Pack alloy refining treating device, and refining processing method

A casting aluminum alloy and processing device technology, which is applied in the field of refining processing devices for non-ferrous metal materials and die-casting aluminum alloys, and can solve the problem that it is not suitable for large-capacity aluminum alloy melt refining processing, and the effective utilization rate of refining agent does not exceed 50%, low effective utilization rate of refining agent, etc., to achieve good refining effect, low price and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

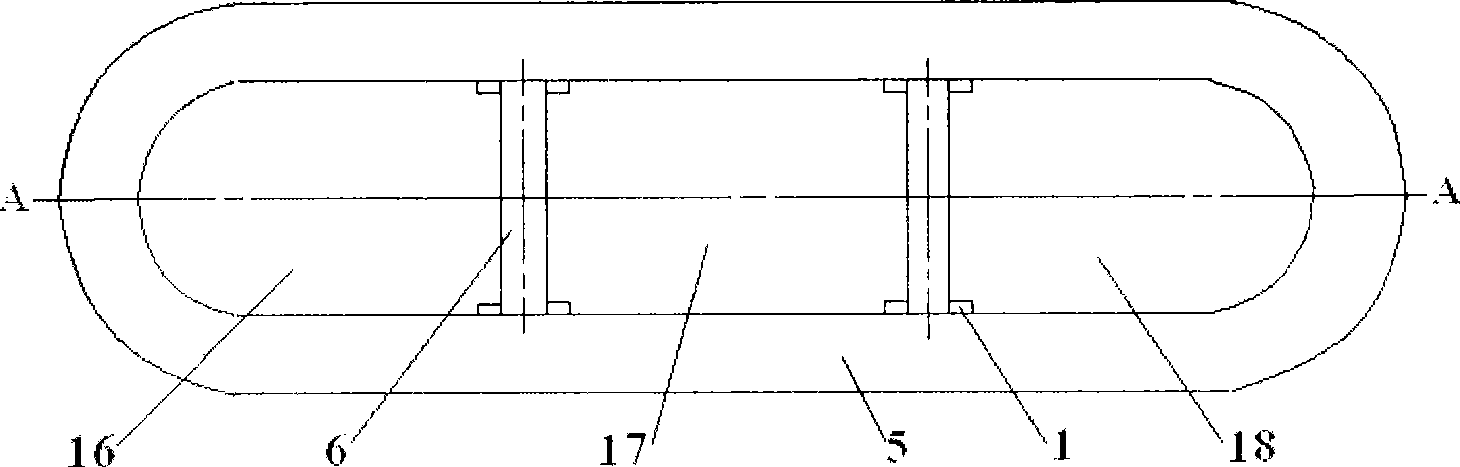

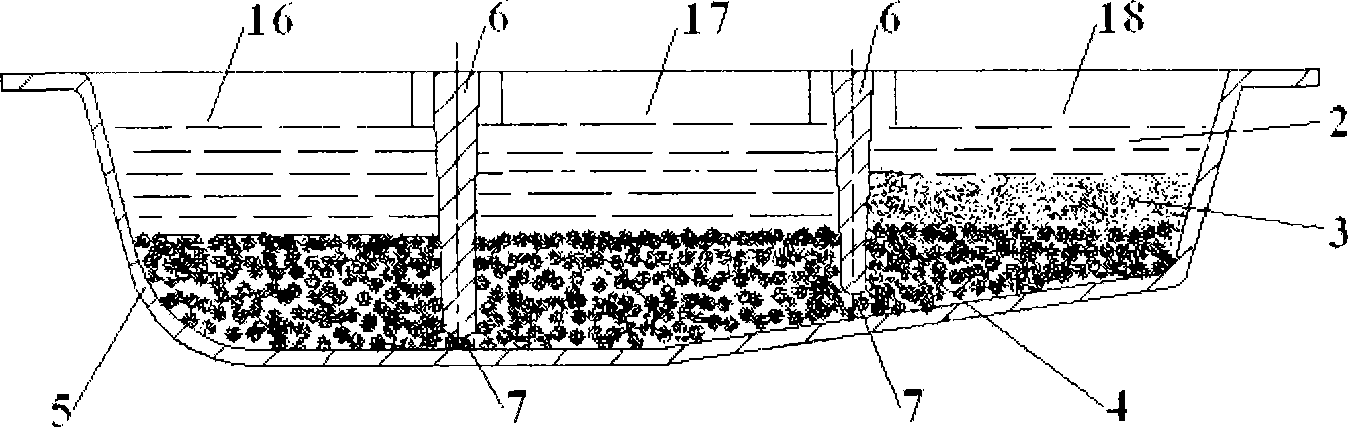

[0048] like figure 2 As shown, the bottoms of the melting chamber 18, the refining chamber 17 and the liquid-taking chamber 16 of the present invention are evenly laid with active filter materials.

[0049] The active filter material not only has the function of mechanical filtration, but also has the function of adsorbing and removing oxidized inclusions. NaF, CaF, Na 3 AlF 6 etc. belong to this category of filter materials. When melting the aluminum alloy, an active filter material is placed at the bottom of the three-chamber crucible furnace 5 . Aluminum alloy liquid 2 must pass through these active filter materials during the flow process of the three chambers to realize the above-mentioned functions of filtration and adsorption.

Embodiment 2

[0051] like figure 2 As shown, the bottoms of the melting chamber 18 and the refining chamber 17, and the bottoms of the refining chamber 17 and the liquid-taking chamber 16 of the present invention communicate with each other, and the aluminum alloy liquid channel is set between the partition plate 6 and the bottom of the crucible furnace 5 7, the channel is the gap between the partition plate 6 and the bottom of the crucible furnace 5; the laying height of the active filter material is higher than the gap between the partition plate 6 and the bottom of the crucible furnace 5.

[0052] like Figure 4 As shown, the specific structure of the aluminum alloy liquid channel 7 is: the bottom edge of the partition plate 6 is a straight edge, and the bottom of the crucible melting furnace 5 is a curved surface suitable for the entire crucible body, so at the bottom of the partition plate 6 A gap is formed between the edge and the bottom of the crucible furnace 5, that is, the alumi...

Embodiment 3

[0054] like figure 2 As shown, at the positions of the melting chamber 18 and the refining chamber 17, the bottom surface of the crucible furnace 5 is an inclined surface, and the bottom surface of the melting chamber 18 is higher than the bottom surface of the refining chamber 17. The purpose is to increase the potential energy of the aluminum alloy liquid 2 so that the aluminum alloy liquid can flow from the melting chamber 18 to the refining chamber 17 better.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com