Lubricating oil regenration apparatus and method

A technology of lubricating oil and lubricating oil tank, which is applied in the directions of lubricating oil distillation, chemical instruments and methods, separation methods, etc., and can solve problems such as lubricating performance degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

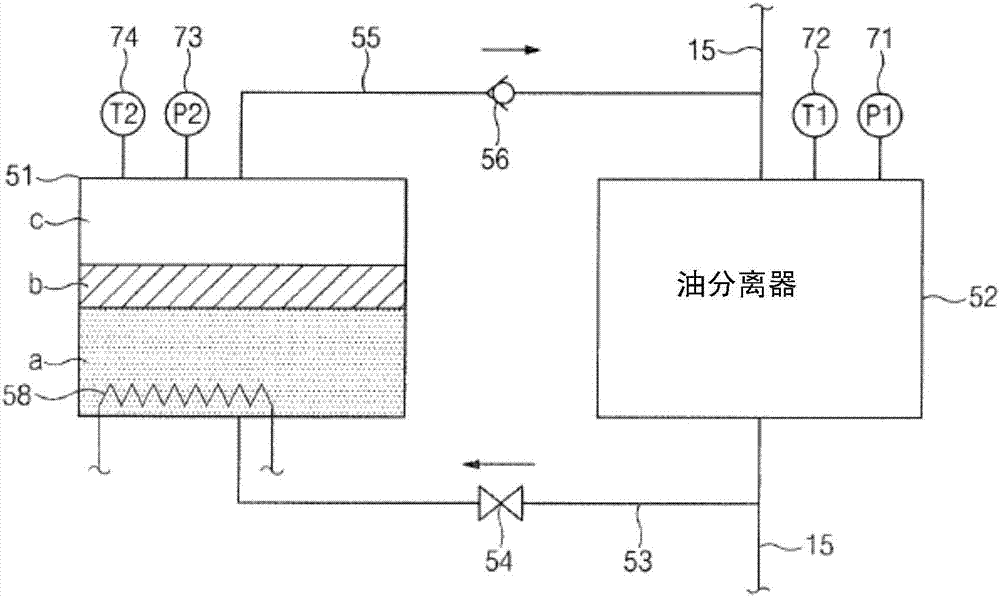

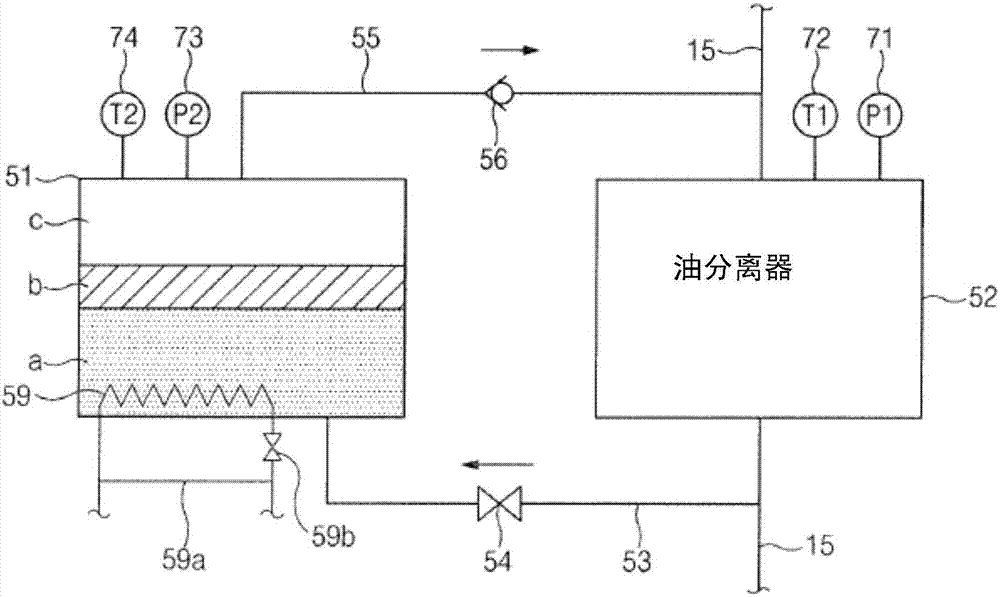

Embodiment Construction

[0032] Hereinafter, embodiments of the present invention will be described in detail with reference to the accompanying drawings. For reference, the size of components, the thickness of lines, etc. shown in the drawings used to describe the exemplary embodiments of the present disclosure may be slightly exaggerated for ease of understanding. Further, terms used to describe the present disclosure may be defined in consideration of functions in the present disclosure and thus may be changed according to users' and operators' intentions, practices, and the like. Therefore, the definitions of terms should be interpreted based on the contents of the entire specification.

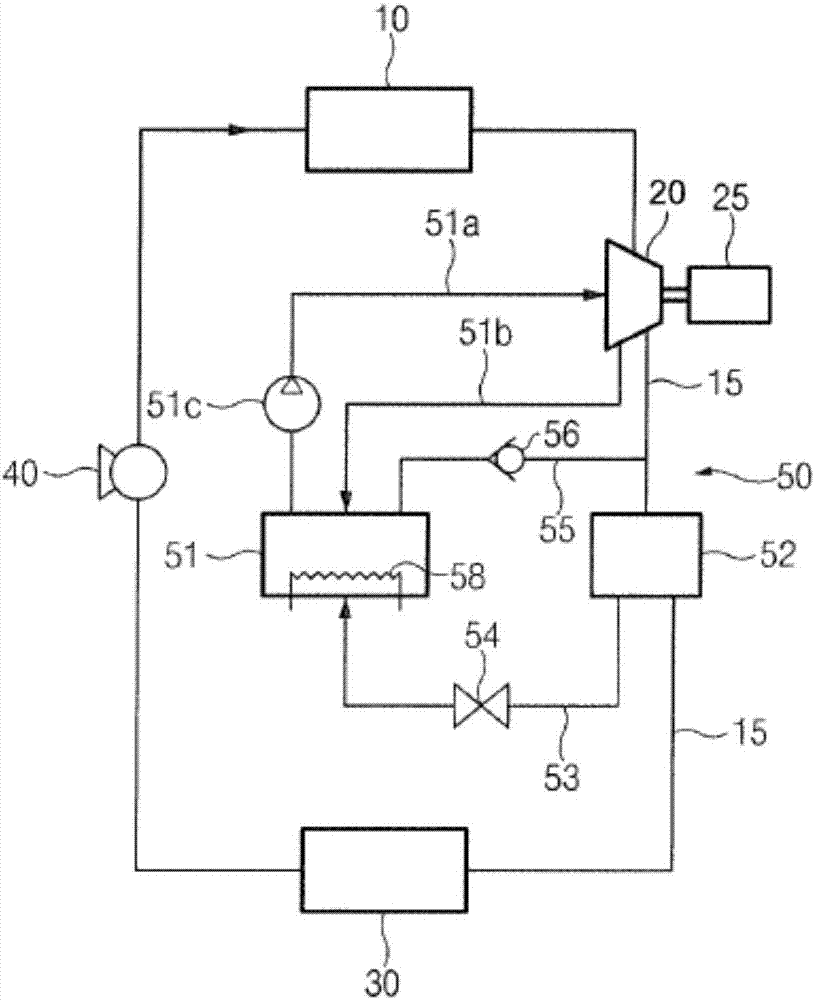

[0033] figure 1 is a diagram showing an example of a general waste heat recovery system.

[0034] refer to figure 1 , the waste heat recovery system may include a working fluid pipe 15 through which a working medium is circulated, wherein the working fluid pipe 15 may include: a boiler 10 configured to pass en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com