Patents

Literature

120results about "Settling tanks heating/cooling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

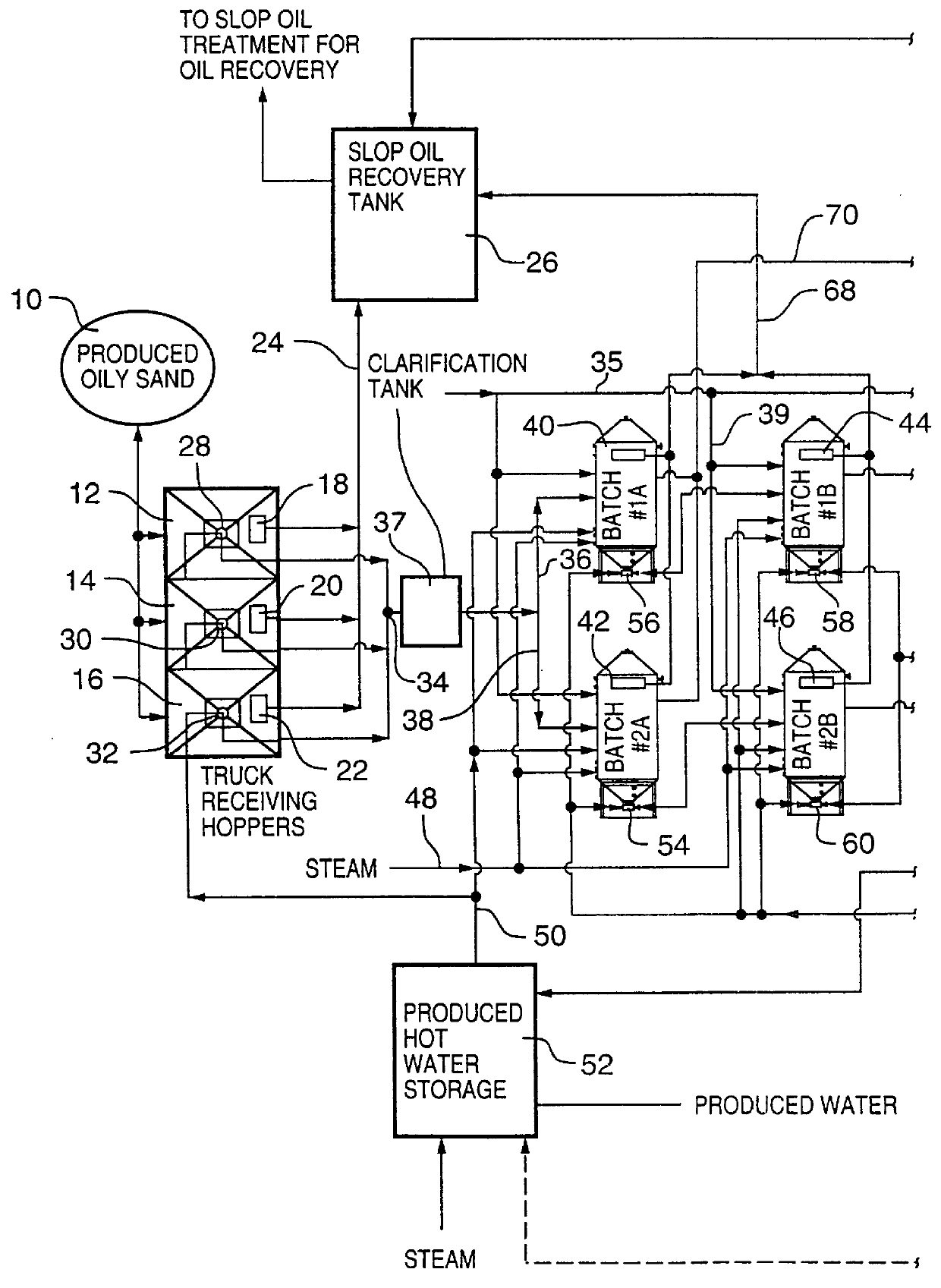

Jet pump treatment of heavy oil production sand

In a process for separating oily films from sand particles carried in a sent free water stream, the use of a jet pump scrubber in a density classification tank to treat such oily coated particles at controlled operating temperatures above 65.degree. C. whereby at such controlled temperature enhanced cavitation in said jet pump separates said oily film from said sand particles to form slop oil, said tank providing for recirculation of sand particles through said jet pump before discharge.

Owner:CANADIAN ENVIRONMENTAL EQUIP & ENG TECH

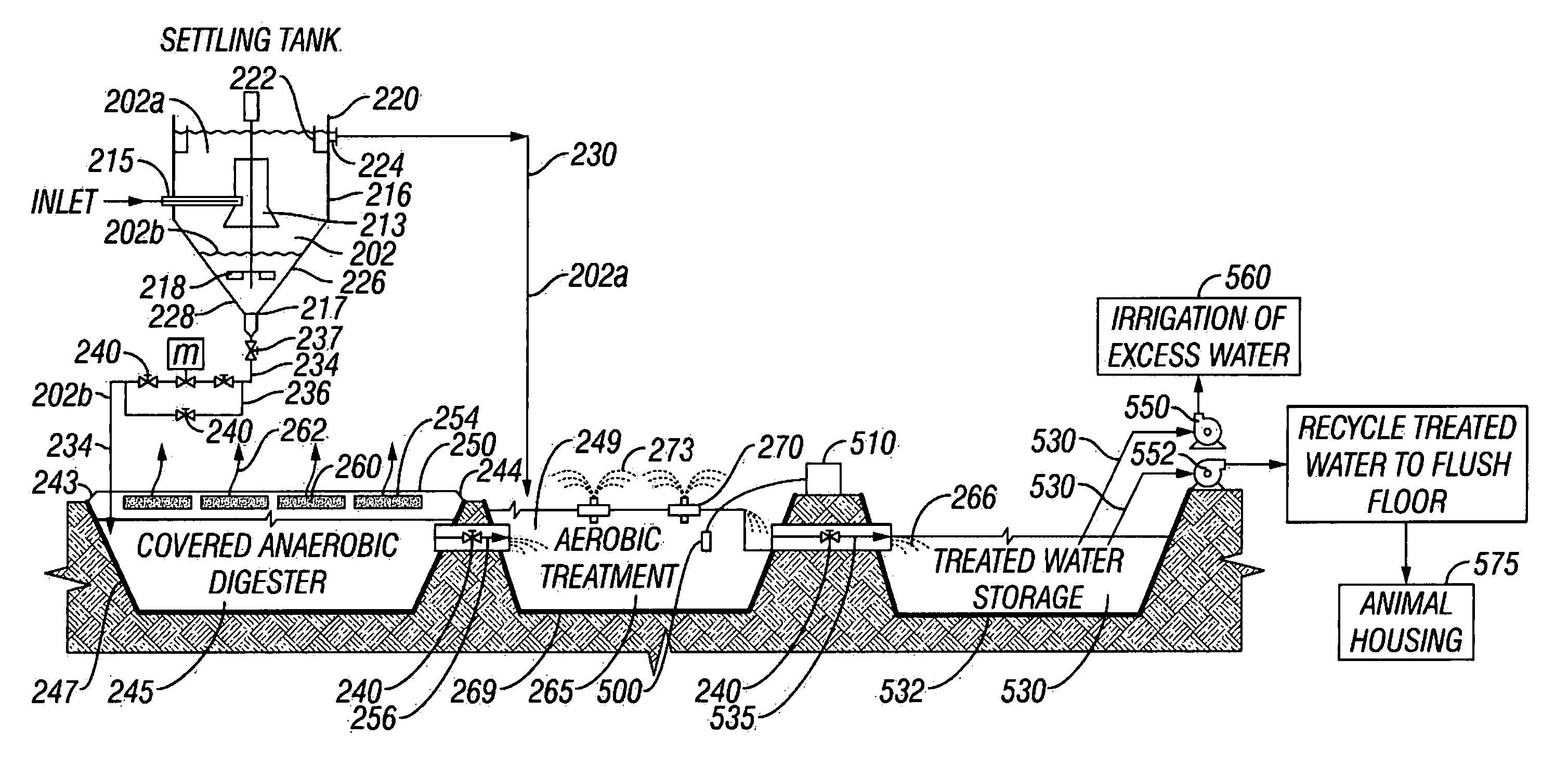

Method and apparatus for treating animal waste and wastewater

InactiveUS20060060525A1Solid waste disposalWaste water treatment from animal husbandryEvaporationWastewater

Novel methods and apparatuses are disclosed for the treatment of wastewater to reduce, often associated, offensive odors. Irrigation of oxygenated liquid on top of a permeable cover effectively creates an aerobic treatment zone at the top of the lagoon whereby odorous gases being produced anaerobically below the cover are metabolized within this zone before being released to the atmosphere. This same system also serves to increase evaporation from the overall waste handling system therefore substantially reducing or eliminating the need for land application of treated wastewater.

Owner:HOFFLAND ROBERT O

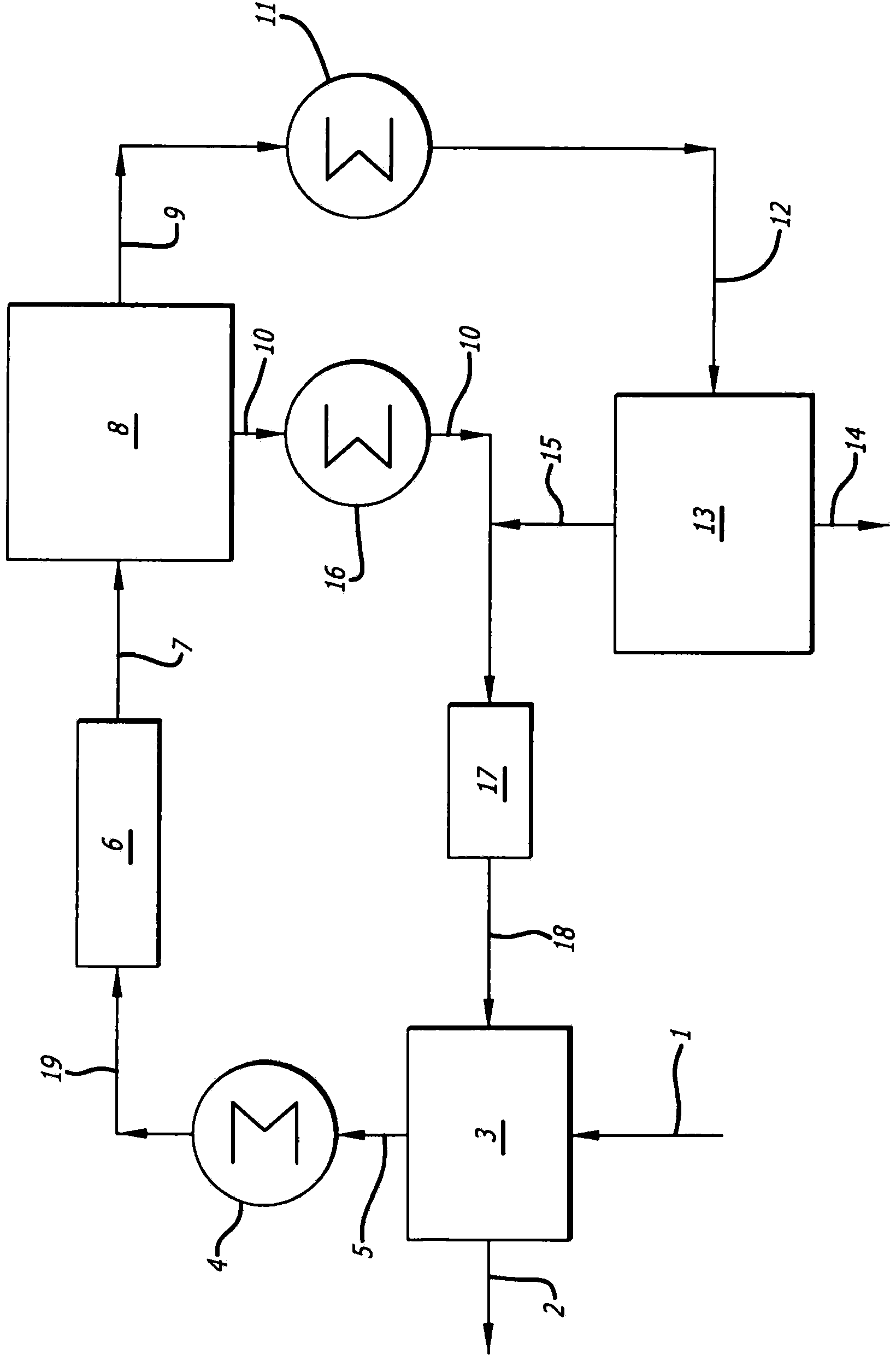

Methods for wastewater treatment

InactiveUS6132630ALow cost of treatmentOptimize present wastewater treatment plantWater/sewage treatment by centrifugal separationWater contaminantsFuel oilOil and natural gas

A method has been invented for separating components of a wastewater stream, the stream containing water, oil (e.g. heavy oil and / or light oil), undesirable organic material (solid and / or liquid), and contaminating solids, the method including feeding a wastewater stream to a first pre-treatment unit producing a first pretreated stream, feeding the first pretreated stream to a first centrifuge for centrifugal separation, producing a first liquid centrifuged stream, and a second liquid stream, and feeding the first liquid centrifuged stream to a second centrifuge producing a resultant centrifuged stream of recoverable oil and a water phase centrifuged stream which can be treated further or fed back to a source for re-use. The source may be a facility from the group including refineries, chemical plants, paper mill plants, and oil and gas processing facilities.

Owner:TUBOSCOPE VETCO INT +1

Fine particle lint filter

A lint filter having a succession of mesh screens which are arranged in parallel in a tank which receives lint-containing water from a laundry facility. The mesh screens are positioned so that the lint-containing water must pass through the screens in order to leave the tank. The lint-containing water is sprayed evenly on one side of the tank and proceeds across the tank toward the mesh screens. The mesh screens are angled so that lint and particles contained in the lint-containing water are allowed to fall to the bottom of the tank. Multiple exits allow lint-filtered water to leave the lint filter.

Owner:PATTEE HARLEY J

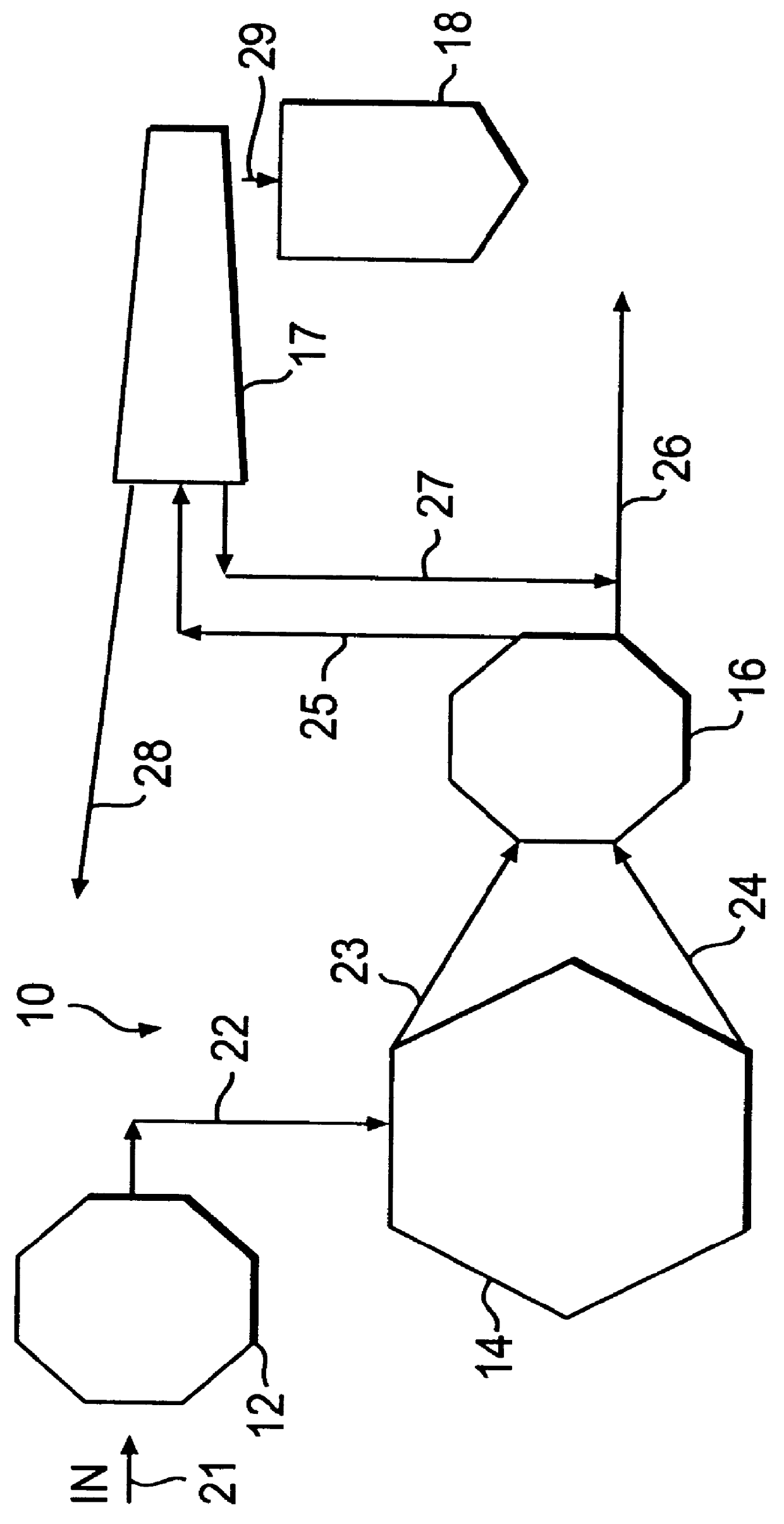

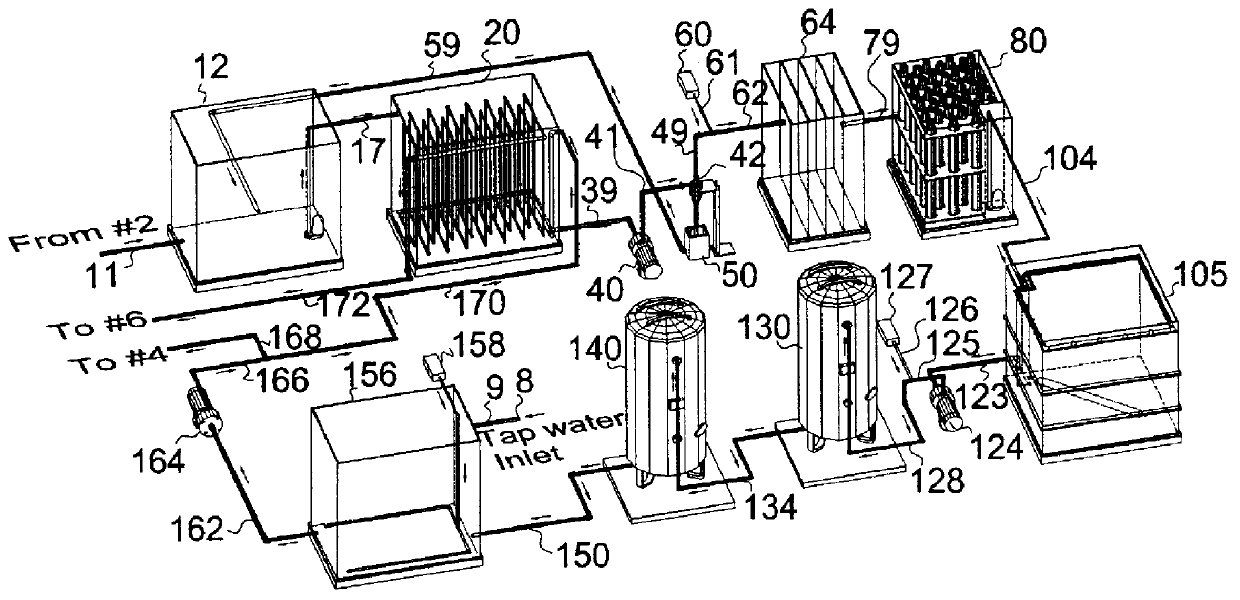

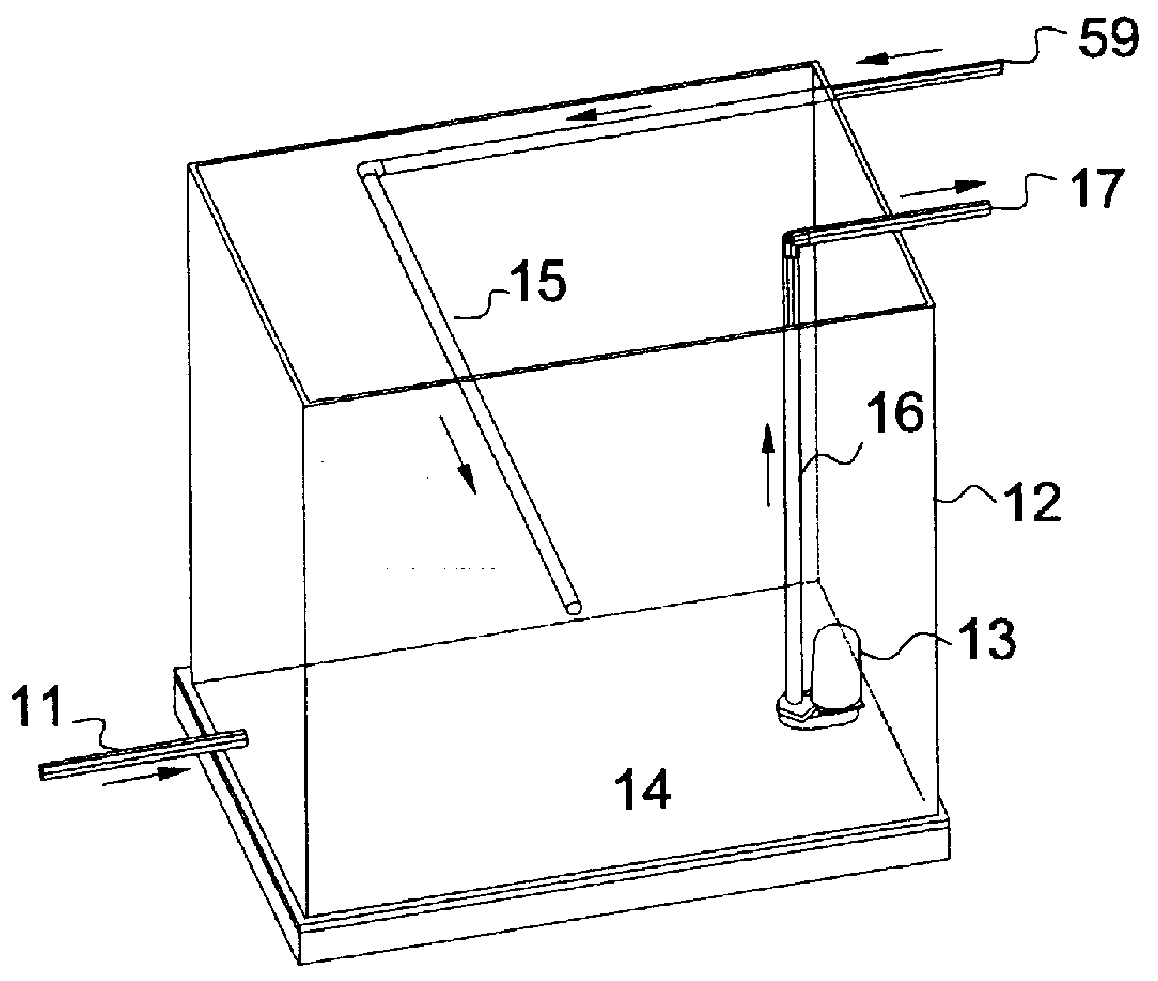

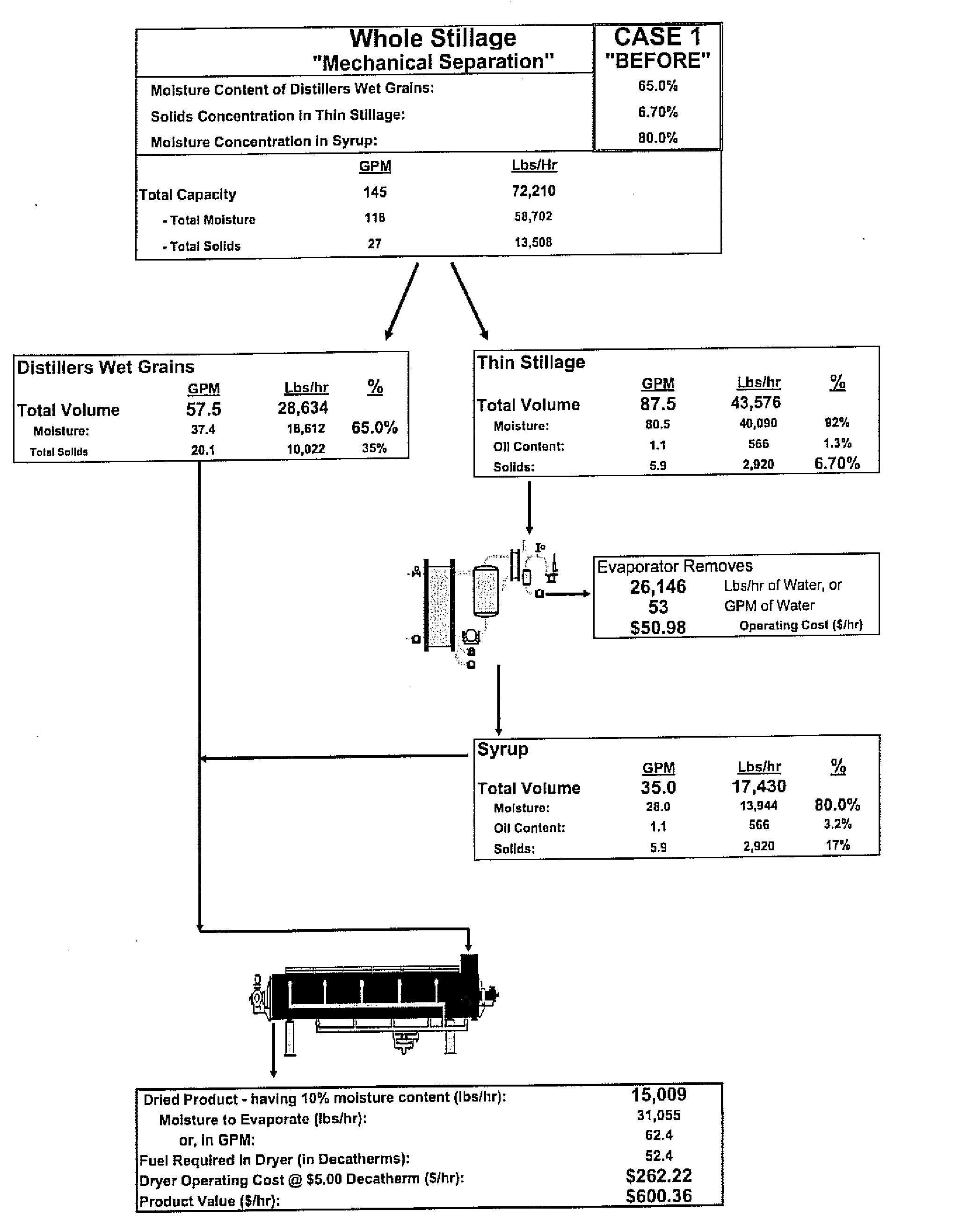

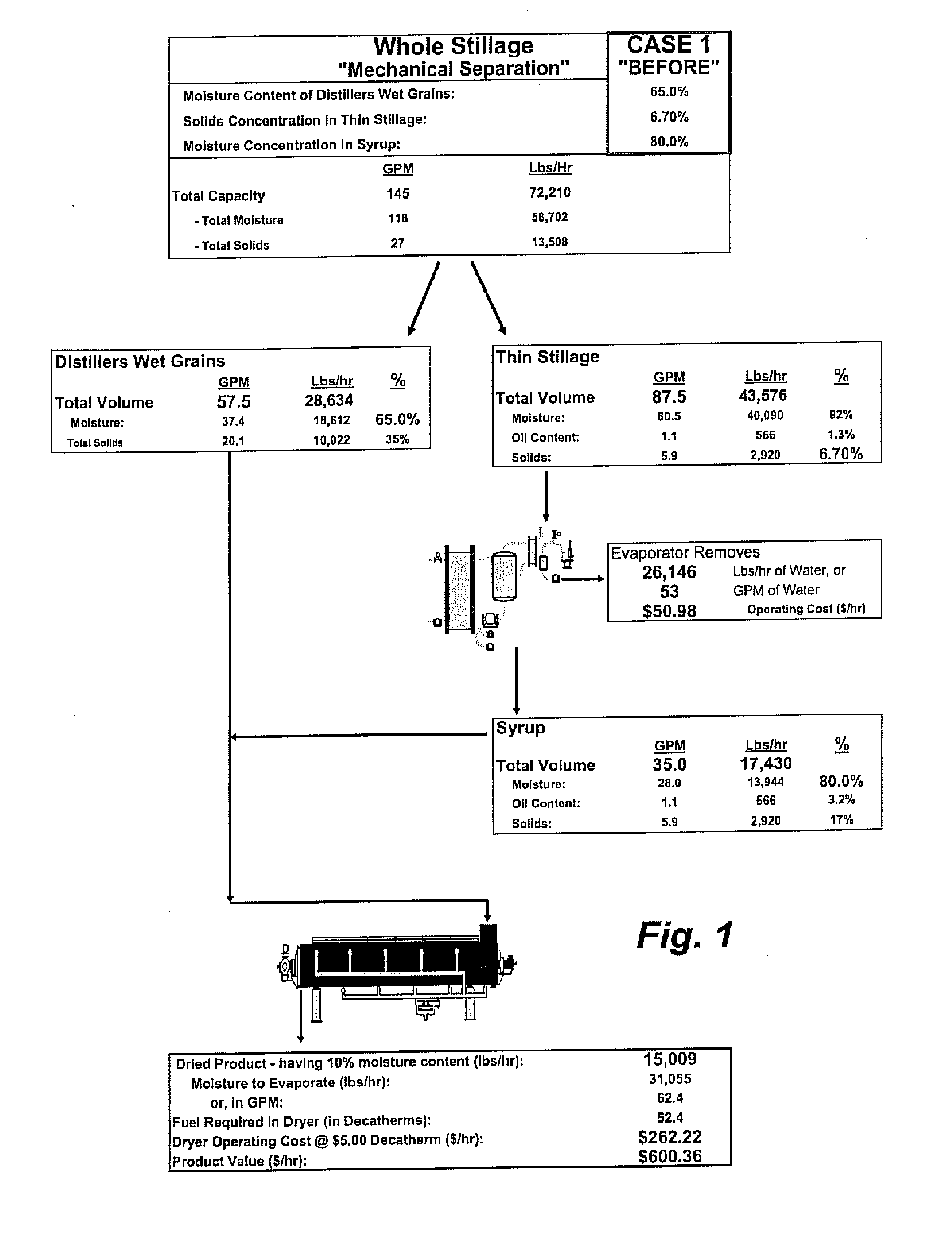

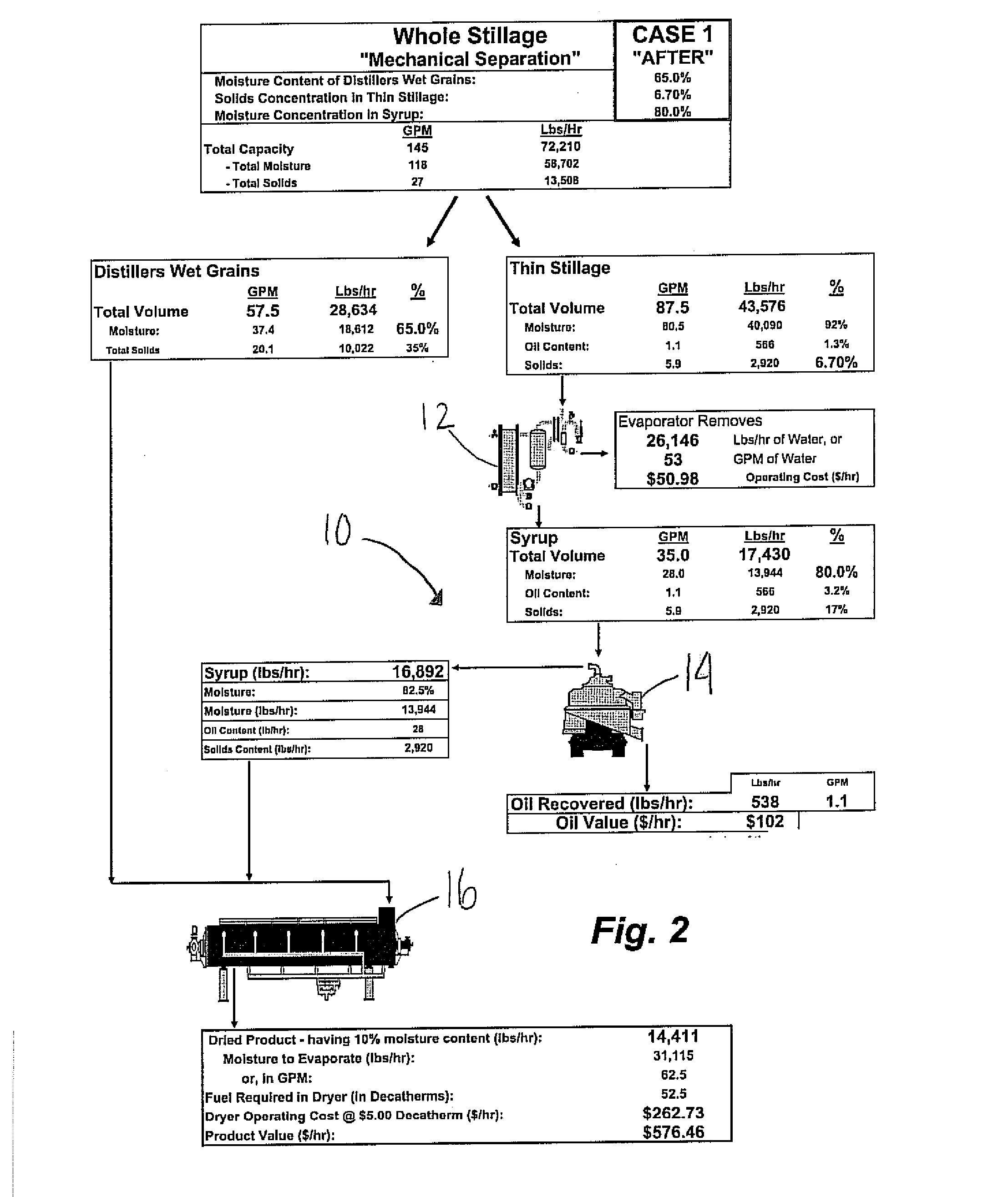

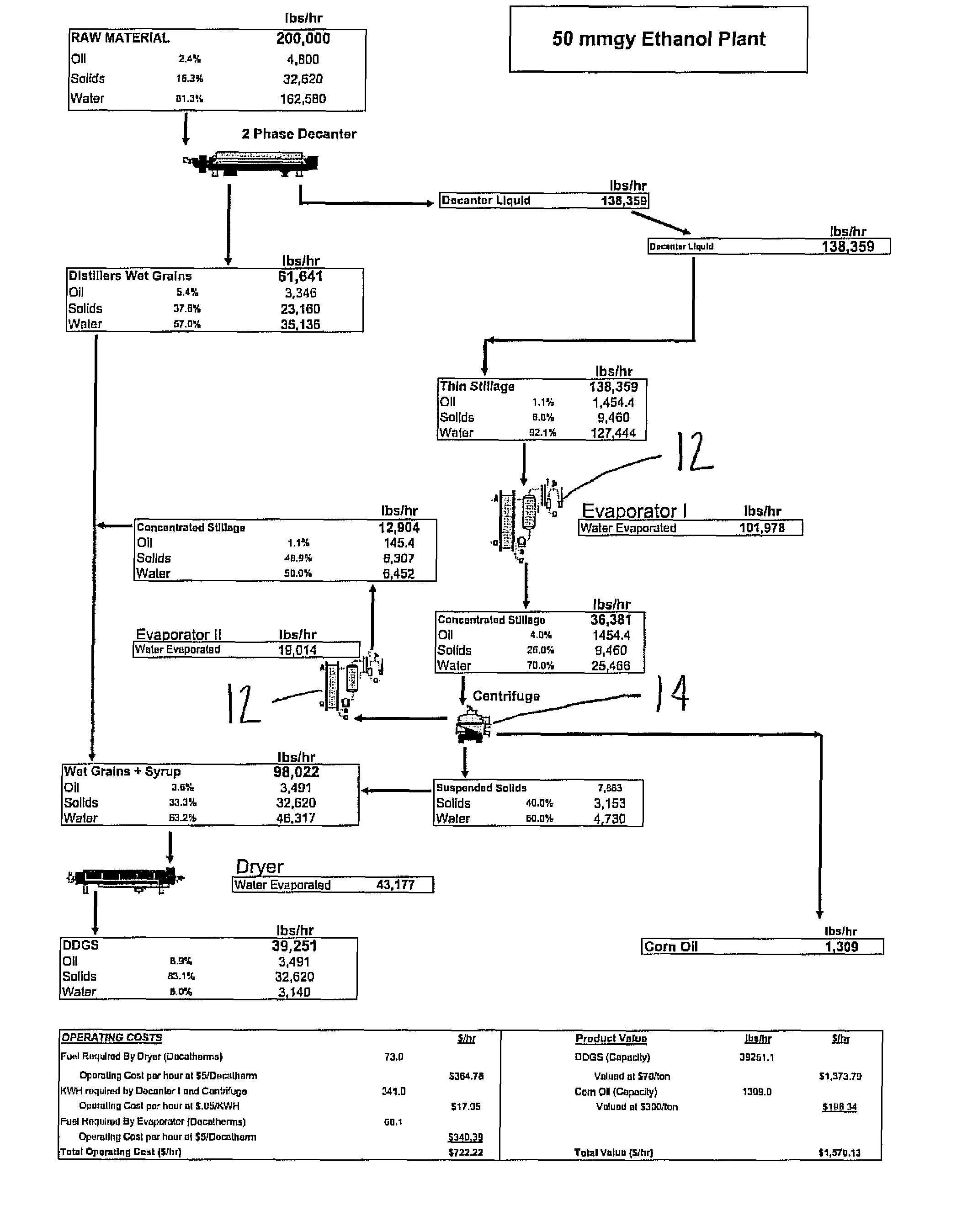

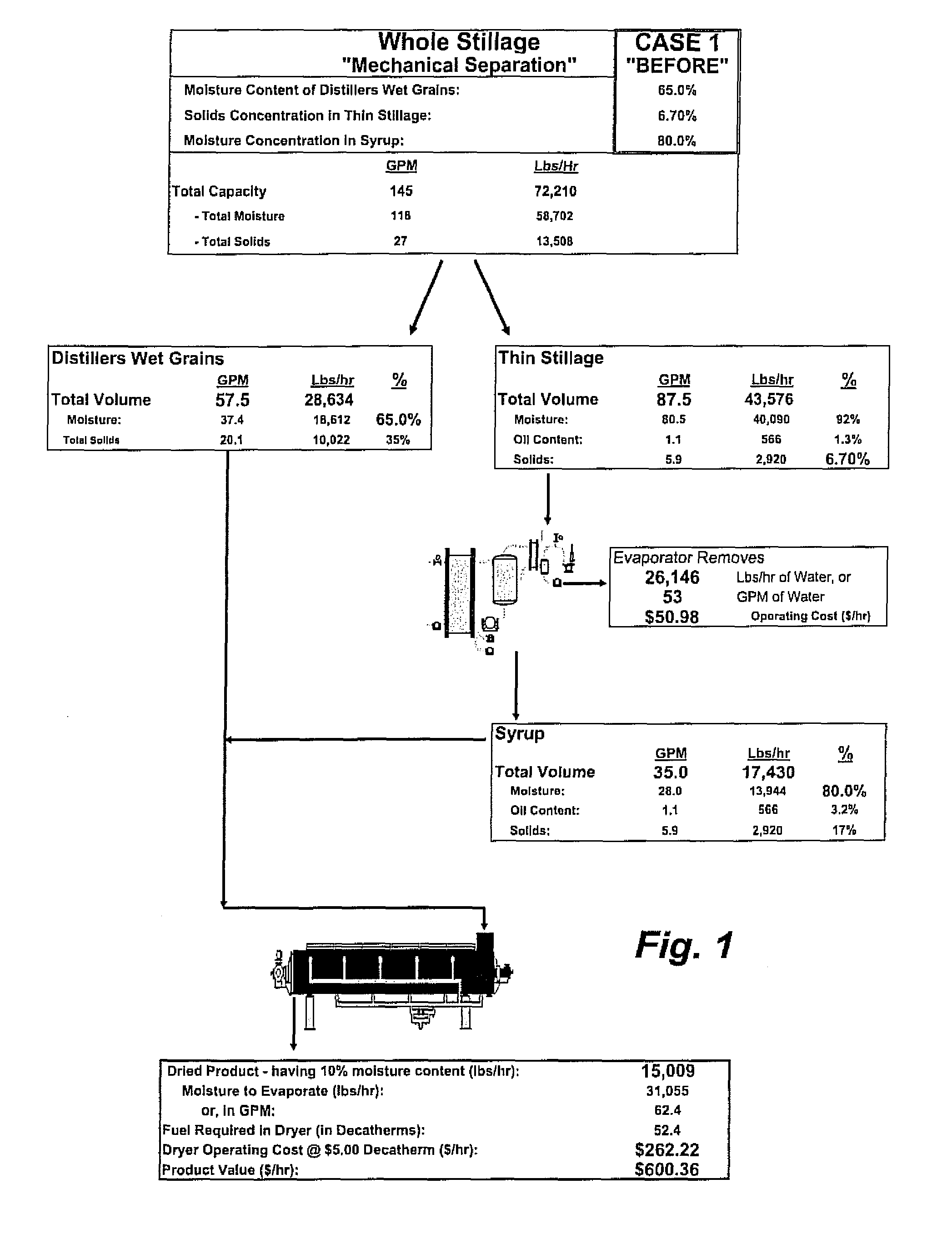

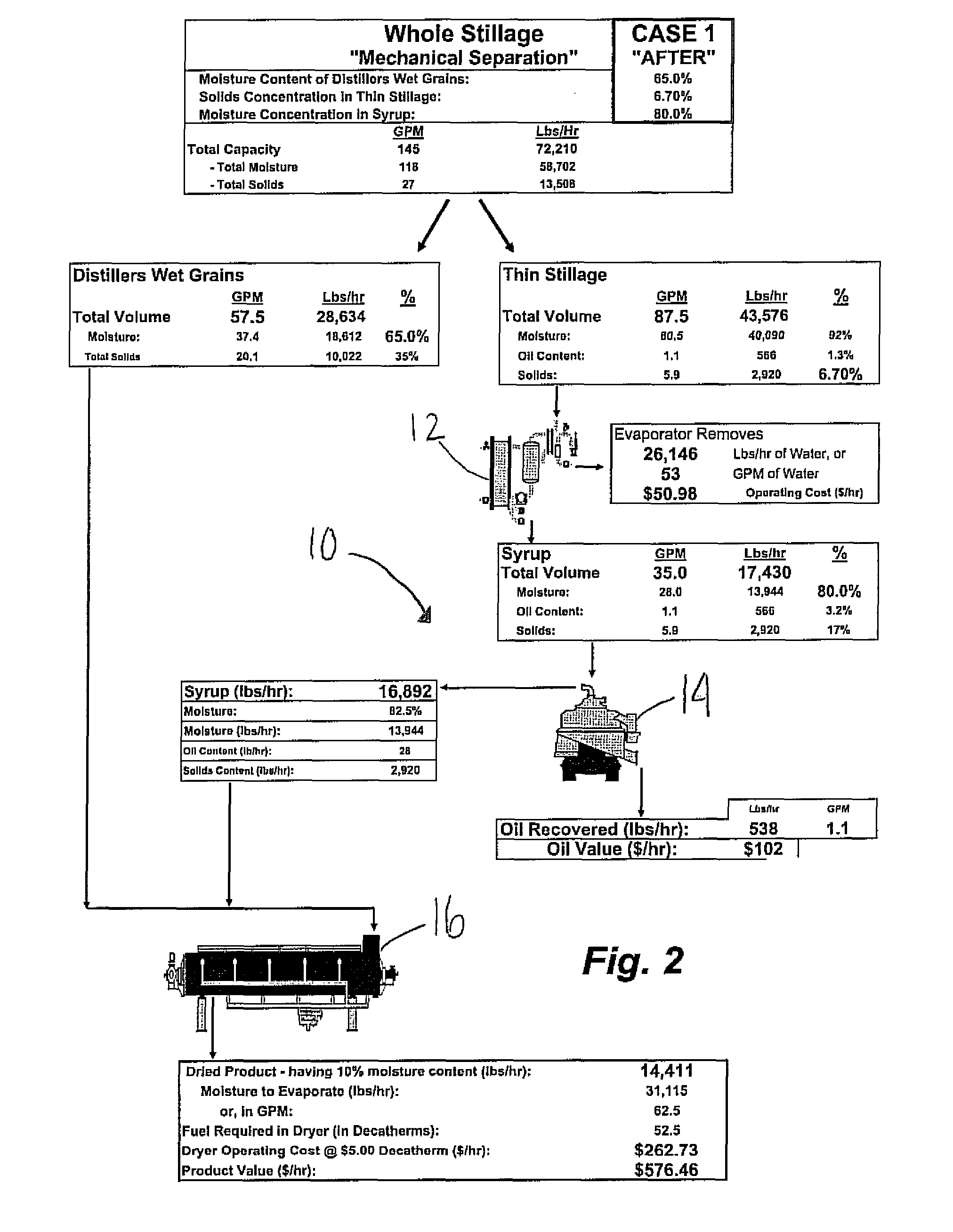

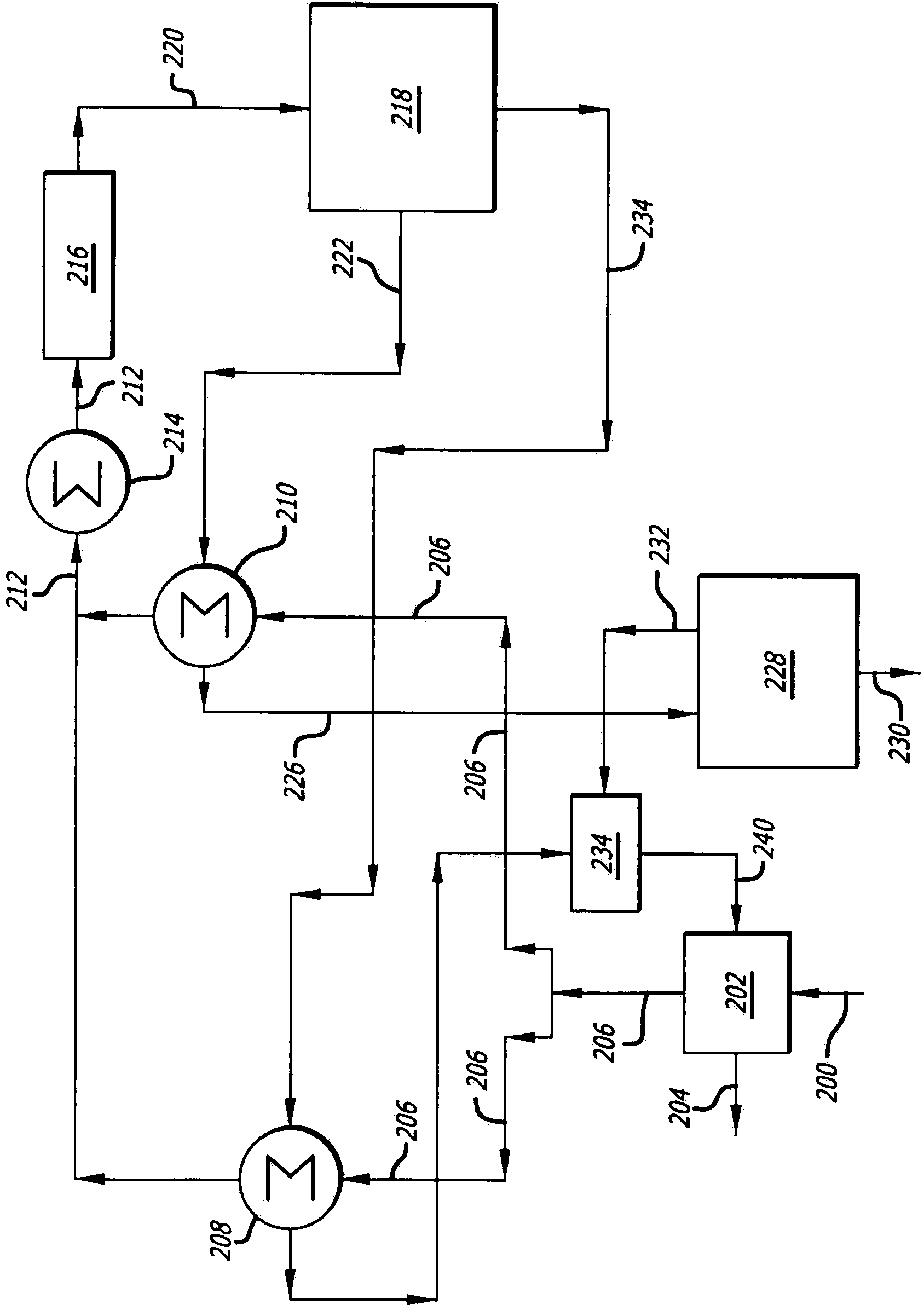

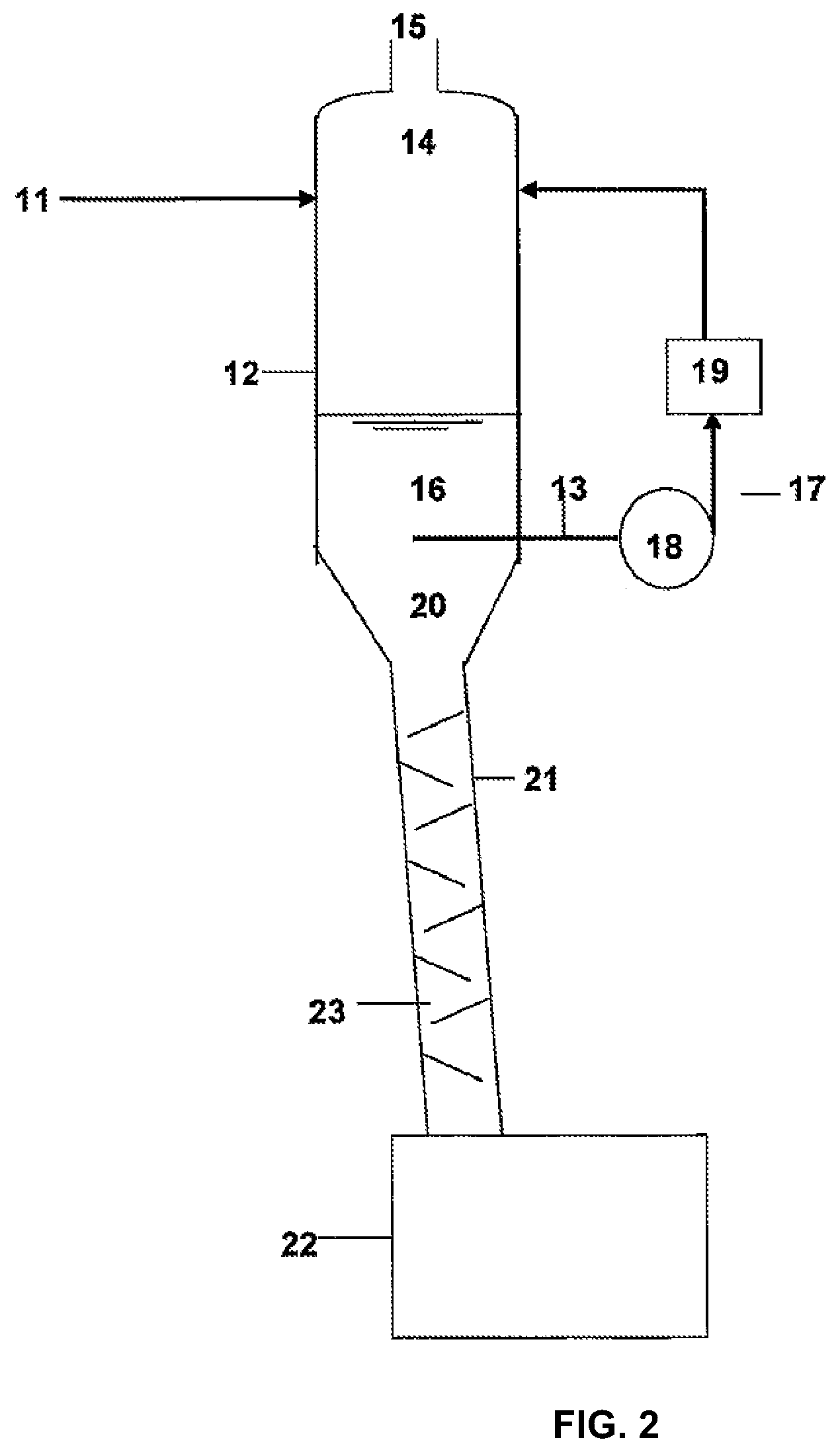

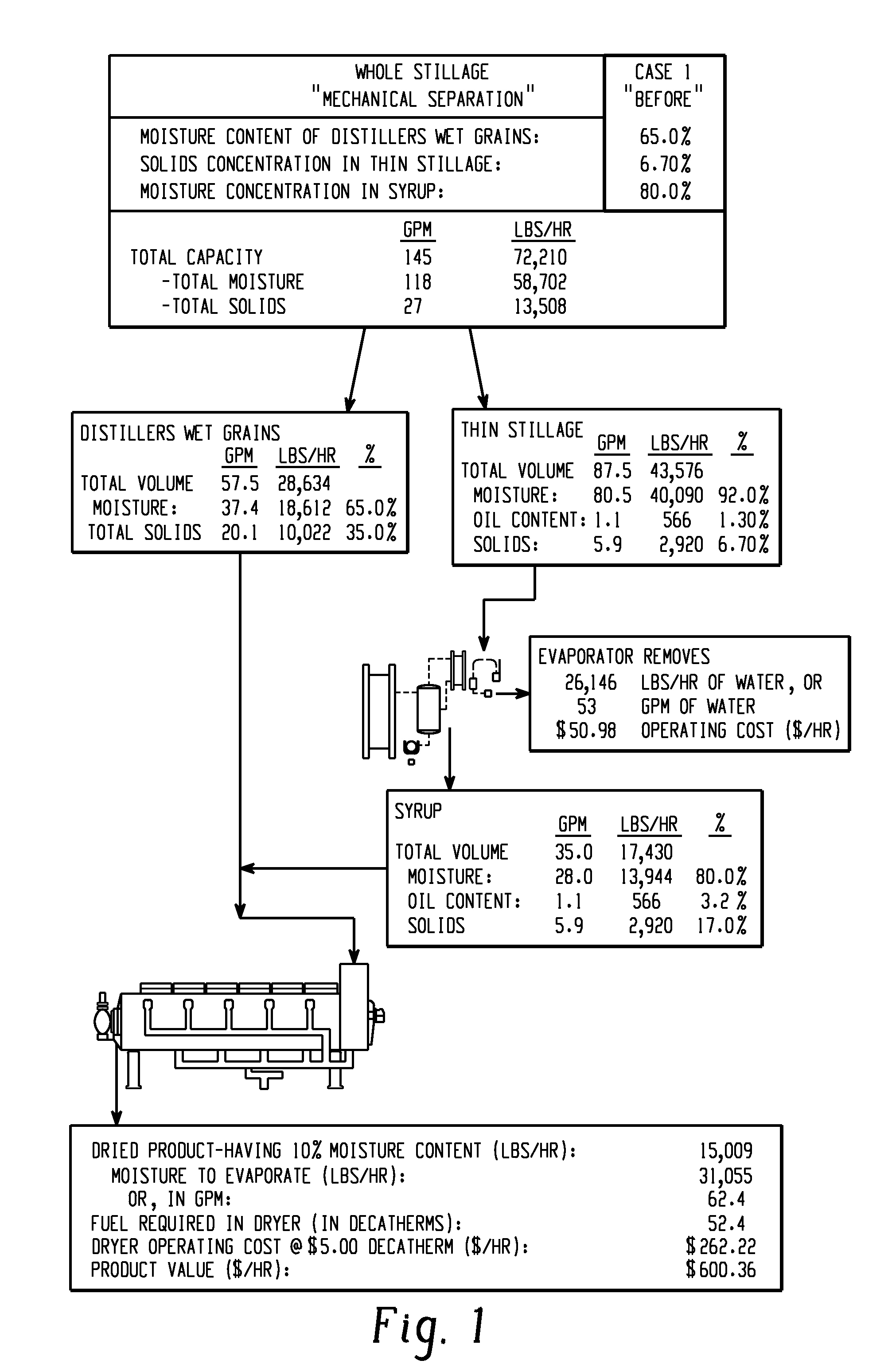

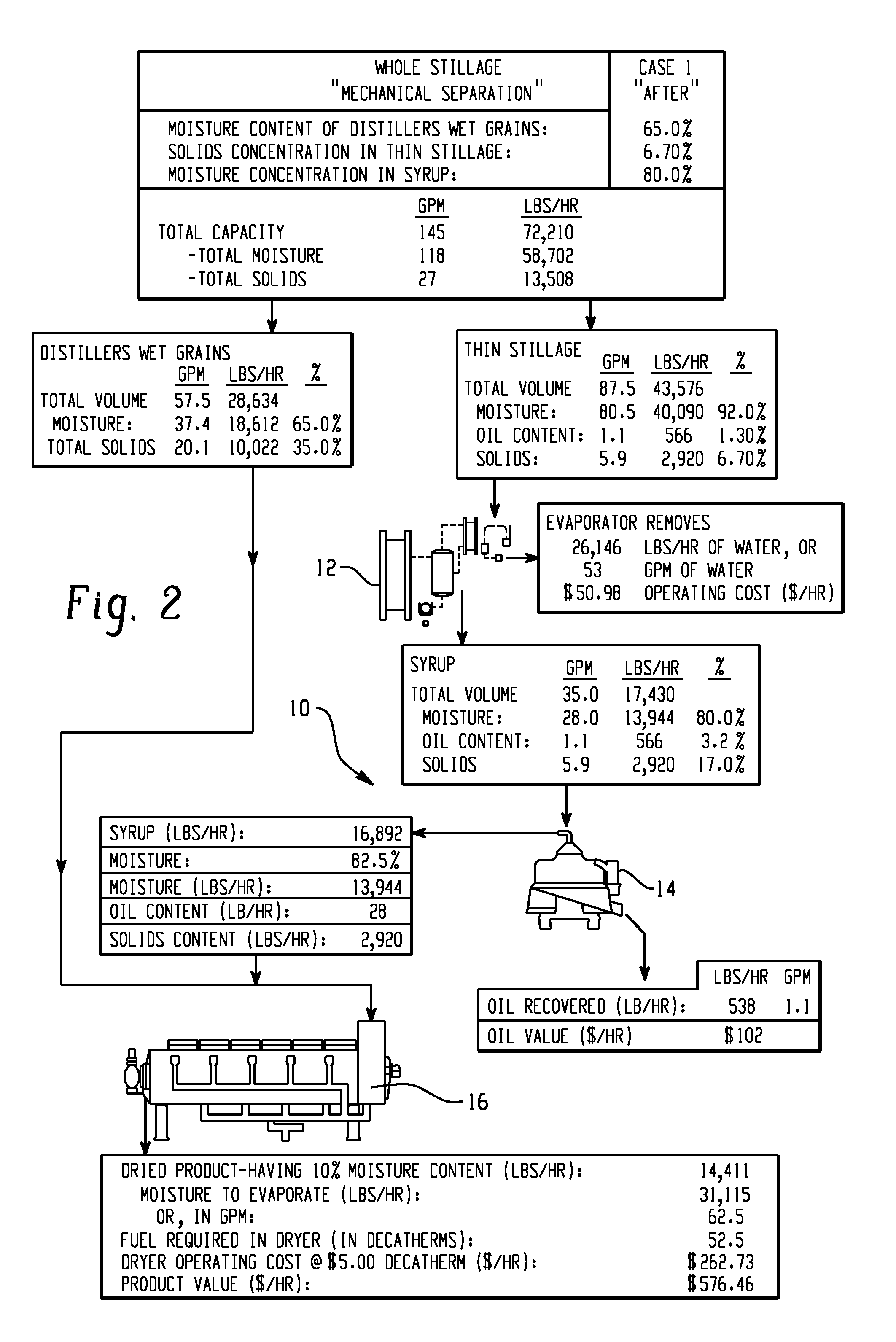

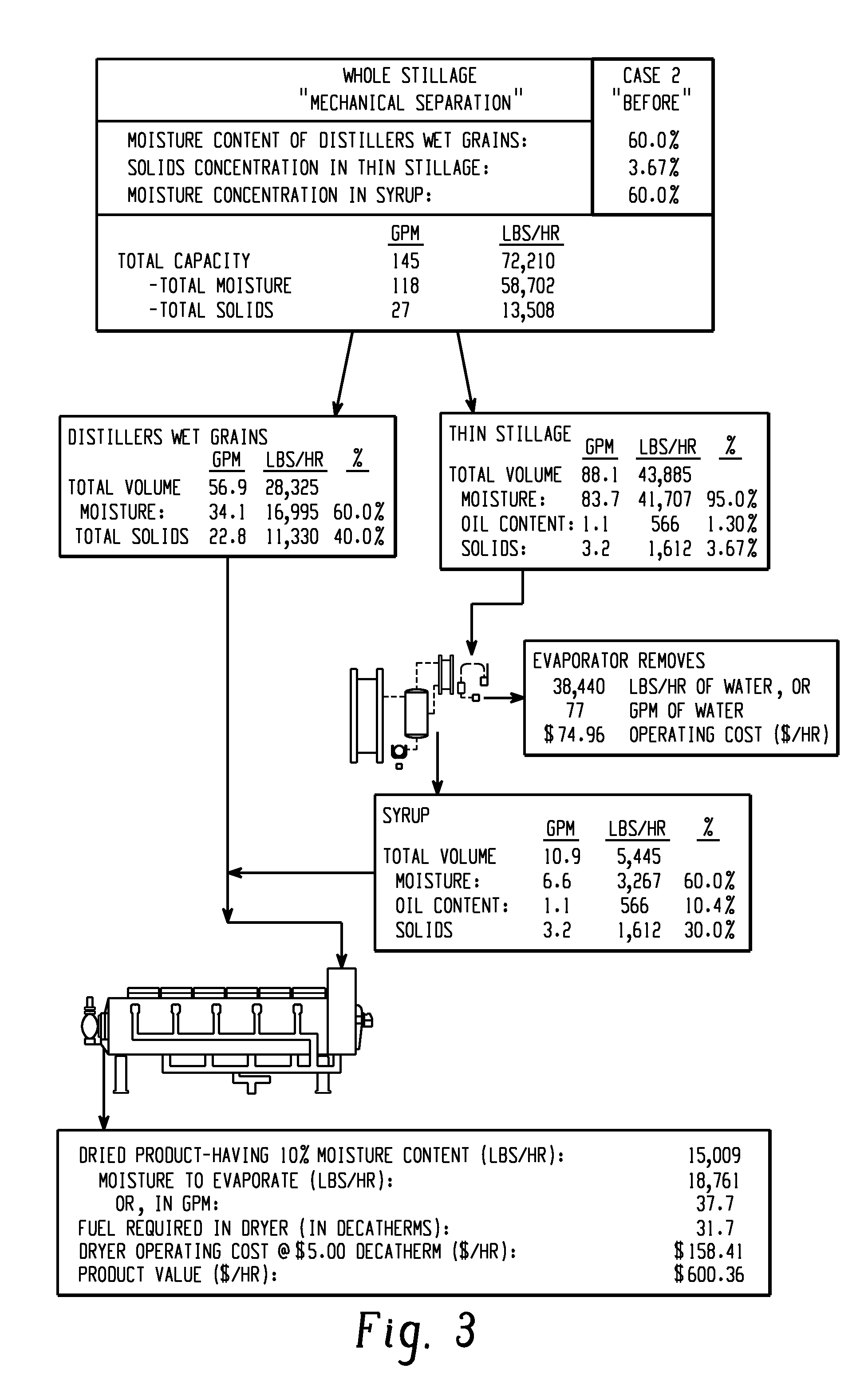

Method and systems for enhancing oil recovery from ethanol production byproducts

ActiveUS20080110577A1Fatty oils/acids recovery from wasteDrying using combination processesEngineeringCentrifuge

Owner:GS CLEANTECH CORP

Method and systems for enhancing oil recovery from ethanol production byproducts

InactiveUS8168037B2Fatty oils/acids recovery from wasteDrying using combination processesEngineeringCentrifuge

Methods and related systems efficiently and effectively recover a significant amount of valuable, useable oil from byproducts formed during a dry milling process used for producing ethanol. The method may include forming a concentrate from the byproduct and recovering oil from the concentrate. The step of forming the concentrate may include evaporating the byproduct using a multi-stage evaporator, as well as recovering the oil before the final stage of the evaporator. Further, the step of recovering oil from the concentrate may include using a centrifuge and, in particular, a disk stack centrifuge. Other aspects of the invention include related methods and subsystems for recovering oil.

Owner:GS CLEANTECH CORP

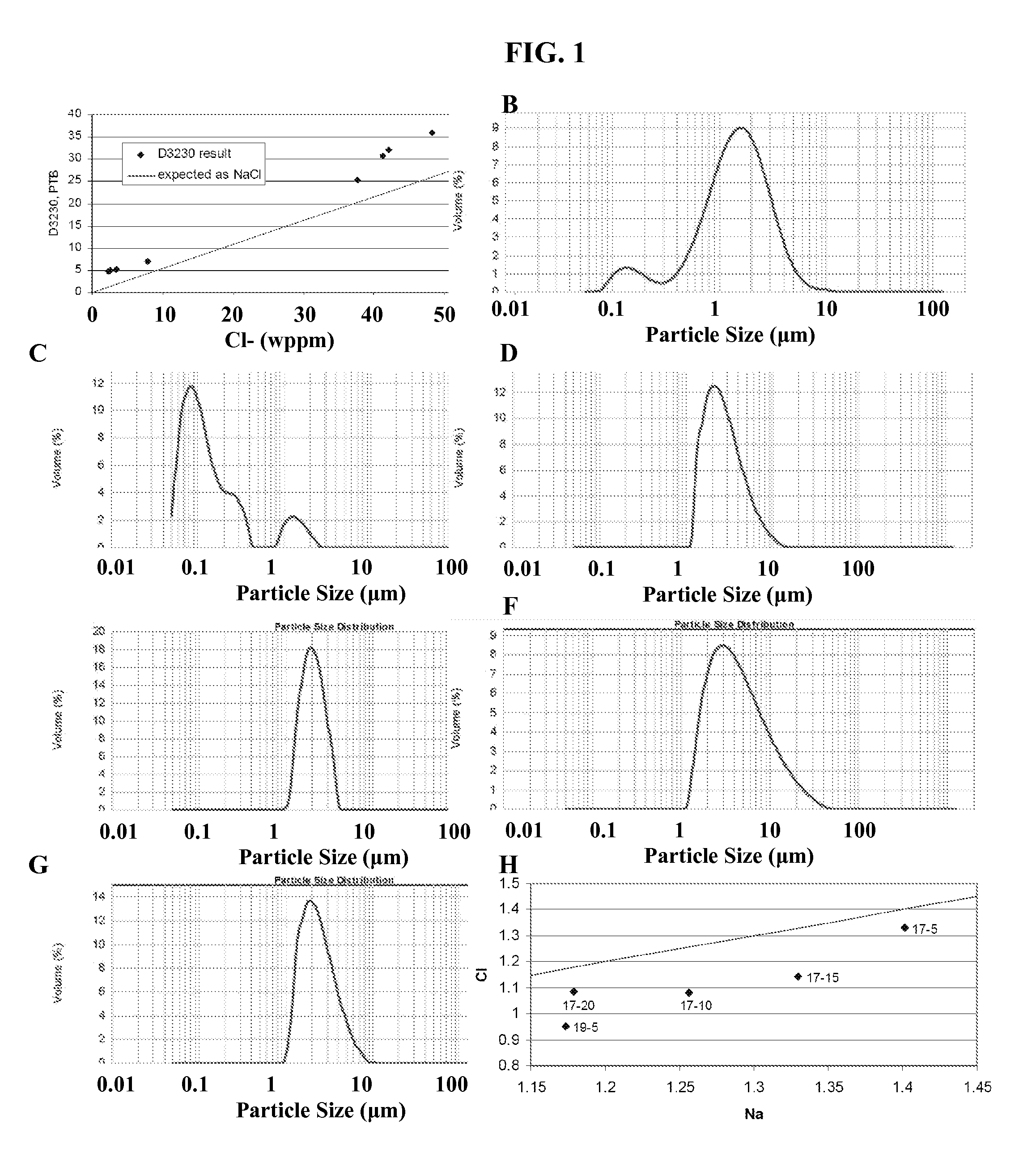

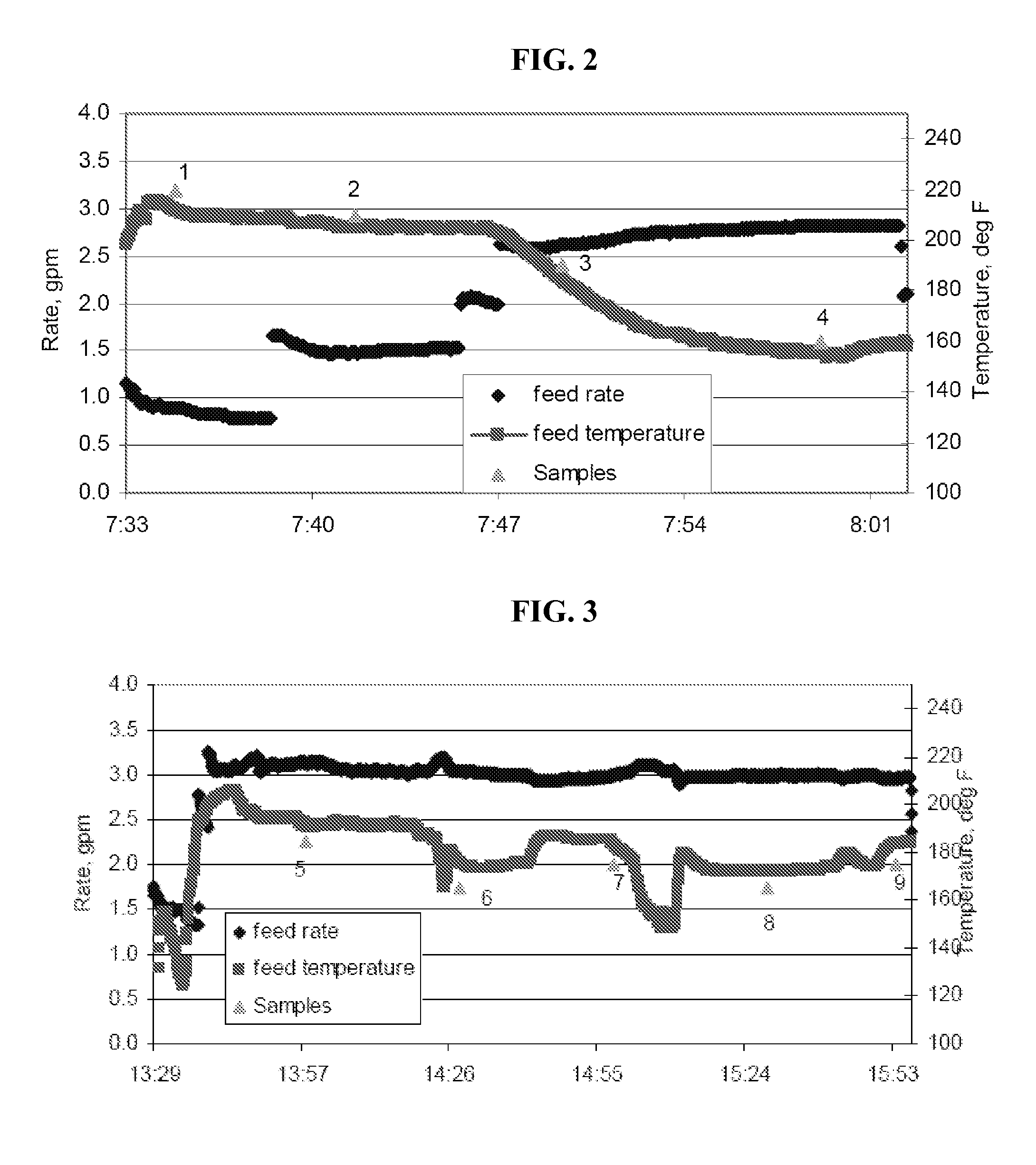

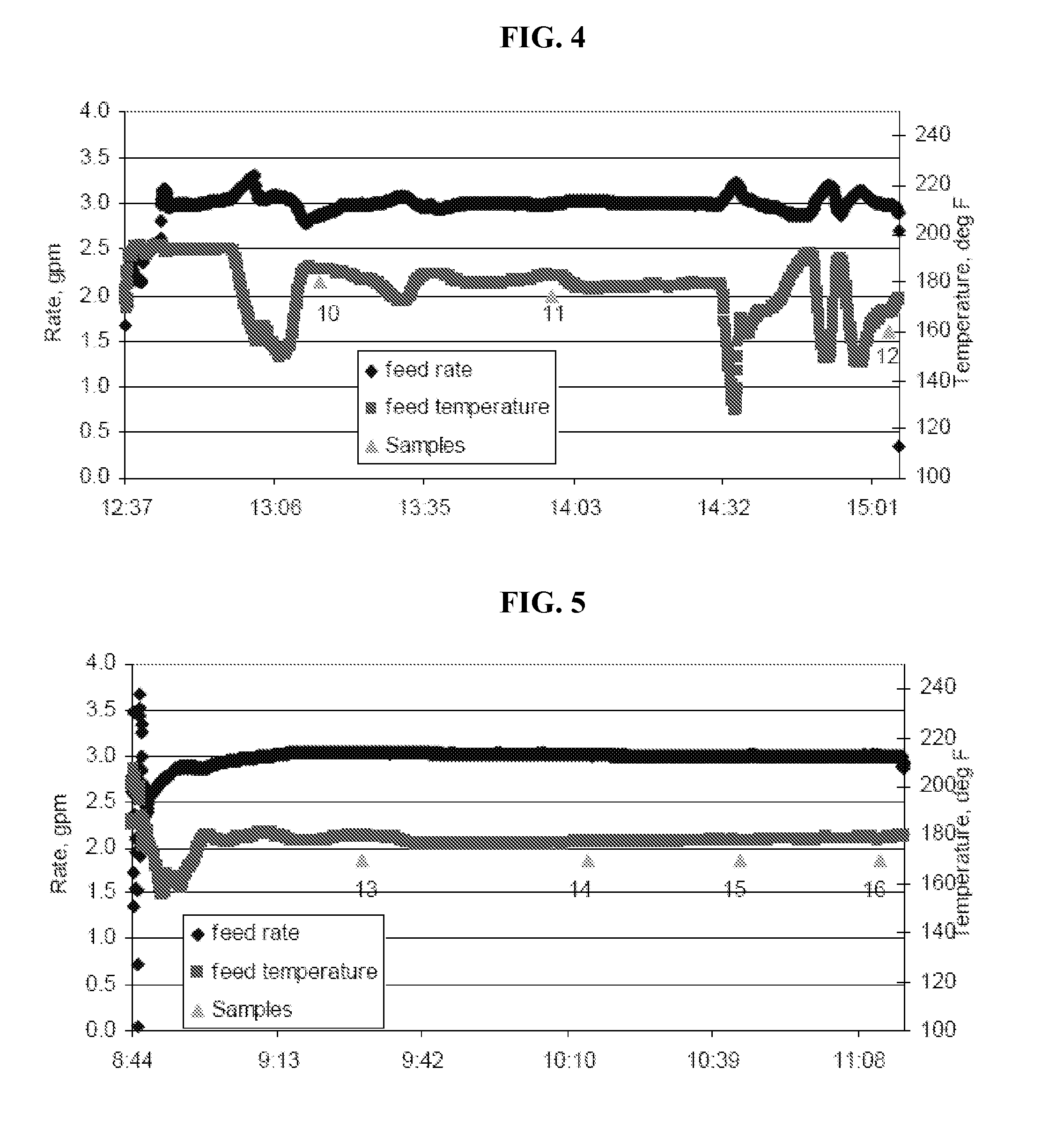

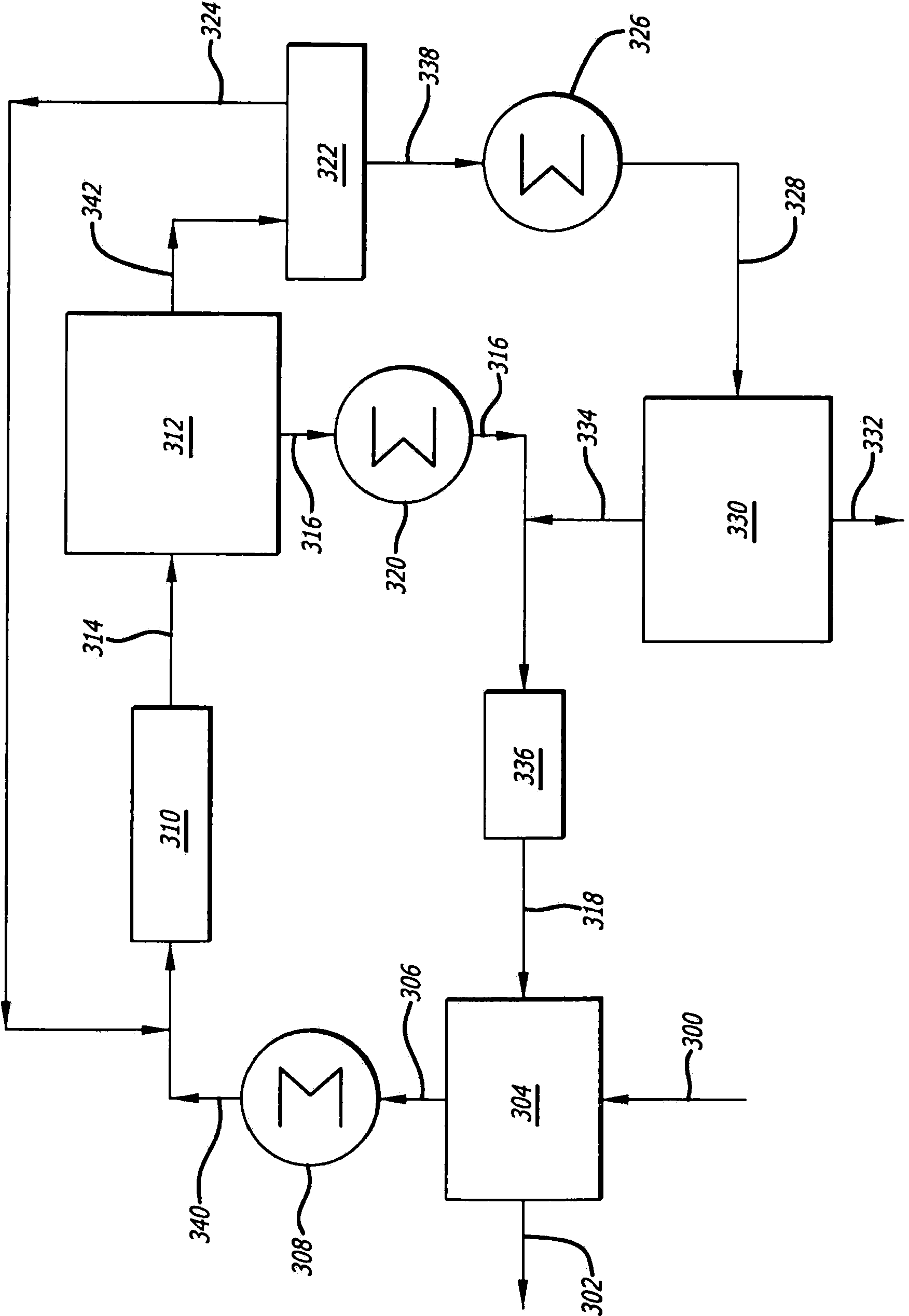

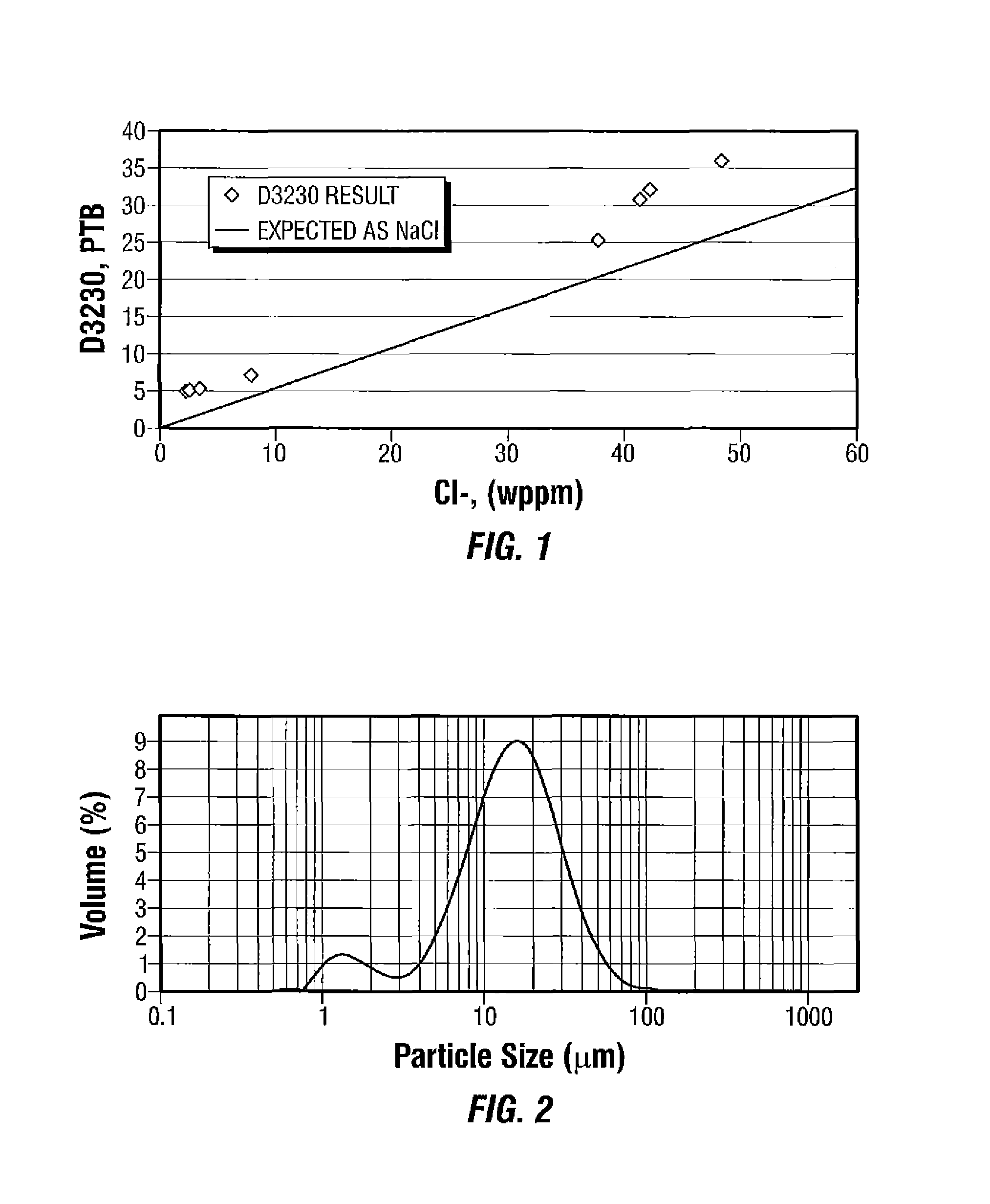

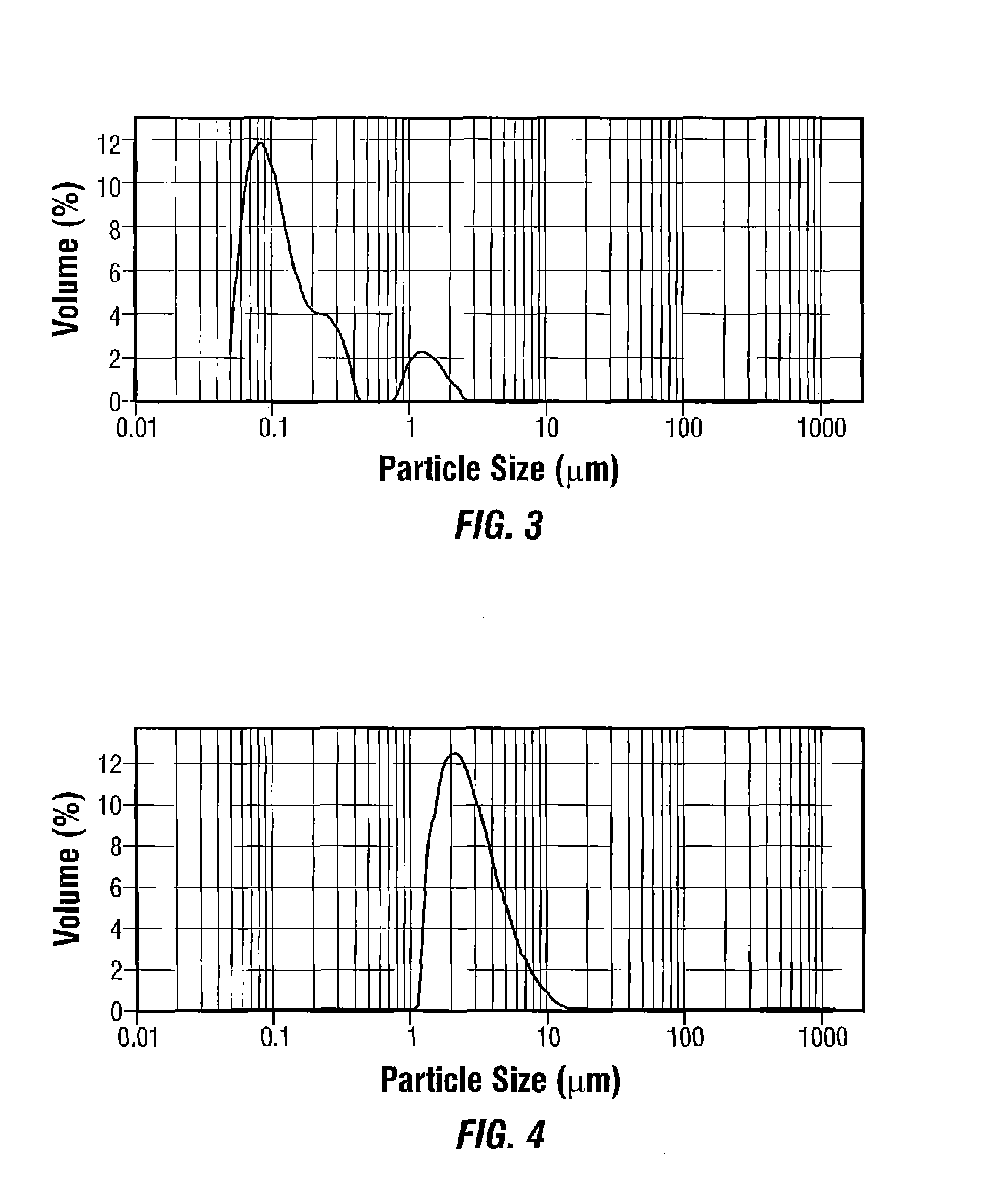

Refinery desalter improvement

ActiveUS20120024758A1Increase capacityEasy to separateDewatering/demulsification with mechanical meansRefining by water treatmentDesalinationDesalter

The invention relates to improved methods of desalting hydrocarbon feeds using a separator with a stacked disk centrifuge to separate an emulsified oil and water rag layer. This method is effective for desalting heavy, high ionic, and non-traditional crude oils.

Owner:PHILLIPS 66 CO

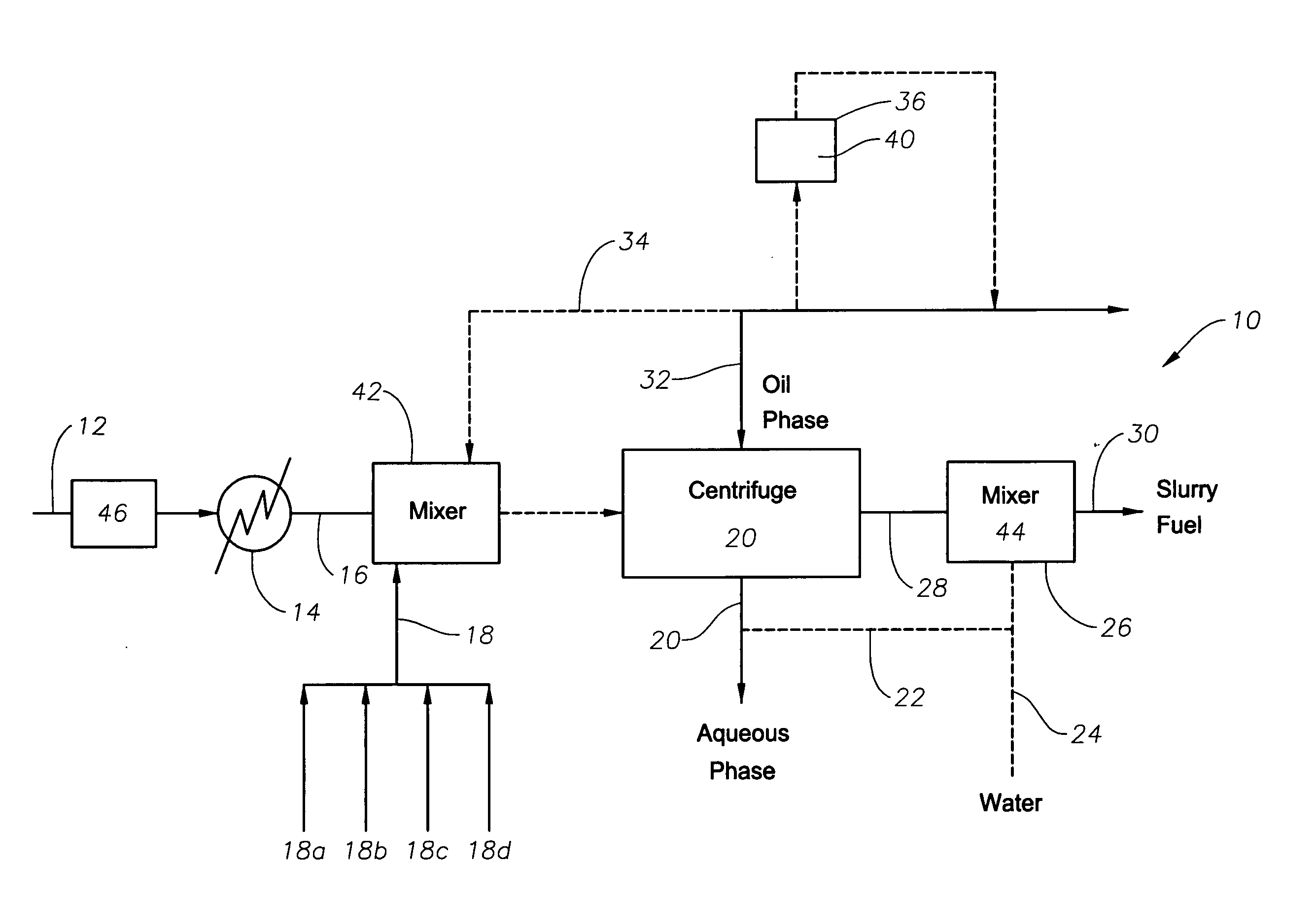

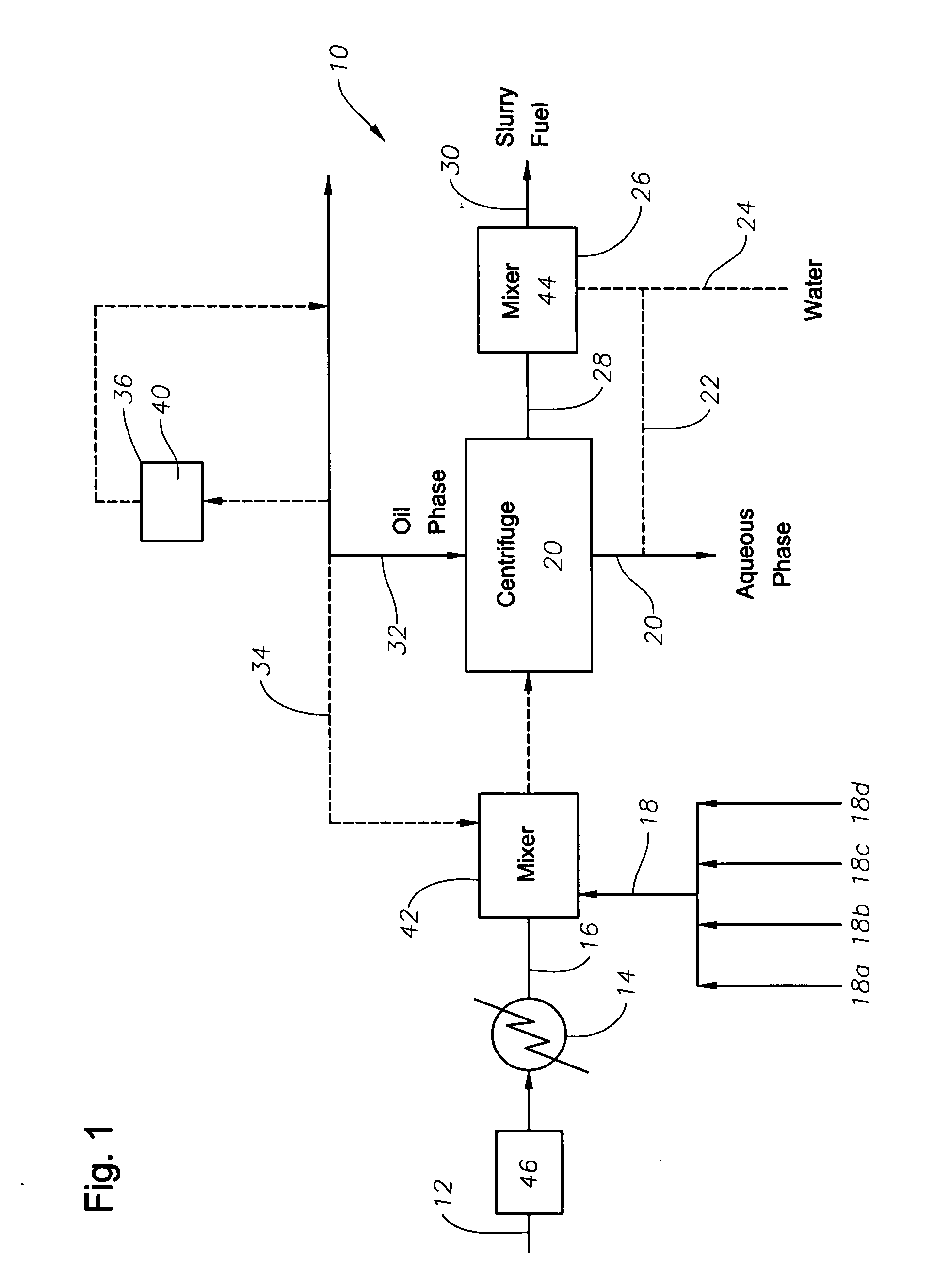

Method for utilizing hydrocarbon waste materials as fuel and feedstock

ActiveUS20060070912A1Low costDewatering/demulsification with mechanical meansRefining by heating/coolingFiberCarbon fibers

The fuel properties of petroleum hydrocarbon waste having an API gravity varying from about 5 to 30 are improved by heating the hydrocarbon to a temperature of about 35° C. to 90° C. and mixing the heated hydrocarbon stream with a suitable solvent to reduce the viscosity of the hydrocarbon, which is then separated by a centrifuge to obtain an aqueous phase stream, an oil phase stream, and a separated solids stream. The oil phase stream has a viscosity range of about 250 centipoise (cP) to about 1000 cP. The oil phase stream is utilized in a refinery, while a slurry fuel is prepared with the separated solids stream and aqueous phase stream as a feedstock for road asphalt, a fuel for a combustor, or a fuel for a gasification process. The oil phase stream is used for fuels and feedstock for making carbon fiber.

Owner:SAUDI ARABIAN OIL CO

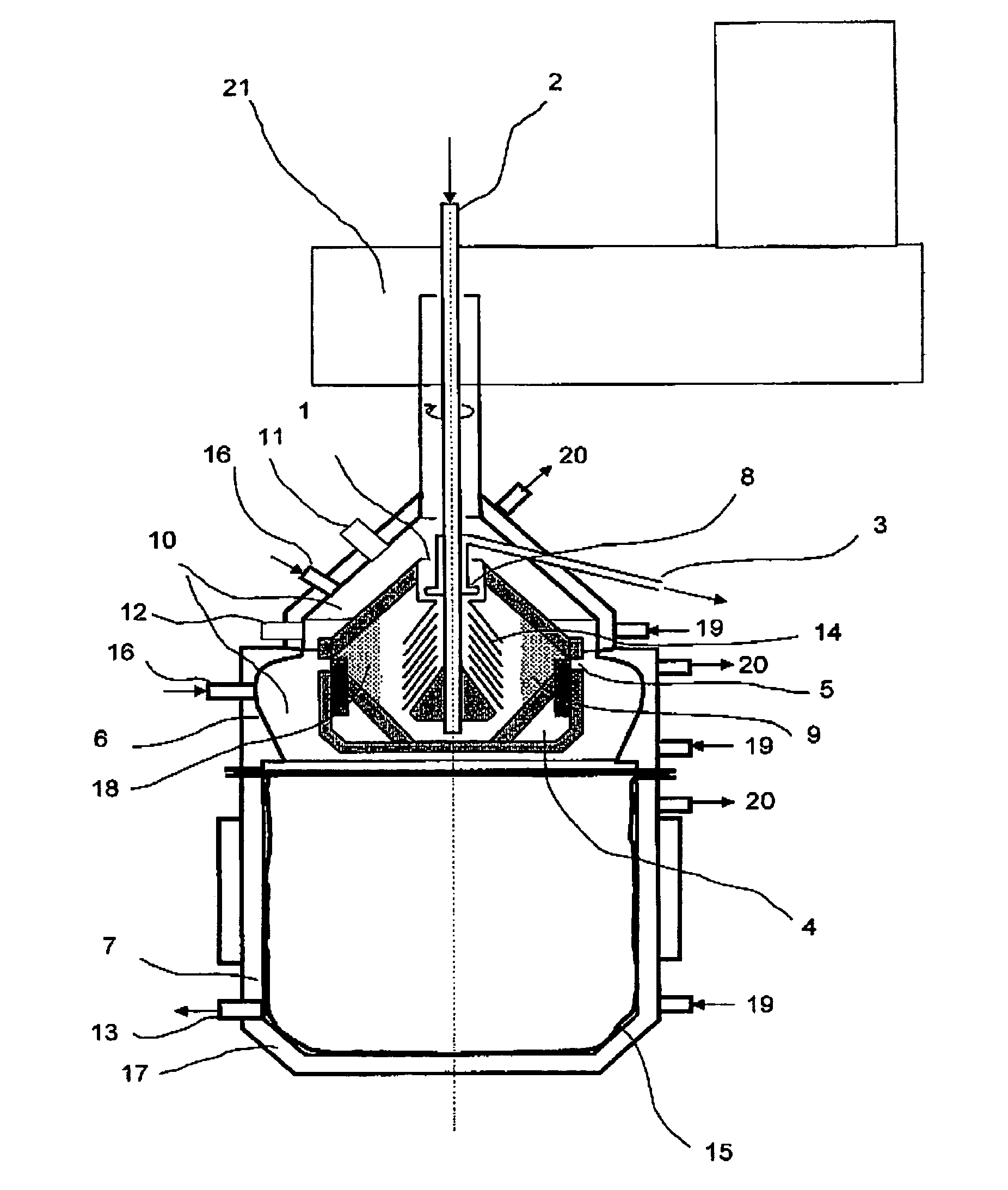

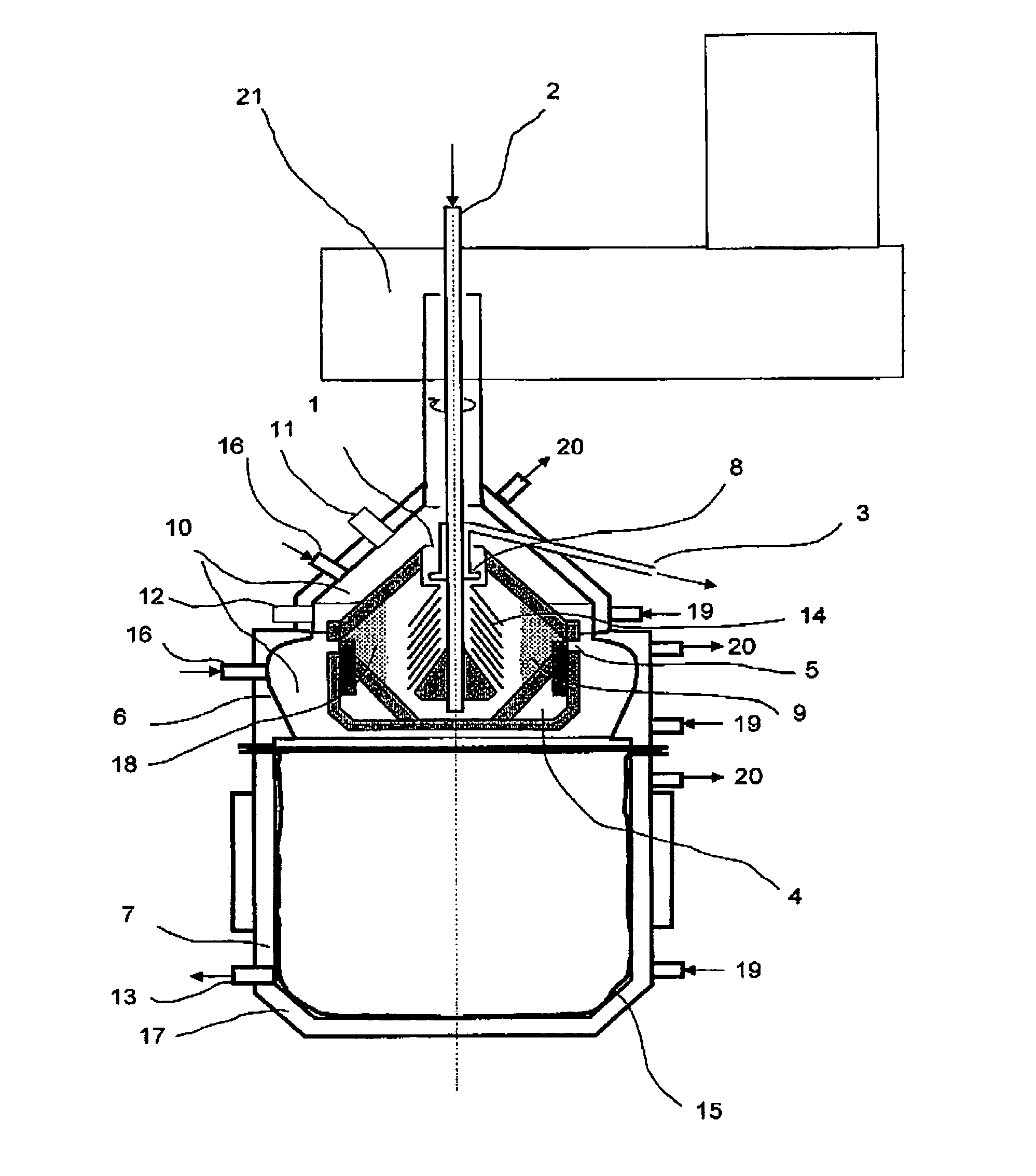

Method for the separation of blood plasma particles from a blood plasma suspension

InactiveUS7081082B2Reduce speedSimple designWater/sewage treatment by centrifugal separationDispersed particle separationEngineeringBlood plasma

Method for separating blood plasma particles from a blood plasma suspension in a self-discharging centrifuge having two or more discharge slits and axially stacked baffle plates, in which the blood plasma particles are separated from the liquid phase by centrifuging and removal of the liquid phase, suctioning off liquid remaining in the drum after separation of the blood plasma particles and discharging the sediment of solid blood plasma particles from the drum by centrifugal force into a collecting container underneath the drum, the drum and the blood plasma sediment being cooled during one or more of the process steps.

Owner:WESTFALIA SEPARATOR AG

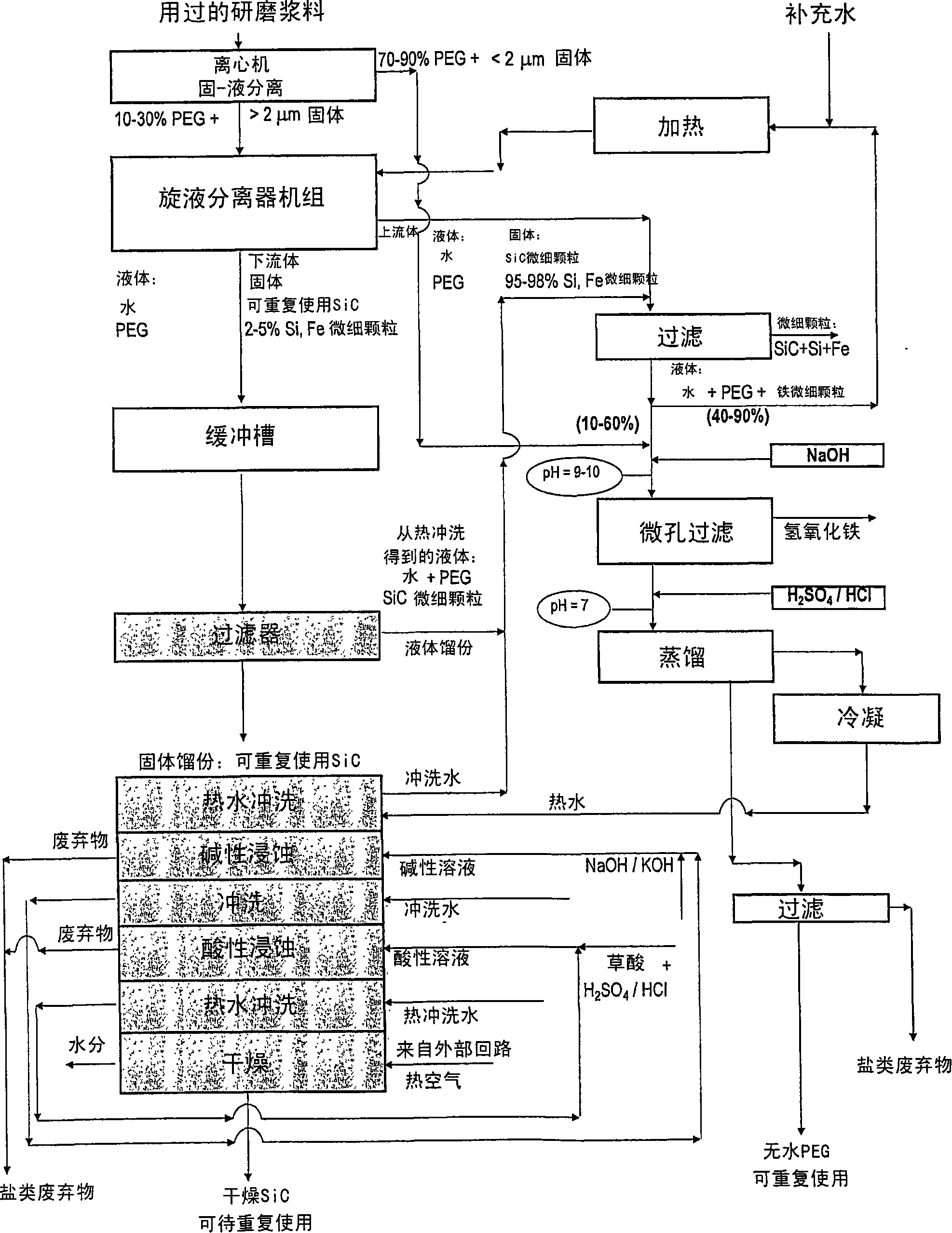

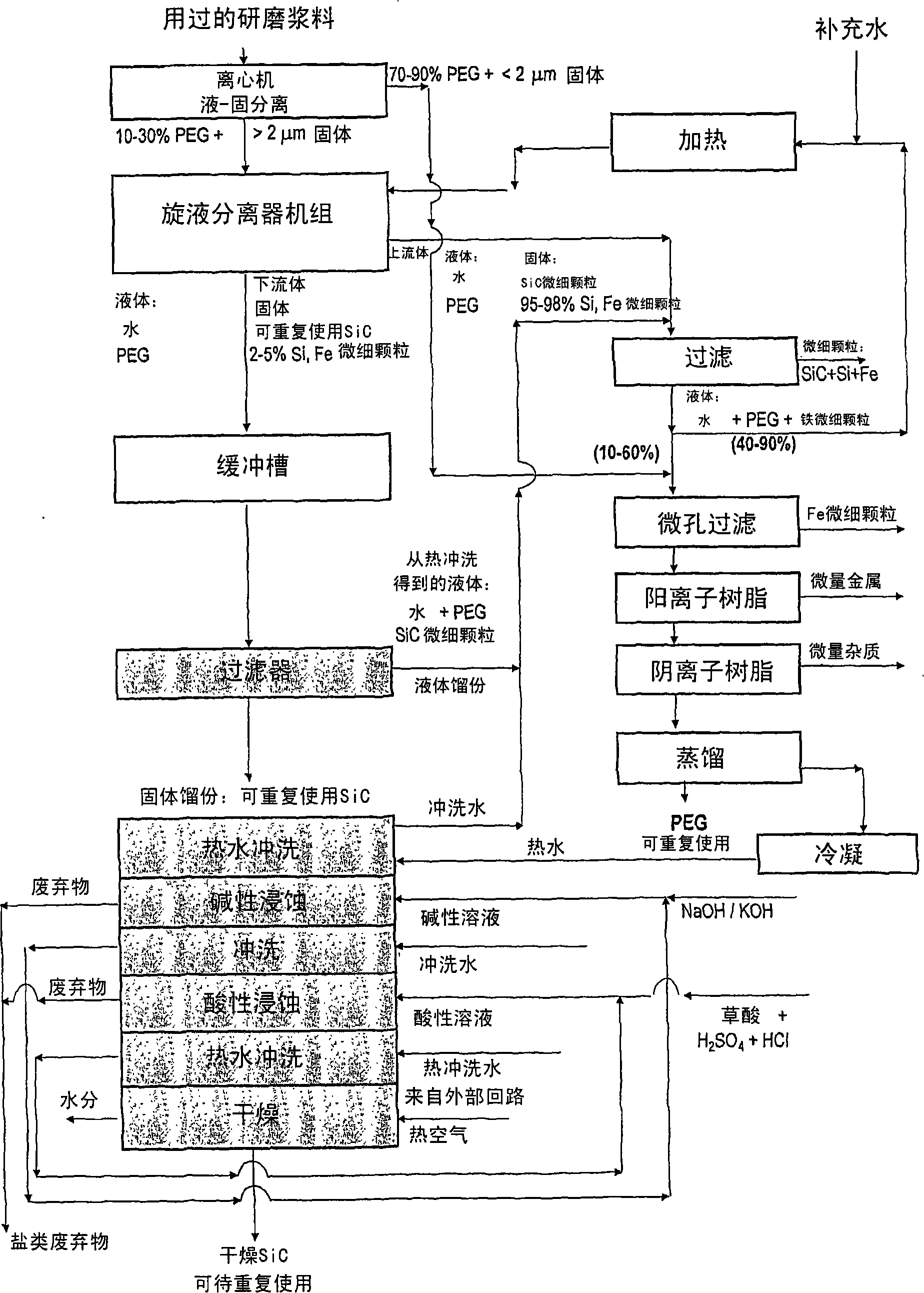

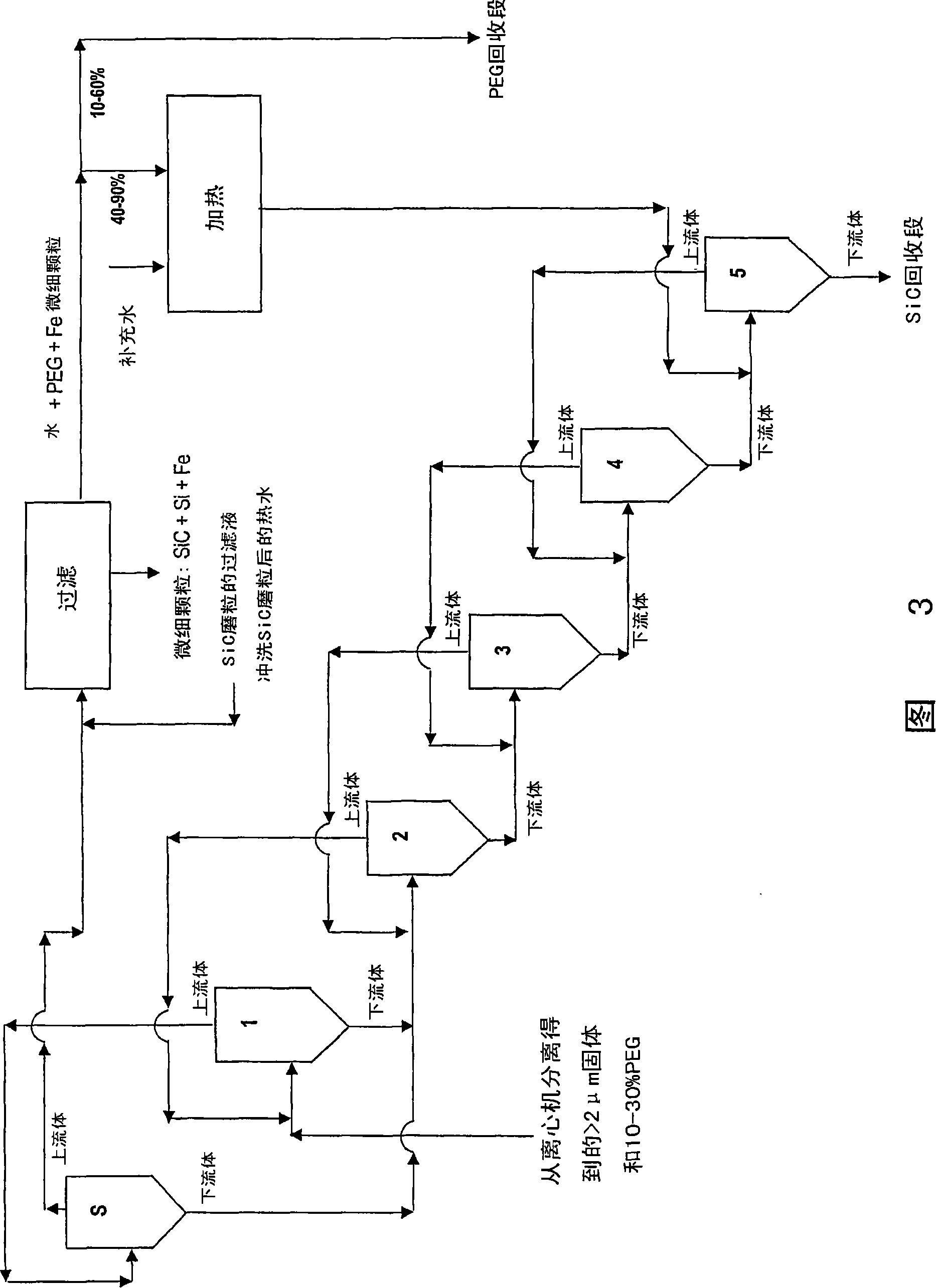

Process and apparatus for treating exhausted abrasive slurries for the recovery of their reusable components

InactiveCN101218068AReduce in quantityOrganic anion exchangersVortex flow apparatusCrystalline materialsSlurry

Process for completely recovering the reusable components of an abrasive slurry used in slicing crystalline materials of silicon, quartz or ceramics when it becomes exhausted and enriched with undesired waste matter. The process consists of an initial centrifuge separation of the exhausted slurry as such and of a wet size-sorting treatment of the fraction containing the abrasive grains obtained from the centrifuge, carried out in a battery of hydrocyclones or centrifuges connected in series. The section for the recovery and purification of the abrasive grains comprises a multifunctional apparatus that performs all the required operations within a single pressure vessel. The process enables the complete recovery of the reusable abrasive grains contained in the exhausted slurry as well as of the suspending or cutting liquid of the abrasive slurry, in order to reuse both components in the manufacturing process. The invention also concerns an apparatus for carrying out the treatment of exhausted abrasive slurries according to the process described.

Owner:SIC PROCESSING

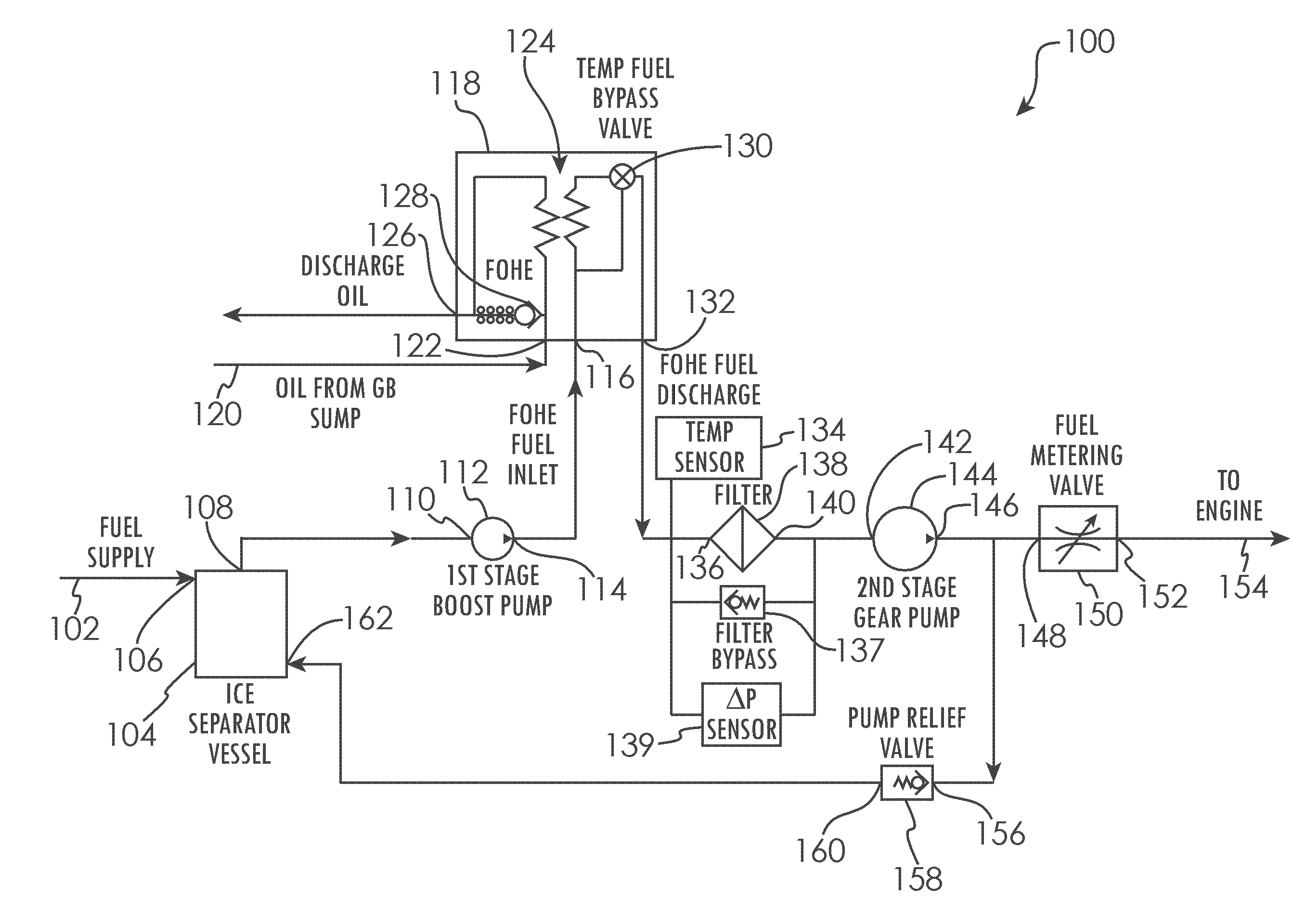

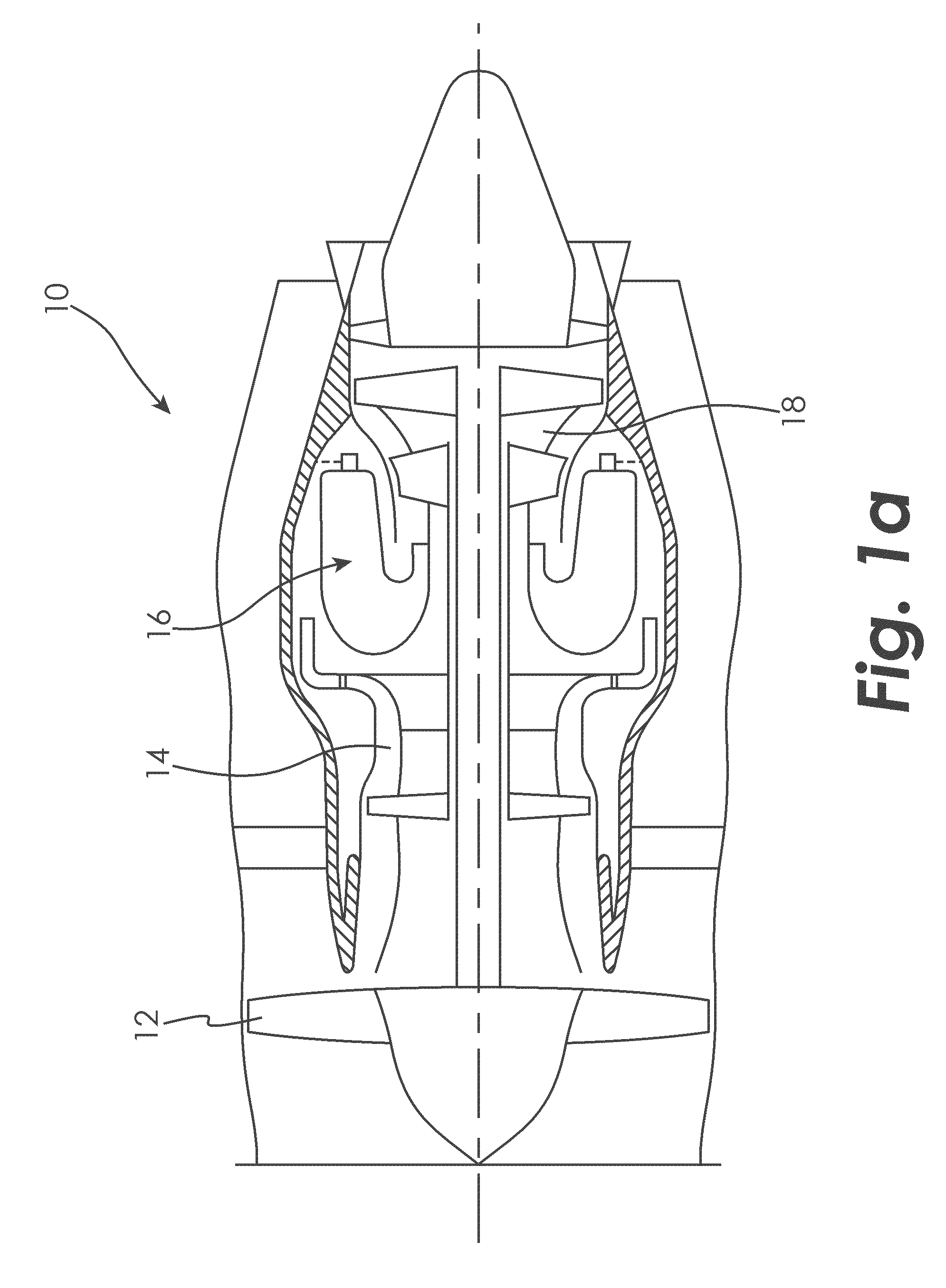

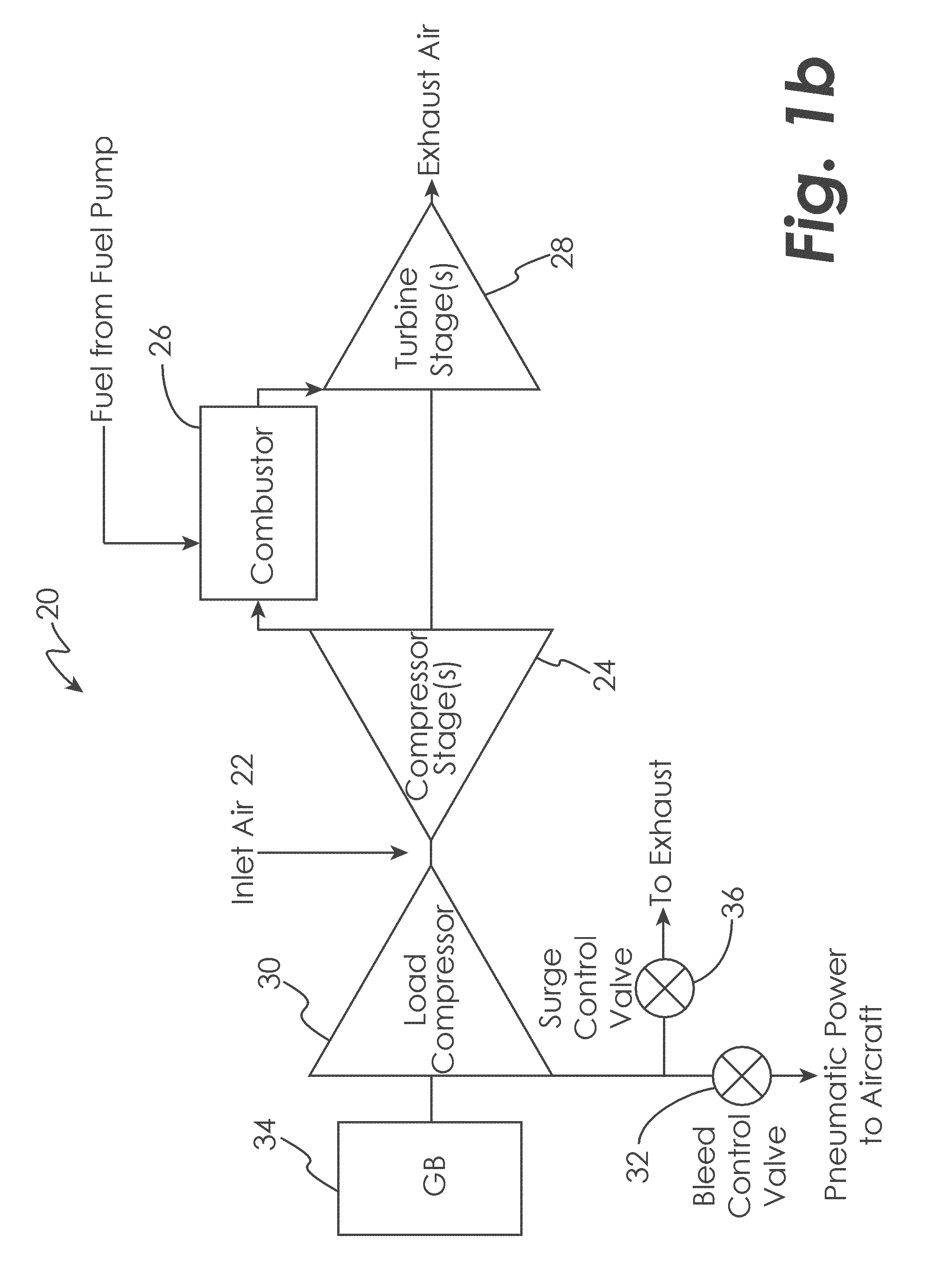

Removing non-homogeneous ice from a fuel system

The presently disclosed embodiments utilize an ice separator vessel to trap ice particles in a non-homogeneous ice / fuel mixture flowing in a fuel system. A source of heat, such as heated fuel provided to the ice separator vessel, is used to melt at least a portion of the ice particles so that they do not enter the fuel system downstream of the ice separator vessel.

Owner:RAYTHEON TECH CORP

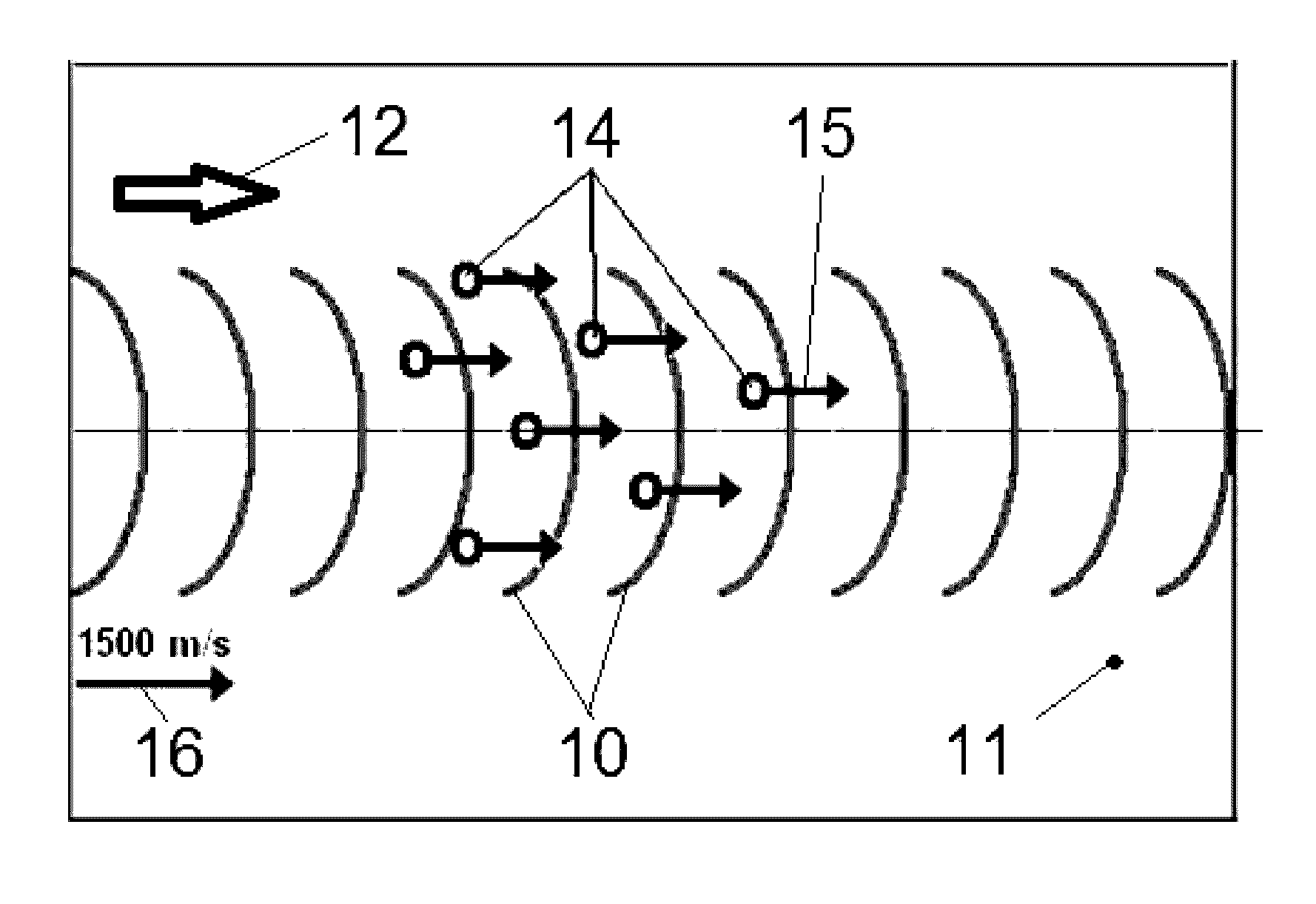

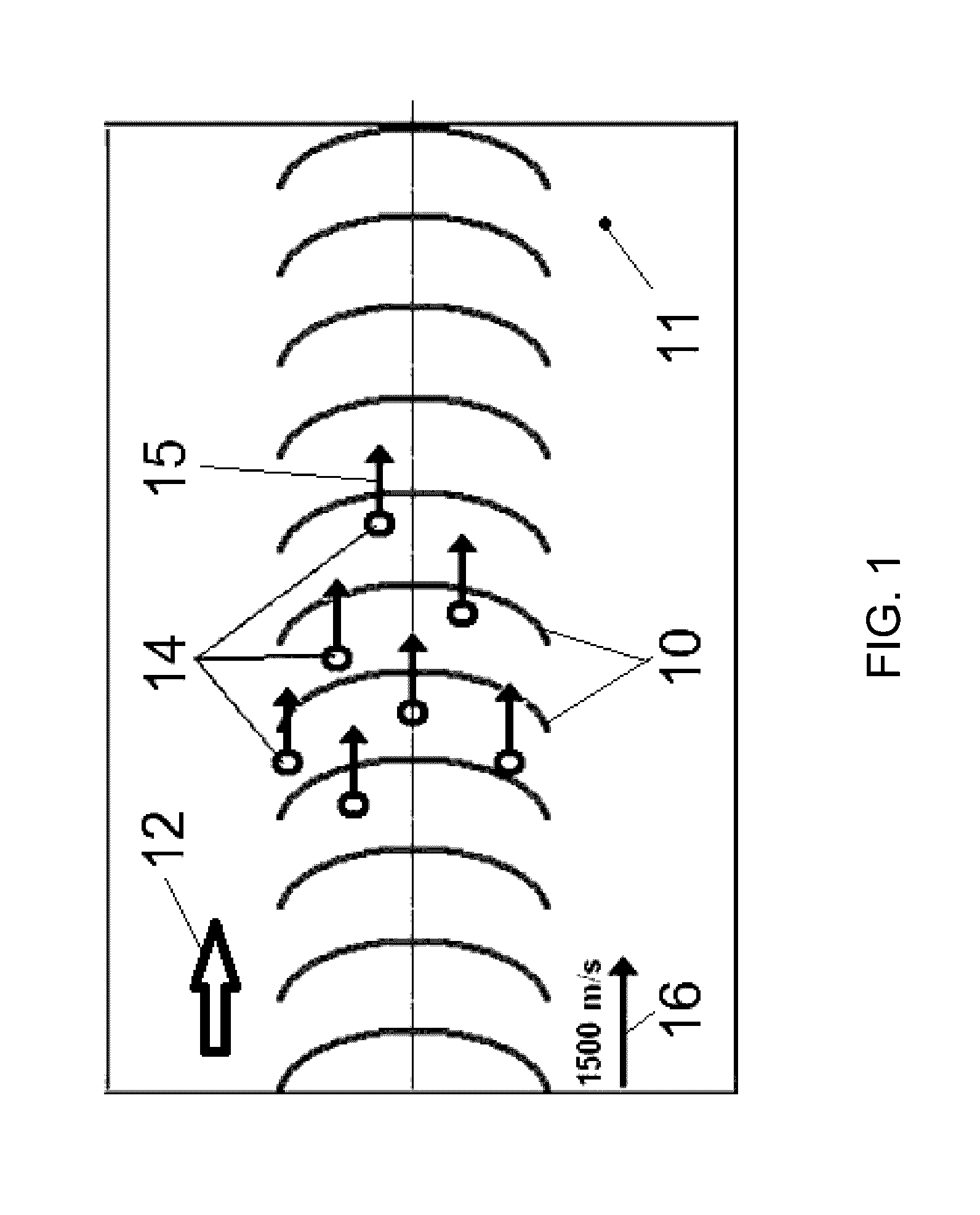

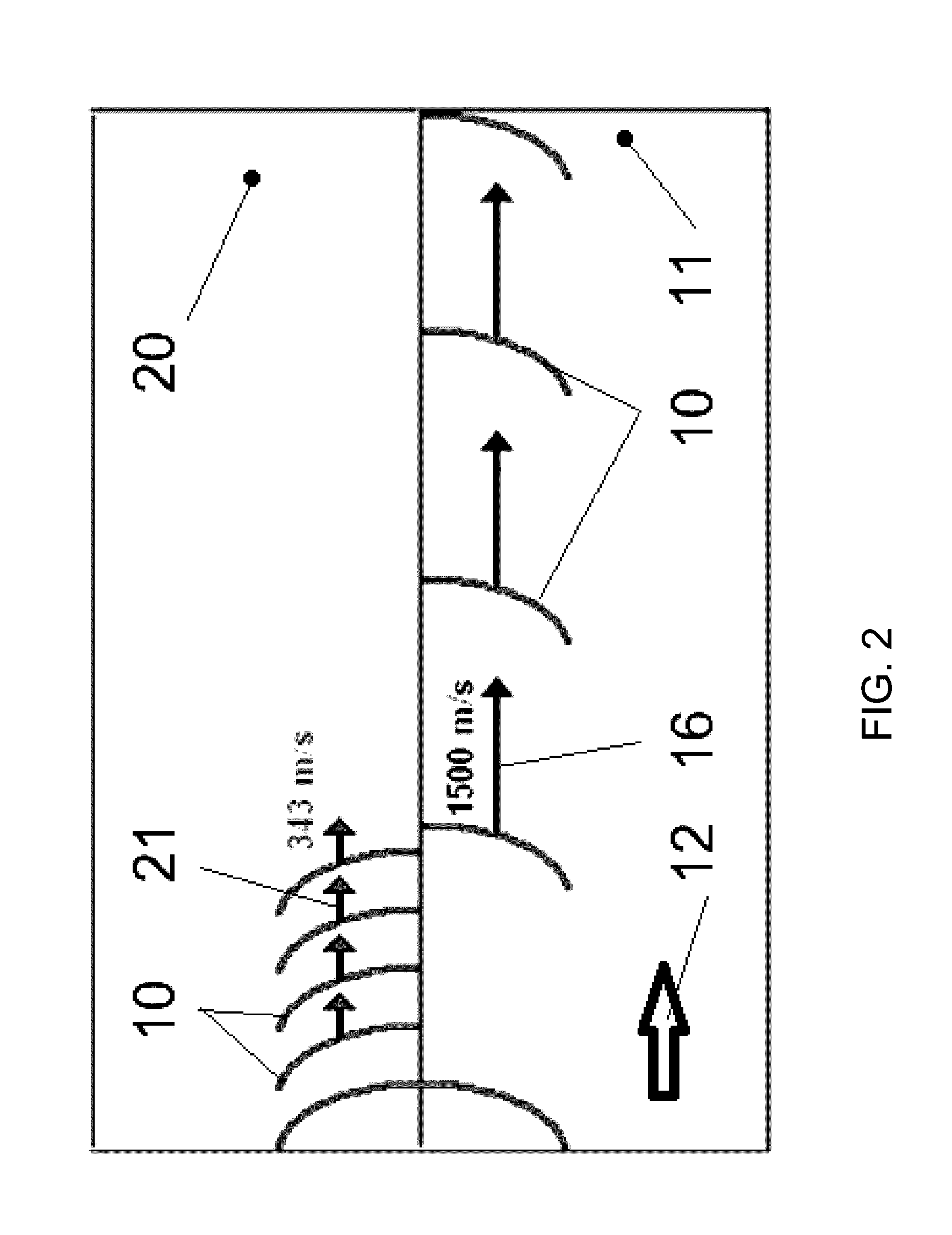

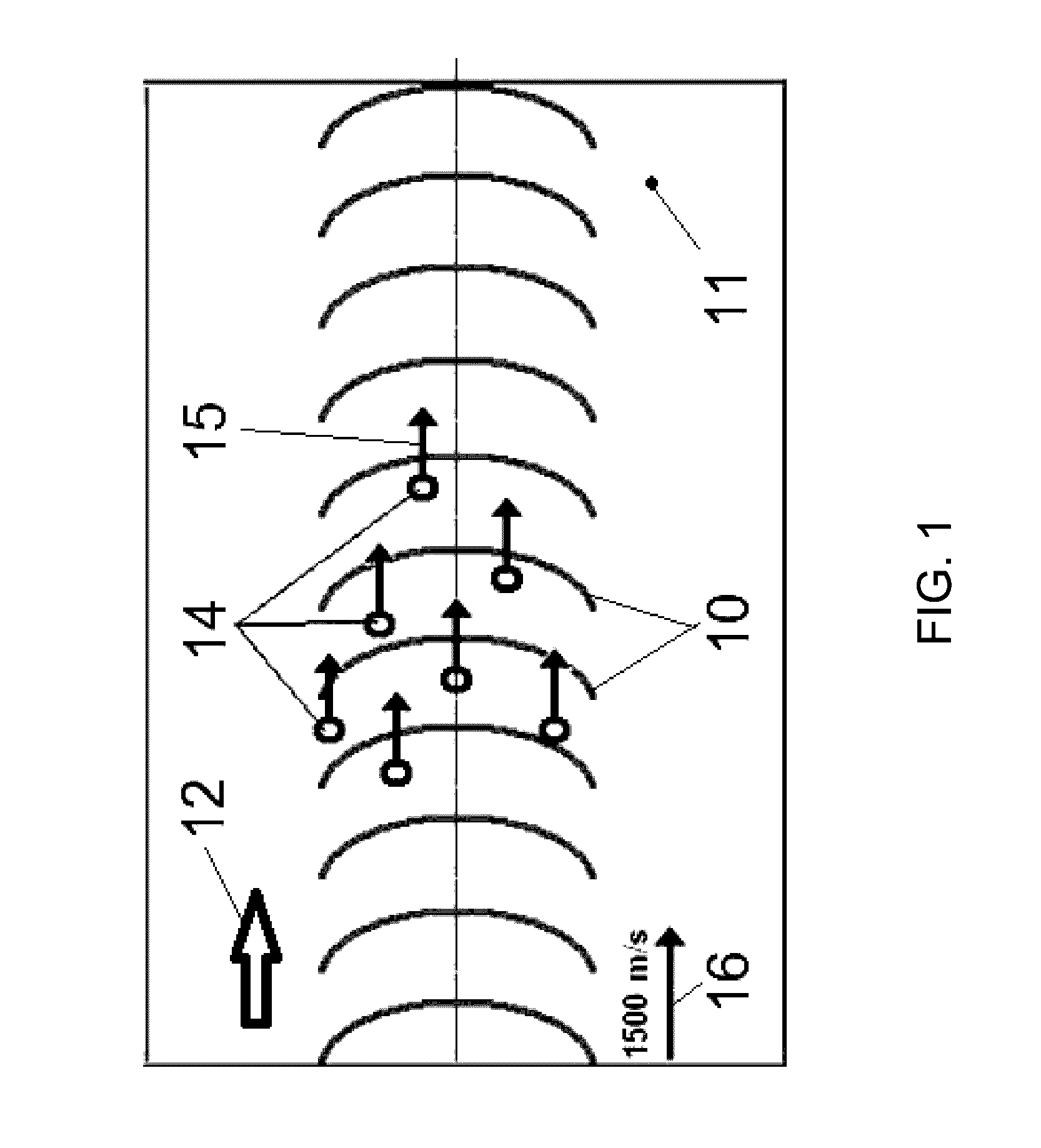

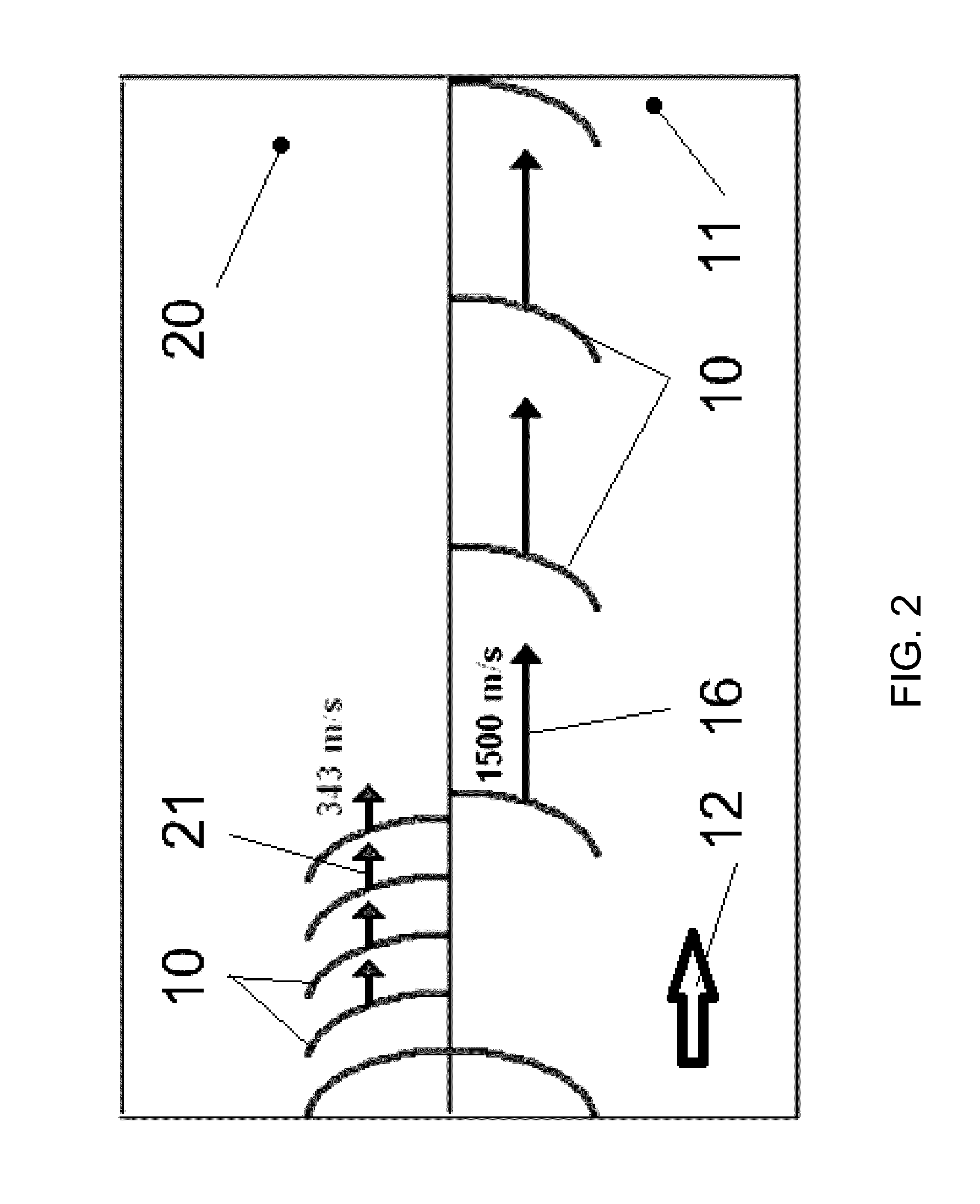

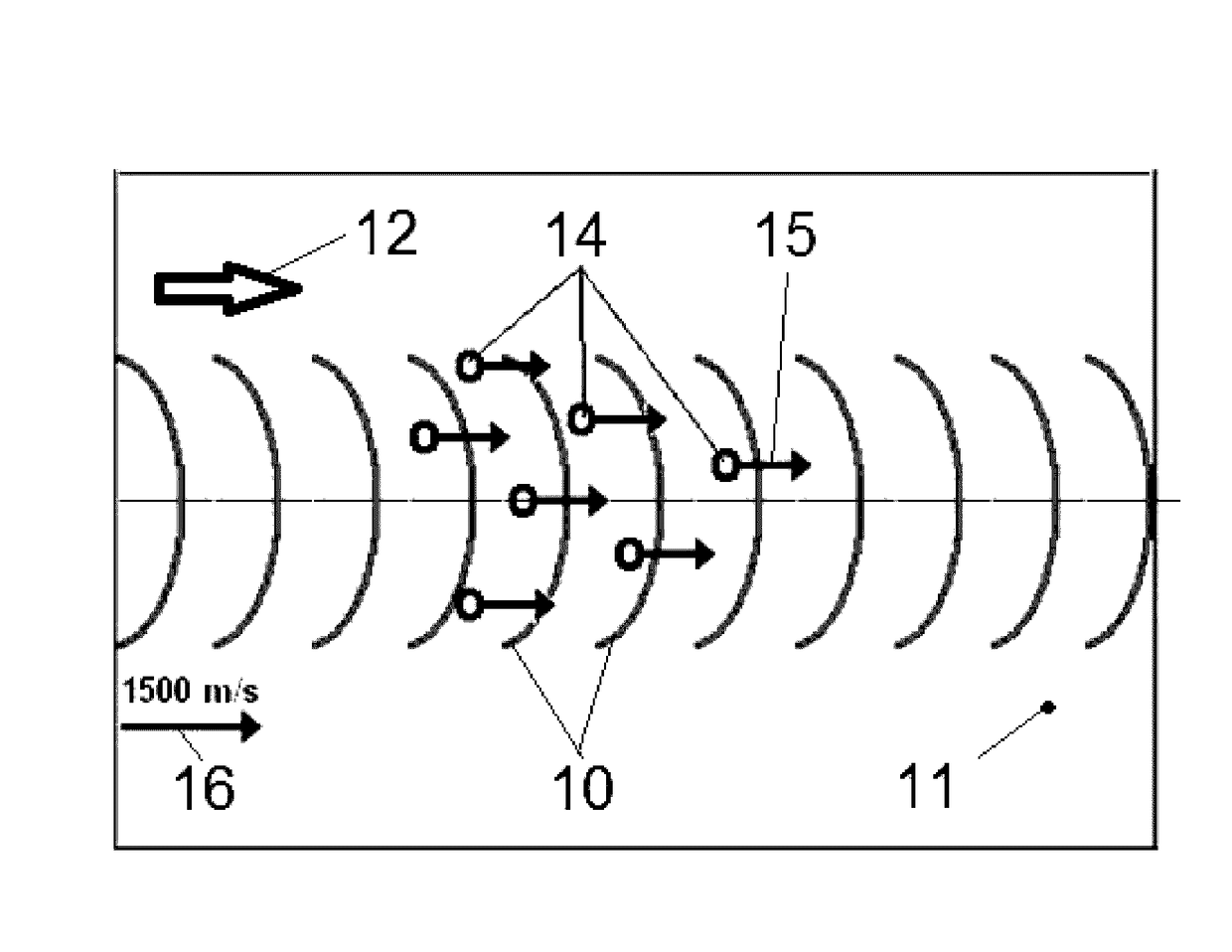

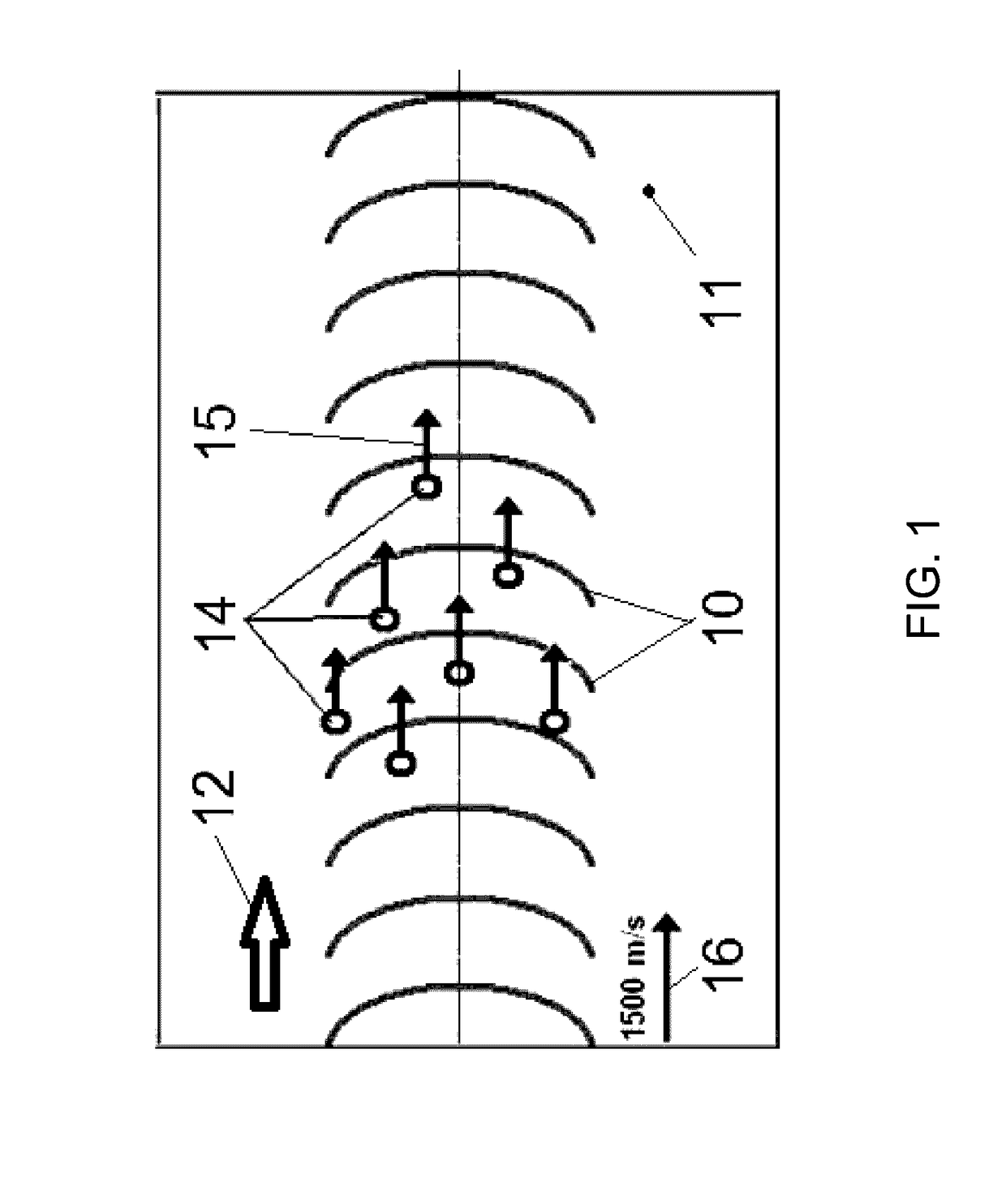

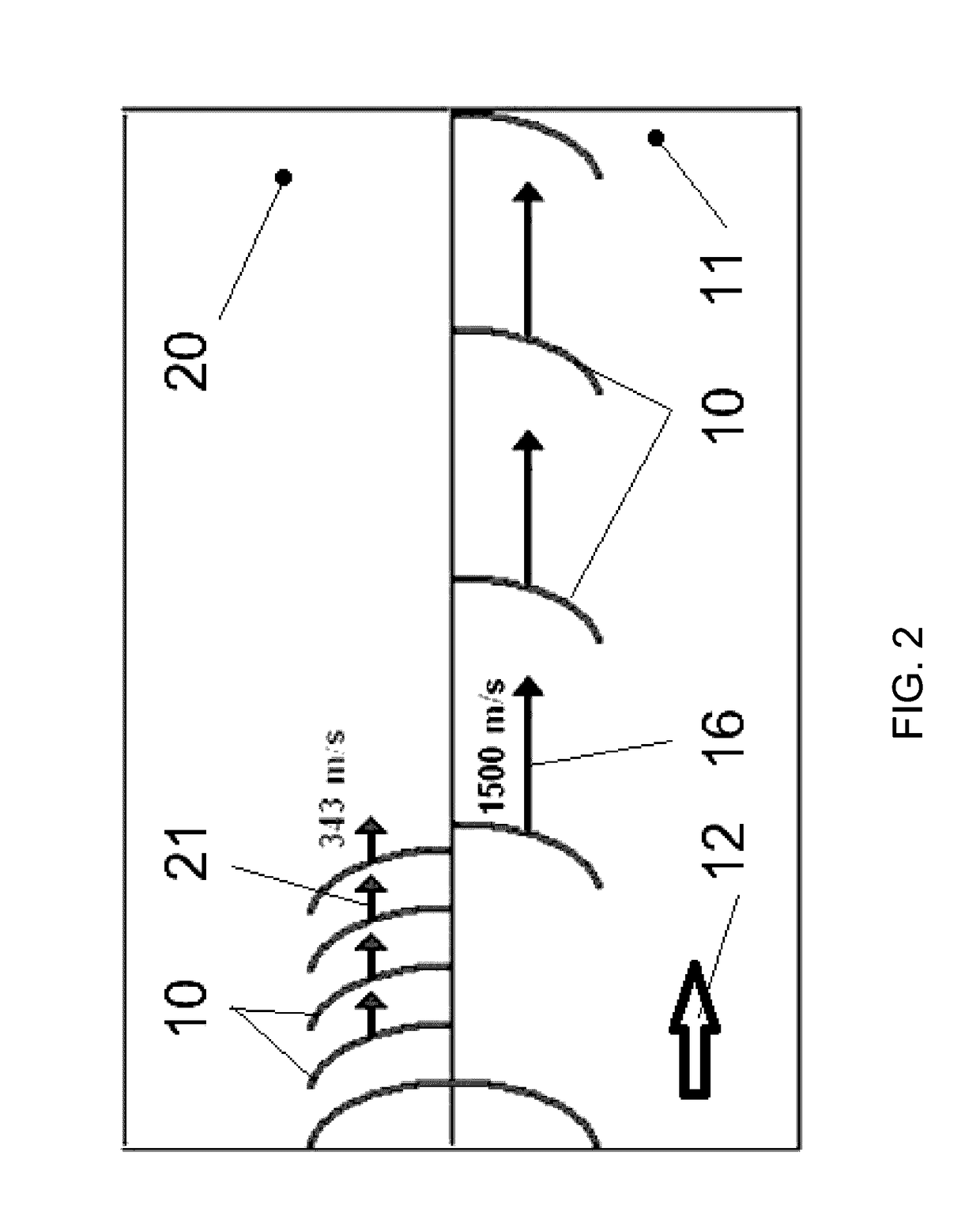

Water desalination using freeze crystallization and acoustic pressure shock waves

ActiveUS20170057843A1Enhancing of acoustic pressure shock wave effectImprove desalination efficiencyGeneral water supply conservationSeawater treatmentShock waveSaline water

A method of desalinating water through application of acoustic pressure shock waves to a slush to separate ice crystals from brine and recovering desalinated water from the separated ice crystals.

Owner:SANUWAVE INC

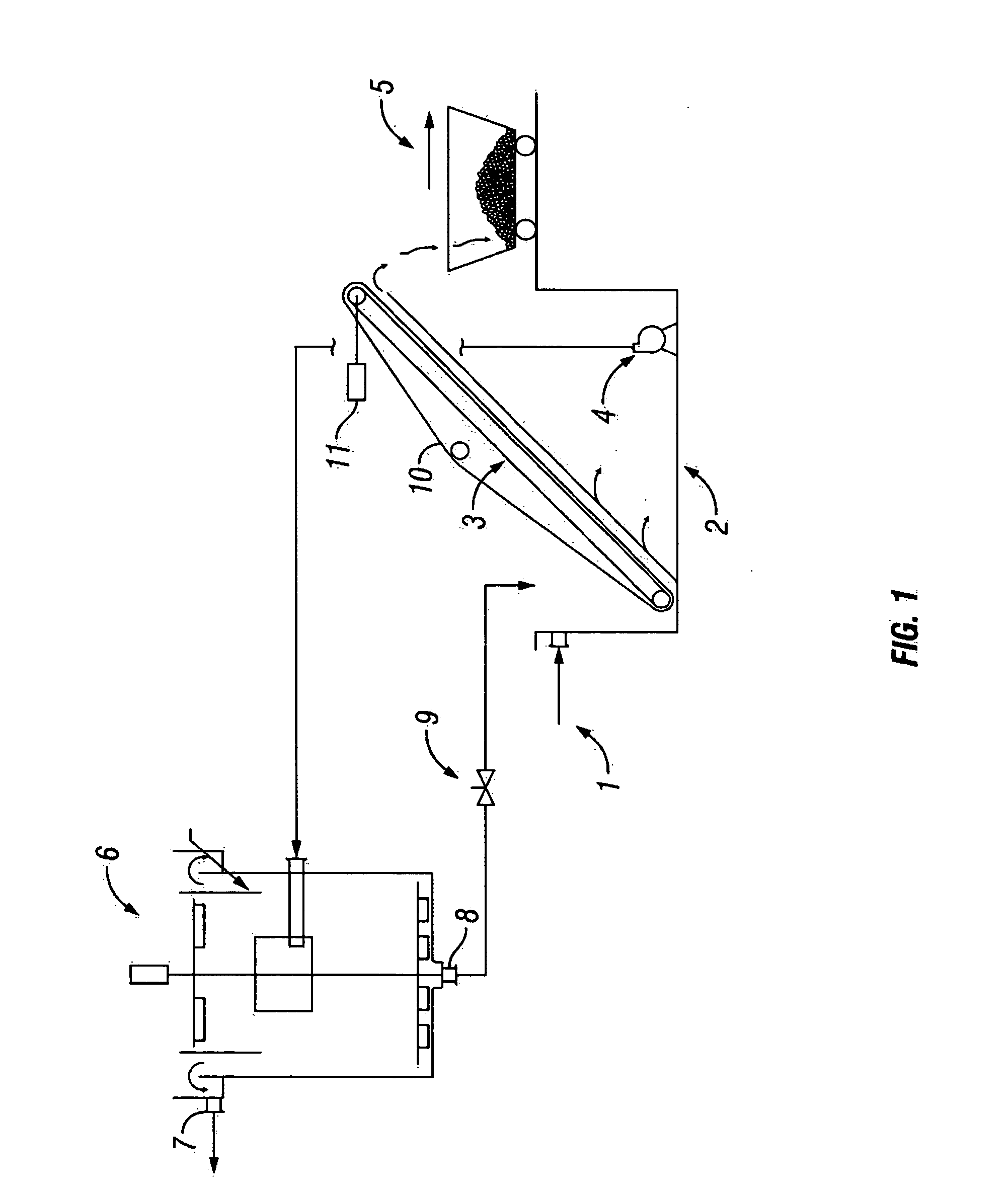

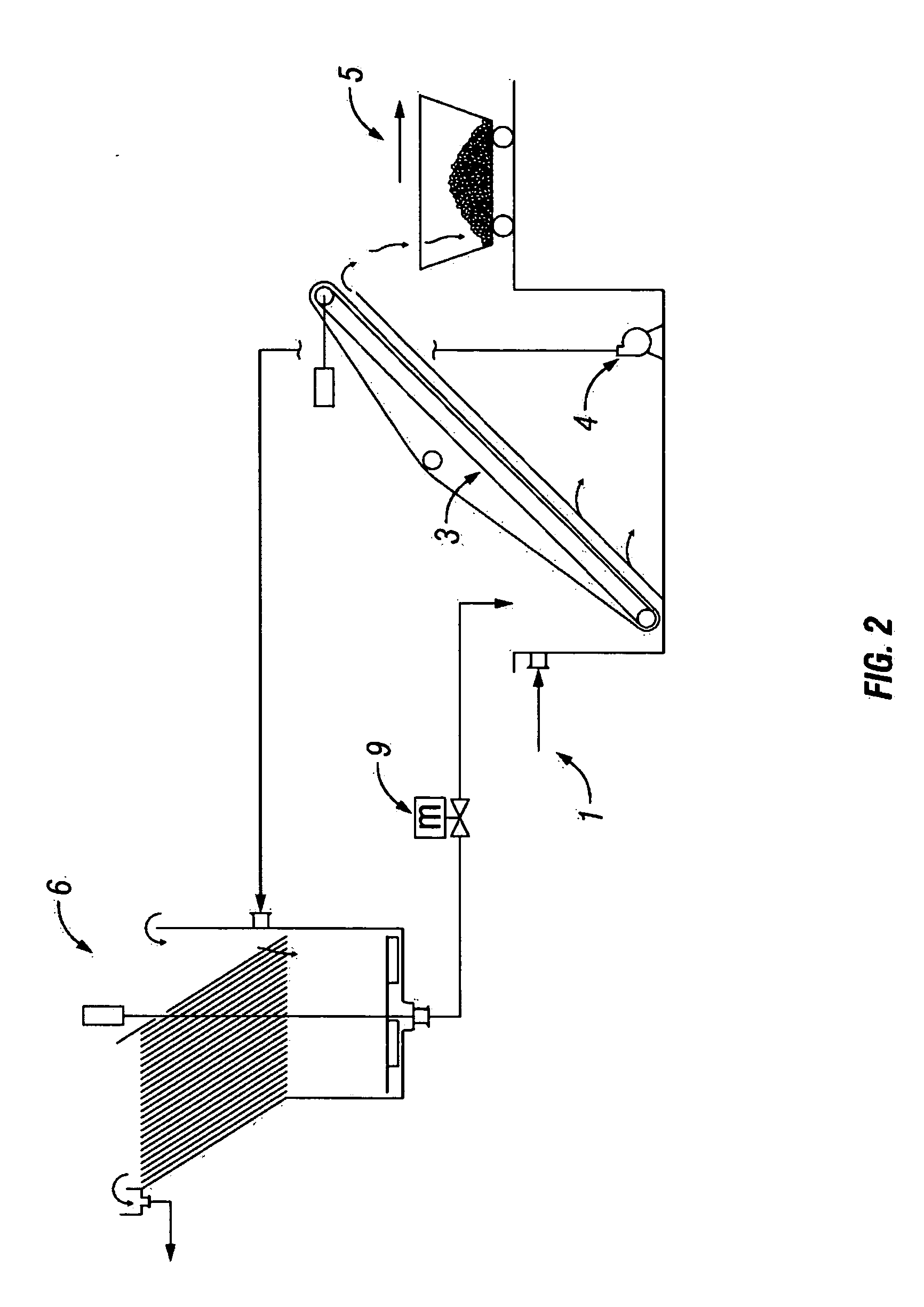

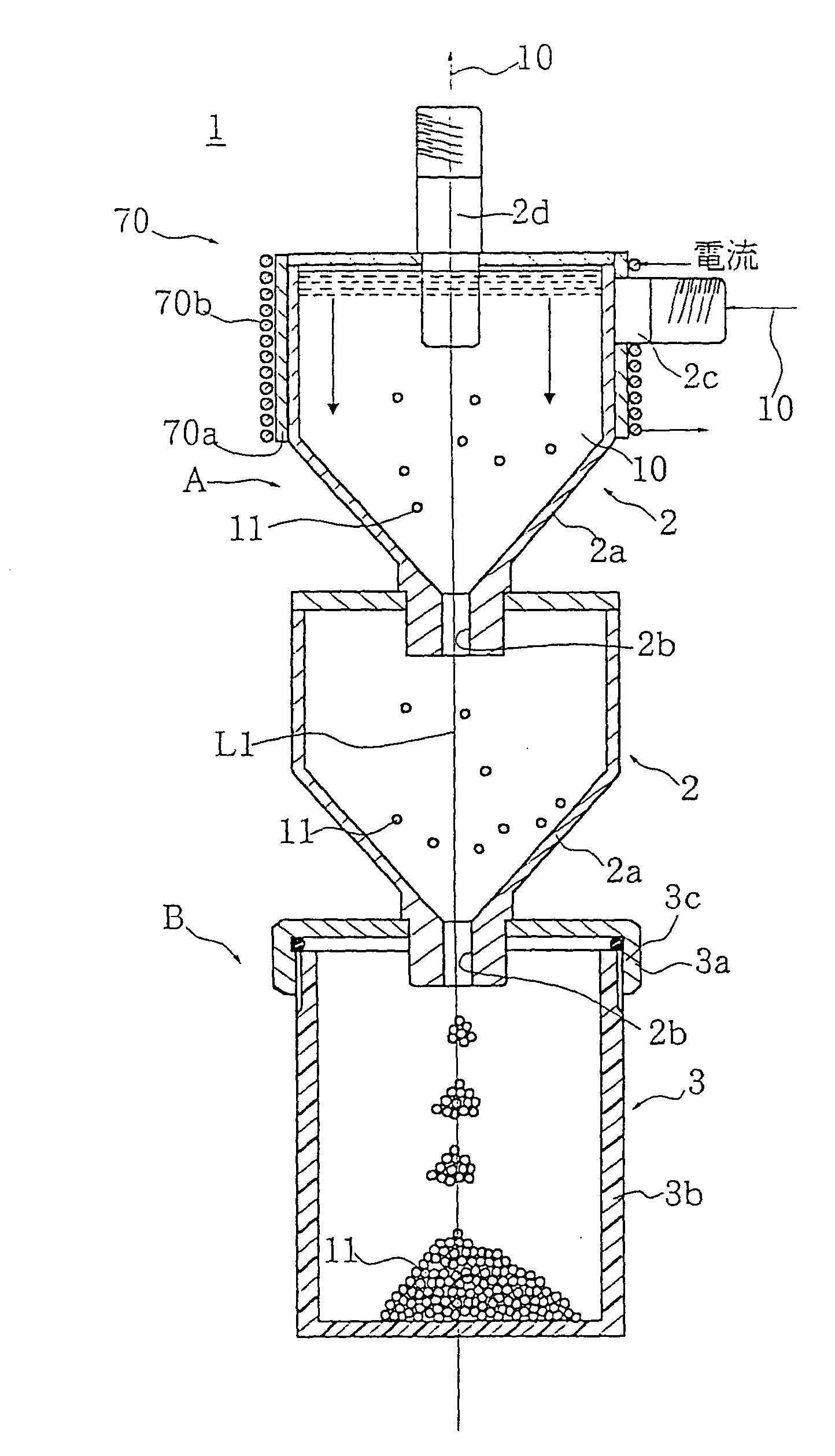

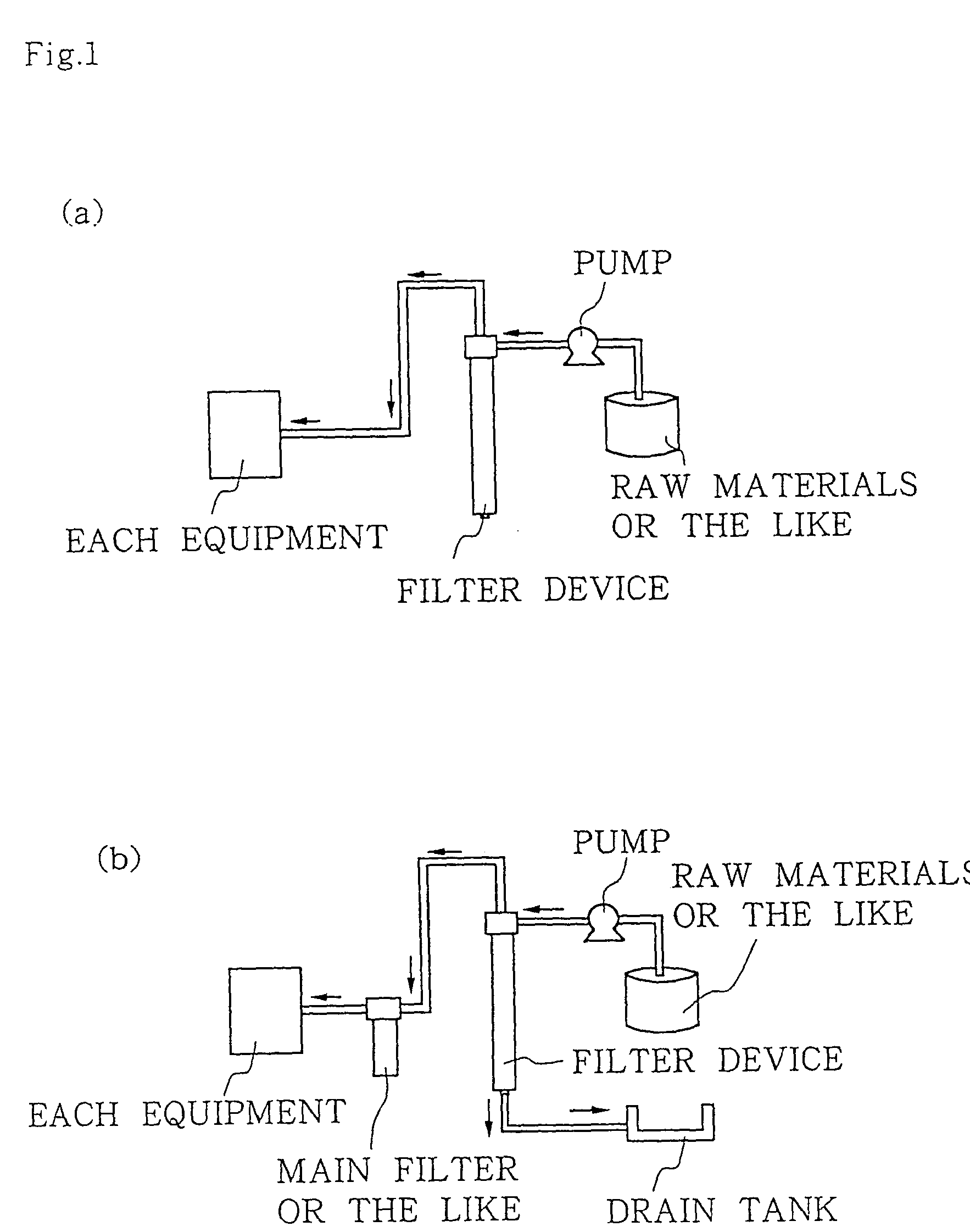

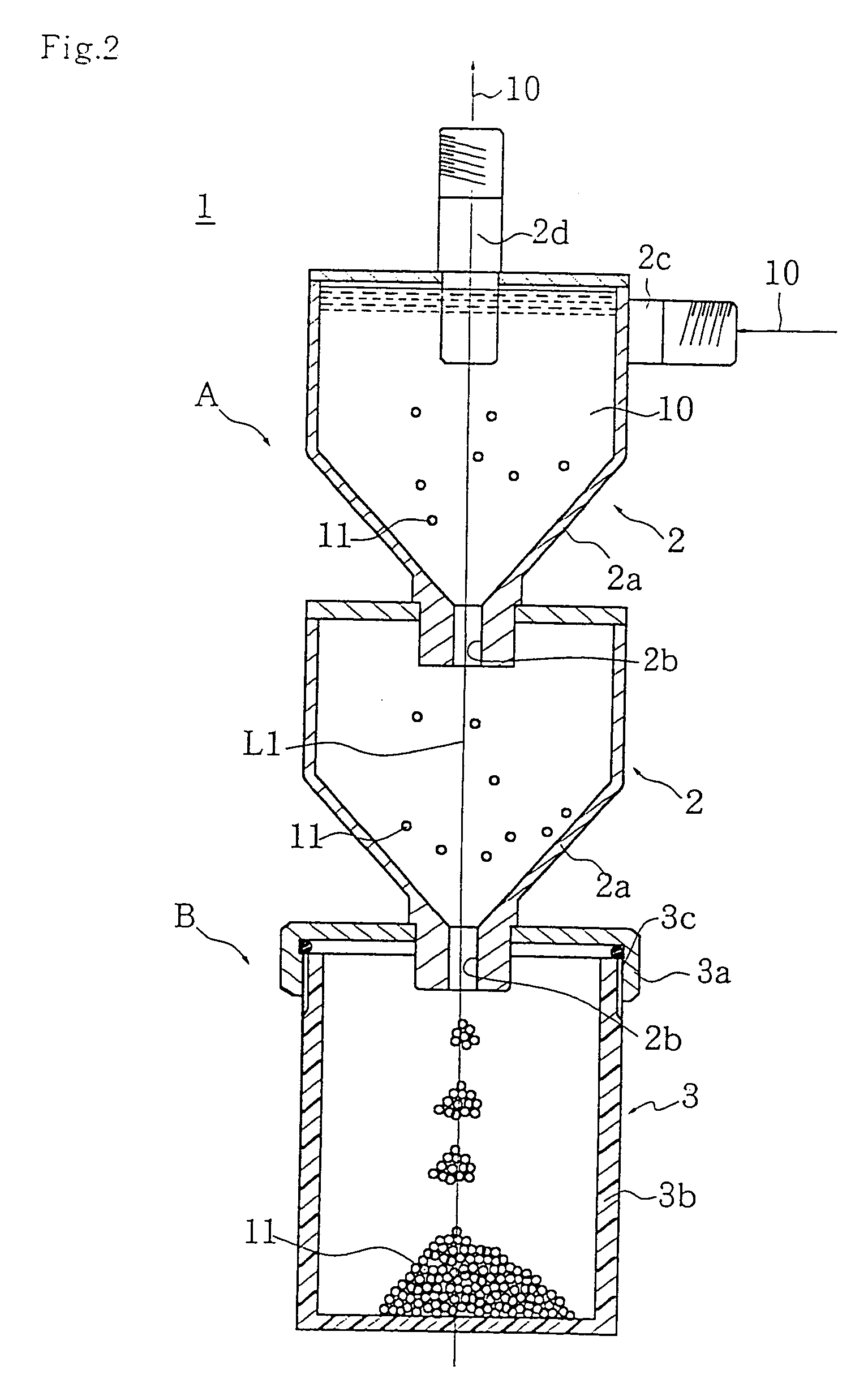

Filter device

InactiveUS7909990B2Reliable removalLow costLiquid separation auxillary apparatusReversed direction vortexEngineeringCentrifugal force

A filter device is made up of: a filter portion having a fluid outlet at its axis, and a fluid inlet in a position away from the axis, in which a fluid containing particles is supplied at a predetermined flow speed from the fluid inlet to cause a swirling, particles are moved outward in a centrifugal state and the fluid from which the particles are separated is discharged from the fluid outlet, and the particles separated by slowing down the swirling are allowed to sink; and a settlement portion in which the particles that settle in the filter portion are allowed to settle. Thus, a fluid containing particles is supplied at a predetermined flow speed to cause swirling, the particles are separated by a centrifugal force caused by the swirling and allowed to sink and settle, and the fluid from which the particles are separated is discharged. A large amount of particles can be allowed to settle and be reliably removed in a short time with this small-sized and simple device. The filter device does not clog, does not need washing and exchanging work and keeps the costs low.

Owner:INDUSTRIA CO LTD

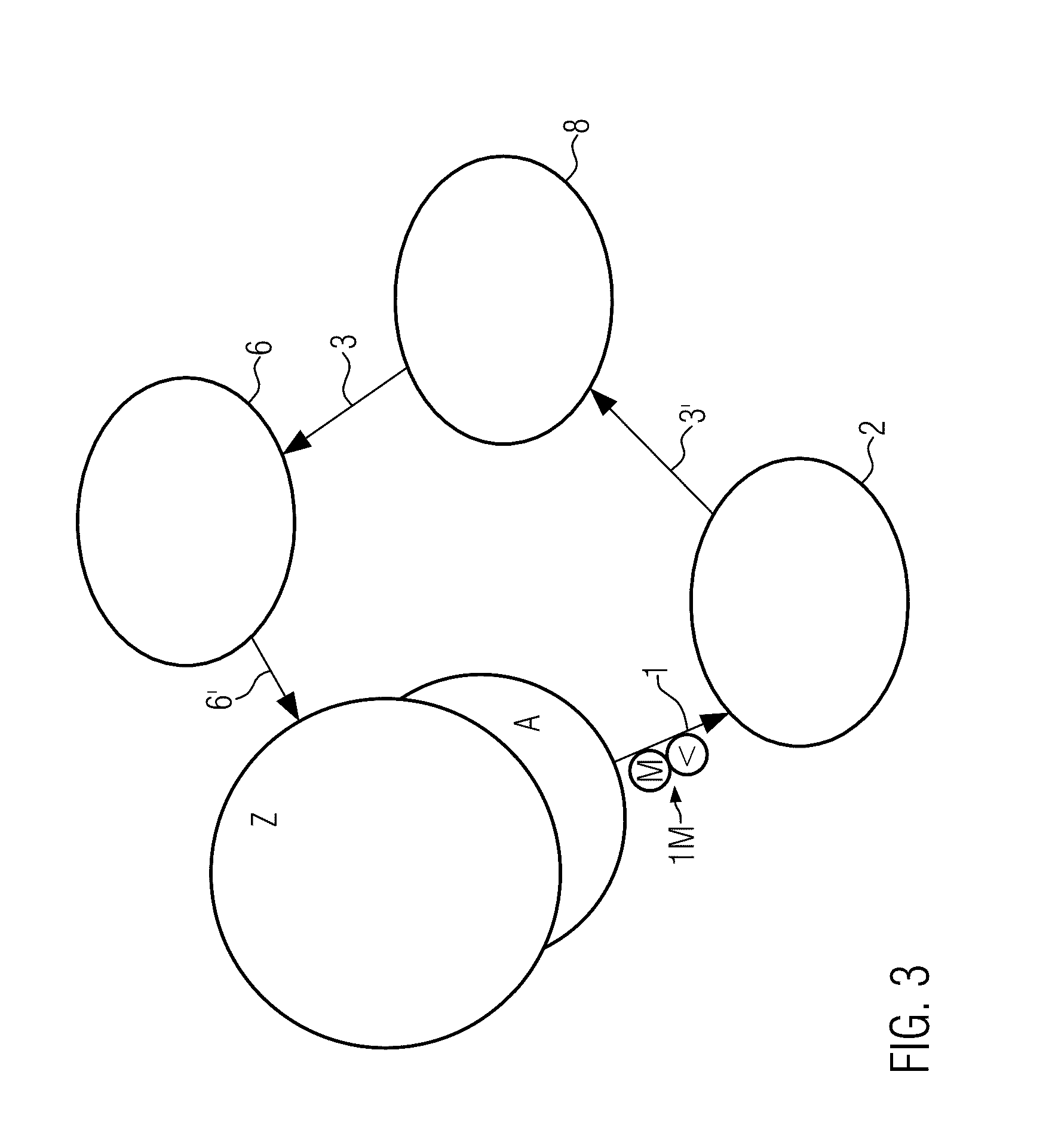

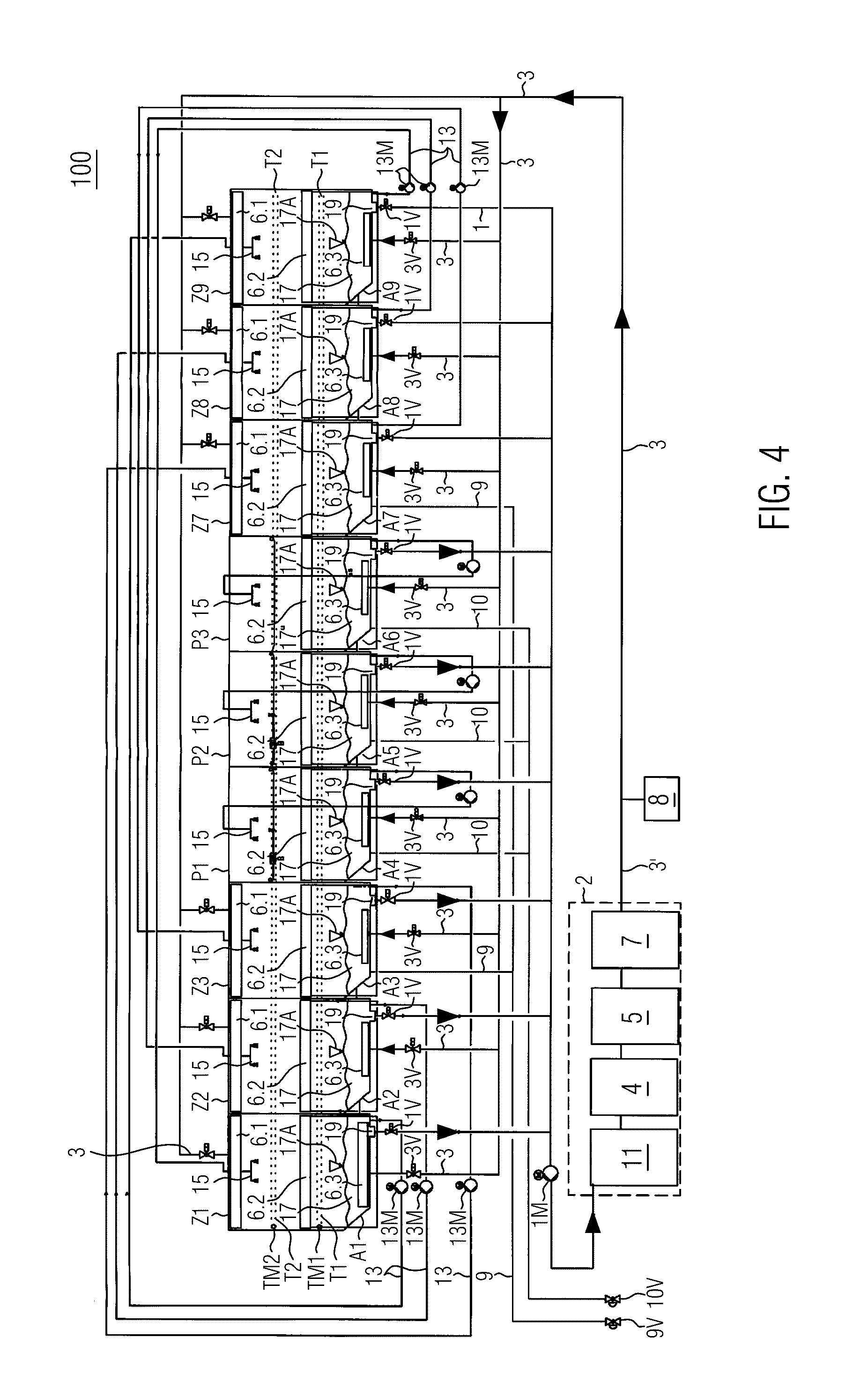

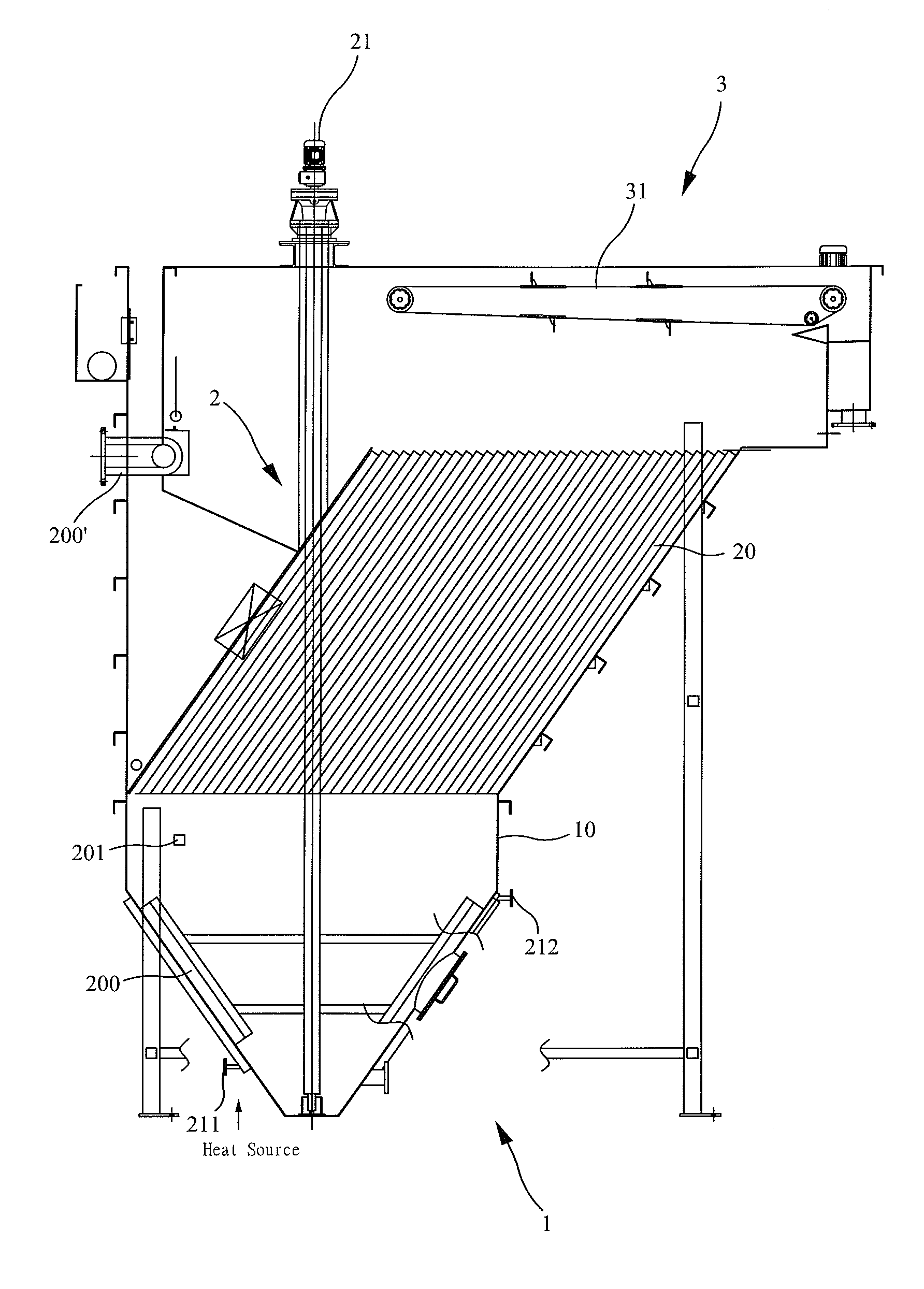

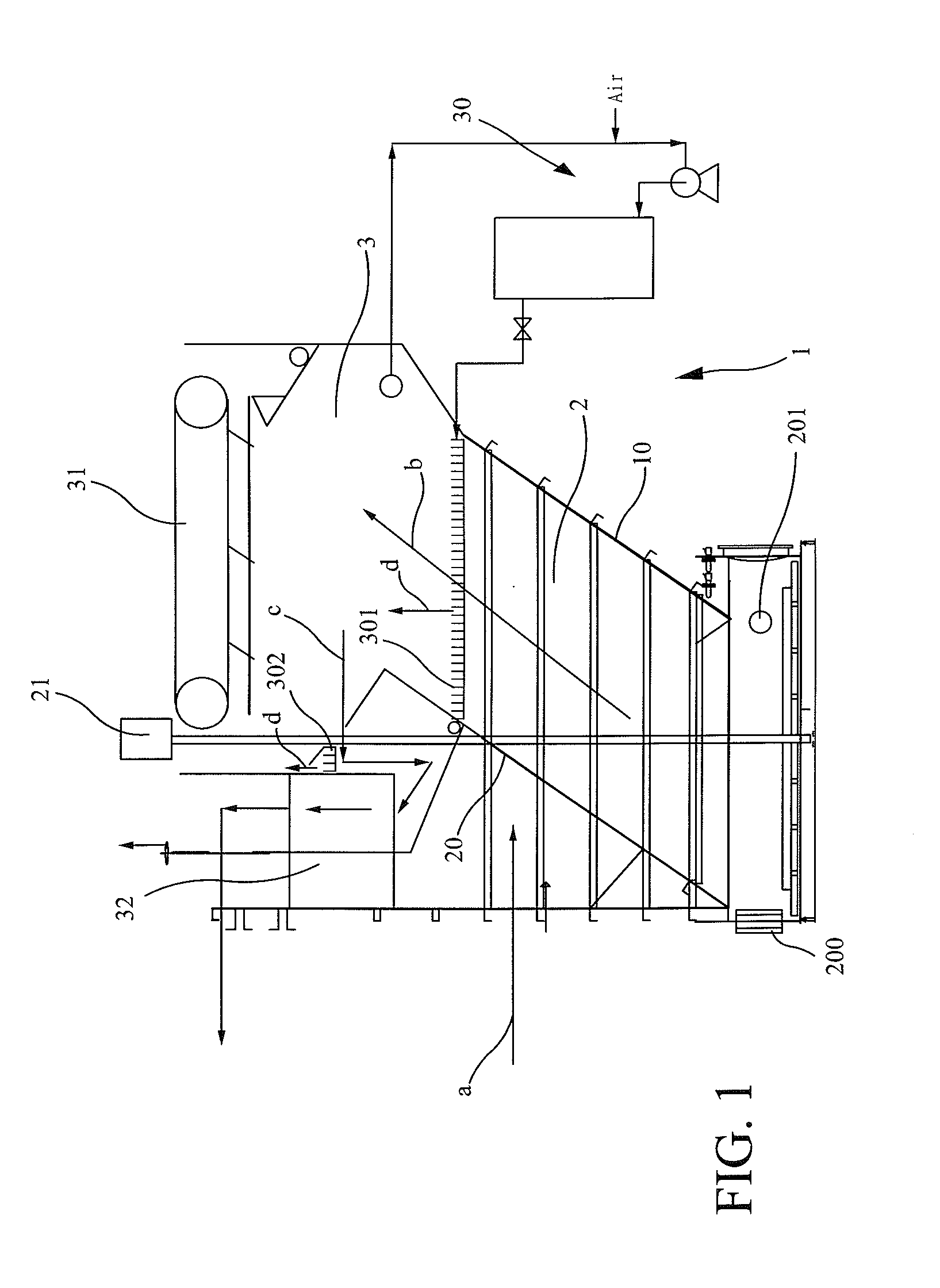

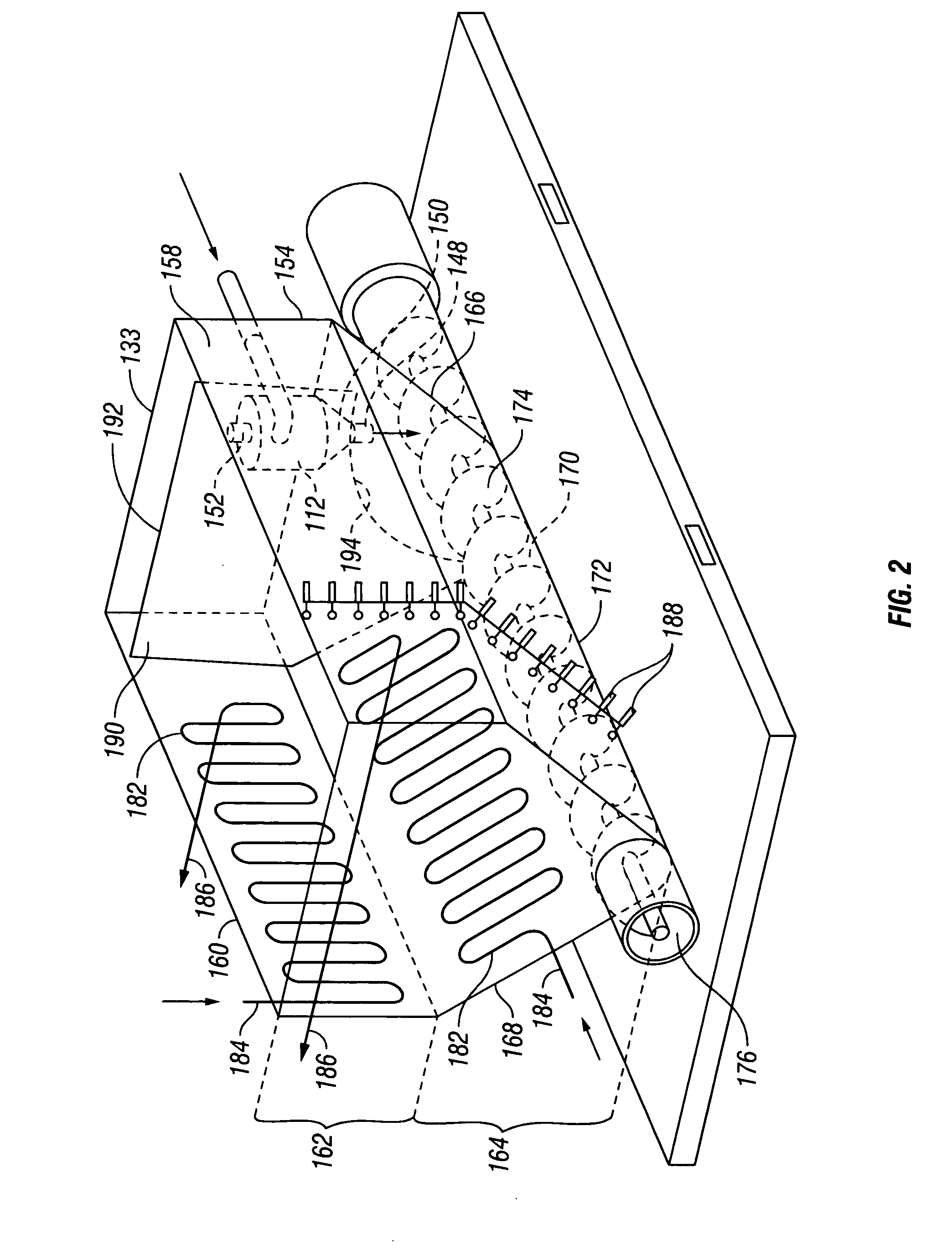

Pasteurization system with purification of the process liquid

ActiveUS20150368135A1Develop newImprove hygieneDialysis systemsWater/sewage treatment using germicide/oligodynamic-processFiltrationClosed loop

Pasteurization system with purification of the process liquid, with a feed and evacuation conveyor system for containers. At least one treatment zone with sprinkling nozzles to spray the containers with a process liquid such as water, the treatment zone including a screening unit with a sedimentation area for the deposition of sediment from the process liquid, a closed-loop circuit to re-use the process liquid, with devices to remove the sediment from the sedimentation area for each zone and to feed the sediment into a central filter unit. The central filter unit has at least one filter module for the filtration of solid matter from the inputted sediment so that the filtered process liquid is conserved. Devices to return the filtered process liquid to one or several treatment zones are also provided.

Owner:KRONES AG

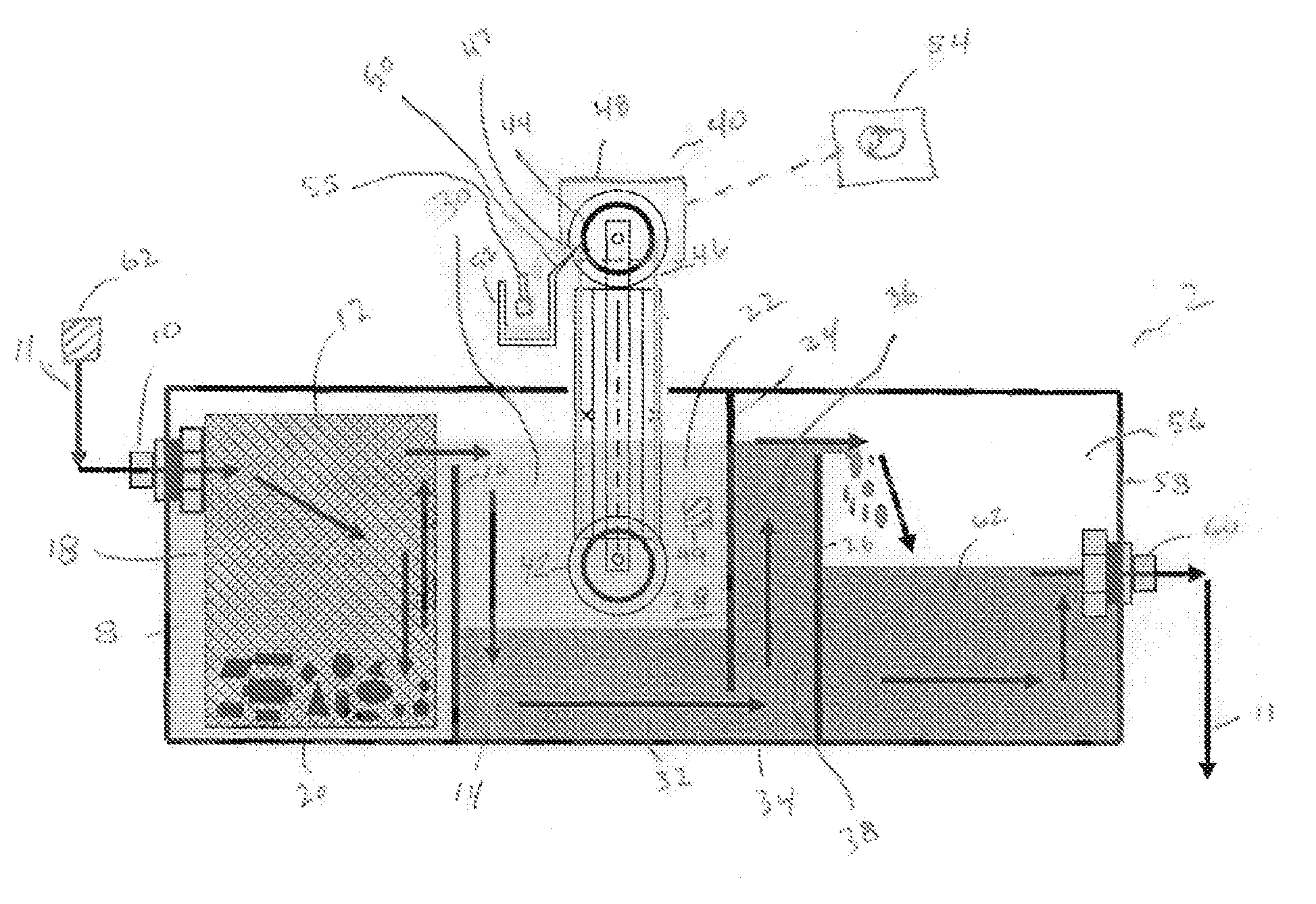

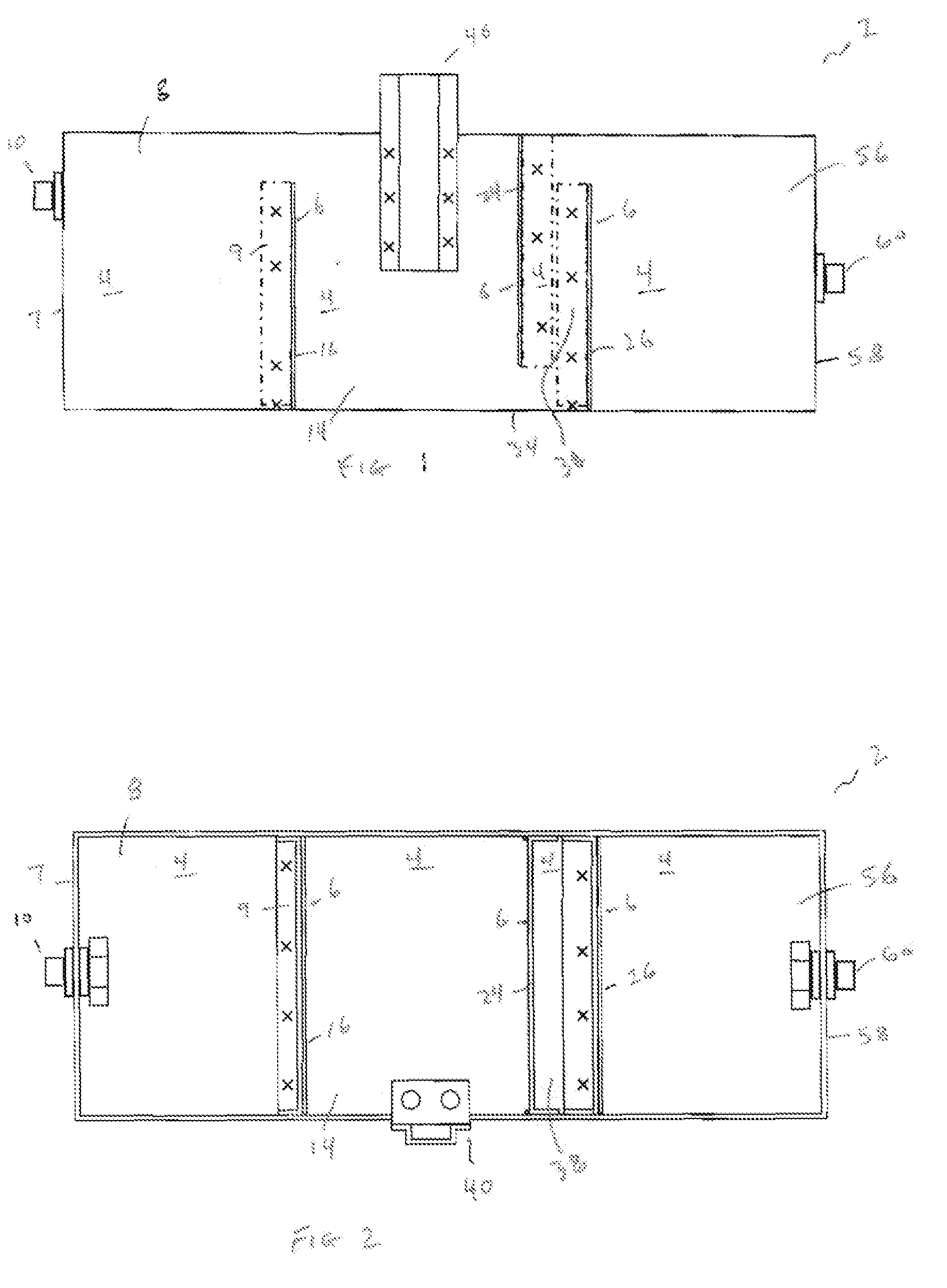

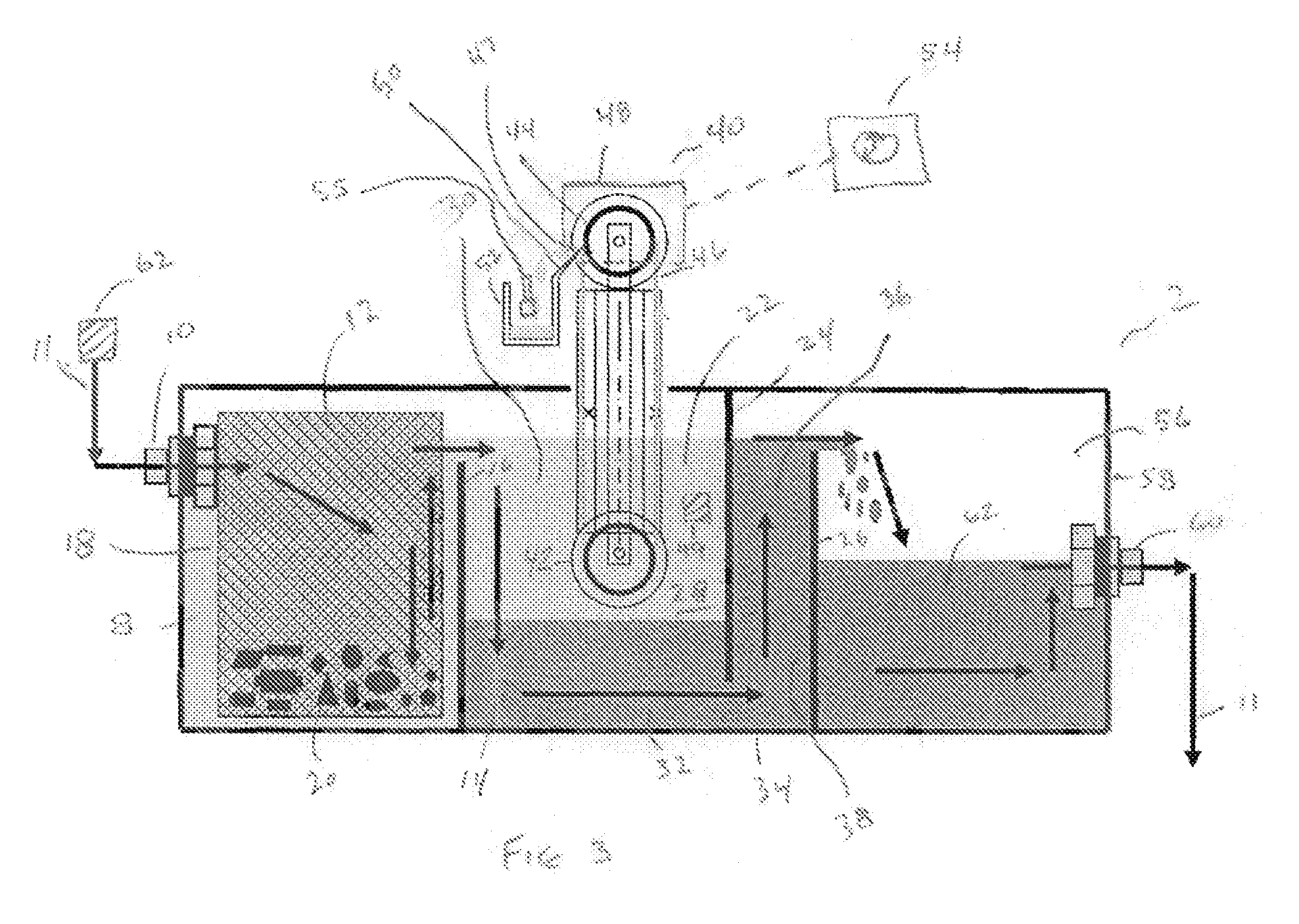

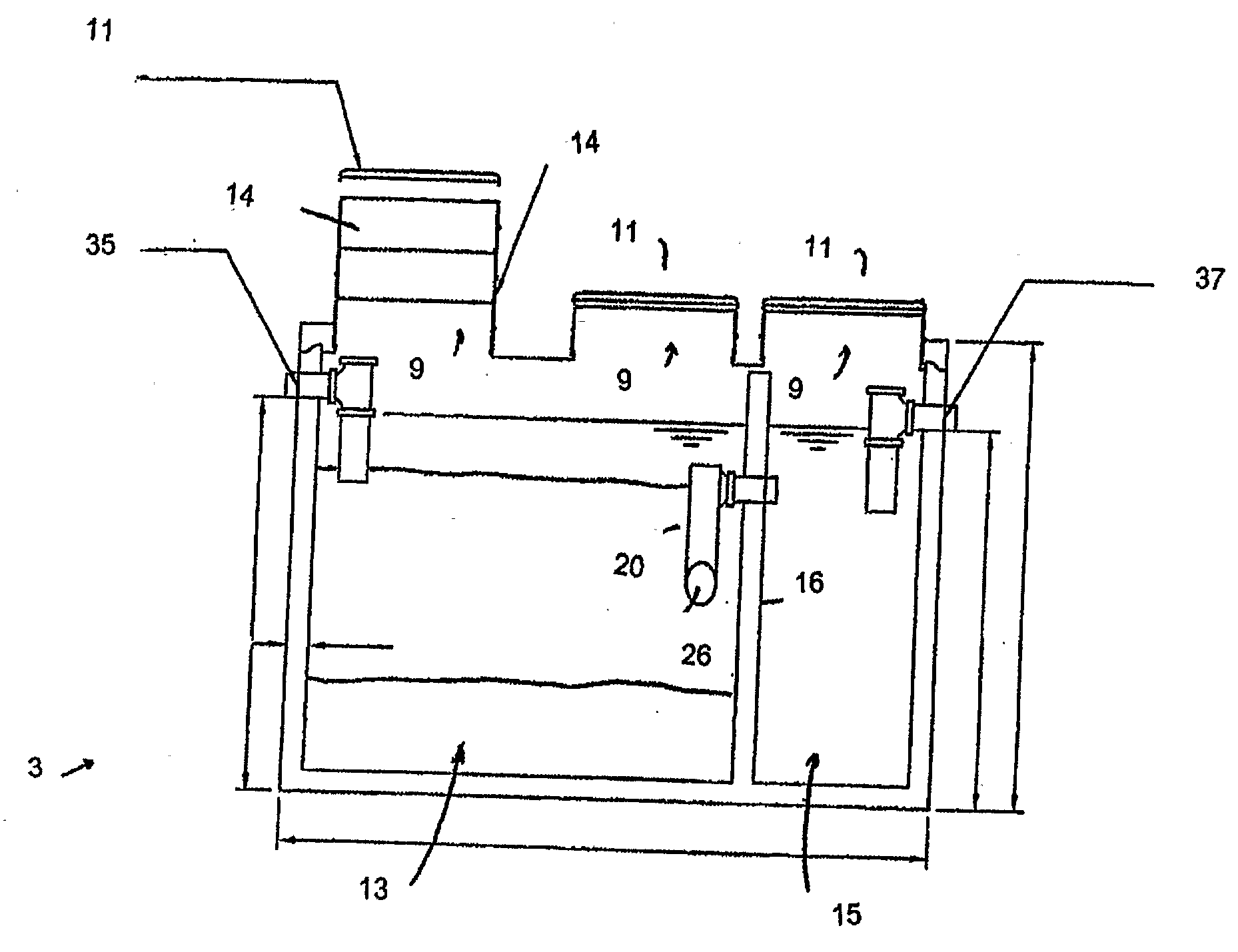

Sedimentation and Floatation Wastewater Treatment Device with a Heater

InactiveUS20120152850A1Water treatment parameter controlSettling tanks feed/dischargeSludgeWastewater

A combined sedimentation and pressure floatation wastewater treatment tank includes a tank body, a sedimentation treatment device and a pressure floatation treatment device. The tank body contains a predetermined amount of wastewater for treatment. The sedimentation treatment device is operated to remove relatively heavier sludge from the wastewater by sedimentation treatment, and the pressure floatation treatment device is operated to remove relatively lighter sludge from the initially treated wastewater by pressure floatation treatment. In operation, the wastewater is initially treated by the sedimentation treatment device and is further treated by the pressure floatation treatment device. Alternatively, the wastewater is initially treated by the pressure floatation treatment device and is further treated by the sedimentation treatment device.

Owner:TSAI KUEI LIN

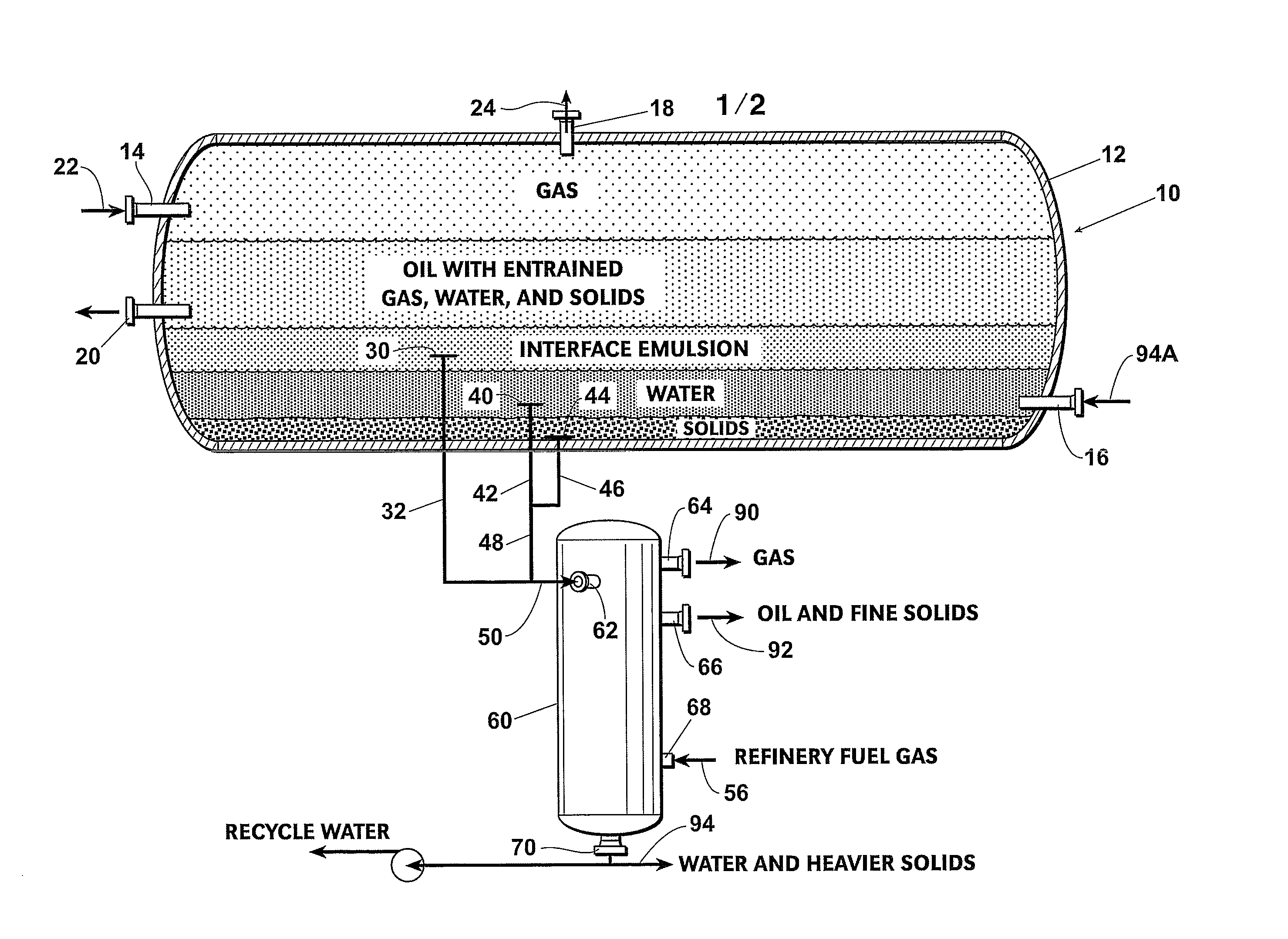

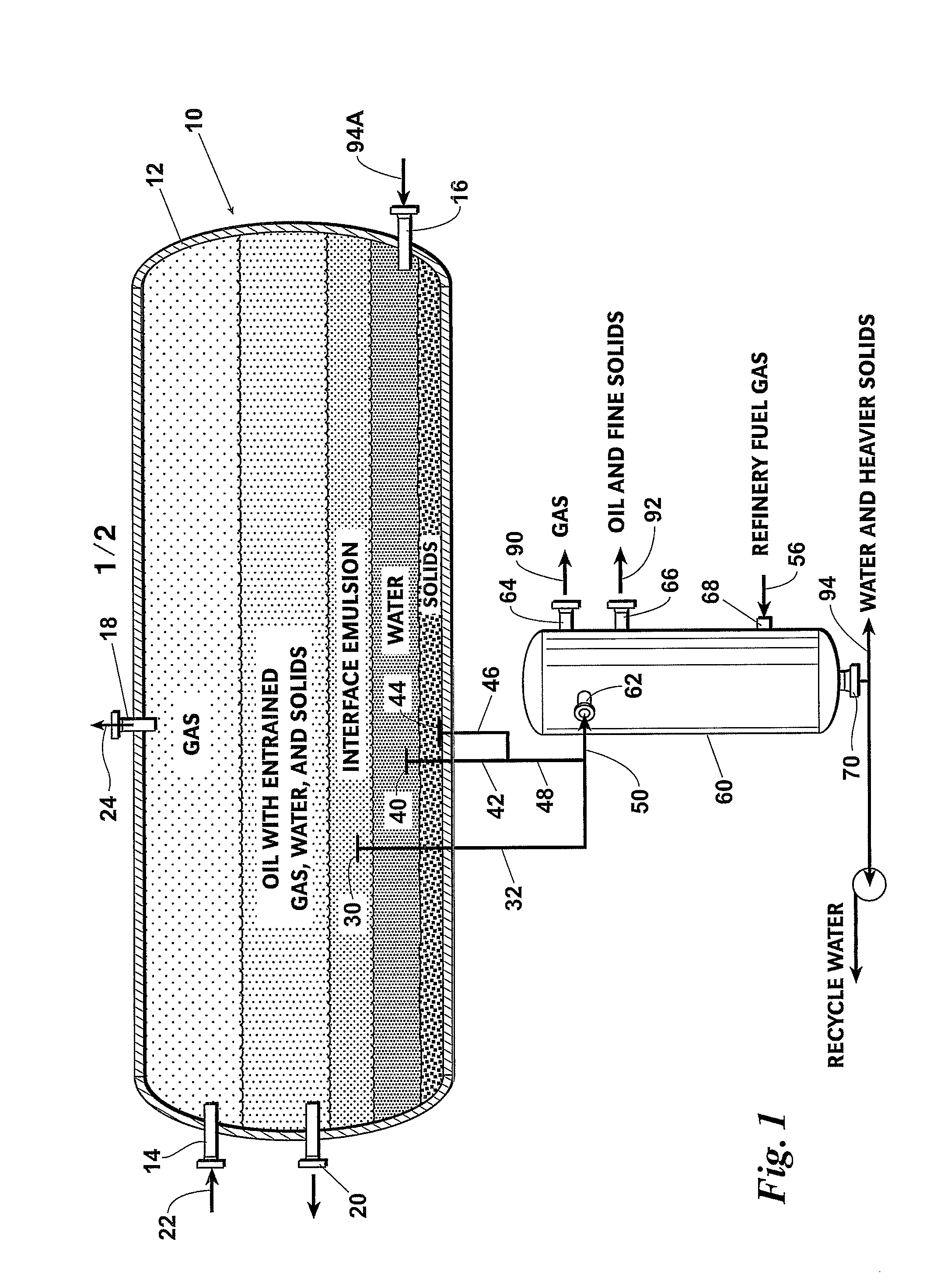

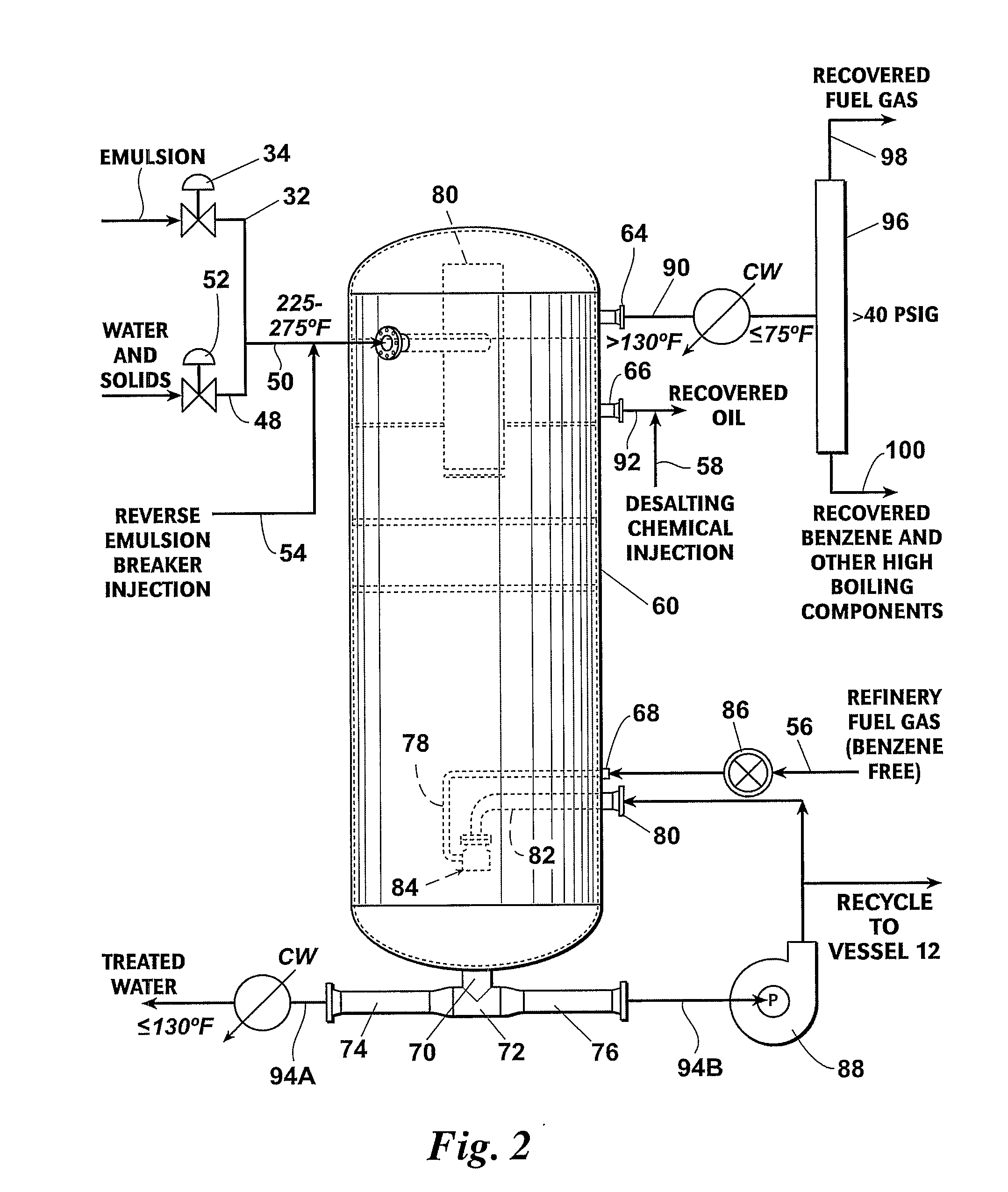

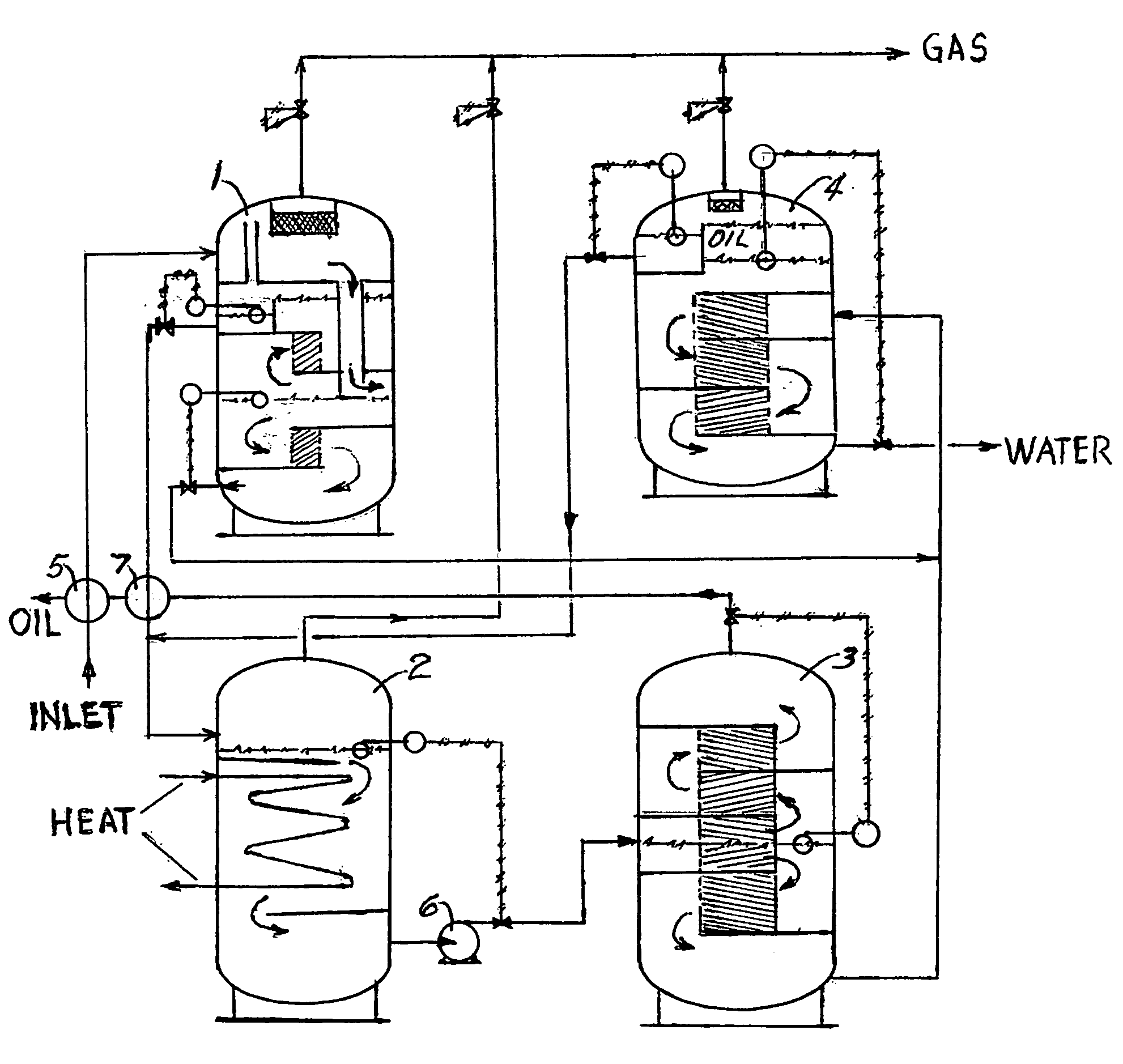

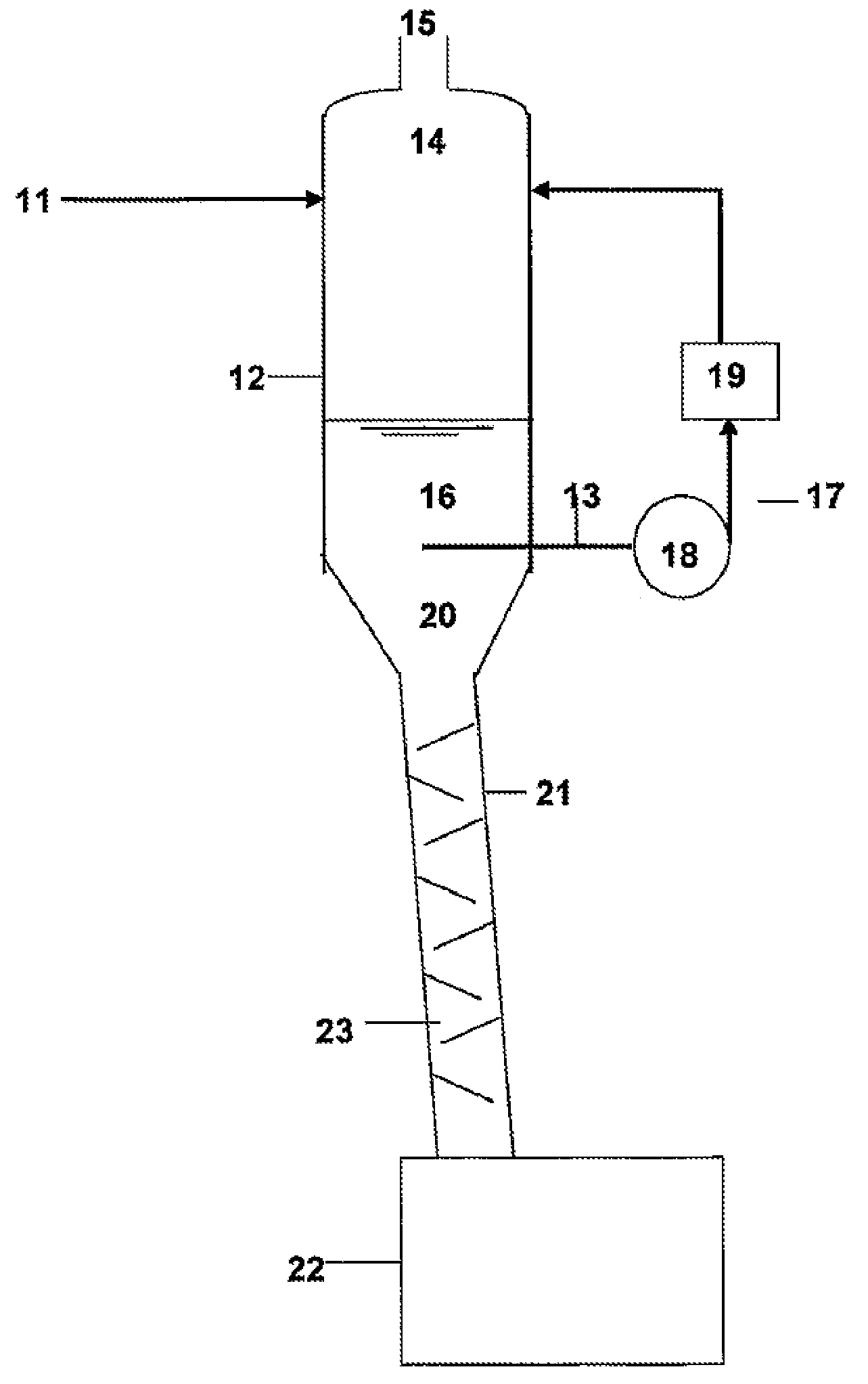

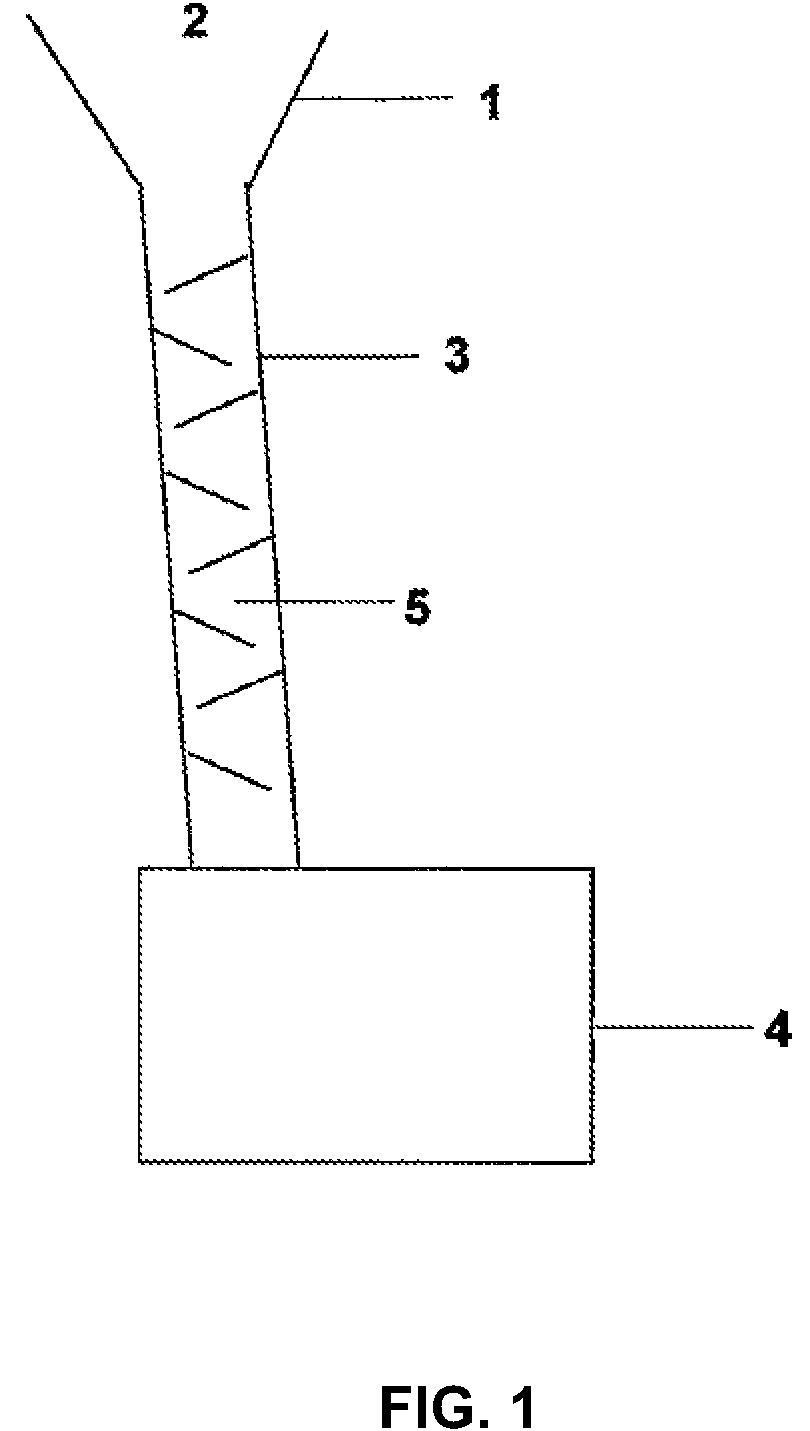

Method to Process Effluent Brine and Interface Rag from an Oil Dehydration/Desalting System

ActiveUS20130082005A1Water treatment parameter controlFatty/oily/floating substances removal devicesEmulsionInduced gas flotation

A method for processing interface emulsion, water, and solids contained within a separator vessel that comprises the steps of continually extracting those components from the vessel and then passing them through a gas flotation cell. The cell, which is preferably a vertical induced gas flotation cell, separates the oil and water contained in the interface emulsion and discharges recovered oil from an upper portion of the cell and treated water from a bottom portion of the cell. The recovered oil and treated water may be further processed and recycled to the vessel or sent elsewhere. The treated water may also be recycled to the cell or sent to a process sewer. Fuel gas residing in an upper portion of the cell may be cooled and passed through a splitter. All the steps of the method comprise a closed system with no air emissions.

Owner:CAMERSON INT CORP

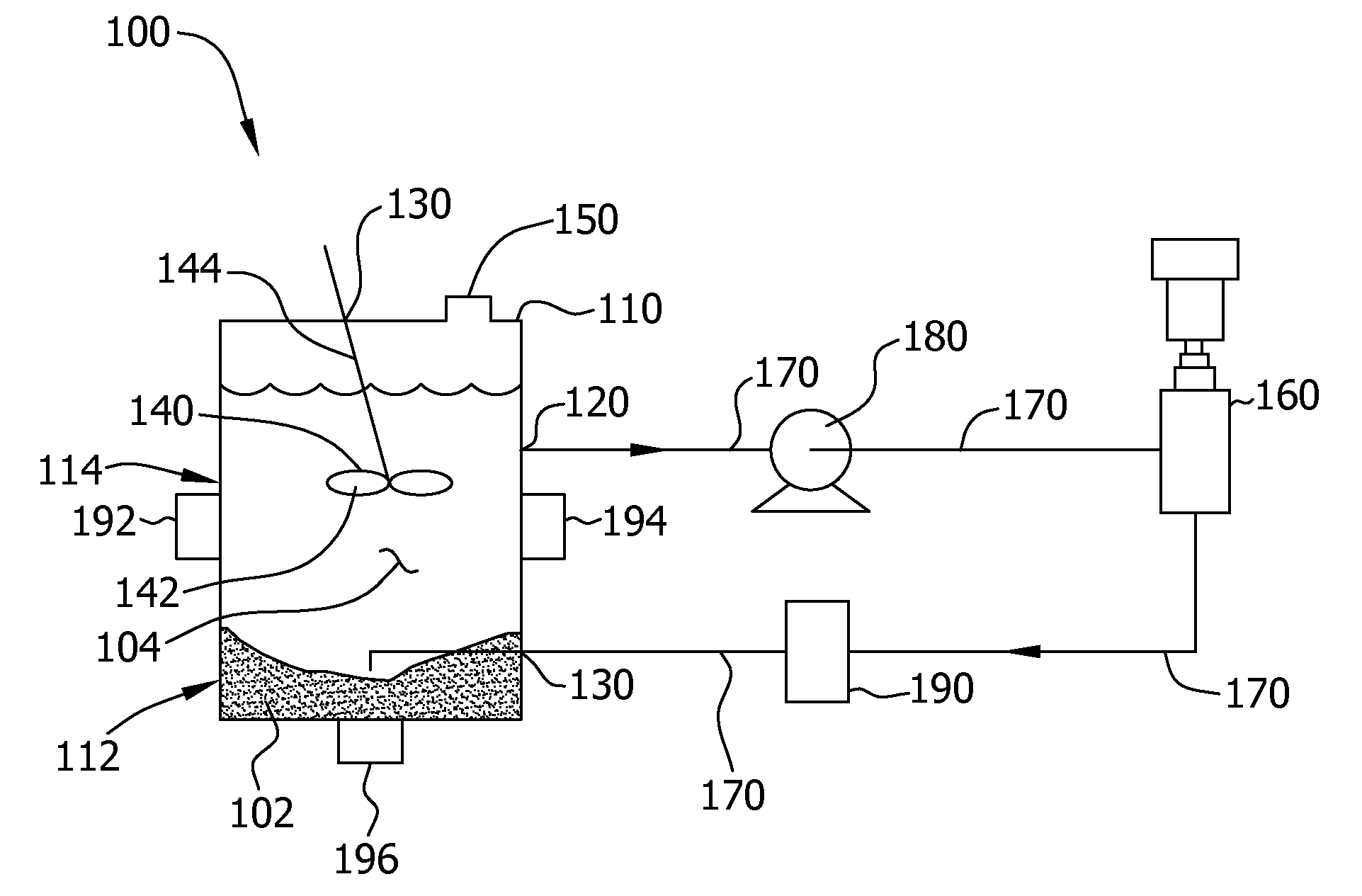

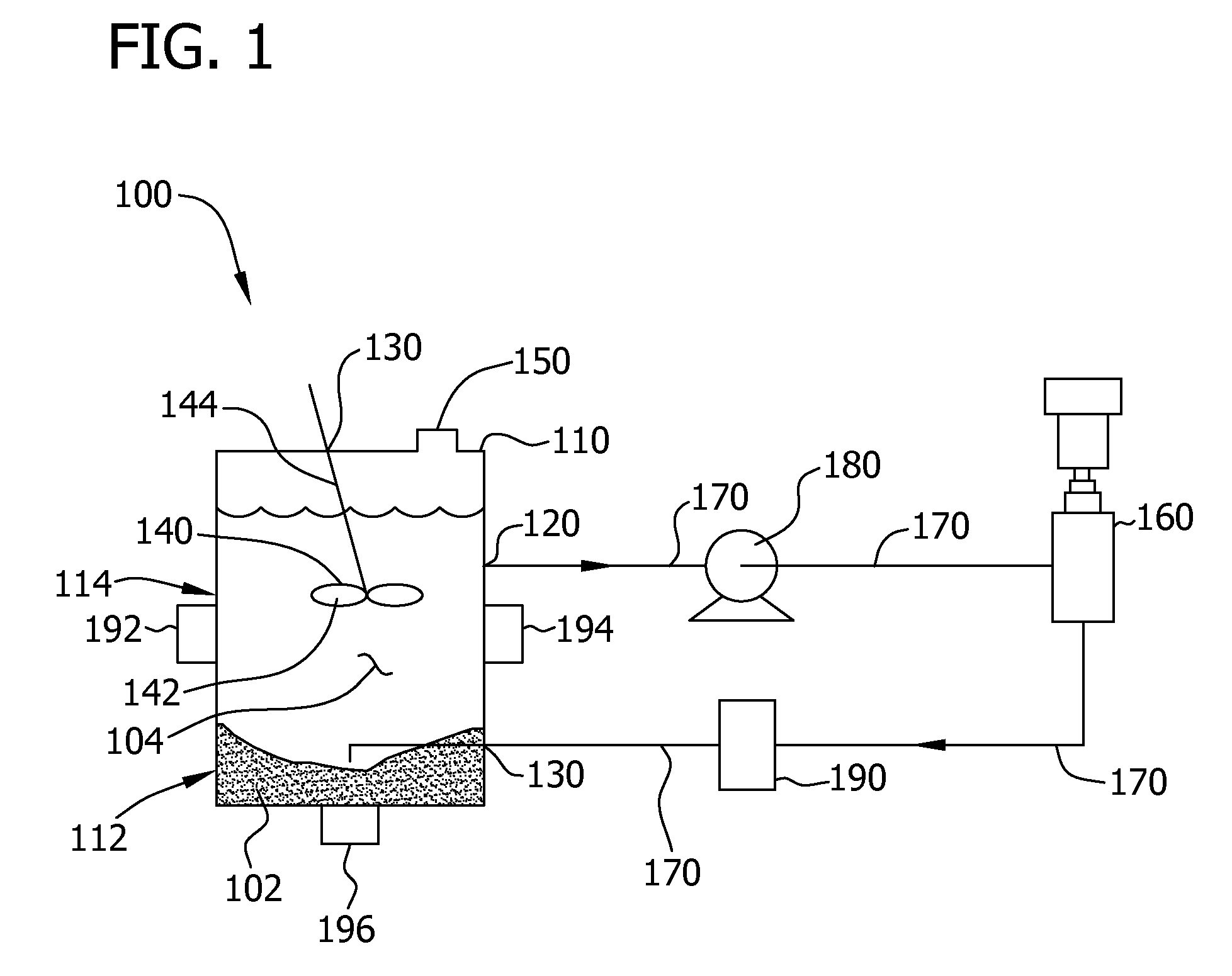

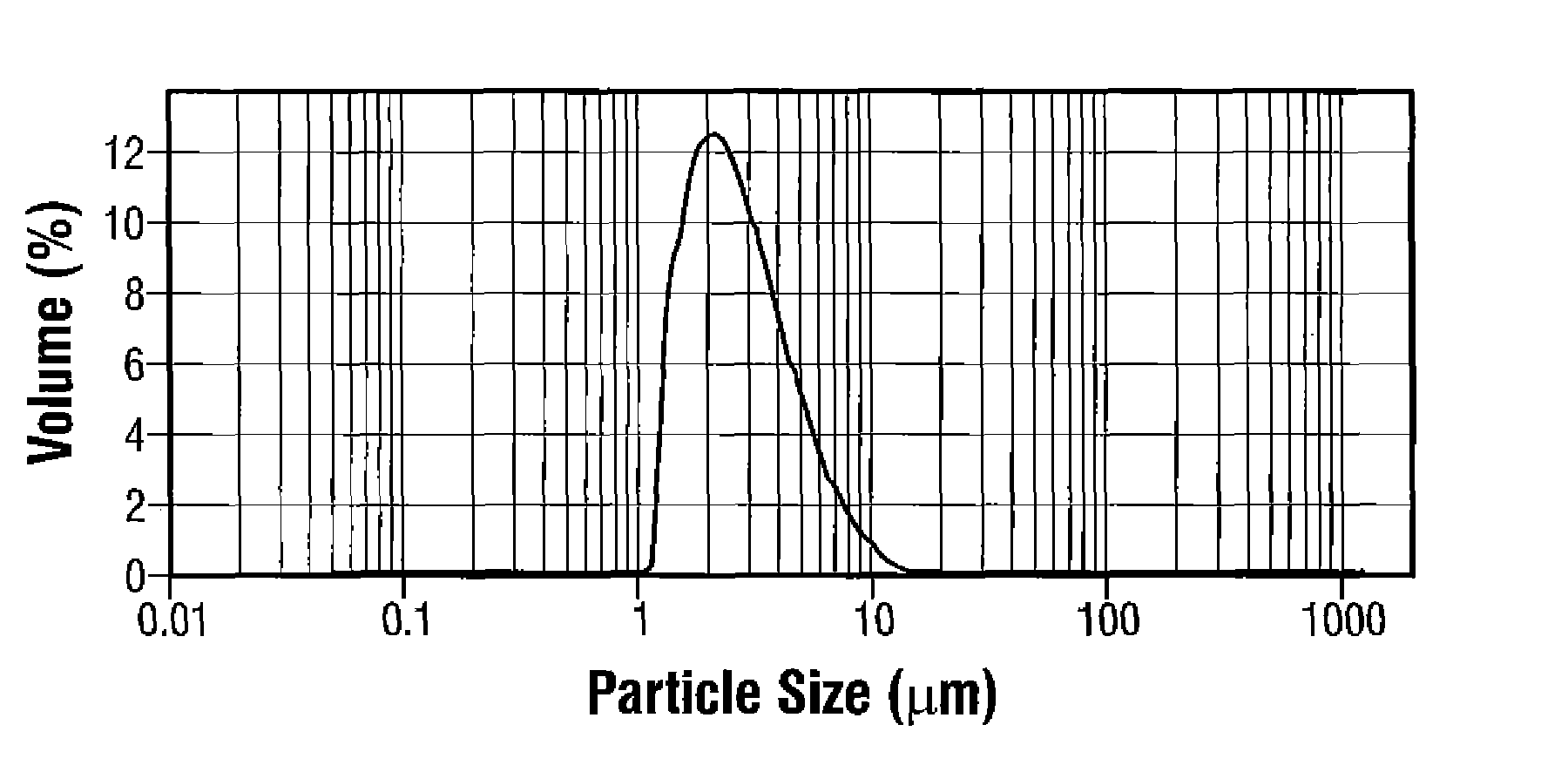

Method and System for Processing Abrasive Slurry

Systems and methods are provided for processing abrasive slurry used in cutting operations. The slurry is mixed with a first solvent in a tank. The slurry is vibrated and / or ultrasonically agitated such that abrasive grain contained in the slurry separates from the other components of the slurry and the first solvent. After the abrasive grain has settled to a bottom portion of the container, the other components of the slurry and the first solvent are removed from the tank. The abrasive grain may then be washed with a second solvent. The abrasive grain is then heated and is suitable for reuse in an abrasive slurry.

Owner:SUNEDISON SEMICON LIMITED UEN201334164H

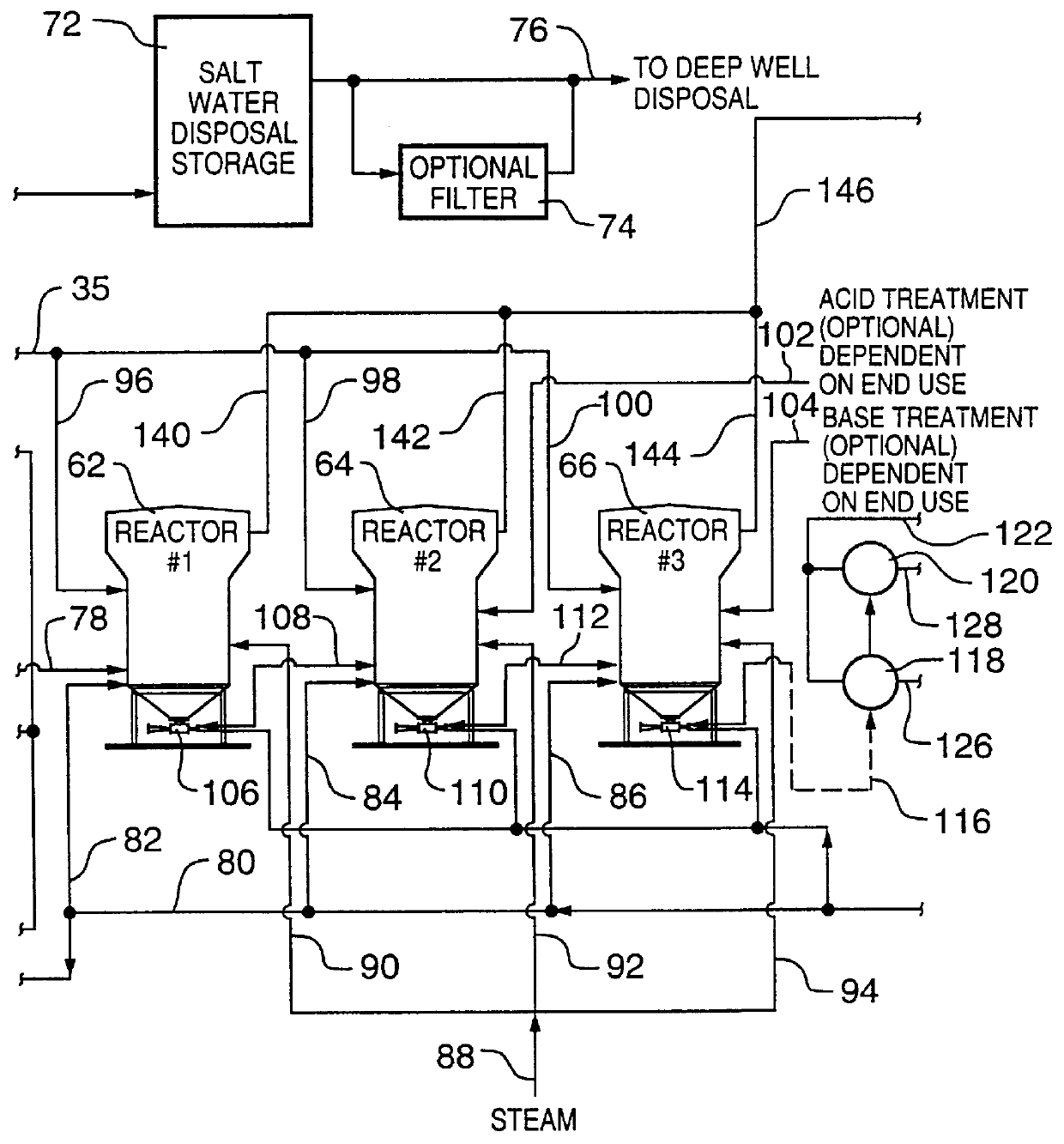

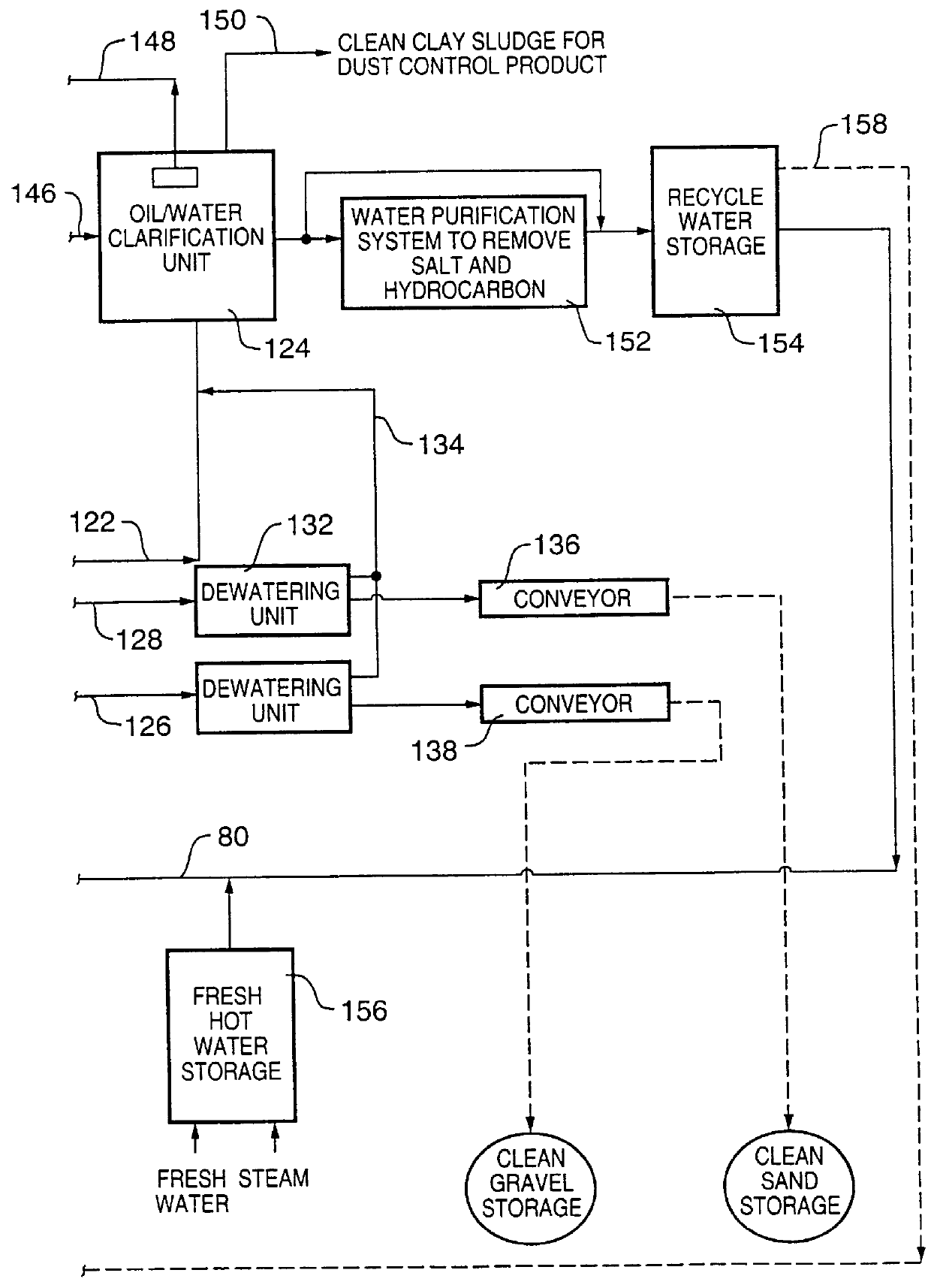

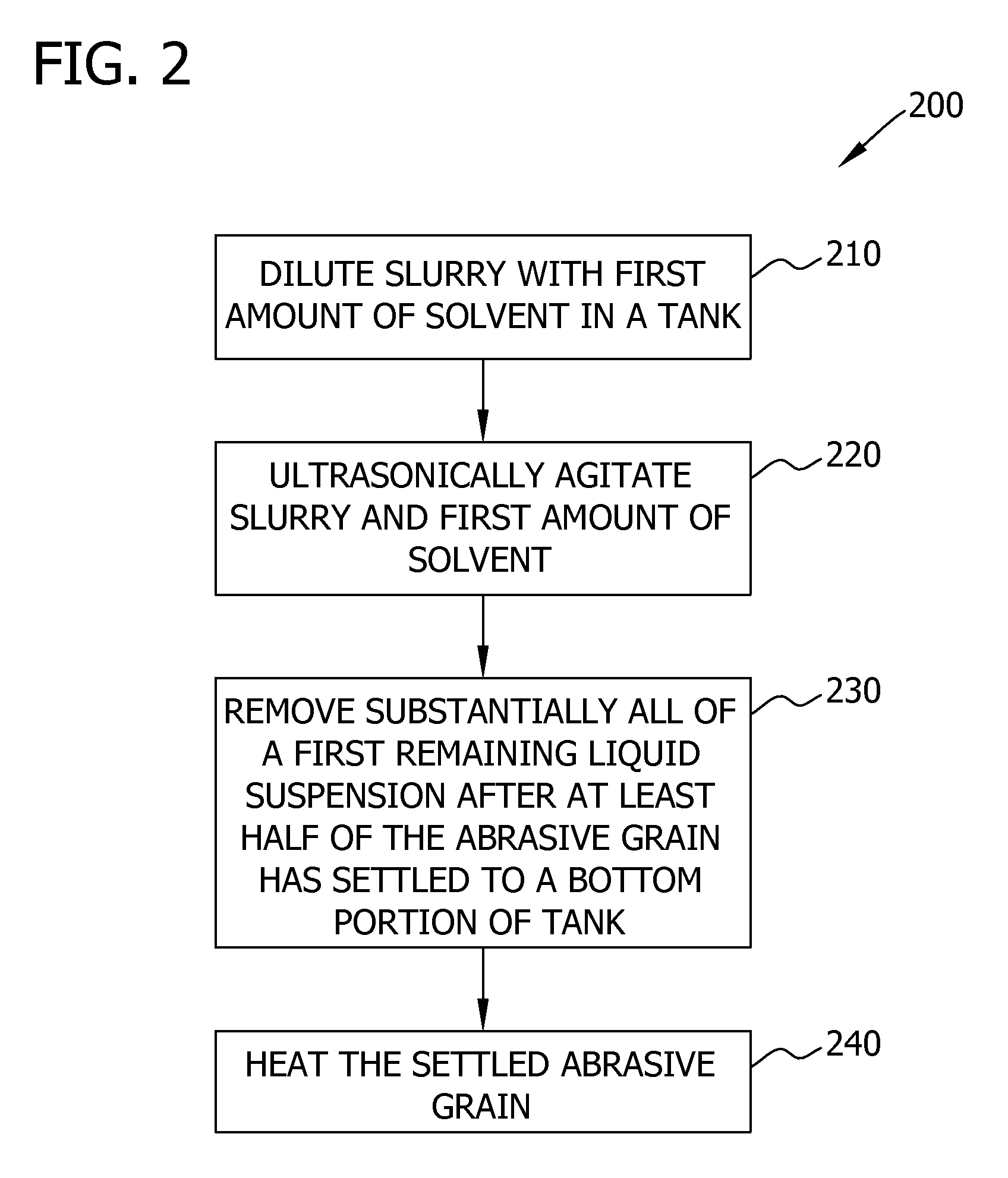

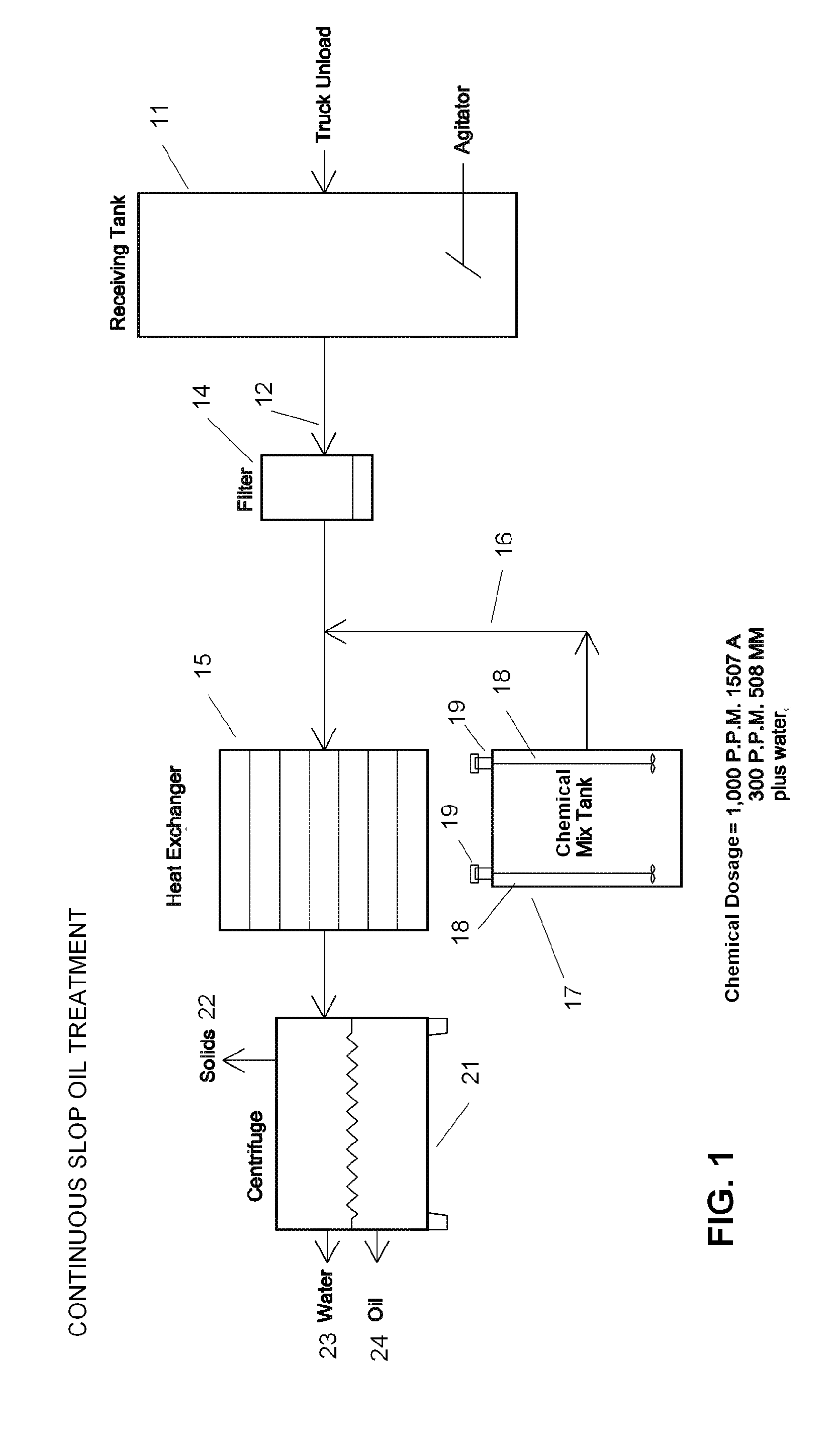

Processes for recycling sag-d process water and cleaning drill cuttings

InactiveUS20110174695A1Centrifugal force sediment separationSettling tanks heating/coolingSludgeSewage

A method of treating slop oil and slops from the SAG-D (steam assisted gravity-drainage) very heavy oil-bitumen crude oil production in such locations as Alberta and Saskatchewan provinces in Canada, Russia, Venezuela, Saudi Arabia, and Kern County, Calif., involves mixing the slop oil and slops with chemicals to help separate out water from the slop oil and slops.

Owner:MALCERA

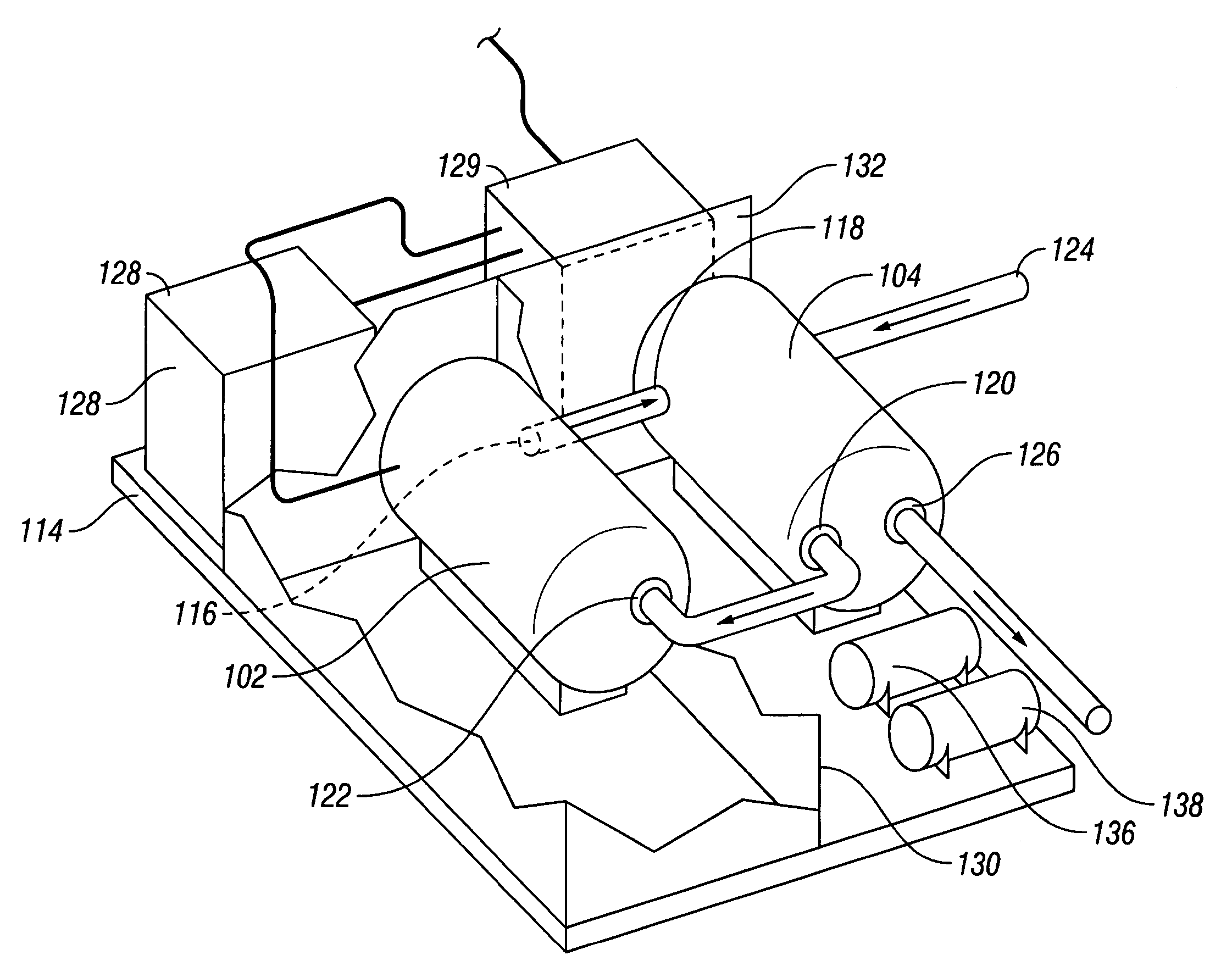

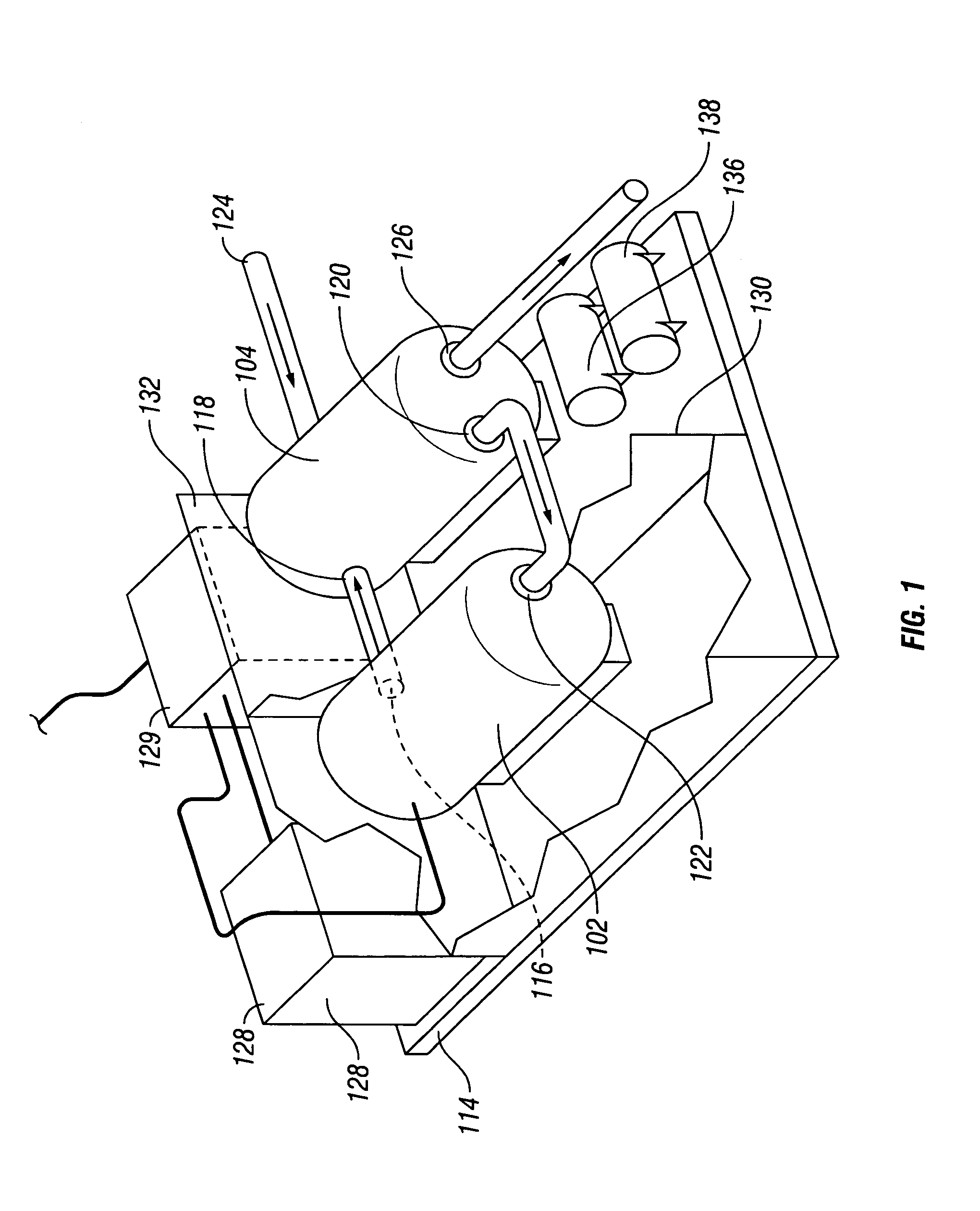

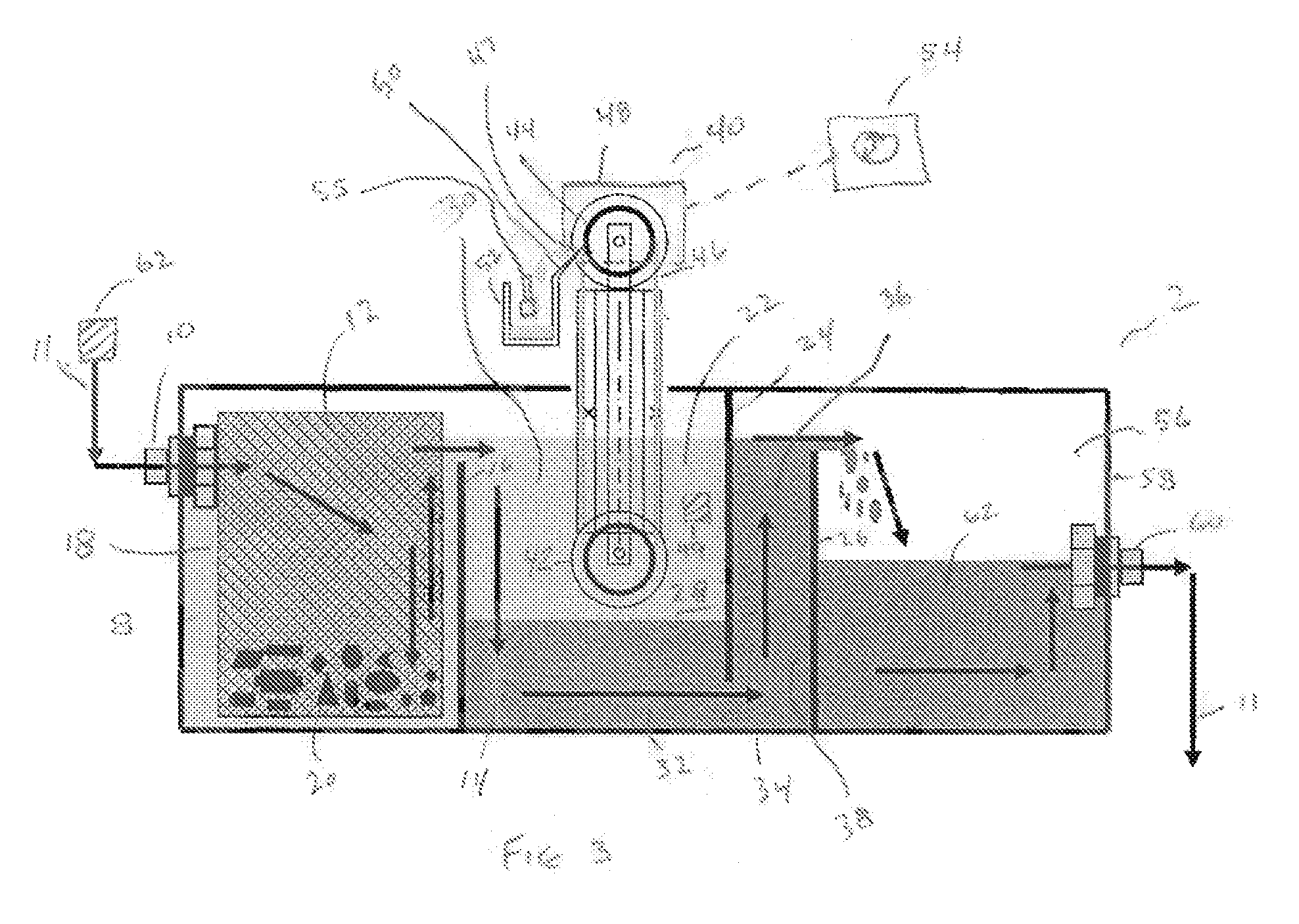

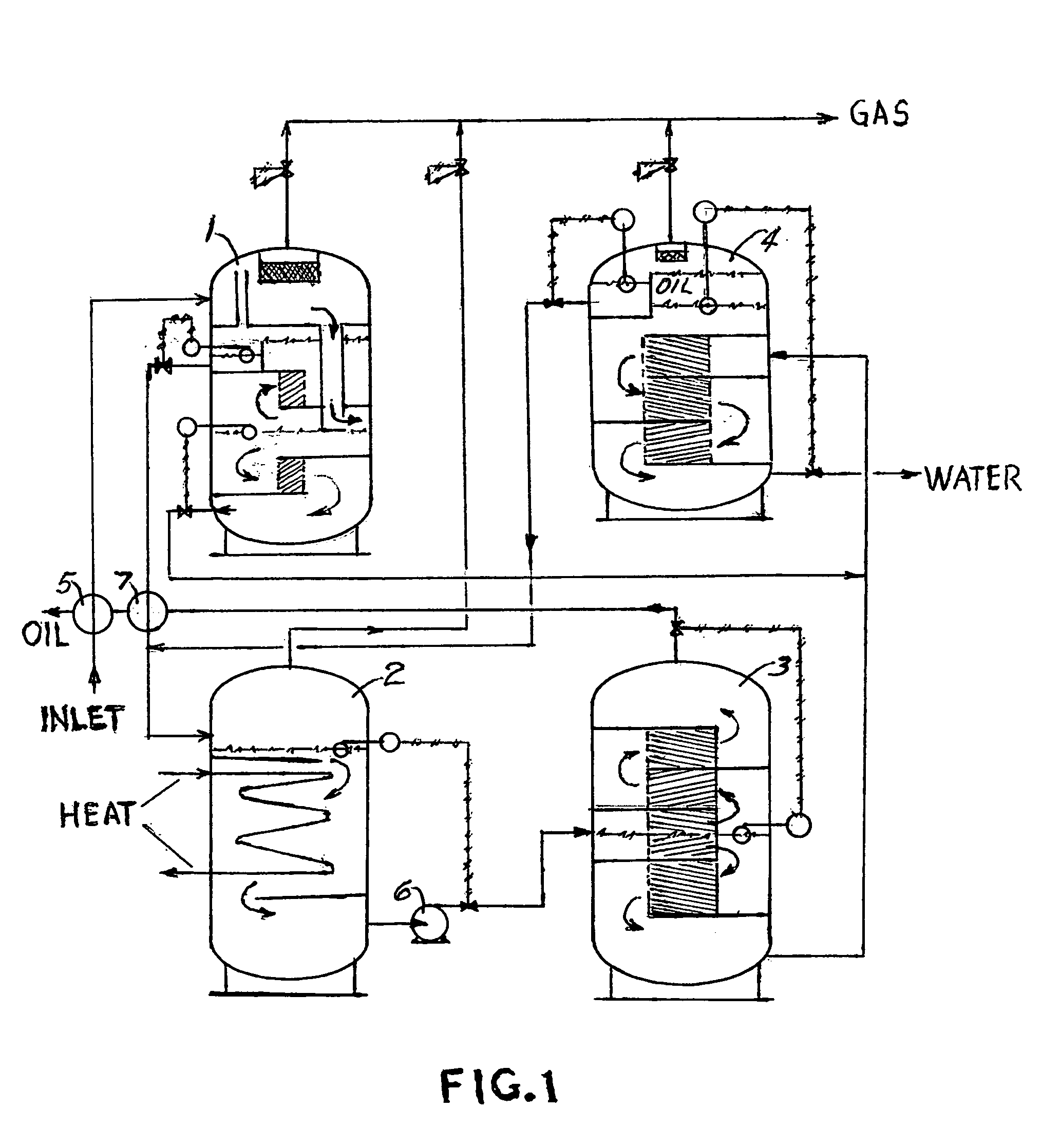

Oil-based sludge separation and treatment system

InactiveUS20060273051A1Reversed direction vortexSolid sorbent liquid separationSolid componentSludge

An apparatus for treating oil-based sludge includes a boiler, a heat exchanger having a circulatory steam path in fluid communication with the boiler and a sludge path receiving sludge, a plurality of serially-aligned mixers in fluid communication with the sludge path of the heat exchanger, a separation tank in fluid communication with the plurality of mixers, and wherein the separation tank includes a tank having a plurality of walls, a hydrocyclone mounted within the tank receiving sludge from the plurality of mixers, wherein the hydrocyclone includes a solids outlet directing a solids component towards a bottom portion of the tank and a fluid outlet directing a fluid component into the tank, a means for conveying separated solids along the bottom portion of the tank to a solids outlet, and a plurality of fluid outlets vertically located along a tank wall, wherein each outlet includes a valve providing selective fluid communication from the tank.

Owner:MI

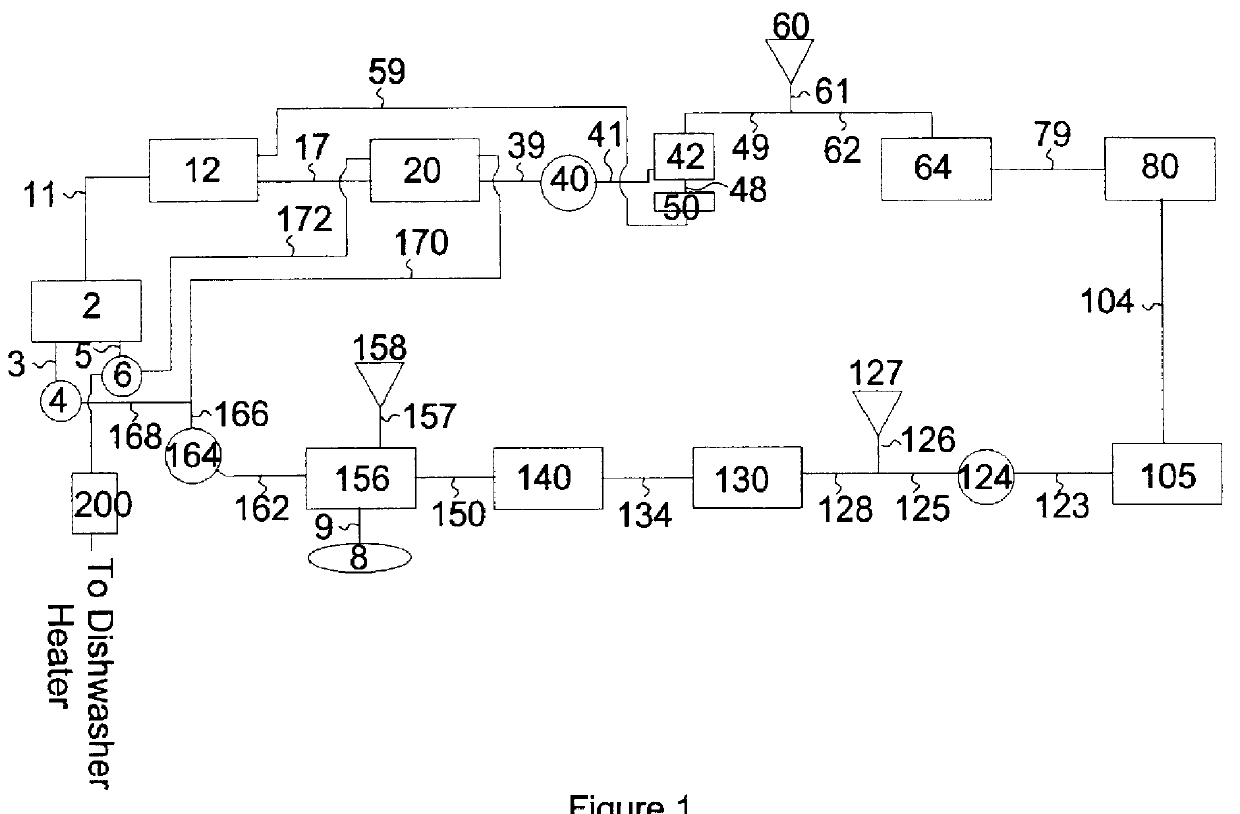

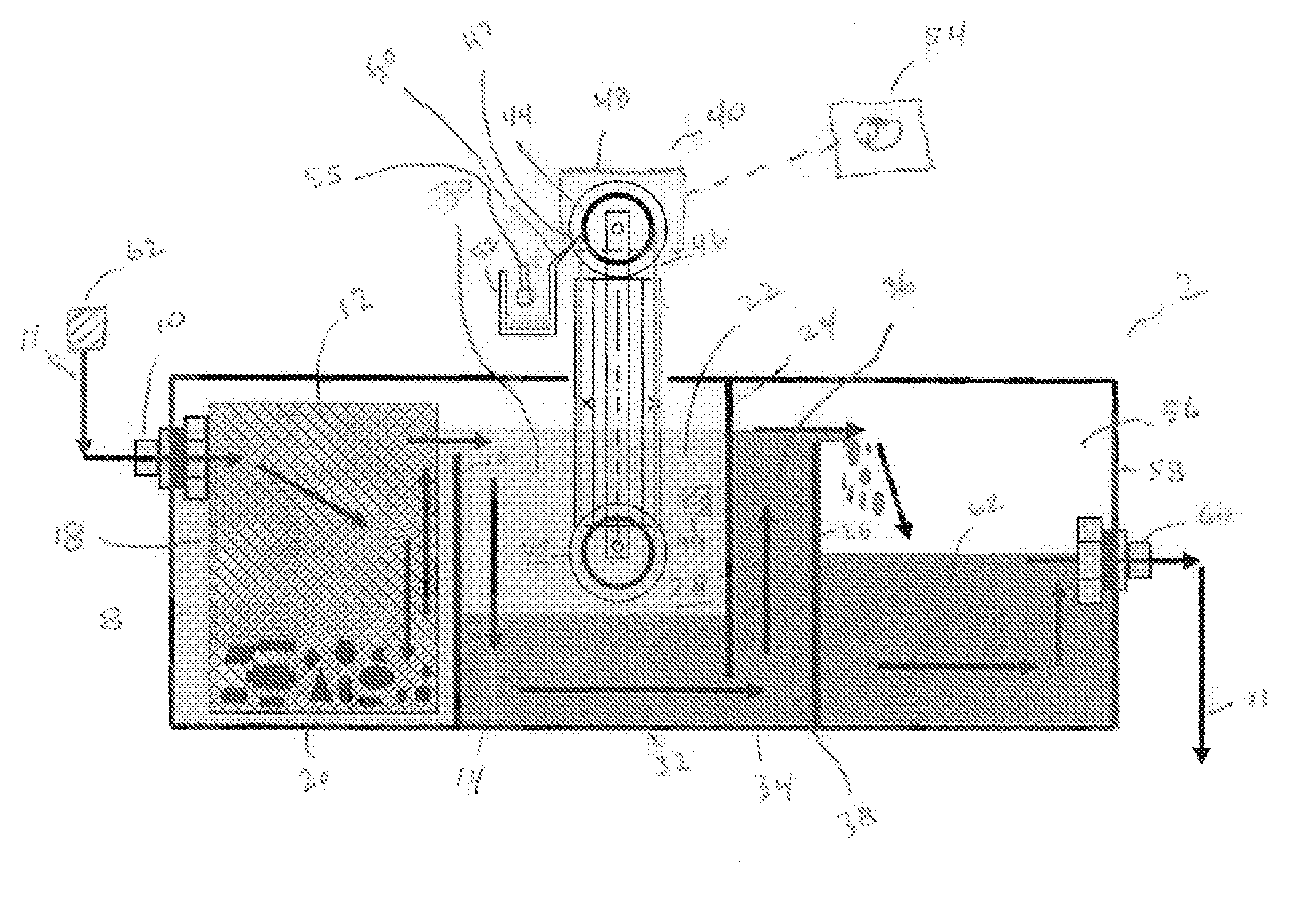

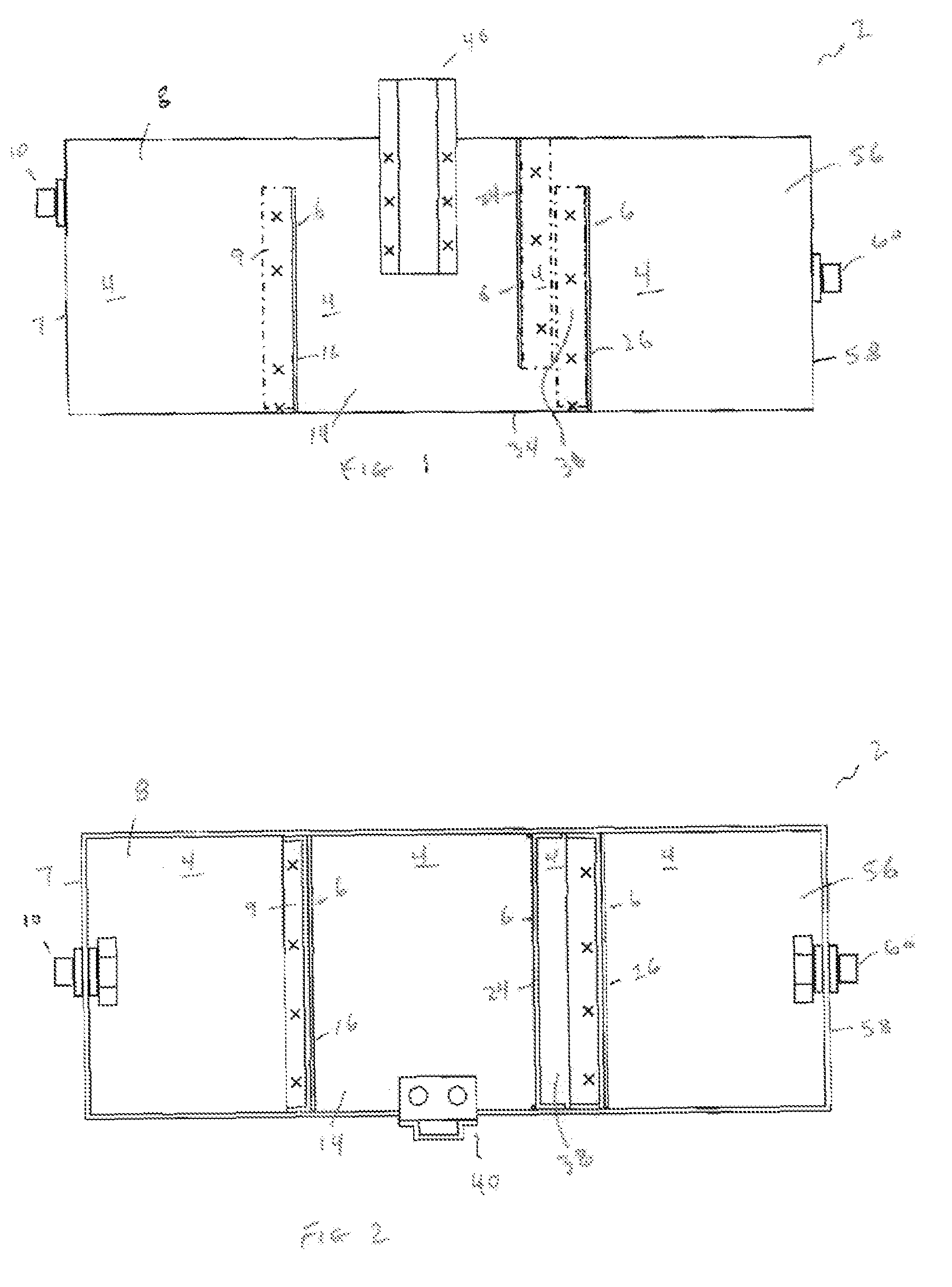

Fats, oil and grease interceptor

InactiveUS7427356B2Reduce maintenanceLess stressSedimentation tanksSewerage structuresOil and greaseGreywater

The present invention comprises a gravity draining automatic FOG interceptor with solids removal capability used as a first stage in the treatment of gray water. A preferred embodiment comprises a multi compartment container, the compartments separated by baffles, having a serviceable solids strainer in a first compartment, a second compartment having a cogged belt for FOG removal and collection, a third compartment for collection of clarified effluent, and a fourth compartment for tertiary treatment of the gray water effluent, for example, the introduction of biotechnology. The unique baffle configuration prevents biotechnology backflow migration from the fourth compartment with resulting bacterial contamination of the FOG.

Owner:CHAPIN PETER

Oil production processing system for swaying service

InactiveUS6968901B2Liquid separation auxillary apparatusDrilling rodsMarine engineeringOil production

A method for processing oil from oil wells having water bound locations whereby it is necessary to place the process containment vessels upon host structures that are floating and subjected to a swaying motion caused by the wave action of the water in which the host structures float. The process containment vessels are of a vertical cylindrical configuration to minimize their footprint and to mitigate the effect of tilting on the spatial process geometry inside of the vessels and further the vessels contain internal baffles that create horizontal flow patterns inside of the vertical vessel for a more efficient gravity separation process.

Owner:EDMONDSON TECH HLDG

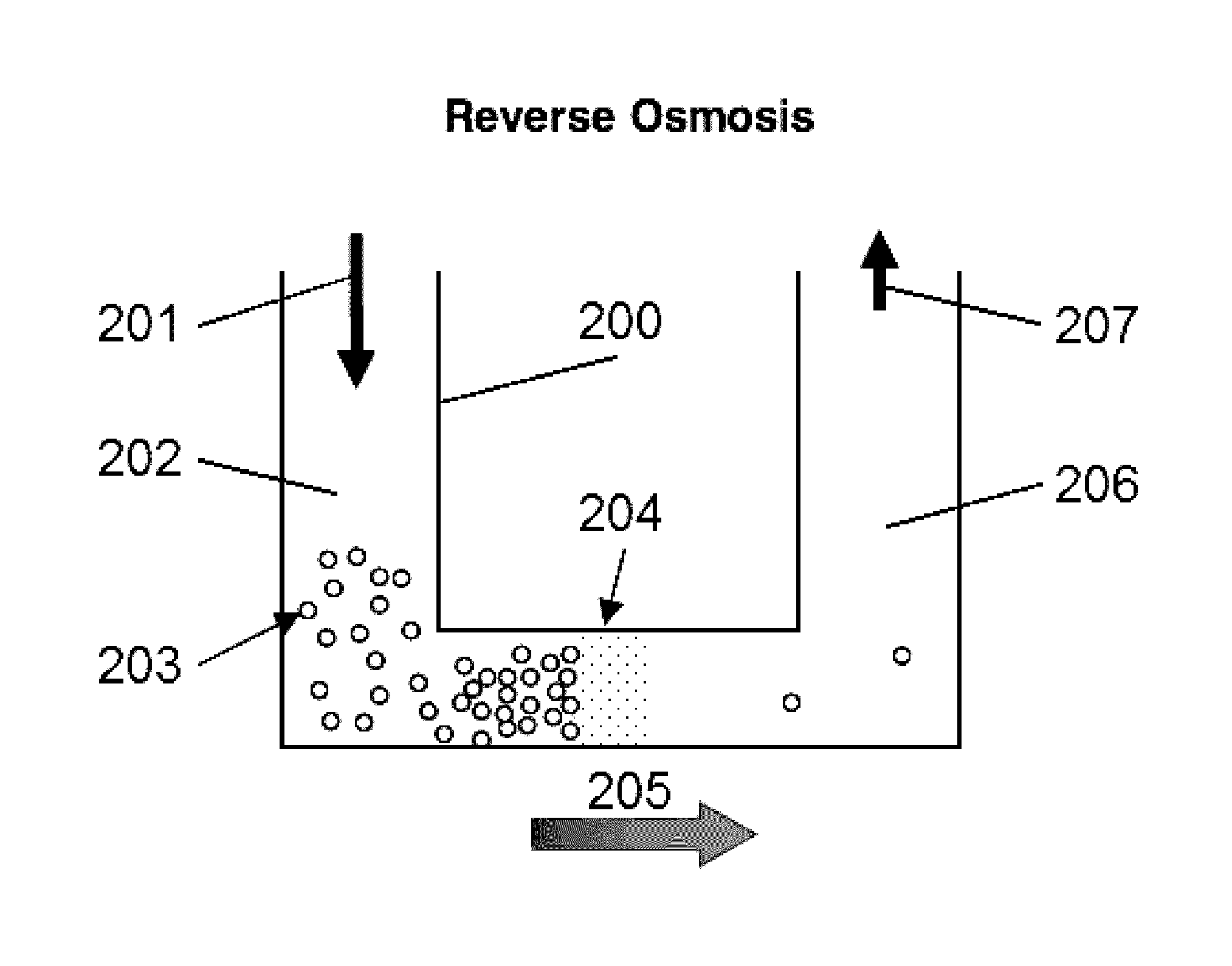

Recovery of retrograde soluble solute for forward osmosis water treatment

ActiveCN103492038ASolvent extractionGeneral water supply conservationDesalinationSemipermeable membrane

Improved systems and processes for forward osmosis water purification or desalination are herein disclosed. According to one embodiment a process for purifying contaminated water is provided wherein a contaminated feed solution stream comprising water and with a first osmotic pressure is passed through a semipermeable membrane to a draw side having a draw solution stream with a second osmotic pressure on a draw side of the semipermeable membrane. The diluted draw solution stream is heated, agglomerated and cooled to produce a cooled single phase water rich stream that is purified to produce a water product stream.

Owner:TREVI SYST

Fats, Oil and Grease Interceptor

InactiveUS20070045182A1Reduce maintenanceLess stressSedimentation tanksSewerage structuresOil and greaseContamination

The present invention comprises a gravity draining automatic FOG interceptor with solids removal capability used as a first stage in the treatment of gray water. A preferred embodiment comprises a multi compartment container, the compartments separated by baffles, having a serviceable solids strainer in a first compartment, a second compartment having a cogged belt for FOG removal and collection, a third compartment for collection of clarified effluent, and a fourth compartment for tertiary treatment of the gray water effluent, for example, the introduction of biotechnology. The unique baffle configuration prevents biotechnology backflow migration from the fourth compartment with resulting bacterial contamination of the FOG.

Owner:CHAPIN PETER

Refinery desalter improvement

ActiveUS8747658B2Increase capacityEasy to separateDewatering/demulsification with chemical meansDewatering/demulsification with mechanical meansDesalterImproved method

The improved methods relate to desalting hydrocarbon feeds using a separator with a stacked disk centrifuge to separate an emulsified oil and water rag layer. This method is effective for desalting heavy, high ionic, and non-traditional crude oils.

Owner:PHILLIPS 66 CO

Process for separating one or more solids from water miscible fluids and an apparatus therefor

This invention relates to a process for removing solid matter from process liquids that are miscible with water. A brine made from water and dissolved salt and which is more dense than the process liquid is placed underneath and in contact with the mixture of process liquid and solid matter. The particles and pieces of solid matter move from the process liquid and then through the brine. In so doing the process liquid that is carried with the solid matter is displaced by the more dense brine.

Owner:CAMERSON INT CORP

Method and Systems for Enhancing Oil Recovery From Ethanol Production Byproducts

Owner:GS CLEANTECH CORP

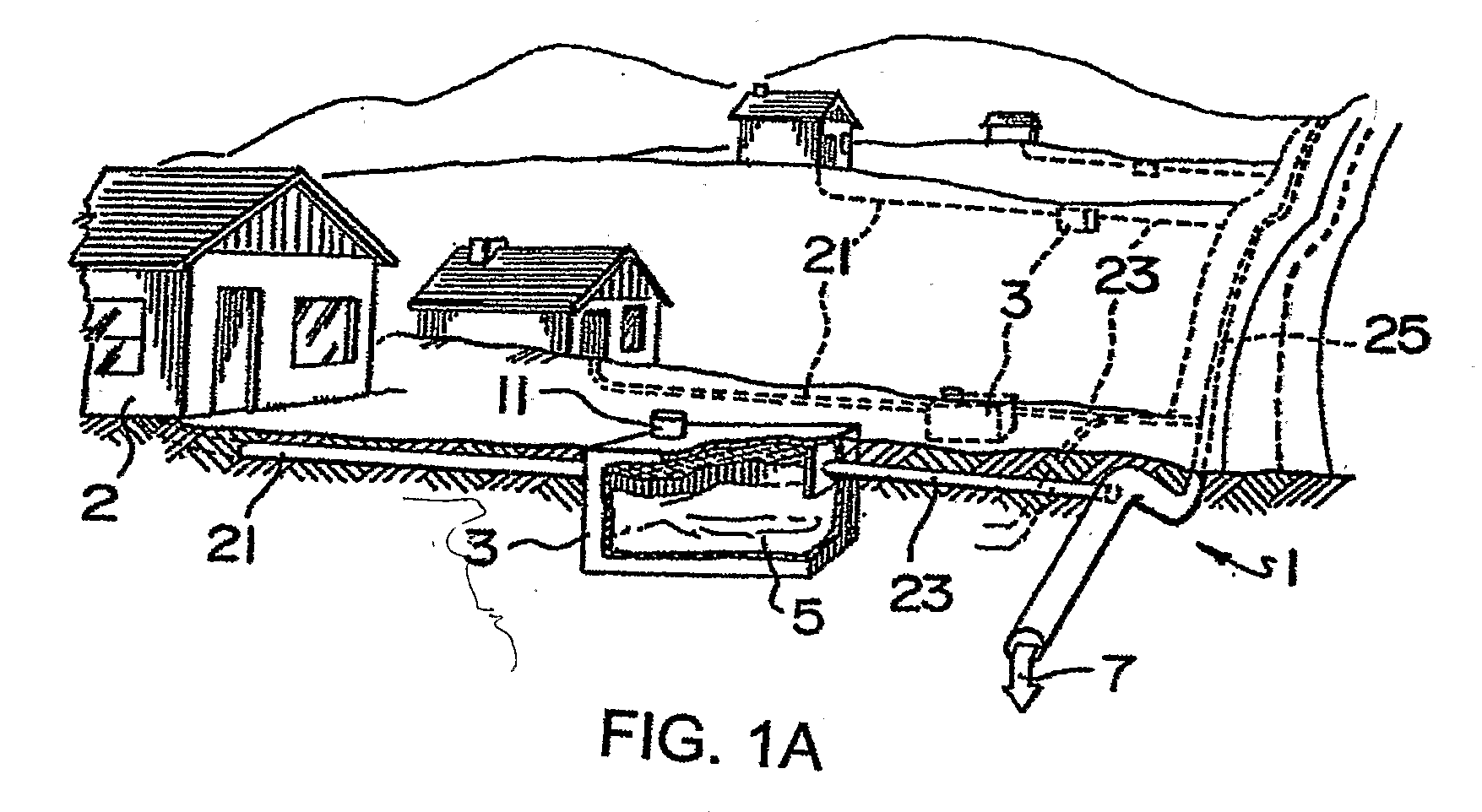

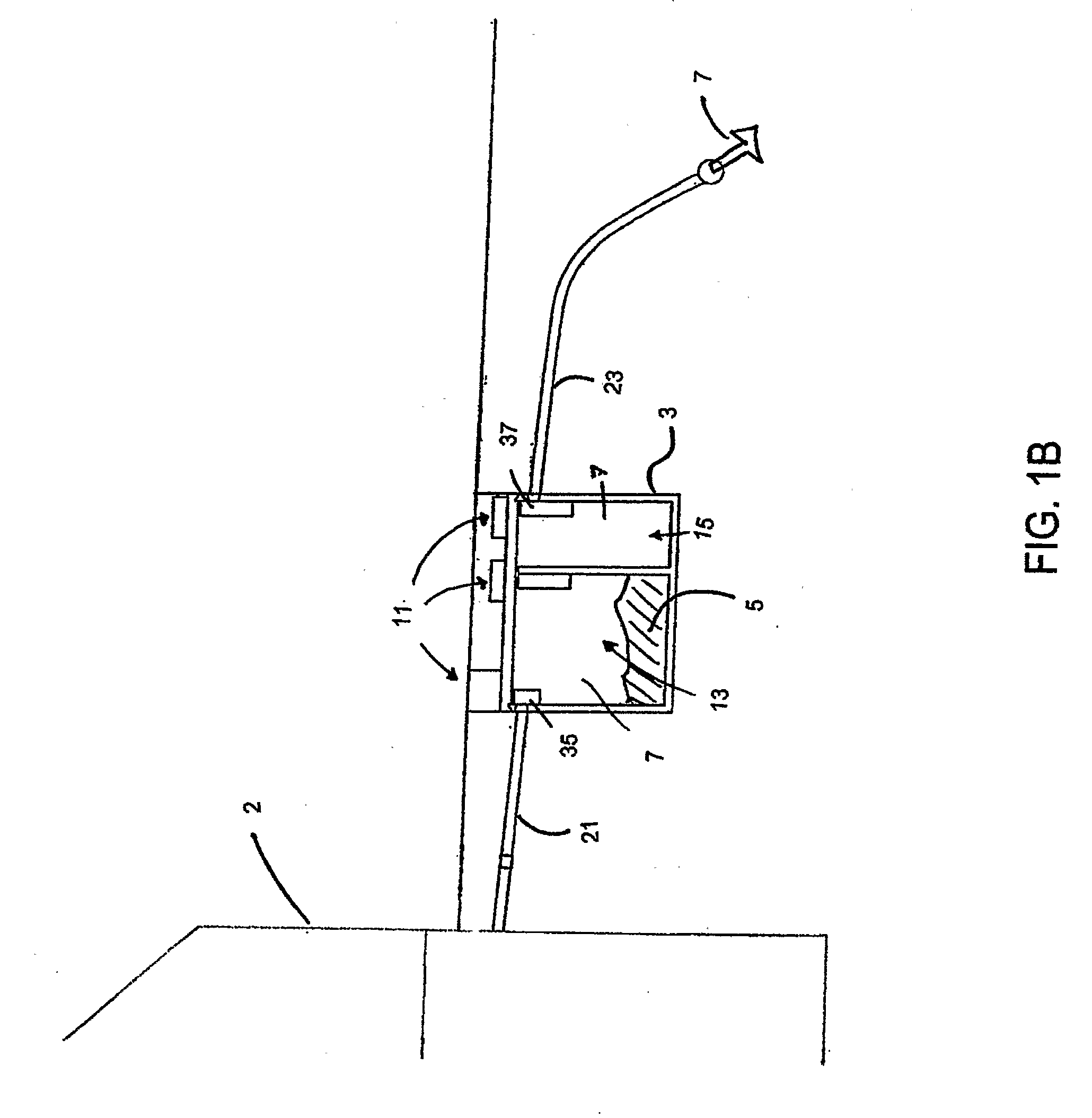

High Performance Sewer System

InactiveUS20090032450A1Avoid passingMinimize disruptionGeneral water supply conservationPipeline expansion-compensationMain processing unitCritical position

The system comprises one or more of the following: primary treatment units, flexible pipes, and optionally, one or more pumps. The system is designed and installed in a manner that enables the flow of liquid to be predominantly due to gravity, although one or more pumps may optionally be included at key positions. The system can be sealed and pressure tested in order for optimal performance to be achieved during operation.

Owner:CLEARFORD IND

Membrane cleaning and desalination with a membrane using acoustic pressure shock waves

ActiveUS20170057844A1Enhancing of acoustic pressure shock wave effectImprove desalination efficiencyGeneral water supply conservationSeawater treatmentShock waveMechanical engineering

Acoustic pressure shock waves are applied to a membrane in a fluid to prevent attachment of or dislodge biological or solid matter for membrane cleaning or desalination with a membrane.

Owner:SANUWAVE INC

Systems and methods for separating heavy water from normal water using acoustic pressure shock waves

ActiveUS20170066663A1Enhancing of acoustic pressure shock wave effectImprove desalination efficiencyGeneral water supply conservationSeawater treatmentWater useShock wave

A method of separating heavy water from normal through application of acoustic pressure shock waves to a fluid including heavy water and normal water and recovering separated normal water.

Owner:SANUWAVE INC

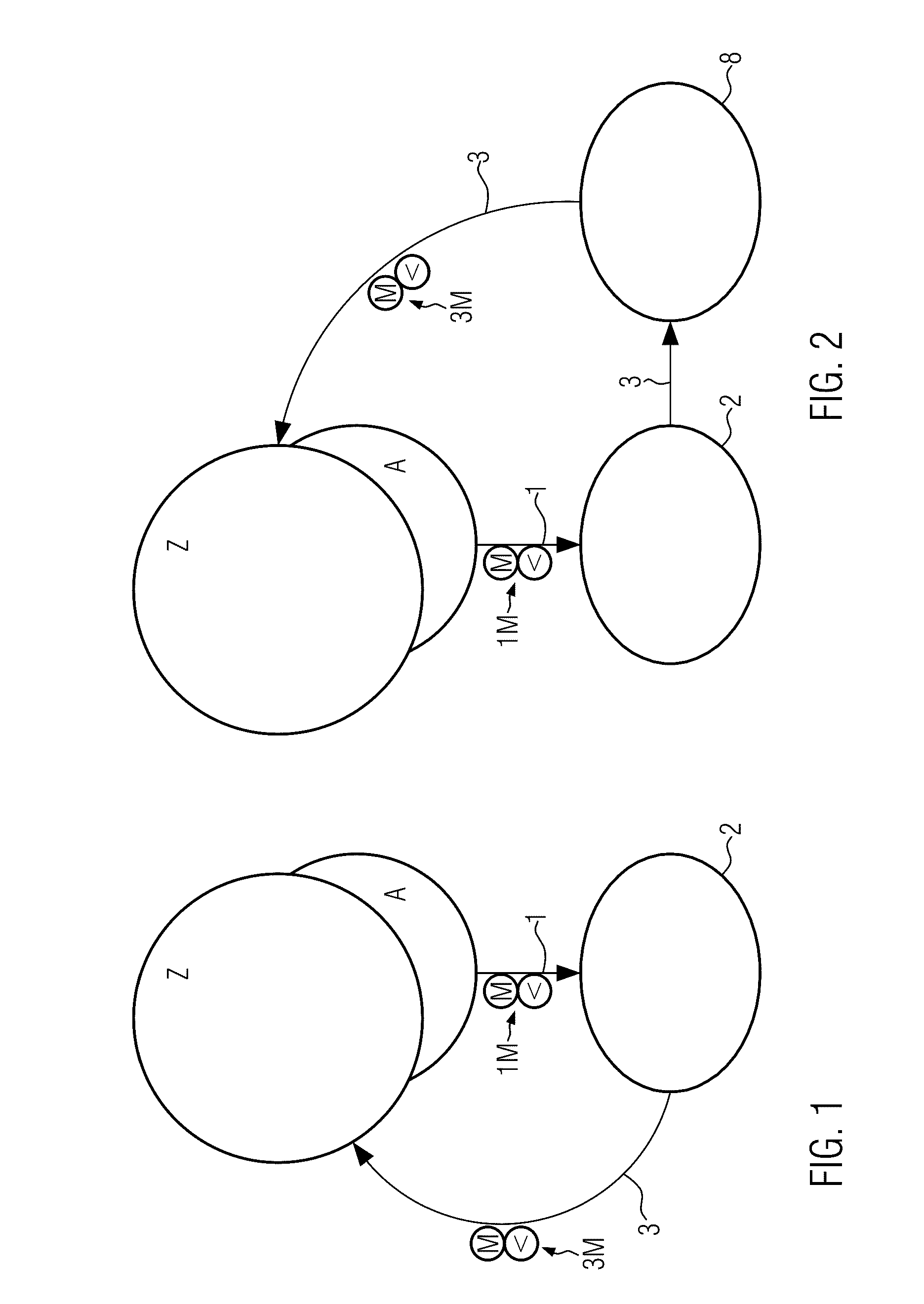

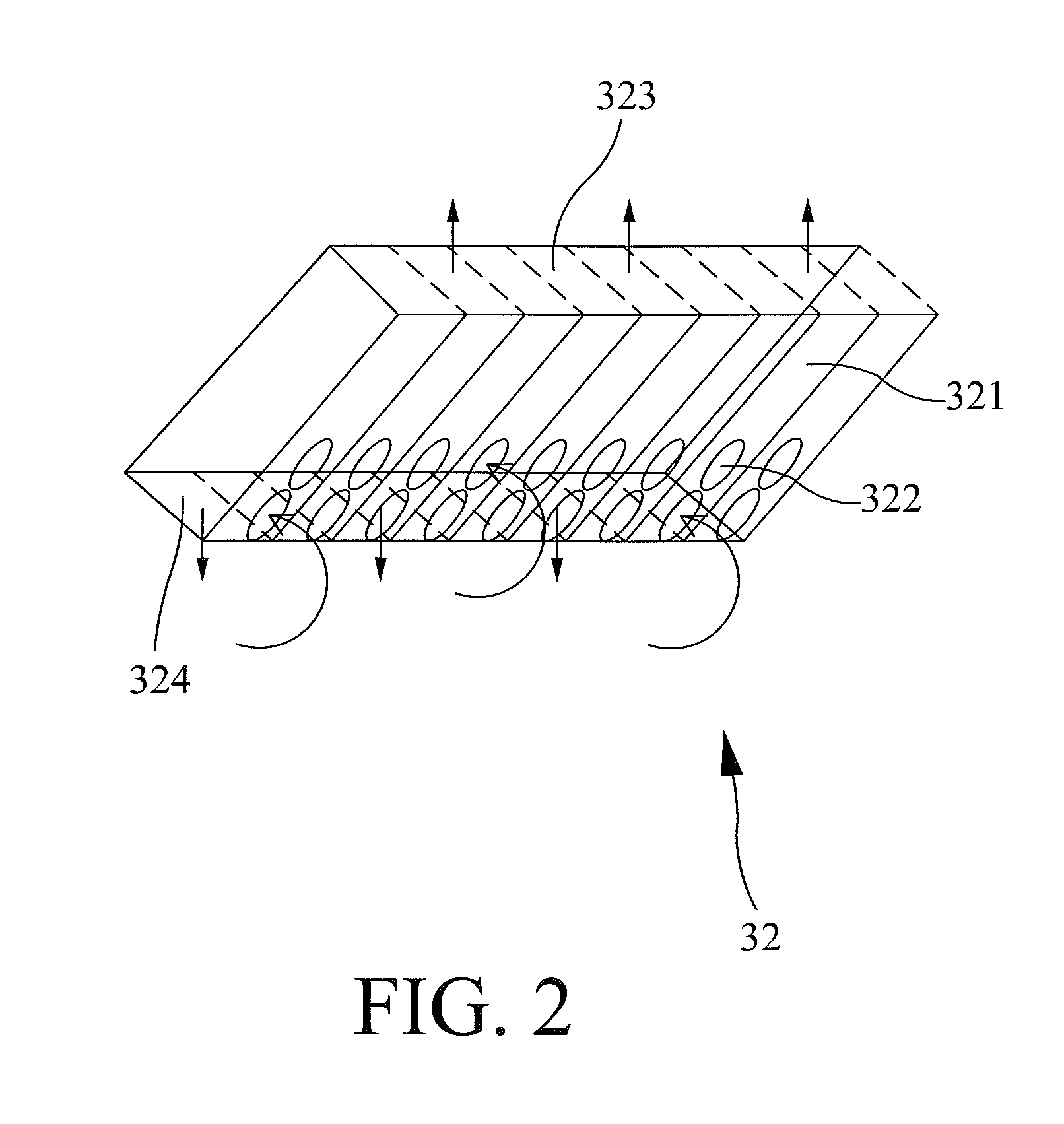

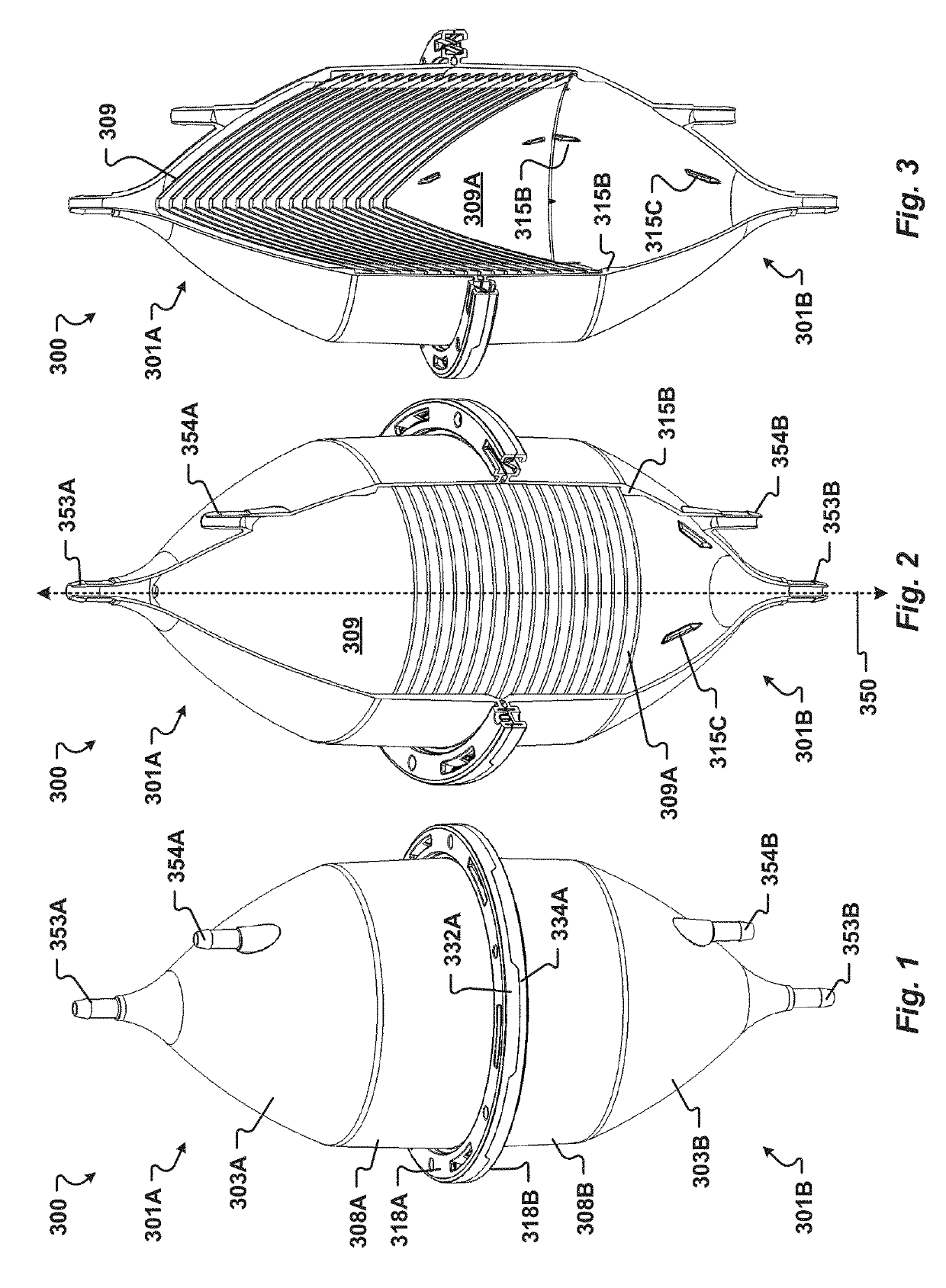

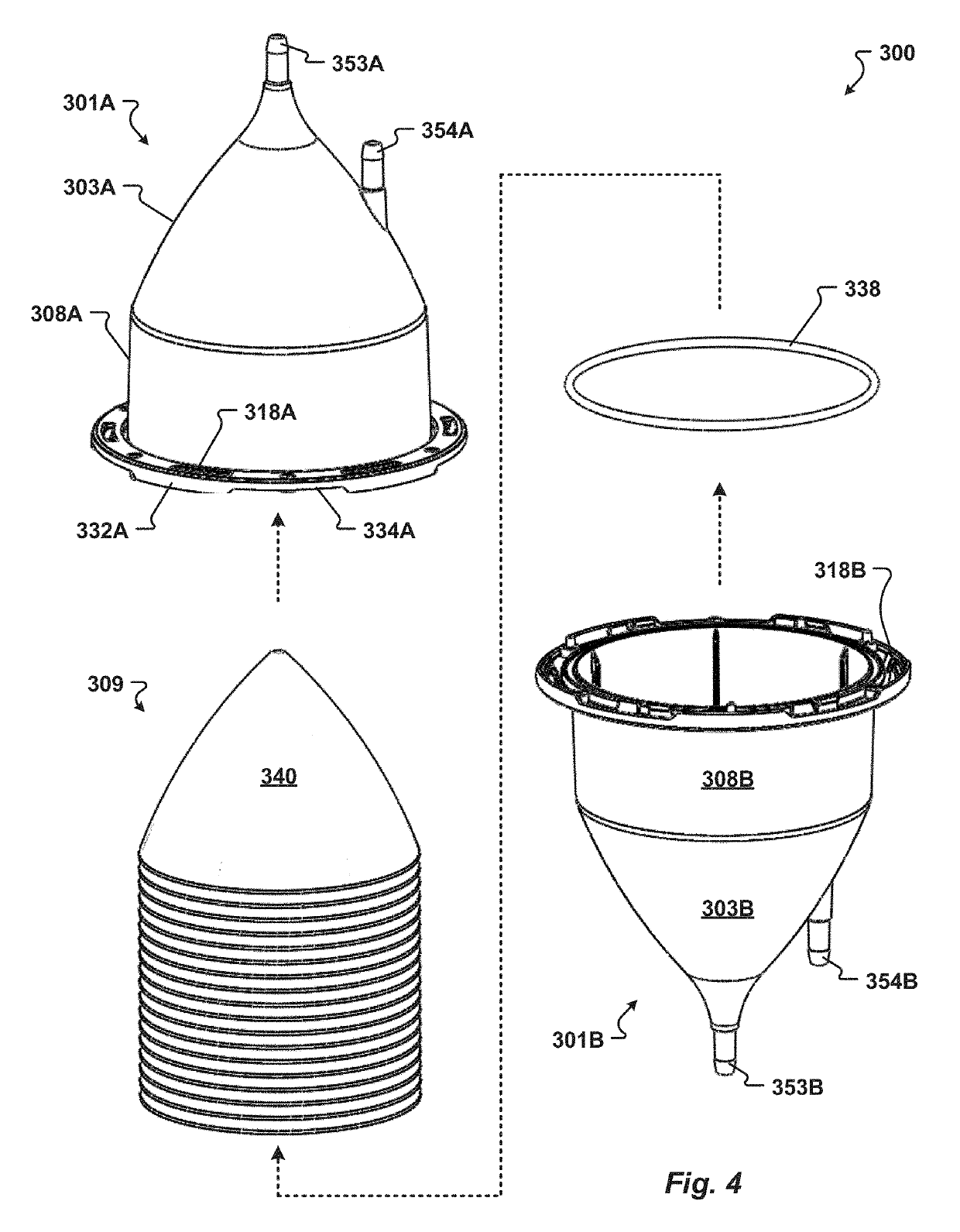

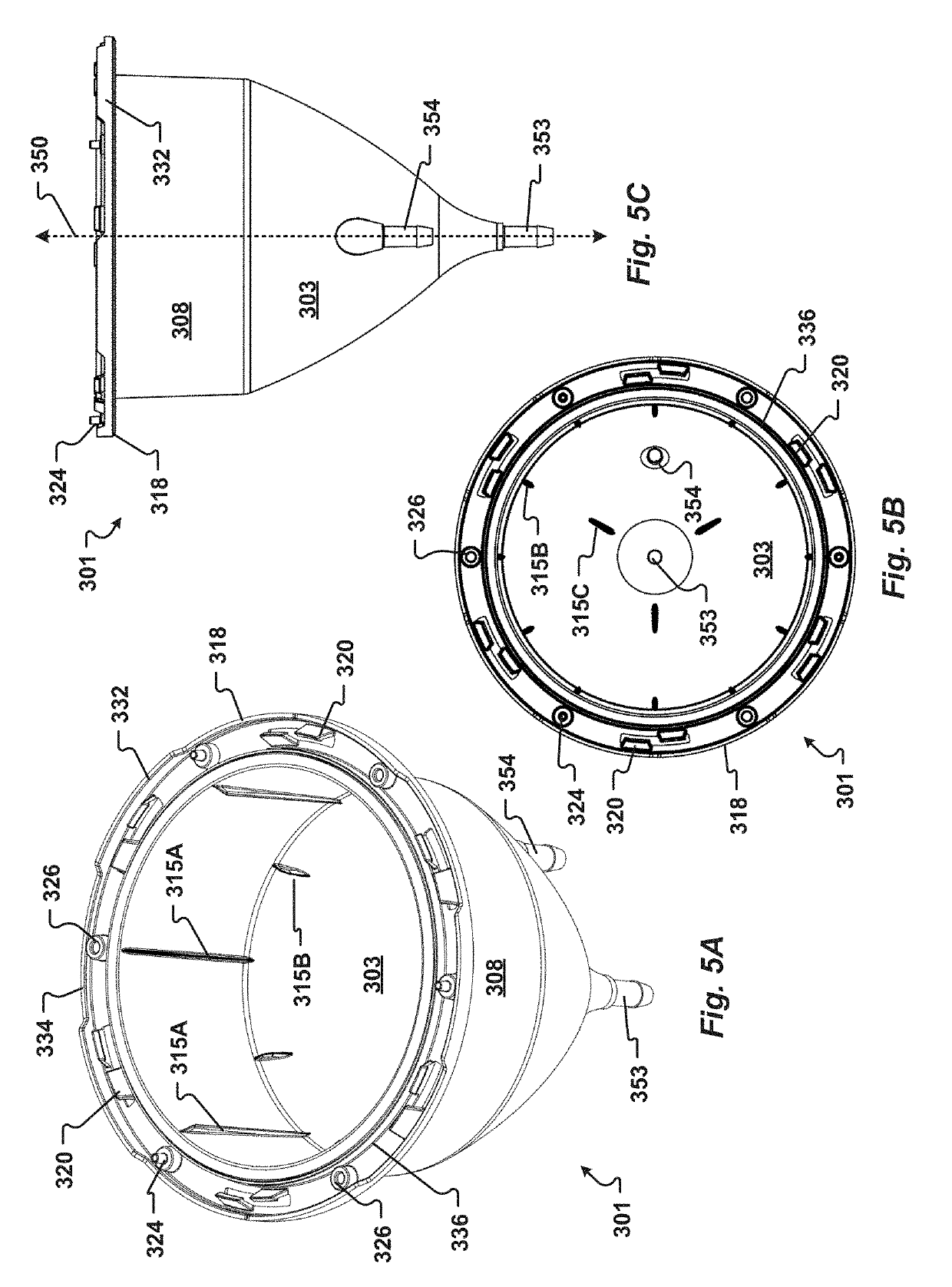

Particle settling devices

ActiveUS20190321756A1Accelerated settlementImprove efficiencyBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringAlgae

Settling devices for separating particles from a bulk fluid with applications in numerous fields. The particle settling devices include a first stack of cones with a small opening oriented upwardly or downwardly. Optionally, the settling devices may include a second stack of cones with a small opening oriented downwardly or upwardly. The cones may be concave or convex. These devices are useful for separating small (millimeter or micron sized) particles from a bulk fluid with applications in numerous fields, such as biological (microbial, mammalian, plant, insect or algal) cell cultures, solid catalyst particle separation from a liquid or gas and waste water treatment.

Owner:SUDHIN BIOPHARMA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com