Process and apparatus for treating exhausted abrasive slurries for the recovery of their reusable components

An abrasive slurry, used technology, used in separation methods, fine working devices, grinding/polishing safety devices, etc., can solve problems such as consumption of large amounts of chemical reagents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

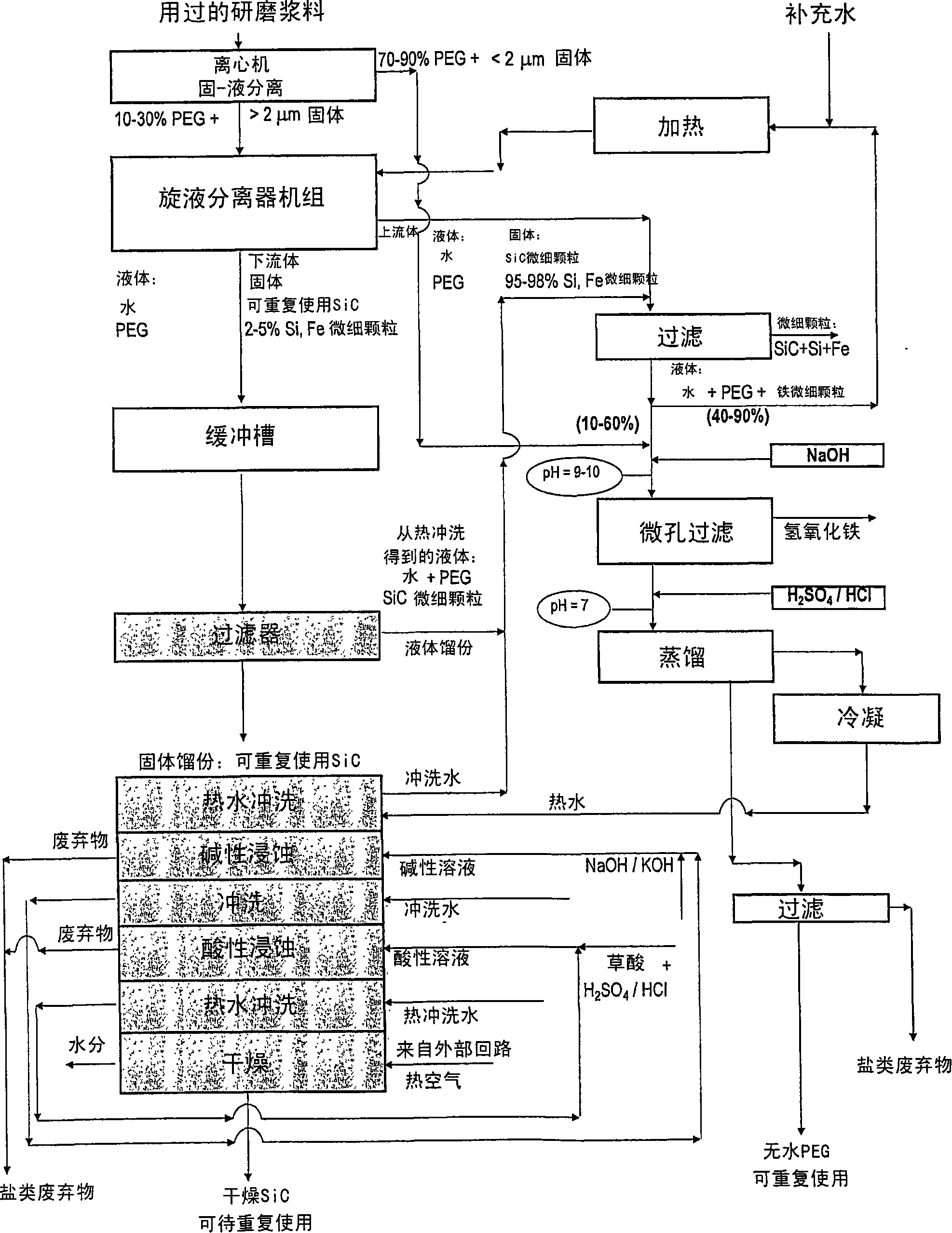

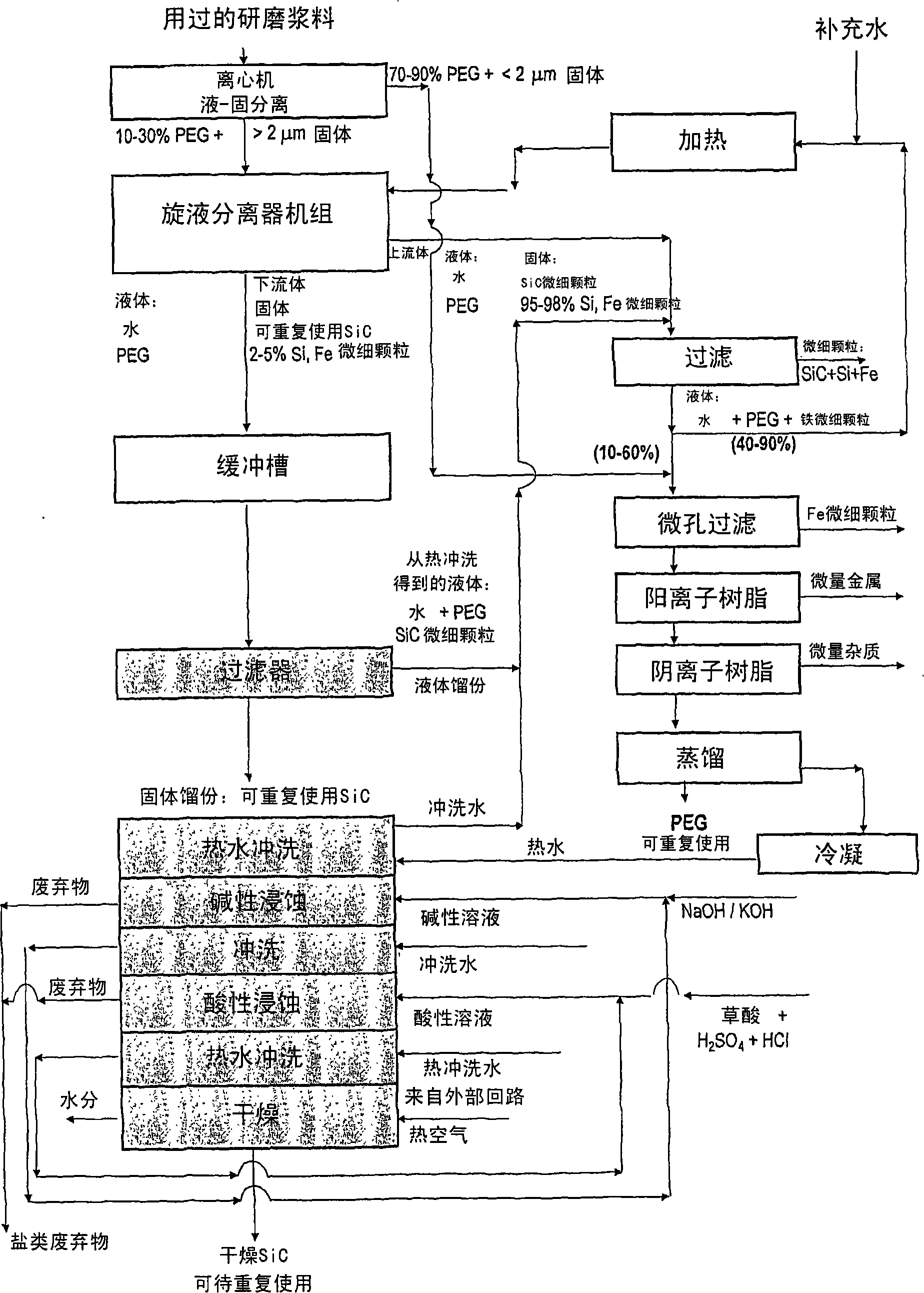

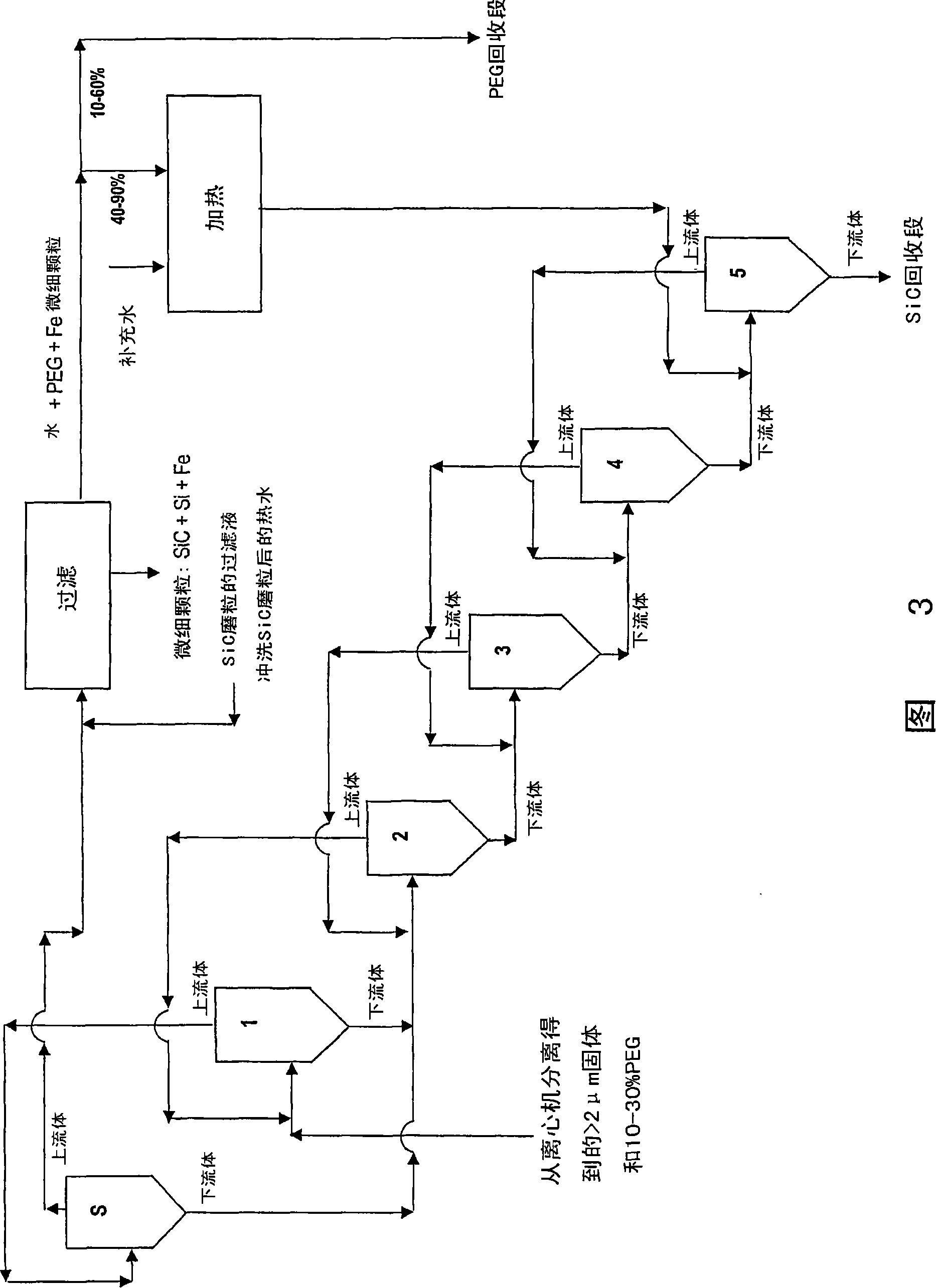

[0080] like figure 1 As shown in the block diagram of , the method of the present invention and the device specially designed for implementing the method are mainly composed of three interconnected processing sections, the first two sections (represented by the left column of the diagram) are used for recovery and purification of reusable Abrasive particles, while the third section (right column) is used to process and recover the suspension liquid.

[0081] The used slurry from the cutting section of the silicon crystal ingot has a solids content of 50-55% by weight, and here for illustration it contains:

[0082] ■Reusable silicon carbide abrasive grains with a particle size between 4 and 35 μm for large-grained abrasive suspensions (type F500) and between 4 and 35 μm for fine-grained abrasive suspensions (type JS 1500 or JS 2000) Between 25 μm; in this example, these abrasive particles accounted for 34-39% by weight of the slurry;

[0083] ■ Non-reusable abrasive particle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com