Diesel oil dewatering process and apparatus

A diesel oil and water content technology, which is applied in the direction of hydrocarbon oil dehydration, etc., can solve the problems that the separation efficiency cannot meet the high precision and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

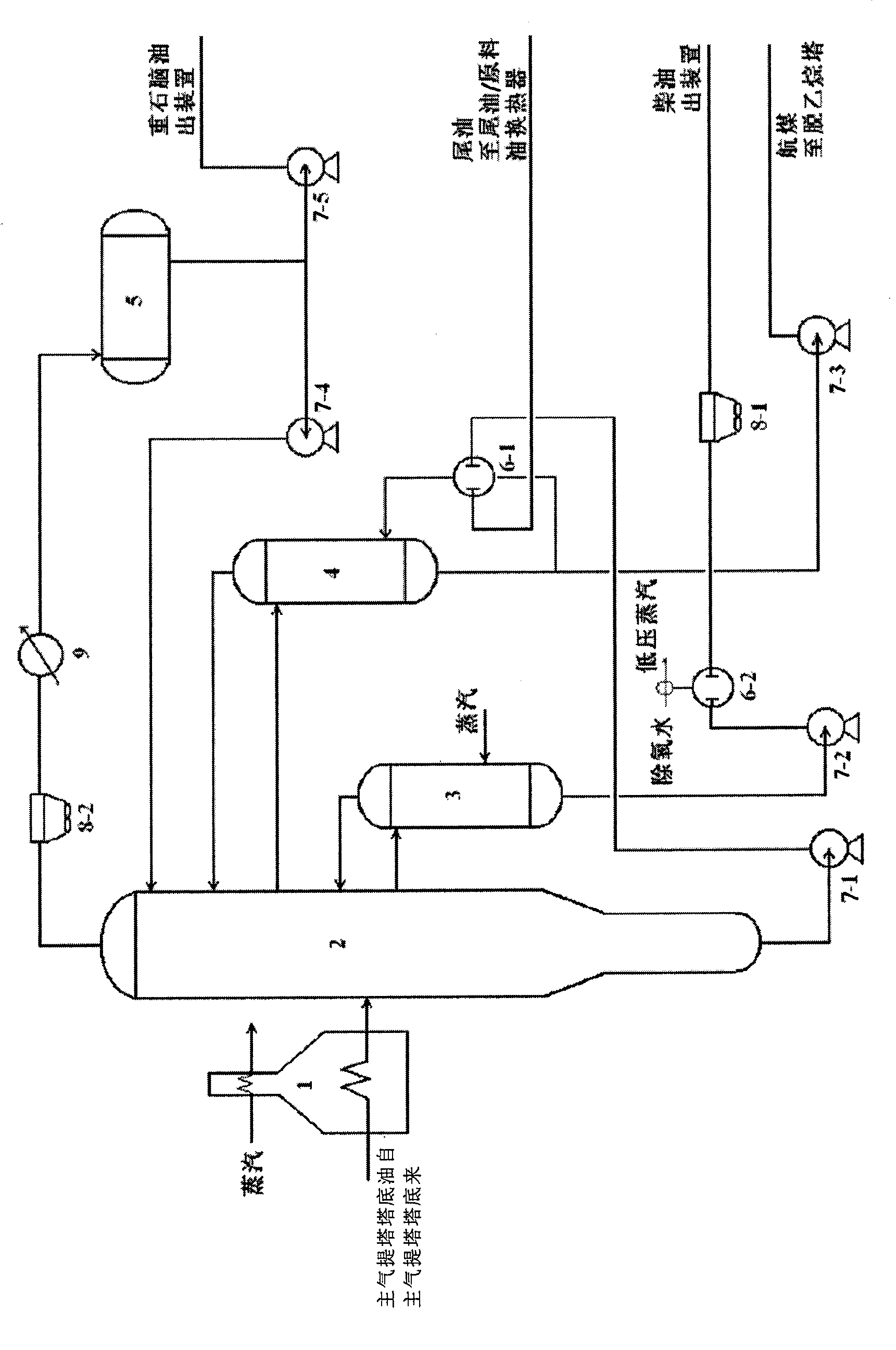

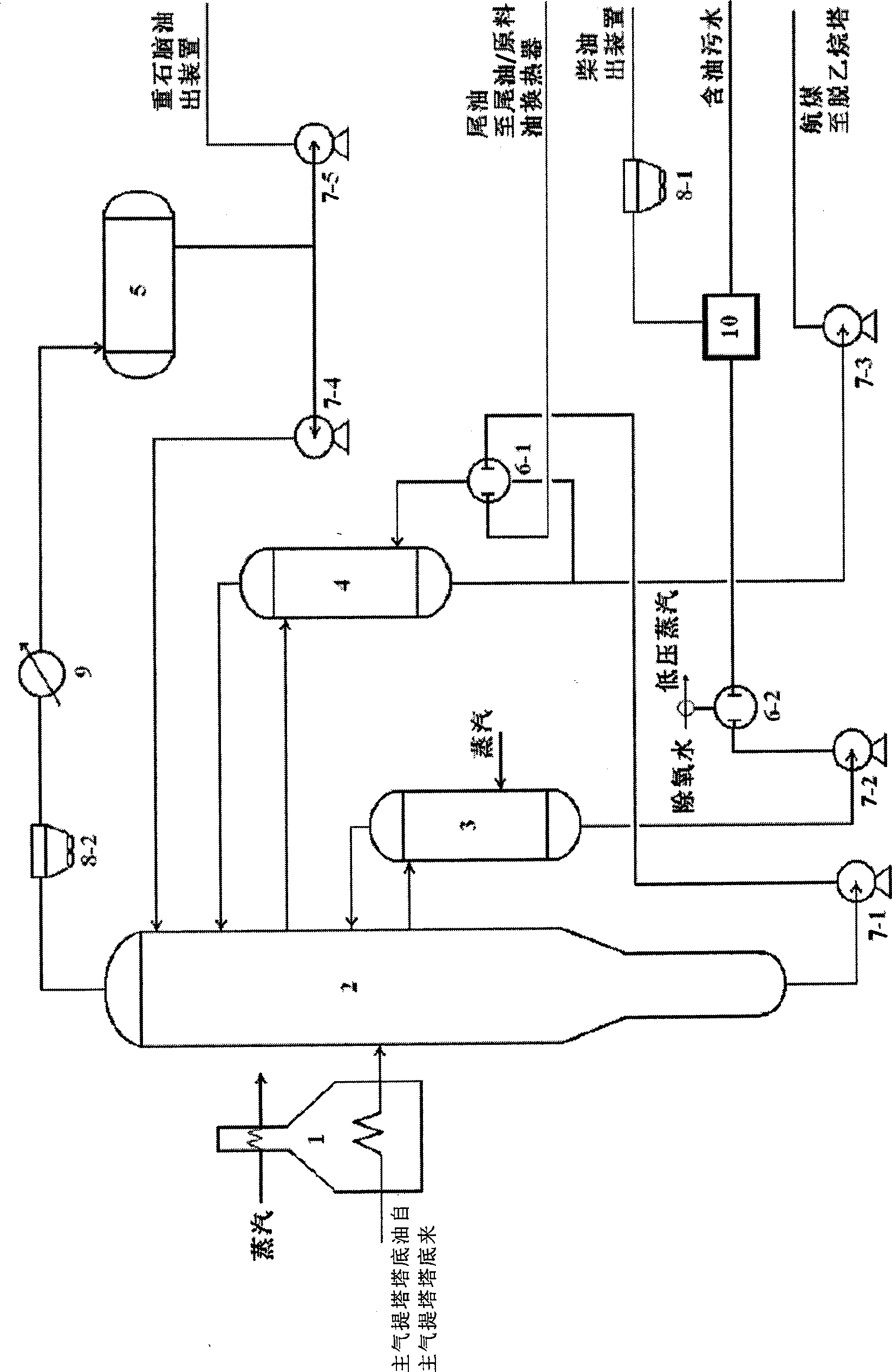

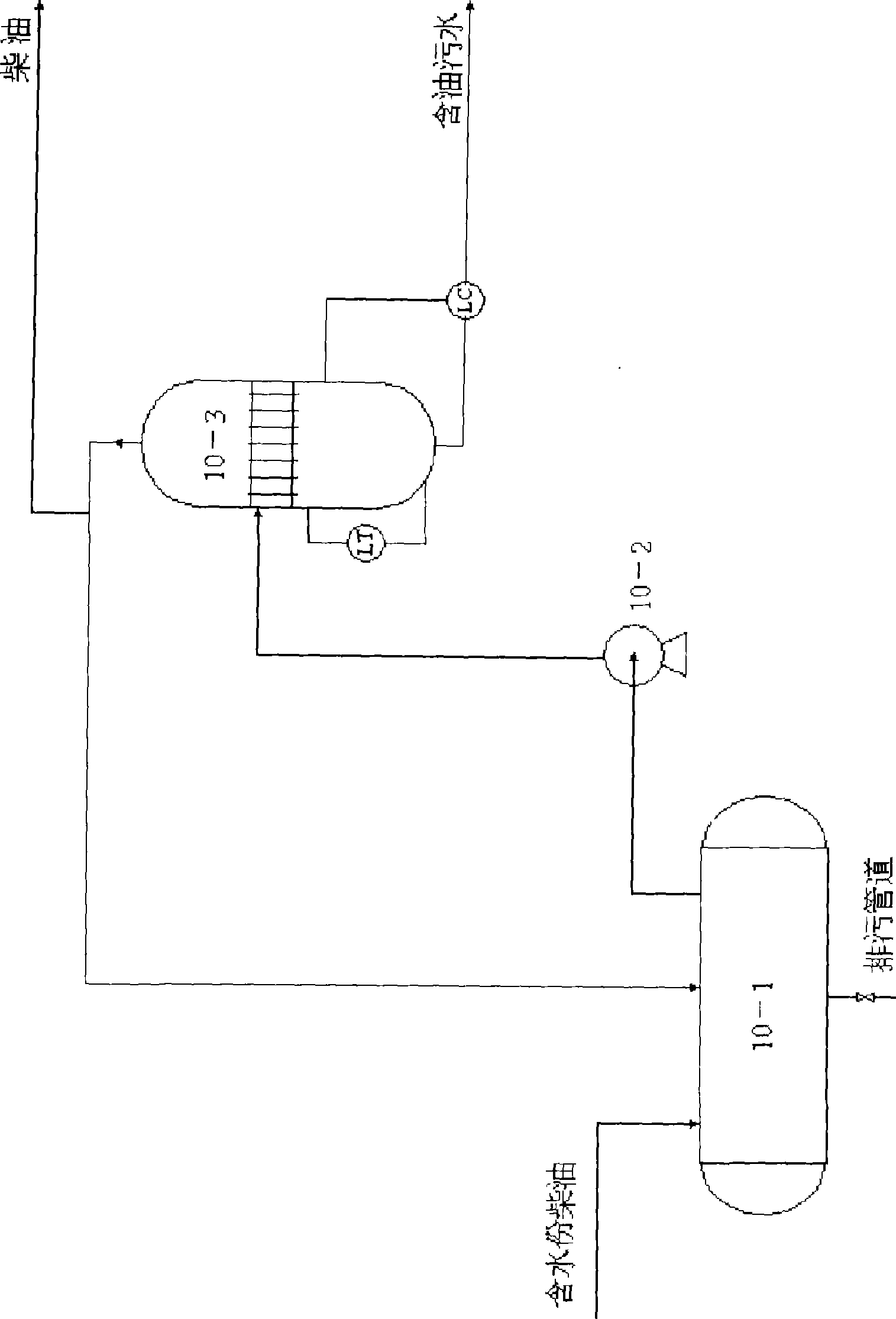

[0023] After extensive and in-depth research, the inventors of the present invention have found that by applying the cyclone separation process to the dehydration of diesel oil in the hydrocracking process, higher separation efficiency can be obtained, and compared with other separation processes used in the prior art Compared with the cyclone separation process, the adaptability is strong, the floor space is small, and it is easy to maintain. The present invention has been accomplished based on the above findings.

[0024] In the presence of hydrogen, catalyst, and appropriate temperature and pressure conditions, the carbon-carbon bonds in the raw oil molecules are broken and the process of generating smaller molecules is called hydrocracking. The main purpose of the hydrocracking process is to convert heavy distillate oil into light oil. Hydrocracking technology is the core technology of today's oil refining industry. Under the action of catalyst and hydrogen, the raw oil u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com