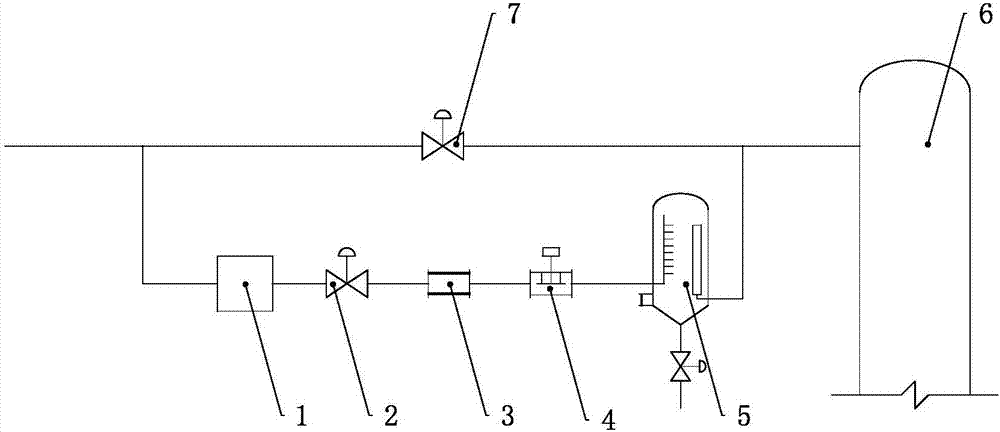

Device for removing corrosive impurities and preventing salt deposition corrosion of fractionating tower

A corrosive and fractionating tower technology, which is applied in the fields of fractionation and distillation to prevent corrosion and dehydration of hydrocarbon oil. The effect of suppressing salt corrosion and small equipment size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] A coking fractionation tower overhead circulating oil contains 300 mg / kg of salt, part of the top circulating oil is injected with 1% fresh water, mixed at a mixing intensity of a mixing pressure difference of 0.04Mpa, and coalesced by a magnetic field with a magnetic field strength of 0.2T, at 2000V / cm Coalesced under an electric field, filtered and separated, the salt content in the oil was reduced to 20mg / kg, and the water content was 130mg / kg. After 3 days of operation, the salt in the top cycle return tower oil has been greatly reduced, and the long-term continuous operation has solved the problems of salt formation and corrosion in the fractionation tower.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com