Production equipment for recycling and reusing waste oil and production technology of production equipment

A technology for production equipment and waste engine oil, applied in the petroleum industry, hydrocarbon oil treatment products, hydrocarbon oil treatment, etc., can solve the problems of low production efficiency, heavy pollution, low resource utilization rate, etc., achieve simple structure, reduce energy waste, Practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

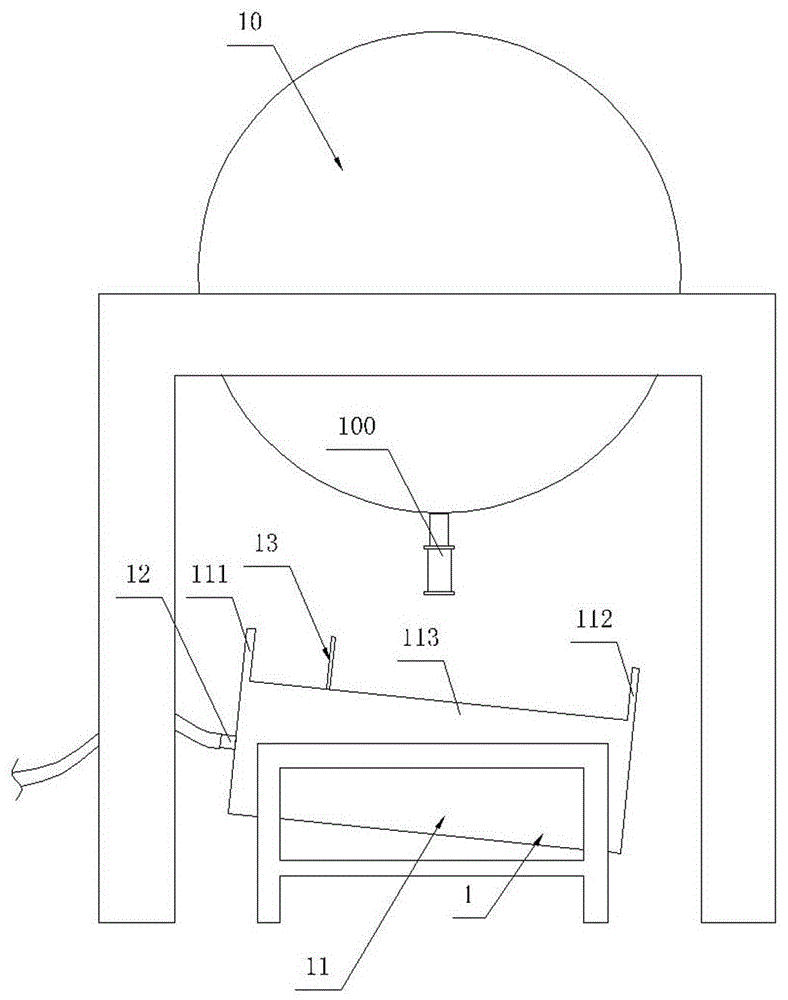

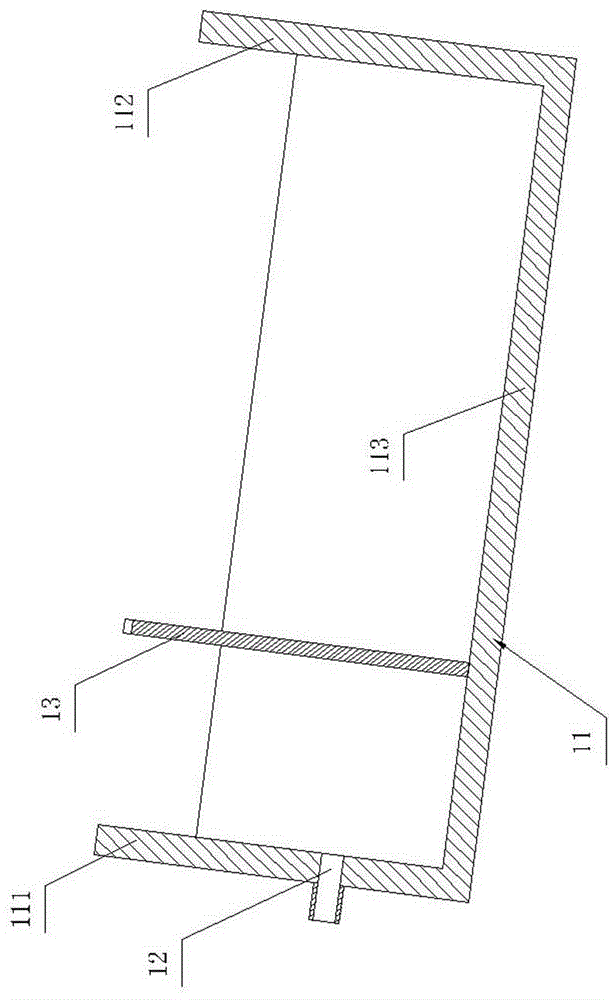

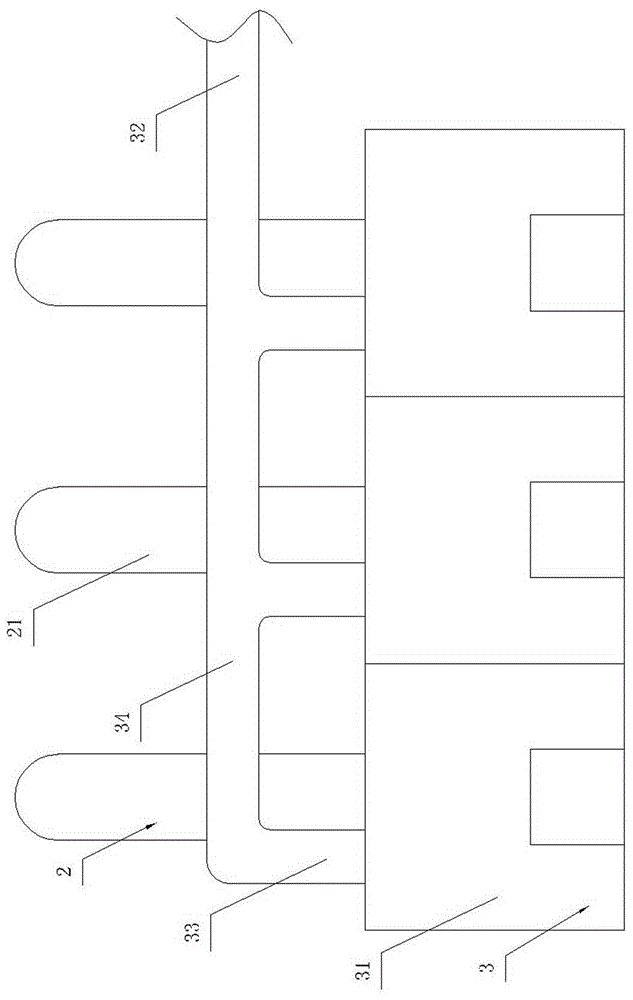

[0055] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 and Figure 12 . A waste engine oil recovery and reuse production equipment, comprising an engine oil storage tank 10, a material receiving device 1, a distillation device 2, a heating device 3, an exhaust gas treatment device 4, a condensation device 5, an intermediate temporary storage tank 6, an accident pool 7, Additive feeding tank 8 and filtration separation device 9;

[0056] Wherein, waste engine oil is stored inside the oil storage tank 10;

[0057] The material receiving device 1 includes a material receiving bucket 11 with an opening on the top and located directly below the oil outlet 100 on the oil storage tank 10, the material receiving bucket 11 is arranged obliquely and has a row at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com