Process and system for recovering base oil from lubrication oil that contains contaminants therein

a technology of lubrication oil and base oil, which is applied in the direction of working up pitch/asphalt/bitumen by distillation, working up by distillation, etc., can solve the problems of affecting the properties of lubrication oil, deterioration of lubrication oil, and contamination by extraneous, so as to maximize the value of recycled products and facilitate the manufacturing of lubrication products. , the effect of flexible flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

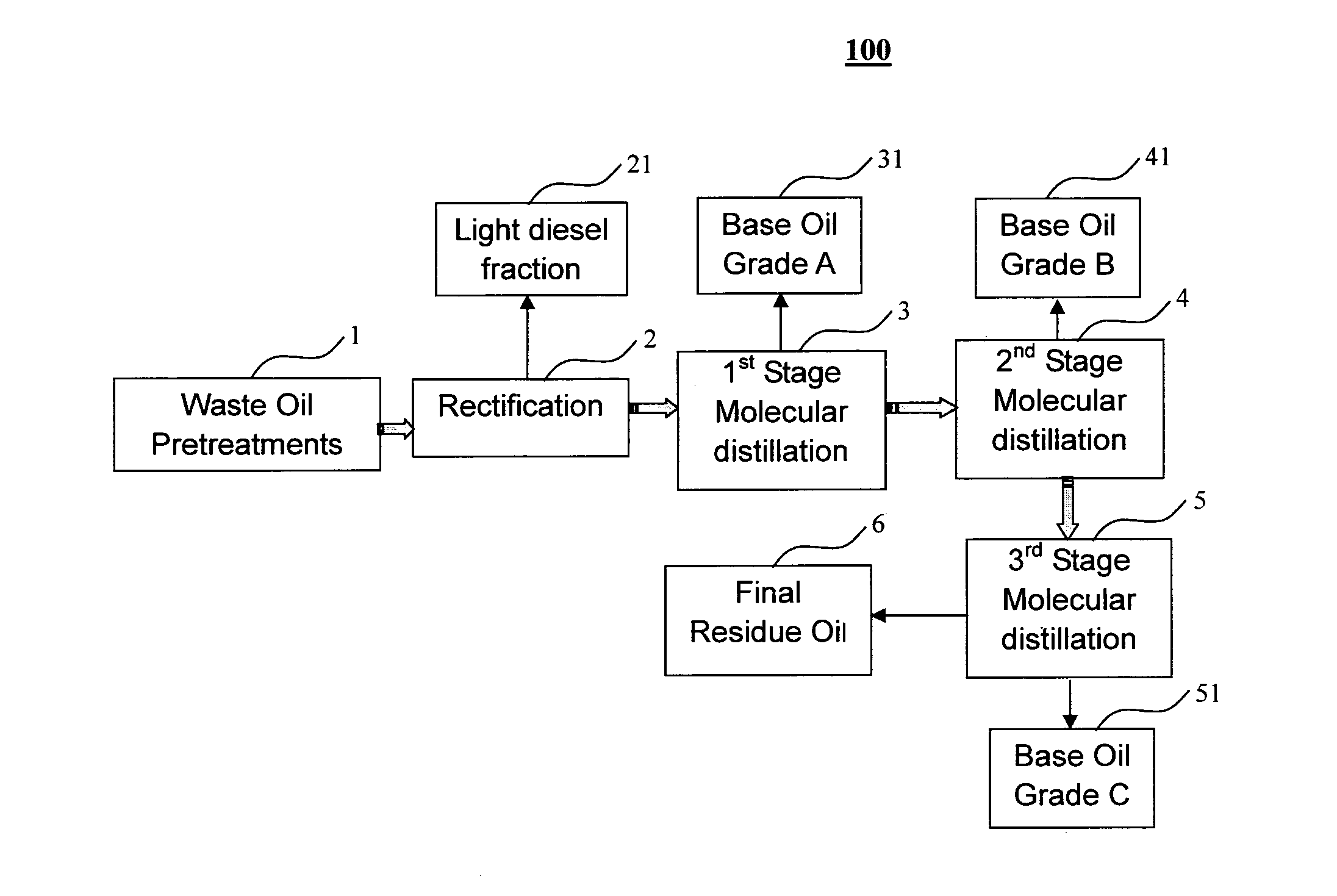

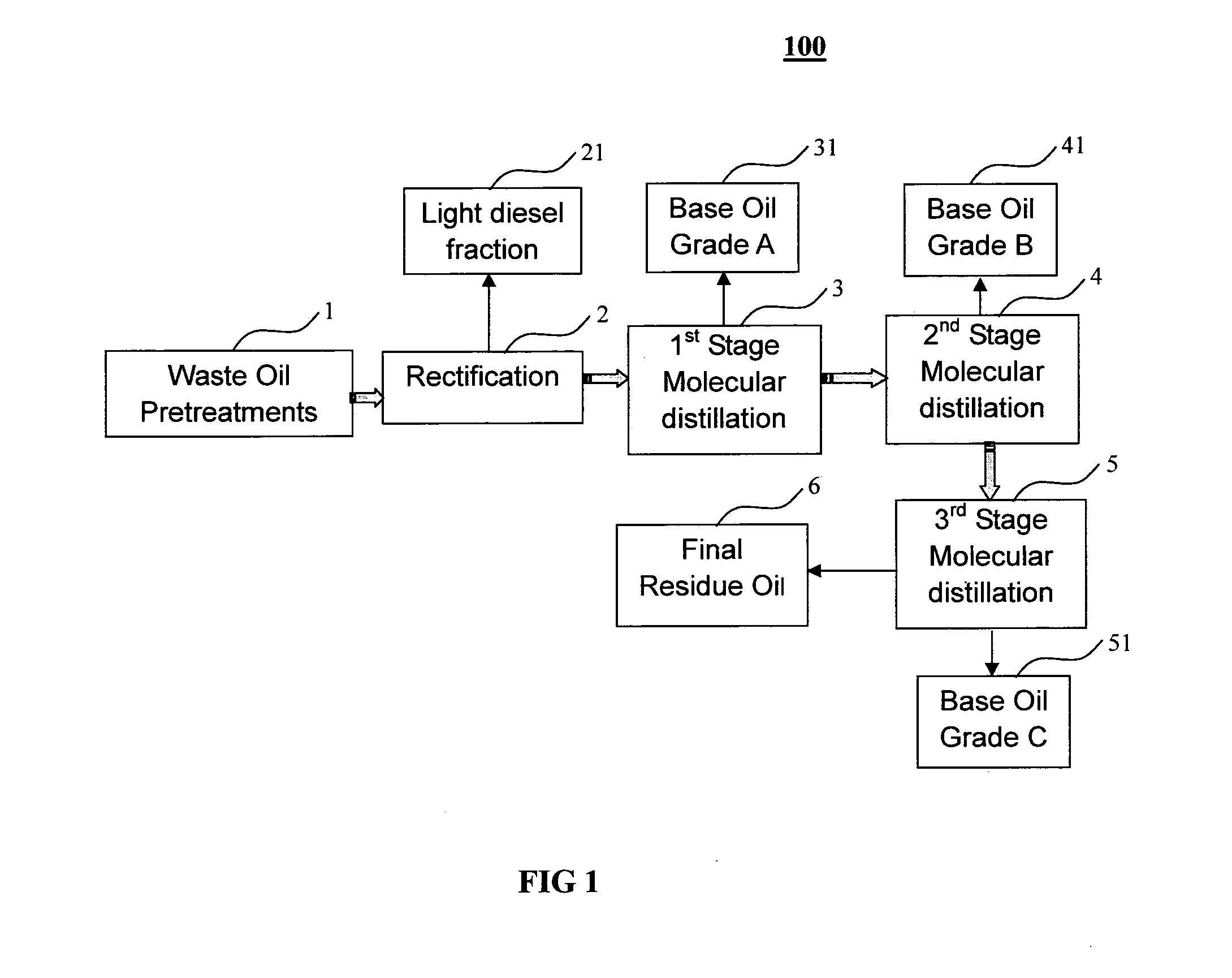

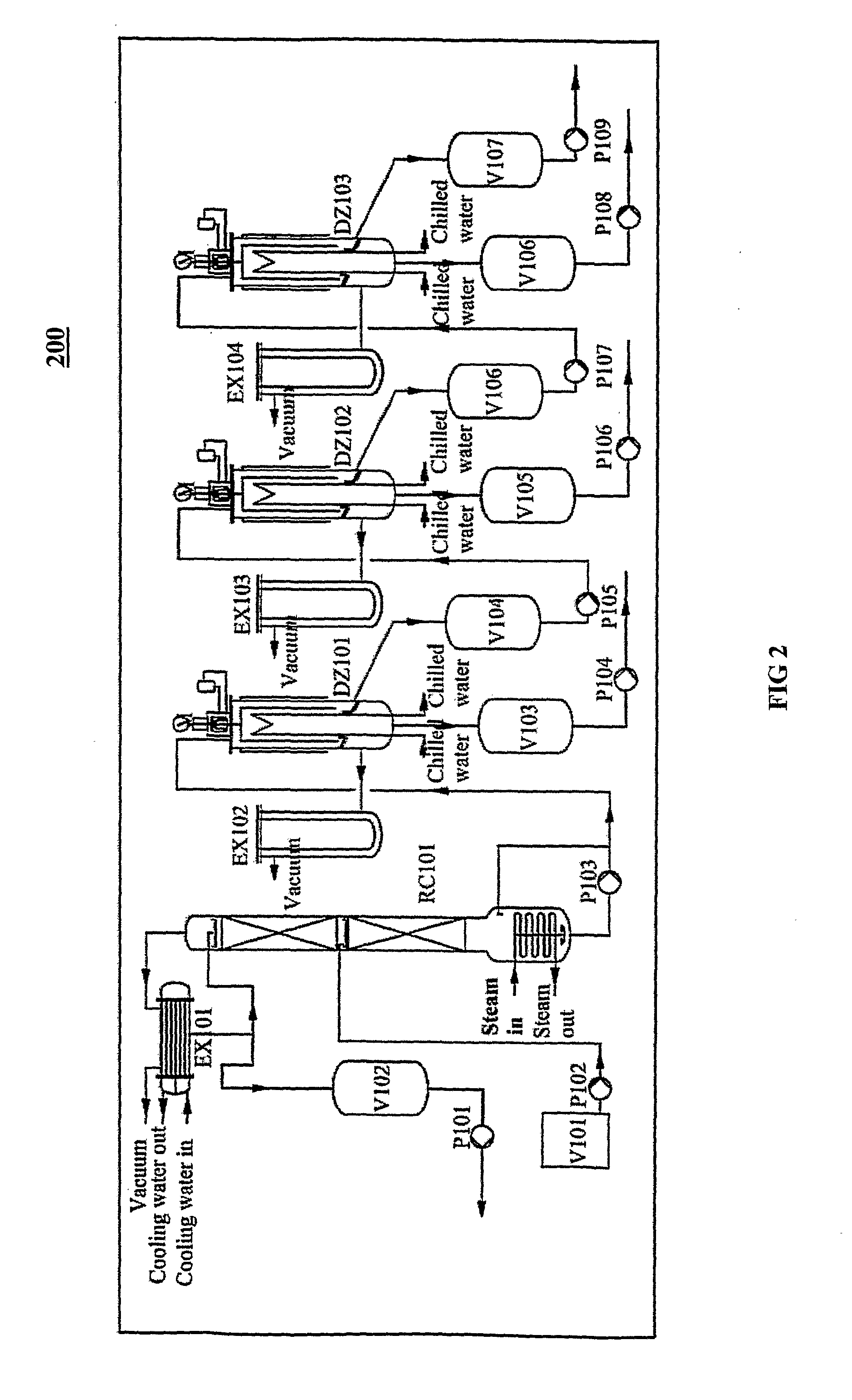

[0067]Example 1 of the regeneration of spent lubrication oil will be described in connection with the system 200 with three stages of molecular distillations as shown in FIG. 2.

[0068]After pretreatments with dehydration and deodorization, the pre-treated waste oil in the storage tank V101 was pumped by the pump P102 to the rectification column RC101 to remove the light diesel fraction, where the light diesel vapor was condensed by the condenser EX101 and transferred to the storage tank V102 and further transferred for any suitable purpose by the pump P101.

[0069]The residue waste oil after rectification treatment was pumped by the pump P103 to the 1st stage molecular distillation DZ101. The 1st stage molecular distillation was operated at the temperature of about 200° C. and the vacuum pressure of about 80 Pa, where the distillation range was from about 370-450° C., and the product recovery rate was about 27%. The flash point and viscosity specifications of the product are in complia...

example 2

[0073]The regeneration of spent lubrication oil of the present invention could be operated with a system employing only two stages of molecular distillations in a similar configuration as shown in FIG. 2. Thus, the description will be made in connection with FIG. 2, where only the differences from Example 1 are highlighted below.

[0074]The 1st stage molecular distillation column DZ101 was operated at the temperature of about 210° C., and the vacuum of about 80 Pa, where the distillation range was from about 370-440° C., and the product recovery rate was about 51%. The flash point and viscosity specifications of the product are in compliance with MVI 200 base oil specifications.

[0075]The 2nd stage molecular distillation column DZ102 was operated at temperature of about 320° C., and the vacuum of about 3 Pa, where the distillation range as from about 440-540° C., and the product recovery rate was about 39%. The viscosity and flash point specifications of the product are in compliance w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com