Patents

Literature

52results about "Lubricating oils distillation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

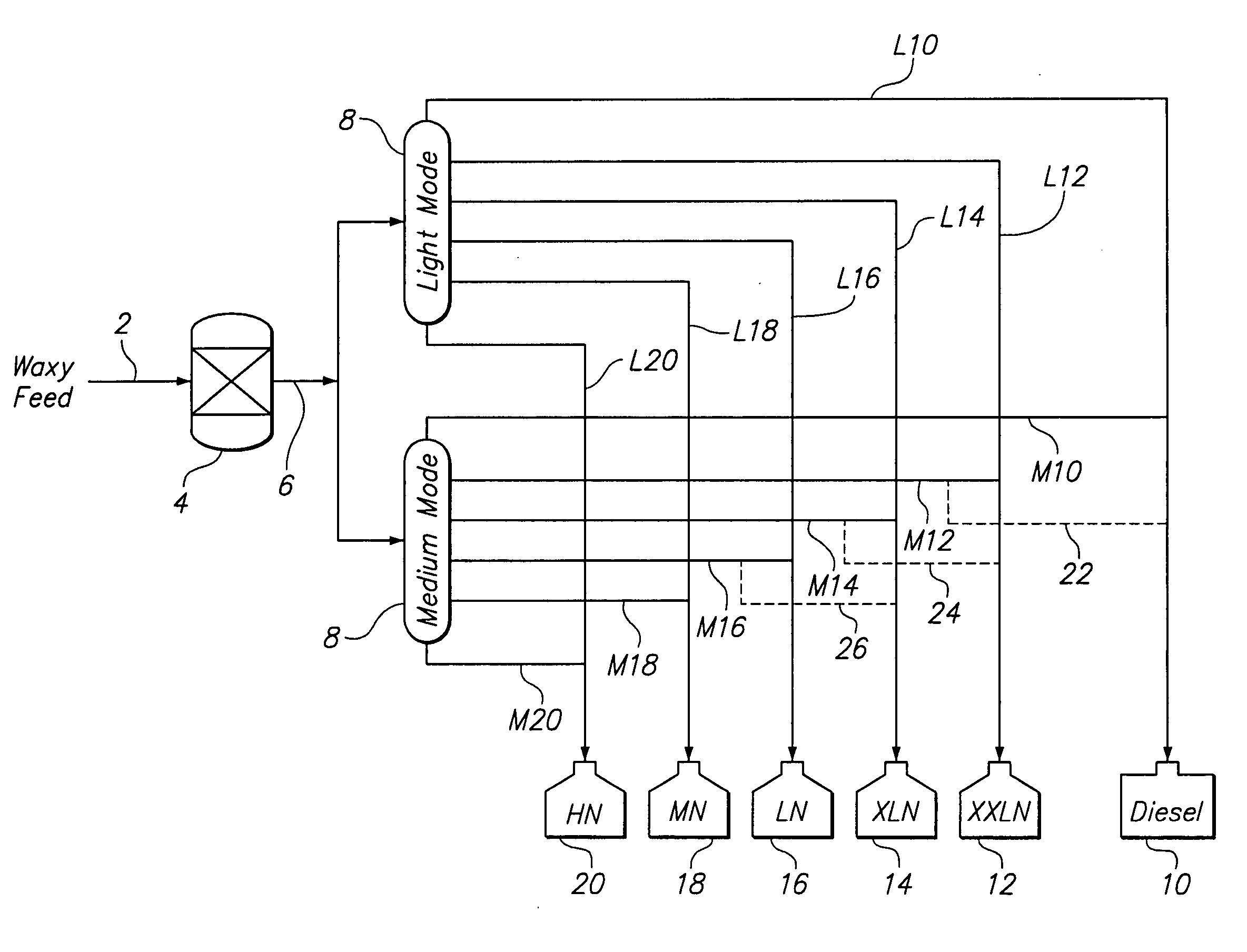

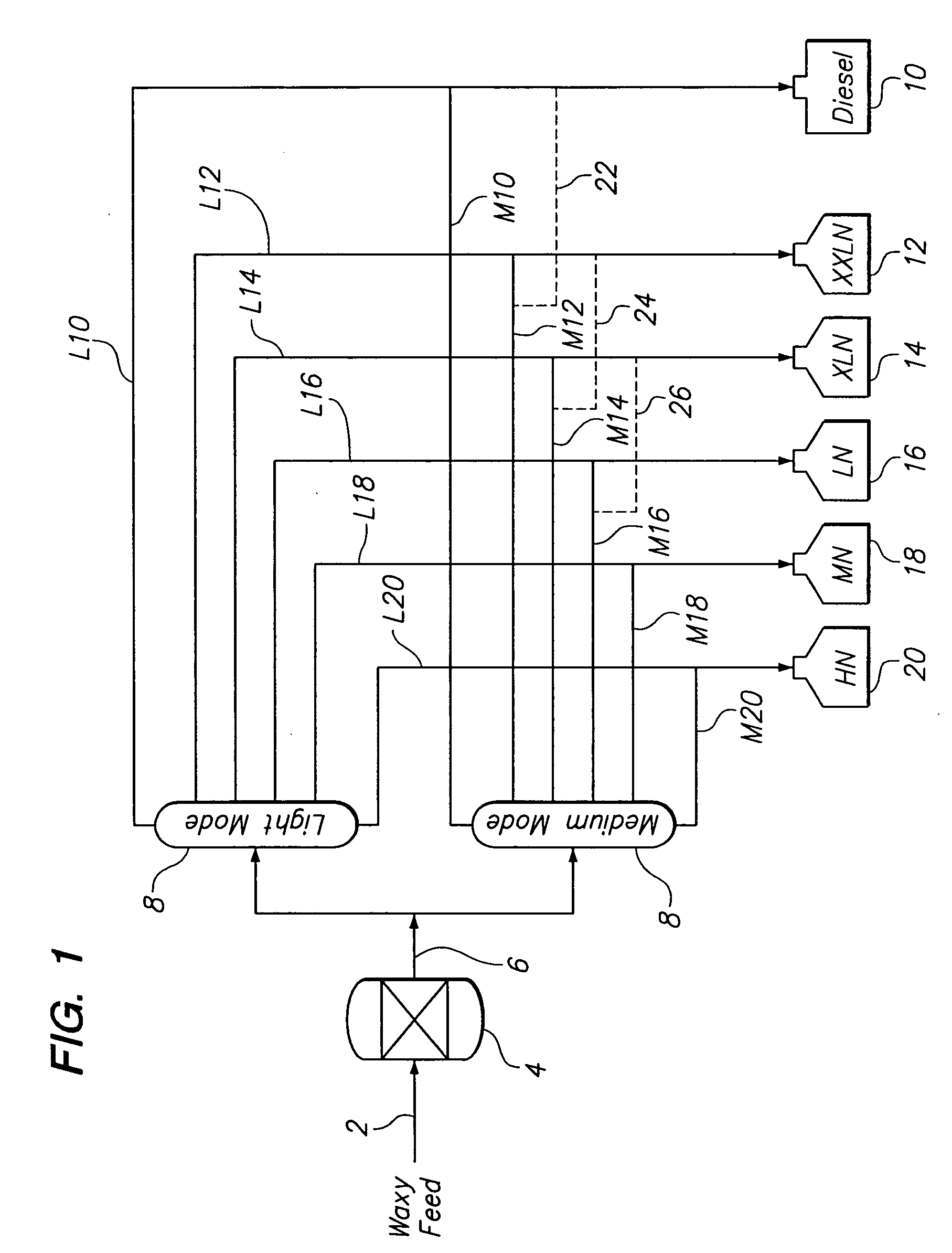

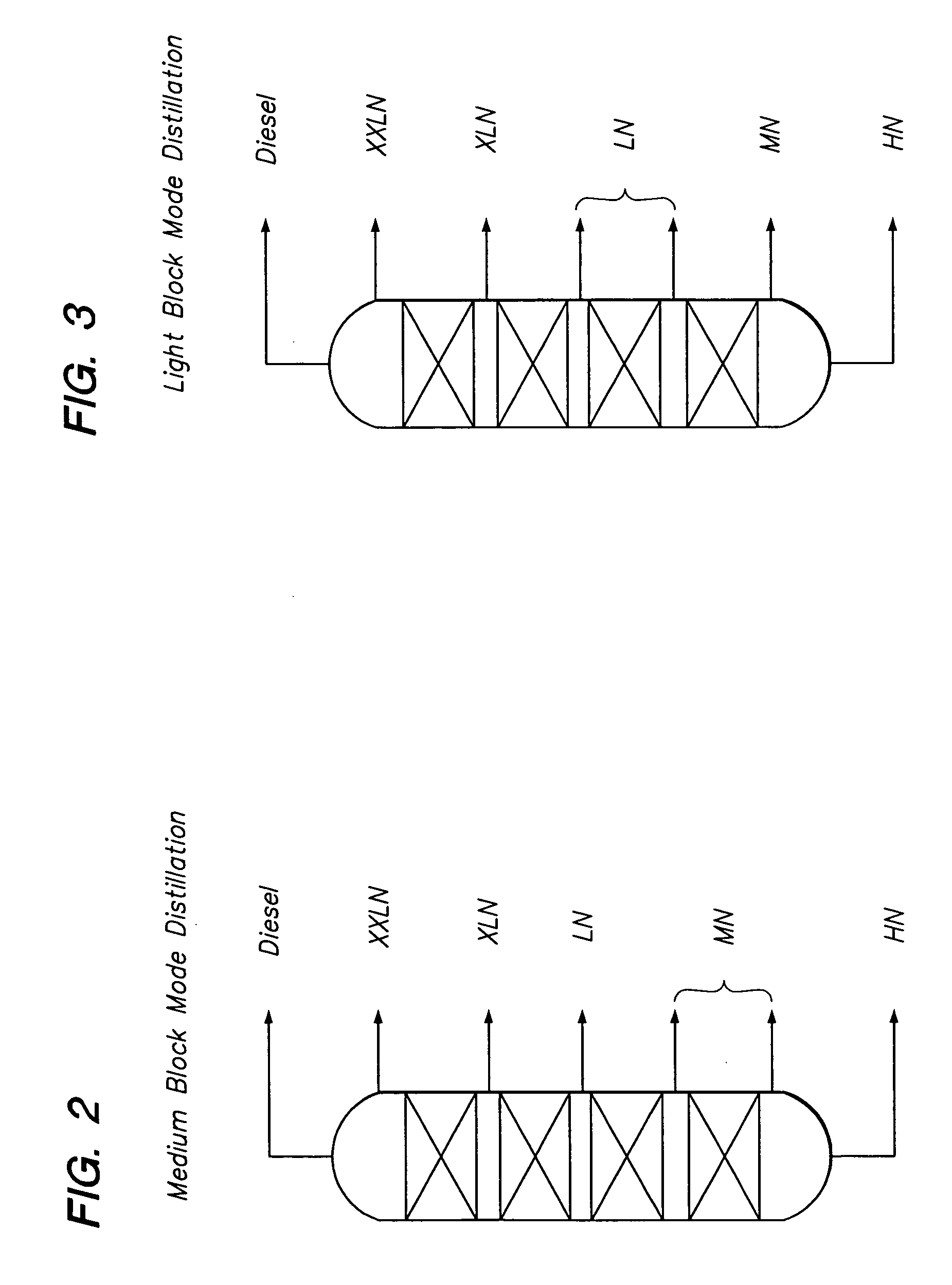

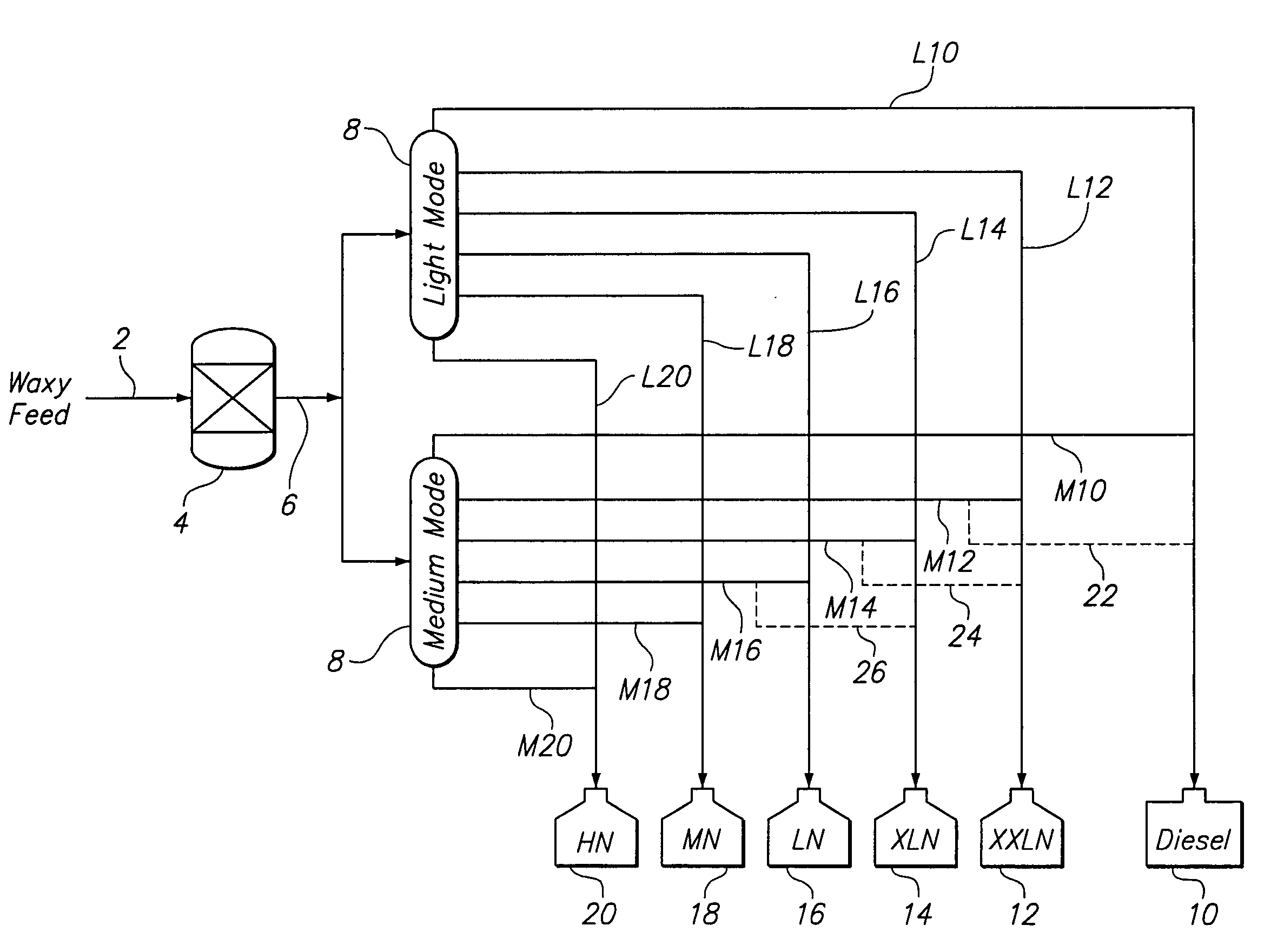

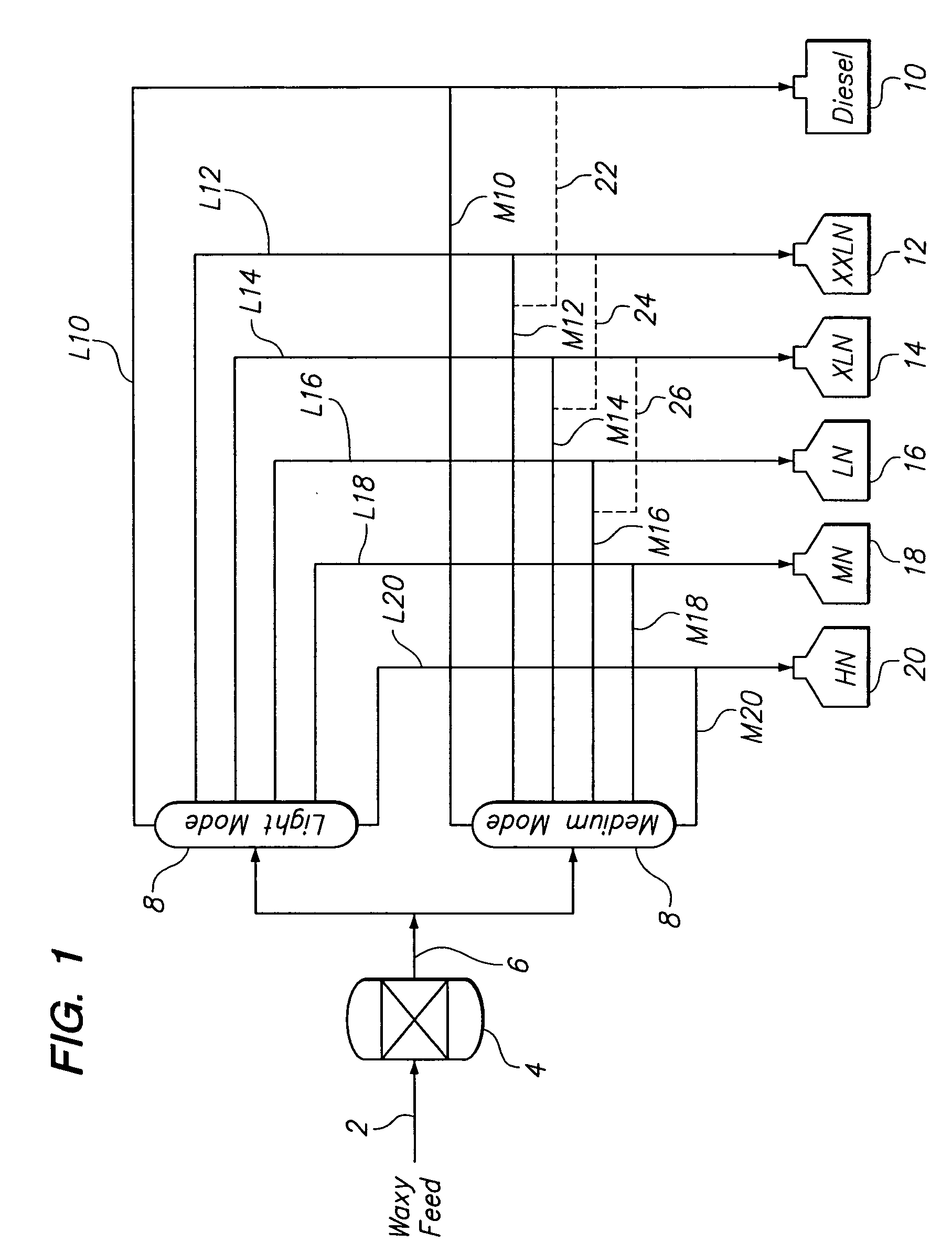

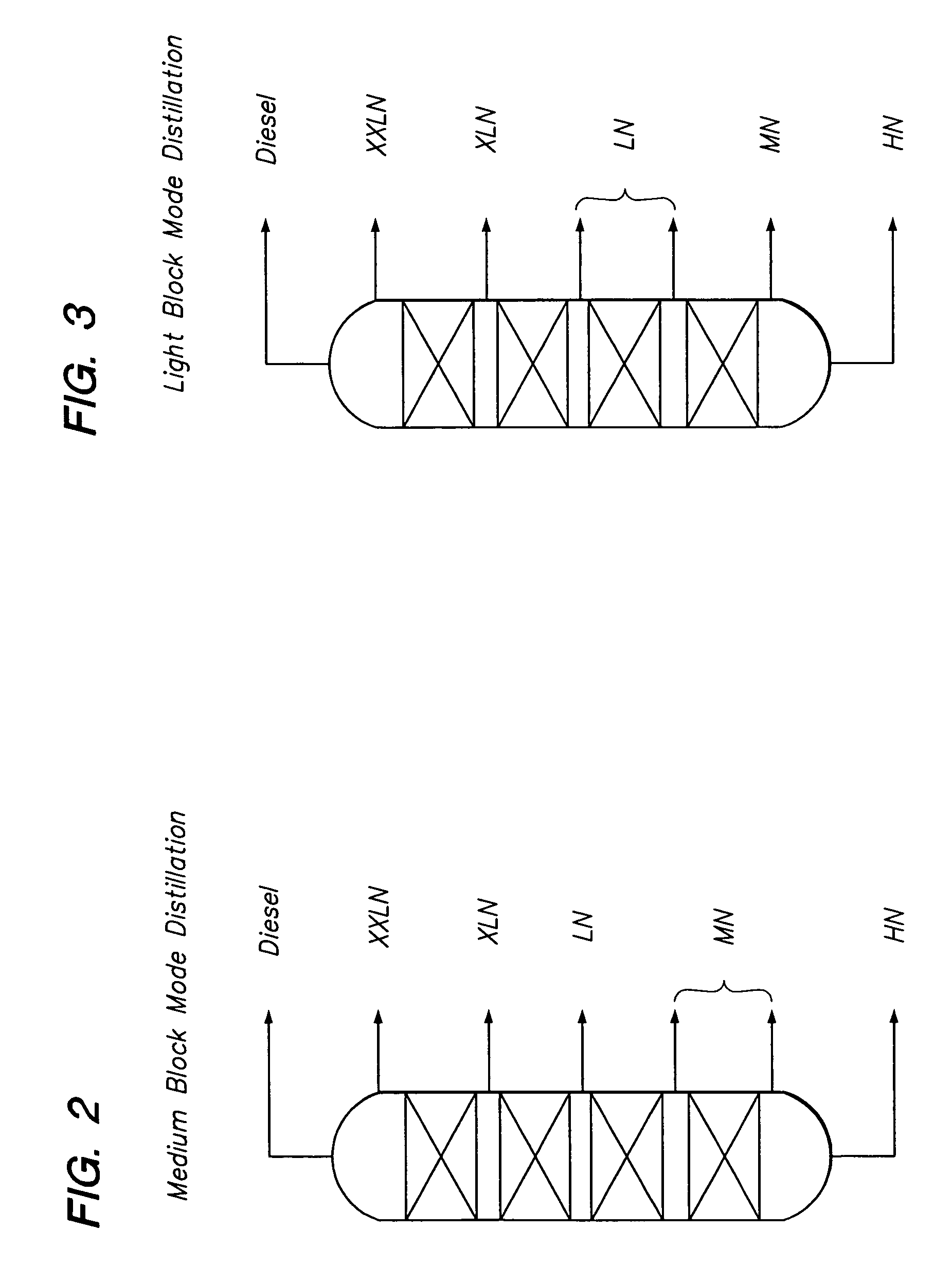

Multiple side draws during distillation in the production of base oil blends from waxy feeds

InactiveUS20060201851A1Refining to change hydrocarbon structural skeletonPetroleum wax refiningIsomerizationDistillation

A process for producing a product slate, which includes at least three base oil grades having kinematic viscosities at 100° C. within the range between about 1.8 cSt and 30 cSt, from a waxy feed having an initial boiling point of about 340° C. or less and a final boiling point of about 560° C. or higher, said process comprising (a) isomerizing at least a portion of the waxy feed, whereby the amount of isoparaffins present are increased; (b) distilling a first portion of the isomerized waxy feed in light block mode operation into at least three base oil fractions having different boiling ranges; (c) distilling a second portion of the isomerized waxy feed in medium block mode operation into at least three base oil fractions having different boiling ranges; and (d) blending at least one base oil fraction produced from light block mode with at least one base oil fraction produced from medium block mode to produce a lubricating base oil blend meeting a target value for at least one pre-selected property.

Owner:CHEVROU USA INC

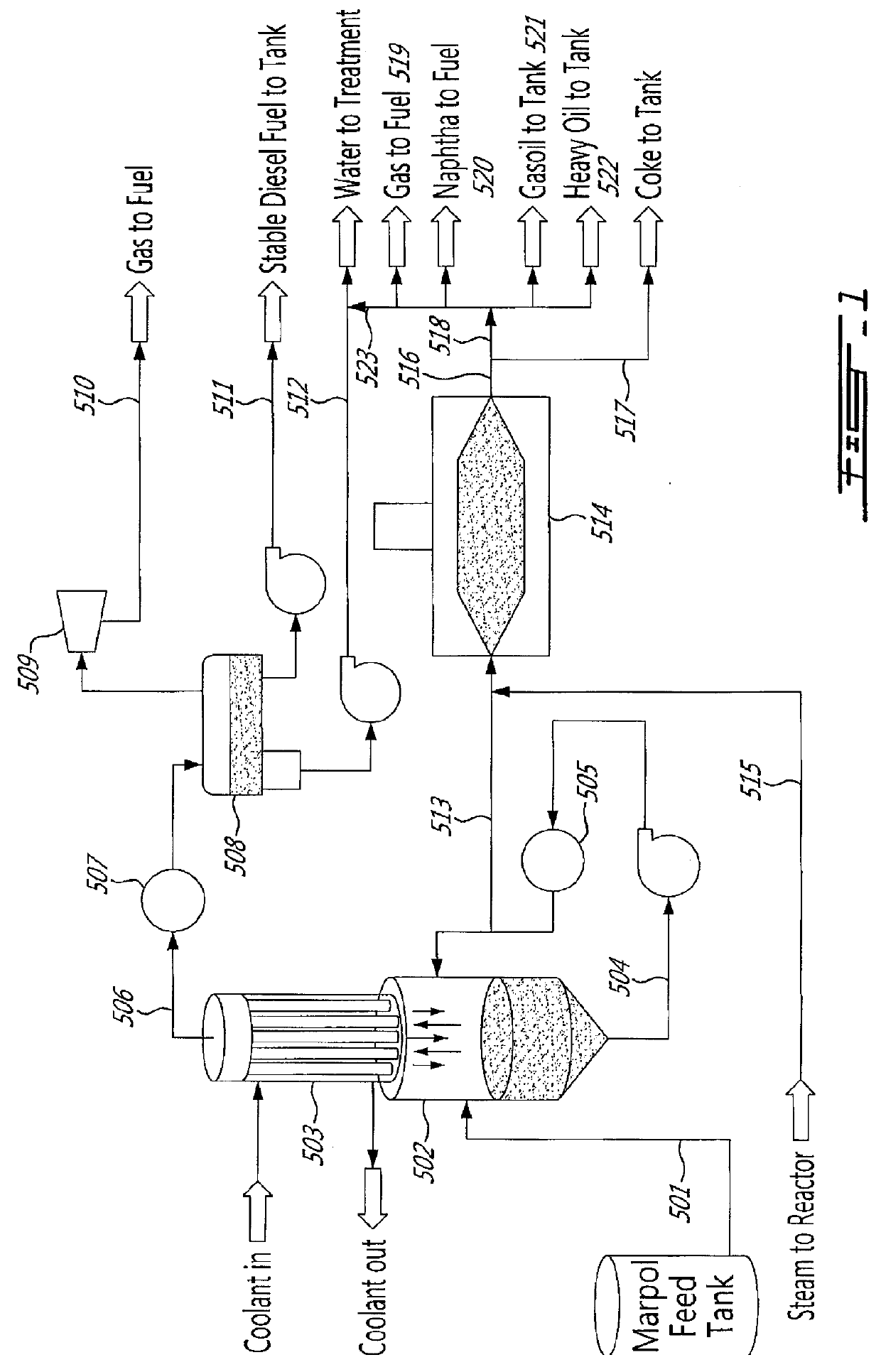

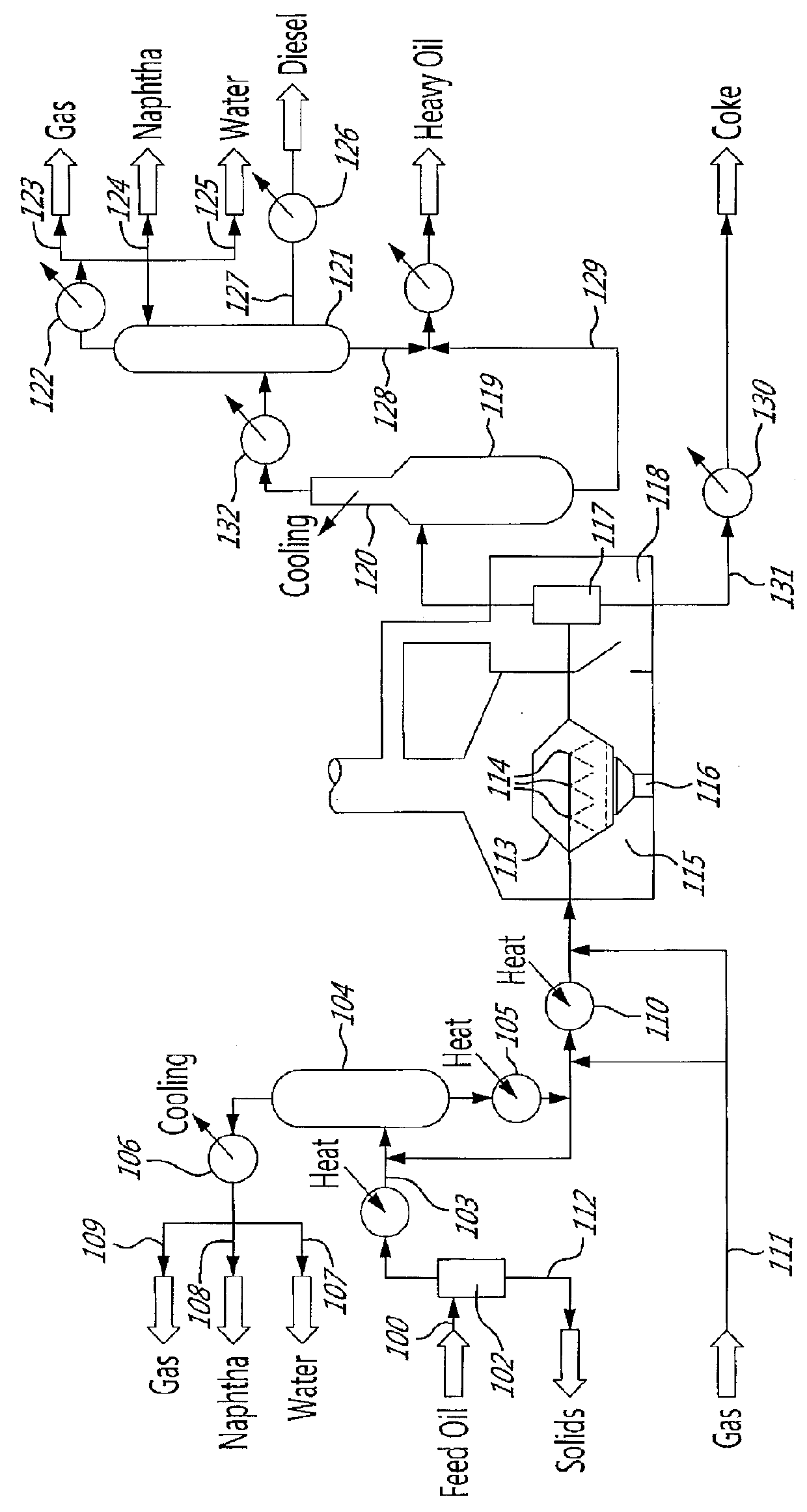

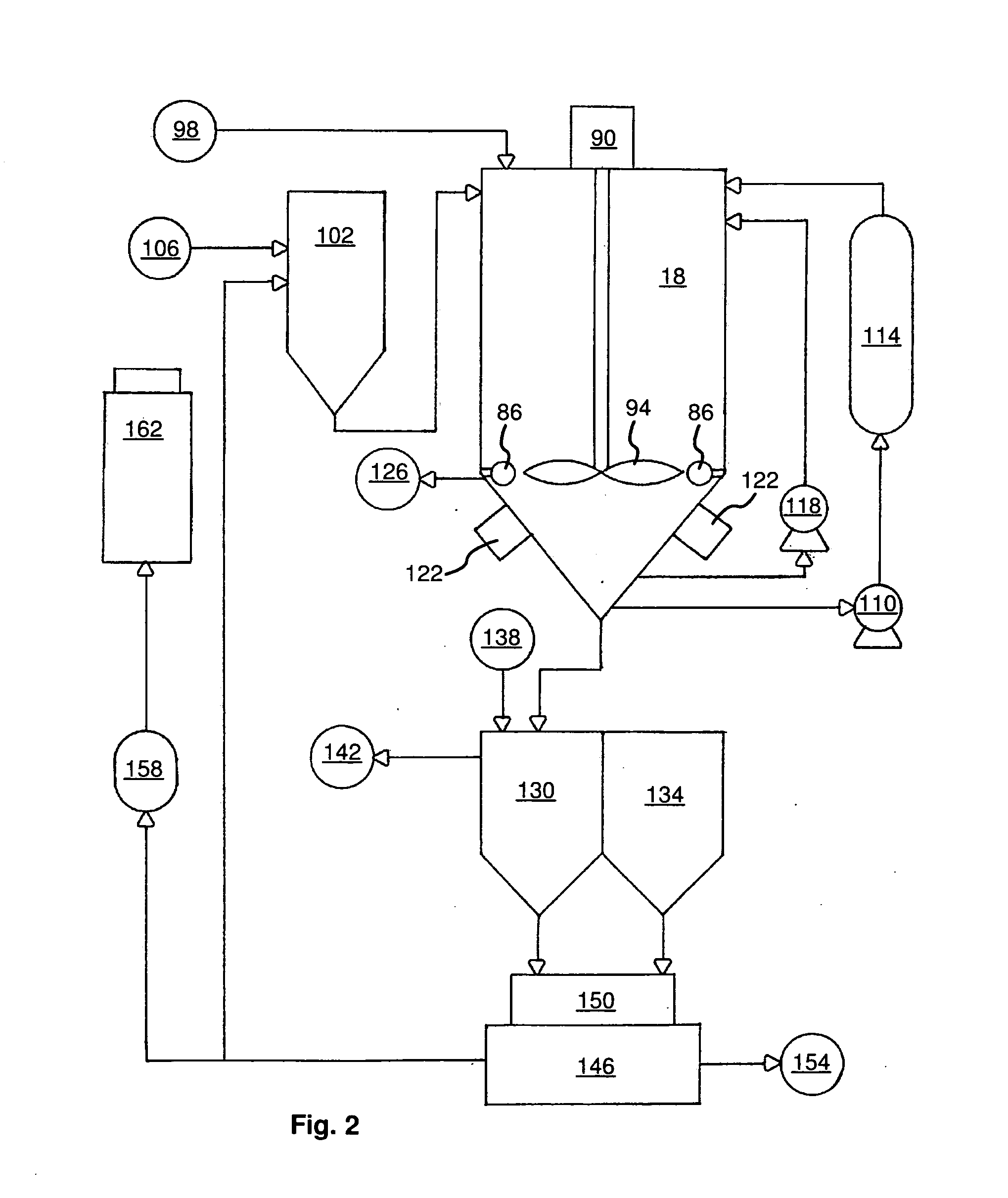

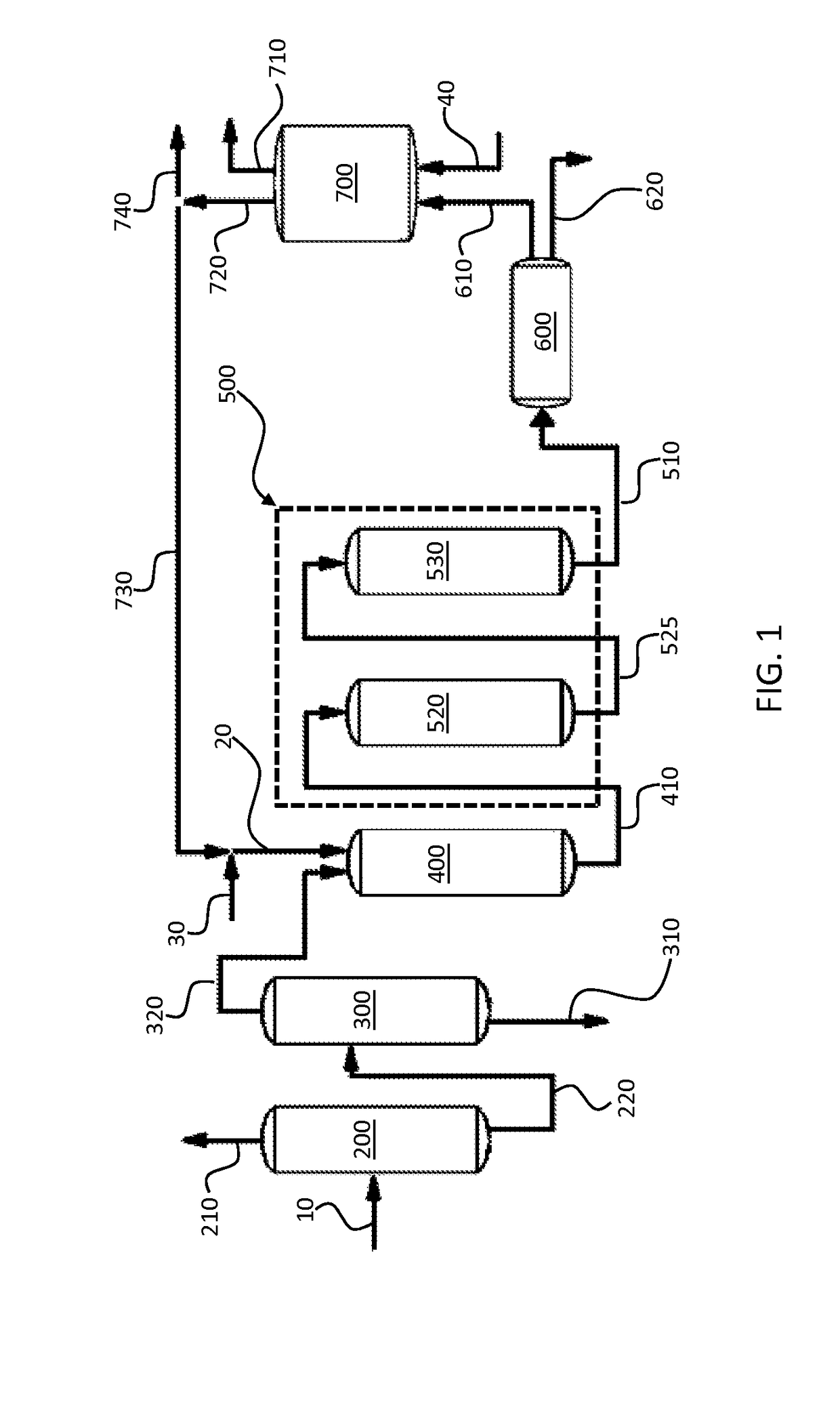

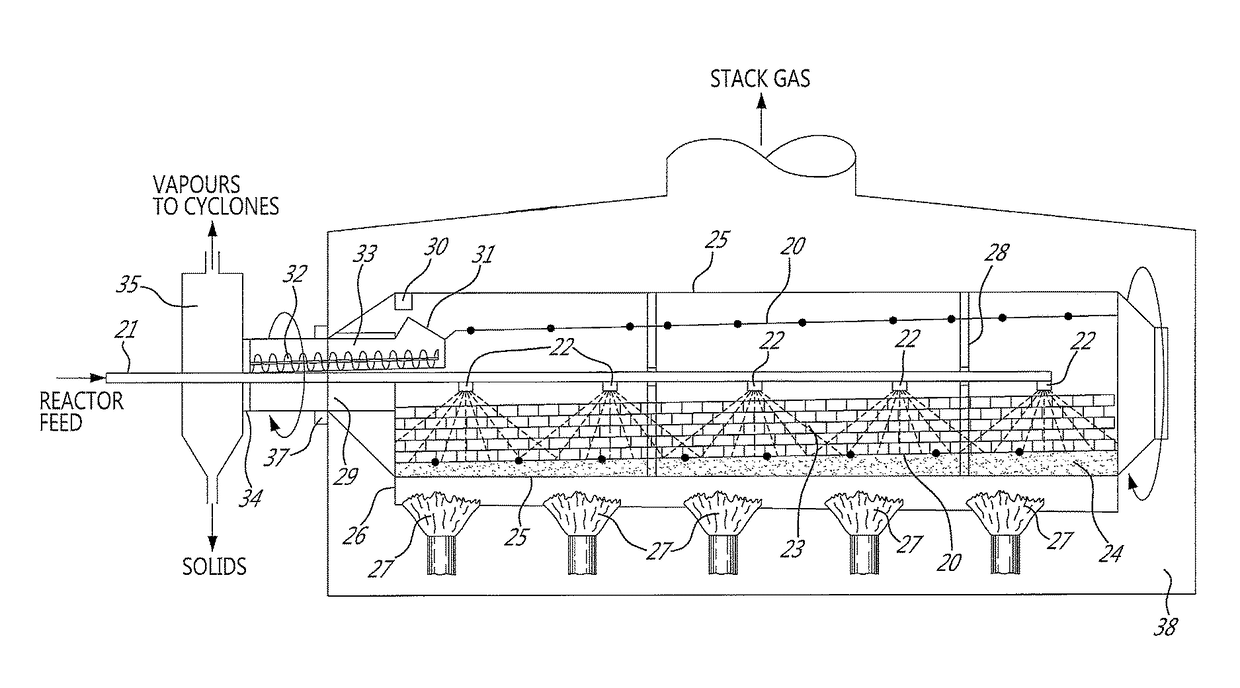

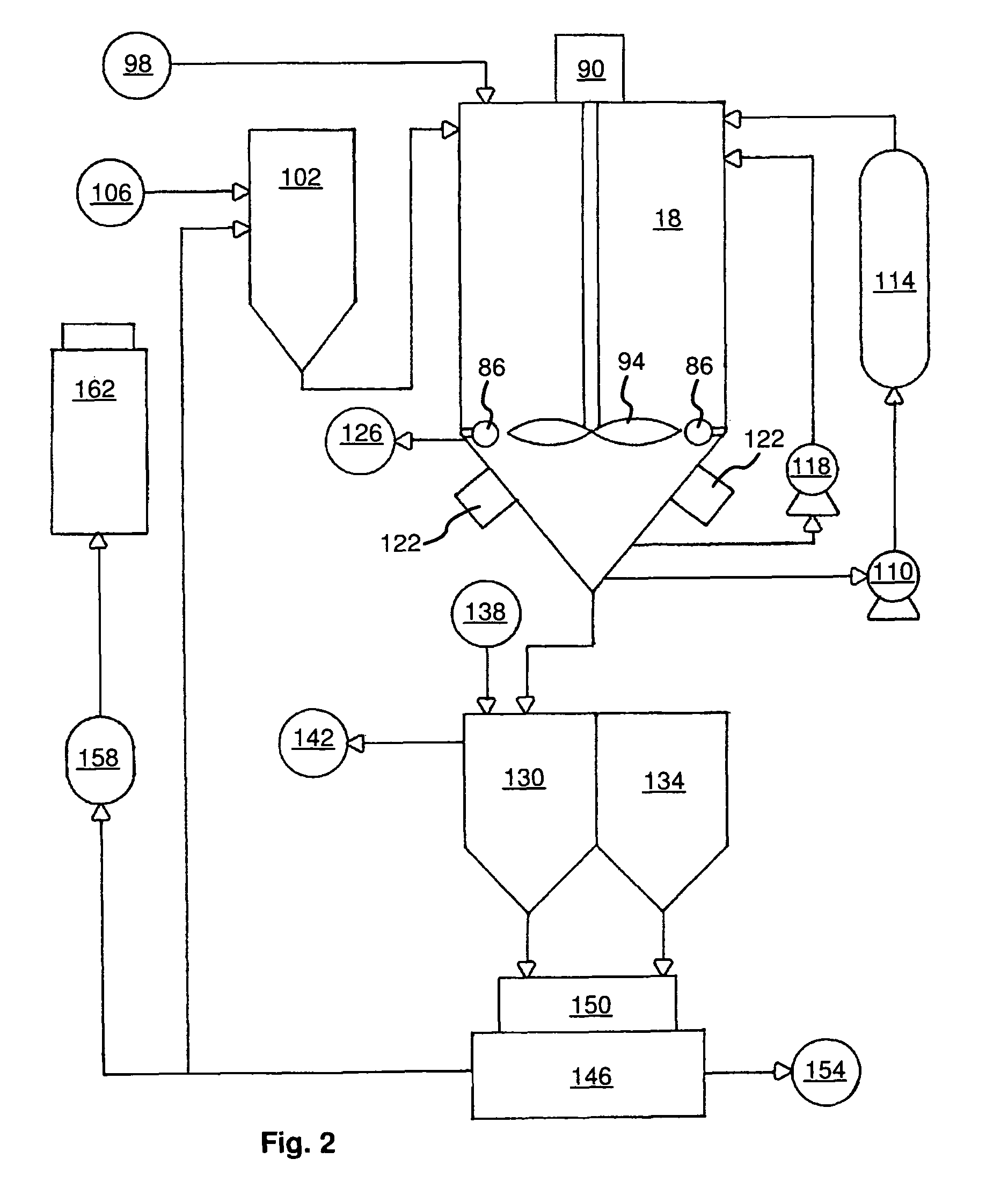

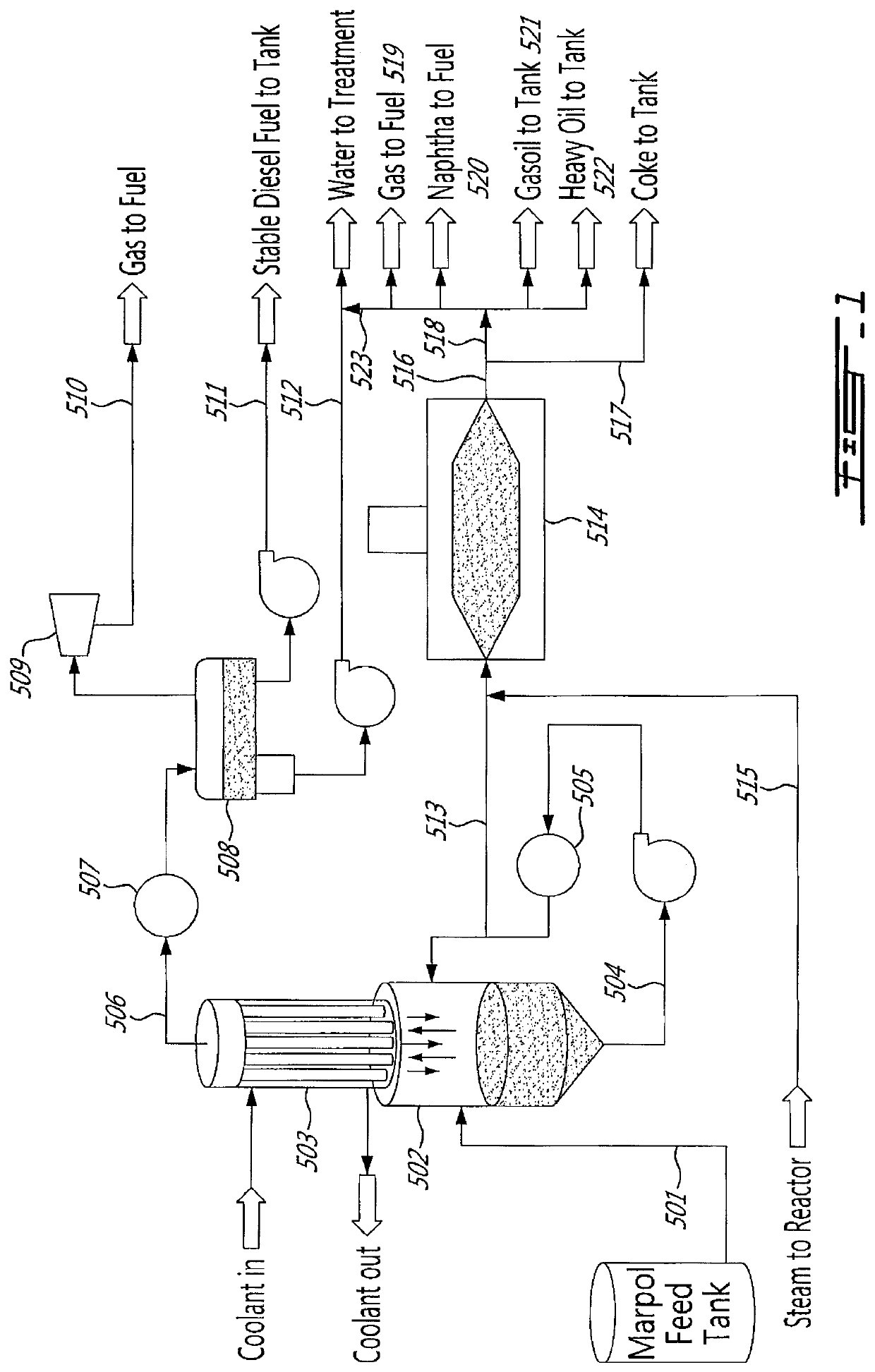

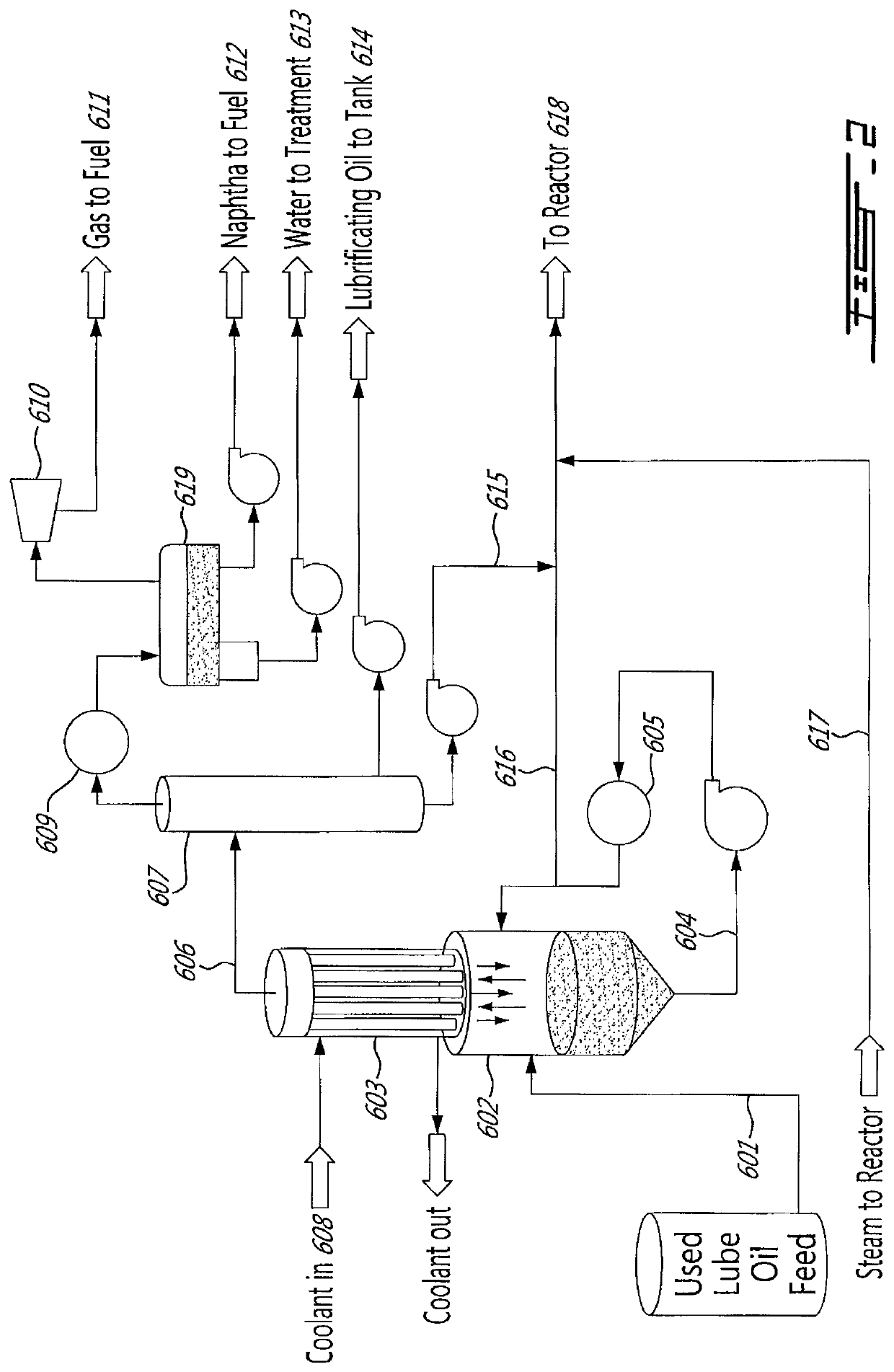

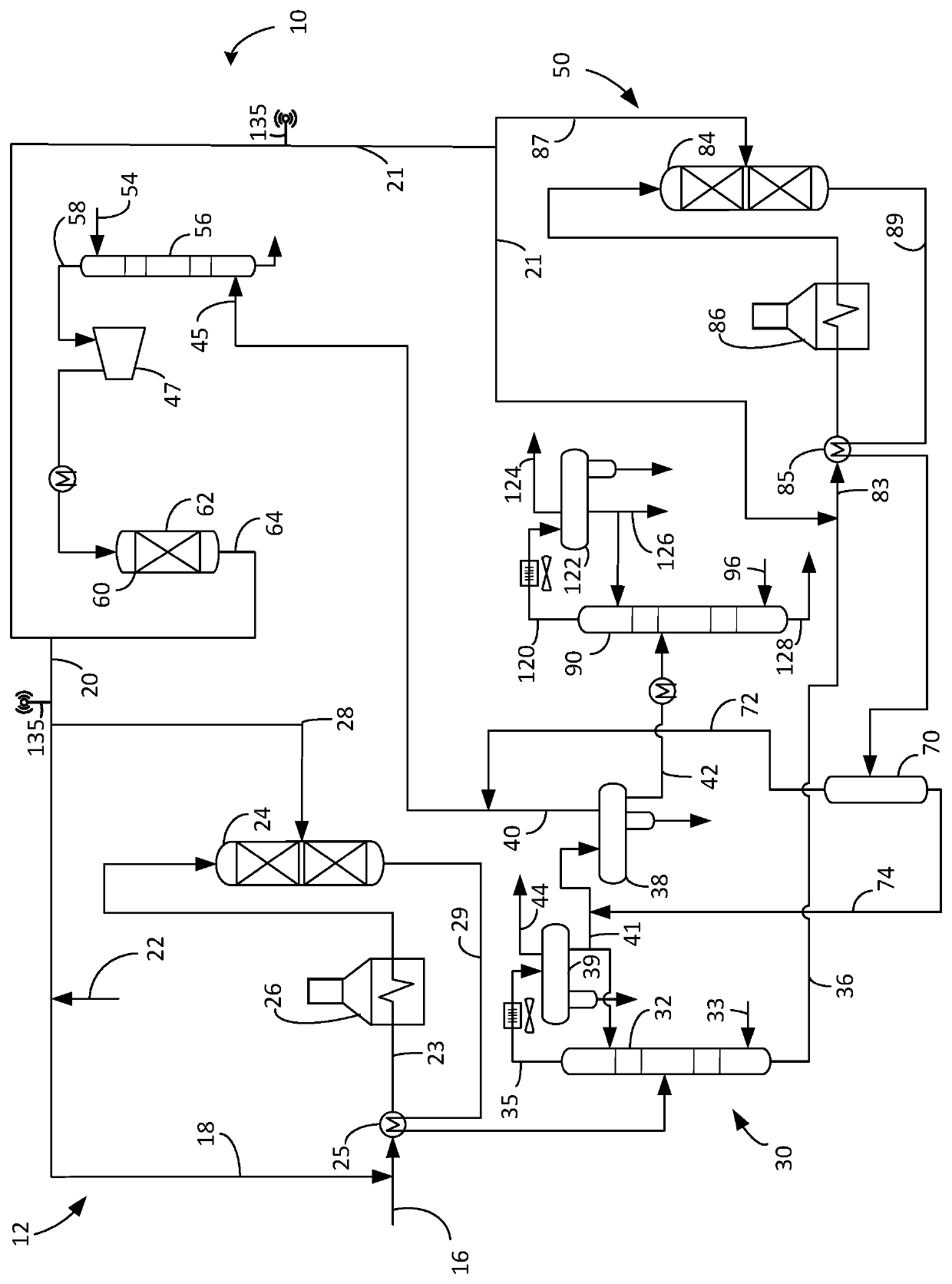

Hybrid thermal process to separate and transform contaminated or uncontaminated hydrocarbon materials into useful products, uses of the process, manufacturing of the corresponding system and plant

ActiveUS20160053184A1Increase volumeReduce contentThermal non-catalytic crackingChemical/physical/physico-chemical reactor detailsChemical compoundWaste oil

Process for reclaiming useful products from a waste oil, comprising a thermal separation step performed in a vessel at conditions, of temperature and pressure, allowing to substantially avoid cracking of the waste oil and to assure the separation of said heated waste oil into a first heavy oil fraction and into a second light oil fraction having, in comparison with the waste oil, a low content in solids and / or in other contaminants that are different from water and from inert gas. The process is further characterized in that while, during the thermal separation treatment, the waste oil is heated to a temperature about the boiling temperature of the heavy oil fraction, and below the cracking temperature of the waste oil, and at a pressure that is preferably below the atmospheric pressure, the heavy oil fraction of the vapours existing the vessel, in contact with a cooler surface, condenses and falls back into the vessel, while the second fraction, in a gaseous state, is eventually submitted to at least one further separation treatment. When water is present in the waste oil, said water is used to improve the amount of recovered light oils; and / or when no water is present in the waste oil, water or at least one inert gas or at least one component that may become an inert gas by heating may be added to the waste oil or to the thermal separation unit. Uses of the process for environmental applications and for treating used oils and to prepare oil products. Systems for reclaiming useful products from waste oils comprising at least one rotating kiln and at least one self-refluxing condenser and / or at least one dephlegmator.

Owner:ENVIROLLEA

Process for upgrading contaminated hydrocarbons

ActiveUS7638040B2Quality improvementThermal non-catalytic crackingCatalytic crackingSolventContamination

A process for the recovery and purification of a contaminated hydrocarbons, wherein the contamination includes metals, finely divided solids and non-distillable components. The process further includes hydroprocessing the oil to remove deleterious compounds, to produce high quality reusable lubricants, solvents and fuels and to improve the quality of water byproduct.

Owner:UOP LLC

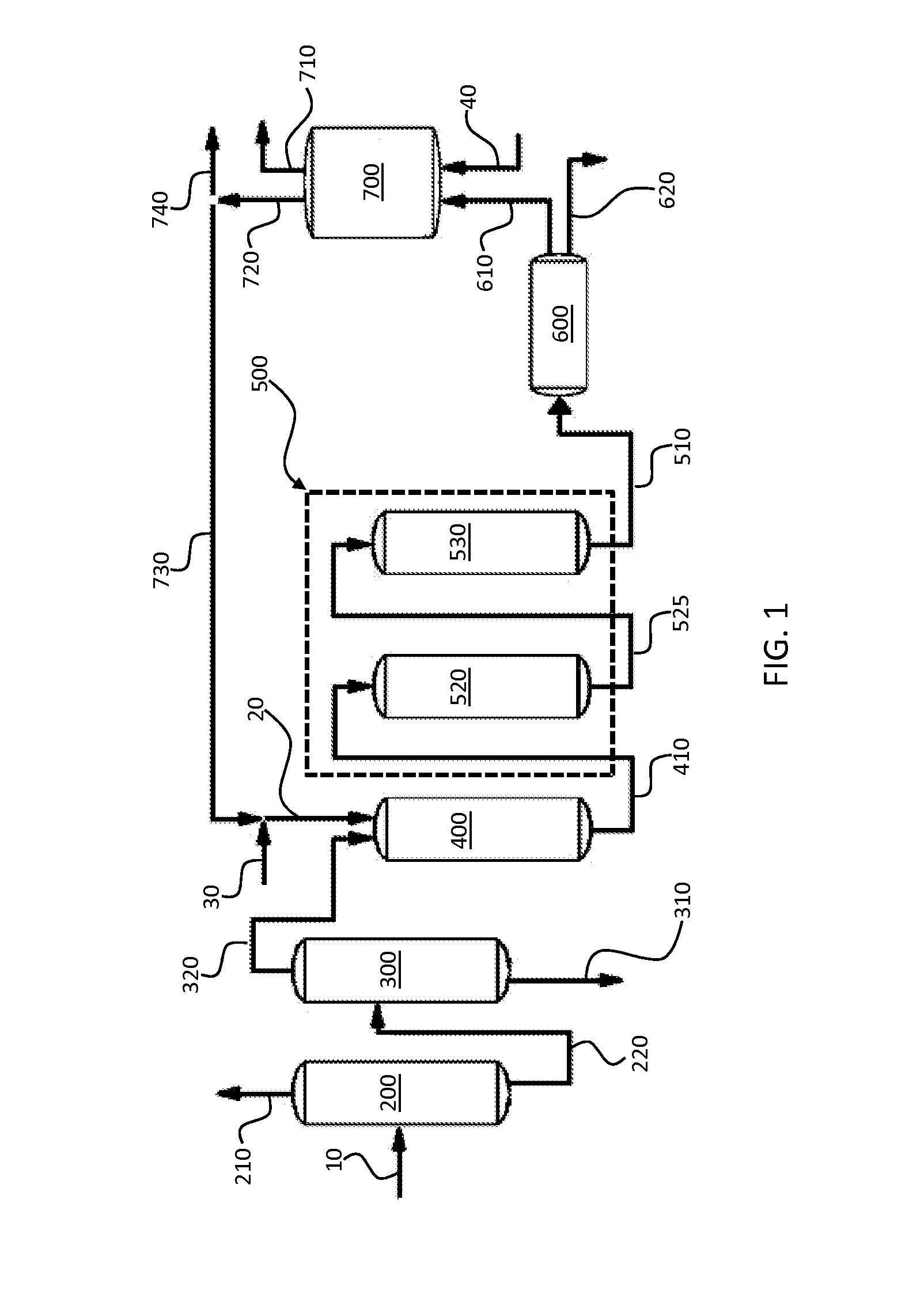

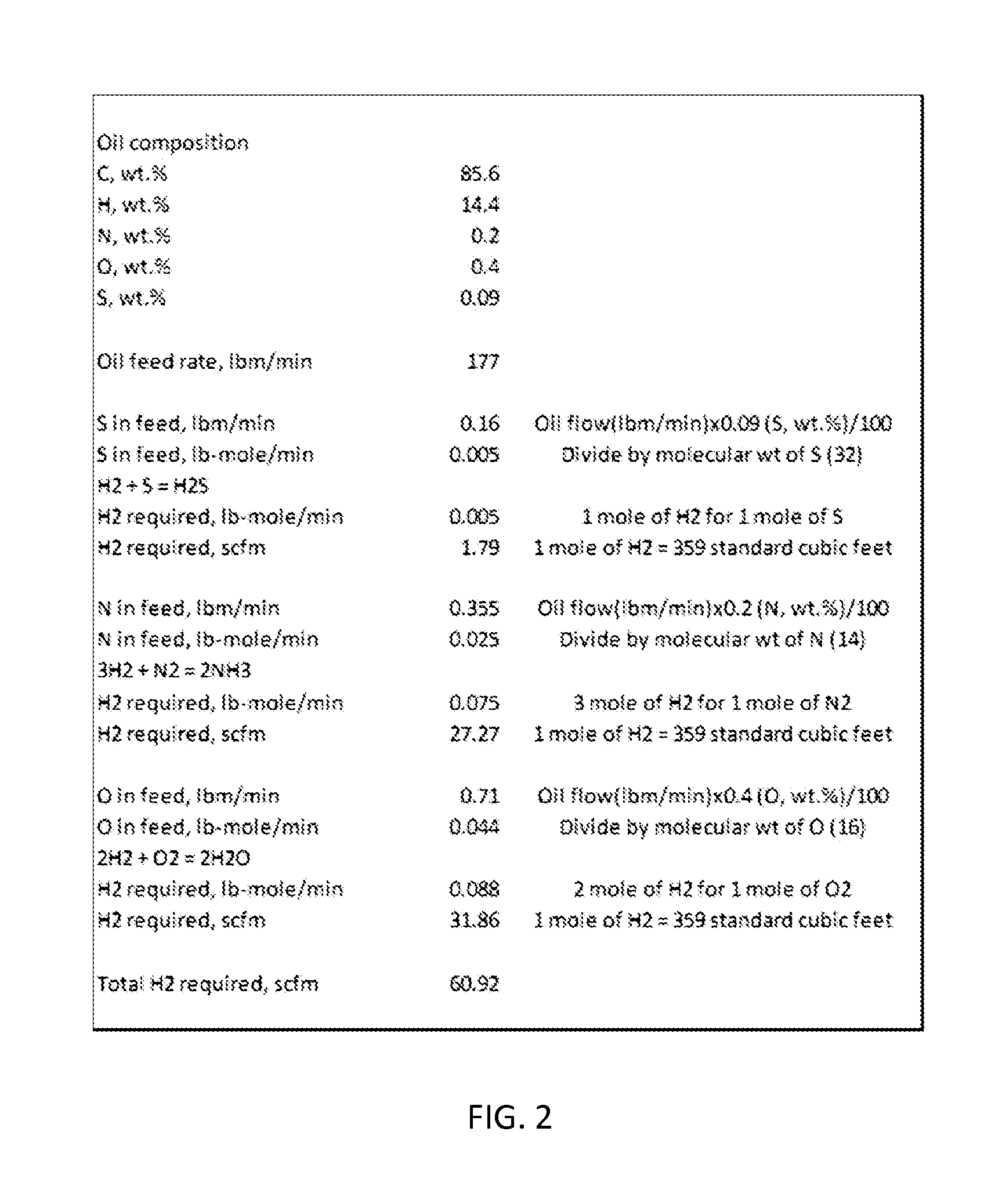

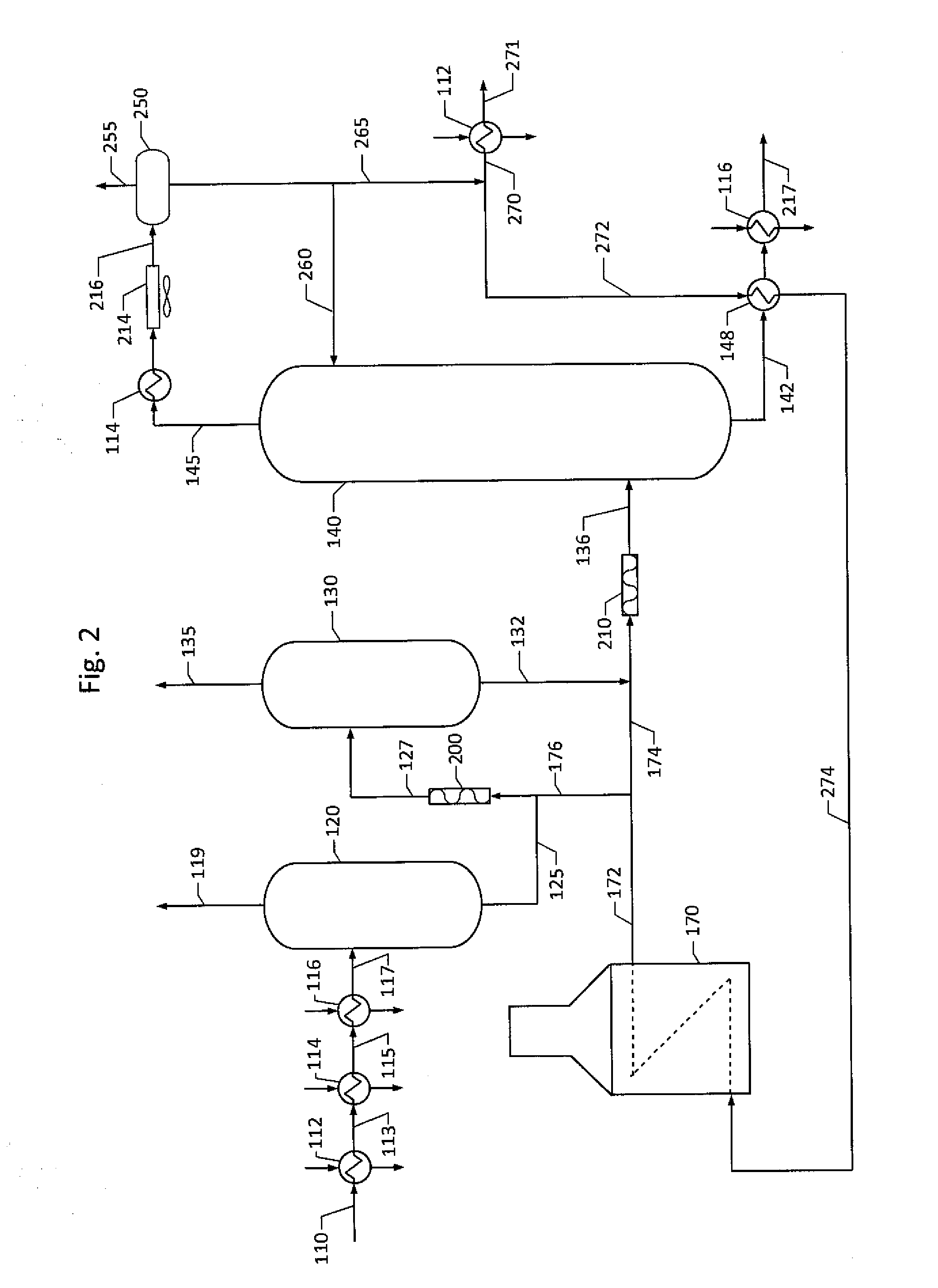

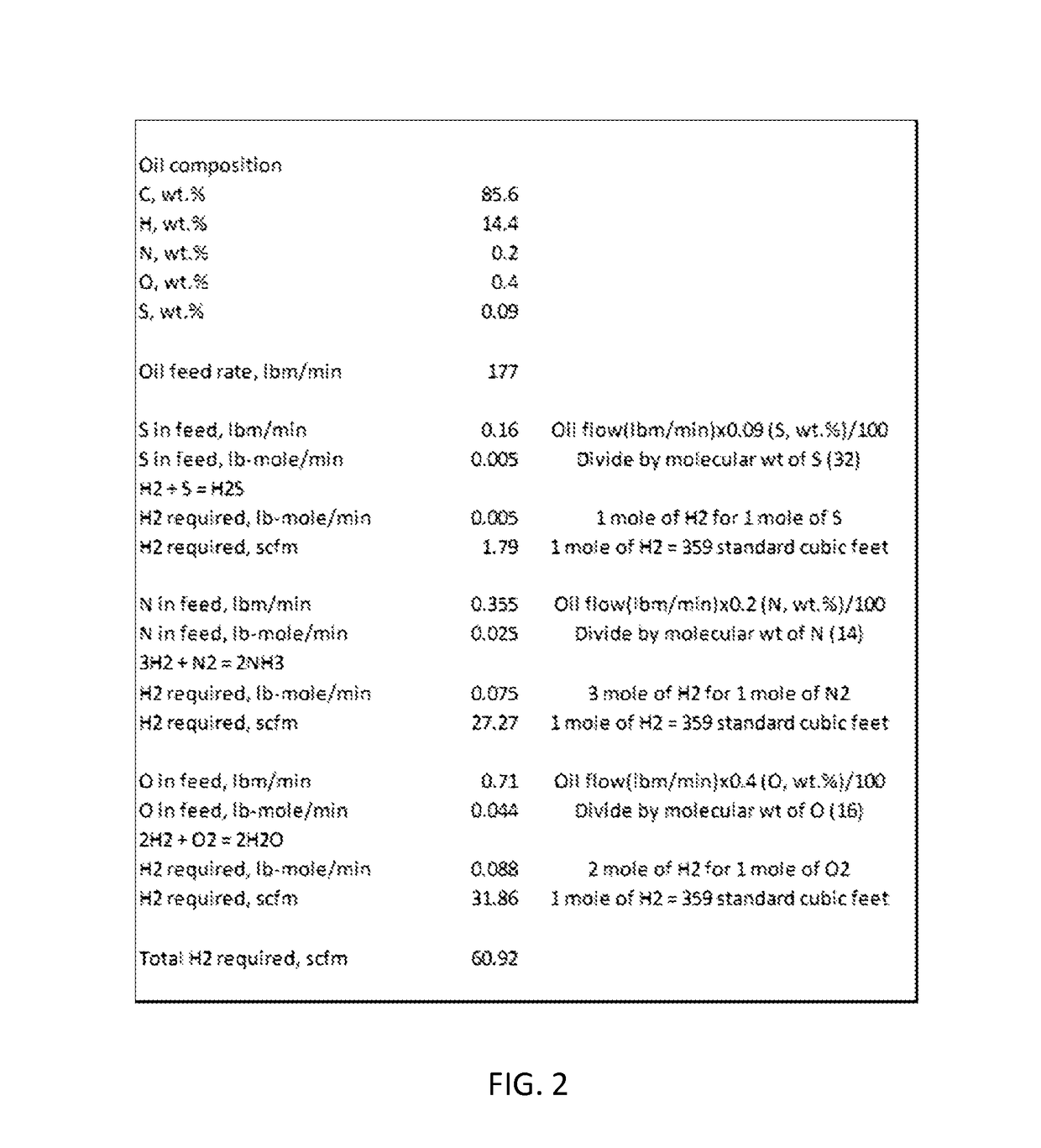

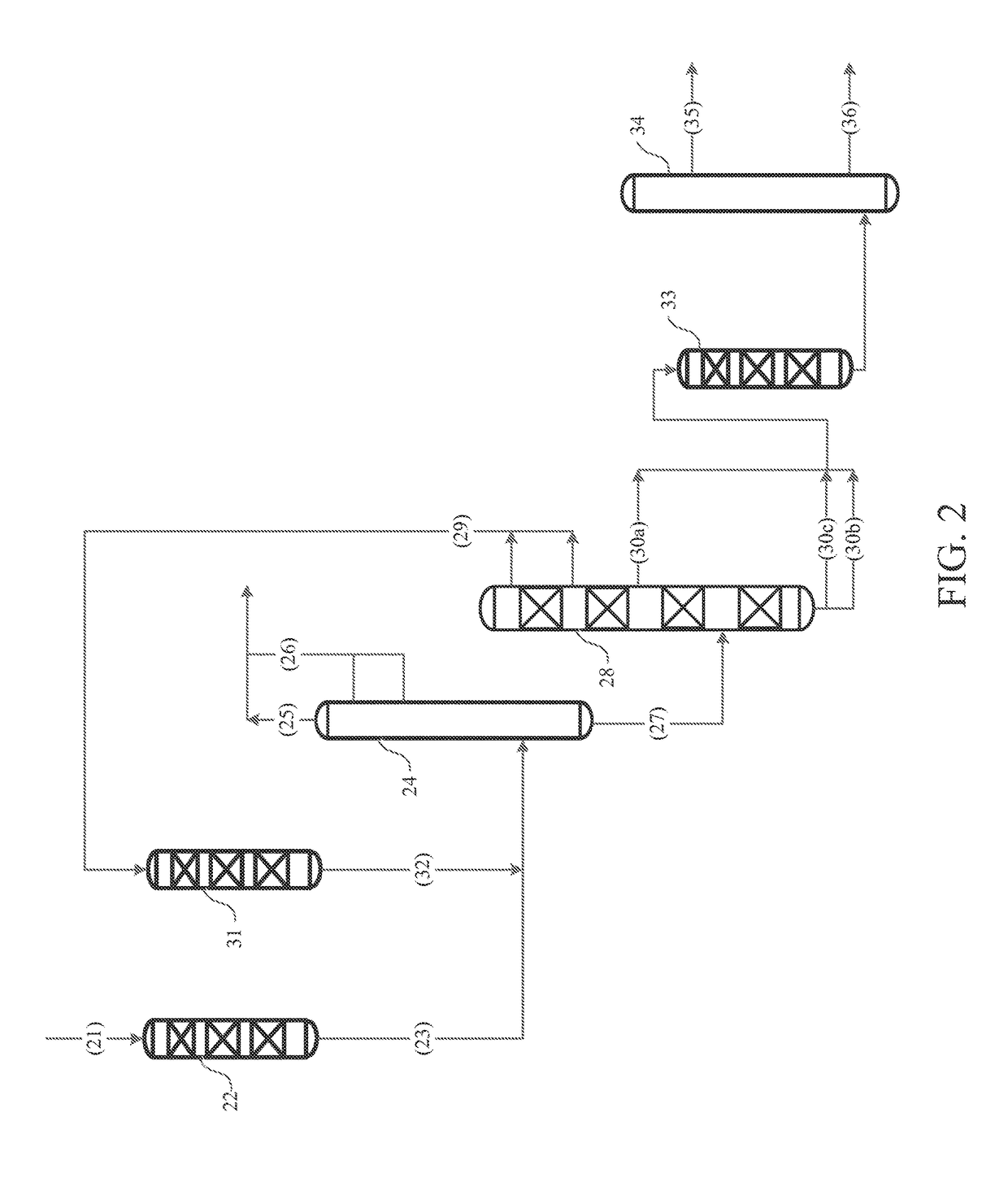

Refining used motor oil through successive hydrotreating processes

ActiveUS20150361356A1Economical efficiency can be improvedAvoid accumulationTreatment with hydrotreatment processesLubricating oils distillationHydrogenGasoline

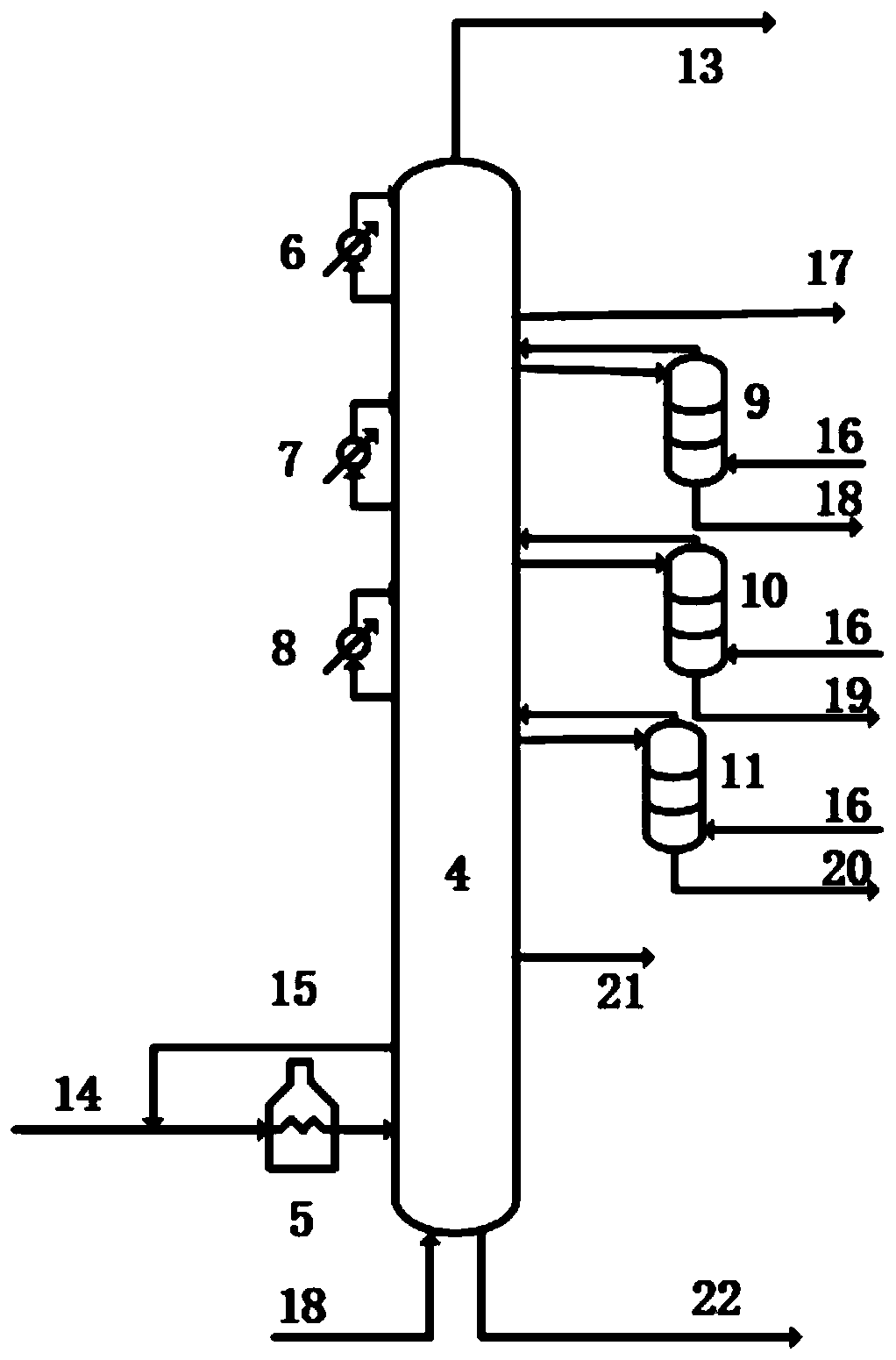

A method for refining used motor oil using two or more hydrotreating reactors arranged in series. The used motor oil may be vacuum distilled to produce an unrefined gasoil. The unrefined gasoil may then be hydrotreated in a first hydrotreating reactor with hydrogen operated at a temperature ranging from approximately 245° C. to approximately 260° C. to produce a hydrotreated gasoil. The hydrogen may comprise a mixture of fresh hydrogen and recycled hydrogen recovered from the last of the two or more hydrotreating reactors. The hydrotreated gasoil may then be hydrotreated in one or more additional hydrotreating reactors operated at temperatures ranging from approximately 260° C. to approximately 330° C. to produce a refined gasoil. The first hydrotreating reactor may remove a substantial portion of metallic impurities from the unrefined impurities, while the one or more additional hydrotreating reactors remove a substantial portion of heteroatom impurities from the unrefined gasoil.

Owner:AIR PROD & CHEM INC

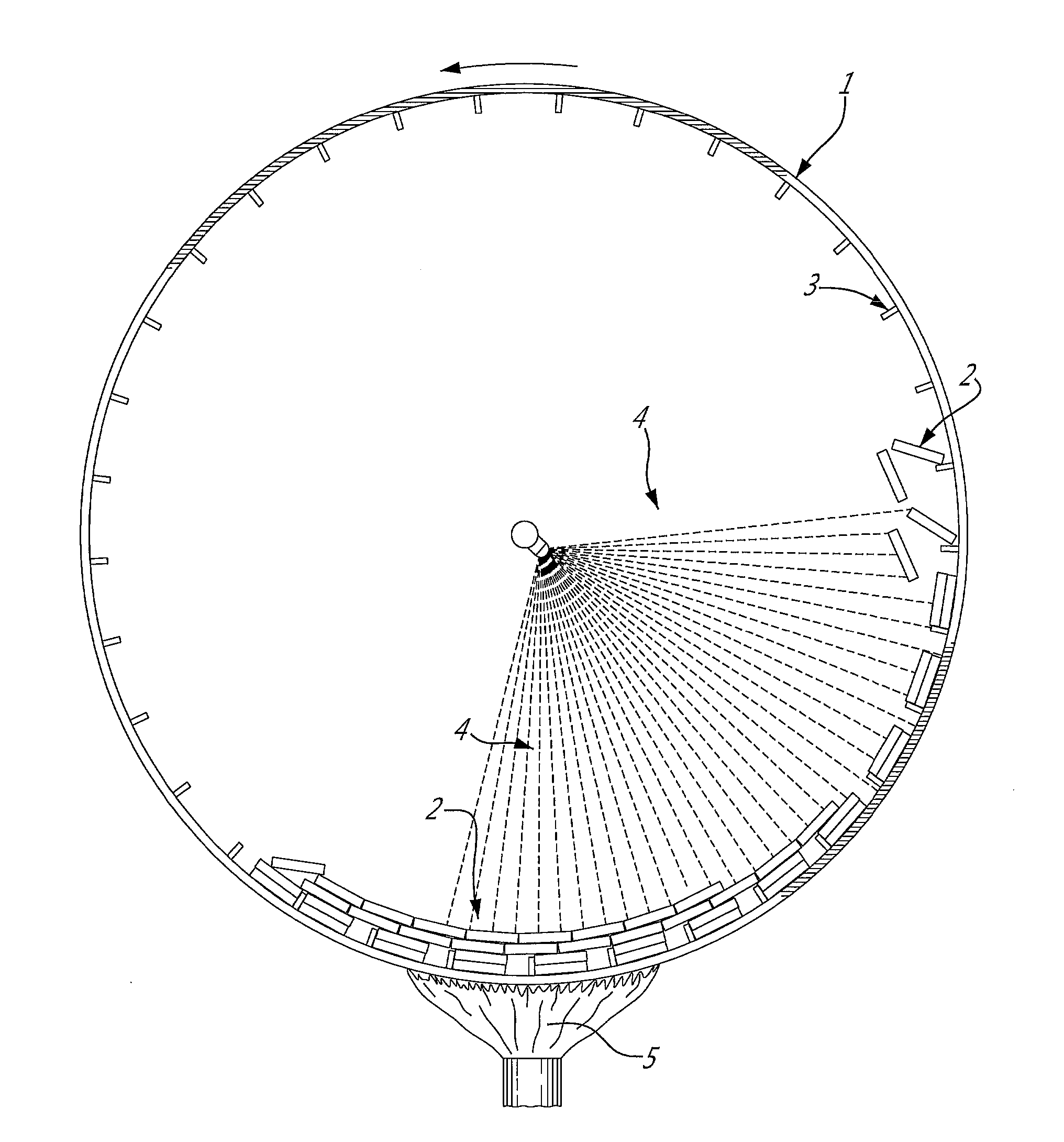

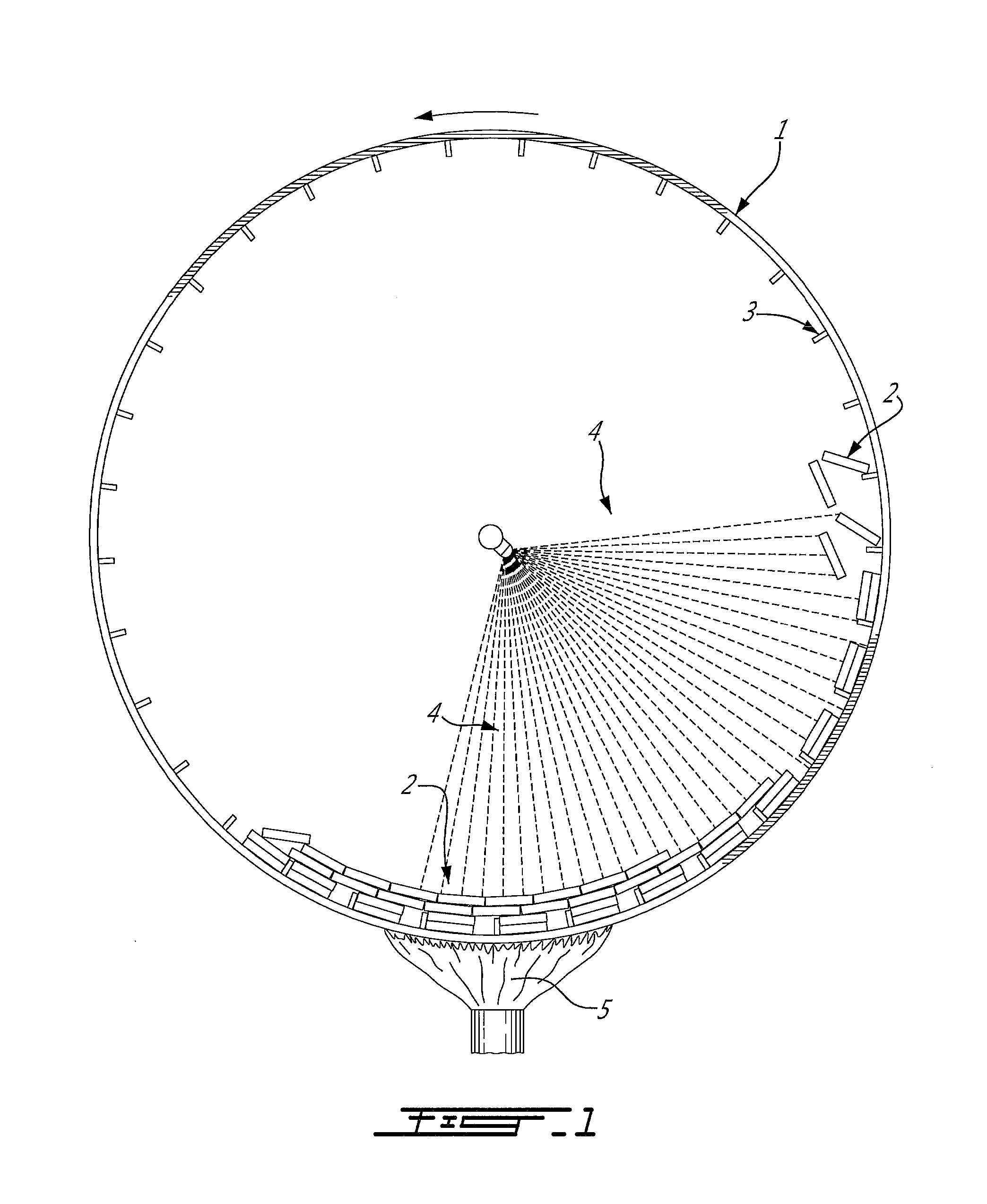

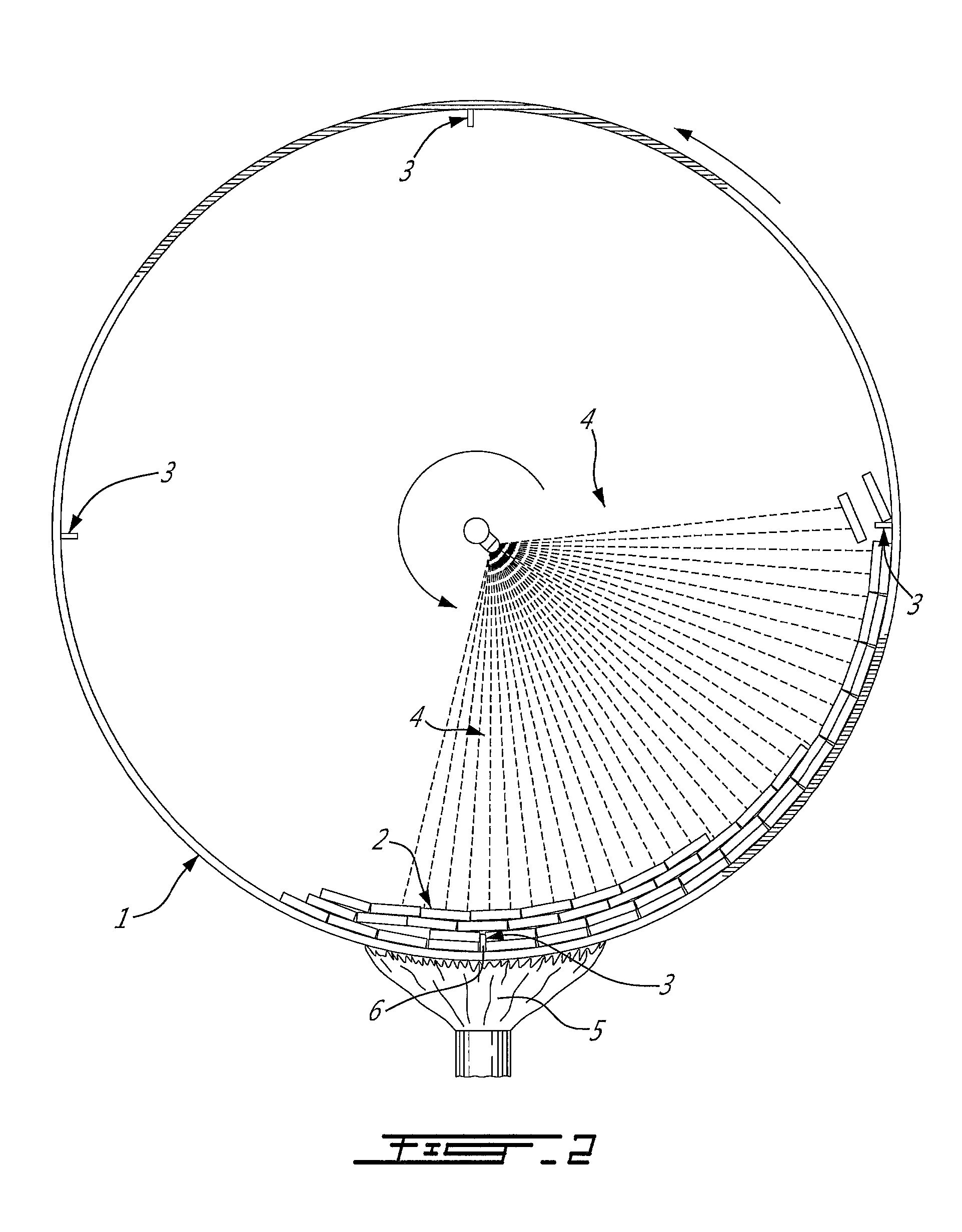

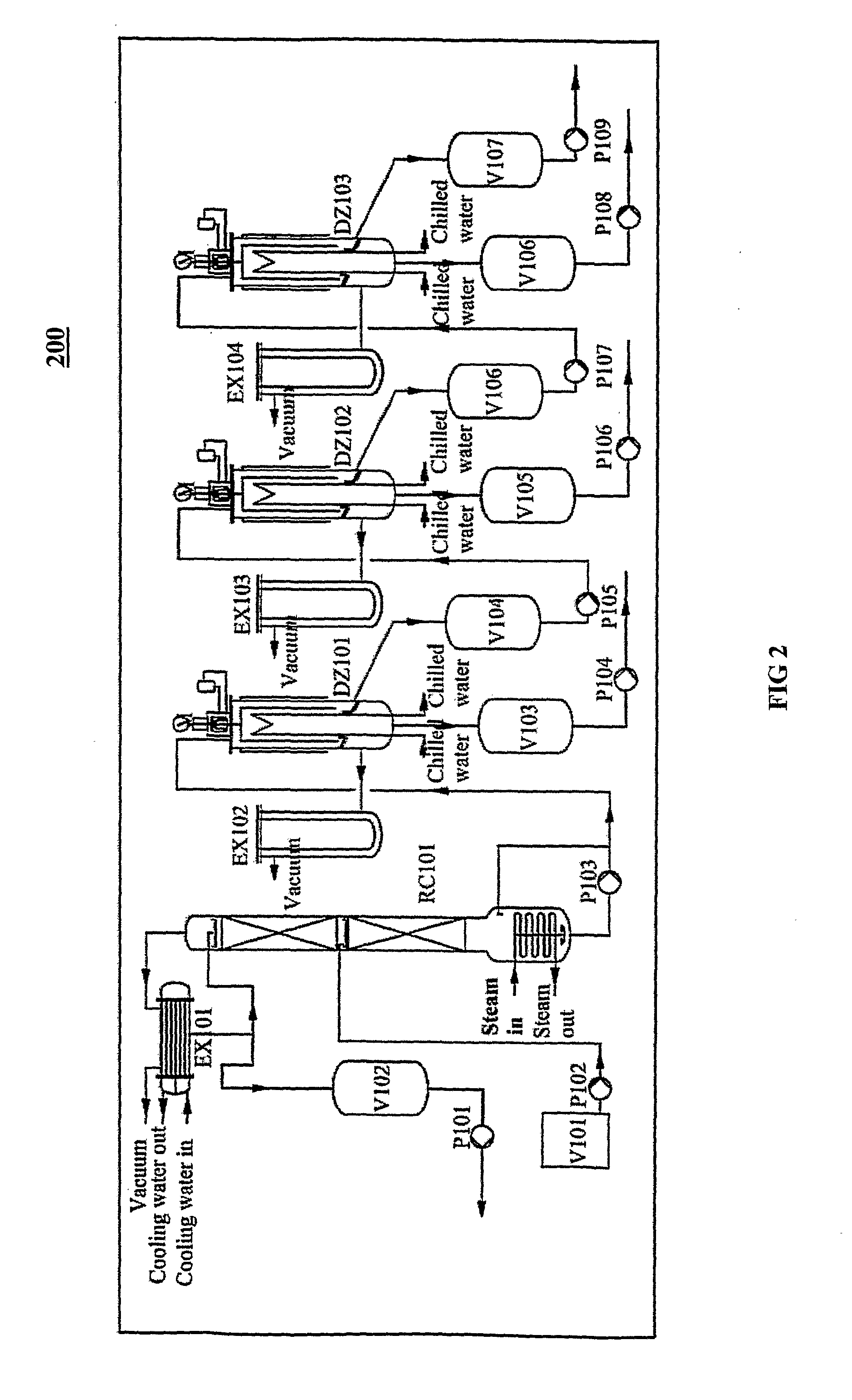

Distillation apparatus and method of use

ActiveUS20080173531A1Improve efficiencySuccessfully and easily distillVacuum distillation separationLubricating oils distillationQuality levelDistillation

A method and apparatus is provided for distilling and processing chemicals. The apparatus is particularly suited for processing and distilling difficult to distill compounds, and is capable of producing diesel fuel and other products from used oil at a quality level similar to that of products produced from virgin crude oil.

Owner:BARKER COURT R

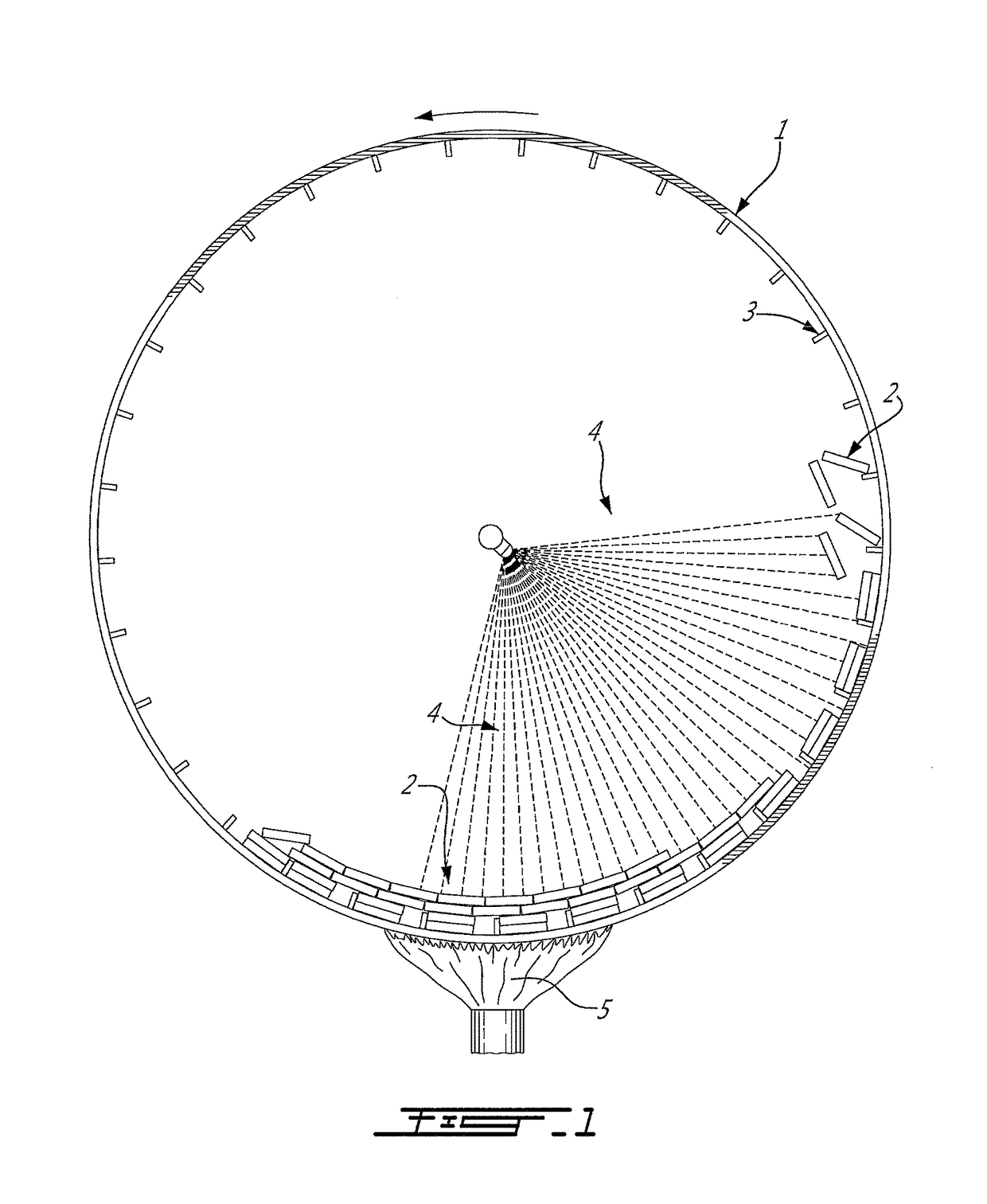

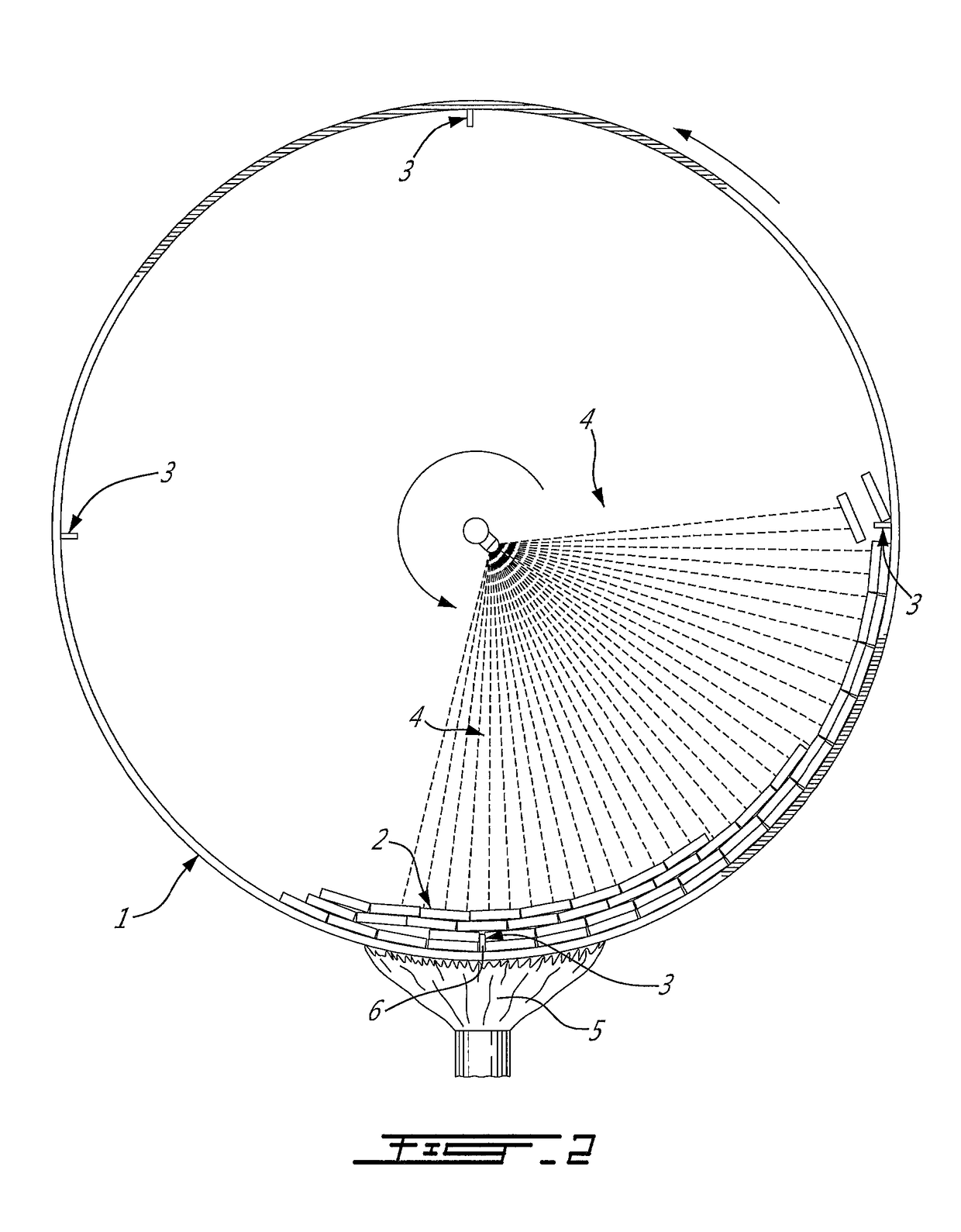

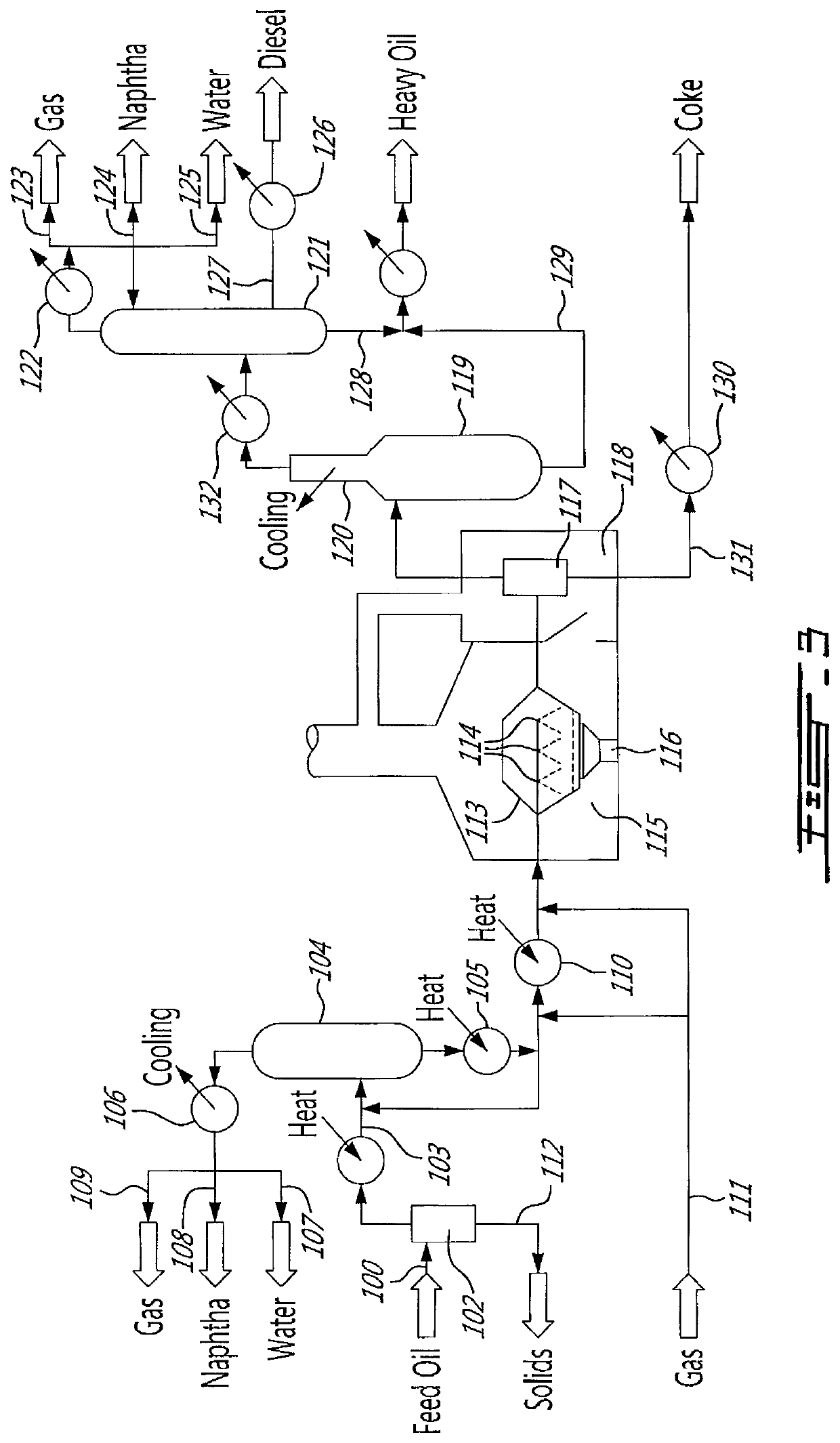

Thermal process to transform contaminated or uncontaminated feed materials into useful oily products, uses of the process, products thereby obtained and uses thereof, manufacturing of the corresponding plant

ActiveUS20150368567A1Thermal non-catalytic crackingDirect heating destructive distillationControl systemReactive gas

The process is for thermally treating a feed material. The process comprises at least one step performed in a rotating kiln operating under positive pressure with a pressure control system and wherein in the process a sweep gas, that is an inert gas or a substantially non-reactive gas, is injected into the rotating kiln or in the feed stream entering the rotating operating kiln; or at least one step performed in a rotating kiln operating under positive pressure managing system; or at least one step performed in a rotating kiln wherein a sweep gas is injected in the rotating kiln or in the feed stream entering the rotating operating kiln. In step a), or in b) or in step c), the conditions of the thermal treatment are managed in order that the exit stream, after cooling, result in at least one liquid phase that is preferably essentially an oily liquid phase.

Owner:ENVIROLLEA

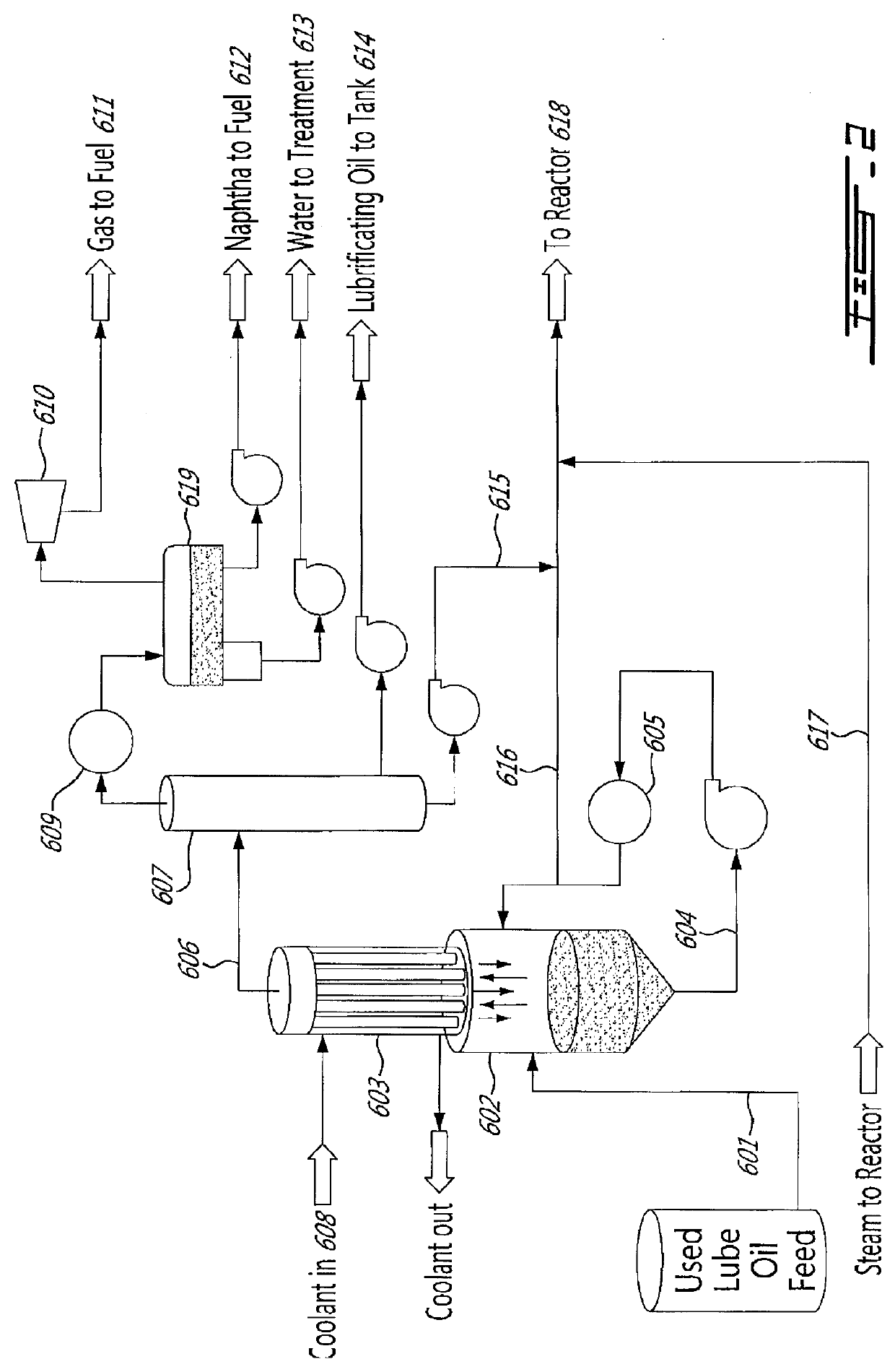

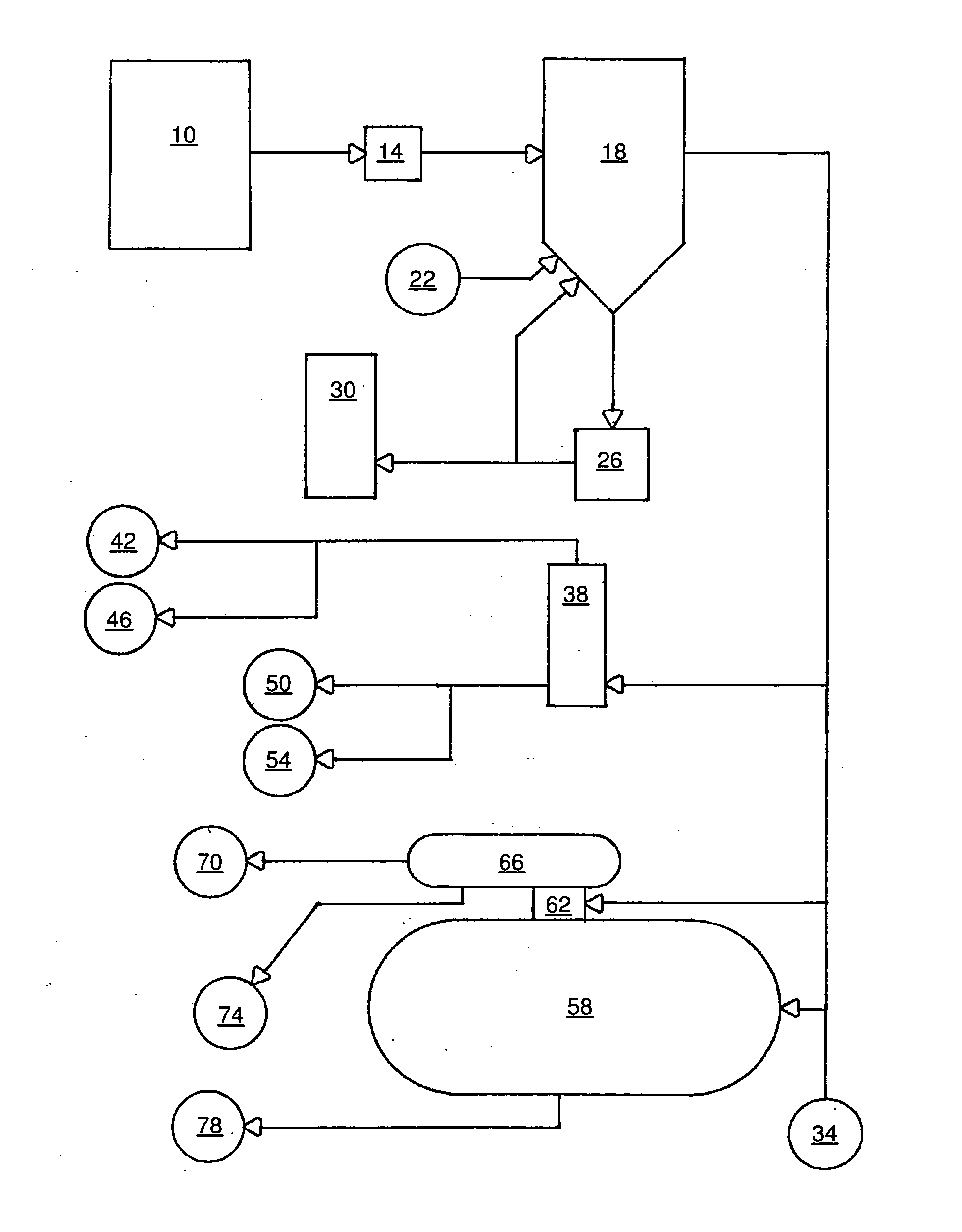

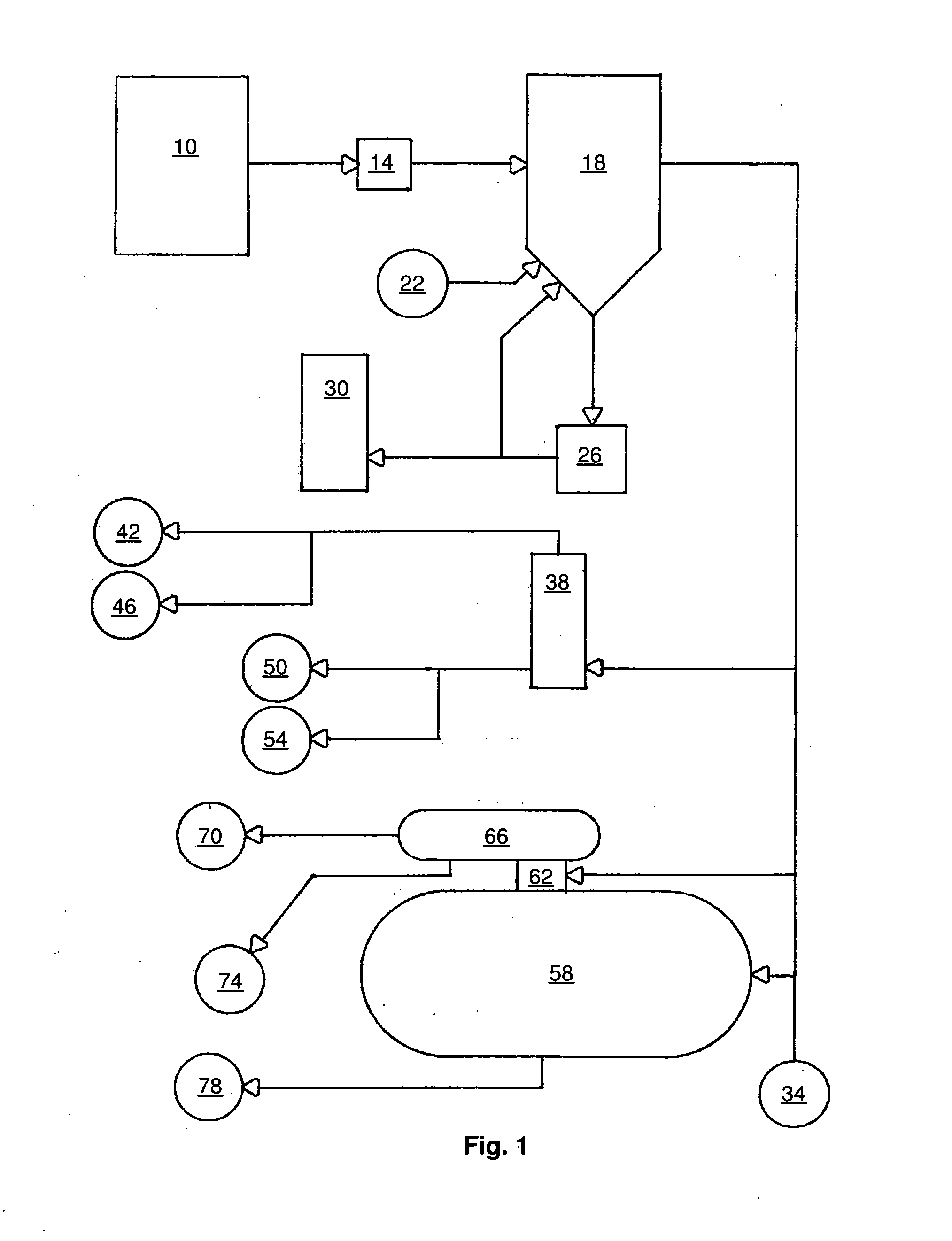

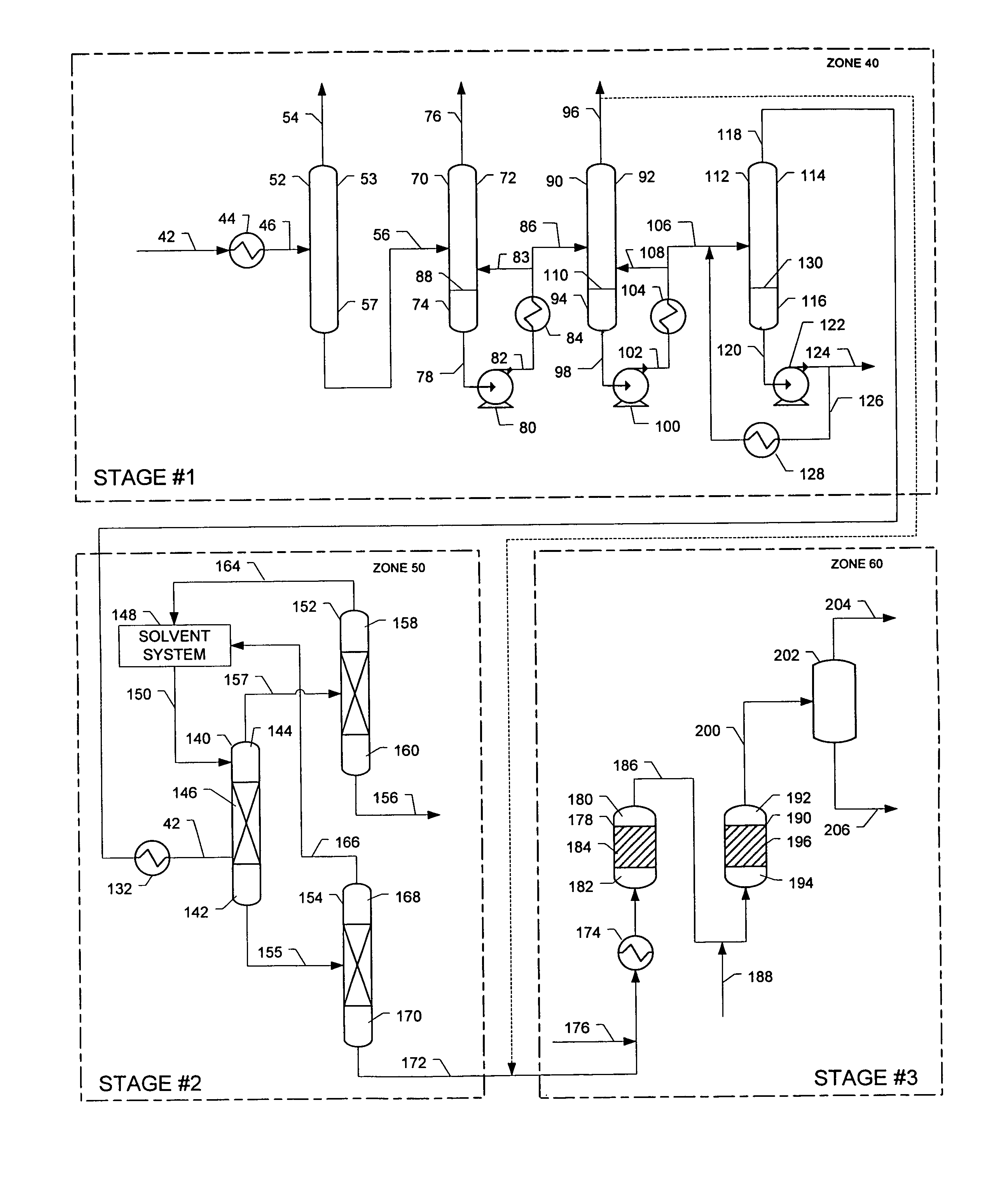

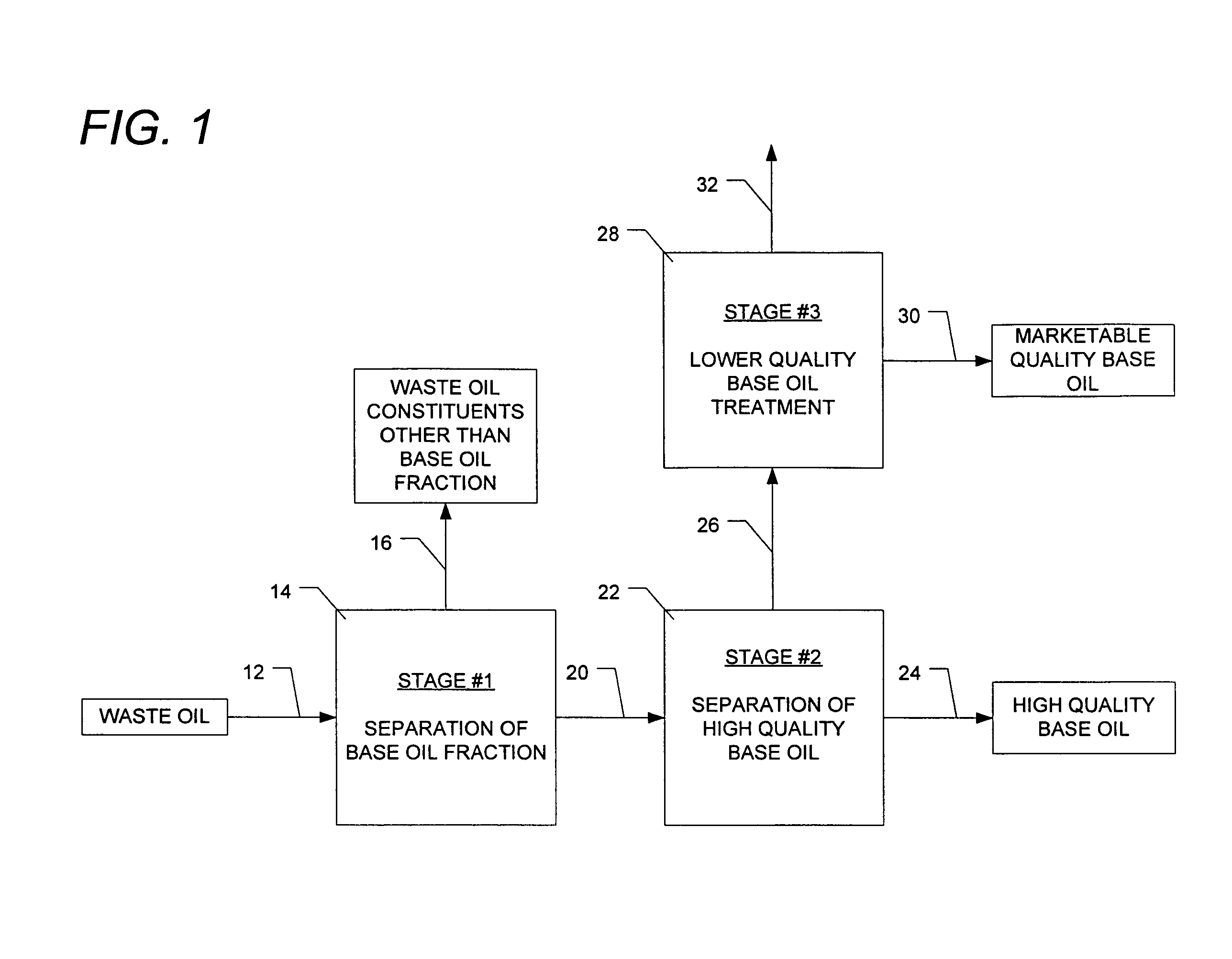

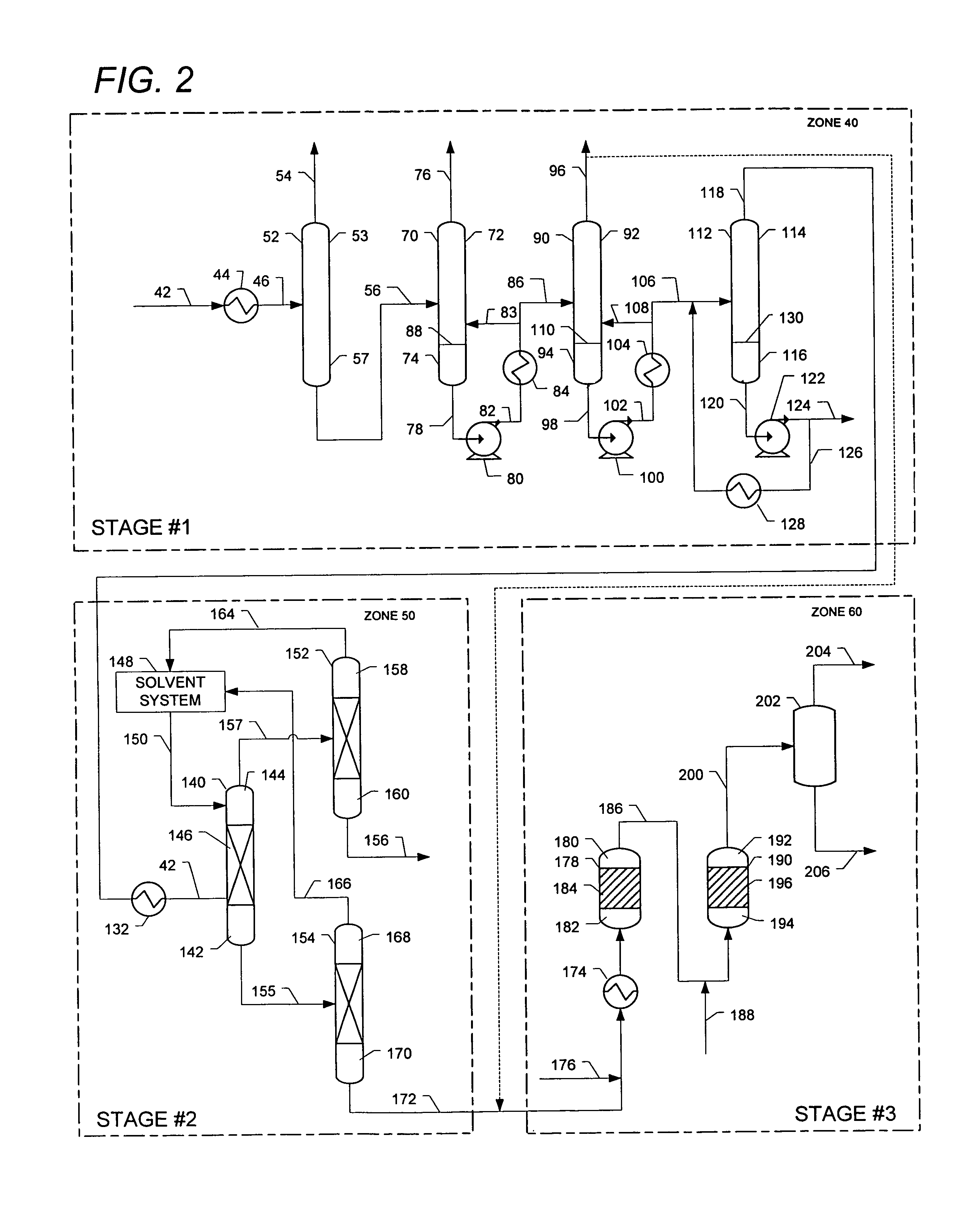

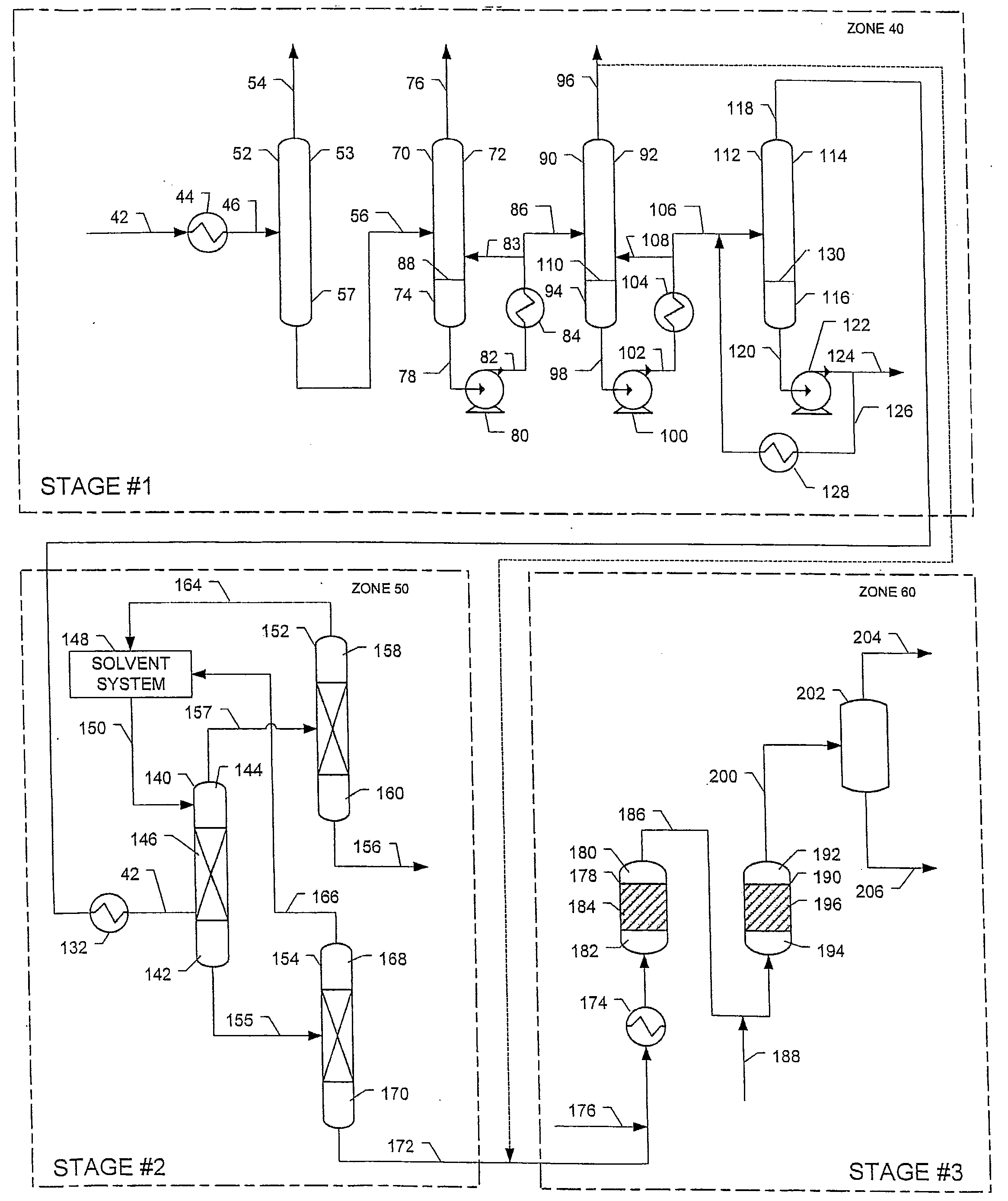

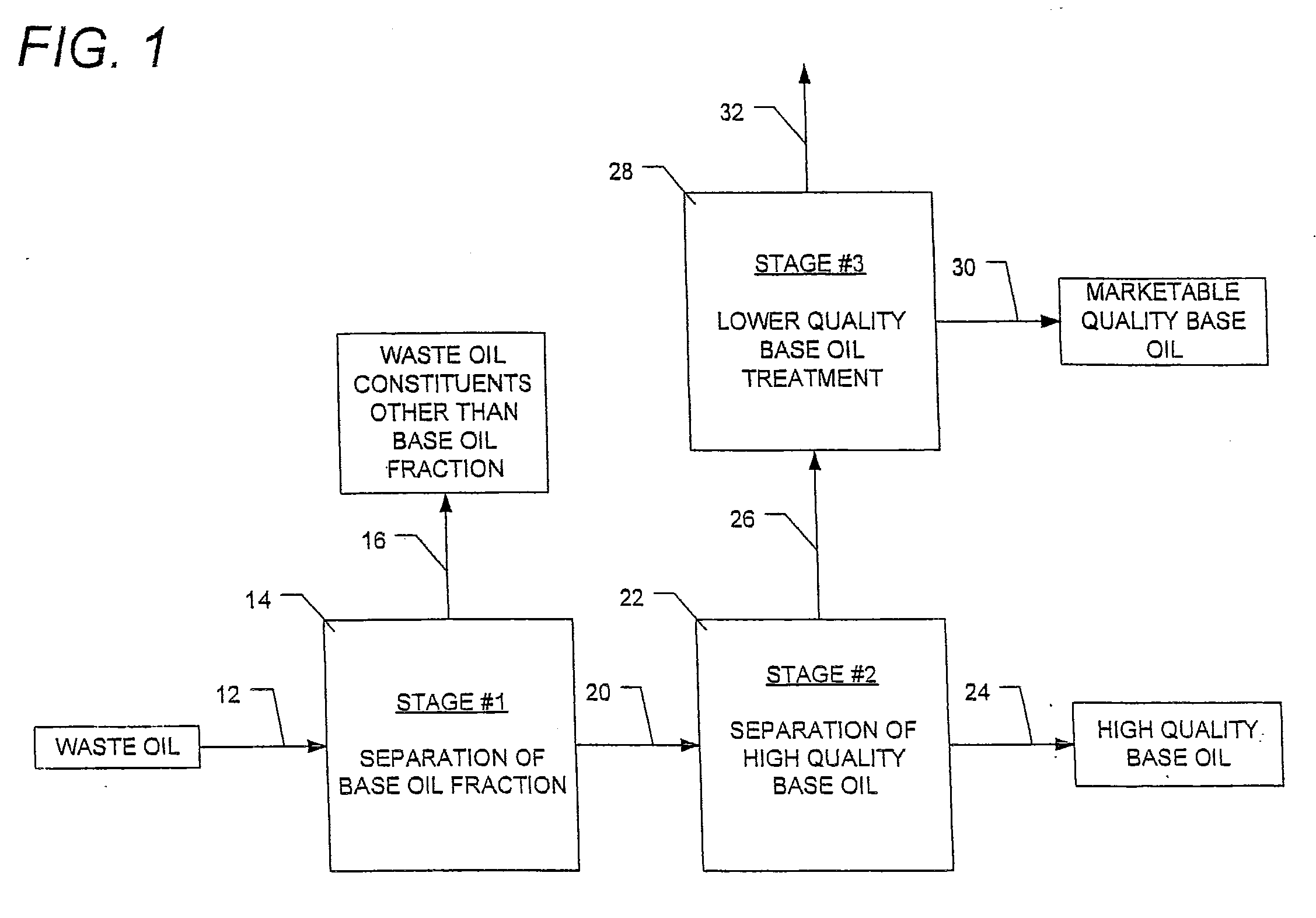

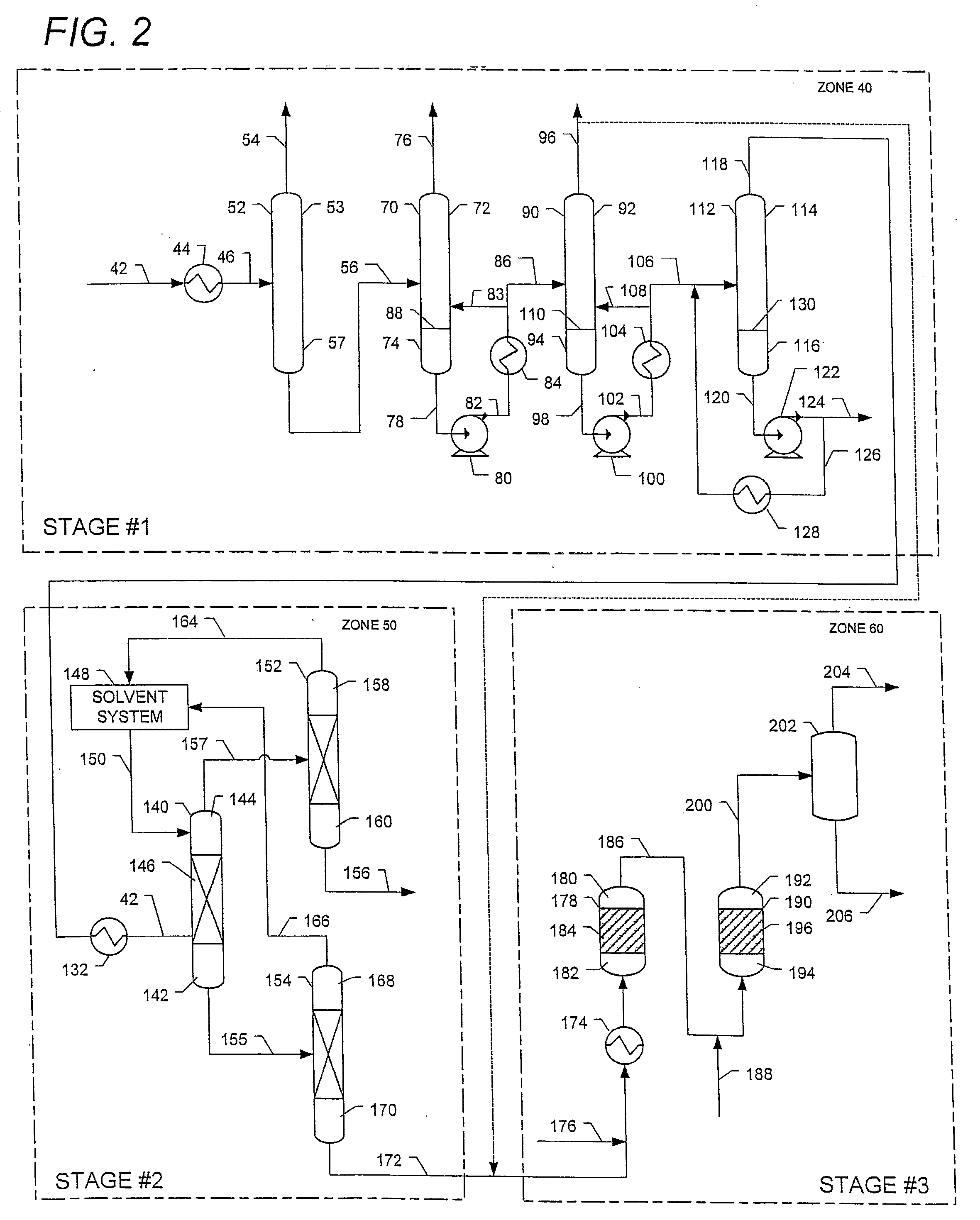

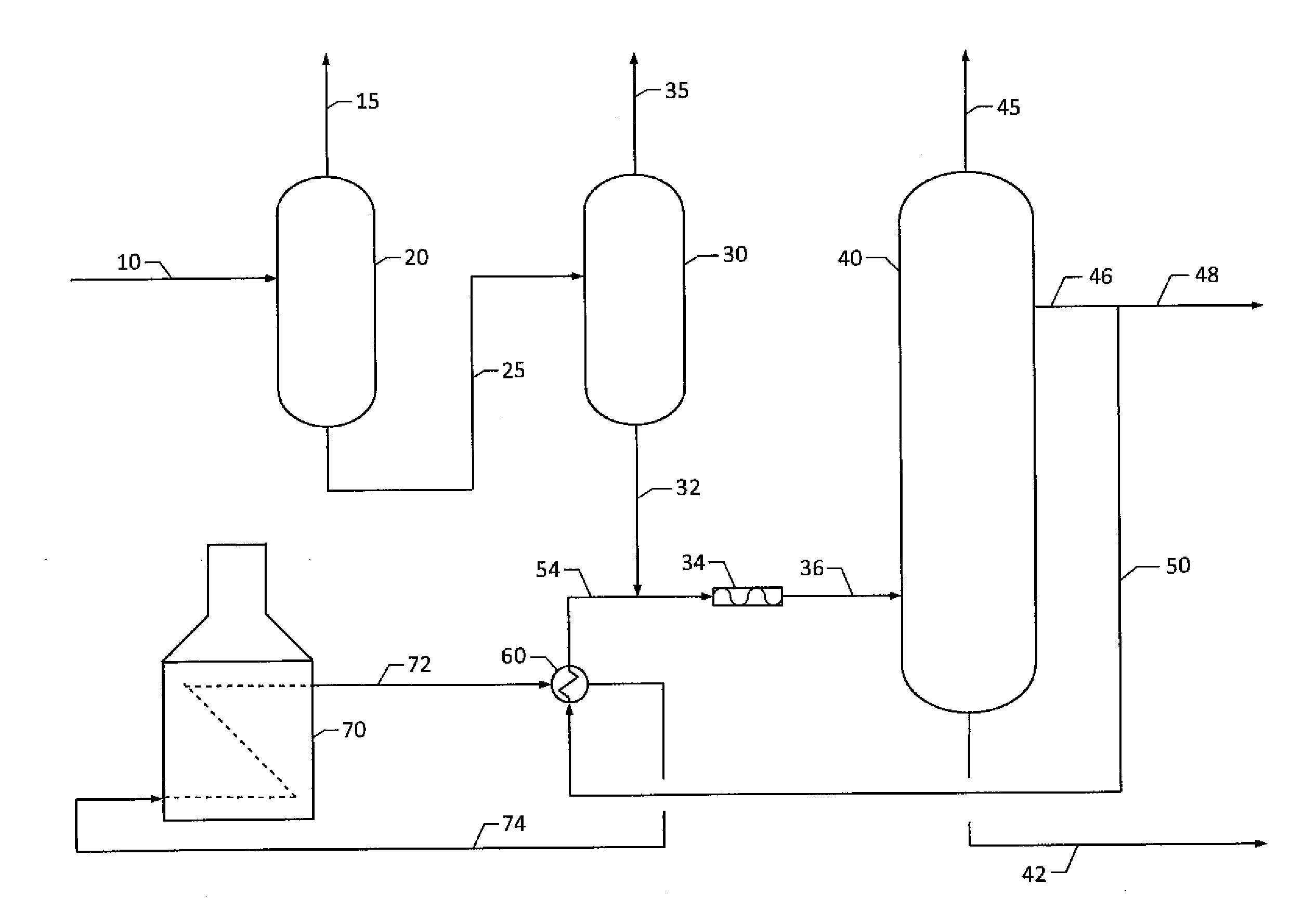

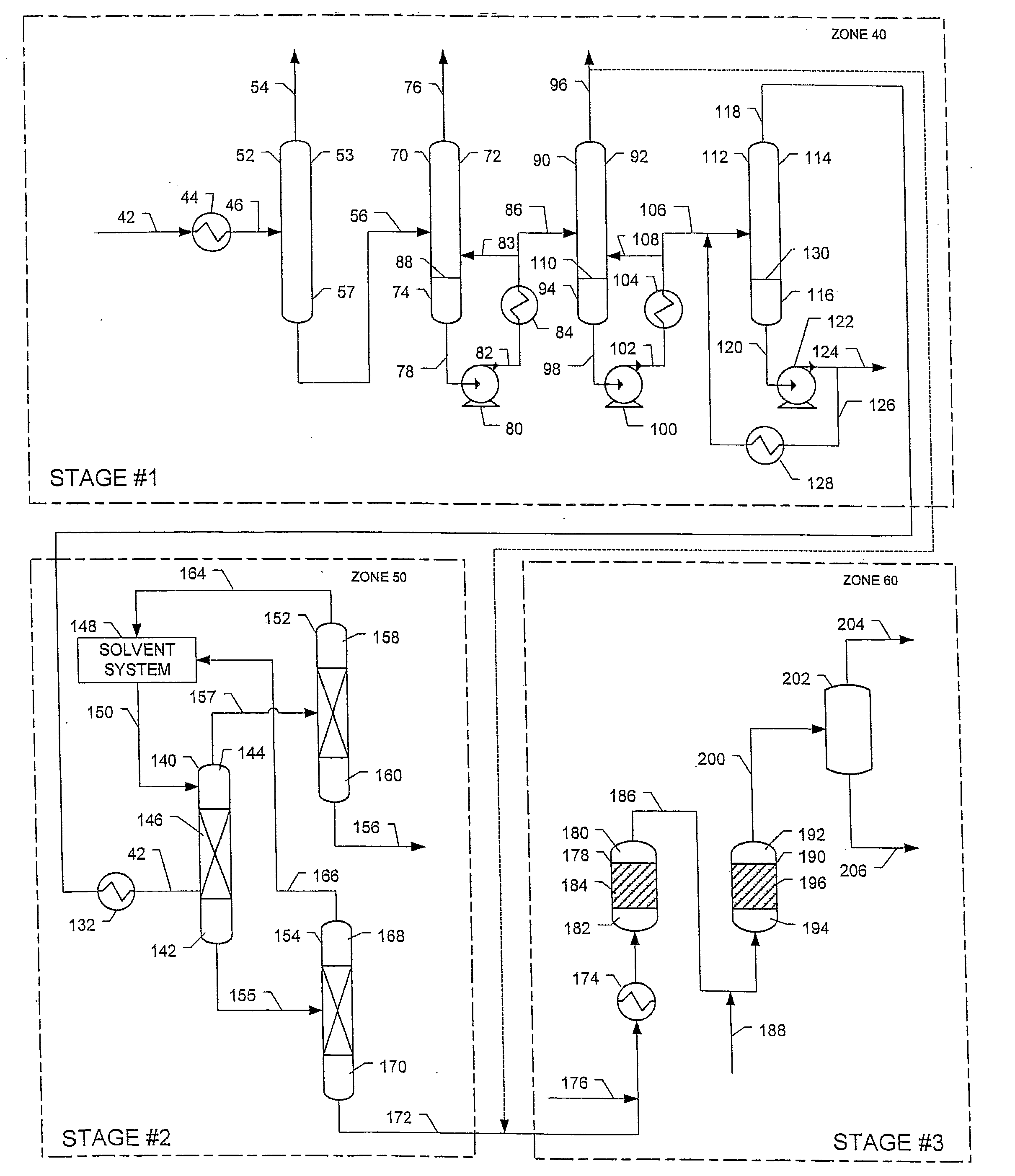

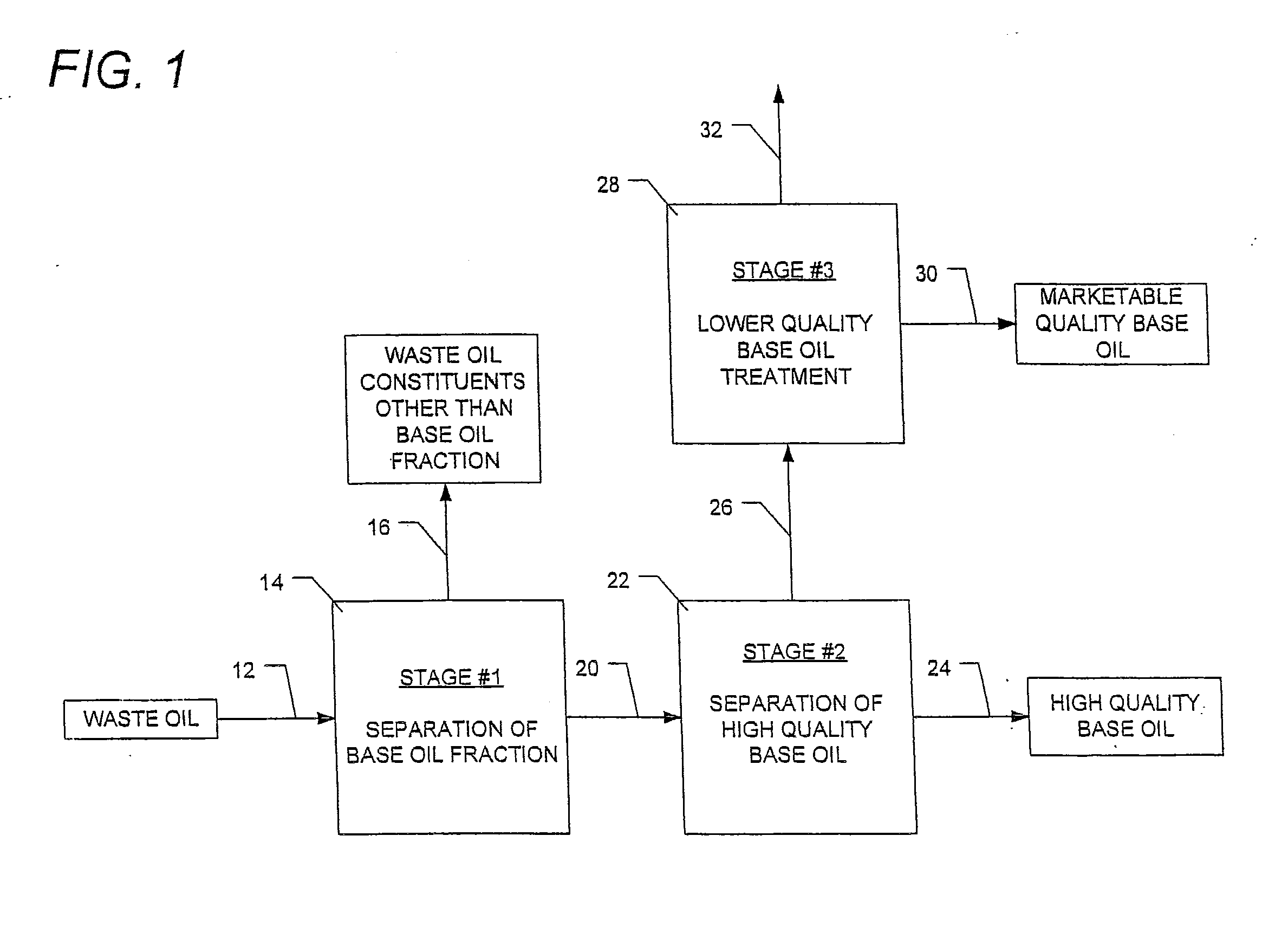

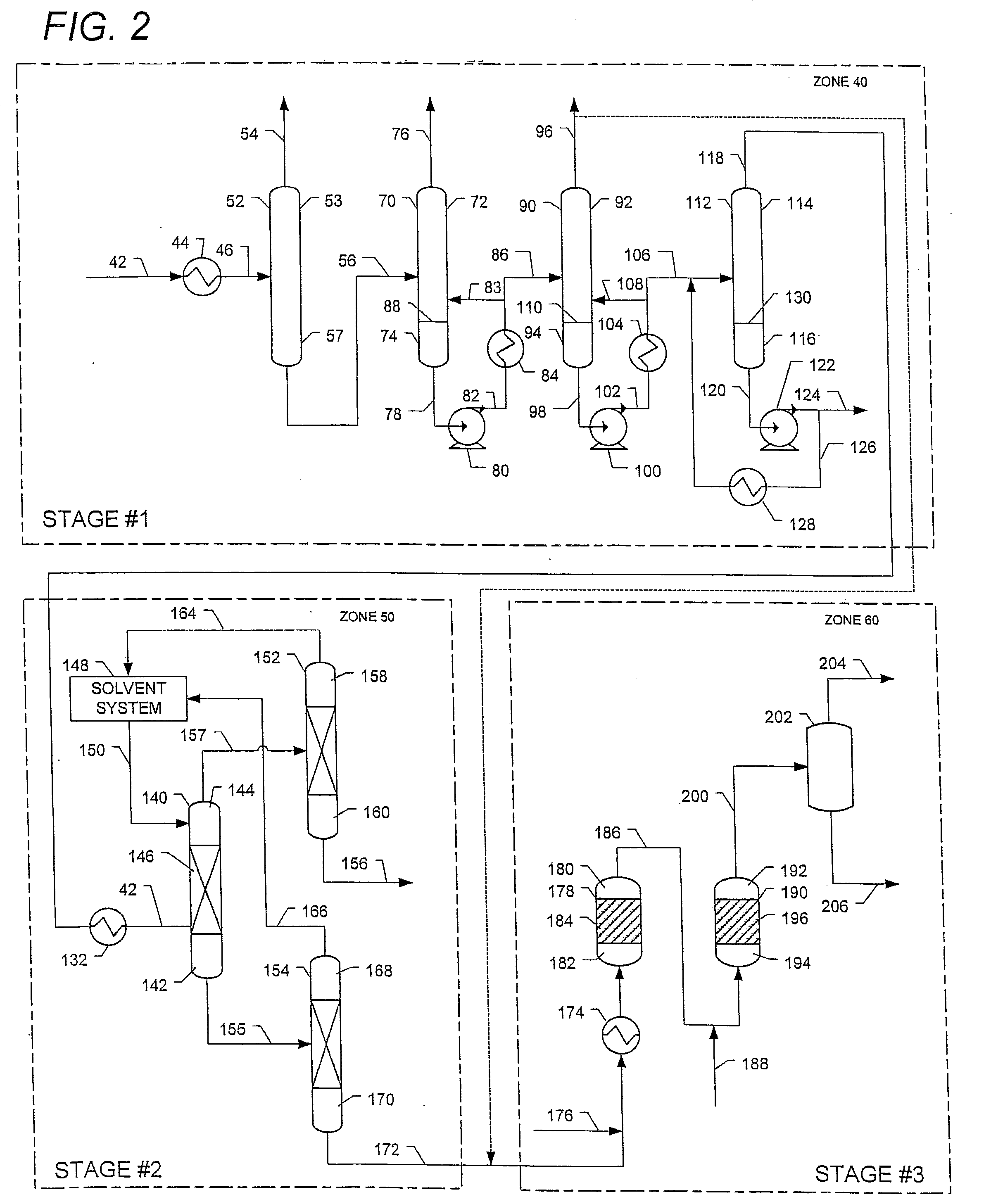

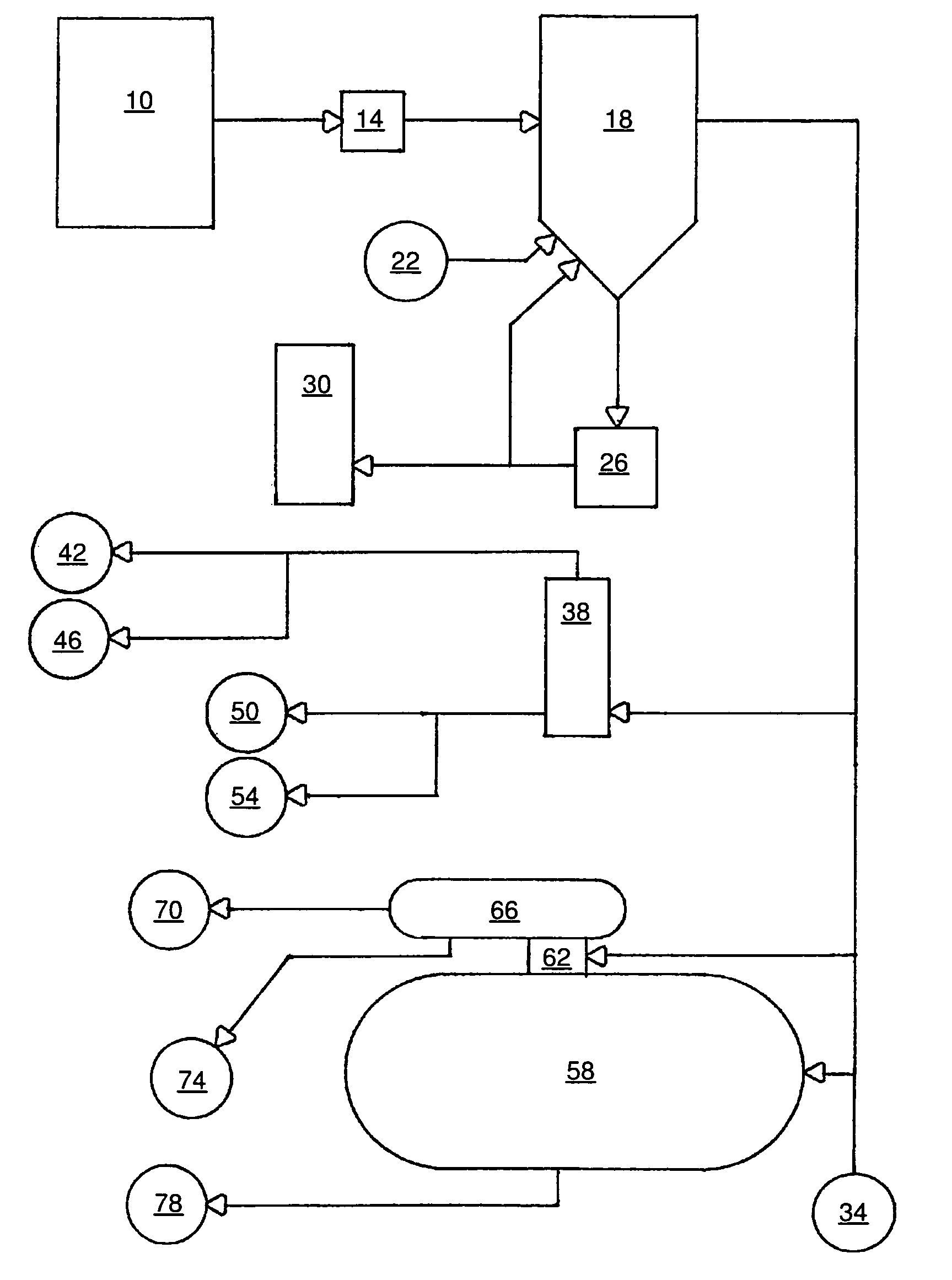

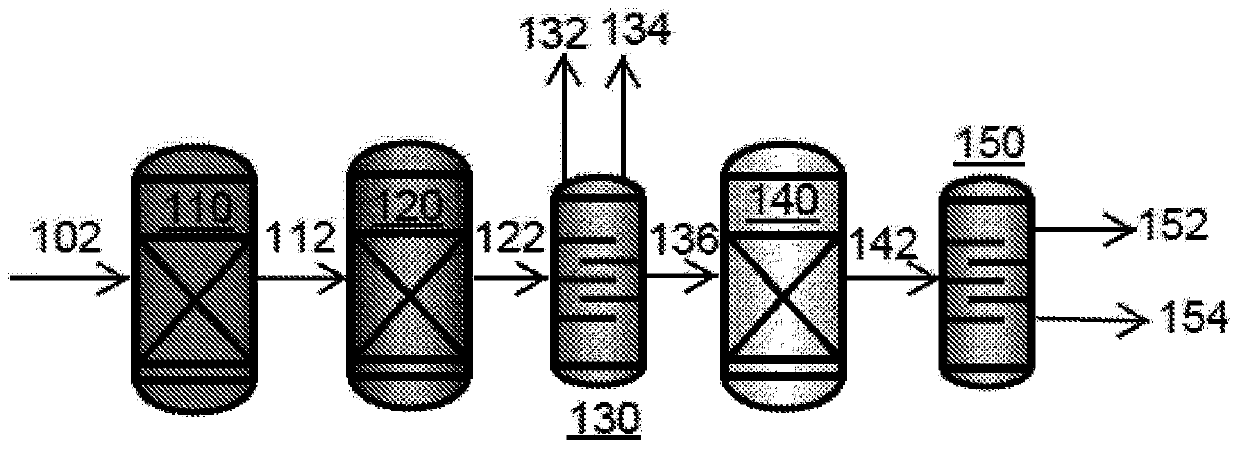

Method for producing base lubricating oil from waste oil

ActiveUS8366912B1Efficient productionQuality improvementThermal non-catalytic crackingHydrocarbon distillation control/regulationWaste oilProduct base

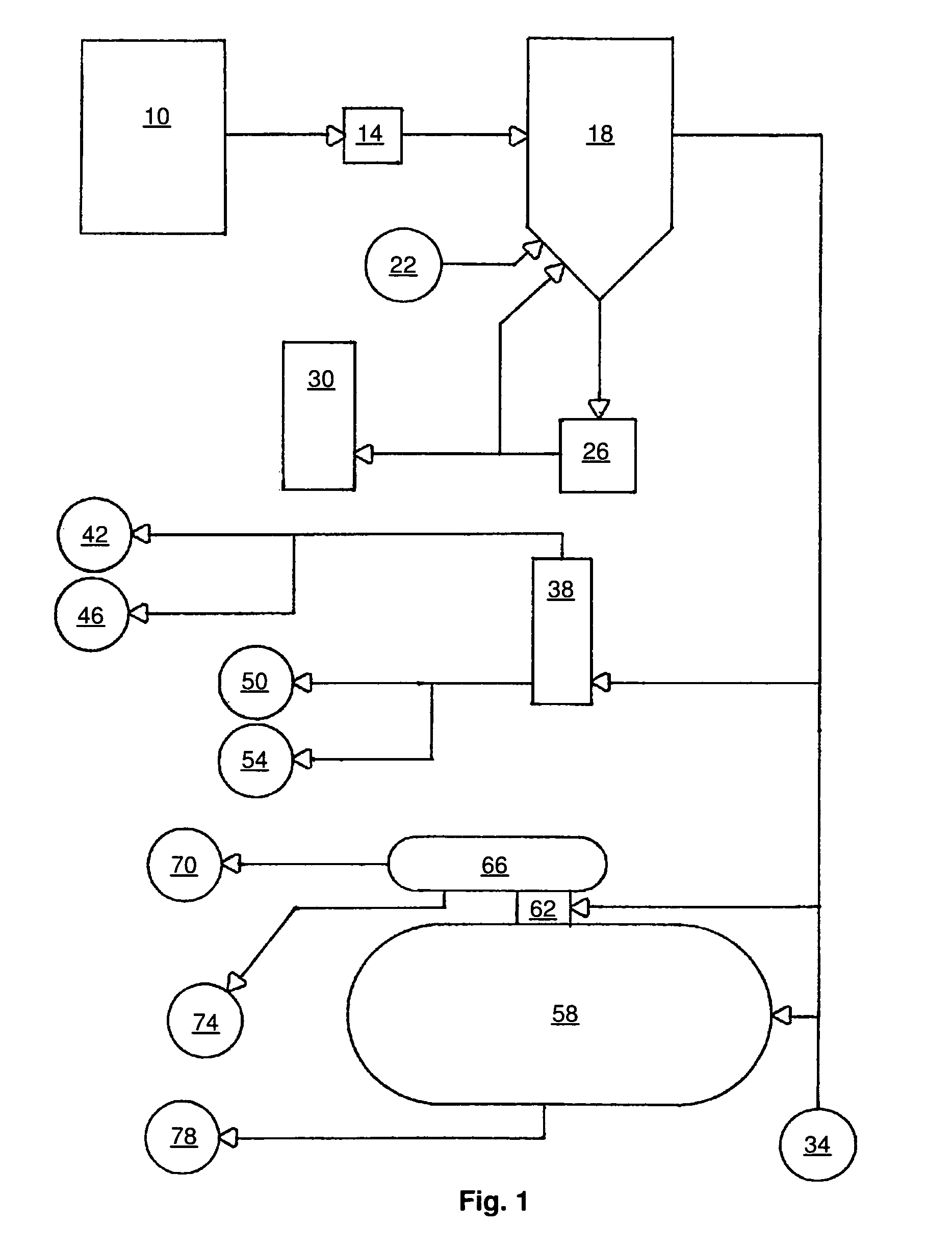

A method for recovering base oil from waste lubricating oil by separating base oil range constituents from a waste lubricating oil mixture, thereafter separating higher quality base oil constituents and lower quality base oil constituents from the base oil recovered from the waste lubricating oil mixture and thereafter treating the lower quality base oil constituents to produce marketable base oil. The total base oil produced from a waste lubricating oil mixture by this process is greater than the quantity producible by previous processes using only base oil separation from the waste lubricating oil mixture or processes which use only treatment of the base oil recovered from the waste lubricating oil mixture to produce the product base oil.

Owner:GEN III OIL CORPORATION

Method for producing base lubricating oil from waste oil

InactiveUS20090223862A1Efficient productionQuality improvementThermal non-catalytic crackingHydrocarbon distillation control/regulationProduct baseWaste oil

A method for recovering base oil from waste lubricating oil by separating base oil range constituents from a waste lubricating oil mixture, thereafter separating higher quality base oil constituents and lower quality base oil constituents from the base oil recovered from the waste lubricating oil mixture and thereafter treating the lower quality base oil constituents to produce marketable base oil. The total base oil produced from a waste lubricating oil mixture by this process is greater than the quantity producible by previous processes using only base oil separation from the waste lubricating oil mixture or processes which use only treatment of the base oil recovered from the waste lubricating oil mixture to produce the product base oil.

Owner:VEROLUBE

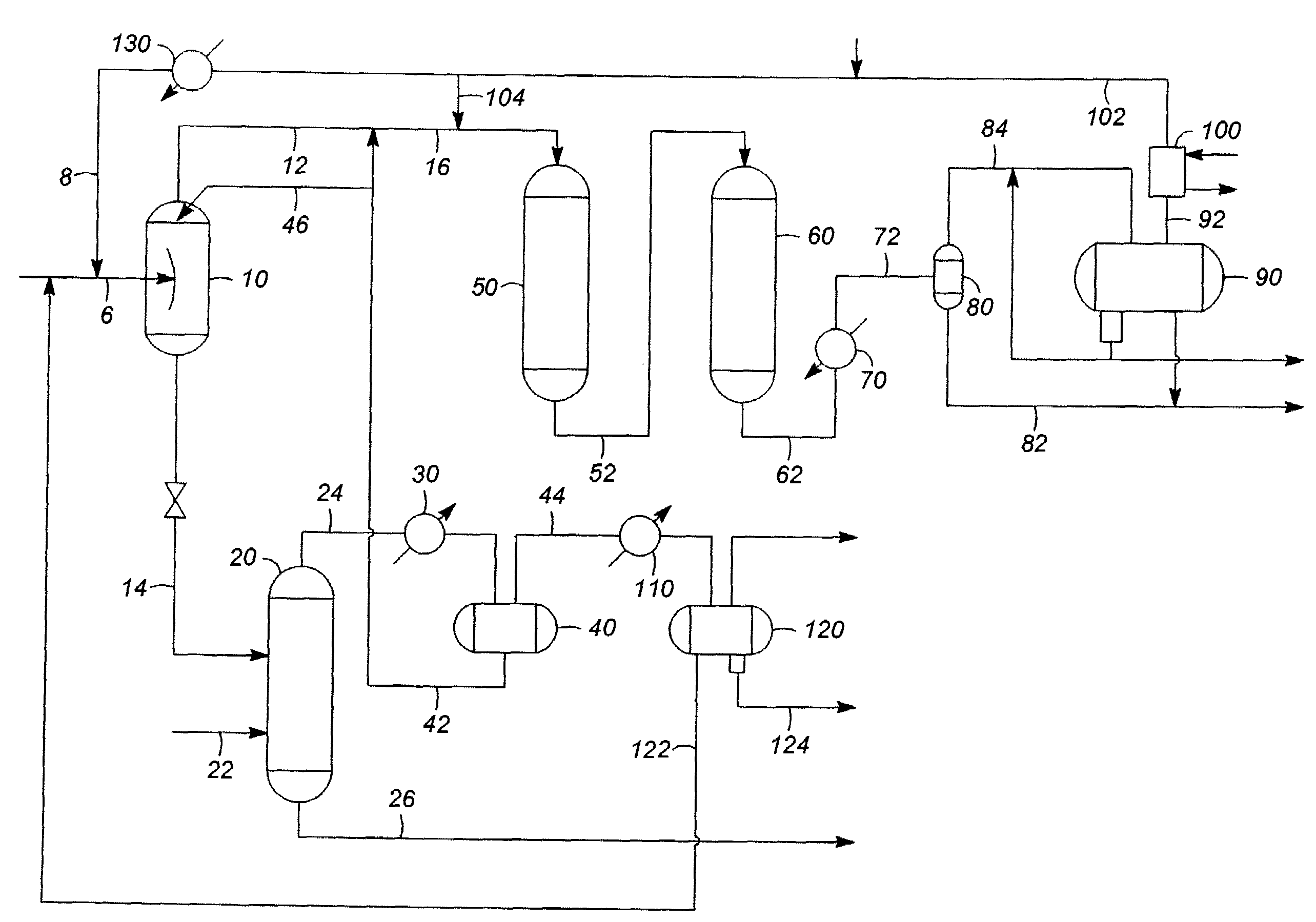

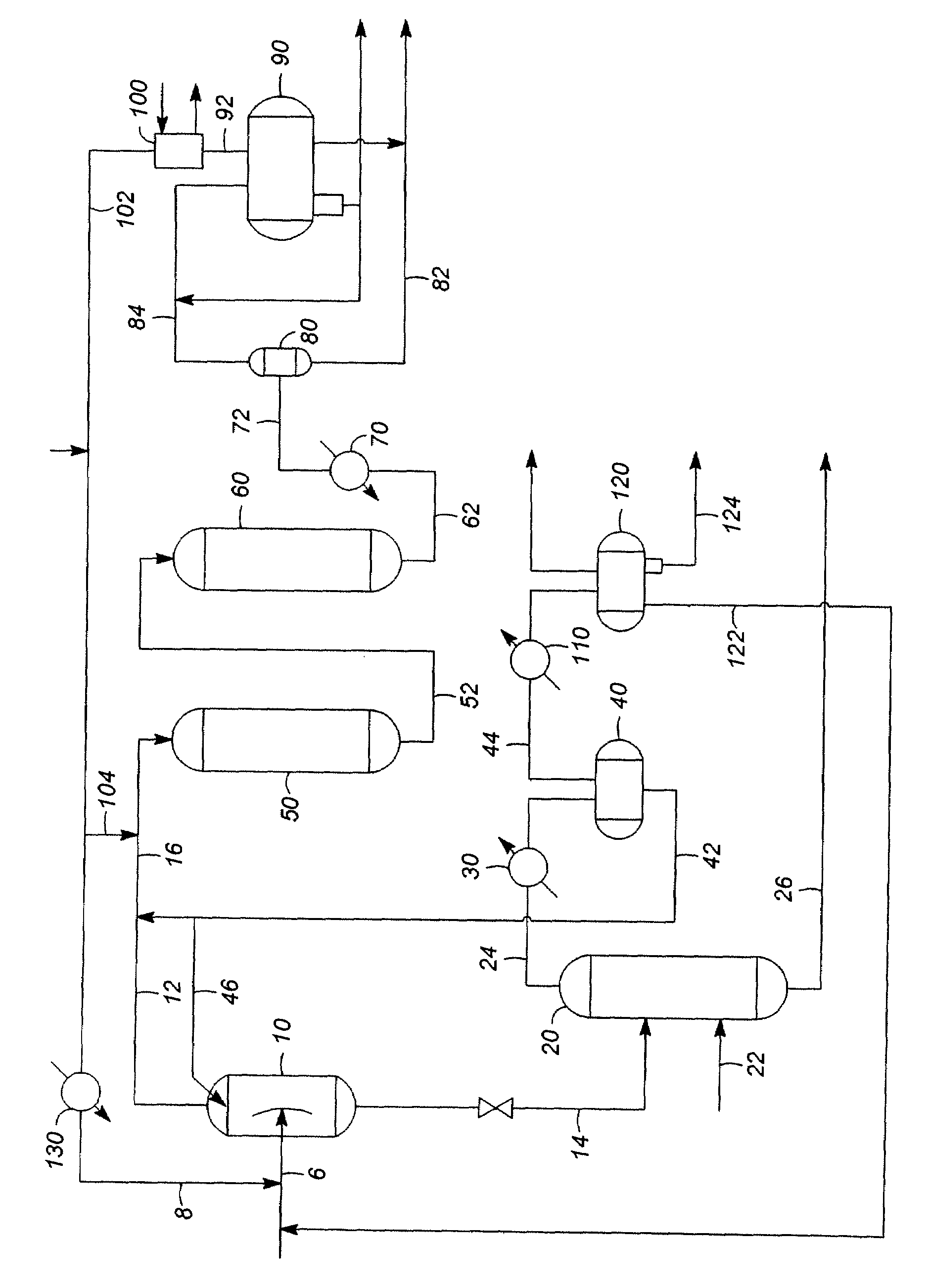

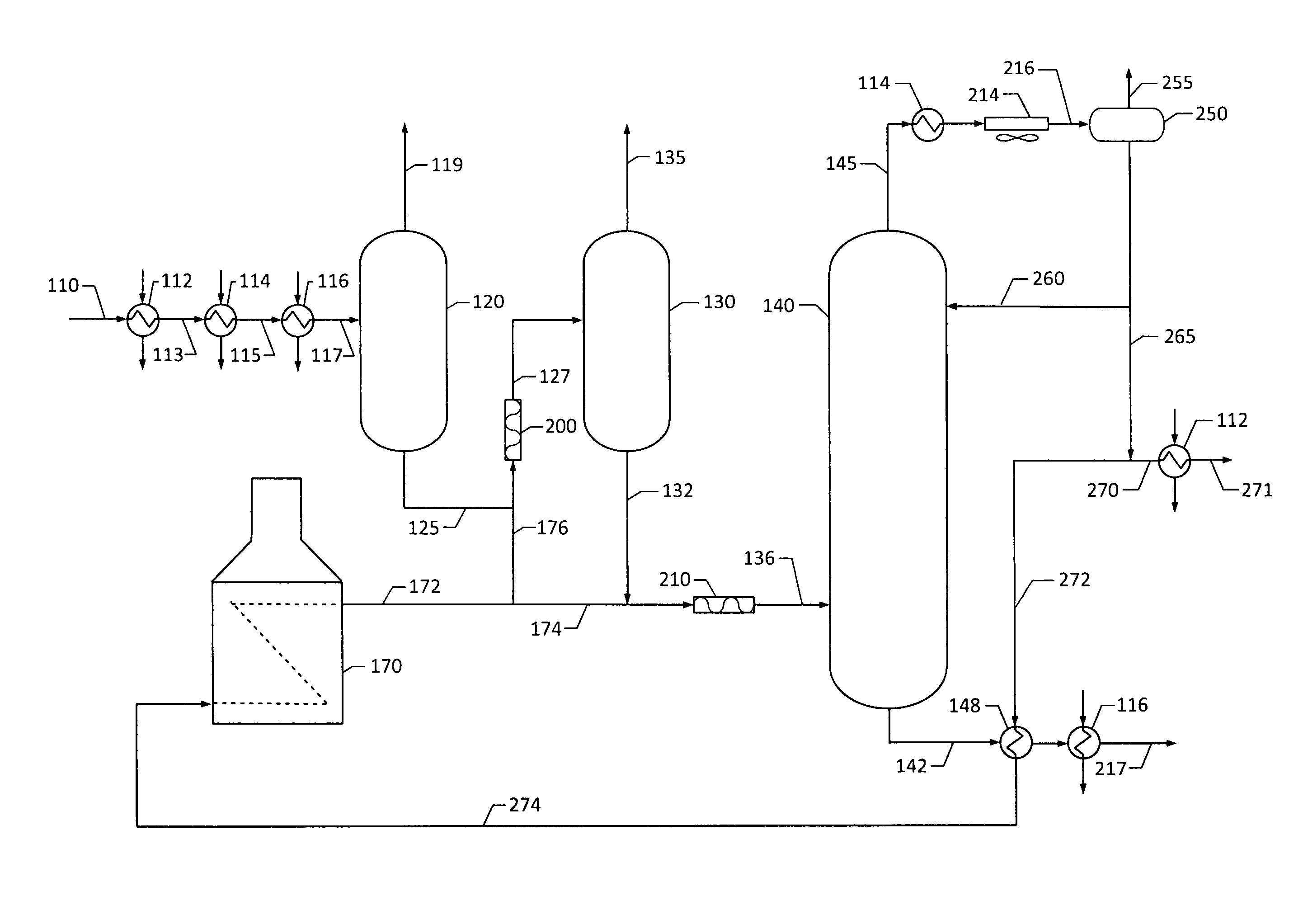

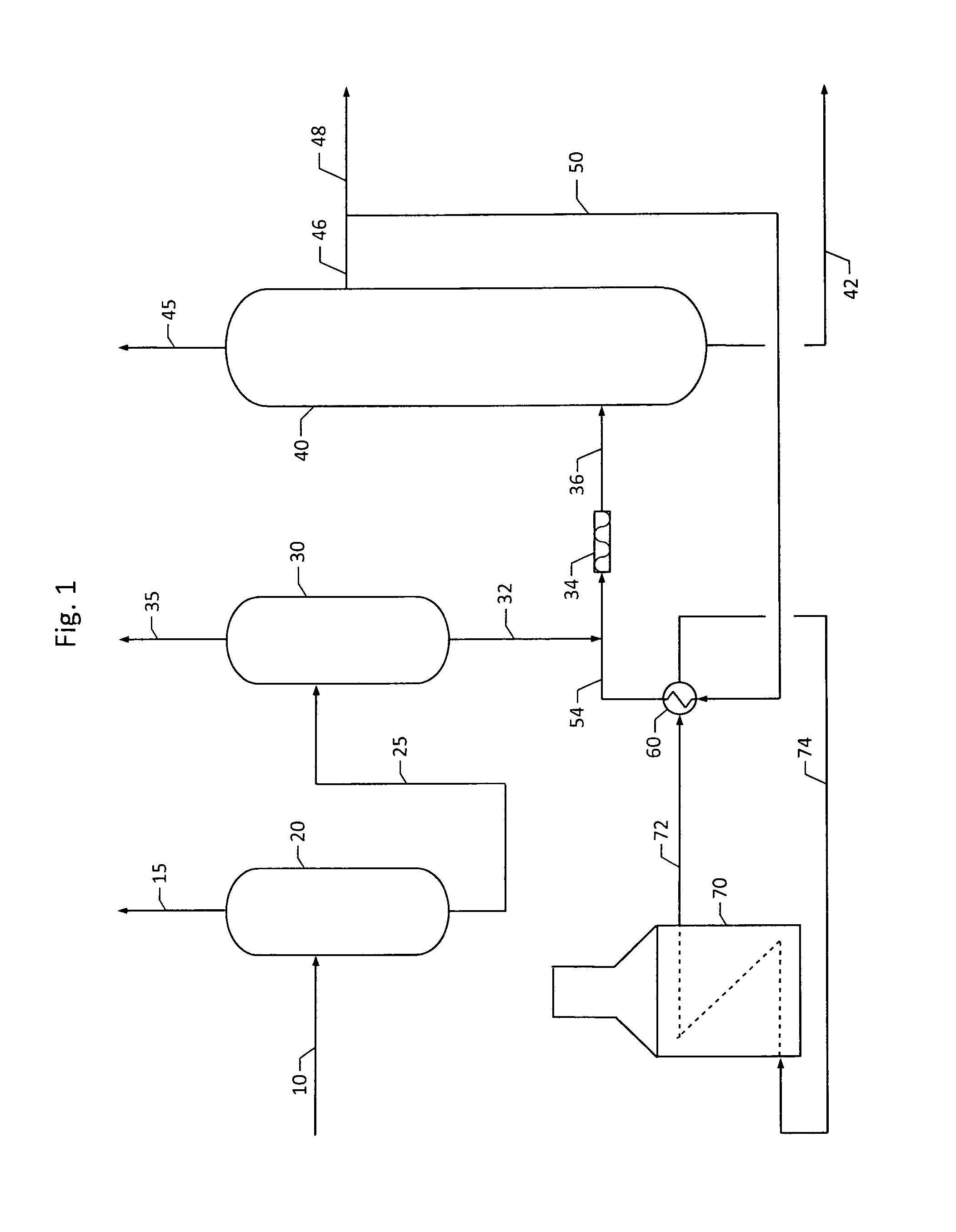

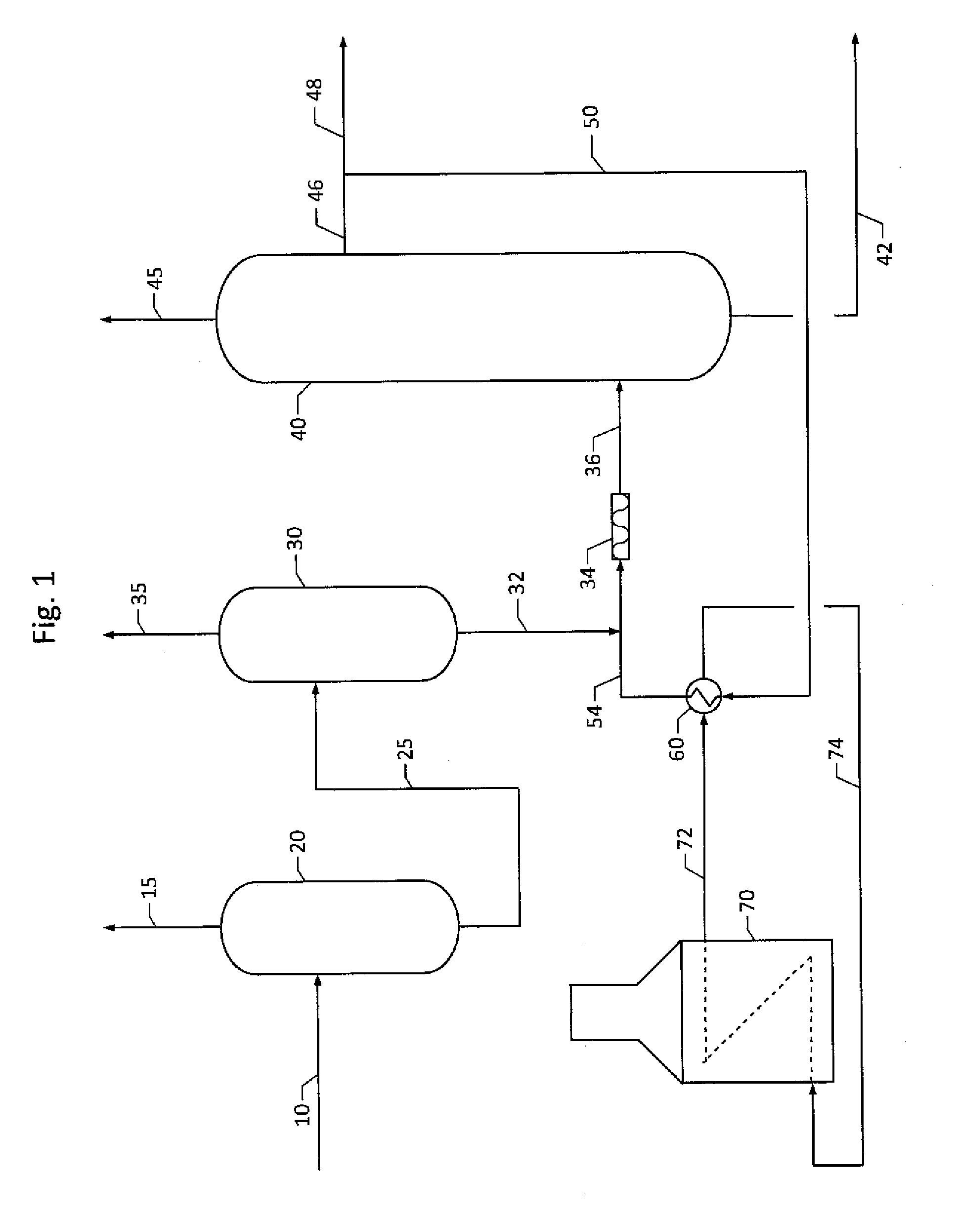

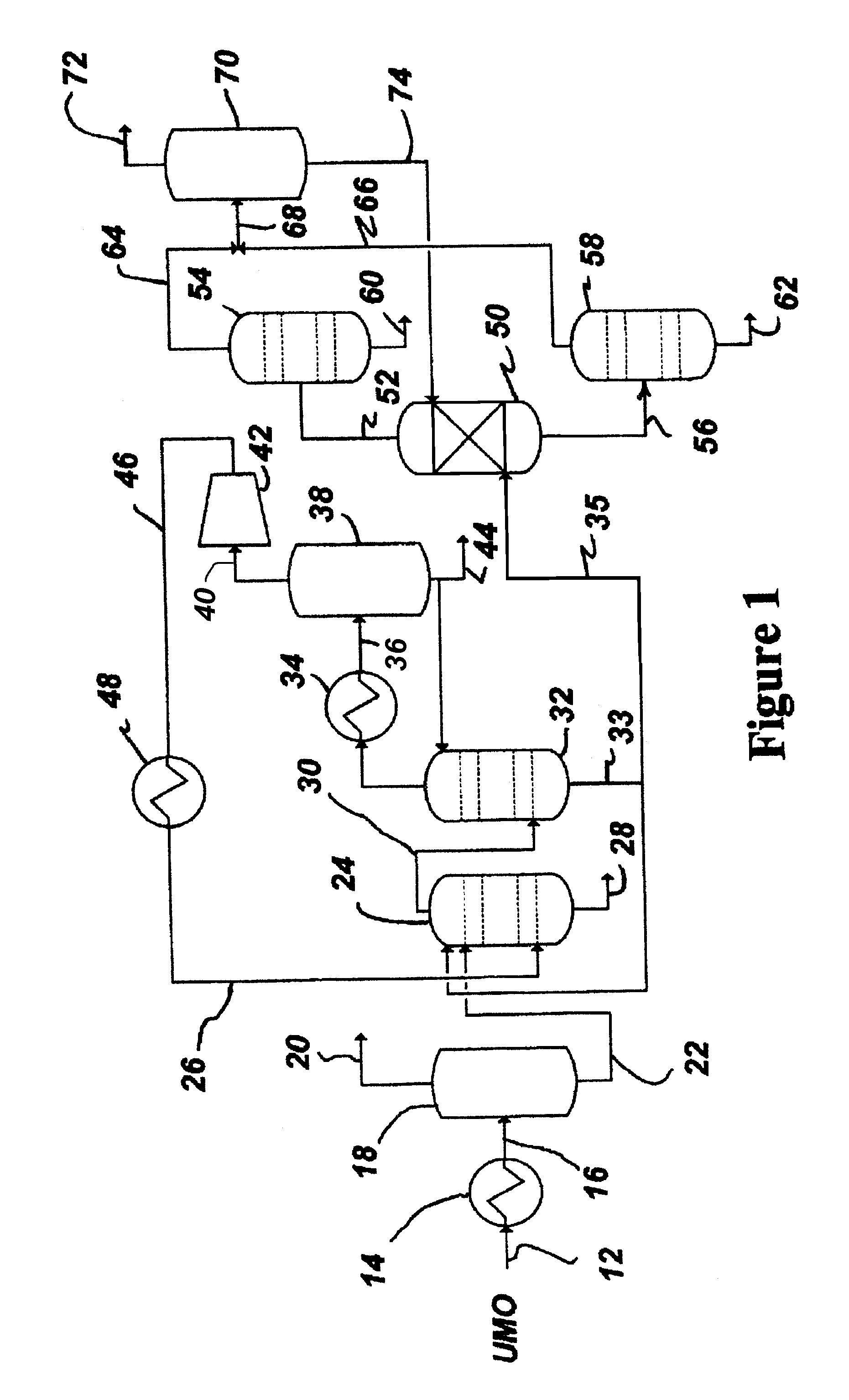

Re-refining used motor oil

A process for re-refining used lubricating oil (ULO) having thermally unstable additives. ULO is heated by mixing with superheated lubricant boiling range hydrocarbons recovered and recycled from the process. The mixture of ULO feed and superheated hydrocarbons is charged to a vacuum column, producing an overhead vapor free of unstable additives and a residual fraction, containing additives. The overhead vapor is condensed to produce an overhead liquid of lubricant boiling range hydrocarbons, a portion of which is recovered as a product and a portion of which is recycled. The overhead liquid free of unstable additives, may be superheated without fouling to produce superheated fluid which can heat the ULO feed sufficiently to permit fractionation. Superheating may occur in a fired heater or preferably in a heat exchanger to prevent high temperatures and cracking of recycled liquid. Mixing of superheated fluid and ULO feed may occur in a pipe in fully developed turbulent flow, and preferably via an inline mixer. Energy efficiency is improved by heat exchanging ULO feed with product streams.

Owner:APPLIED MICROCURRENT TECH LTD +1

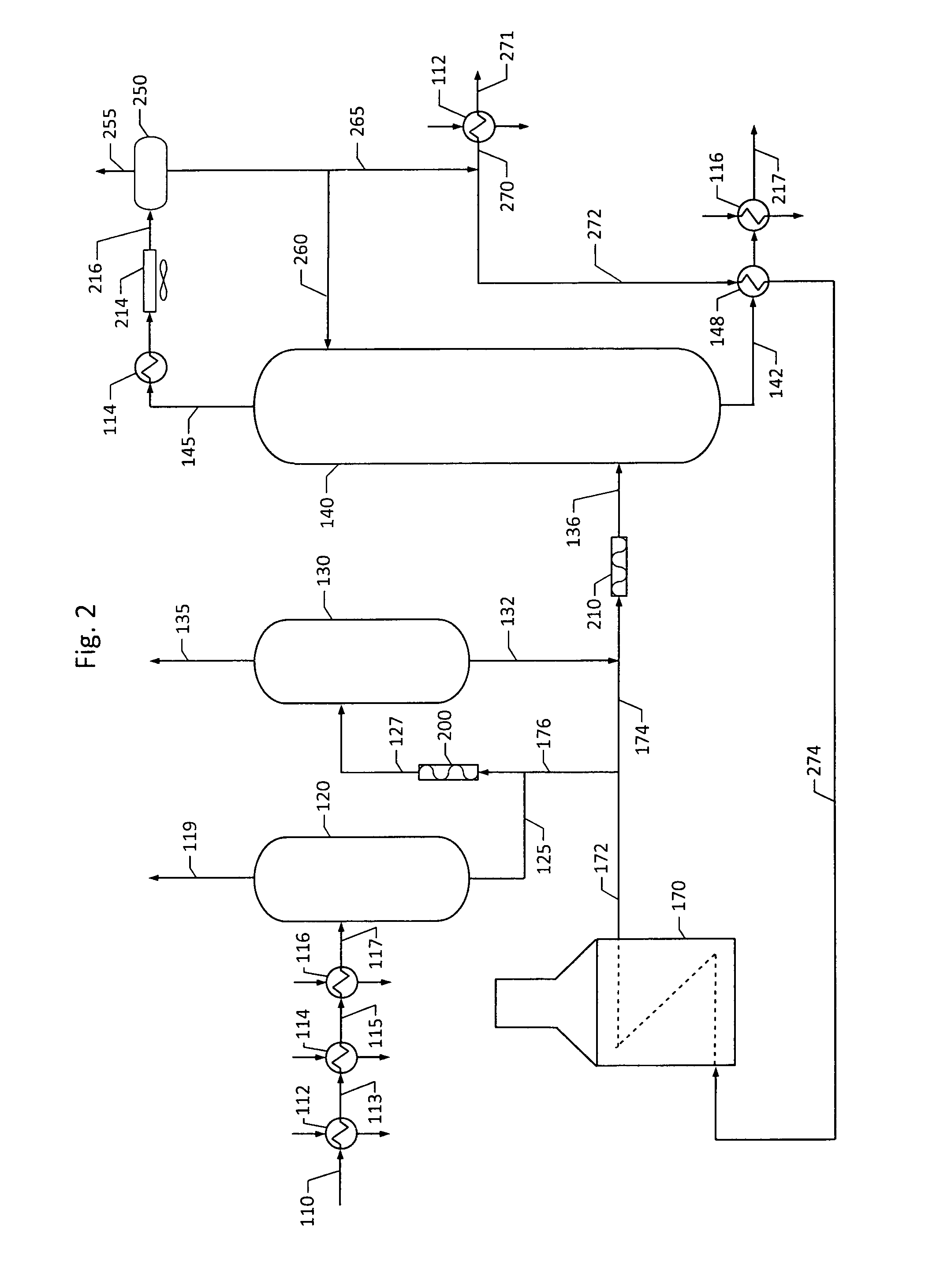

Distillation of used motor oil with distillate vapors

A process and apparatus for re-refining used lubricating oil (ULO) having thermally unstable additives such as zinc compounds. ULO is mixed with a superheated distillate which may be a recycle stream, an outside stream, or combination, then charged to a vacuum flash or fractionator, to produce an overhead vapor and a residual fraction comprising additives and / or decomposition products thereof. Overhead vapor is condensed to yield a liquid lubricant boiling range product. Superheating may occur in a fired heater, heat exchanger or combination. Mixing of superheated fluid and ULO may occur in a pipe in turbulent flow and / or an in line mixer. Energy efficiency is improved by heat exchanging ULO feed with vapor or liquid product streams. An aromatic rich and thermally stable outside stream such as FCC LCO can be readily superheated. Recovered lubricant boiling range material can be recycled, used as a lube stock or for FCC feed.

Owner:WTL TECH LLC

Method for Producing Base Lubricating Oil from Waste Oil

ActiveUS20110278151A1Efficient productionQuality improvementThermal non-catalytic crackingHydrocarbon distillation control/regulationBase oilComponents of crude oil

Owner:GEN III OIL CORPORATION

Refining used motor oil through successive hydrotreating processes

ActiveUS9932530B2Economical efficiency can be improvedAvoid accumulationTreatment with hydrotreatment processesLubricating oils distillationHydrogenGasoline

A method for refining used motor oil using two or more hydrotreating reactors arranged in series. The used motor oil may be vacuum distilled to produce an unrefined gasoil. The unrefined gasoil may then be hydrotreated in a first hydrotreating reactor with hydrogen operated at a temperature ranging from approximately 245° C. to approximately 260° C. to produce a hydrotreated gasoil. The hydrogen may comprise a mixture of fresh hydrogen and recycled hydrogen recovered from the last of the two or more hydrotreating reactors. The hydrotreated gasoil may then be hydrotreated in one or more additional hydrotreating reactors operated at temperatures ranging from approximately 260° C. to approximately 330° C. to produce a refined gasoil. The first hydrotreating reactor may remove a substantial portion of metallic impurities from the unrefined impurities, while the one or more additional hydrotreating reactors remove a substantial portion of heteroatom impurities from the unrefined gasoil.

Owner:AIR PROD & CHEM INC

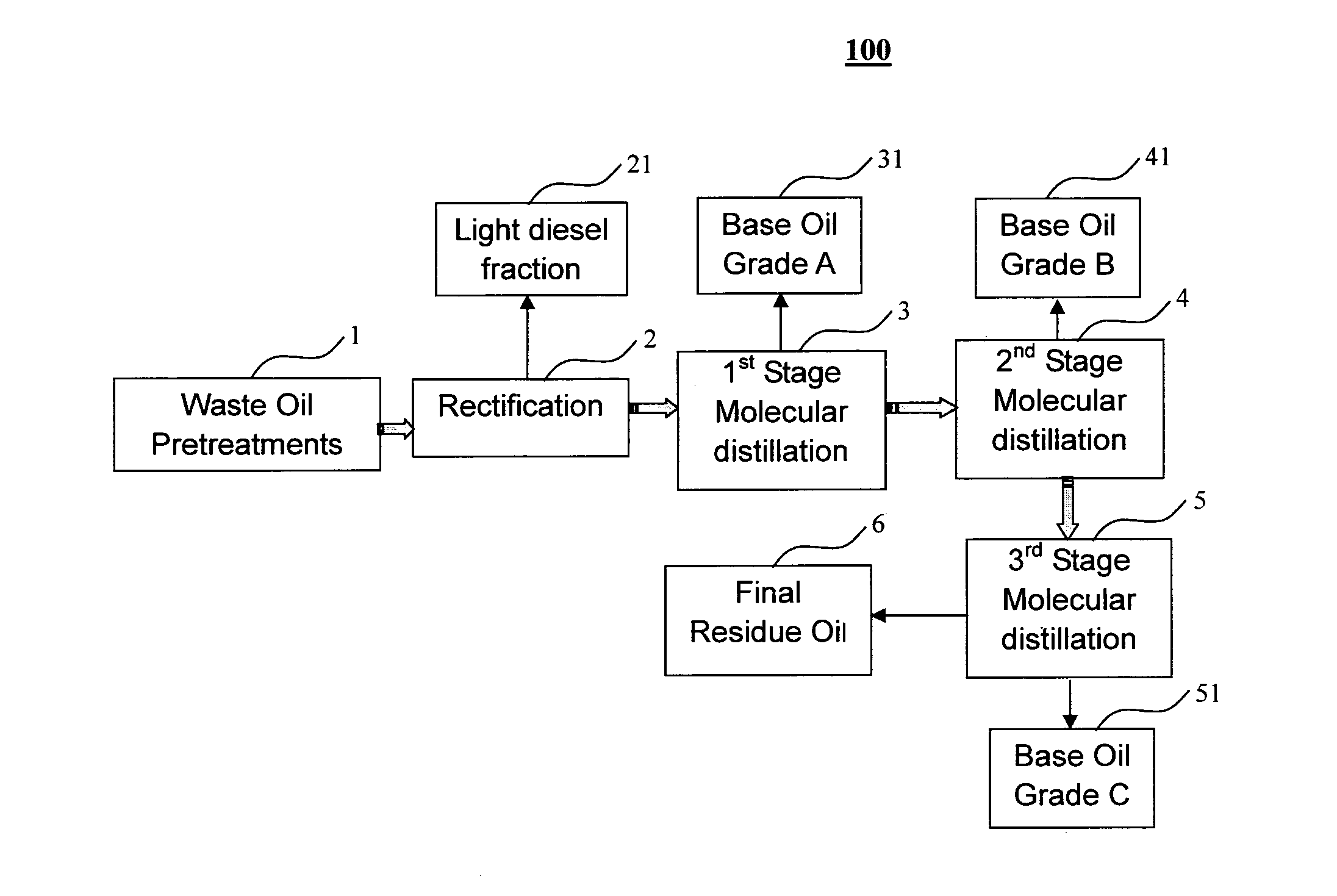

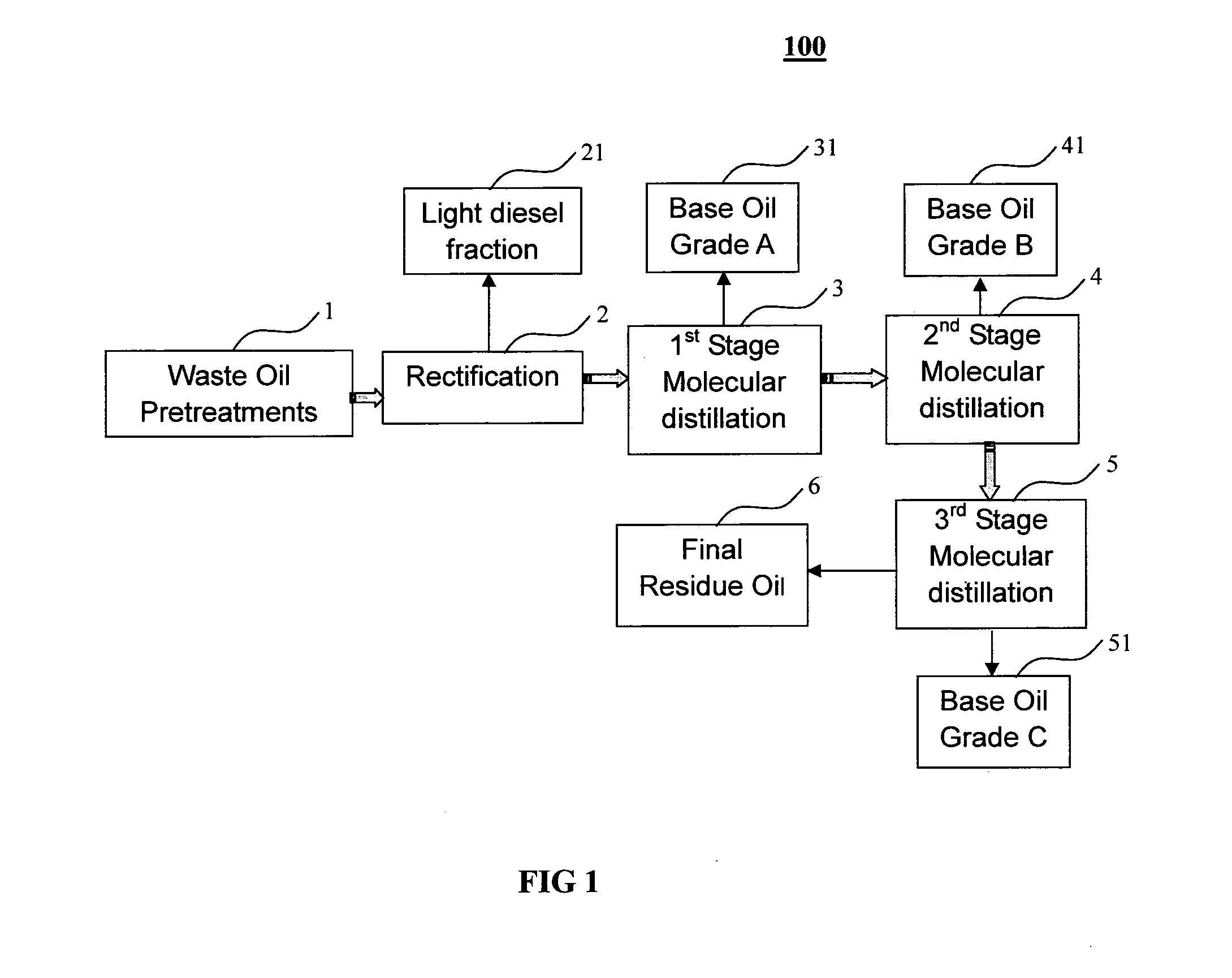

Process and system for recovering base oil from lubrication oil that contains contaminants therein

InactiveUS20110259795A1Value maximizationGood flexibilityWorking-up pitch/asphalt/bitumen by distillationThermal non-catalytic crackingBase oilLubrication

A process of recovering base oil from lubrication oil that contains contaminants therein, the process comprises the steps of: (i) extracting a light diesel fraction from the lubrication oil; and (ii) distilling the lubricating oil under vacuum conditions after said extracting step (i) to obtain a base oil that is substantially free of said contaminants.

Multiple side draws during distillation in the production of base oil blends from waxy feeds

InactiveUS7708878B2Refining to change hydrocarbon structural skeletonPetroleum wax refiningAlkaneBoiling point

Owner:CHEVROU USA INC

Thermal process to transform contaminated or uncontaminated feed materials into useful oily products

ActiveUS9828553B2Thermal non-catalytic crackingRefining by heating/coolingPositive pressureReactive gas

The process is for thermally treating a feed material. The process comprises at least one step performed in a rotating kiln operating under positive pressure with a pressure control system and wherein in the process a sweep gas, that is an inert gas or a substantially non-reactive gas, is injected into the rotating kiln or in the feed stream entering the rotating operating kiln; or at least one step performed in a rotating kiln operating under positive pressure managing system; or at least one step performed in a rotating kiln wherein a sweep gas is injected in the rotating kiln or in the feed stream entering the rotating operating kiln. In step a), or in b) or in step c), the conditions of the thermal treatment are managed in order that the exit stream, after cooling, result in at least one liquid phase that is preferably essentially an oily liquid phase.

Owner:ENVIROLLEA

Distillation apparatus and method of use

InactiveUS7976699B2Improve efficiencySuccessfully and easily distillVacuum distillation separationLubricating oils distillationQuality levelDistillation

Owner:BARKER COURT R

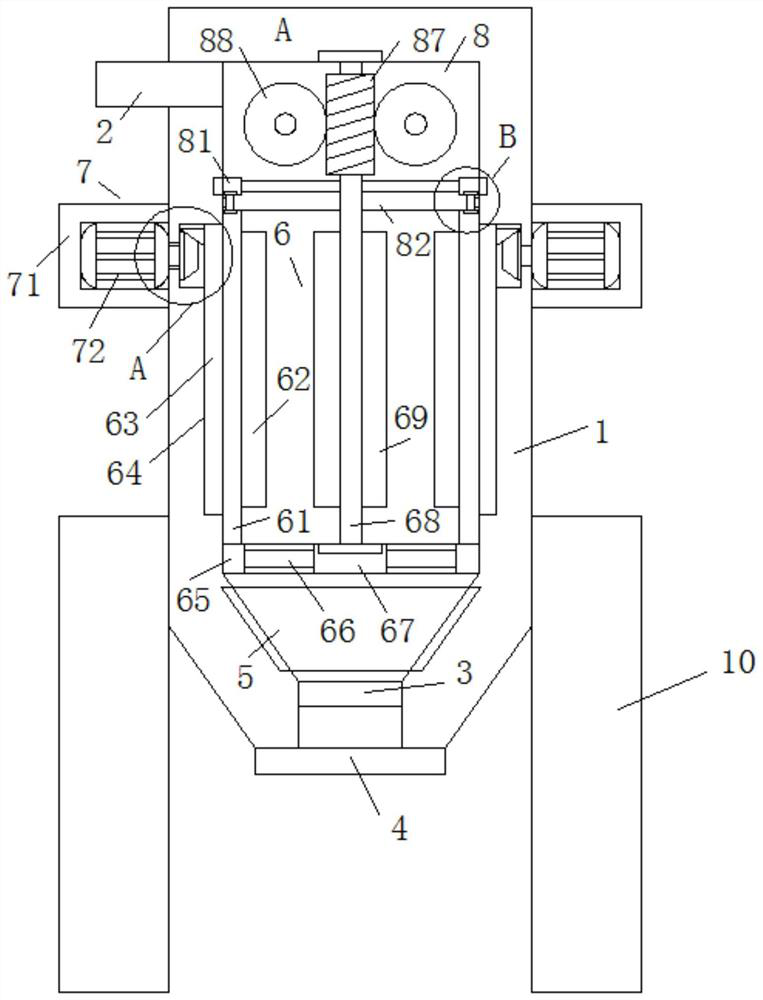

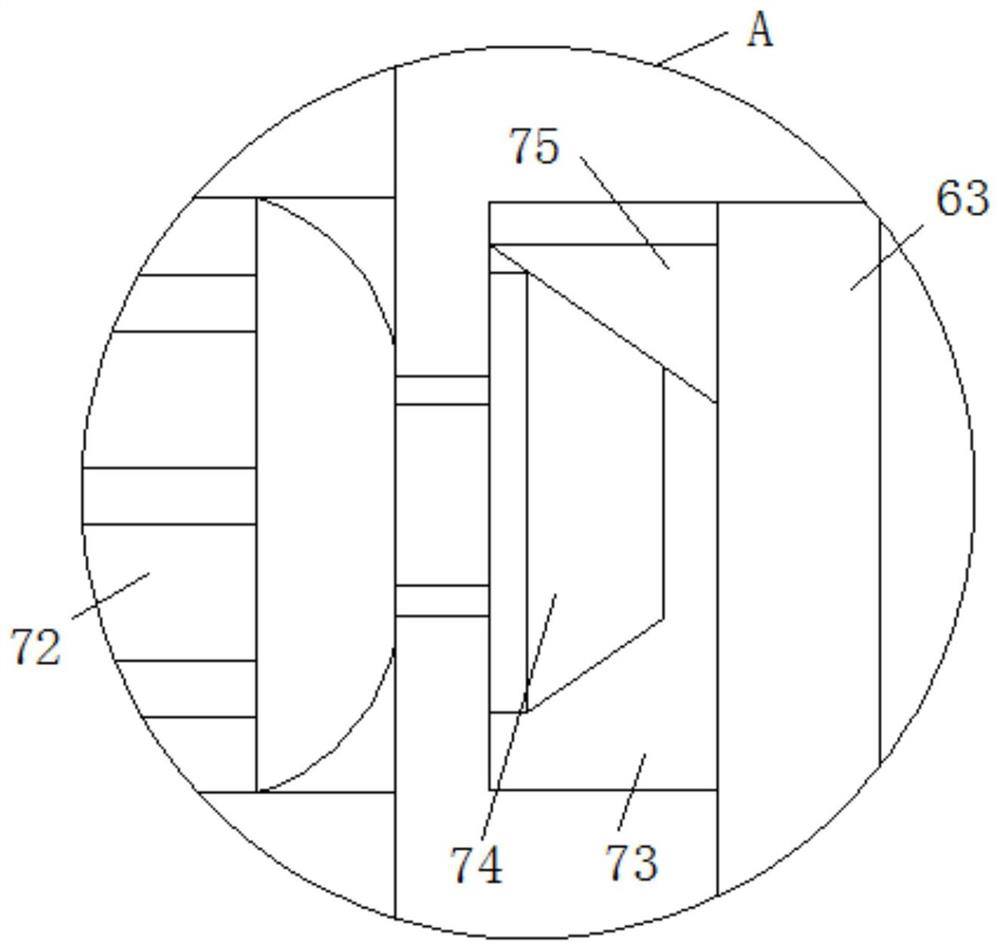

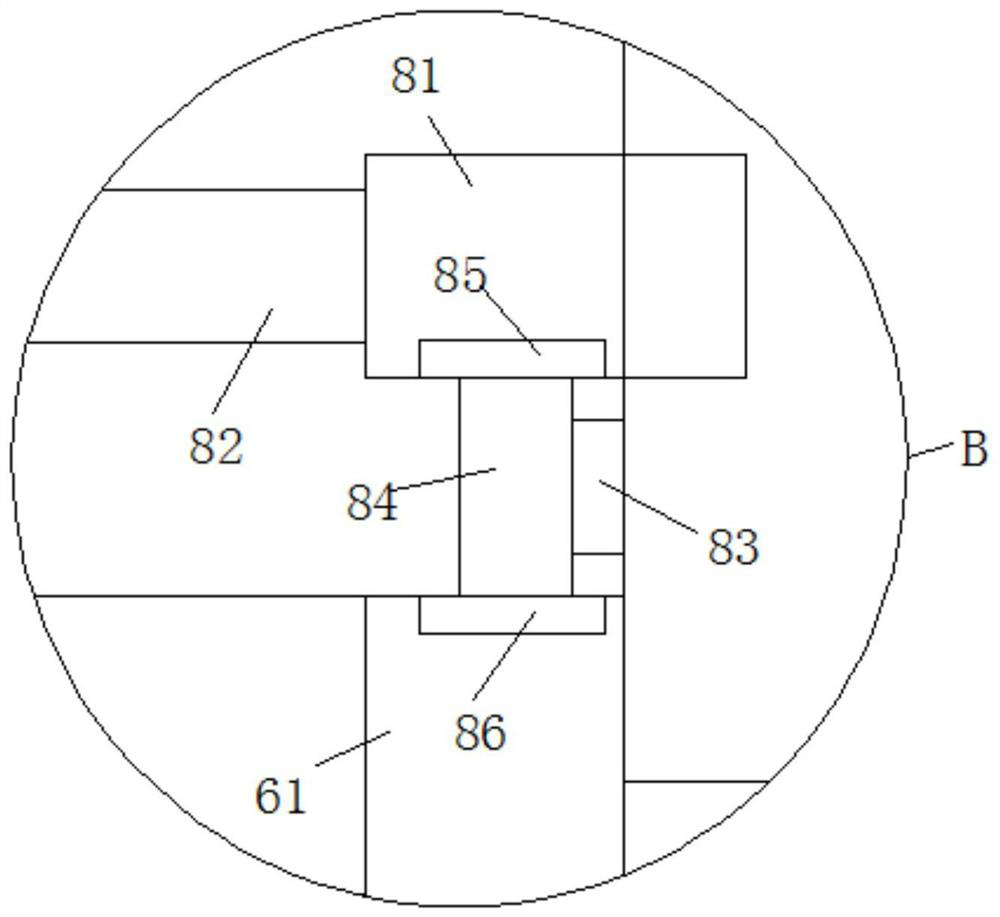

Distillation dehydration device for lubricating oil production

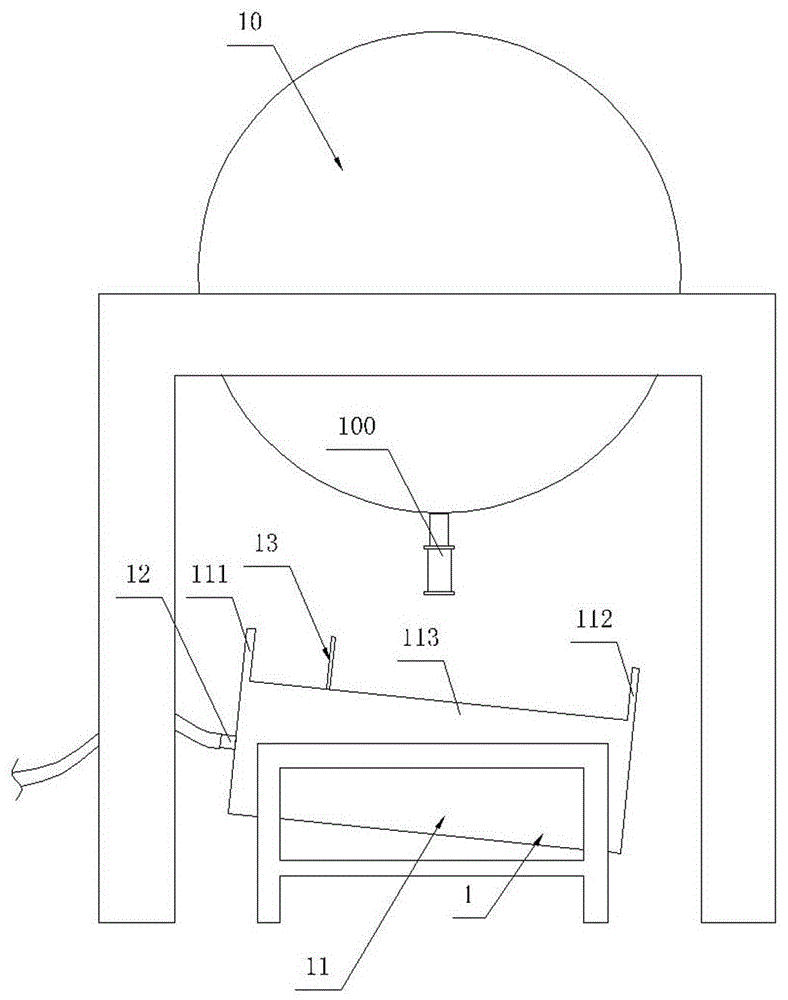

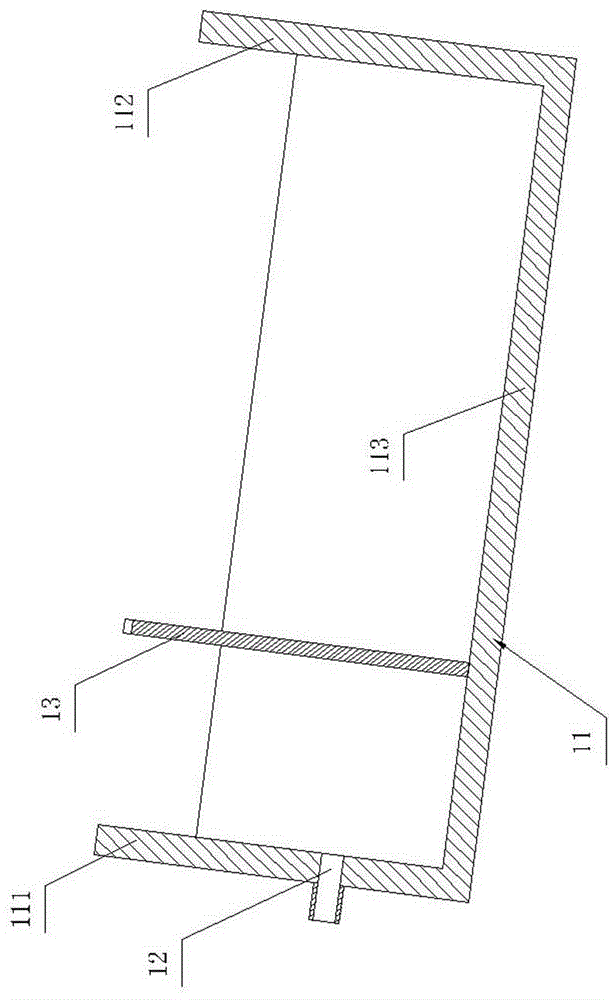

PendingCN113337305AStir wellIncrease water evaporation rateLubricating oils distillationHydrocarbon dewateringProcess engineeringFan blade

The invention discloses a distillation dehydration device for lubricating oil production. The device comprises a distillation box, wherein the lower end of the distillation box is provided with a discharge port, a sealing plug is clamped in the discharge port, the side wall of the upper end of the distillation box is fixedly connected with a feed pipe, and the inner wall of the lower end of the distillation box is fixedly connected with a heating plate. A group of supporting columns are fixedly connected to the outer side of the lower end of the distillation box, and a stirring mechanism is arranged in the distillation box and located in the middle position of the distillation box. Beneficial effects of the device are that: a linkage gear drives a linkage rotating shaft to rotate and through transmission of a worm and a turbine, an exhaust rotating shaft of an exhaust mechanism is driven to rotate, so that exhaust fan blades can rotate, the outward exhaust efficiency of the distillation box is improved, evaporated water vapor can be quickly discharged, and the condition that the water vapor drops into lubricating oil again after being condensed in the distillation box is avoided.

Owner:江苏朗斯汽车用品有限公司

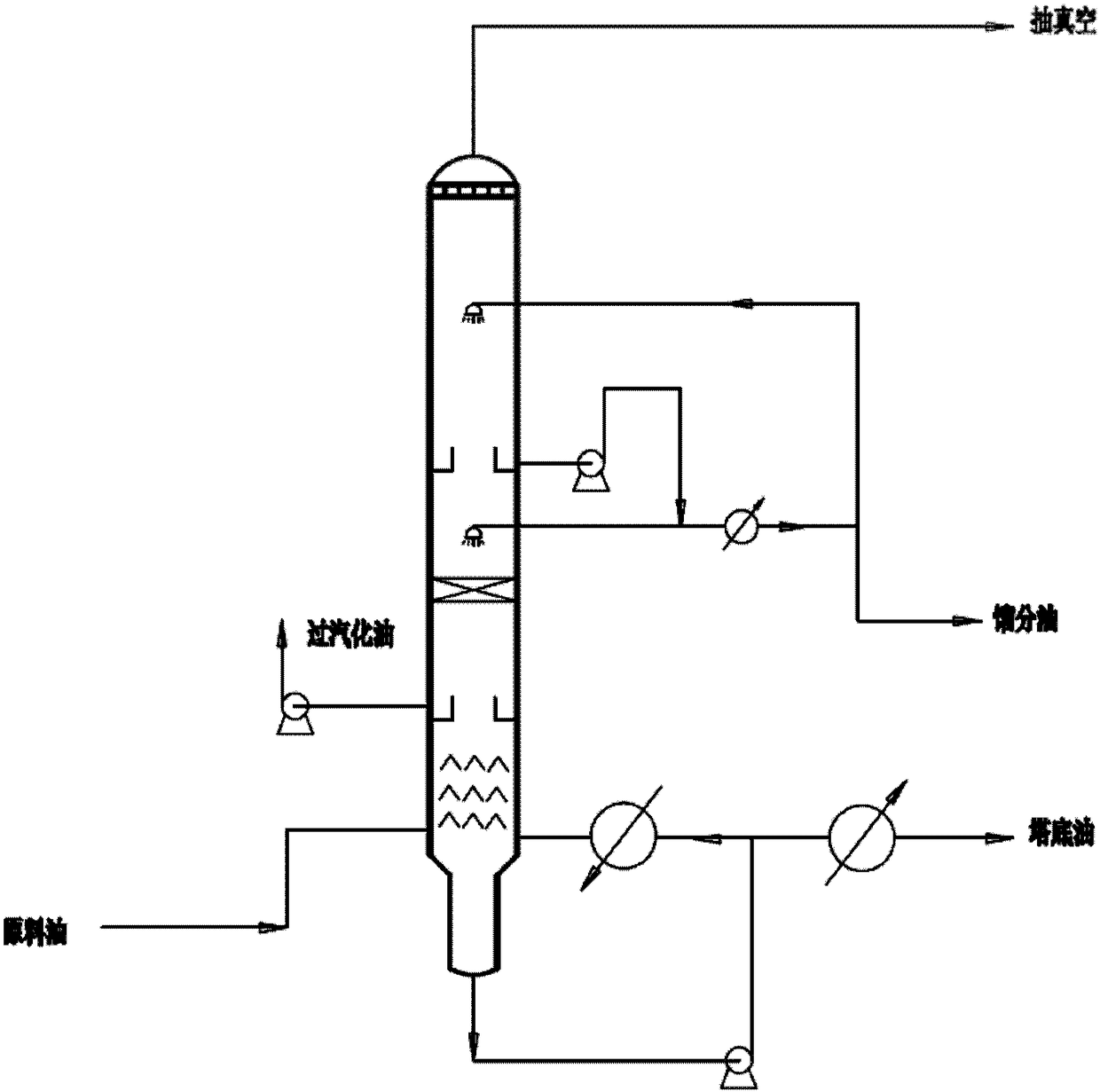

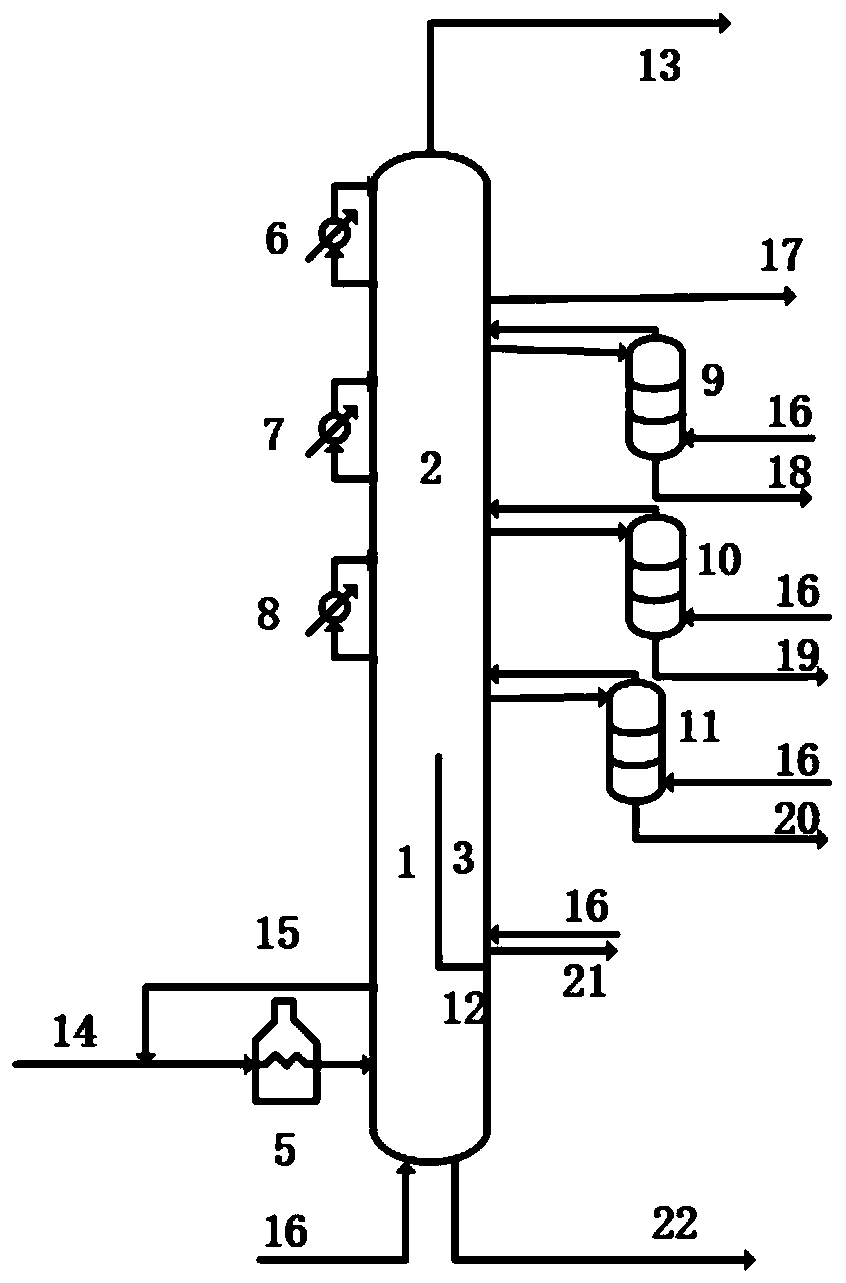

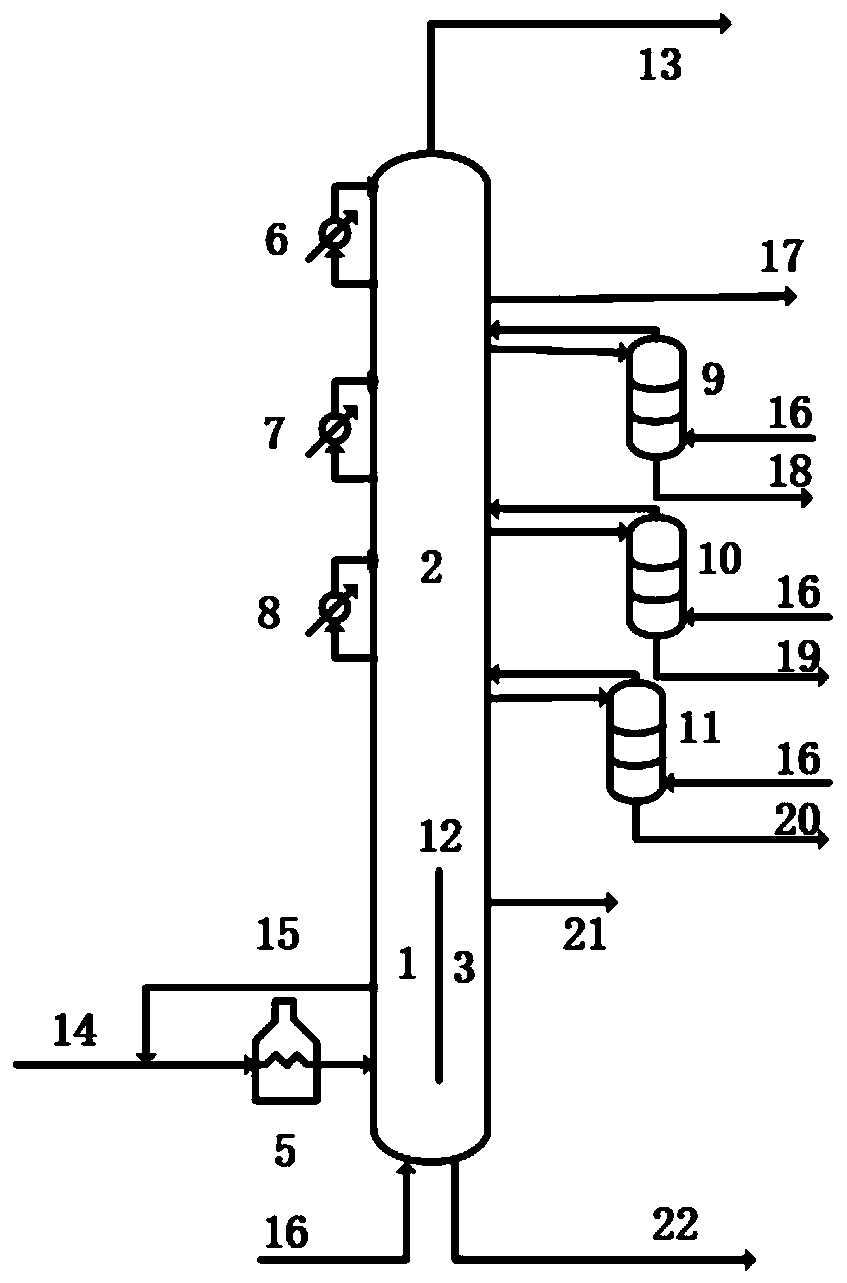

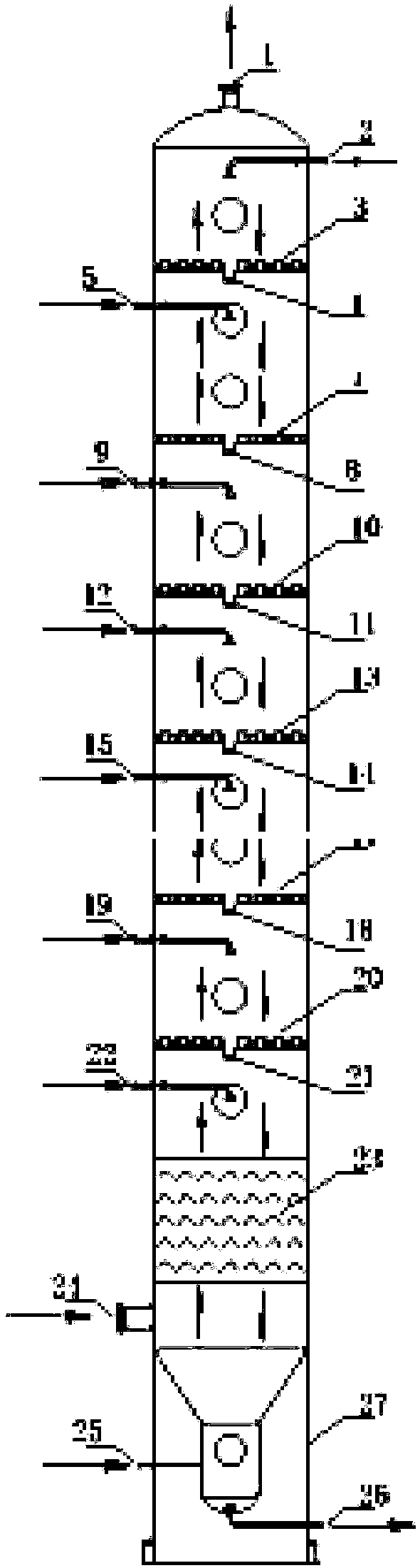

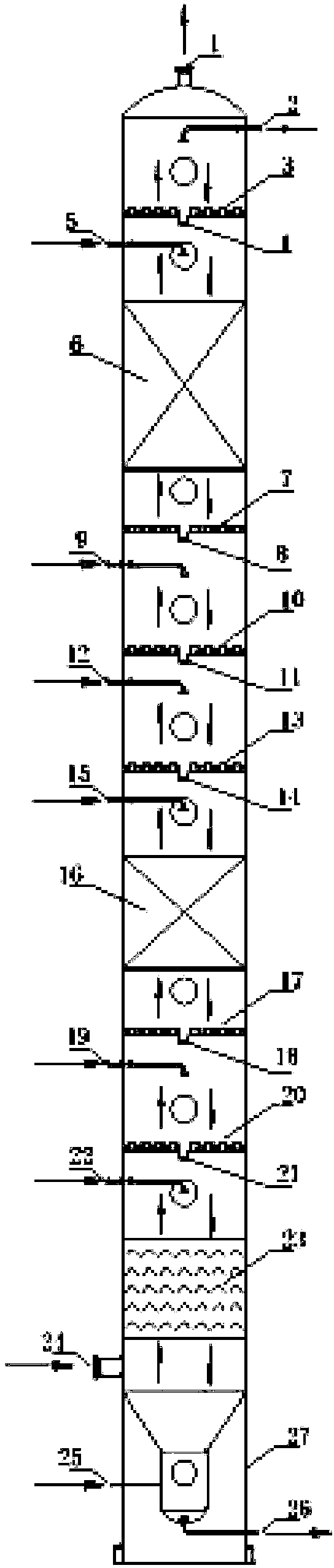

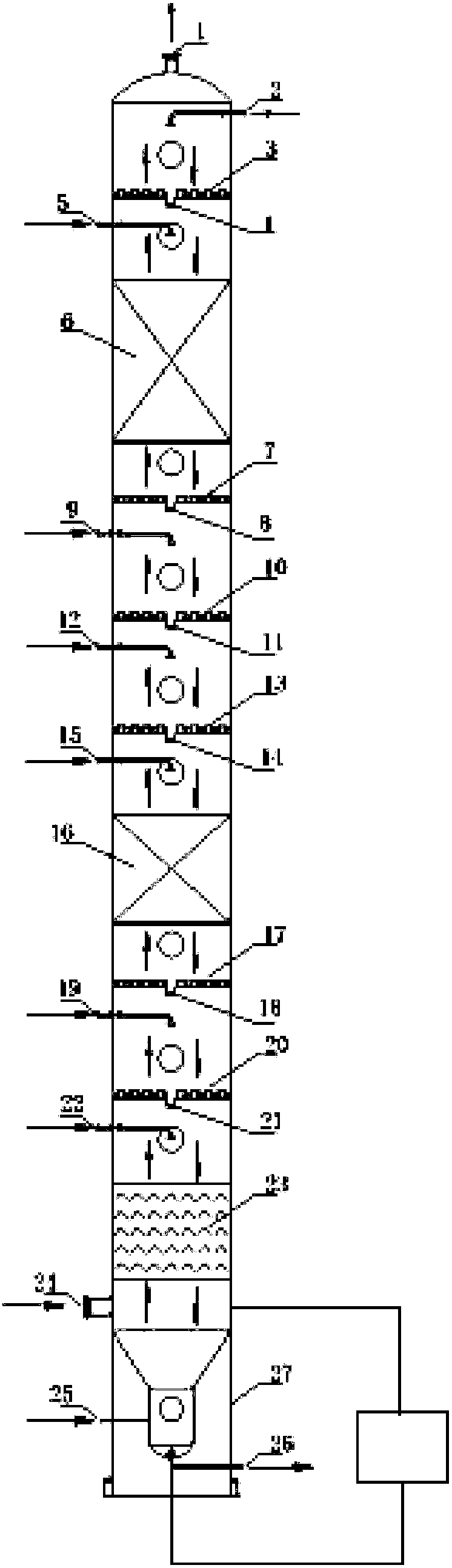

Reduced-pressure distillation equipment for pretreatment of waste lubricant oil

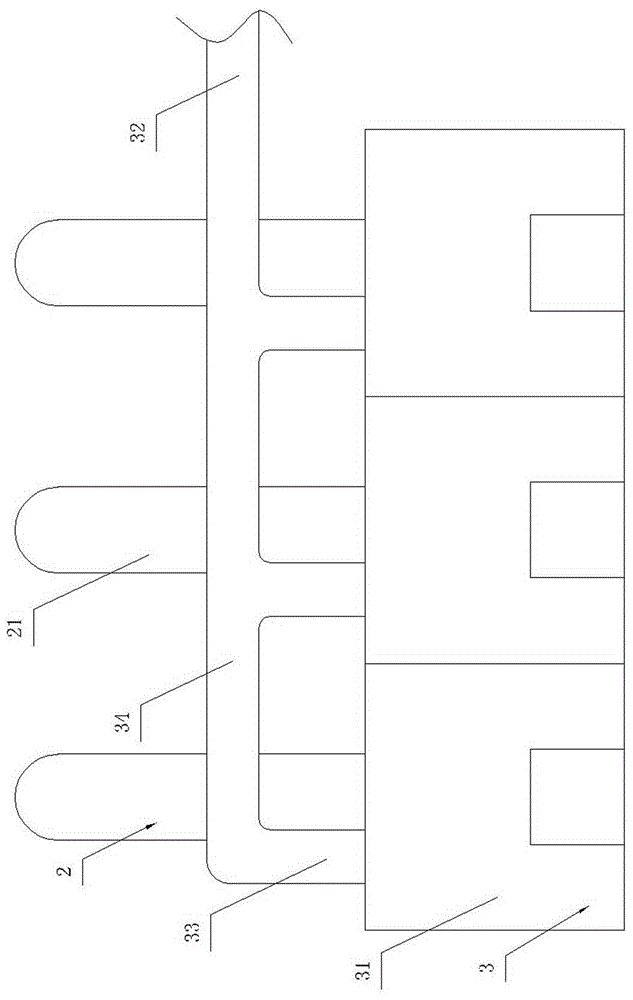

PendingCN108211406AEfficient refining effectDistillation regulation/controlHydrocarbon distillation control/regulationSprayerFractionation

The invention provides reduced-pressure distillation equipment for pretreatment of waste lubricant oil. The reduced-pressure distillation equipment comprises a tower bottom part, a rectification section and a tower top part and is characterized in that the tower bottom part comprises a raw oil inlet and a baffle, the rectification section of the reduced-pressure distillation equipment is free of atower tray and a tower plate, and sprayers are arranged at the top of the rectification section; through arranging the sprayers, sprayed liquid droplets can downwards fall off, under the condition that evaporated raw materials continuously rise from a tower bottom, and can be in direct contact with evaporated waste lubricant oil, so as to achieve a rectification effect. According to the reduced-pressure distillation equipment, the sprayers are used for directly replacing the tower tray and filler, and the column plate and the filler are replaced in a spraying fractionation mode, so that the pressure drop is lowered, and the process is simple, convenient and practical. Significantly, by the technical scheme provided by the invention, the problem that continuous production is affected due to coking of all places in a vacuum distillation tower is solved.

Owner:深圳至诚环境科技有限公司

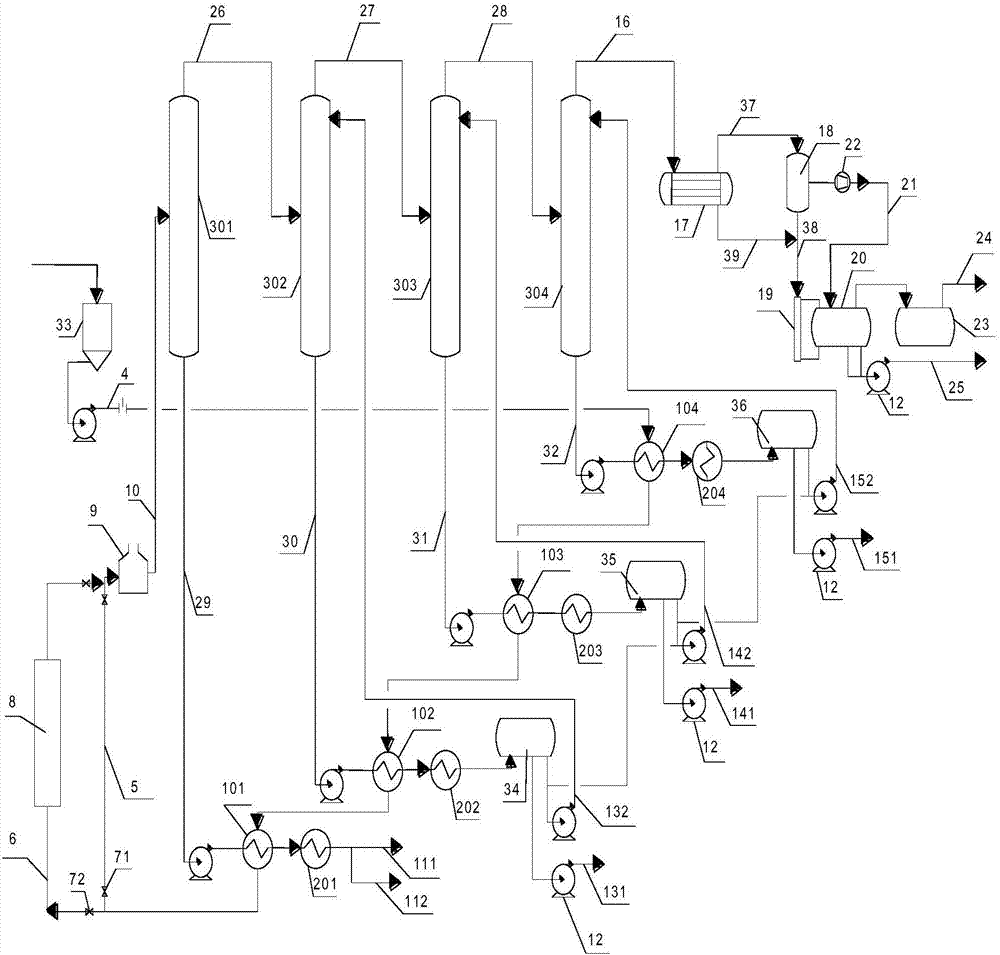

Device for producing diesel oil through catalytic distillation of waste engine oil

InactiveCN104650949ASolve problems that cannot be effectively removedRealize recyclingCatalytic crackingLubricating oils distillationFractionationCatalytic distillation

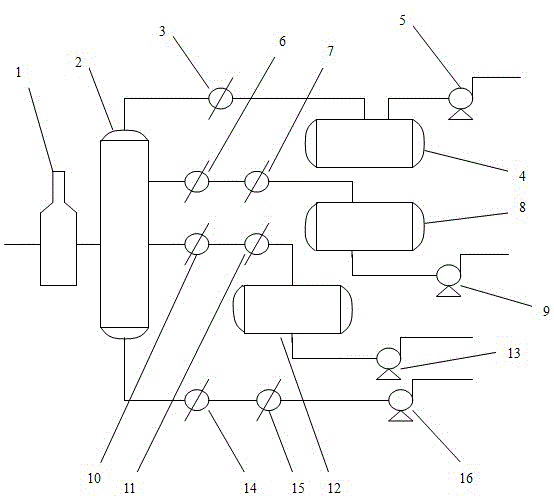

The invention provides a device for producing diesel oil through catalytic distillation of waste engine oil. The technical scheme of the device is described as follows: a heating furnace (1) is connected to a fractionation reaction column (2). A pipeline on the top of the fractionation reaction column (2) is connected to a liquid separating pot (4) through a condenser (3). The liquid separating pot (4) is connected to a vacuum pump (5). A middle-upper pipeline on the fractionation reaction column (2) is connected to a diesel oil pot (8) through a first heat exchanger (6) and a first cooler (7). The diesel oil pot (8) is connected to a diesel oil pump (9). A middle pipeline of the fractionation reaction column (2) is connected to a middle oil pot (12) through a second heat exchanger (10) and a second cooler (11). The middle oil pot (12) is connected to a middle oil pump (13). A bottom pipeline of the fractionation reaction column (2) is connected to a heavy oil pump (16) through a third heat exchanger (14) and a third cooler (15). The device is reasonable and practical in design, solves a problem that impurities cannot be effectively removed in the prior art and meanwhile solves a problem of environmental pollution.

Owner:DONGYING ZHENGFENG NEW ENERGY TECH

Production equipment for recycling and reusing waste oil and production technology of production equipment

ActiveCN106753507AWon't hurtSimple structureLubricating oils distillationHydrocarbon oil dewatering/demulsificationResource utilizationDistillation

The invention discloses production equipment for recycling and reusing waste oil and a production technology of the production equipment. The production equipment comprises an oil storage tank, a material receiving device, a distillation device, a heating device, an exhaust treatment device, a condensation device, an intermediate temporary storage tank, an accident pool, an additive feed pot and a filtering and separating device. According to the production equipment, pollution can be effectively reduced, the recycling and reusing efficiency is high, the resource utilization rate is high and implementation of a sustainable development strategy is greatly facilitated.

Owner:沙县盛福环保节能燃料有限公司

Hybrid thermal process to separate and transform contaminated or uncontaminated hydrocarbon materials into useful products, uses of the process, manufacturing of the corresponding system and plant

ActiveUS10655070B2Thermal non-catalytic crackingChemical/physical/physico-chemical reactor detailsHydrocotyle bowlesioidesWaste oil

Owner:ENVIROLLEA

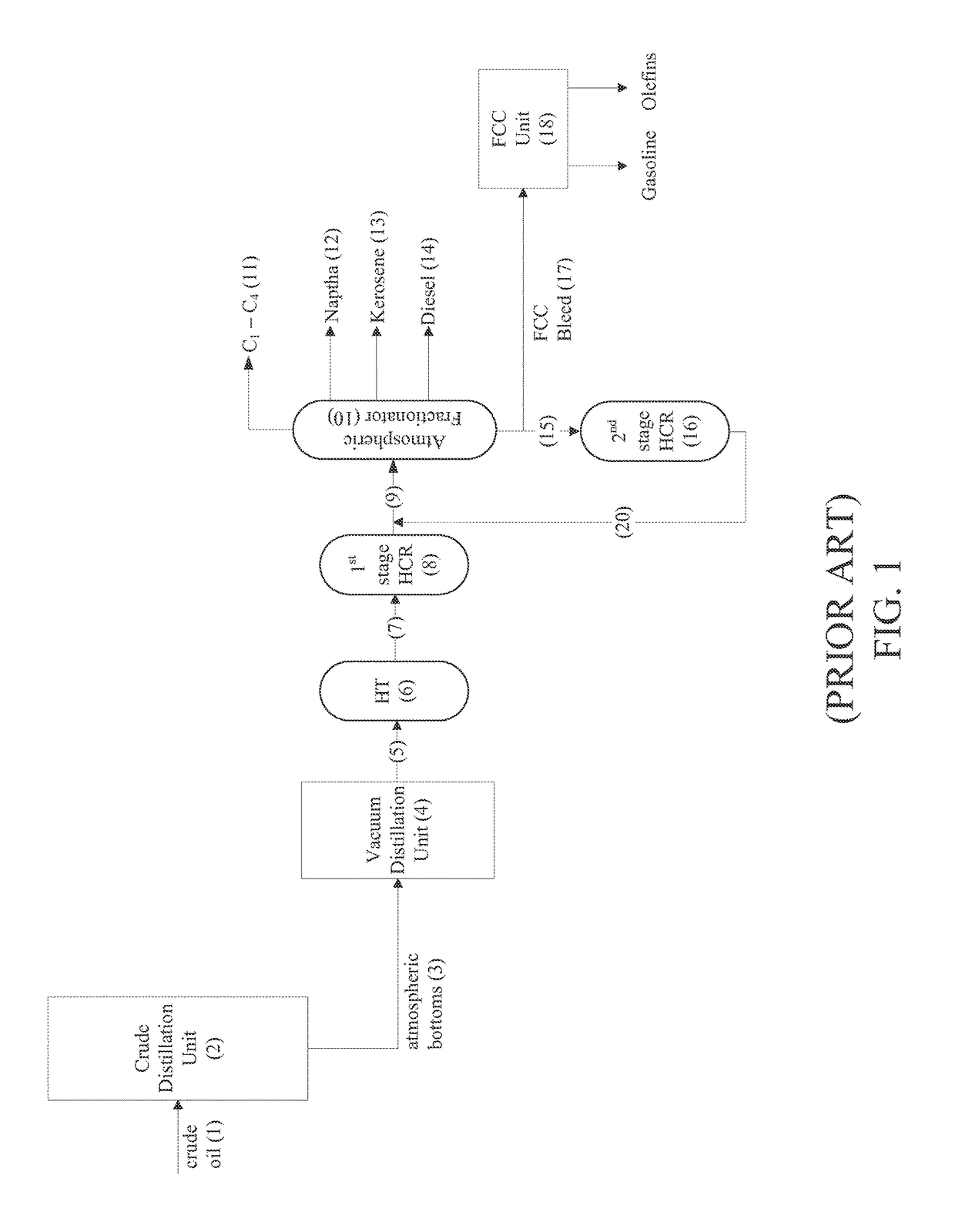

Two-stage hydrocracking process for making heavy lubricating base oil from a heavy coker gas oil blended feedstock

ActiveUS9914887B2Treatment with hydrotreatment processesLubricating oils distillationBase oilOrganic chemistry

The present invention is directed to a refining process for producing heavy lubricating base oils (LBO) from a blended hydrocarbonaceous feedstock containing a heavy coker gas oil, a visbroken gas oil, heavy cycle oil, oils from residue hydrocracking, aromatic extract or any other feedstock normally not conducive to lube oil basestock production, using a two-stage hydrocracking process.

Owner:CHEVROU USA INC

System and Method for Stripping and Extraction of Used Lubricating Oil

ActiveUS20150048005A1High yieldLower the volumeRefining by heating/coolingLubricating oils distillationBase oilSolvent

Owner:SOLVEX PROCESS TECH

Production of diesel and base stocks from crude oil

PendingCN110662822AHigh viscosityEliminate needTreatment with hydrotreatment processesLubricating oils distillationPtru catalystNaphtha

A process of producing Group III base oils, along with a naphtha product and diesel product, from whole waxy crude oil is provided. The inventive process omits the typical vacuum distillation stage and separations to form the typical cuts off of the vacuum tower. By selecting a waxy crude oil suitable for processing without separations, the crude oil may be hydroprocessed, dearomatized, dewaxed, and hydrofinished to produce a Group III base oil. Additionally, the dewaxing catalyst will isomerize the naphtha range molecules to increase the octane value to a suitable level for blending into gasoline and the diesel range molecules to reduce the diesel cloud point.

Owner:EXXONMOBIL RESEARCHK & ENG CO

Process and apparatus for recycling hydrogen to hydroprocess biorenewable feed

ActiveUS11136514B2Liquid hydrocarbon mixture productionTreatment with hydrotreatment processesMethanationEnvironmental engineering

Owner:UOP LLC

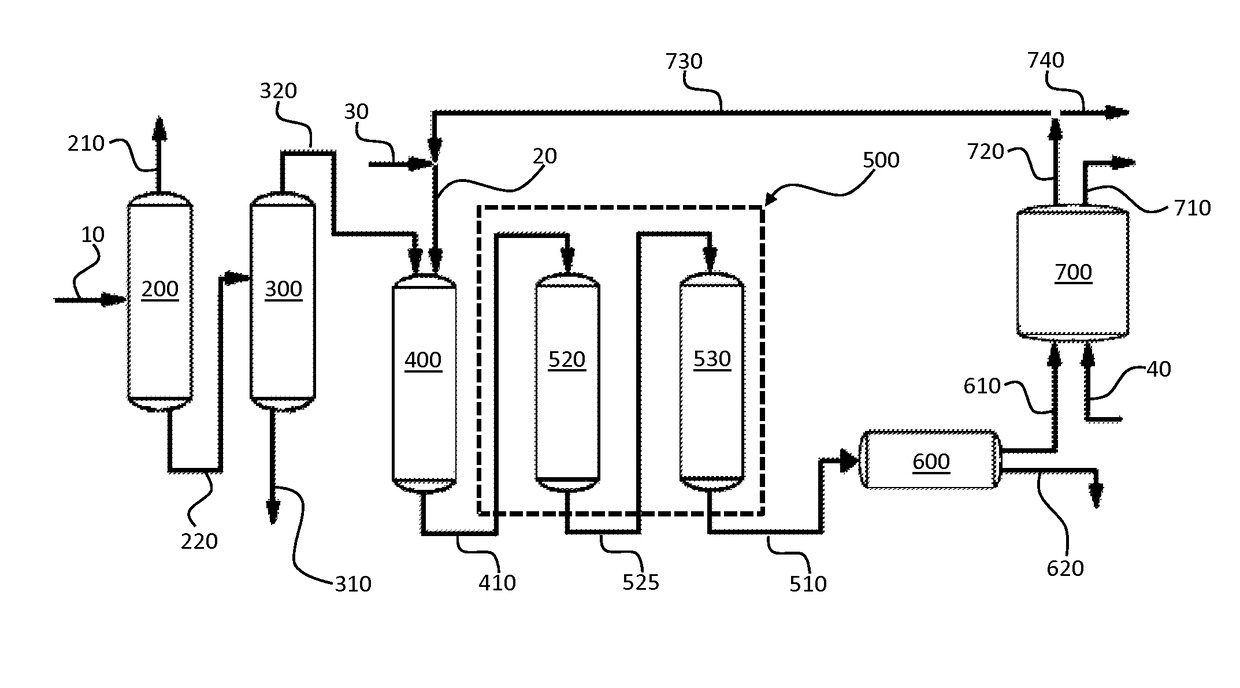

Production of High Quality Base Oils

InactiveUS20190016973A1High yieldEfficient conversion and operationTreatment with hydrotreatment processesLubricating oils distillationProcess engineeringBase oil

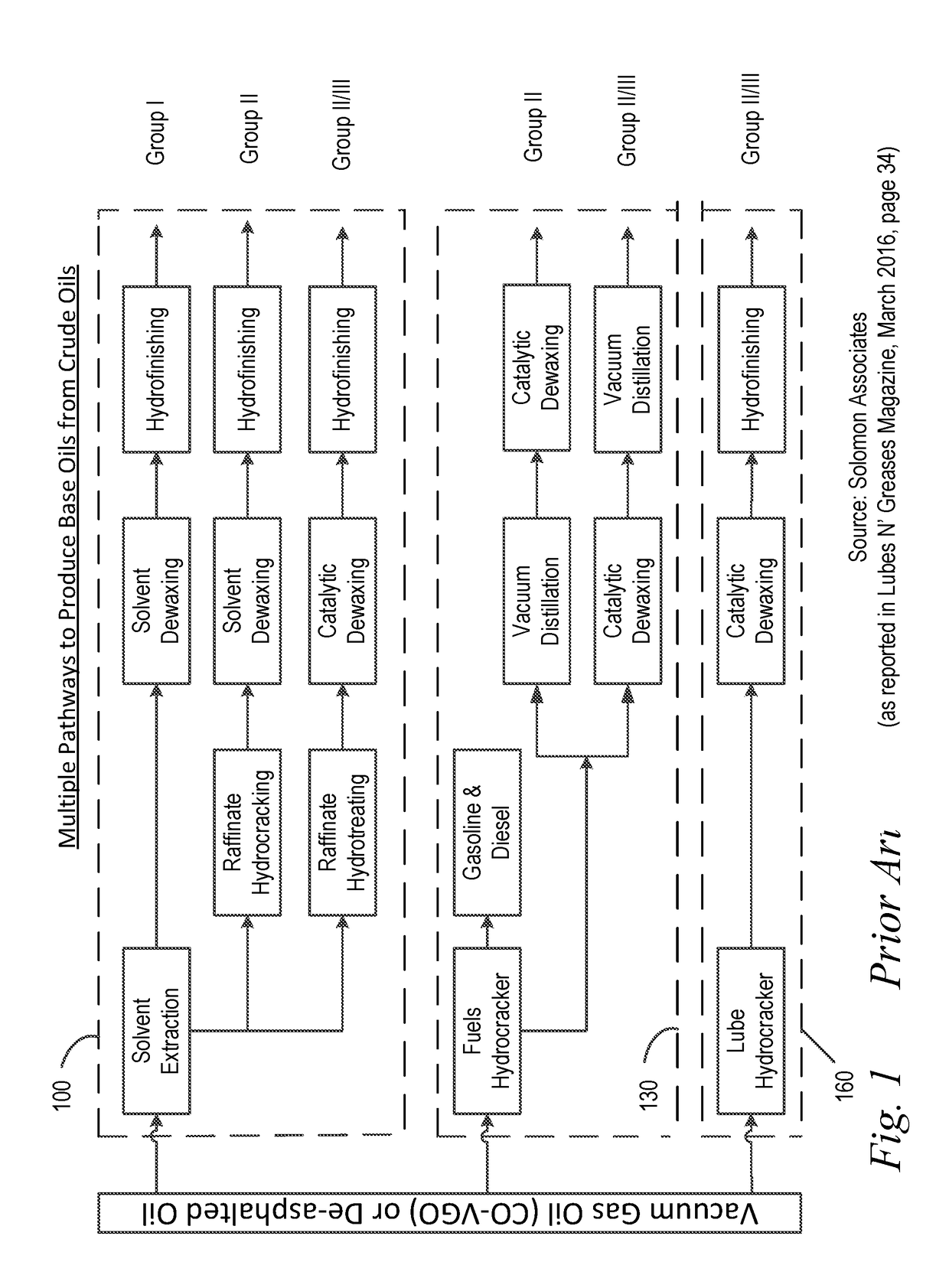

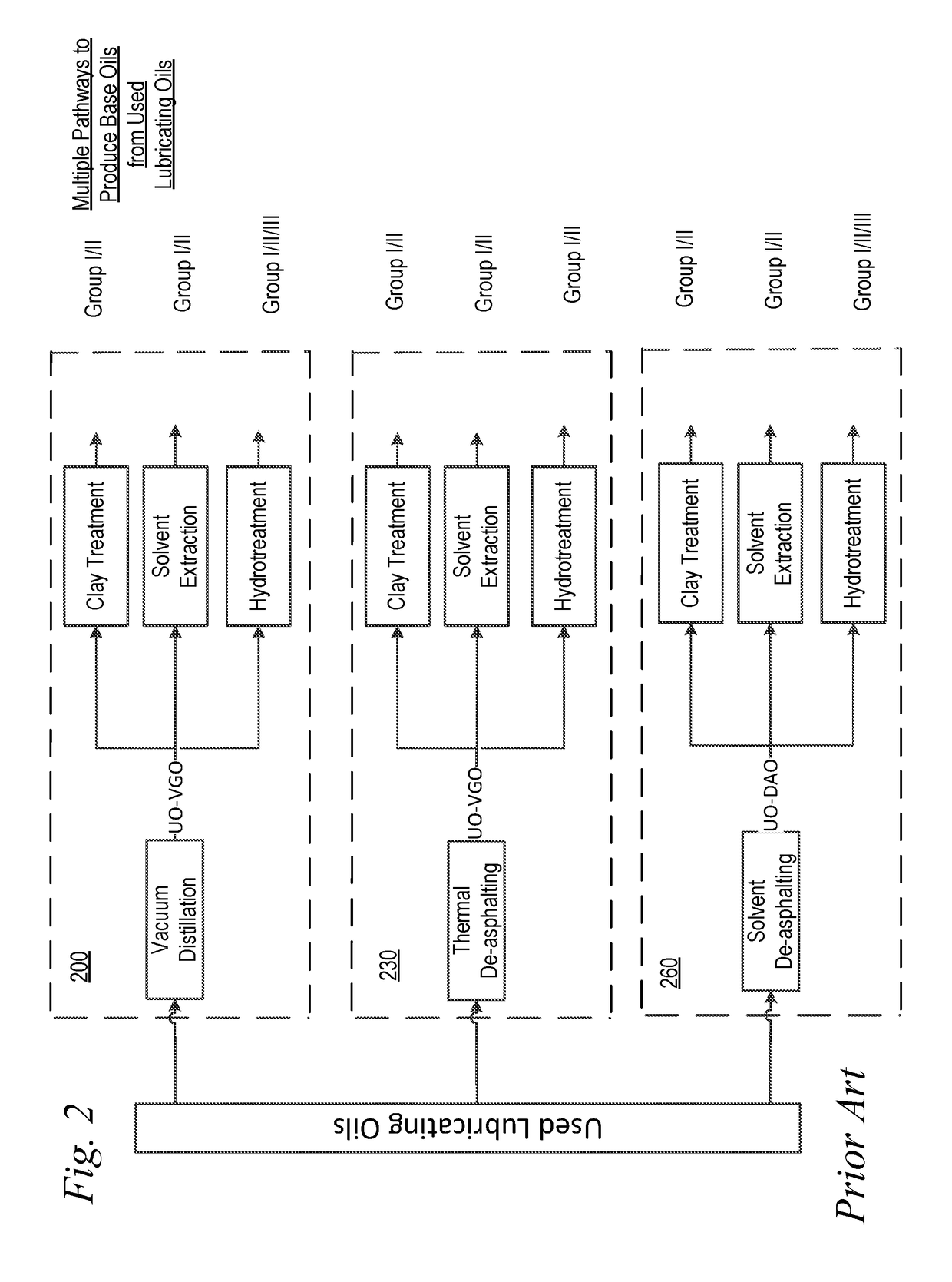

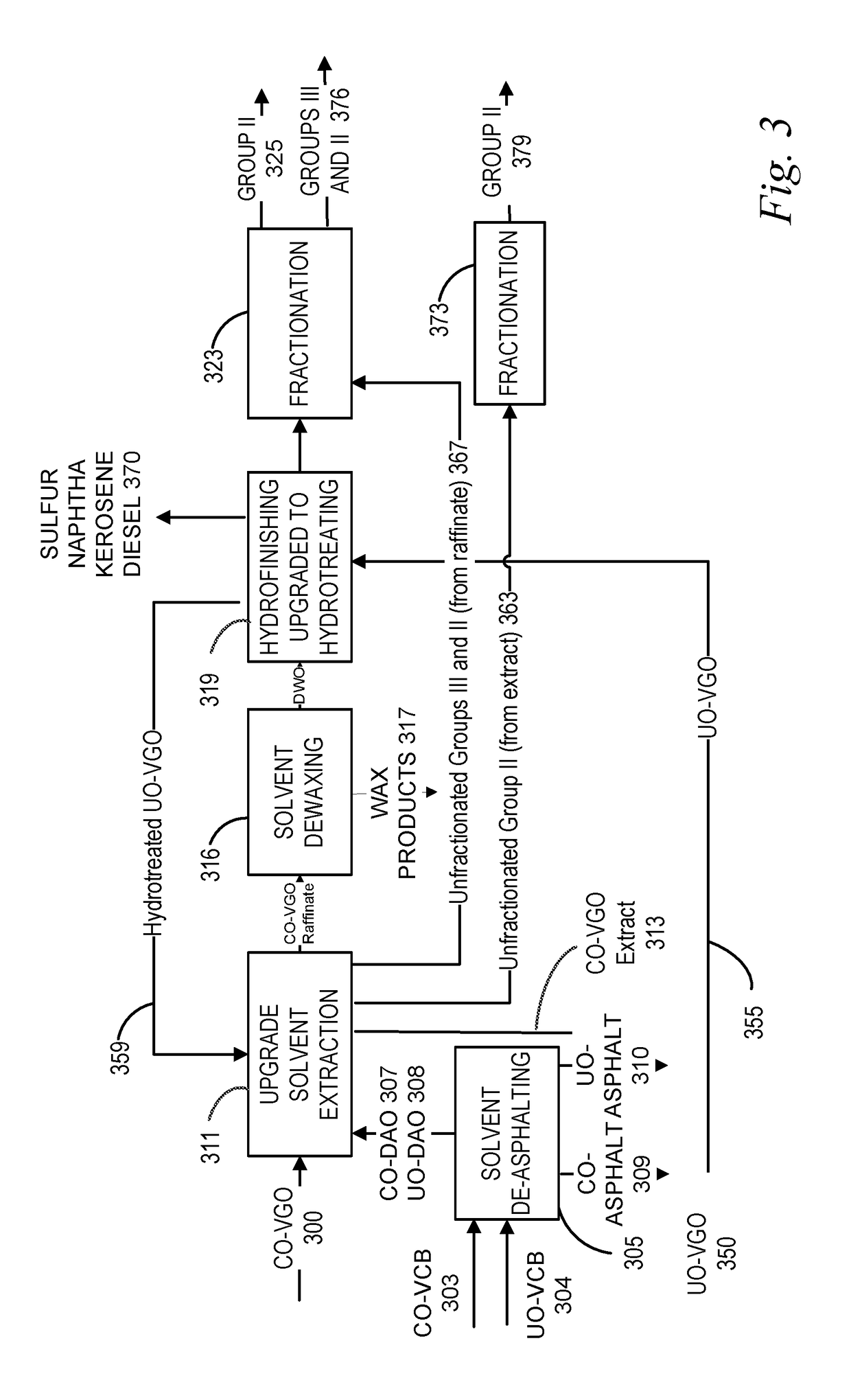

A process for creating higher quality and lower quality base oils from used lubricating oils and crude oils, wherein the higher quality base oils may be either Group III or Group II and the lower quality base oils may be either Group II or Group I. Vacuum gas oils produced from used lubricating oils and from crude oils are processed via two or more process steps, including solvent extraction, solvent or catalytic or iso dewaxing, and hydrotreating. Such process enables efficient conversion and operation of refineries formerly capable only of making Group I base oils, even as their ability to make heavier base oils, waxes, and bright stocks is preserved, substantially to the same extent as such products had been made prior to undertaking the conversion.

Owner:MURRAY EXTRACTION TECH LLC

A method for improving the quality of the five-line product of a lubricating oil-type decompression partition tower

ActiveCN108467744BReduce overlapImprove qualityLubricating oils distillationFractional distillationFluid phaseHeating furnace

The invention relates to a method for improving quality of a vacuum fifth line product of a lubricating oil type vacuum separator tower, and a novel separator tower is introduced in a conventional lubricating oil type vacuum tower. A lower right angle separator is adopted, one side of the vertical section of the separator is used for feeding, the other side of the vertical section of the separatoris used for discharging, the horizontal section of the discharge side of the separator is connected with a tower wall by welding, and the separator tower is divided into three working sections, respectively comprising a pre-fractionation section, a common rectification section and a vacuum fifth line collection section. Normal bottom residue oil to be separated is heated by a heating furnace, enters from the middle of the pre-fractionation section, and is stripped by tower bottom steam, after the stripping, a liquid phase as vacuum residue oil is discharged from the bottom of the tower, a gasphase is sent to the common rectification section, and further separated by a side stripping tower to obtain product diesel and vacuum second line, vacuum third line and vacuum fourth lubricating oil. A stream of steam is introduced in the lower part of a vacuum fifth-line collecting section for stripping, and the vacuum fifth-line lubricating oil product is collected at the bottom. Under the premise of no increasing of the energy consumption of a vacuum furnace, the distillation range of the vacuum fifth-line lubricating oil product and overlapping degree with adjacent products are significantly reduced, and the method is used in the design of a new tower, also in the technical transformation of an old tower.

Owner:TIANJIN UNIV

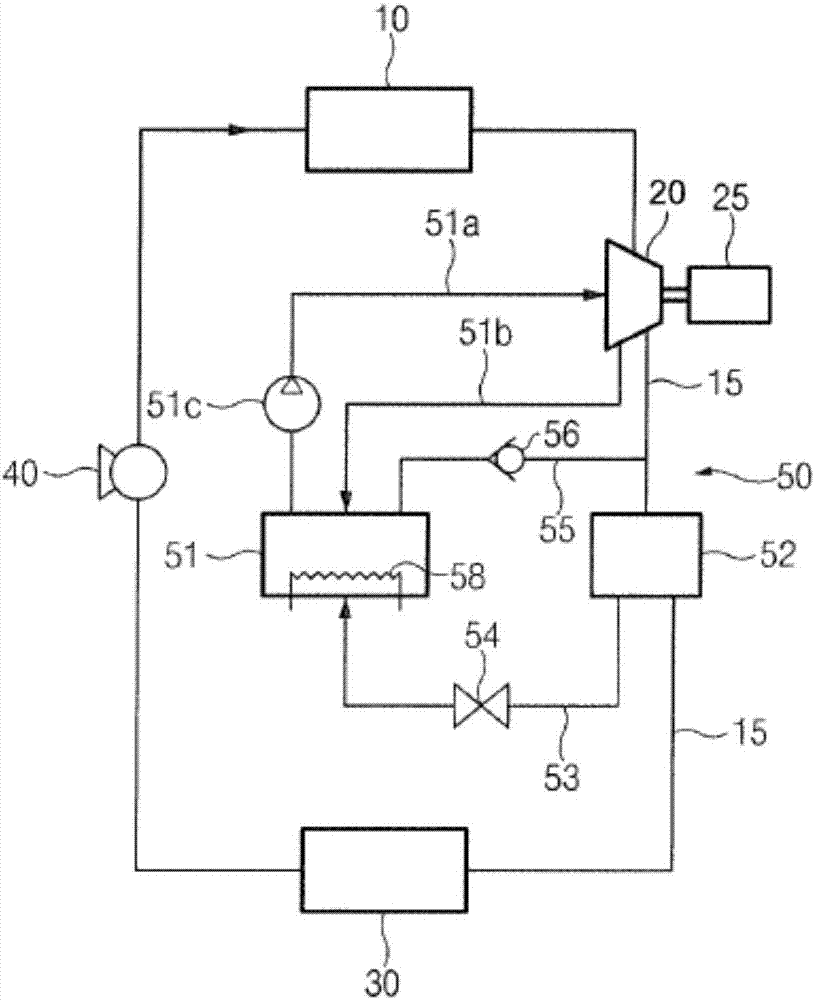

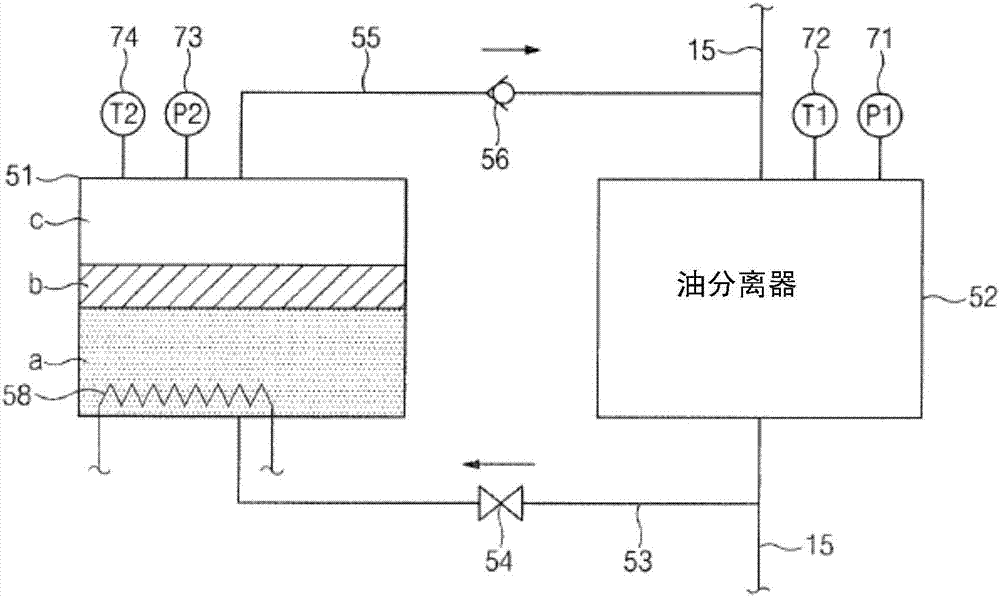

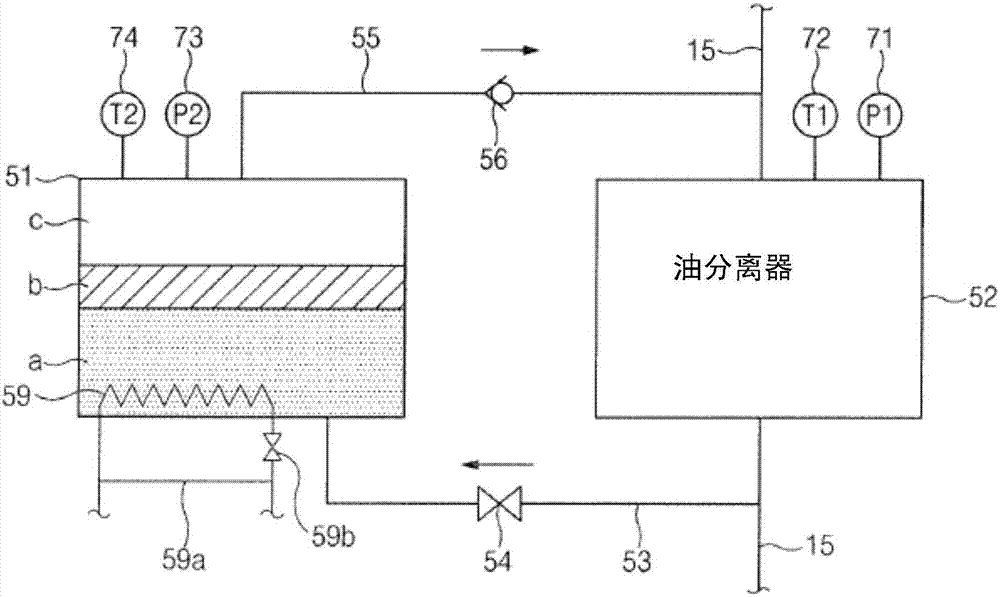

Lubricating oil regenration apparatus and method

InactiveCN107974339AHydrocarbon distillation control/regulationLubricating oils distillationWorking fluidWaste heat

The invention provides an apparatus comprising a lubricating oil tank storing a lubricating oil. An oil separator separates the lubricating oil from a working fluid discharged from an expander of a waste heat recovery system. A lubricating oil return conduit is connected between the oil separator and the lubricating oil tank. A working fluid return conduit is connected between the lubricating oiltank and the oil separator. A vaporizer unit is installed in the lubricating oil tank to vaporize a liquefied working fluid mixed with the separated lubricating oil in the lubricating oil tank.

Owner:HYUNDAI MOTOR CO LTD

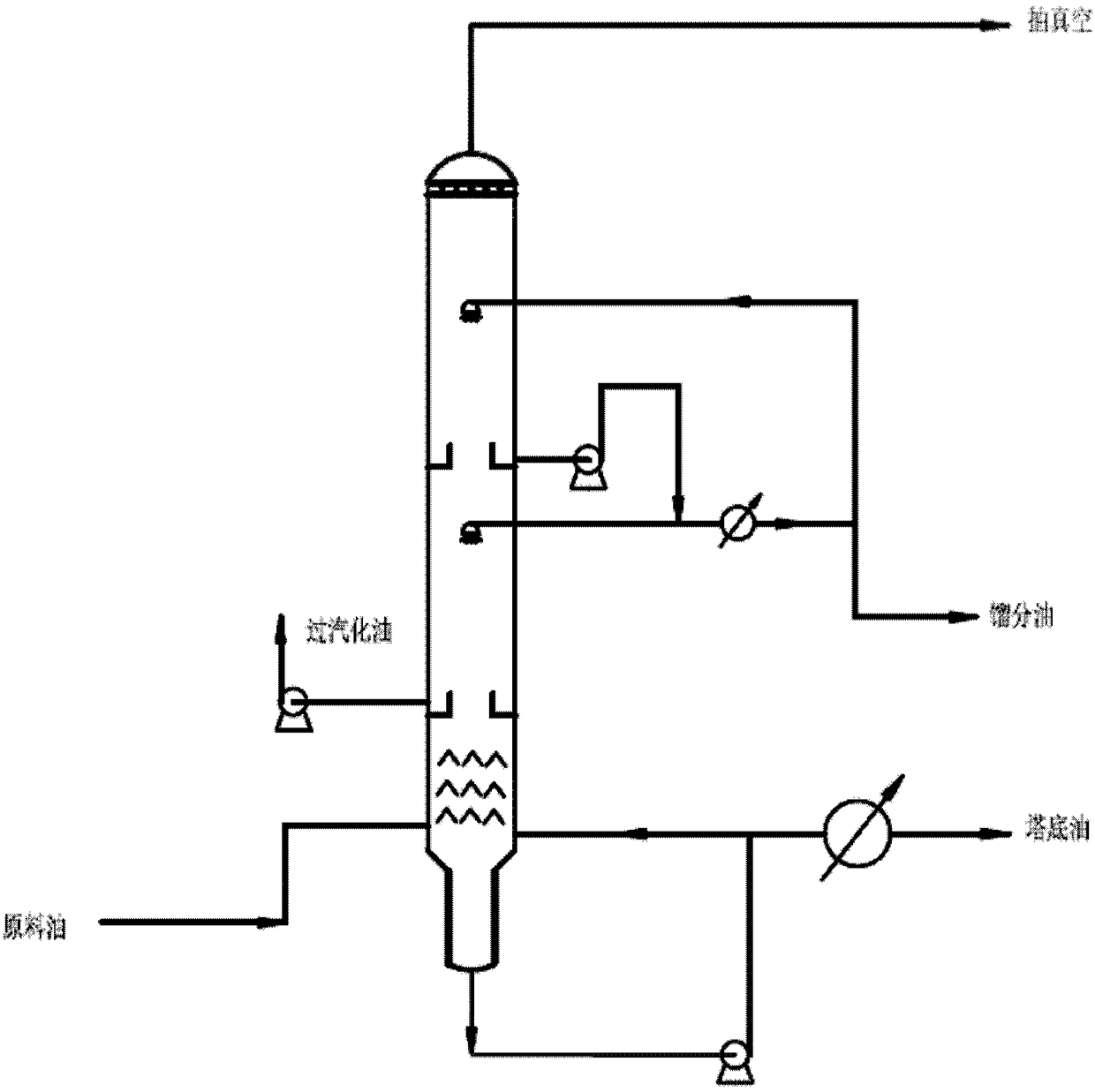

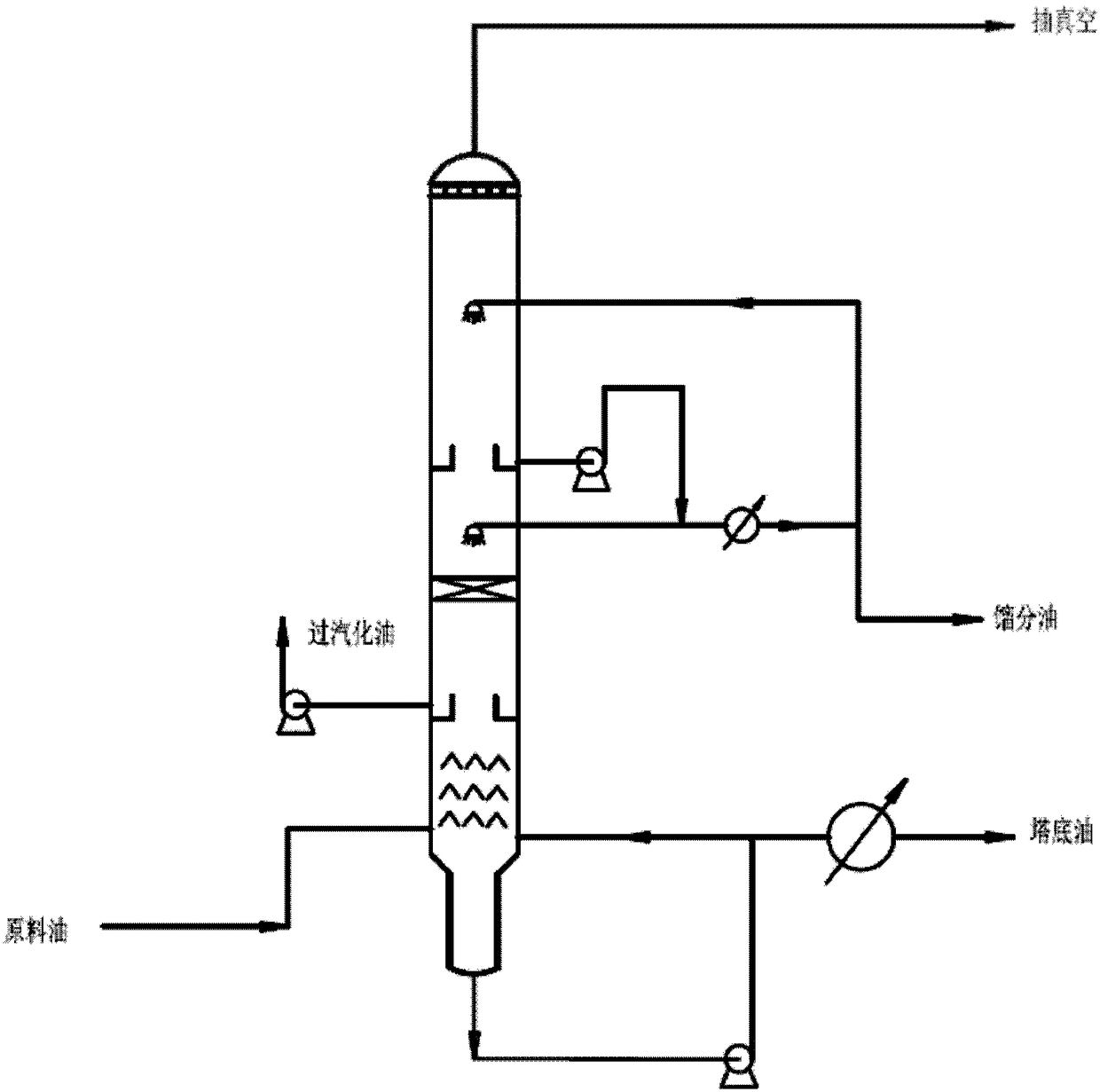

Vacuum tower for waste lubricating oil pretreatment

PendingCN108251152ASolve easy cokingAchieve rectification effectLubricating oils distillationHydrocarbon oils treatmentSprayerFractionation

The invention provides a vacuum tower for waste lubricating oil pretreatment. The vacuum tower is of a cylinder vertical structure; a tower tray is not arranged in the vacuum tower; a tower skirt, a feeding port, a baffle, an over-vaporized oil production section, a distillate oil production section, a diesel production section and a gas outlet are formed in the vacuum tower; two packing sectionscan be arranged among the diesel production section, the distillate oil production section and the over-vaporized oil production section according to the difficulty of separation of distillate oil ineach of the production sections; further, backflow spray distributors are respectively arranged on the three oil production sections and the packing sections. According to the vacuum tower in the scheme of the invention, the tower tray and fillers are directly replaced by utilizing a sprayer, the pressure drop is reduced in a manner of spray fractionation, the separation effect is good, and the process is simple, convenient and practical; moreover, according to the fraction separation difficulty, whether the fillers are provided or not can be freely selected, the heat and mass transfer efficiency is enhanced, and flexible and variable effects are realized, Importantly, the technical scheme of the invention solves the problem of influence on continuous production due to coking in all positions in the vacuum tower.

Owner:深圳至诚环境科技有限公司

Waste lubricating oil regeneration device and regeneration technology thereof

InactiveCN107474932ASave electricitySave heatLubricating oils distillationLubricant compositionThermal energyFractionating column

The invention discloses a waste lubricating oil regeneration device and a regeneration technology thereof. The waste lubricating oil regeneration device comprises at least one heat exchanger, at least one cooler, a lubricating oil heating furnace and at least one distilling tower, wherein a pipeline containing waste lubricating oil is connected with an inlet of a shell pass of the heat exchanger; a pipeline is arranged at an outlet of the shell pass of the heat exchanger and is connected with a material inlet at the middle lower part of the lubricating oil heating furnace; a pipeline is arranged at a material outlet of the lubricating oil heating furnace and is connected with the middle upper part of the distilling tower; a pipeline is arranged on a tower kettle of the distilling tower and is connected with an inlet of a tube pass of the cooler; a finished lubricating oil pipeline and a pipeline for communicating with the waste lubricating oil pipeline are arranged at an outlet of the tube pass of the cooler. The waste lubricating oil regeneration device has the advantages that the to-be-treated waste lubricating oil in the pipeline exchanges heat with the raw material which does not enter the treatment process by the heat exchanger, so that the consumption of heat energy is reduced; the waste lubricating oil is heated to the required temperature by the lubricating oil heating furnace, and then is sent into the distilling tower, and multiple types of lubricating oil are separated out according to different fractions, so that the recycling rate is high.

Owner:苏州中吴能源科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com