A method for improving the quality of the five-line product of a lubricating oil-type decompression partition tower

A clapboard column and lubricating oil technology, applied in the direction of lubricating oil distillation, separation methods, chemical instruments and methods, etc., can solve problems such as large reflux ratio, unfavorable separation economic benefits, and inability to be used as lubricating oil base oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

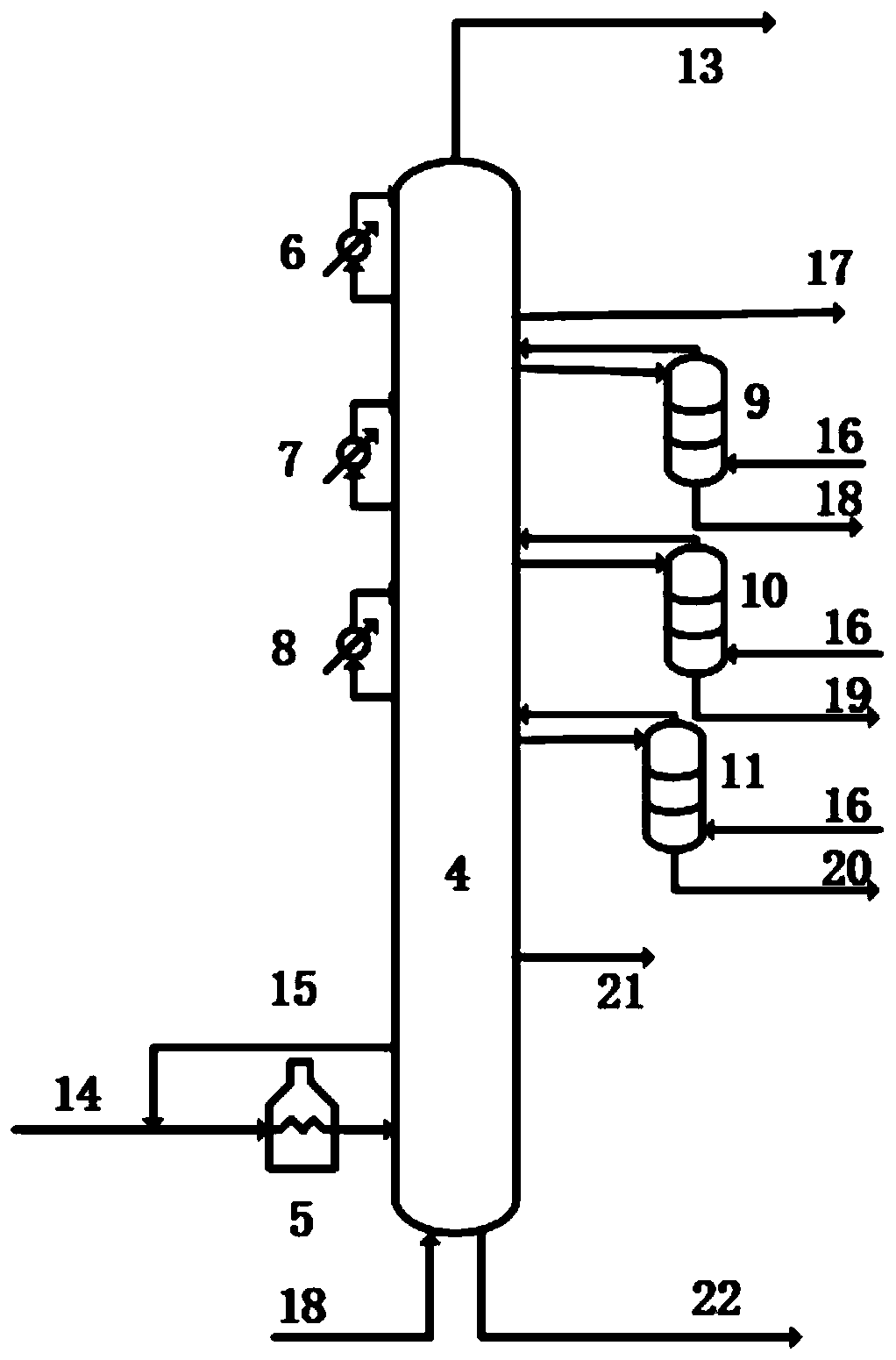

[0028] In order to improve the quality of lubricating oil produced by the fifth-line product so that the distillation range is less than 50°C, a certain device adopts the following figure 2 The lower partition column shown is applied to the lubricating oil type vacuum column scheme. The normal bottom residue (14) to be separated is heated by the heating furnace (5) and enters from the middle of the pre-fractionation section, and the liquid phase is extracted from the bottom of the tower as a vacuum residue (22) after steam stripping (16) at the bottom of the tower, and the gas phase Go to the public rectification section, and recover the heat in the tower through the first middle section circulation (6), the second middle section circulation (7), and the third middle section circulation (8). After further separation, the product diesel oil (17) is obtained, the second-line stripping tower (9) is used to obtain the second-line lubricating oil fraction (18), and the third-line ...

Embodiment 2

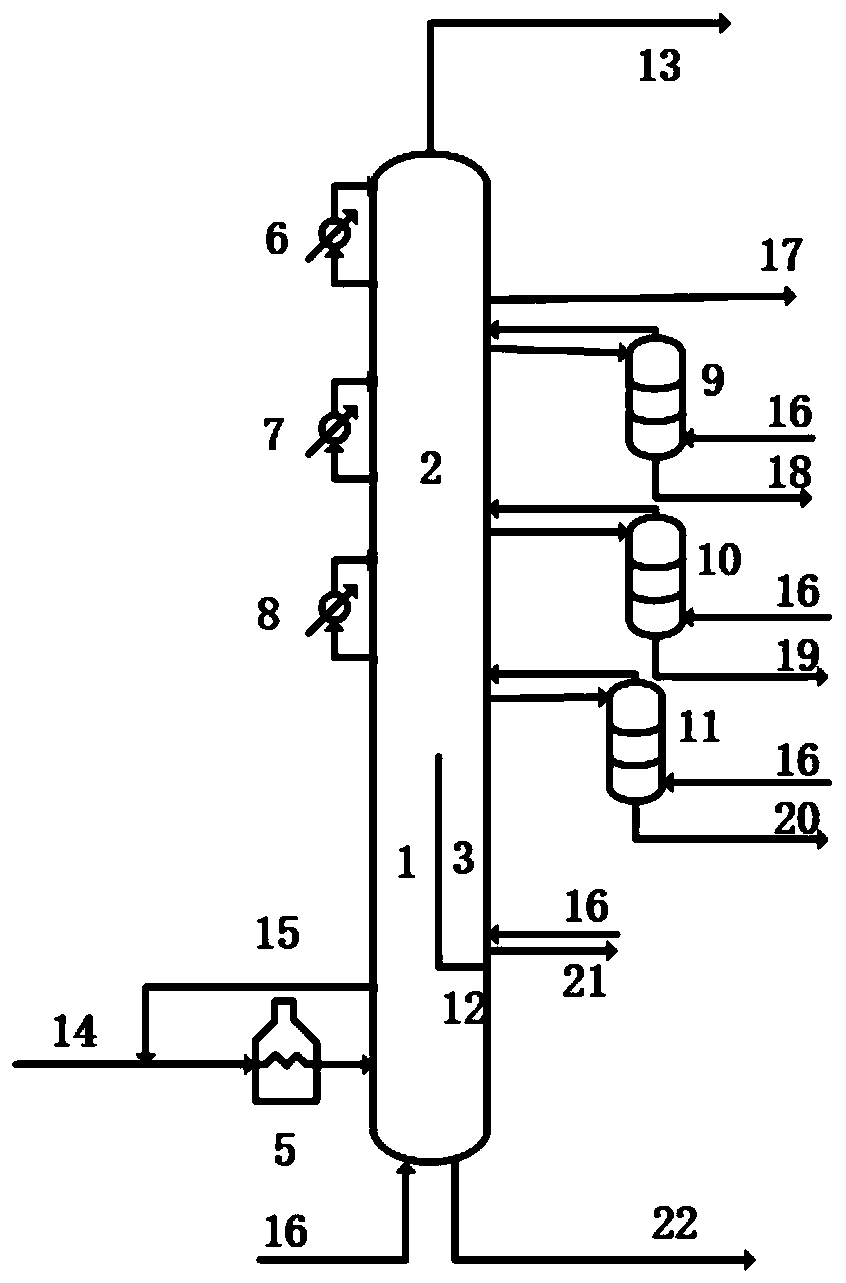

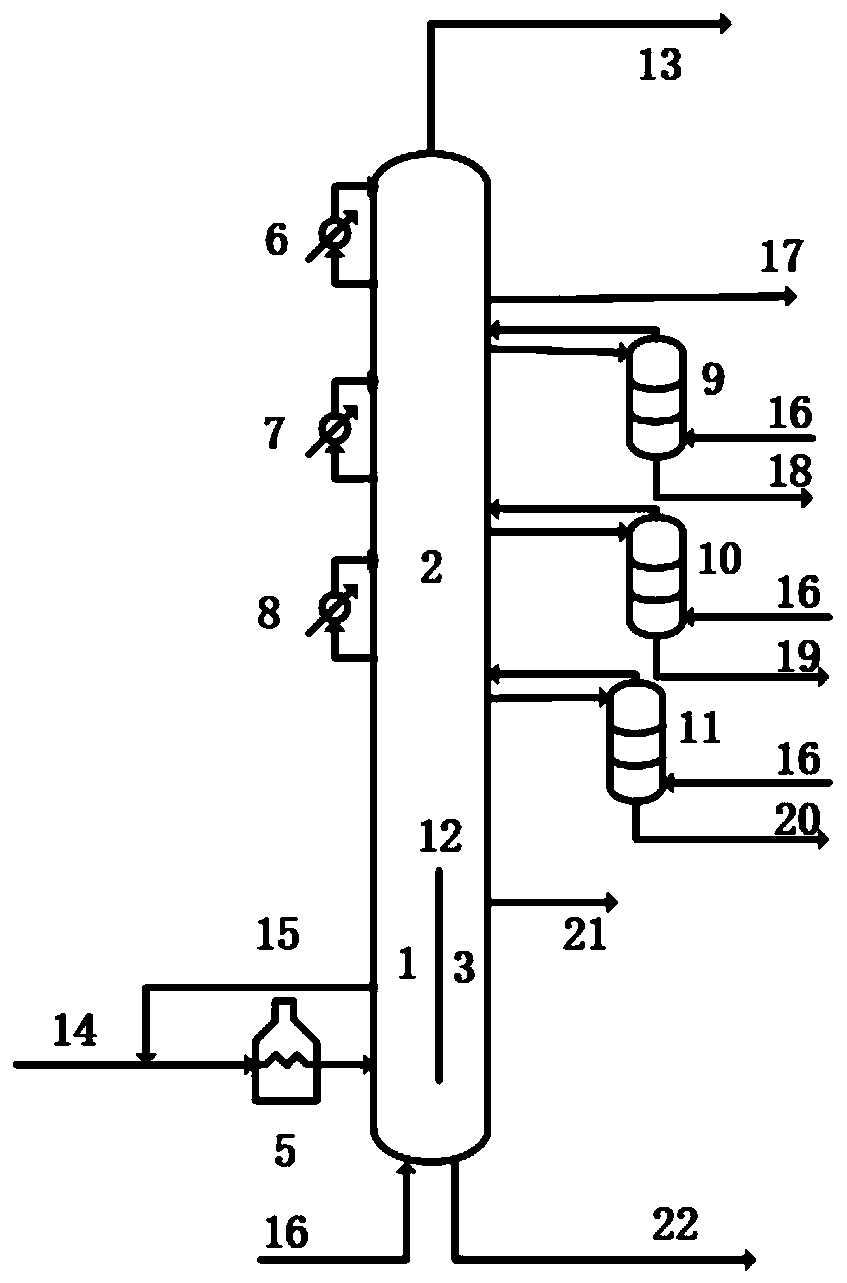

[0040] In order to improve the quality of the lubricating oil of the five-line product, a device adopts the following image 3The partition tower shown is applied to the lubricating oil type vacuum tower scheme. The normal bottom residue (14) to be separated is heated by the heating furnace (5) and enters from the middle of the pre-fractionation section, and the liquid phase is extracted from the bottom of the tower as a vacuum residue (22) after steam stripping (16) at the bottom of the tower, and the gas phase Go to the public rectification section, and recover the heat in the tower through the first middle section circulation (6), the second middle section circulation (7), and the third middle section circulation (8). After further separation, the product diesel oil (17) is obtained, the second-line stripping tower (9) is used to obtain the second-line lubricating oil fraction (18), and the third-line stripping tower (10) is used to obtain the third-line lubricating oil fra...

Embodiment example 2

[0041] Table 5 Main operating conditions of the device in implementation case 2

[0042]

[0043]

[0044] Table 6 Implementation Case 2 Product Properties

[0045]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com