Low-volatile liquid vacuum dehydrating method and device

A low-volatility, vacuum dehydration technology, which is applied in the field of vacuum dehydration of low-volatility liquids, vacuum dehydration methods and devices for low-volatility liquids, and can solve problems such as large volume of vacuum dehydration equipment, foam oil leakage, and dehydration problems , to achieve high reliability, easy operation, volume and weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

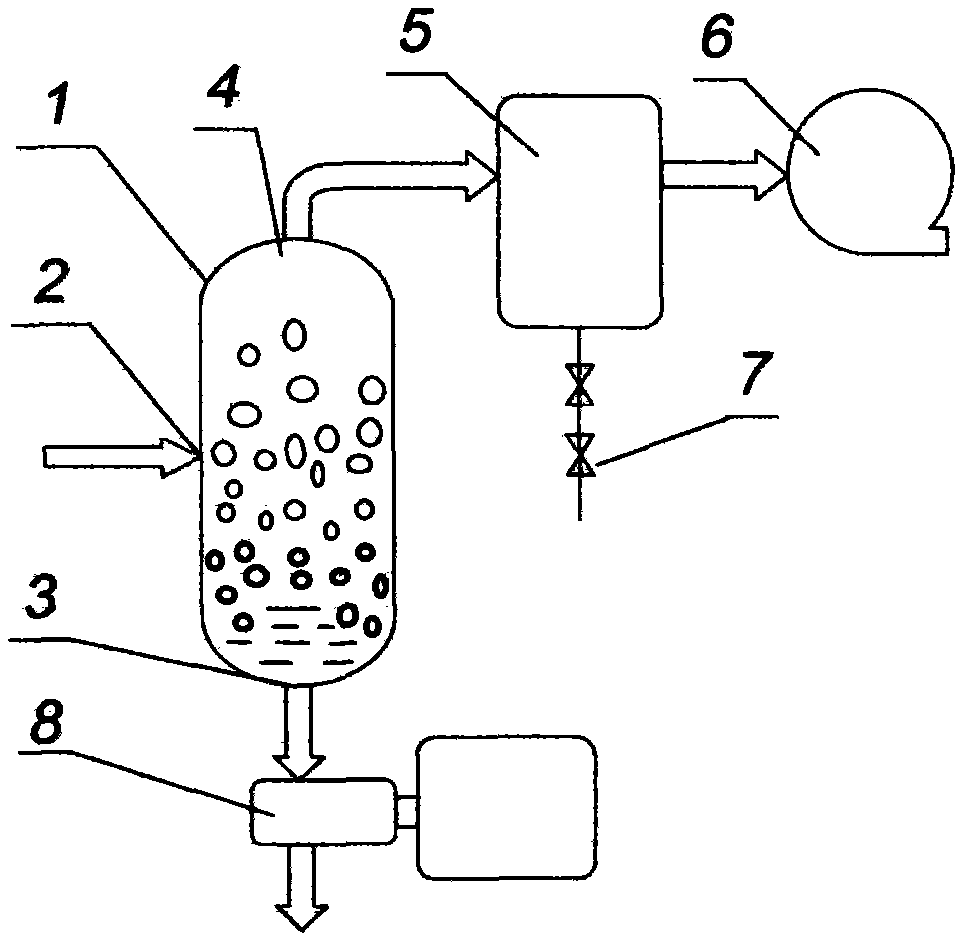

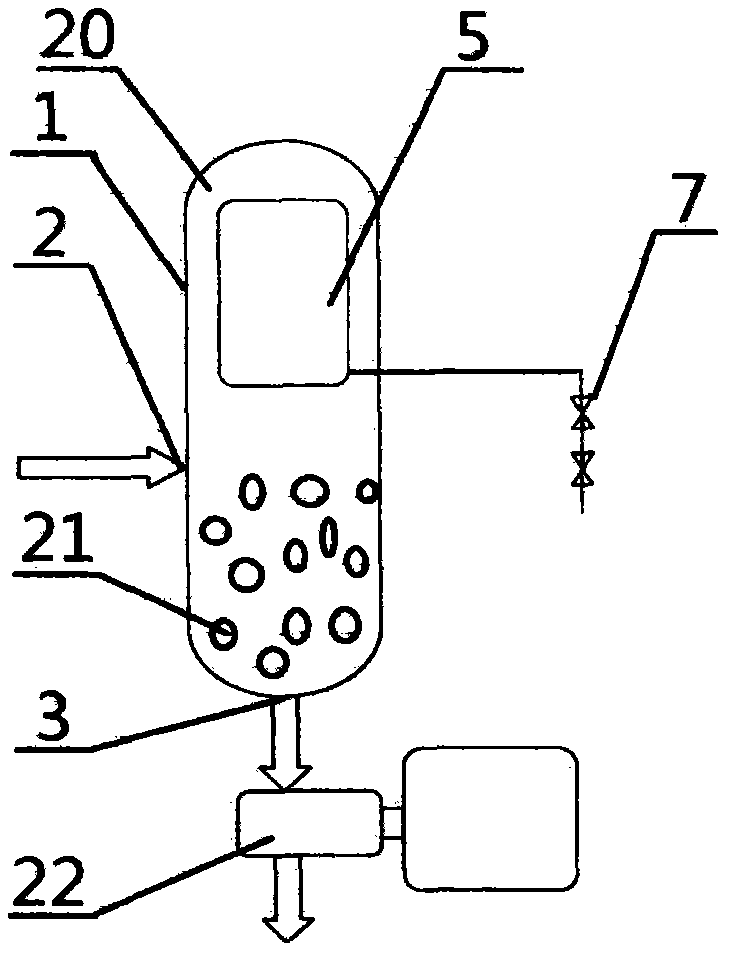

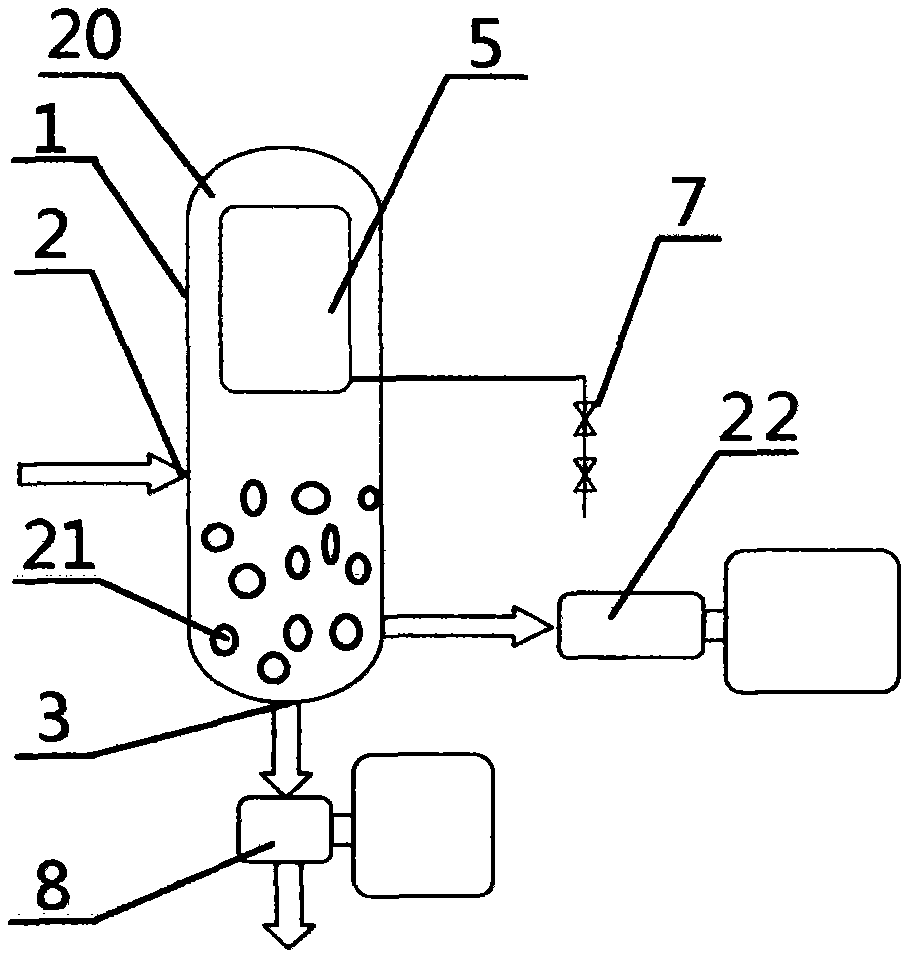

[0026] Implementation of this technique involves two new components: a condenser 5 (usually containing a drain 7 ) installed in the gas phase space of the vacuum tank, and a draining vacuum pump 22 .

[0027] The condenser used in this technology should have the following properties: 1. The temperature of the condenser should be lower than the temperature of the oil. The greater the temperature difference, the better the dehydration effect, but if it freezes, it needs to be defrosted and drained intermittently; 2. Condensate down 3. The drainage device with the condenser can drain the water out of the vacuum tank; 4. It is best to have a fan to promote the rapid flow of water vapor and other gases to the cooling surface of the condenser to improve dehydration Speed; 5. The condensing part is suitable for working in a vacuum environment in a vacuum tank. In order to meet the above conditions, one or more combinations of cold water cooling, compressor refrigeration, semiconducto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com