Production of diesel and base stocks from crude oil

A lubricating oil base oil and crude oil technology, which is applied in the direction of hydrocarbon oil treatment products, hydrocarbon oil treatment, petroleum industry, etc., can solve the problem that the base oil cannot be produced

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

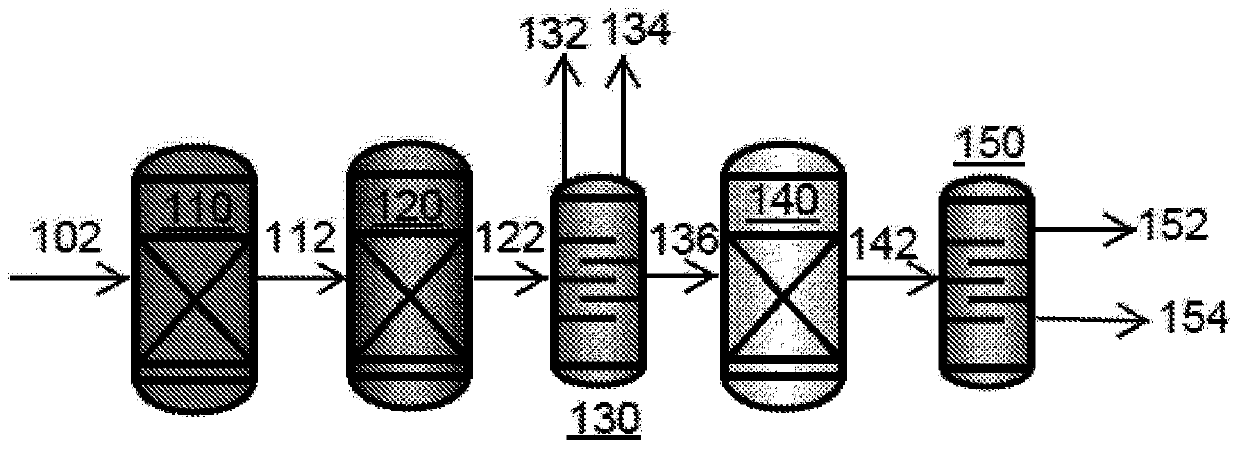

Image

Examples

Embodiment

[0051] A fully waxy crude oil having the properties listed in Table 1 below is provided. The 350°F–(176°C–) fraction of the full waxy crude oil has an octane number of 40, and the 350-650°F (176-343°C) distillate fraction has a cloud point of 25°C.

[0052] APIs 52 wt%H 14.6 wt%200℉+ 85 wt%350℉+ 40 wt%650℉+ 30 wt%1050℉+ 7 % Aromatic Carbon 6.8 ppm S 100 ppm N 134 wt% saturated hydrocarbon 88 wt% aromatics 12 MCRT, wt% 0.25 Ni+V, ppm 1

[0053] Table 1

[0054]The waxy crude was run on a stacked bed of three commercially available nickel molybdenum sulfidation hydroprocessing catalysts at about 1800 psig for about 0.4 hr -1 LHSV and an initial cycle temperature of about 340°C for processing. The yield of 650°F+ (343°C+) product was about 28 wt%. The total liquid product has a sulfur content of -1 Dewaxing was performed at LHSV, about 340°C and 1800 psig. The dewaxed effluent was distilled...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pour point | aaaaa | aaaaa |

| pour point | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com