Waste lubricating oil regeneration device and regeneration technology thereof

A technology of waste lubricating oil and regeneration device, which is applied in the direction of lubricating oil distillation, petroleum industry, lubricating composition, etc., can solve the problems of high heat and electric energy consumption rate, low recovery rate, etc., and achieve the effect of heat energy reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

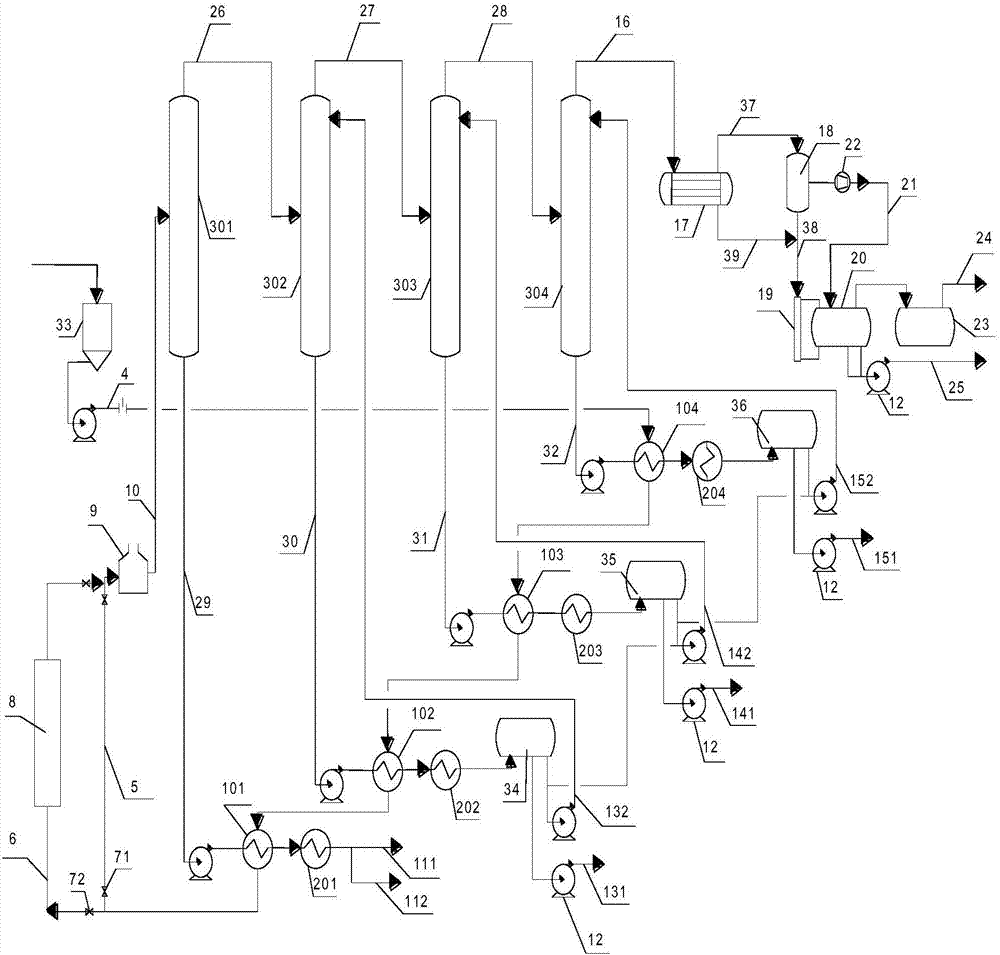

[0032] See attached figure 1 As shown, in the waste lubricating oil regeneration device in this embodiment, the pipeline 4 that enters the waste lubricating oil is sequentially connected to the inlets of 11 waste lubricating oil intermediate tanks 33, and the discharge of the last waste lubricating oil intermediate tank 33 The port is connected to the feed end of the pipeline 4, and the discharge end of the pipeline 4 containing waste lubricating oil is connected to the fourth-stage heat exchanger 104, the third-stage heat exchanger 103, the second-stage heat exchanger 102, and The inlet of the shell side of the primary heat exchanger 101 is connected in series, and the outlet of the shell side of the primary heat exchanger 101 is connected to the lubricating oil heating furnace through two parallel pipelines 5 and 6, one of which is pipeline 5 There are 1# solenoid valves 71 at both ends, the other pipeline 6 is connected in series with a preliminary distillation tower 8, and ...

Embodiment 2

[0049] As the second embodiment of the present invention, the equipment and process flow adopted are the same as those of embodiment 1. The trays of the first-stage distillation tower 301, the second-stage distillation tower 302, the third-stage distillation tower 303, and the fourth-stage distillation tower 304 The number is 18, the feed line 10 of the primary distillation column 301 is connected to the 11th tray of the primary distillation column 301, and the feed line 26 of the secondary distillation column 302 is connected to the second The twelfth tray of the three-stage distillation tower 302 is connected, and the feed line 27 of the three-stage distillation tower 303 is connected to the thirteenth tray of the three-stage distillation tower 303. The feed of the four-stage distillation tower 304 is The line 28 is connected to the 15th tray of the four-stage distillation column 304, and the line 132 at the reflux inlet of the two-stage distillation column 302 is connected to...

Embodiment 3

[0053] As the third embodiment of the present invention, the equipment and process flow adopted are the same as those of embodiment 1. The trays of the first-stage distillation tower 301, the second-stage distillation tower 302, the third-stage distillation tower 303, and the fourth-stage distillation tower 304 The number is 18, the feed line 10 of the first stage distillation column 301 is connected to the tenth tray of the first stage distillation column 301, and the feed line 26 of the second stage distillation column 302 is connected to the second The 13th plate of the three-stage distillation column 302 is connected, and the feed line 27 of the three-stage distillation column 303 is connected to the 13th plate of the three-stage distillation column 303. The feed of the four-stage distillation column 304 is The line 28 is connected to the 15th tray of the four-stage distillation column 304, and the line 132 at the reflux inlet of the two-stage distillation column 302 is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com