Reduced-pressure distillation equipment for pretreatment of waste lubricant oil

A technology for distillation equipment and waste lubricating oil, which is applied in the direction of lubricating oil distillation, distillation control/regulation of hydrocarbon oil, hydrocarbon distillation, etc., and can solve the problem of increased internal pressure, coking, and reduced equipment operating efficiency and production capacity of equipment or vacuum towers and other issues, to achieve the effect of improving efficiency and high-efficiency refining effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

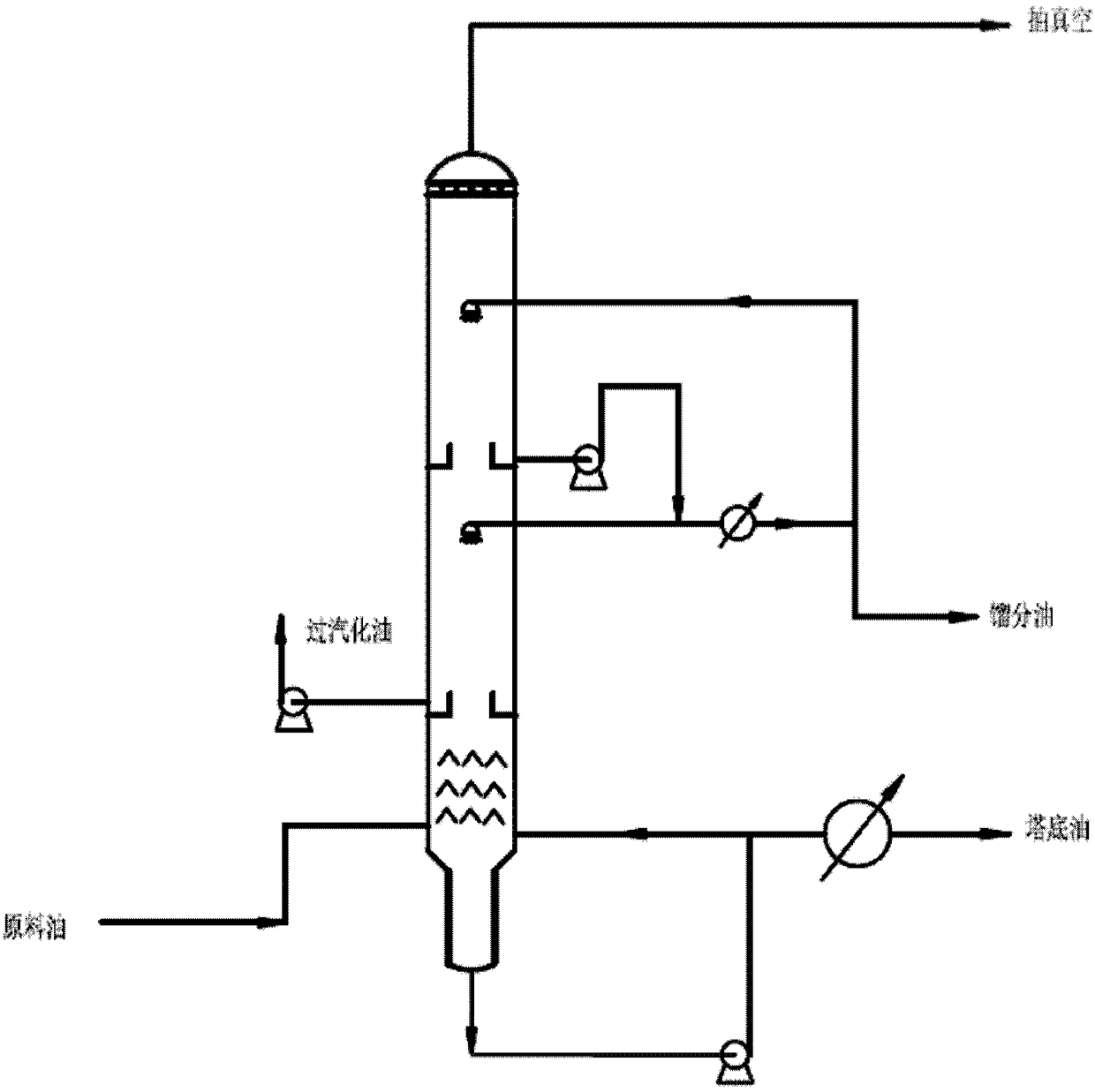

[0051] The structure of the present embodiment decompression tower is as figure 1 , in the present embodiment, after the waste oil entering the feed port is vaporized, it passes through the refining process of the distillate rectification section (1 rectification section), and the obtained distillate is carried out through the oil collection tank below the sprayer. Pull out collection.

[0052] In this embodiment, no filler is used, and the rectification part and rectification section only adopt the shower structure to carry out the rectification process.

[0053] The specific operation process is as follows:

[0054] The waste lubricating oil is heated in the heating furnace (the heating furnace is not shown), and the waste lubricating oil heated by the heating furnace enters the decompression tower through the oil transfer line arranged between the heating furnace and the decompression tower.

[0055] Then in the decompression tower, a high-vacuum spray fractionation proce...

Embodiment 2

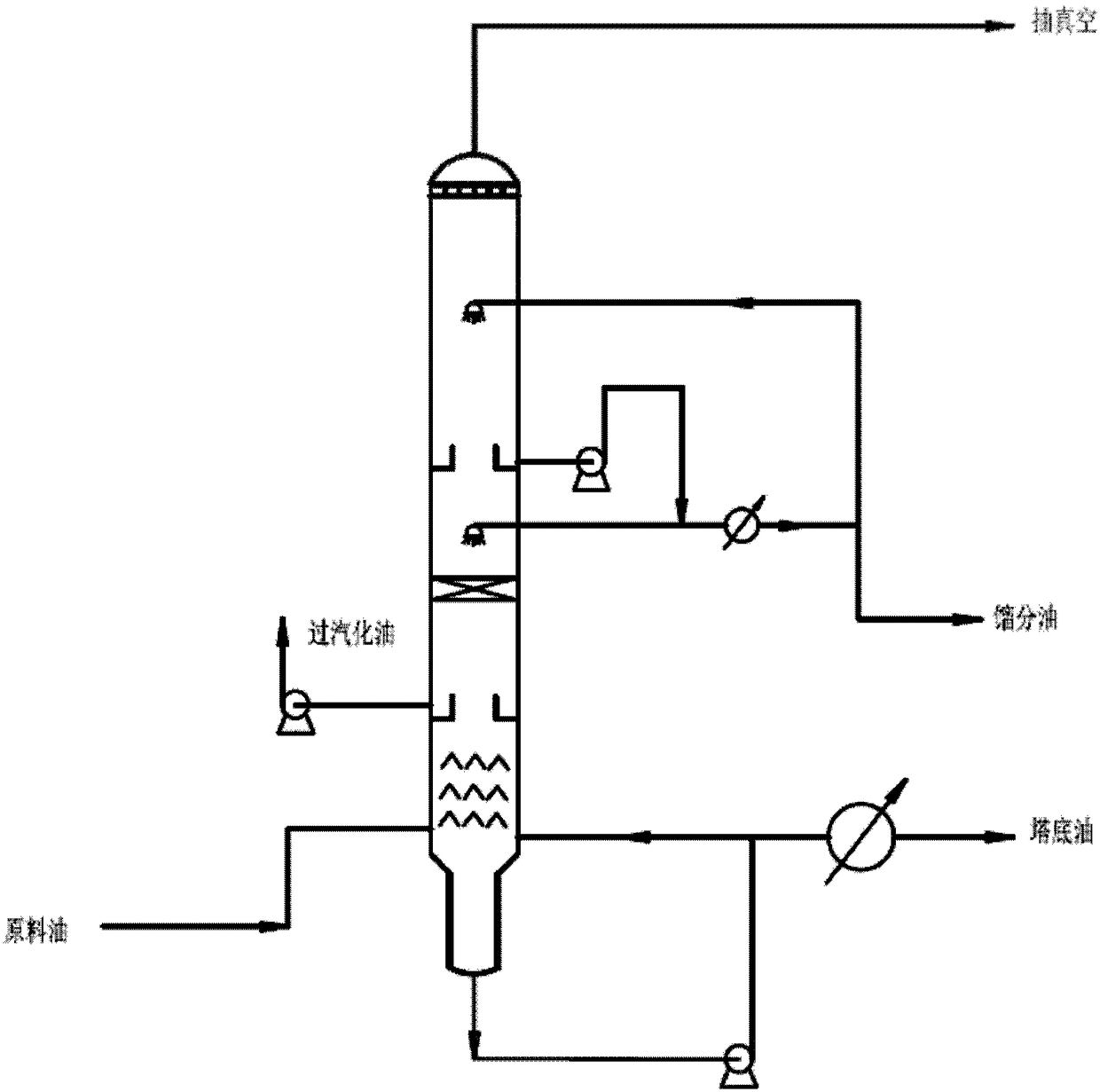

[0065] The technical scheme of this specific embodiment is substantially the same as that of Example 1, except that a section of packing is added below the shower. The setting of this section of filler can further assist in enhancing the effect of rectification. In this embodiment, sprayers are still used to replace trays and trays. In the waste lubricating oil pretreatment decompression tower of this embodiment, high vacuum and low pressure drop are still used in the decompression tower, so that the sprayed droplets Fully disperse and directly contact with the updraft for heat and mass exchange, and realize the residual pressure at the top of the device below 30mmHg, which reduces the use of trays in the vacuum tower, simplifies equipment, controls pressure drop, and prevents coking to a large extent. Effect.

Embodiment 3

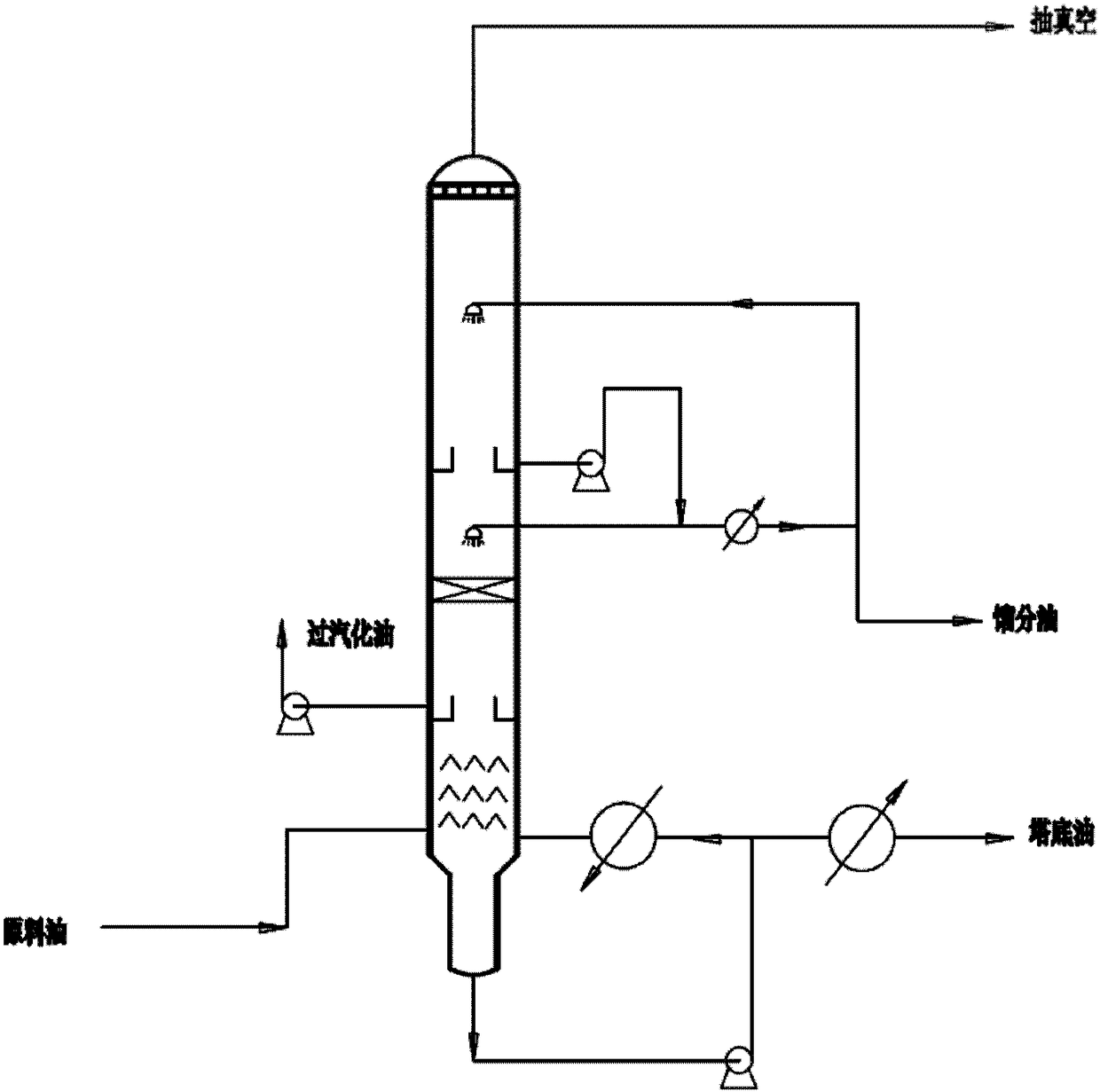

[0067] In this embodiment, after the waste oil entering the feed port is vaporized, it sequentially passes through the over-vaporized oil recovery section, including a packing section and a distillate oil recovery section. For details, please refer to image 3 .

[0068] Firstly, different from Embodiment 1, Embodiment 3 also sets a section of packing under the sprinkler. After the packing section is set, the present embodiment still adopts the shower to replace the tray and the tray. In addition, different from the examples 1 and 2, the present embodiment adopts a further step for the circulation of the bottom oil. craft. Specifically, after the tower bottom oil is released from the bottom of the tower, it is pumped and first passed through the bottom oil reheater ( image 3The component on the upper left of the middle tower bottom oil pump represents the reheater), which is recirculated back into the tower. The setting of the reheater can make up for the insufficient tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com