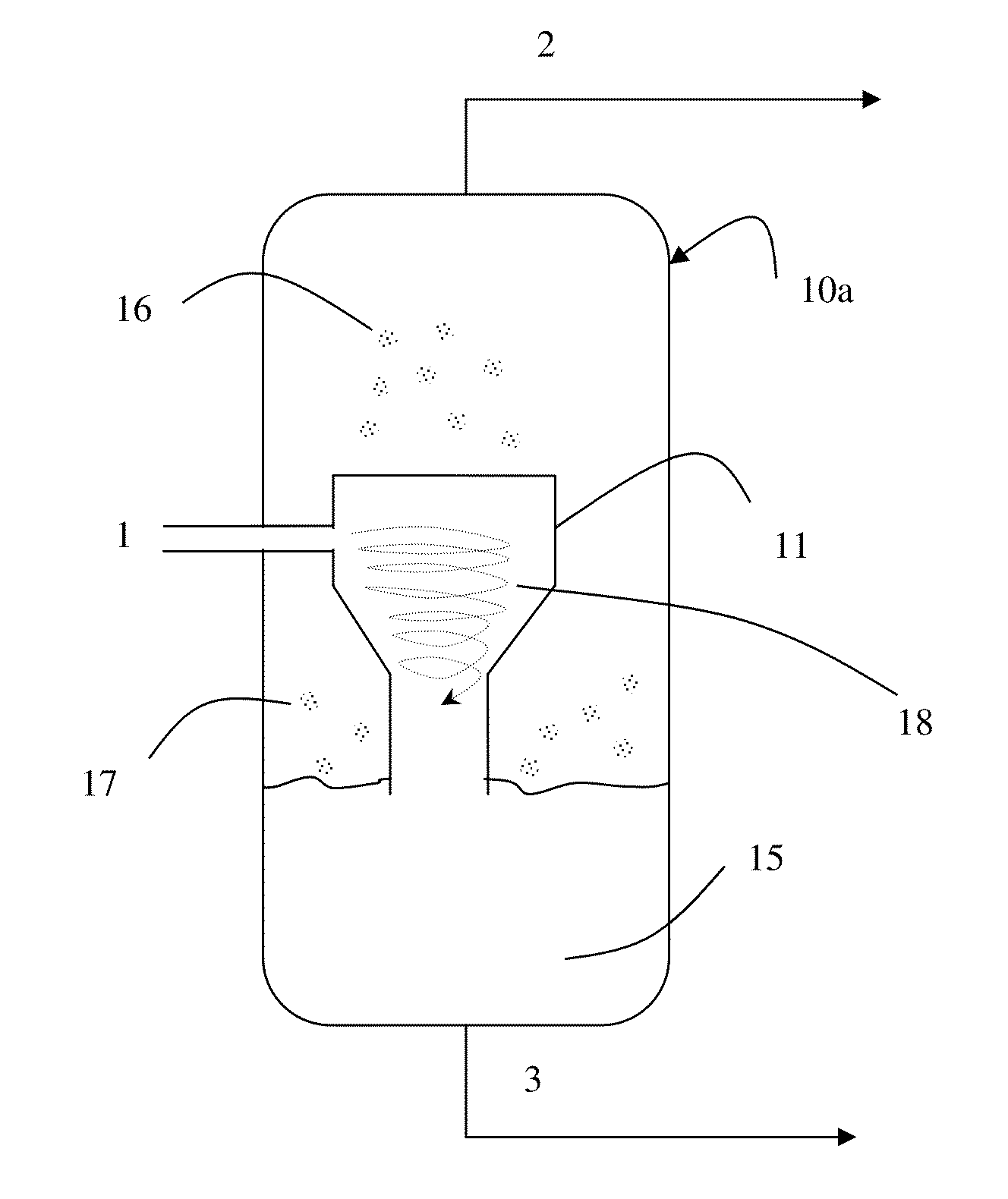

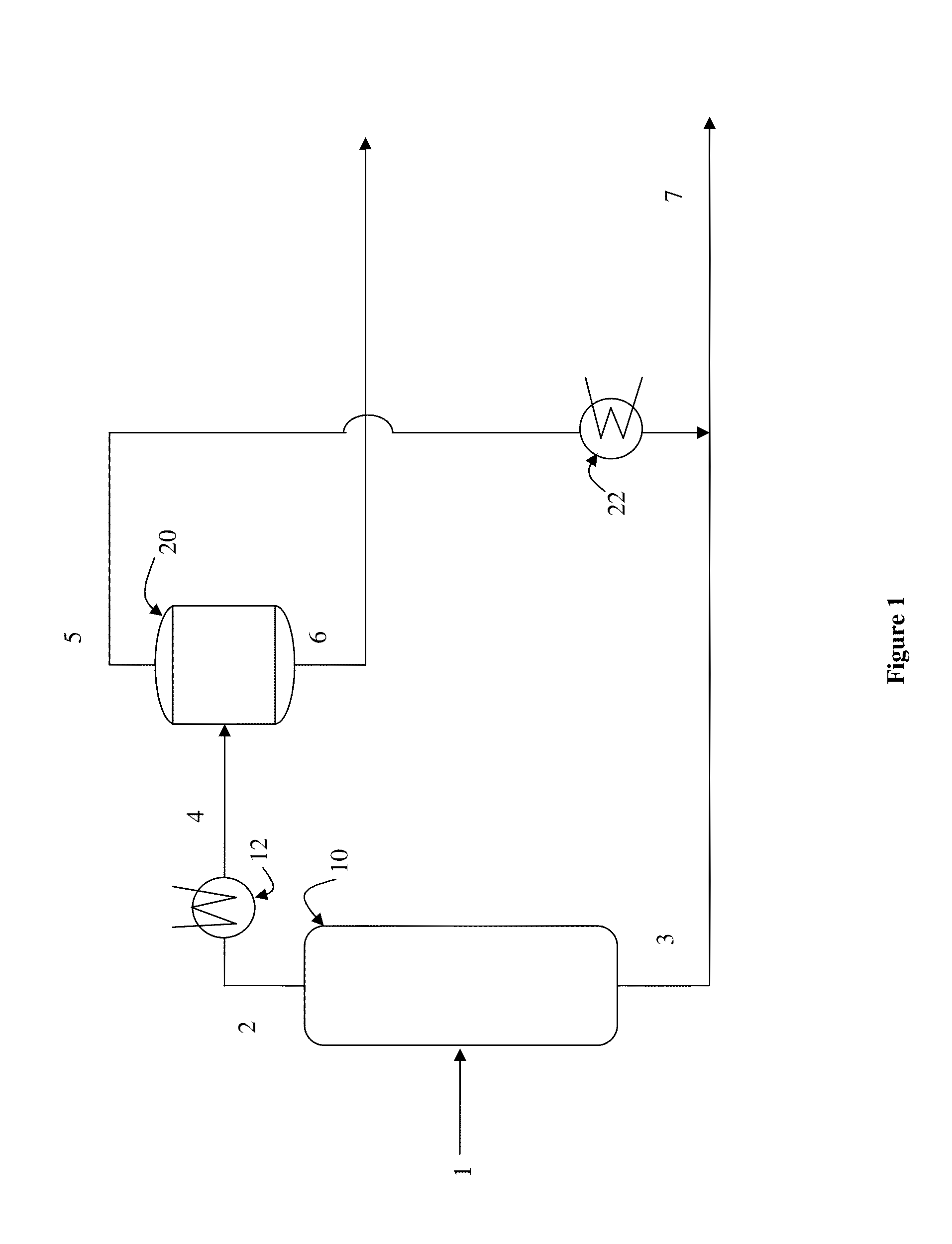

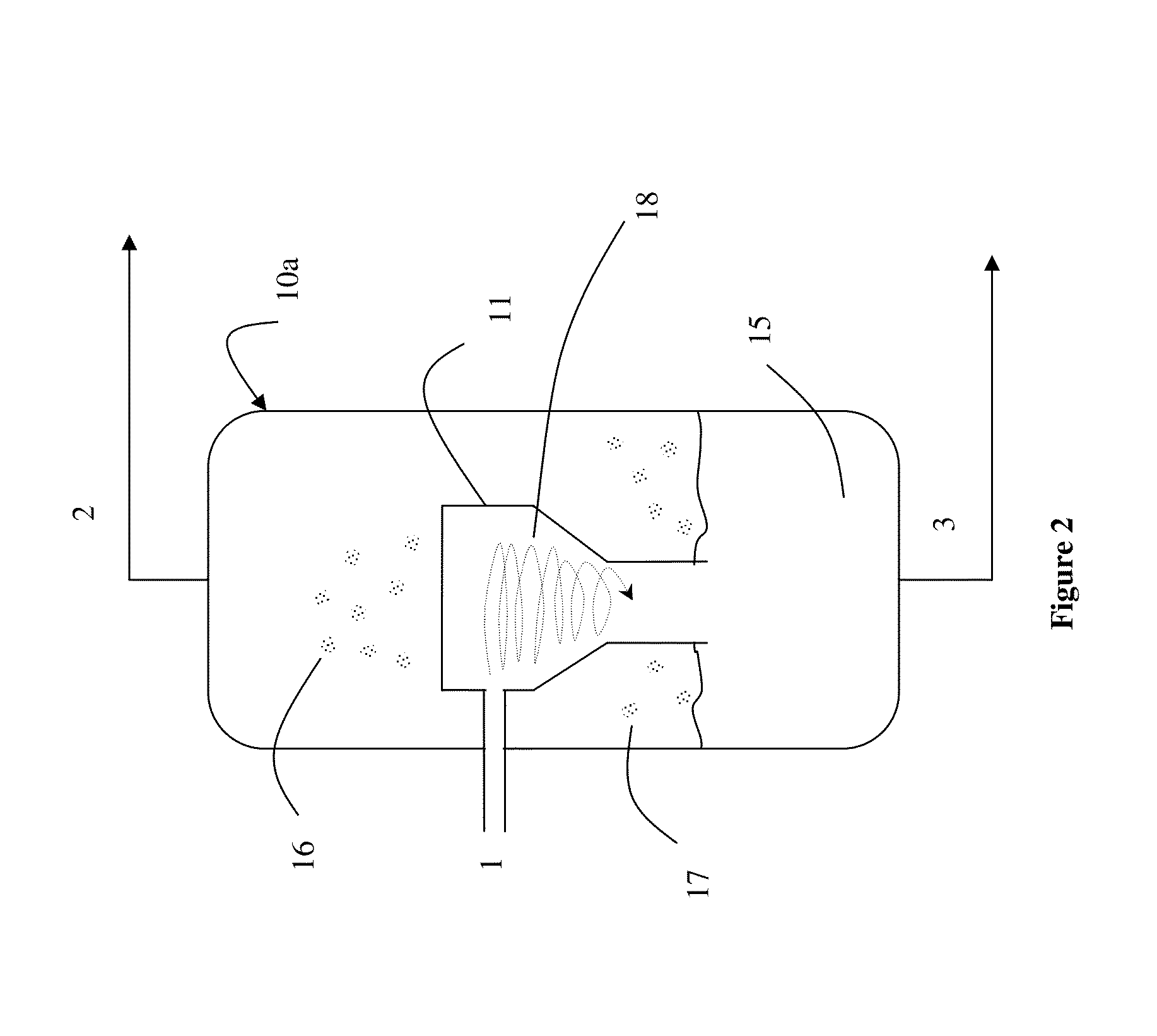

Configurations and methods of dewatering crude oil

ActiveUS20150344789A1Small sizeSampled-variable control systemsDewatering/demulsification with mechanical meansEngineeringWaste management

A process for dewatering crude oil is described. The process includes feeding crude oil onto a separation of a cyclone separator that is at least partially disposed in a flash vessel. The temperature are pressure in the flash vessel are selected such that at least 20% of the water contained in the crude oil is flashed from the crude oil as it moves on the separation surface of the cyclone separator. The flow rate and angle of the crude oil inlet is selected such that the crude oil moves across the separation surface as a film in a helical pattern, providing a substantial foaming-free manner. The vapor that is flashed from the crude oil exits the flash vessel at a top outlet and the liquid crude oil exits the flash vessel at a bottom outlet.

Owner:FLUOR TECH CORP

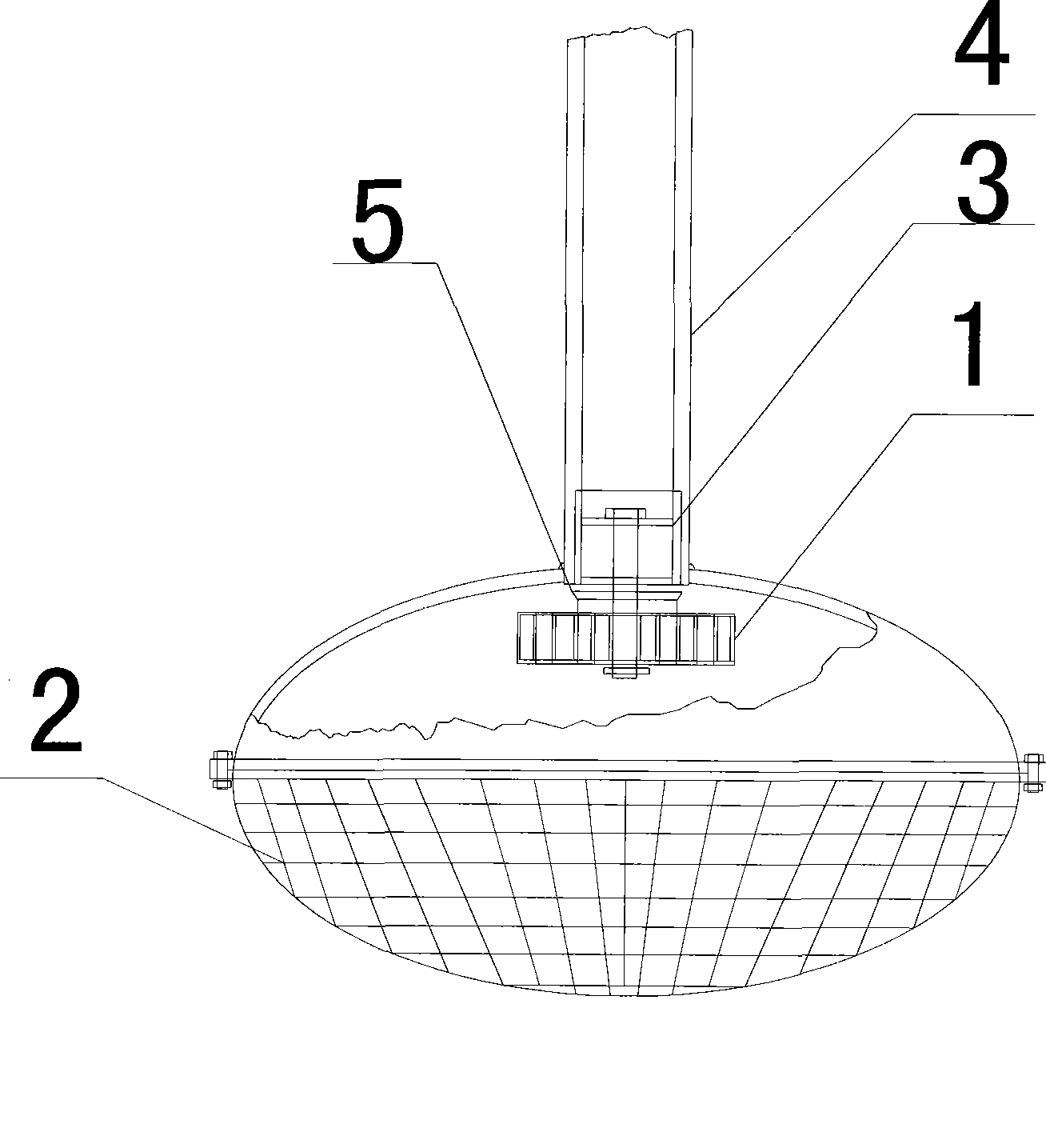

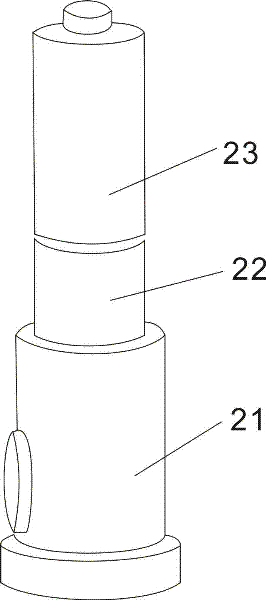

Rotary type atomizing sprayer

InactiveCN101371951AIncrease volumeReduce the probability of bindingEvaporation by sprayingHydrocarbon dewateringImpellerSprayer

The present invention relates to a rotary atomizing spray device which is used in the part of the product of a high-viscidity oil cleaning device of large mechanical equipment, realizes the function of improving the atomization effect and belongs to the technical field of spray device manufacture. The device comprises a rotary impeller (1), a sprayer nozzle (2), an impeller fixing base (3), an oil guide pipe (4) and an impeller guide cover (5). An outlet of the oil guide pipe (4) is provided with the impeller guide cover (5). The impeller fixing base (3) is arranged in the impeller guide cover (5). The rotary impeller (1) is arranged under the impeller guide cover (5) and the impeller fixing base (3). The rotating shaft of the rotary impeller (1) is arranged in the impeller fixing base (3). The sprayer nozzle (2) is arranged under the rotary impeller (1). A vane of the rotary impeller (1) forms obliquity with the rotary impeller (1) along the axial direction.

Owner:镇江市长江机电设备厂有限公司

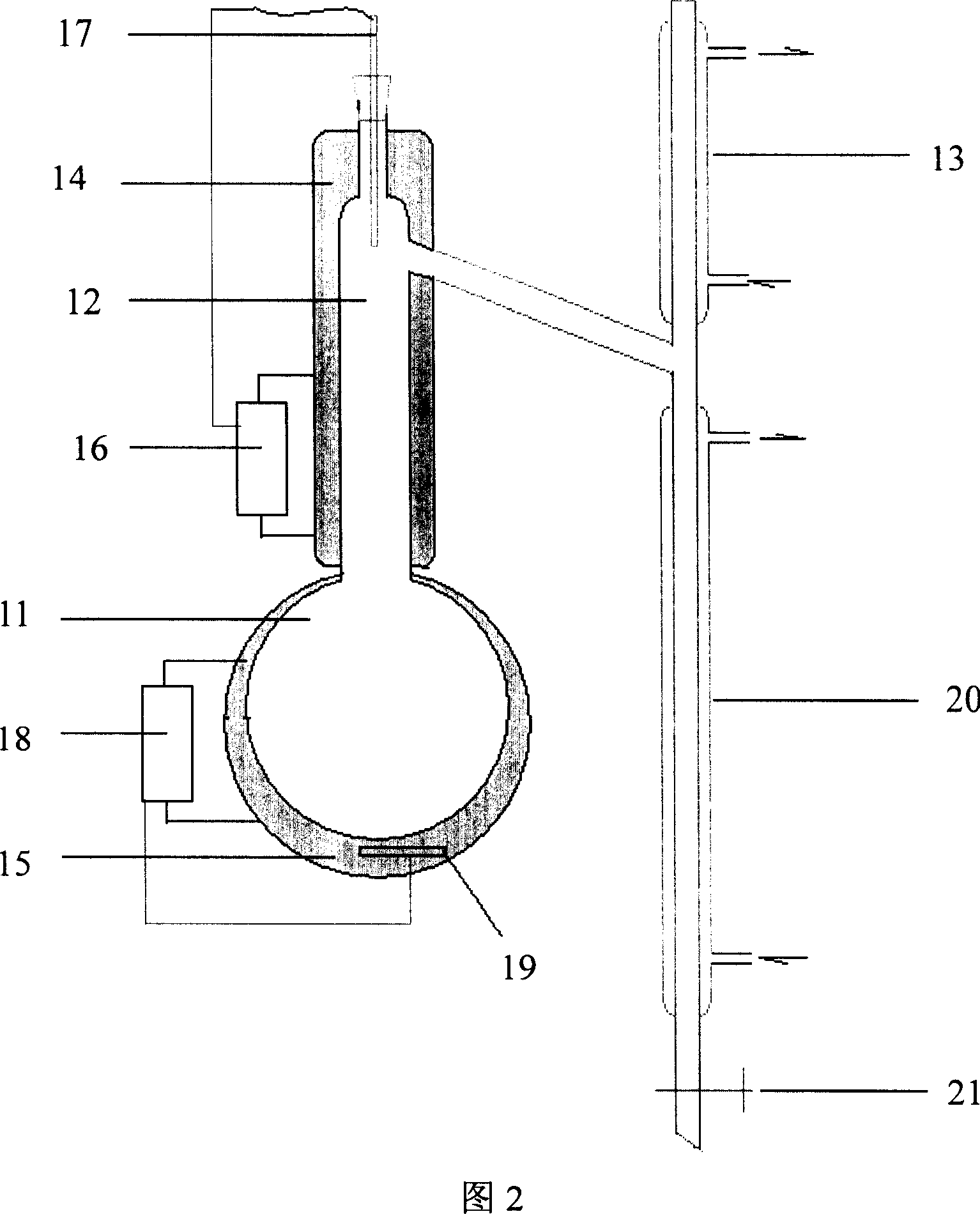

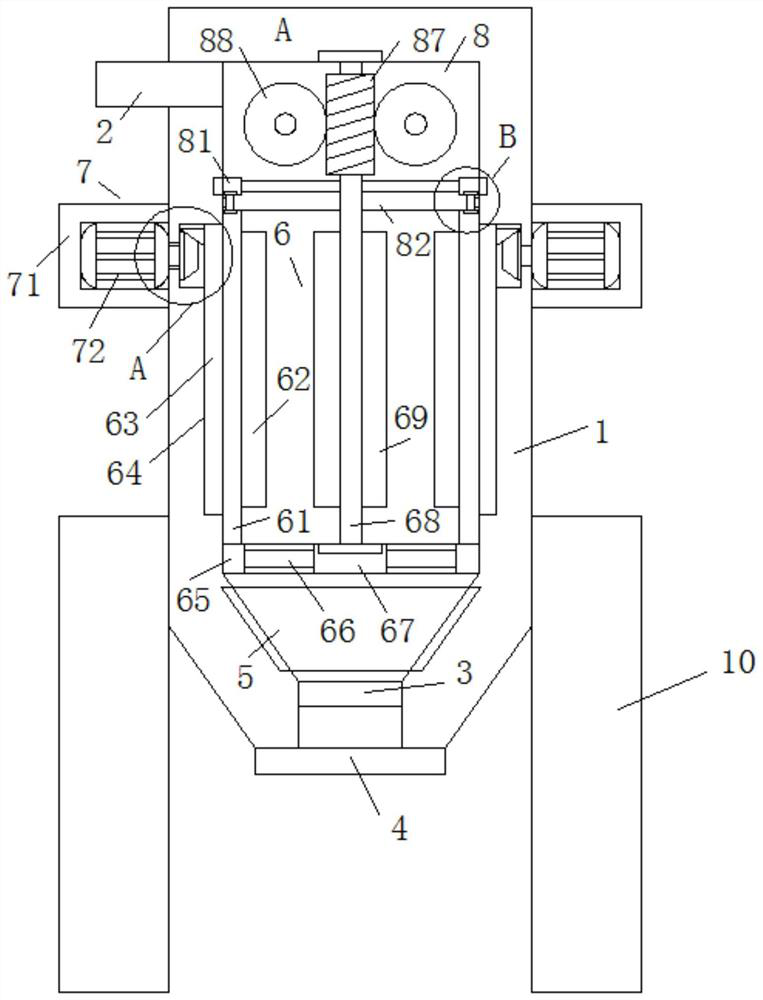

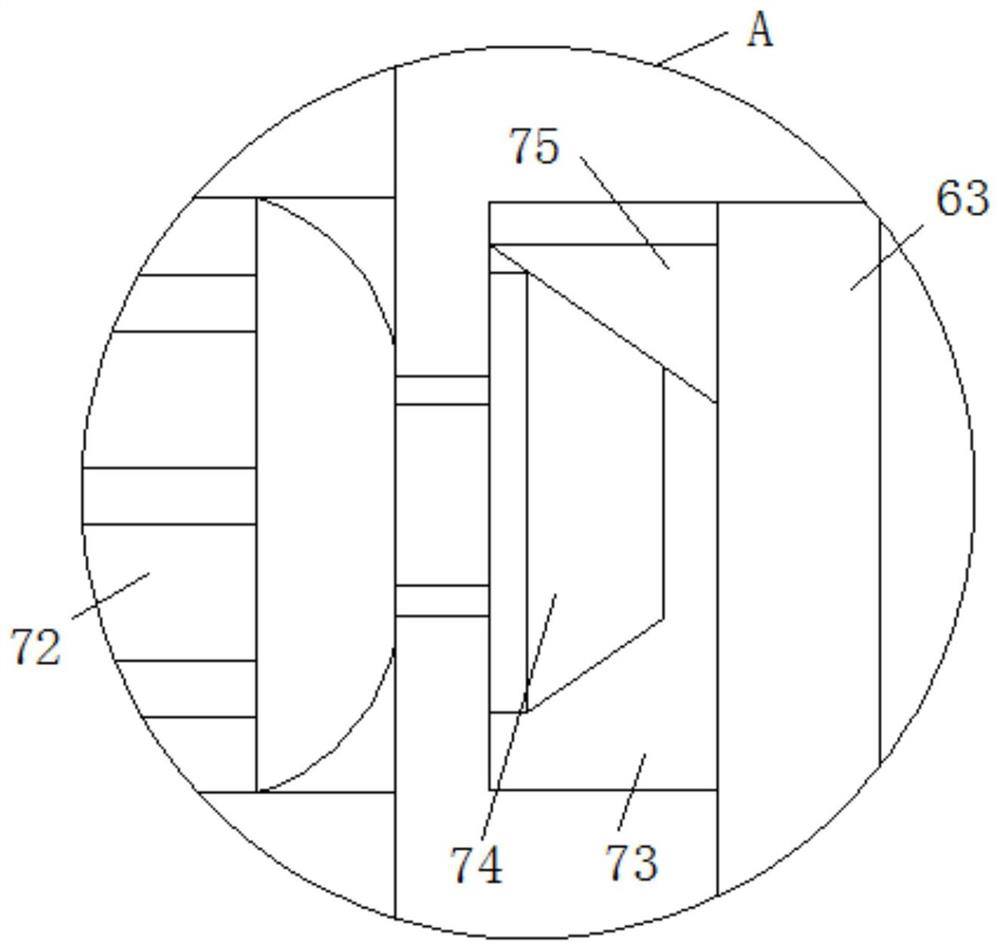

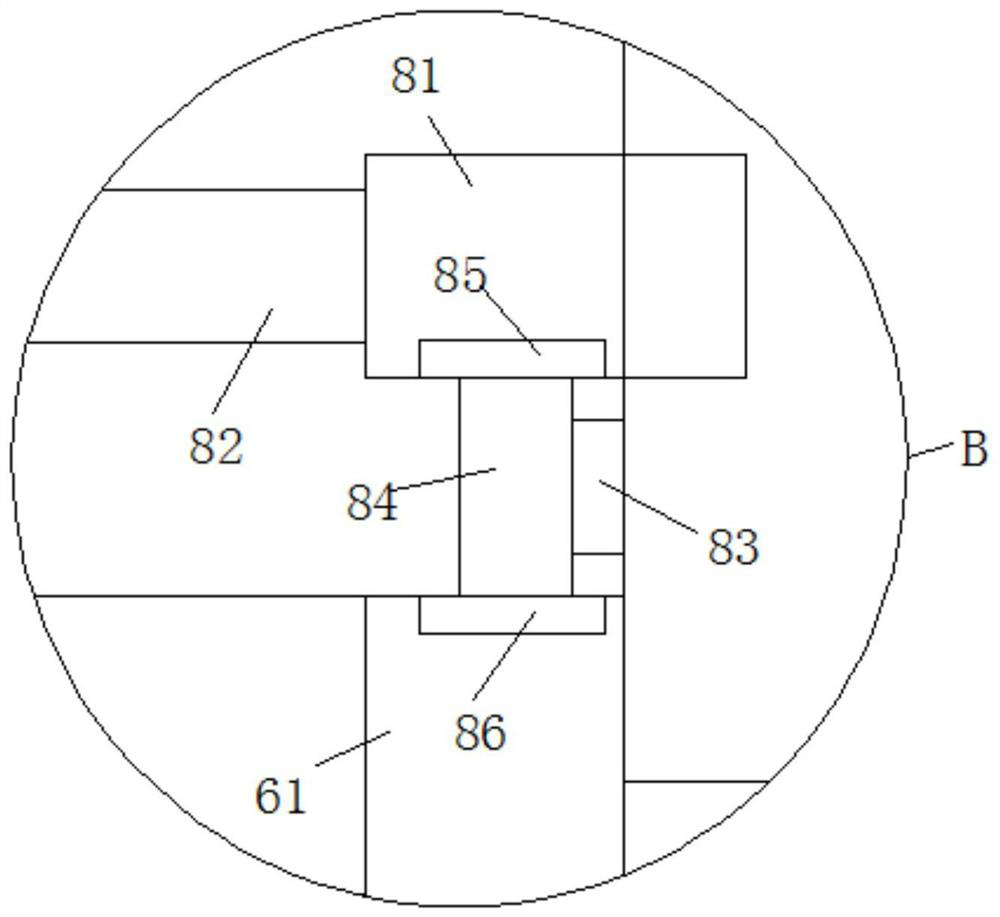

Distillation dehydration device for lubricating oil production

PendingCN113337305AStir wellIncrease water evaporation rateLubricating oils distillationHydrocarbon dewateringProcess engineeringFan blade

The invention discloses a distillation dehydration device for lubricating oil production. The device comprises a distillation box, wherein the lower end of the distillation box is provided with a discharge port, a sealing plug is clamped in the discharge port, the side wall of the upper end of the distillation box is fixedly connected with a feed pipe, and the inner wall of the lower end of the distillation box is fixedly connected with a heating plate. A group of supporting columns are fixedly connected to the outer side of the lower end of the distillation box, and a stirring mechanism is arranged in the distillation box and located in the middle position of the distillation box. Beneficial effects of the device are that: a linkage gear drives a linkage rotating shaft to rotate and through transmission of a worm and a turbine, an exhaust rotating shaft of an exhaust mechanism is driven to rotate, so that exhaust fan blades can rotate, the outward exhaust efficiency of the distillation box is improved, evaporated water vapor can be quickly discharged, and the condition that the water vapor drops into lubricating oil again after being condensed in the distillation box is avoided.

Owner:江苏朗斯汽车用品有限公司

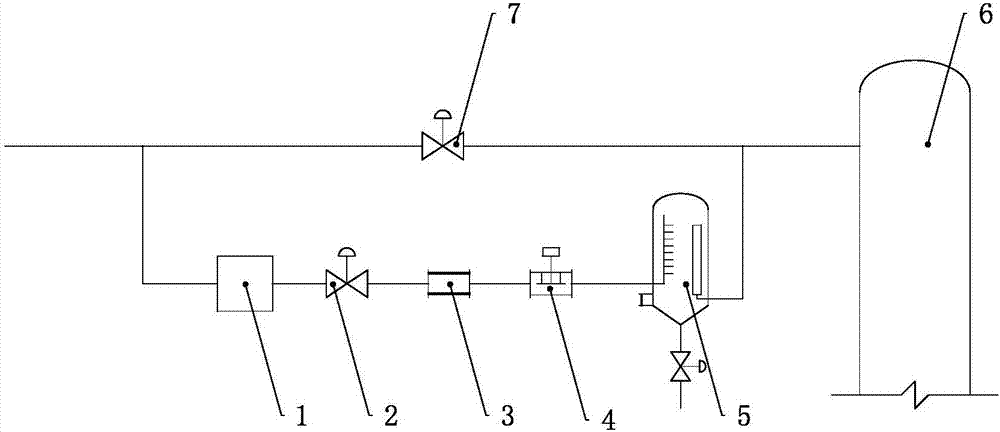

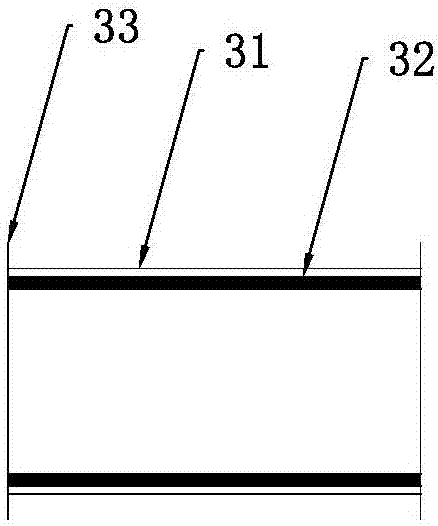

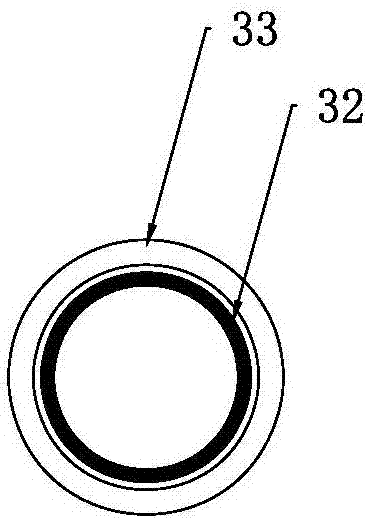

Device for removing corrosive impurities and preventing salt deposition corrosion of fractionating tower

PendingCN107050909AFully dispersedAdjust the mixing intensityDistillation corrosion inhibitionGeneral water supply conservationFiltrationSmall footprint

The invention discloses a device for removing corrosive impurities and preventing salt deposition corrosion of a fractionating tower. The device and a flow control valve (7) of a top cycle oil return tower are arranged in parallel; the device comprises a static mixer (1), a mixing valve (2), a magnetic field coalescer (3), an electric field coalescer (4) and a filter separator (5) which are sequentially connected in series; an inlet of the static mixer (1) communicates with the inlet of the flow control valve (7) of the top cycle oil return tower and also communicates with a water inlet pipe; a top cycle oil outlet (54) of the filter separator (5) communicates with an outlet of the flow control valve (7) of the top cycle oil return tower; and the outlet of the flow control valve (7) of the top cycle oil return tower communicates with the fractionating tower (6). The device is adjustable in mixing strength, the corrosive impurities causing salt deposition corrosion of the fractionating tower can be effectively eliminated, magnetic field and electric field coalescence, filtration, separation and deep dehydration are adopted, the device is small in volume, high in desalination efficiency, small in floor area and low in investment, and salt deposition corrosion of the fractionating tower can be effectively inhibited.

Owner:洛阳绿景环保科技有限公司

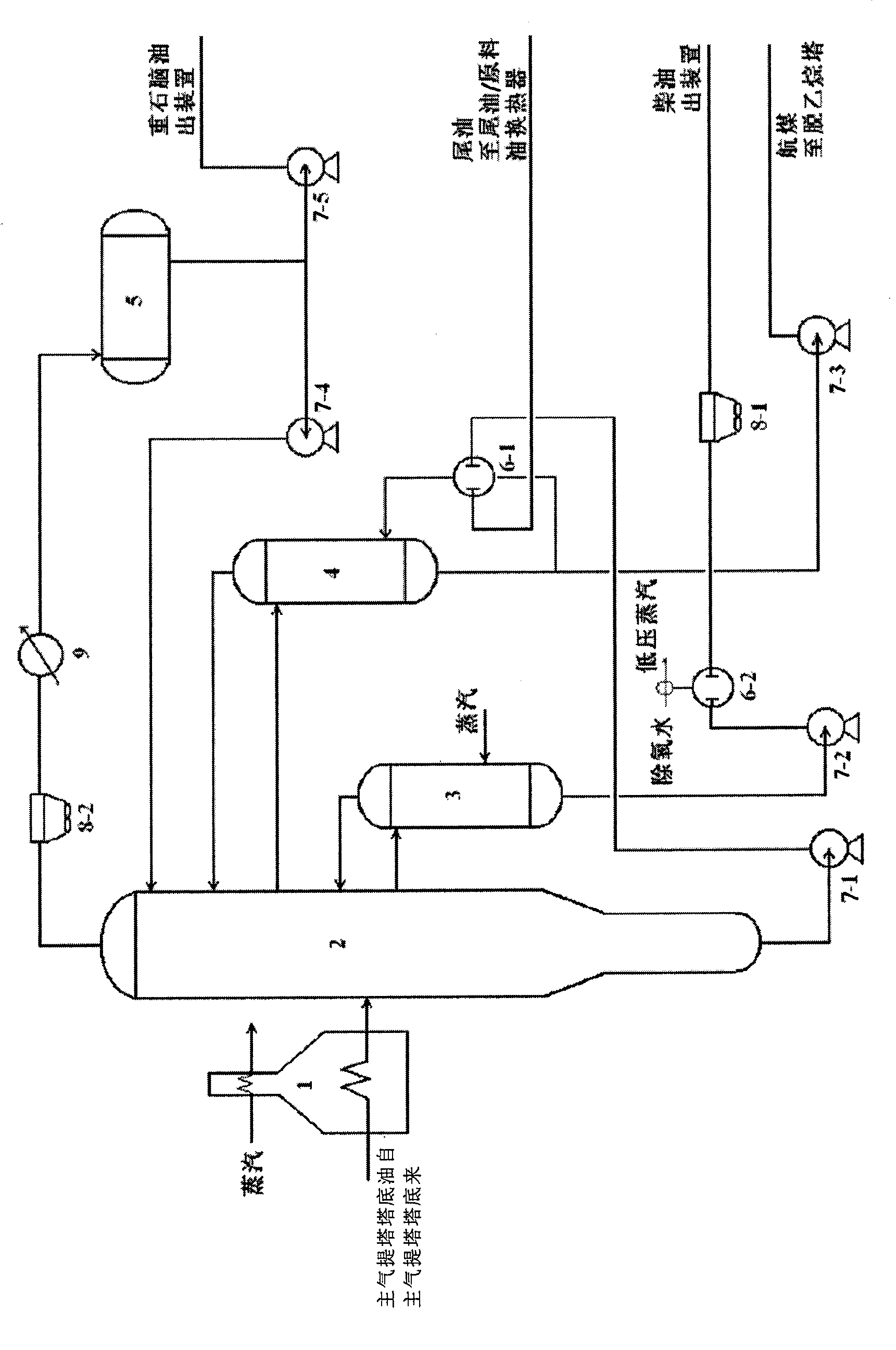

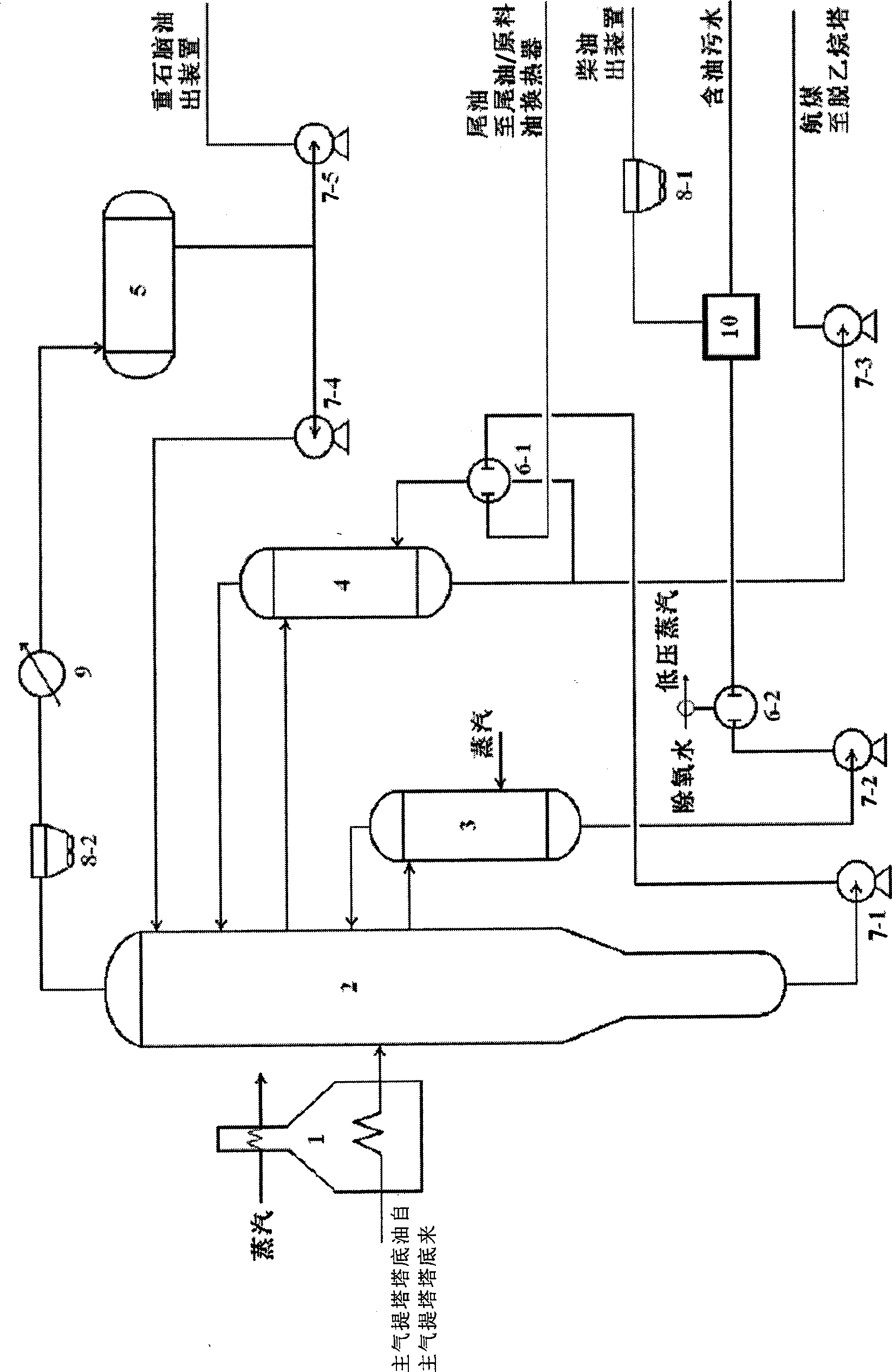

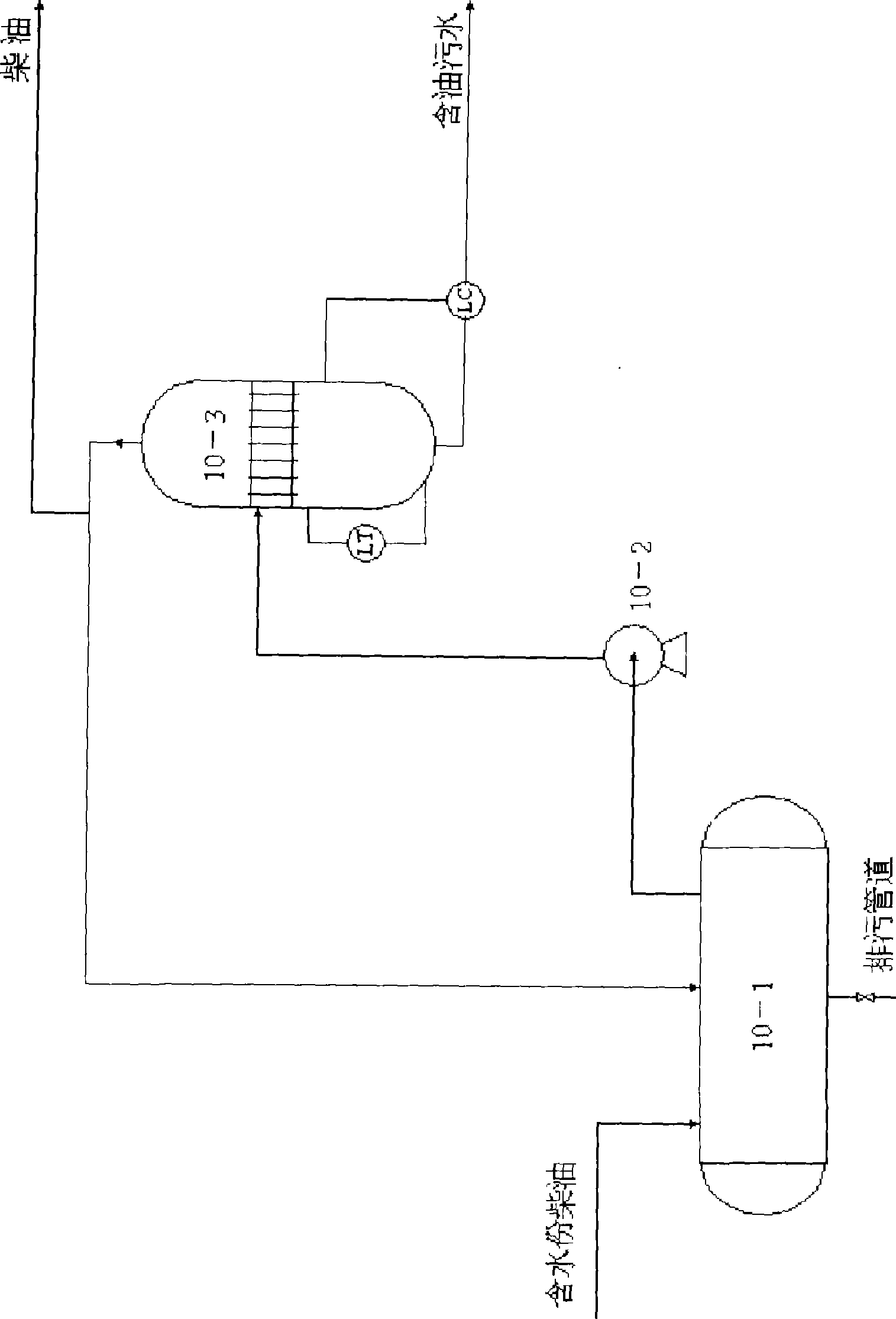

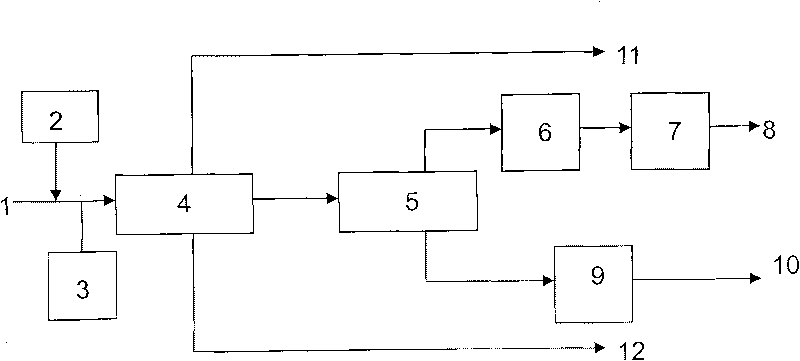

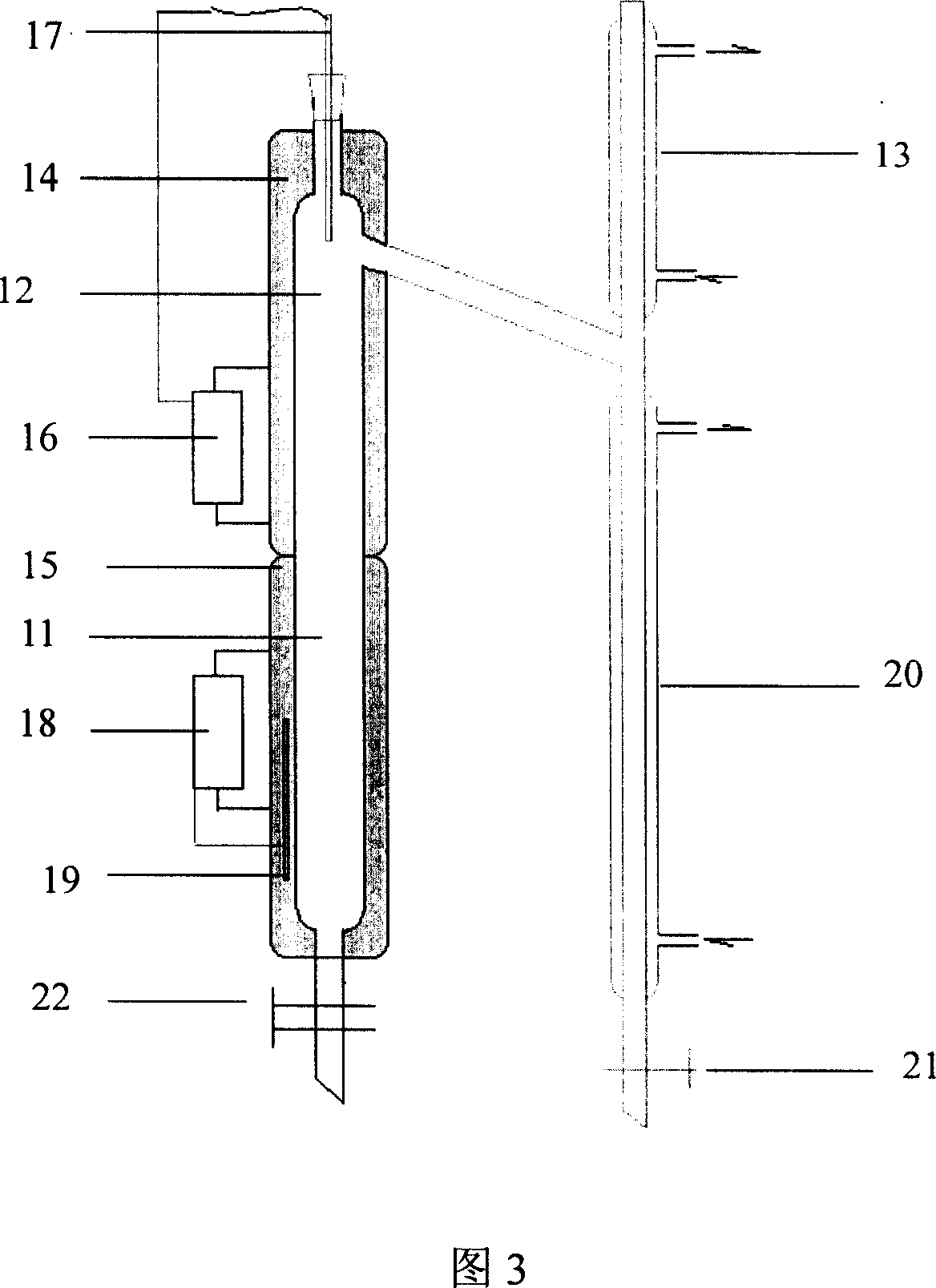

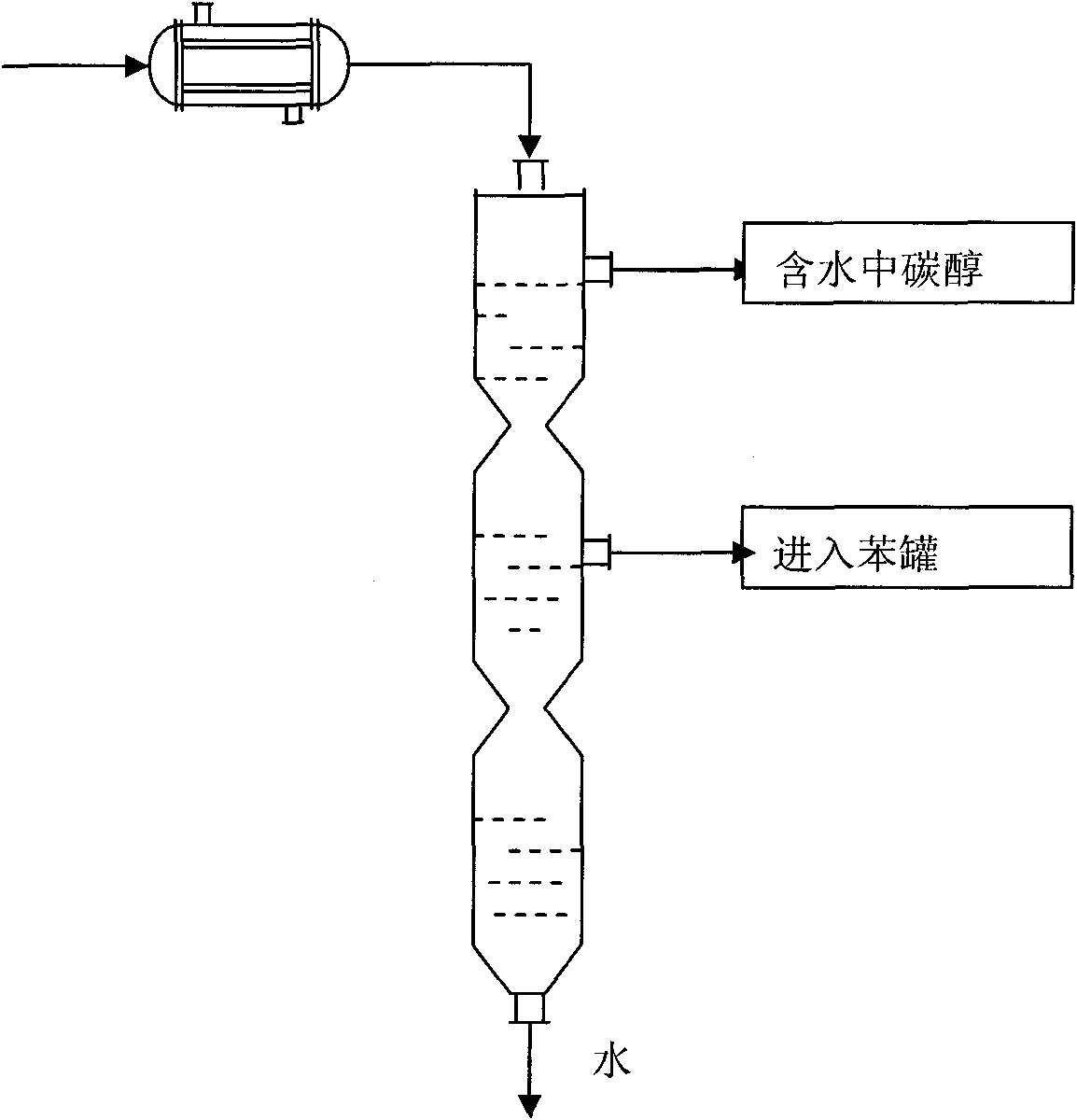

Process method for removing water from diesel or jet fuel by using compound function vacuum tower

InactiveCN103045286ASimple processSmall footprintVacuum distillationHydrocarbon dewateringReboilerFractionation

The invention relates to a process method for removing water frrrom diesel or jet fuel by using a vacuum tower. The vacuum tower is divided into an upper part and a lower part, diesel or jet fuel with temperature between 100 DEG C and 300 DEG C enters the lower part of the vacuum tower, and is subjected to balanced flash evaporation under an absolute pressure of 0KPa to 90KPa; water in an oil product and partial oil product are simultaneously gasified, and then enter the upper part of the vacuum tower to be condensed and subjected to oil-water separation; separated water is discharged out of the tower, separated oil is returned to the bottom-lower part of the vacuum tower, and the separated oil and un-gasified oil become qualified water-containing products and discharged out of the tower. According to the invention, the problem that the diesel or jet fuel contains water is solved, and especially, in a diesel hydrogenation unit and a jet fuel refining device of an oil refinery, by adopting the process method, the problem of unqualified mass caused by water containing is effectively solved. Compared with a reboiler furnace fractionation process adopted in the diesel hydrogenation unit and the jet fuel refining device, the process method remarkably has the characteristics of convenience for implementation, less occupation area, low energy consumption and low investment.

Owner:李芝玲 +1

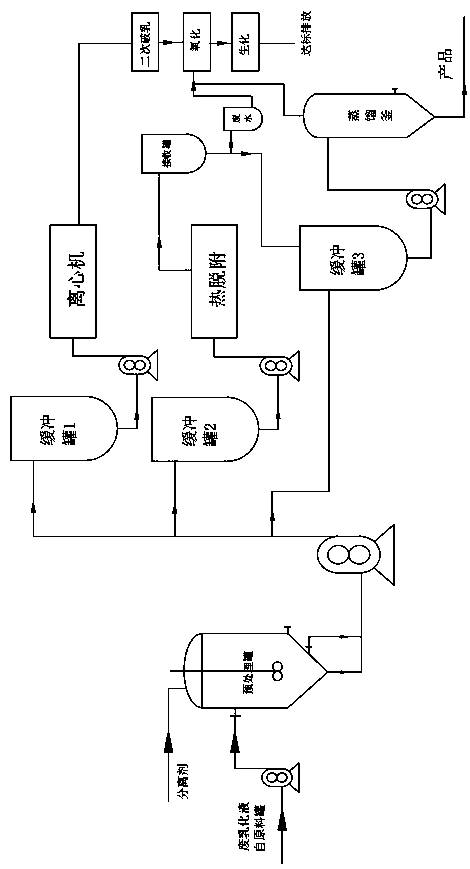

Technological method for recycling treatment of waste emulsified liquid

ActiveCN109111032AReduce in quantityLow running costWater/sewage treatment by centrifugal separationFatty/oily/floating substances removal devicesGas phaseFractionating column

The invention discloses a technological method for recycling treatment of waste emulsified liquid. The technological method comprises the following steps: (1) filtering the waste emulsified liquid andconveying the waste emulsified liquid into a pre-treatment tank; raising the temperature and stirring; adding a separation agent; dividing separated emulsified liquid into an upper layer, a middle layer and a lower layer; (2) conveying a lower-layer material into a centrifugal machine and separating to obtain waste dreg and wastewater I; carrying out high-temperature desorption on a middle-layermaterial; after condensing a gas phase, thus obtaining an oil-water mixture; meanwhile, obtaining wastewater II; conveying an upper-layer material into a distillation tower and carrying out vacuum treatment to obtain recyclable fuel oil; (3) carrying out secondary demulsification, Fenton oxidation and biochemical treatment on the wastewater I of step (2) and then discharging; carrying out the Fenton oxidation and the biochemical treatment on the wastewater II and discharging; (4) conveying tower-bottom waste dreg of the distillation tower in step (2) into a thermal desorption device and carrying out the high-temperature desorption; taking a generated gas phase as fuel gas for thermal desorption. The technology disclosed by the invention has the advantages that the quantity of the generatedwaste dreg is reduced, the oil content of residues can be reduced to be 1 percent or lower and the precipitation of leachate in treatment processes of backfilling and the like can be effectively prevented.

Owner:LUOYANG HAOHAI IND & TRADE

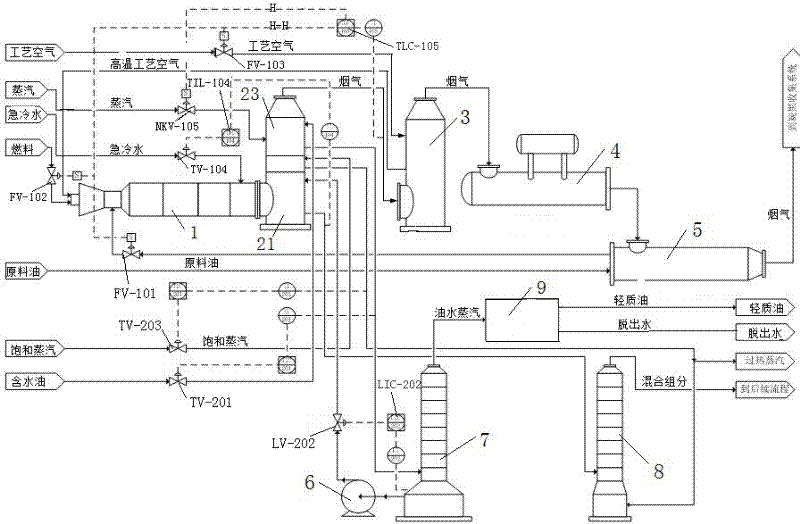

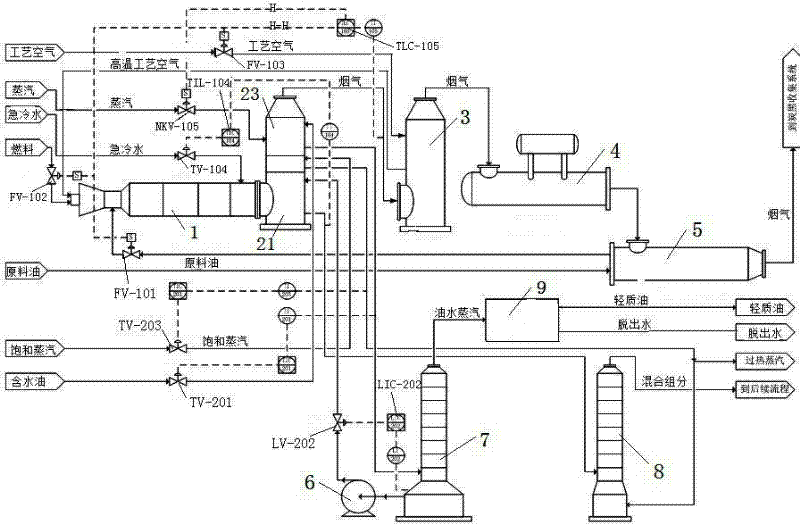

Co-production processing method and equipment for carbon black and oil

ActiveCN102226044ALess quantityRealize expansionPigmenting treatmentTar working-up by distillationAir preheaterOil processing

The present invention discloses a co-production processing method and equipment for carbon black and oil. The co-production processing method and equipment are characterized in that: an online tubular furnace is arranged between a carbon black reaction furnace and an air preheater; the online tubular furnace is divided into, from the bottom to top in turn, a radiation section, an overheating section and a convection section; a water-containing oil heating temperature adjusting system, a superheated steam temperature adjusting system, a water-free oil heating temperature adjusting system, a temperature alarm interlock system and other systems are also arranged; the physical heat of high-temperature carbon black flue gas is used as a heat source for heating raw oil, so that the water-containing oil and water-free oil are heated to the required temperatures; saturated steam is superheated to a specified temperature, thus meeting the feed requirements of an oil processing unit; and simultaneously the oil-containing water discharged from the top of a first-stage evaporator of the oil processing unit can be directly mixed with chilling water of a carbon black device, thereby solving thedifficulty of oil-containing wastewater treatment, effectively reducing the addition amount of the chilling water, decreasing the amount of exhaust gases, increasing the chemical heat value of the exhaust gases, reducing energy consumption in exhaust gas transport, reducing the requirement capacity of processing equipment and simultaneously achieving the security operation.

Owner:中昊黑元化工研究设计院有限公司

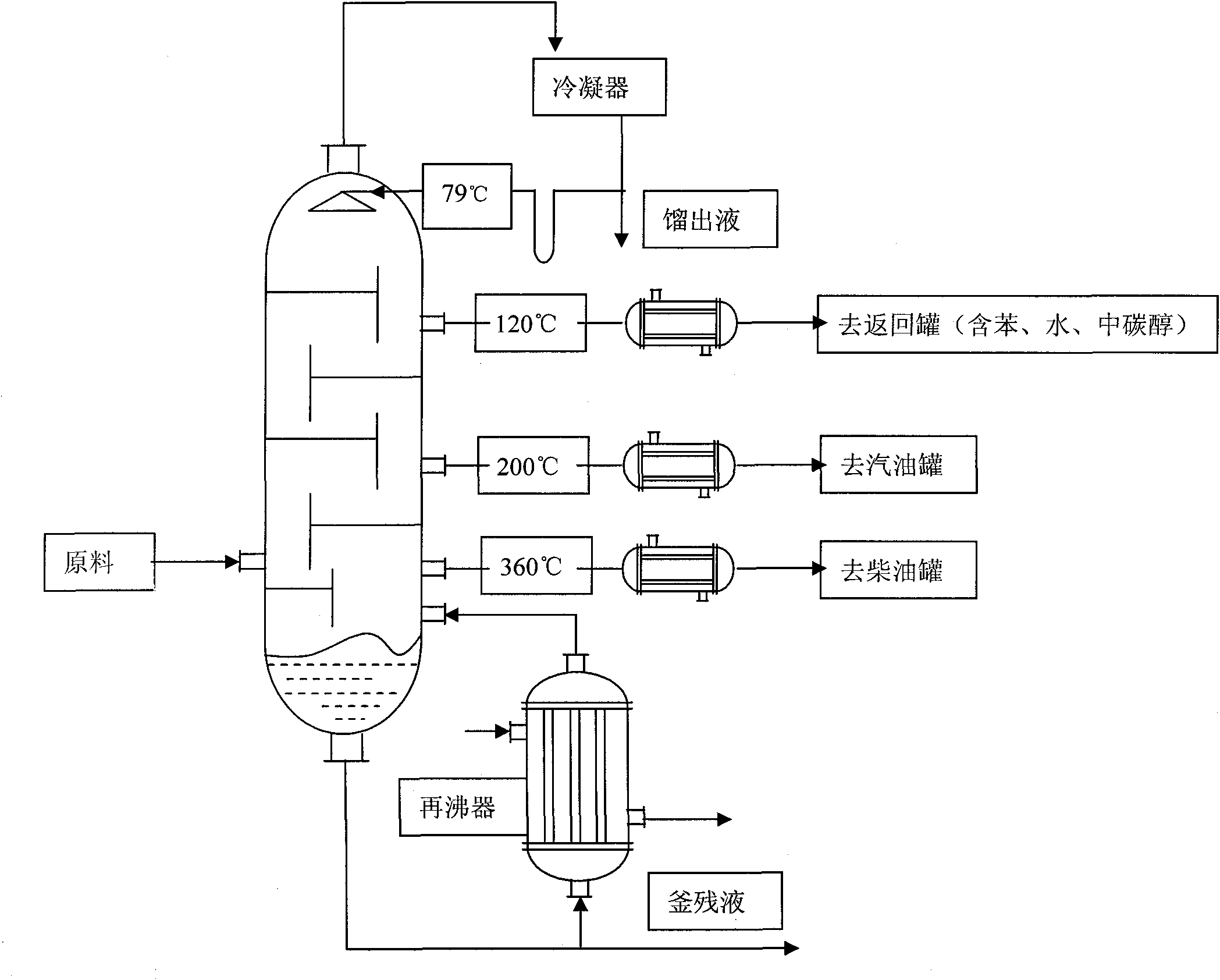

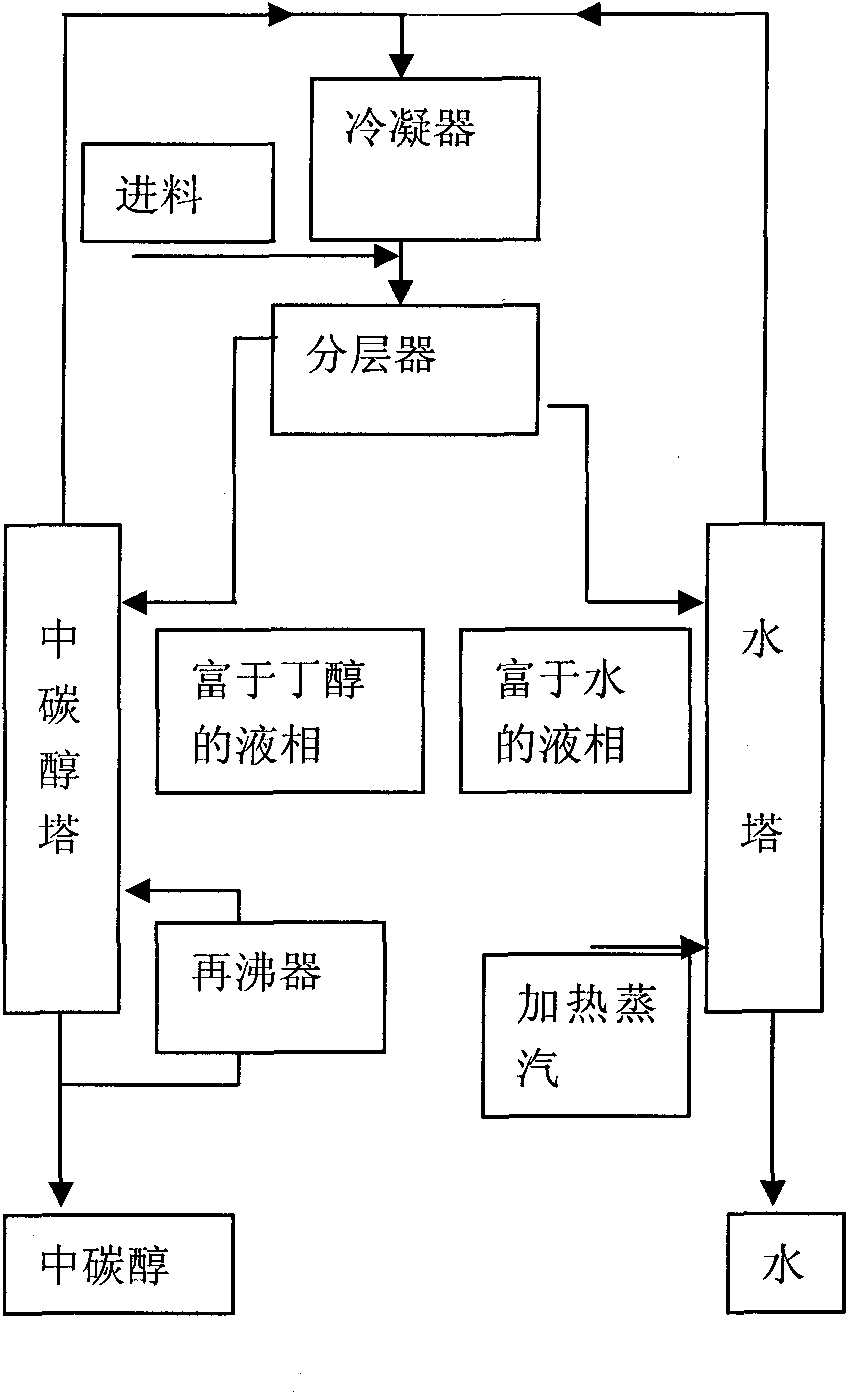

Dewatering technology of biological gasoline and diesel oil

The invention relates to a dewatering technology of biological gasoline and diesel oil, which belongs to the technical filed of biomass oil refining. The invention comprises a stratified distillation step, a benzene separation process and a water and carbon alcohol separation step. The invention perfectly utilizes distillates between 80 DEG C and 117 DEG C in the biological oil preparation process, recovers precious chemical engineering resources on the premise of ensuring the dewatering, improves the fuel heat value, and saves a large number of energy.

Owner:王方茂

Popular searches

Separation devices Treatment with plural serial refining stages Liquid separation Refining by centrifugal force Tar working-up by chemical refining Bio-feedstock Flash distillation Dewatering/demulsification regulation/control Carboxylic compound separation/purification Liquid hydrocarbon mixture production

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com