Processes for recycling sag-d process water and cleaning drill cuttings

a technology of process water and drill cuttings, applied in the field of slop oil, can solve the problem of not having a large supply of water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

Water Recovery (Recycle) Invention:

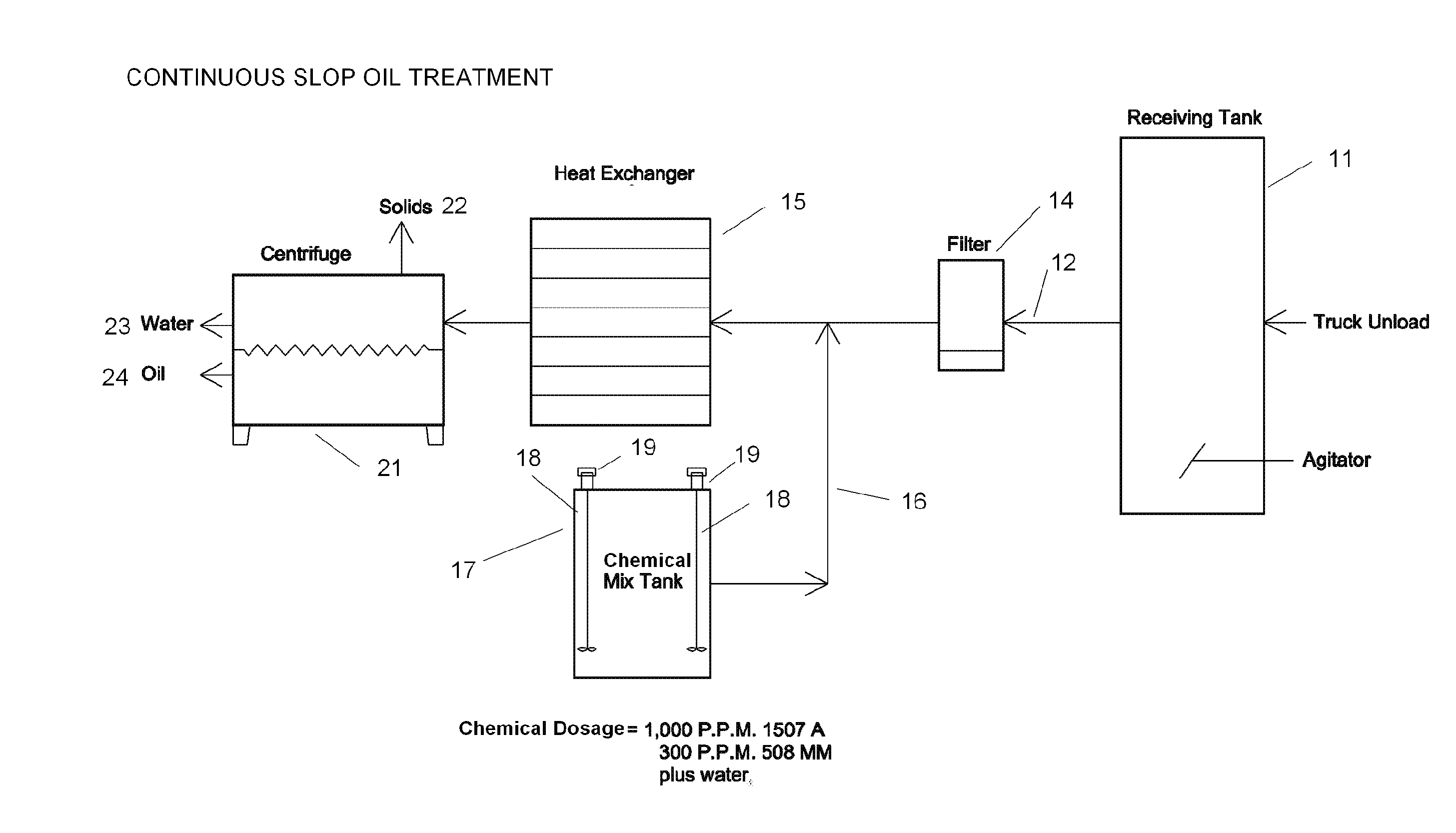

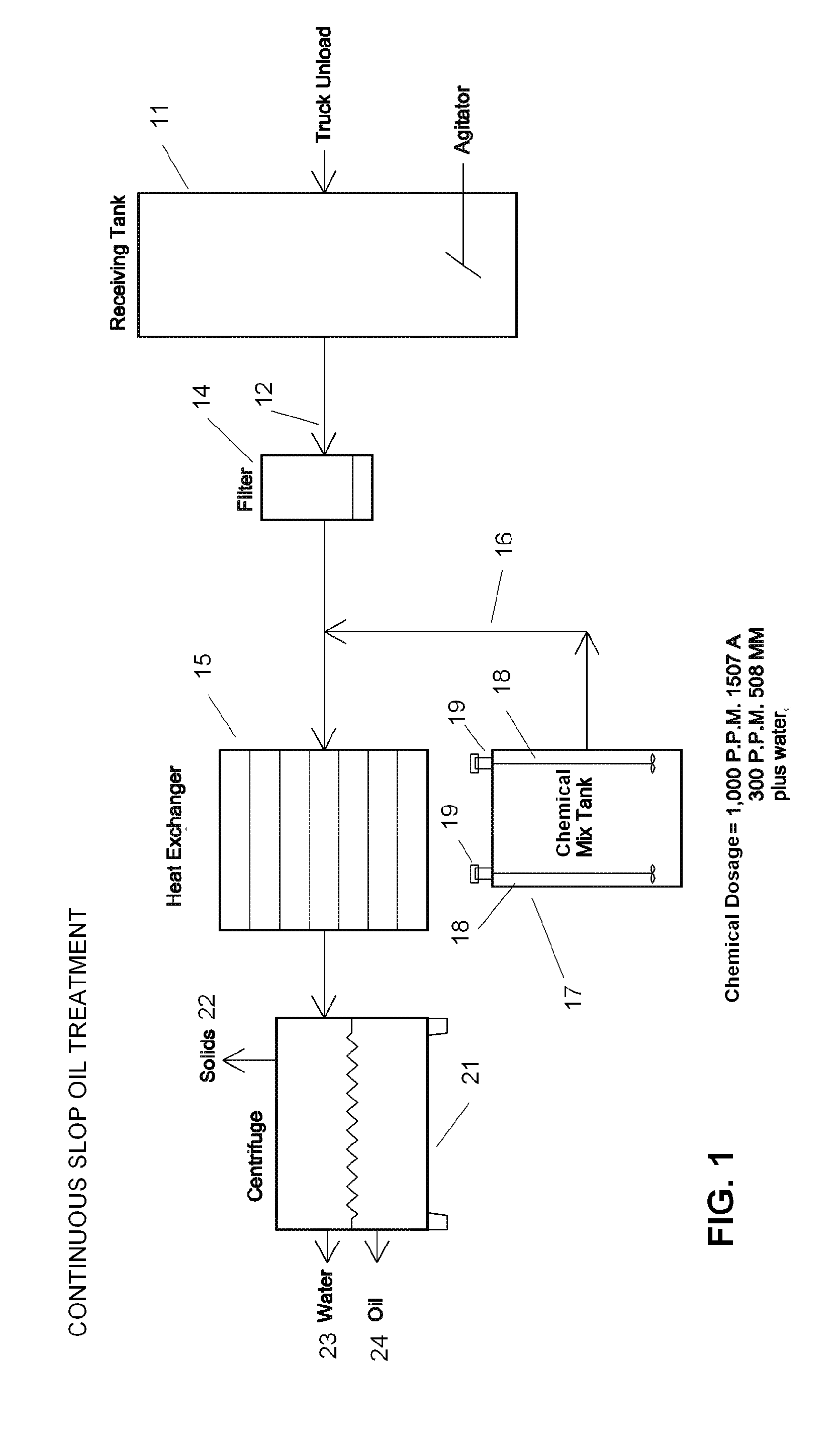

[0022]The following disclosure describes a process methodology, whereby Slop Oil generated as byproduct in the SAG-D Very Heavy Oil (Bitumen) production process is treated with select chemicals to separate and recover water, solids, and oil from the slop oil emulsion.

[0023]The process preferably involves the following steps:

[0024]mixing a first quantity of water with a first quantity of a first chemical blend to create a water / chemical mixture;

[0025]heating and stirring the water / chemical mixture (preferably for about 10-30 minutes until the mixture reaches about 50-70 degrees C.) (while not preferred, one could heat first to the desired temperature, then stir);

[0026]adding to the mixture SAG-D slop oil to create a water / chemical / slop oil mixture;

[0027]heating and stirring the water / chemical / slop oil mixture (preferably for about 30-60 minutes until the mixture reaches about 50-100 degrees C.) (while not preferred, one could heat first to the desir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com